Characteristics of Milk Fermented by Streptococcus thermophilus MGA45-4 and the Profiles of Associated Volatile Compounds during Fermentation and Storage

Abstract

:1. Introduction

2. Results and Discussion

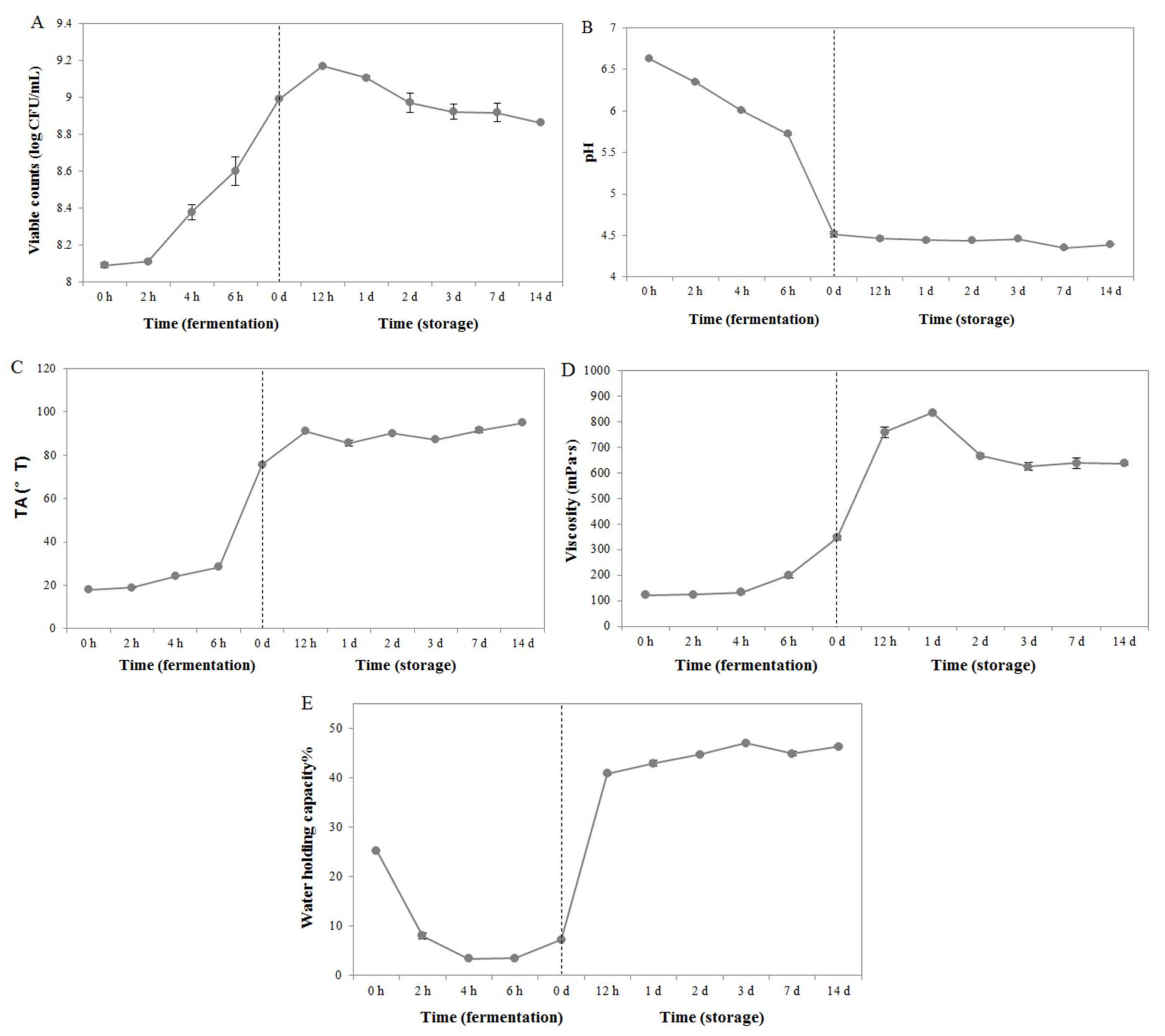

2.1. Physicochemical Characteristics of Milk Fermented Using S. thermophilus

2.2. Analysis of Volatile Compounds in Fermented Milk

2.3. Evaluation of OAVs

3. Experimental

3.1. Bacterial Isolates and Reagents

3.2. Preparation of Fermented Milk

3.3. Determining Viable Cell Counts

3.4. Determination of pH and TA

3.5. Determination of Viscosity

3.6. Determination of WHC

3.7. HS-SPME-GC-MS Analysis

3.8. Identification of Volatile Compounds

3.9. Determination of OAV

3.10. Sensory Evaluation

3.11. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Del, R.B.; Linares, D.M.; Ladero, V.; Redruello, B.; Fernández, M.; Martin, M.C.; Alvarez, M.A. Putrescine production via the agmatine deiminase pathway increases the growth of Lactococcus.Lactococcus lactis and causes the alkalinization of the culture medium. Appl. Microbiol. Blot. 2015, 99, 897–905. [Google Scholar] [CrossRef] [PubMed]

