Preparation and Improved Physical Characteristics of Propylene Oxide Rubber Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

5. Patents

Author Contributions

Funding

Conflicts of Interest

References

- Chersky, I.N.; Morov, V.A. Analysis and prediction of rubber and seals serviceability in arctic conditions. Kautsch. Gummi Kunstst. 1990, 43, 128–129. [Google Scholar]

- Nau, B.S. The state of the art of rubber-seal technology. Rubber Chem. Technol. 1987, 60, 381–416. [Google Scholar] [CrossRef]

- Papkov, V.N.; Yuryev, A.N. Butadiene nitrile rubbers. In Handbook of Rubber Technologist; Reznichenko, S.V., Morozov, Y.L., Eds.; Izdatelskii Tsentr “Tekhinform” MAI: Moscow, Russia, 2012; Volume 1, pp. 186–210. ISBN 978-5-89551-023-0. [Google Scholar]

- Petrova, N.N.; Popova, A.F.; Fedotova, E.S. Investigation of the influence of low temperatures and hydrocarbon media on the properties of rubbers based on propylene oxide and butadiene nitrile rubbers. Kauchuk I Rezina 2002, 3, 6–10. [Google Scholar]

- Bishop, A.; Bremner, C.; Laake, A.; Strobbia, C.; Parno, P.; Utskot, G. Petroleum potential of the arctic: Challenges and solutions. Oilfield Rev. 2011, 22, 36–49. [Google Scholar]

- Govorova, O.A.; Vishnitsky, A.S.; Chubarova, G.V.; Morozov, Y.L. Development of weather-resistant rubbers with improved low-temperature and adhesive properties. Kauchuk I Rezina 1999, 2, 18–20. [Google Scholar]

- Rodgers, B.; Waddell, W. The science of rubber compounding. In Science and Technology of Rubber, 3rd ed.; Mark, E.J., Erman, B., Eirich, F.R., Eds.; Elsevier Academic Press: Burlington, VT, USA, 2005; pp. 401–452. ISBN 0-12-464786-3. [Google Scholar]

- Petrova, N.N. Principles of Oil and Frost Resistant Rubbers Creation and Their Implementation for Operation in Cold Climate Conditions. Ph.D. Thesis, Moscow State University of Fine Chemical Technologies, Moscow, Russia, 2006. [Google Scholar]

- Petrova, N.N.; Portnyagina, V.V.; Biklibaeva, R.F. Wear Resistant Rubber Blend Based on Propylene Oxide Rubber. Russian Patent 2,294,346, 27 February 2007. [Google Scholar]

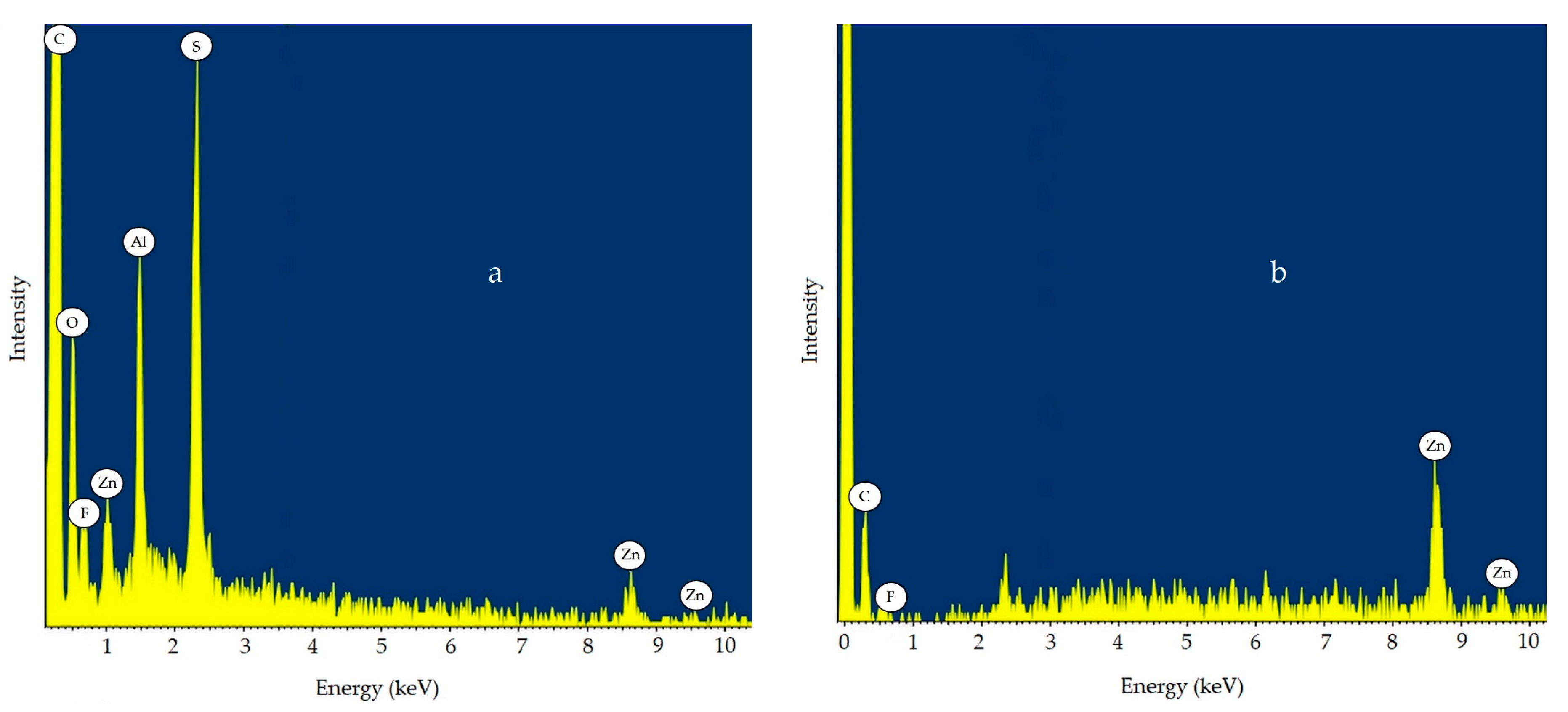

- Petrova, N.N.; Portnyagina, V.V. Propylene rubbers based on propylene oxide rubber and PTFE compositions. Kauchuk I Rezina 2007, 4, 8–11. [Google Scholar]

- Bouznik, V.M.; Fomin, V.M.; Alkhimov, A.P. Metal-Polymer Nanocomposites, 2nd ed.; SB RAS Publishing House: Novosibirsk, Russia, 2005; pp. 8–97. ISBN 5-7692-0735-3. [Google Scholar]