- Blaiotta, G.; Sorrentino, A.; Ottombrino, A.; Aponte, M. Short communication: technological and genotypic comparison between Streptococcus macedonicus and Streptococcus thermophilus strains coming from the same dairy environment. J. Dairy Sci. 2011, 94, 5871–5877. [Google Scholar] [CrossRef] [PubMed]

- Fatih, O.; Broadbent, J.R.; Oberg, C.J.; Mcmahon, D.J. Growth and gas formation by Lactobacillus wasatchensis, a novel obligatory heterofermentative nonstarter lactic acid bacterium, in Cheddar-style cheese made using a Streptococcus thermophilus starter. J. Dairy Sci. 2015, 98, 7473–7482. [Google Scholar]

- Han, N.; Park, S.Y.; Kim, S.Y.; Yoo, M.Y.; Paik, H.D.; Lim, S.D. Short communication: Change of naturally occurring benzoic acid during skim milk fermentation by commercial cheese starters. J. Dairy Sci. 2016, 99, 8633–8637. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Song, J.; Kwok, L.Y.; Wang, J.; Dong, Y.; Yu, H.; Hou, Q.; Zhang, H.; Chen, Y. Influence of Lactobacillus plantarum on yogurt fermentation properties and subsequent changes during postfermentation storage. J. Dairy Sci. 2017, 100, 2512–2525. [Google Scholar] [CrossRef] [PubMed]

- Ning, L.; Fu-Ping, Z.; Hai-Tao, C.; Si-Yuan, L.; Chen, G.; Zhen-Yang, S.; Bao-Guo, S. Identification of volatile components in Chinese Sinkiang fermented camel milk using SAFE, SDE, and HS-SPME-GC/MS. Food Chem. 2011, 129, 1242–1252. [Google Scholar] [CrossRef] [PubMed]

- Leroy, F.; Vuyst, L.D. Lactic acid bacteria as functional starter cultures for the food fermentation industry. Trends Food Sci. Technol. 2004, 15, 67–78. [Google Scholar] [CrossRef]

- Condurso, C.; Verzera, A.; Romeo, V.; Ziino, M.; Conte, F. Solid-phase microextraction and gas chromatography mass spectrometry analysis of dairy product volatiles for the determination of shelf-life. Int. Dairy J. 2008, 18, 819–825. [Google Scholar] [CrossRef]

- Pan, D.D.; Wu, Z.; Peng, T.; Zeng, X.Q.; Li, H. Volatile organic compounds profile during milk fermentation by Lactobacillus pentosus and correlations between volatiles flavor and carbohydrate metabolism. J. Dairy Sci. 2014, 97, 624–631. [Google Scholar] [CrossRef] [PubMed]

- Settachaimongkon, S.; Nout, M.J.; Antunes Fernandes, E.C.; Hettinga, K.A.; Vervoort, J.M.; van Hooijdonk, T.C.; Zwietering, M.H.; Smid, E.J.; van Valenberg, H.J. Influence of different proteolytic strains of Streptococcus thermophilus in co-culture with Lactobacillus delbrueckii subsp. bulgaricus on the metabolite profile of set-yoghurt. Int. J. Food Microbiol. 2014, 177, 29–36. [Google Scholar] [CrossRef] [PubMed]

- Ziadi, M.; Wathelet, J.P.; Marlier, M.; Hamdi, M.; Thonart, P. Analysis of volatile compounds produced by 2 strains of lactis isolated from leben (Tunisian fermented milk) using solid-phase microextraction-gas chromatography. J. Food Sci. 2008, 73, 247–252. [Google Scholar] [CrossRef]

- Beshkova, D.M.; Simova, E.D.; Frengova, G.I.; Simov, Z.I.; Dimitrov, Z.P. Production of volatile aroma compounds by kefir starter cultures. Int. Dairy J. 2003, 13, 529–535. [Google Scholar] [CrossRef]

- Hols, P.; Hancy, F.; Fontaine, L.; Grossiord, B.; Prozzi, D.; Leblond-Bourget, N.; Decaris, B.; Bolotin, A.; Delorme, C.; Dusko, E.S. New insights in the molecular biology and physiology of Streptococcus thermophilus revealed by comparative genomics. Fems. Microbiol. Rev. 2005, 29, 435–463. [Google Scholar] [PubMed]

- Linares, D.M.; O’Callaghan, T.F.; O’Connor, P.M.; Ross, R.P.; Stanton, C. Streptococcus thermophilus APC151 strain is suitable for the manufacture of naturally GABA-enriched bioactive yogurt. Front. Microbiol. 2016, 7, 1876. [Google Scholar] [CrossRef] [PubMed]

- Rabha, B.; Nadra, R.S.; Ahmed, B. Effect of threonine on growth and acetaldehyde production by streptococcus thermophilus. World Appl. Sci. J. 2011, 15, 160–163. [Google Scholar]

- Dan, T.; Wang, D.; Jin, R.L.; Zhang, H.P.; Zhou, T.T.; Sun, T.S. Characterization of volatile compounds in fermented milk using solid-phase microextraction methods coupled with gas chromatography-mass spectrometry. J. Dairy Sci. 2017, 100, 2488–2500. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, V.; Ortín, N.; Escudero, A.; López, R.; Cacho, J. Chemical characterization of the aroma of Grenache rose wines: aroma extract dilution analysis, quantitative determination, and sensory reconstitution studies. J. Agric. Food Chem. 2002, 50, 4048. [Google Scholar] [CrossRef] [PubMed]