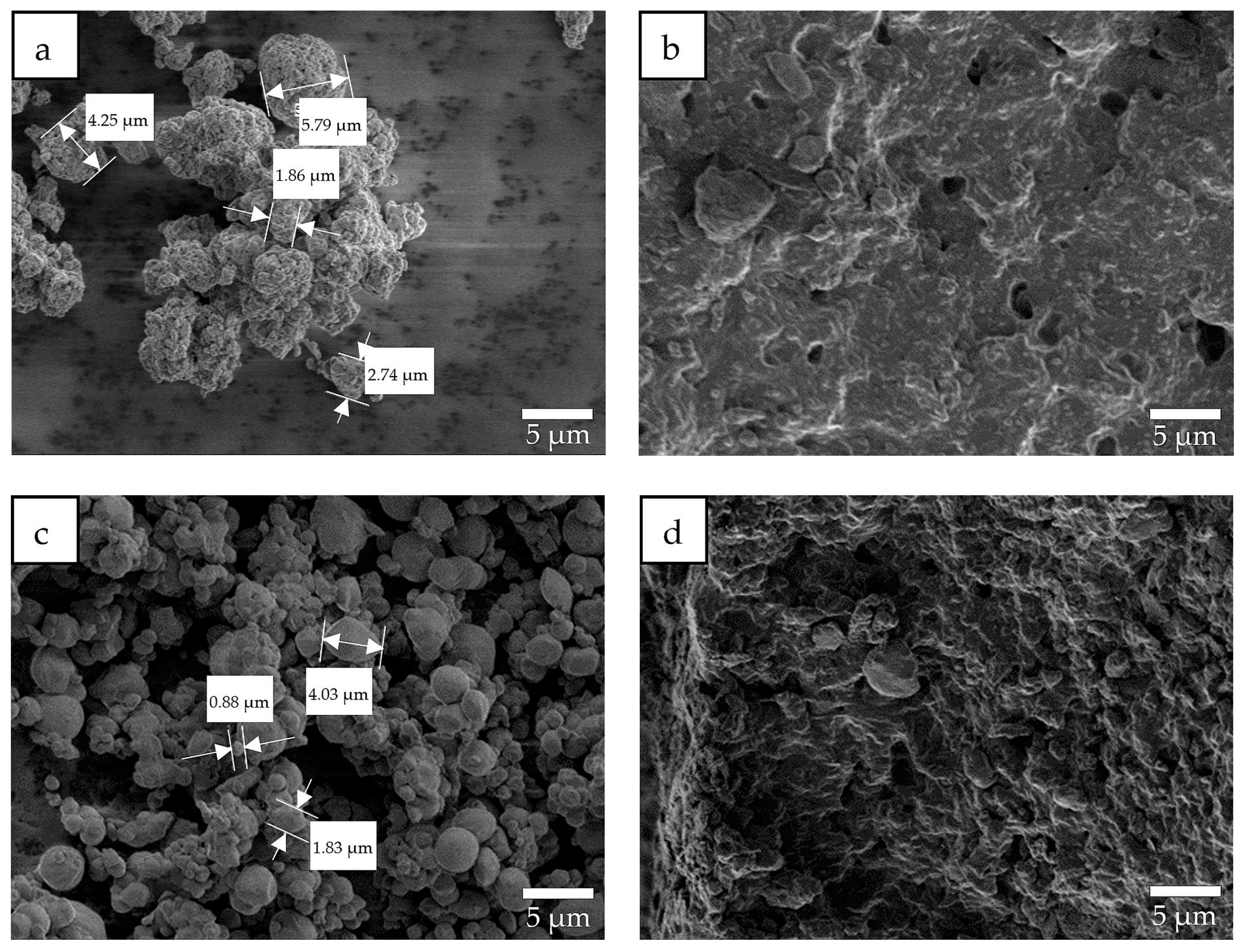

- Bouznik, V.M.; Kuryavy, V.G. Morphology and structure of micron and nanosized powders of PTFE obtained by gas-phase method. Rus. J. Gen. Chem. 2008, LII, 131–139. [Google Scholar]