- Capone, S.; Tufariello, M.; Siciliano, P. Analytical characterisation of Negroamaro red wines by “Aroma Wheels”. Food Chem. 2013, 141, 2906–2915. [Google Scholar] [CrossRef] [PubMed]

- González, Á.M.; Gonzálezbarreiro, C.; Canchogrande, B.; Simalgándara, J. Relationships between Godello white wine sensory properties and its aromatic fingerprinting obtained by GC-MS. Food Chem. 2011, 129, 890–898. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Dan, T.; Sun, T.; Zhang, H.; Menghe, B. Analysis of key volatile compounds in fermented cow milk produced by pure and mixed cultures by SPME-GC-MS combined with ROAV. Food Sci. 2017, 38, 145–152. [Google Scholar]

- Ayad, E.H.E.; Verheul, A.; Wouters, J.T.M.; Smit, G. Application of wild starter cultures for flavour development in pilot plant cheese making. Int. Dairy J. 2000, 10, 169–179. [Google Scholar] [CrossRef]

- Ren, Y.; Liu, W.; Zhang, H. Identification of coccoidal bacteria in traditional fermented milk products from Mongolia, and the fermentation properties of the predominant species, Streptococcus thermophilus. Korean J. Food Sci. Anim. Resour. 2015, 35, 683–691. [Google Scholar] [CrossRef] [PubMed]

- Molimard, P.; Spinnler, H.E. Review: Compounds Involved in the Flavor of Surface Mold-Ripened Cheeses: Origins and Properties. J. Dairy Sci. 1996, 79, 169–184. [Google Scholar] [CrossRef]

- Cheng, H. Volatile flavor compounds in yogurt: a review. Crit. Rev. Food Sci. 2010, 50, 938–950. [Google Scholar] [CrossRef] [PubMed]

- Panagiotidis, P.; Tzia, C.; Spanier, A.M.; Shahidi, F.; Parliament, T.H.; Mussinan, C.; Ho, C.T.; Contis, E.T. Effect of milk composition and heating on flavor and aroma of yogurt. SPEC Publ.-R. Soc. Chem. 2001, 274, 160–170. [Google Scholar]

- Patton, S. Flavor thresholds of volatile fatty acids. J. Food Sci. 2010, 29, 679–680. [Google Scholar] [CrossRef]

- Afzal, M.I.; Delaunay, S.; Paris, C.; Borges, F.; Revol-Junelles, A.M.; Cailliez-Grimal, C. Identification of metabolic pathways involved in the biosynthesis of flavor compound 3-methylbutanal from leucine catabolism by Carnobacterium.Carnobacterium maltaromaticum LMA 28. Int. J. Food Microbiol. 2012, 157, 332–339. [Google Scholar] [CrossRef] [PubMed]

- Afzal, M.I.; Boulahya, K.A.; Jacquot, M.; Delaunay, S.; Cailliezgrimal, C. Biosynthesis and role of 3-methylbutanal in cheese by lactic acid bacteria: Major metabolic pathways, enzymes involved, and strategies for control. Crit. Rev. Food Sci. 2015, 57, 339. [Google Scholar] [CrossRef] [PubMed]

- Peralta, G.H.; Wolf, I.V.; Bergamini, C.V.; Perotti, M.C.; Hynes, E.R. Evaluation of volatile compounds produced by Lactobacillus paracasei I90 in a hard-cooked cheese model using solid-phase microextraction. Dairy Sci. Technol. 2014, 94, 73–81. [Google Scholar] [CrossRef]

- Chu, F.L.; Yaylayan, V.A. Model studies on the oxygen-induced formation of benzaldehyde from phenylacetaldehyde using pyrolysis gc-ms and ftir. Agric. Food Chem. 2008, 56, 10697–10704. [Google Scholar] [CrossRef] [PubMed]

- Sidira, M.; Kandylis, P.; Kanellaki, M.; Kourkoutas, Y. Effect of immobilized Lactobacillus casei on the evolution of flavor compounds in probiotic dry-fermented sausages during ripening. Meat Sci. 2015, 100, 41–51. [Google Scholar] [CrossRef] [PubMed]

- Marco, A.; Navarro, J.L.; Flores, M. The influence of nitrite and nitrate on microbial, chemical and sensory parameters of slow dry fermented sausage. Meat Sci. 2006, 73, 660. [Google Scholar] [CrossRef] [PubMed]

- Jensen, K.A.; Evans, K.M.; Kirk, T.K.; Hammel, K.E. Biosynthetic pathway for veratryl alcohol in the ligninolytic fungus phanerochaete chrysosporium. Appl. Environ. Microb. 1994, 60, 709–714. [Google Scholar]

- Adhikari, K.; Hein, K.A.; Elmore, J.R.; Heymann, H.; Willott, A.M. Flavor threshold as affected by interaction among three dairy-related flavor compounds. J. Sens. Stud. 2010, 21, 626–643. [Google Scholar] [CrossRef]

- Hayaloglu, A.A.; Karabulut, I. SPME/GC-MS characterization and comparison of volatiles of eleven varieties of turkish cheeses. Int. J. Food Prop. 2013, 16, 1630–1653. [Google Scholar] [CrossRef]

- Smit, G.; Smit, B.A.; Engels, W.J. Flavour formation by lactic acid bacteria and biochemical flavour profiling of cheese products. Fems. Microbiol. Rev. 2005, 29, 591–610. [Google Scholar] [CrossRef] [PubMed]

- Rincon-Delgadillo, M.I.; Lopez-Hernandez, A.; Wijaya, I.; Rankin, S.A. Diacetyl levels and volatile profiles of commercial starter distillates and selected dairy foods. J. Dairy Sci. 2012, 95, 1128. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.G. Flavoring; Chemical Industry Press: Beijing, China, 2003; pp. 20–28. [Google Scholar]

- Angerosa, F.; Camera, L.; d’Alessandro, A.N.; Mellerio, G. Characterization of seven new hydrocarbon compounds present in the aroma of virgin olive oils. J. Agric. Food Chem. 1998, 46, 648. [Google Scholar] [CrossRef] [PubMed]

- Zha, M.; Yu, J.; Zhang, Y.; Wang, H.; Bai, N.; Qin, Y.; Liangliang, D.; Liu, W.; Zhang, H.; Bilige, M. Study on Streptococcus thermophilus isolated from Qula and associated characteristic of acetaldehyde and diacetyl in their fermented milk. J. Gen. Appl. Microbiol. 2015, 61, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Attaie, R. Quantification of volatile compounds in goat milk Jack cheese using static headspace gas chromatography. J. Dairy Sci. 2009, 92, 2435. [Google Scholar] [CrossRef] [PubMed]

- Qian, M.; Reineccius, G.A. Quantification of aroma compounds in parmigiano reggiano cheese by a dynamic headspace gas chromatography-mass spectrometry technique and calculation of odor activity value. J. Dairy Sci. 2003, 86, 770–776. [Google Scholar] [CrossRef]

- Leffingwell, J.C.; Leffingwell, D. GRAS flavor chemicals-detection thresholds. Perfumer Flavorist. 1991, 16, 2–19. [Google Scholar]

- John, C. Flavor-Base (Demo), 10th ed.; Leffingwell and Associates: Canton, GA, USA, 2001. [Google Scholar]

- Gemert, L.J.V. Compilations of Odour Threshold Values in Air, Water and Other Media, 10th ed.; Oliemans Punter & Partners: Utrecht, The Netherlands, 2003. [Google Scholar]

- Tharmaraj, N.; Shah, N.P. Selective enumeration of Lactobacillus delbrueckii ssp. bulgaricus, Streptococcus thermophilus, Lactobacillus acidophilus, Bifidobacteria, Lactobacillus casei, Lactobacillus rhamnosus, and Propionibacteria. J. Dairy Sci. 2003, 86, 2288–2296. [Google Scholar] [CrossRef]

- Bao, Y.; Zhang, Y.; Li, H.; Liu, Y.; Wang, S.; Dong, X.; Su, F.; Yao, G.; Sun, T.; Zhang, H. In vitro screen of Lactobacillus plantarum as probiotic bacteria and their fermented characteristics in soymilk. Ann. Microbiol. 2012, 62, 1311–1320. [Google Scholar] [CrossRef]

- Galmarini, M.V.; Baeza, R.; Sanchez, V.; Zamora, M.C.; Chirife, J. Comparison of the viscosity of trehalose and sucrose solutions at various temperatures: Effect of guar gum addition. LWT-Food Sci. Technol. 2011, 44, 186–190. [Google Scholar] [CrossRef]

- Li, C.; Li, W.; Chen, X.; Feng, M.; Rui, X.; Jiang, M.; Dong, M. Microbiological, physicochemical and rheological properties of fermented soymilk produced with exopolysaccharide (EPS) producing lactic acid bacteria strains. LWT Food Sci. Technol. 2014, 57, 477–485. [Google Scholar] [CrossRef]

Sample Availability: Not available. |

| Volatile Compound | Chemical Formula | RT 1 | RI 2 | RI 3 | Method 4 | μg/L | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 h (F) 5 | 2 h (F) | 4 h (F) | 6 h (F) | 0 d (S) 6 | 12 h (S) | 1 d (S) | 2 d (S) | 3 d (S) | 7 d (S) | 14 d (S) | |||||||

| Carboxylic acid compounds | |||||||||||||||||

| 1 | Acetic acid | C2H4O2 | 2.71 | 630.71 | 638 | MS, RI | - | - | - | - | 70.07 | 24.76 | 21.08 | 24.28 | 19.80 | 18.19 | 17.21 |

| 2 | Hexanoic acid | C6H12O2 | 14.72 | 1021.01 | 1020 | MS, RI | - | - | - | - | 35.17 | 29.77 | 7.68 | 7.49 | 7.89 | 7.52 | 7.36 |