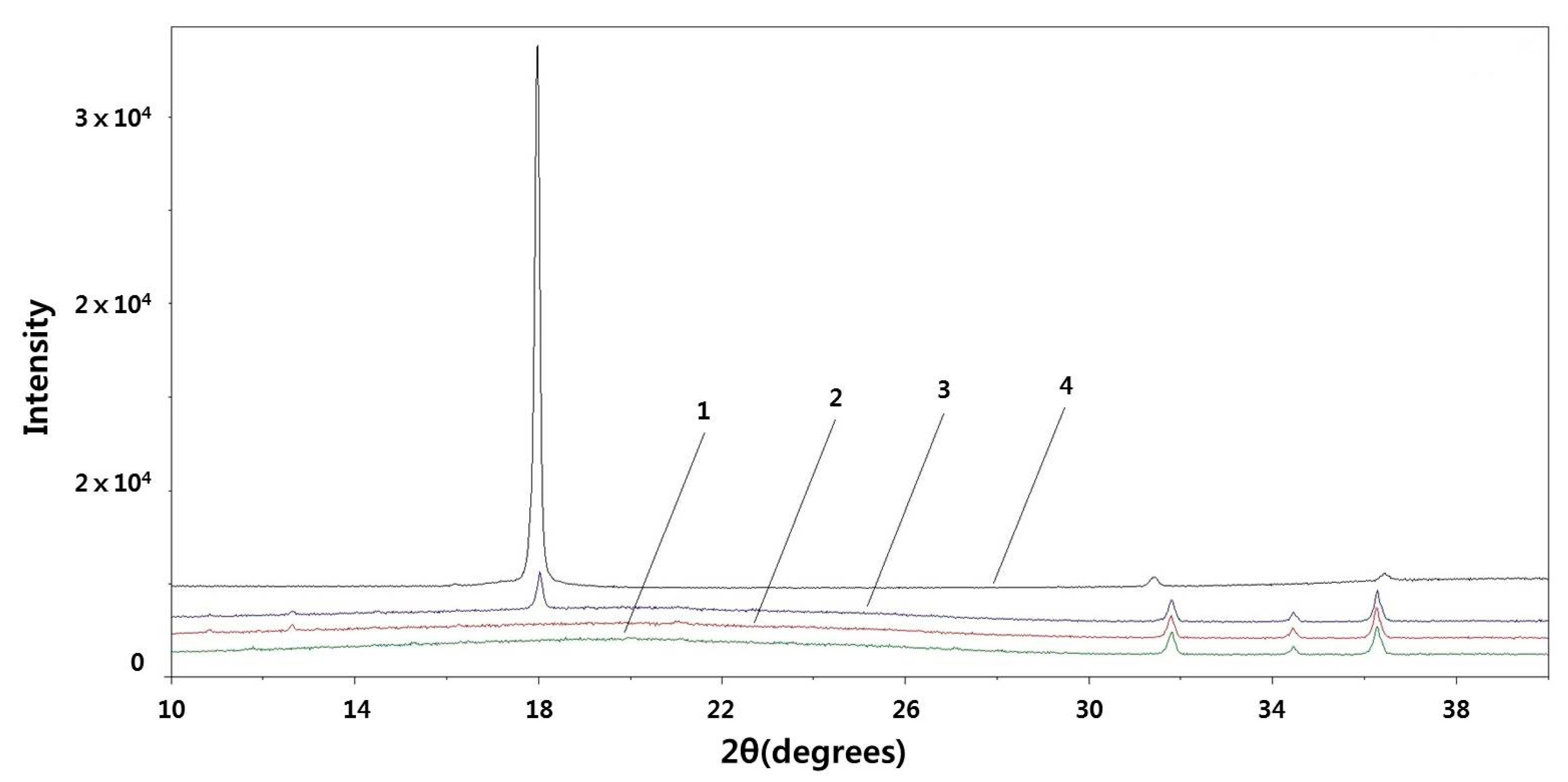

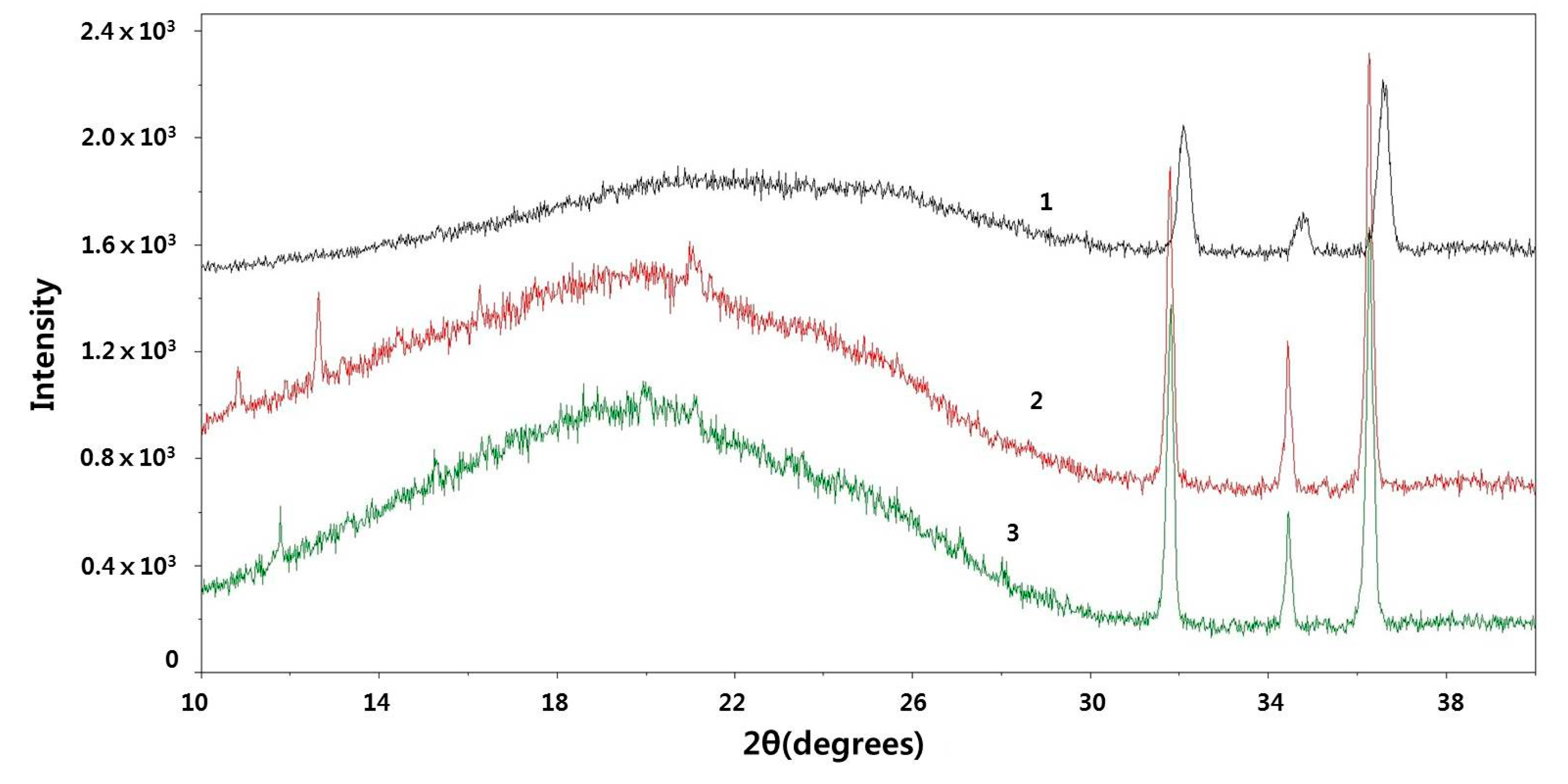

- Bouznik, V.M.; Kirik, S.D.; Solovyov, L.A.; Tsvetnikov, A.K. A crystal structure of ultra–dispersed form of polytetrafluoroethylene based on X–ray powder diffraction data. Powder Diffr. 2004, 19, 135–141. [Google Scholar] [CrossRef]

- Bouznik, V.M.; Vopilov, Y.E.; Dedov, S.A.; Ignatieva, L.N.; Murin, A.S.; Slobodyuk, A.B. Structure of ultrafine polytetrafluoroethylene powders obtained from industrial wastes via hydrothermal method. Chem. Sustain. Dev. 2010, 18, 33–39. [Google Scholar]

- Kuryavy, V.G.; Tsvetnikov, A.K.; Bouznik, V.M. Peculiarities of the hierarchical and morphological structure of the UPTFE particles according data from transmission electron and atomic force microscopy. Perspekt. Mater. 2005, 3, 86–90. [Google Scholar]

- Polonik, V.D.; Prokopchuk, N.R.; Shashok, Z.S. Swelling degree of the ultrafine polytetrafluoroethylene containing elastomers. In Chemical Technology and Biotechnology of New Materials and Products, Proceedings of IV Mendeleev D.I. International Conference of Russian Chemical Society Dedicated to Sarkisov P.D., Moscow, Russia, 23–25 October 2012; Dmitry Mendeleev University of Chemical Technology of Russia: Moscow, Russia, 2012; pp. 140–141. [Google Scholar]

- Prorokova, N.P.; Vavilova, S.Y.; Bouznik, V.M.; Zavadsky, A.E. Modification of the polypropylene fibrous materials with ultrafine polytetrafluorethylene. Polym. Sci. Ser. A 2013, 55, 1333–1342. [Google Scholar] [CrossRef]

- Vopilov, Y.E.; Nikitin, L.N. Separation of low-molecular-weight fractions of ultrafine polytetrafluoroethylene with supercritical carbon dioxide. Rus. J. Phys. Chem. B 2009, 3, 1074–1081. [Google Scholar] [CrossRef]

- Morozov, A.V.; Petrova, N.N. Method of evaluating the coefficient of friction of frost-resistant sealing rubbers. J. Frict. Wear 2016, 37, 124–128. [Google Scholar] [CrossRef]