| 3 | Heptanoic acid | C7H14O2 | 15.80 | 1053.46 | 1062 | MS, RI | - | - | - | - | 8.31 | 4.34 | 3.05 | 3.47 | 3.33 | 2.15 | 3.20 |

| 4 | Nonanoic acid | C9H18O2 | 21.09 | 1224.43 | 1226 | MS, RI | - | - | - | - | - | - | - | 0.75 | 0.18 | - | - |

| 5 | Octanoic acid | C8H16O2 | 20.21 | 1193.85 | 1191 | MS, RI | - | - | - | - | - | - | - | 3.64 | - | - | - |

| Aldehydes | |||||||||||||||||

| 1 | Methacrolein | C4H6O | 2.30 | 599.69 | 567 | MS, RI | - | - | - | 1.38 | - | - | - | - | - | - | - |

| 2 | Butanal, 3-methyl- | C5H10O | 3.47 | 689.08 | 689 | MS, RI | 7.52 | 15.02 | 16.95 | 12.62 | - | - | - | - | - | - | - |

| 3 | Butanal, 3-hydroxy- | C4H8O2 | 3.53 | 693.79 | - | MS | - | - | - | - | 4.45 | 6.83 | 3.59 | 1.79 | - | - | - |

| 4 | 2-Pentenal, (E)- | C5H8O | 5.52 | 765.69 | 765 | MS, RI | - | - | - | 1.93 | 1.15 | 1.03 | 1.02 | 1.23 | 1.25 | 1.60 | 1.88 |

| 5 | Hexanal | C6H12O | 6.87 | 809.39 | 809 | MS, RI | 99.08 | 91.58 | 58.12 | 52.03 | 3.96 | - | - | - | - | - | - |

| 6 | 2-Pentenal, 2-methyl- | C6H10O | 7.53 | 826.57 | 826 | MS, RI | - | - | - | - | 1.89 | - | - | - | - | - | - |

| 7 | 2-Hexenal, (E)- | C6H10O | 8.95 | 863.25 | 861 | MS, RI | 1.91 | 1.92 | 1.96 | 5.58 | 6.33 | 2.82 | 1.89 | 2.03 | 1.71 | 1.71 | 1.93 |

| 8 | Heptanal | C7H14O | 10.87 | 905.14 | 906 | MS, RI | 191.95 | 129.22 | 78.60 | 32.93 | 4.41 | 1.84 | 1.01 | 1.25 | 1.73 | 1.34 | 2.25 |

| 9 | 2-Heptenal, (E)- | C7H12O | 12.87 | 965.33 | 964 | MS, RI | 10.03 | 11.41 | 10.42 | 11.53 | 23.47 | 7.45 | 3.39 | 6.20 | 2.97 | 4.90 | 5.78 |

| 10 | Benzaldehyde | C7H6O | 12.94 | 970.87 | 971 | MS, RI | 7.14 | 6.81 | 5.65 | - | - | - | - | - | - | - | - |

| 11 | Octanal | C8H16O | 14.57 | 1009.21 | 1005 | MS, RI | 89.55 | 45.12 | 23.49 | 18.24 | 7.73 | 2.95 | - | - | - | - | - |

| 12 | 2,4-Heptadienal, (E,E)- | C7H10O | 14.81 | 1023.54 | 1023 | MS, RI | - | 1.42 | 1.85 | 1.40 | 1.15 | - | - | - | - | - | - |

| 13 | 2-Octenal, (E)- | C8H14O | 16.41 | 1069.45 | 1067 | MS, RI | 13.29 | 13.86 | 15.07 | 15.66 | 20.48 | 10.21 | 4.74 | 4.44 | 3.58 | 3.49 | 4.28 |

| 14 | Nonanal | C9H18O | 17.92 | 1118.91 | 1119 | MS, RI | 52.04 | 35.95 | 28.60 | 9.58 | 4.01 | 1.52 | 1.43 | 1.03 | 1.50 | 1.12 | 1.13 |

| 15 | 2-Nonenal, (E)- | C9H16O | 19.62 | 1172.50 | 1172 | MS, RI | 26.20 | 30.44 | 22.48 | 25.42 | 31.14 | 18.42 | 6.26 | 12.15 | 4.62 | 6.46 | 6.58 |

| 16 | Decanal | C10H20O | 21.02 | 1216.62 | 1214 | MS, RI | 3.63 | 2.83 | 2.59 | 1.87 | - | - | - | - | - | - | - |

| 17 | 2-Decenal, (Z)- | C10H18O | 22.61 | 1277.90 | 1280 | MS, RI | 12.13 | 15.01 | 19.53 | 22.75 | 28.22 | 16.54 | 7.93 | 7.64 | 7.42 | 6.07 | 7.02 |

| 18 | 2-Decenal, (E)- | C10H18O | 22.75 | 1281.57 | 1279 | MS, RI | 3.80 | 6.69 | 19.01 | - | - | - | - | - | - | - | - |

| 19 | Undecanal | C11H22O | 23.51 | 1310.47 | 1300 | MS, RI | - | - | - | - | 1.94 | - | - | - | - | - | - |

| 20 | 2-Undecenal, E- | C11H20O | 24.55 | 1349.47 | 1340.00 | MS, RI | - | - | - | 1.56 | - | - | - | - | - | - | - |