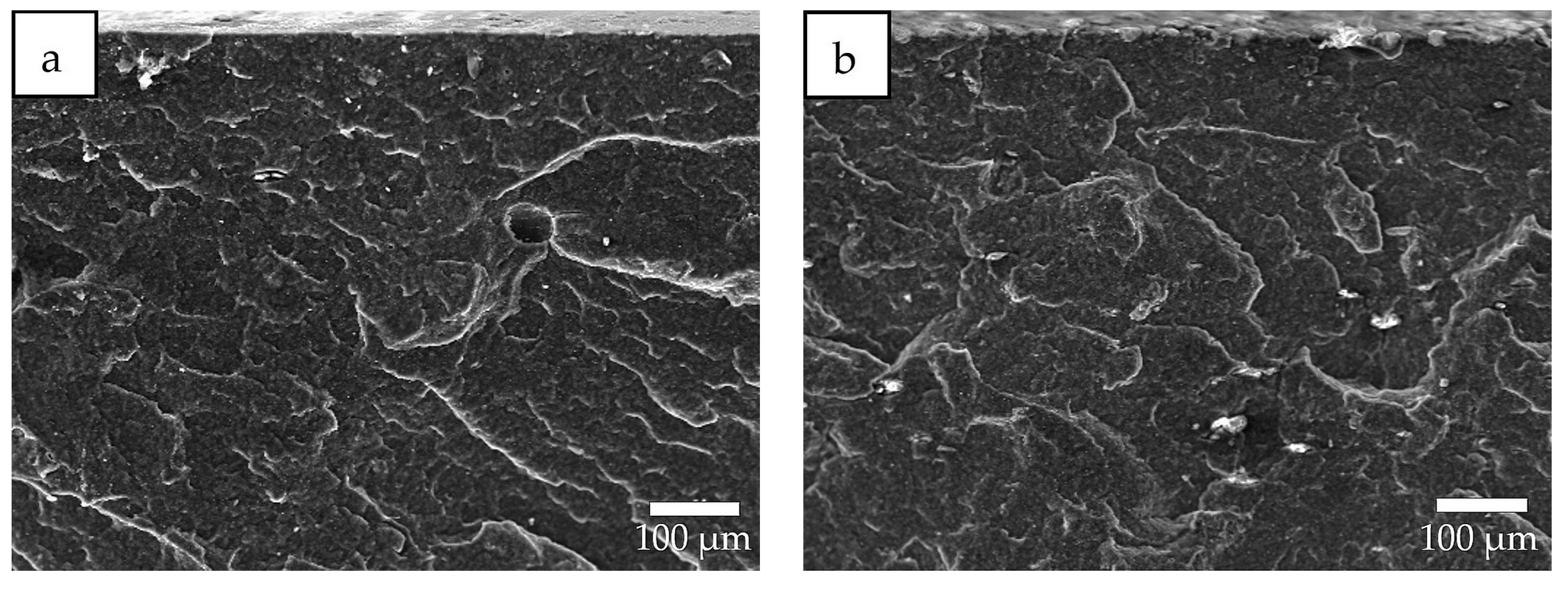

- Stolyarova, O.O.; Muravyeva, T.I.; Morozov, A.V.; Zagorskiy, D.L.; Gainutdinov, R.V.; Petrova, N.N.; Portnyagina, V.V. Electron and probe microscopy investigation of the surface of elastomers modified with antifriction fillers. J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 2016, 10, 925–932. [Google Scholar] [CrossRef]

- GOST 270-84 State Standard. Rubber: Method of the Determination Elastic and Tensile Stress-Strain Properties. Available online: http://vsegost.com/Catalog/21/21850.shtml (accessed on 24 January 2018).

- GOST 9.024-74 State Standard. Unified System of Corrosion and Aging Protection—Rubbers: Methods of Heat Aging Stability Determination. Available online: http://vsegost.com/Catalog/36/36404.shtml (accessed on 24 January 2018).

- GOST 408-78 State Standard. Rubber: Methods of Measuring Low Temperature Resistance at Extension. Available online: http://vsegost.com/Catalog/24/24460.shtml (accessed on 24 January 2018).

- GOST 9.030-74 State Standard. Unified System of Corrosion and Aging Protection—Vulcanized Rubbers: Method of Testing Resistance to Attack by Corrosive Media in Limp State. Available online: http://vsegost.com/Catalog/35/3586.shtml (accessed on 24 January 2018).

- GOST 23509-79 State Standard. Rubber: Method of Determining the Abrasion Resistance of the Sliding on Renewable Surface. Available online: http://vsegost.com/Catalog/80/8045.shtml (accessed on 24 January 2018).

- Van Krevelen, D.W.; te Nijenhuis, K. Properties of Polymers, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 229–244. [Google Scholar]

- Martínez, L.; Román, E.; Nevshupa, R. X-Ray photoelectron spectroscopy for characterization of engineered elastomer surfaces. In Advanced Aspects of Spectroscopy; Farrukh, M.A., Ed.; InTech: Rijeka, Croatia, 2012; pp. 165–194. ISBN 978-953-51-0715-6. [Google Scholar]

- Petrova, N.N.; Portnyagina, V.V. Wear Resistant Rubber Based on Propylene Oxide Rubber and Ultrafine polytetrafluoroethylene. Russian Patent 2,502,759, 27 December 2013. [Google Scholar]

- Petrova, N.N.; Portnyagina, V.V. Wear-Resistant Rubber Based on Propylene Oxide Rubber and Ultrafine Polytetrafluoroethylene. U.S. Patent 8,841,370, 23 November 2014. [Google Scholar]

Sample Availability: Samples of the compounds are not available from the authors. |

| Ingredients | SKPO | SKPO + 20 PTFE | SKPO + UPTFE |

|---|---|---|---|

| SKPO | 100 | 100 | 100 |

| Stearic acid | 1.0 | 1.0 | 1.0 |

| Zinc oxide | 5.0 | 3.0 | 3.0 |

| 2-mercapto-benzothiazole | - | 2.0 | 2.0 |

| Dibenzothiazyl disulfide | 1.5 | - | - |

| Thiuram disulfide | 1.0 | 2.0 | 2.0 |

| Phenyl-β naphthylamine | 2.0 | - | - |

| Carbon black P-803 | 60.0 | 60.0 | 60.0 |

| Dibutoxyethyl adipate | 10.0 | - | - |

| Sulfur | 1.5 | 1.5 | 1.5 |

| PTFE | - | 20 | - |

| UPTFE | 0 | - | 0.5, 1, 3, 5, 10 |

| Properties | SKPO | SKPO + 20 PTFE | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|---|

| fP (MPa) | 7.5 | 8.5 | 7.4 | 7.4 | 7.9 | 7.9 | 7.4 | 7.9 |

| εp (%) | 192 | 180 | 240 | 268 | 268 | 232 | 230 | 228 |

| f100 (MPa) | 4.9 | 5.8 | 3.3 | 3.2 | 3.2 | 3.2 | 3.6 | 3.7 |

| KV | 0.88 | 0.47 | 0.99 | 0.97 | 0.98 | 0.96 | 0.95 | 0.90 |

| C (%) | 58.3 | 53.5 | 54.0 | 52.0 | 52.0 | 62.0 | 63.0 | 68.0 |

| ΔV (cm3) | 0.17 | 0.11 | 0.11 | 0.10 | 0.12 | 0.13 | 0.14 | 0.15 |

| ΔQ (%) | 22.0 | 18.0 | 17.0 | 17.2 | 18.3 | 19.4 | 21.5 | 22.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrova, N.N.; Portnyagina, V.V.; Mukhin, V.V.; Shim, E.L.; Cho, J.-H. Preparation and Improved Physical Characteristics of Propylene Oxide Rubber Composites. Molecules 2018, 23, 2150. https://doi.org/10.3390/molecules23092150

Petrova NN, Portnyagina VV, Mukhin VV, Shim EL, Cho J-H. Preparation and Improved Physical Characteristics of Propylene Oxide Rubber Composites. Molecules. 2018; 23(9):2150. https://doi.org/10.3390/molecules23092150

Chicago/Turabian StylePetrova, Natalia N., Viktoriya V. Portnyagina, Vasilii V. Mukhin, Ee Le Shim, and Jin-Ho Cho. 2018. "Preparation and Improved Physical Characteristics of Propylene Oxide Rubber Composites" Molecules 23, no. 9: 2150. https://doi.org/10.3390/molecules23092150

APA StylePetrova, N. N., Portnyagina, V. V., Mukhin, V. V., Shim, E. L., & Cho, J.-H. (2018). Preparation and Improved Physical Characteristics of Propylene Oxide Rubber Composites. Molecules, 23(9), 2150. https://doi.org/10.3390/molecules23092150