| 21 | 2-Undecenal | C11H20O | 24.81 | 1359.26 | 1359 | MS, RI | 2.12 | 3.50 | 6.48 | 6.25 | 8.91 | 4.28 | 3.65 | 3.53 | 2.44 | 2.02 | 2.22 |

| Ketones | |||||||||||||||||

| 1 | 2,3-Butanedione | C4H6O2 | 2.16 | STD | MS. STD | MS, RI | - | - | - | - | 16.08 | 16.49 | 15.25 | 16.07 | 9.03 | - | - |

| 2 | 2-Butanone, 3-methyl- | C5H10O | 2.26 | STD | MS. STD | MS, RI | - | 3.34 | 5.89 | 18.97 | 16.91 | 16.13 | 10.85 | 10.25 | 8.54 | 7.84 | 7.01 |

| 3 | 2-Pentanone | C5H10O | 3.42 | 685.33 | 687 | MS, RI | - | - | - | - | - | - | - | 0.78 | - | - | - |

| 4 | Acetoin | C4H8O2 | 4.22 | 720.87 | MS. STD | MS | - | - | 3.22 | 20.24 | 58.48 | 27.30 | 29.87 | 24.10 | 21.12 | 24.38 | 23.98 |

| 5 | 3-Pentanone, 2-methyl- | C6H12O | 5.23 | 755.70 | 752 | MS, RI | - | - | - | - | - | - | - | 1.88 | - | - | - |

| 6 | 3-Hexen-2-one | C6H10O | 8.51 | 852.38 | 845 | MS, RI | - | - | - | - | 3.07 | 1.40 | 1.54 | 1.49 | 0.80 | 0.98 | 1.19 |

| 7 | 2-Hexanone, 5-methyl- | C7H14O | 8.97 | 864.56 | 857 | MS, RI | - | - | - | 14.49 | - | - | - | - | - | - | - |

| 8 | 2-Heptanone | C7H14O | 10.43 | 891.82 | 891 | MS, RI | 31.60 | 32.13 | 32.41 | 31.62 | 53.88 | 26.19 | 19.54 | 17.78 | 18.53 | 17.43 | 17.66 |

| 9 | 3-Heptanone, 5-methyl- | C8H16O | 12.87 | 968.76 | 962 | MS, RI | 2.60 | 2.79 | 3.12 | 3.09 | - | - | - | - | - | - | - |

| 10 | 2-Octanone | C8H16O | 14.15 | 1003.70 | 1003 | MS, RI | 14.44 | 15.14 | 15.44 | 15.34 | 17.96 | 9.16 | 7.58 | 7.34 | 7.55 | 7.19 | 7.22 |

| 11 | 3-Octen-2-one | C8H14O | 15.79 | 1049.21 | 1046 | MS, RI | 7.55 | 7.83 | 7.85 | 7.52 | 9.88 | 5.00 | 4.98 | 4.53 | 1.18 | - | - |

| 12 | 2-Nonanone | C9H18O | 17.54 | 1098.98 | 1096 | MS, RI | 26.03 | 28.38 | 32.78 | 28.02 | 26.66 | 13.78 | 7.39 | 5.95 | - | - | - |

| 13 | 2-Undecanone | C11H22O | 23.52 | 1310.70 | 1305 | MS, RI | 3.41 | 3.48 | 3.89 | 3.33 | 3.90 | 2.18 | 1.78 | 1.45 | 1.70 | 1.10 | 1.43 |

| Alcohols | |||||||||||||||||

| 1 | Butanol, 3-methyl- | C5H12O | 5.71 | 772.37 | 767 | MS, RI | 5.17 | 4.28 | 5.03 | 18.39 | 23.37 | 10.80 | 10.76 | 10.83 | 10.39 | 11.29 | 11.09 |

| 2 | 1-Pentanol | C5H12O | 5.71 | 772.37 | 772 | MS, RI | - | - | - | - | - | - | - | - | - | - | 10.95 |

| 3 | 2-Heptanol, 3-methyl- | C8H18O | 7.23 | 818.65 | - | MS | - | - | - | - | 2.88 | 2.56 | 2.69 | 2.06 | - | - | - |

| 4 | Hexanol | C6H14O | 9.66 | 882.39 | 880 | MS, RI | 40.75 | 42.70 | 49.69 | 53.72 | 152.25 | 74.39 | 44.01 | 38.35 | 43.49 | 43.49 | 41.13 |

| 5 | Heptanol | C7H16O | 13.26 | 979.30 | 974 | MS, RI | 58.68 | 121.58 | 142.23 | 196.00 | 244.29 | 121.75 | 82.17 | 71.20 | 70.59 | 72.54 | 68.06 |

| 6 | cis-Hept-4-enol | C7H14O | 13.26 | 979.36 | - | MS | - | 2.54 | 2.21 | 3.79 | 7.84 | 4.11 | 1.75 | 1.47 | 1.47 | 1.52 | 0.96 |

| 7 | 1-Octen-3-ol | C8H16O | 13.75 | 991.78 | 986 | MS, RI | 4.93 | 7.35 | 4.47 | 5.78 | 9.88 | 4.16 | 2.21 | 1.66 | 1.10 | 1.87 | 1.09 |

| 8 | 3,5-Octadien-2-ol | C8H14O | 15.32 | 1039.01 | 1037 | MS, RI | - | - | - | - | 10.36 | 6.66 | 1.67 | 1.78 | 1.88 | 1.89 | 1.19 |

| 9 | 2-Octen-1-ol, (E)- | C8H16O | 15.41 | 1041.72 | 1059 | MS, RI | - | 3.21 | 2.81 | 1.87 | 1.69 | 1.65 | 0.73 | 0.74 | 0.57 | 0.64 | 0.34 |

| 10 | 3,5-Octadien-2-ol | C8H14O | 15.80 | 1053.31 | 1039 | MS, RI | - | - | - | - | - | - | - | 1.67 | - | - | - |

| 11 | 1-Octanol | C8H18O | 16.88 | 1086.07 | 1087 | MS, RI | - | 78.97 | 95.89 | - | - | - | - | - | - | - | - |

| 12 | 5-Octen-2-ol, 5-methyl- | C9H18O | 17.54 | 1106.30 | - | MS | - | 30.29 | 24.30 | 19.03 | 17.98 | 17.88 | 14.98 | 15.08 | 13.68 | 9.62 | 9.80 |

| 13 | 3-Decyn-2-ol | C10H18O | 17.70 | 1111.55 | 1101 | MS, RI | - | 3.05 | - | - | - | - | - | - | - | - | - |

| 14 | 2-Nonen-1-ol, (E)- | C9H18O | 19.91 | 1183.74 | 1171 | MS, RI | - | - | - | - | 3.97 | 3.22 | 1.82 | 1.34 | 1.13 | 1.23 | 1.50 |

| 15 | 1-Nonanol | C9H20O | 19.99 | 1186.58 | 1186 | MS, RI | - | 13.28 | 23.21 | 22.71 | 45.23 | 25.13 | 17.42 | 14.07 | 12.11 | 12.34 | 13.38 |

| 16 | 1-Decanol | C10H22O | 22.90 | 1288.14 | 1279 | MS, RI | - | - | - | - | - | - | - | 1.96 | - | - | - |

| Esters | |||||||||||||||||

| 1 | Formic acid, hexyl ester | C7H14O2 | 11.87 | 941.92 | 927 | MS, RI | - | - | - | - | 2.54 | 2.09 | 2.66 | 1.98 | 1.07 | 1.27 | 1.01 |

| 2 | Formic acid, octyl ester | C9H18O2 | 16.90 | 1086.66 | - | MS | - | - | 87.96 | 77.06 | 132.20 | 68.07 | 62.10 | 55.59 | 43.15 | 39.37 | 32.29 |

| 3 | 1-Octen-3-yl-acetate | C10H18O2 | 17.25 | 1097.11 | 1097 | MS, RI | - | - | - | - | - | 1.20 | 1.09 | 1.34 | 1.32 | 1.02 | 1.21 |

| 4 | Acetic acid, octyl ester | C10H20O2 | 20.34 | 1197.97 | 1200 | MS, RI | - | - | - | - | 7.83 | 3.29 | 2.44 | 2.09 | 1.79 | 1.23 | 1.24 |

| 5 | Oxirane, decyl- | C12H24O | 23.51 | 1310.47 | 1307 | MS, RI | - | 2.43 | 2.48 | 2.07 | - | - | - | - | - | - | - |

| Aromatic hydrocarbons | |||||||||||||||||

| 1 | Cyclopentane, methyl- | C6H12 | 2.65 | 626.43 | 624 | MS, RI | - | 1.86 | 1.65 | - | - | - | - | - | - | - | - |

| 2 | n-Hexane | C6H14 | 3.46 | 687.93 | - | MS | - | - | - | 2.52 | - | - | - | - | - | - | - |

| 3 | Heptane | C7H16 | 3.58 | 697.48 | - | MS | - | - | - | - | 8.38 | 5.40 | 2.30 | 1.83 | 1.99 | 2.28 | 2.21 |

| 4 | 1-Octene | C8H16 | 6.53 | 797.74 | 794 | MS, RI | 3.94 | 4.93 | 4.33 | 5.91 | - | - | - | - | - | - | - |

| 5 | Hexane, 2,4-dimethyl- | C8H18 | 6.81 | 807.75 | - | MS | - | - | - | - | - | 15.65 | 7.43 | 7.78 | 1.62 | - | - |

| 6 | 1-Nonene | C9H18 | 9.70 | 883.77 | 893 | MS, RI | 46.10 | 15.82 | 11.12 | 5.48 | - | - | - | - | - | - | - |

| 7 | Octane, 2,7-dimethyl- | C10H22 | 11.55 | 933.18 | 934 | MS, RI | 3.33 | - | - | - | - | - | - | - | - | - | - |

| 8 | 4,6-Decadiene | C10H18 | 18.53 | 1133.78 | 1145 | MS, RI | 4.02 | 3.96 | 4.23 | 4.29 | 4.33 | 3.02 | 2.78 | 1.40 | 1.40 | - | - |

| 9 | 4-Dodecyne | C12H22 | 20.45 | 1201.69 | 1203.00 | MS, RI | - | - | - | 1.76 | - | - | - | - | - | - | - |

| 10 | 3-Dodecyne | C12H22 | 20.78 | 1213.20 | 1210 | MS, RI | 3.37 | - | - | - | - | - | - | - | - | - | - |

| 11 | 1-Octadecyne | C18H34 | 21.56 | 1240.88 | 1238 | MS, RI | 3.12 | 3.13 | - | - | - | - | - | - | - | - | - |

| 12 | 5-Tridecene, (Z)- | C13H26 | 22.48 | 1273.35 | 1272.8 | MS, RI | 2.21 | 1.98 | 1.60 | 1.18 | 1.13 | 1.23 | 0.93 | 0.99 | 0.82 | 0.96 | 1.38 |

| 13 | 2-Dodecenal, (E)- | C12H22O | 27.56 | 1457.11 | 1452 | MS, RI | - | 1.24 | 1.45 | 1.52 | 1.23 | 1.06 | 0.22 | - | - | - | - |

| Internal standard | |||||||||||||||||

| 1 | 1,2-Dichloro-benzene | C6H4Cl2 | 14.89 | 1018 | 1014 | MS, RI | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Volatile Compound | Chemical Formula | Odor threshold (μg/L) | References | OAV | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 h (F) 1 | 2 h (F) | 4 h (F) | 6 h (F) | 0 d (S) 2 | 12 h (S) | 1 d (S) | 2 d (S) | 3 d (S) | 7 d (S) | 14 d (S) | ||||

| Butanal, 3-methyl- | C5H10O | 5.4 | [42] | 1.39 | 2.78 | 3.14 | 2.34 | - | - | - | - | - | - | - |

| 2-Pentenal, (E)- | C5H8O | 1.2 | [38] | - | - | - | 1.61 | 0.96 | 0.86 | 0.85 | 1.03 | 1.04 | 1.33 | 1.57 |

| Hexanal | C6H12O | 3 | [38] | 33.03 | 30.53 | 19.37 | 17.34 | 1.32 | - | - | - | - | - | - |

| 2-Heptenal, (E)- | C7H12O | 13 | [43] | 0.77 | 0.88 | 0.80 | 0.89 | 1.81 | 0.57 | 0.26 | 0.48 | 0.23 | 0.38 | 0.44 |

| Octanal | C8H16O | 0.7 | [38] | 127.93 | 64.46 | 33.56 | 26.06 | 11.04 | 4.21 | - | - | - | - | - |

| 2-Octenal, (E)- | C8H14O | 3 | [44] | 4.43 | 4.62 | 5.02 | 5.22 | 6.83 | 3.40 | 1.58 | 1.48 | 1.19 | 1.16 | 1.43 |

| Nonanal | C9H18O | 1 | [45] | 52.04 | 35.95 | 28.60 | 9.58 | 4.01 | 1.52 | 1.43 | 1.03 | 1.50 | 1.12 | 1.13 |

| 2,3-Butanedione | C4H6O2 | 10 | [42] | - | - | - | - | 1.61 | 1.65 | 1.53 | 1.61 | 0.90 | - | - |

| Acetoin | C4H8O2 | 55 | [44] | - | - | 0.06 | 0.37 | 1.06 | 0.50 | 0.54 | 0.44 | 0.38 | 0.44 | 0.44 |

| Hexanol | C6H14O | 120 | [42] | 0.34 | 0.36 | 0.41 | 0.45 | 1.27 | 0.62 | 0.37 | 0.32 | 0.36 | 0.36 | 0.34 |

| 1-Octen-3-ol | C8H16O | 10 | [23] | 0.49 | 0.74 | 0.45 | 0.58 | 0.99 | 0.42 | 0.22 | 0.17 | 0.11 | 0.19 | 0.11 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dan, T.; Jin, R.; Ren, W.; Li, T.; Chen, H.; Sun, T. Characteristics of Milk Fermented by Streptococcus thermophilus MGA45-4 and the Profiles of Associated Volatile Compounds during Fermentation and Storage. Molecules 2018, 23, 878. https://doi.org/10.3390/molecules23040878

Dan T, Jin R, Ren W, Li T, Chen H, Sun T. Characteristics of Milk Fermented by Streptococcus thermophilus MGA45-4 and the Profiles of Associated Volatile Compounds during Fermentation and Storage. Molecules. 2018; 23(4):878. https://doi.org/10.3390/molecules23040878

Chicago/Turabian StyleDan, Tong, Rulin Jin, Weiyi Ren, Ting Li, Haiyan Chen, and Tiansong Sun. 2018. "Characteristics of Milk Fermented by Streptococcus thermophilus MGA45-4 and the Profiles of Associated Volatile Compounds during Fermentation and Storage" Molecules 23, no. 4: 878. https://doi.org/10.3390/molecules23040878

APA StyleDan, T., Jin, R., Ren, W., Li, T., Chen, H., & Sun, T. (2018). Characteristics of Milk Fermented by Streptococcus thermophilus MGA45-4 and the Profiles of Associated Volatile Compounds during Fermentation and Storage. Molecules, 23(4), 878. https://doi.org/10.3390/molecules23040878