Physicochemical Properties and Microbial Quality of Tremella aurantialba Packed in Antimicrobial Composite Films

Abstract

:1. Introduction

2. Results and Discussion

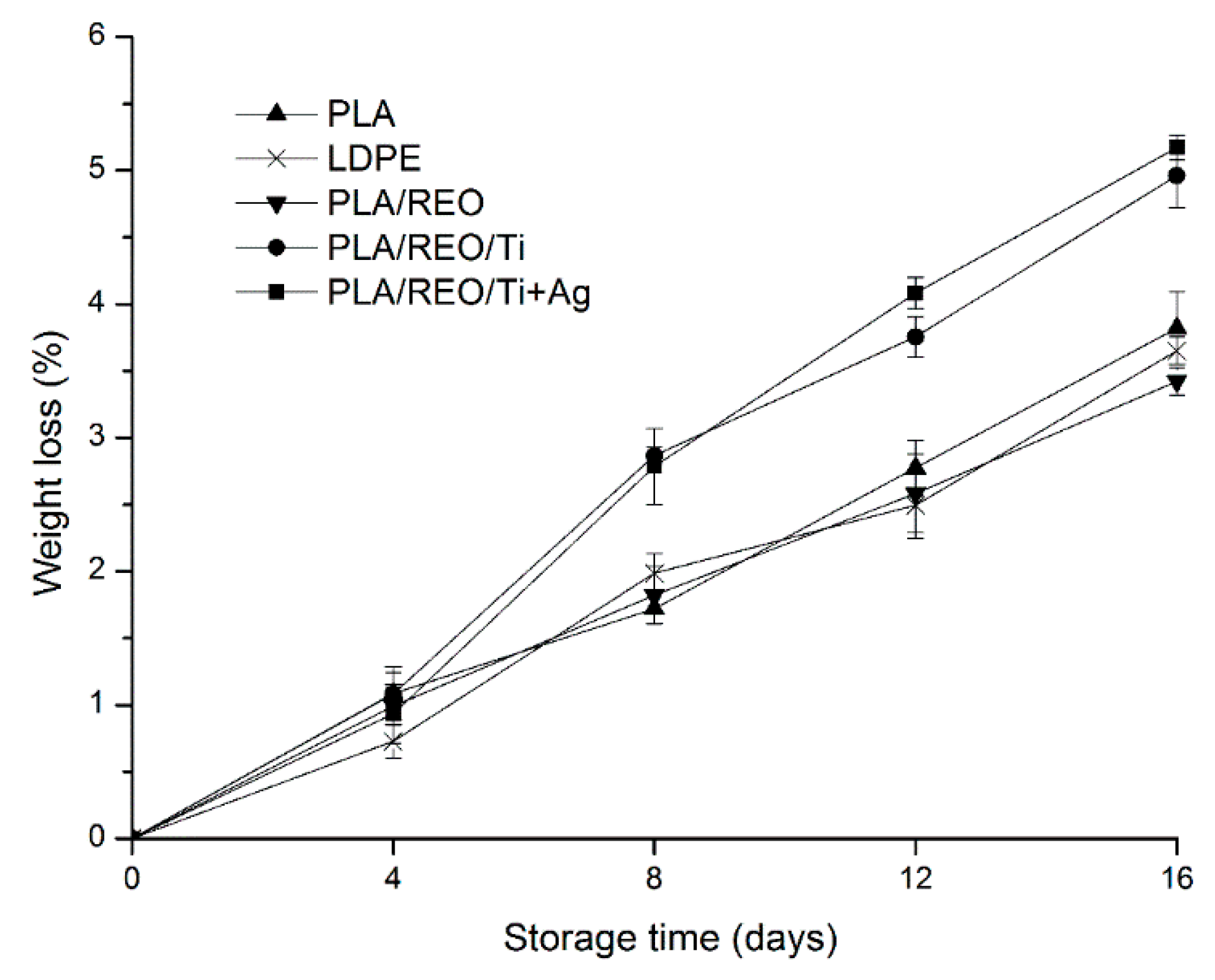

2.1. Weight Loss

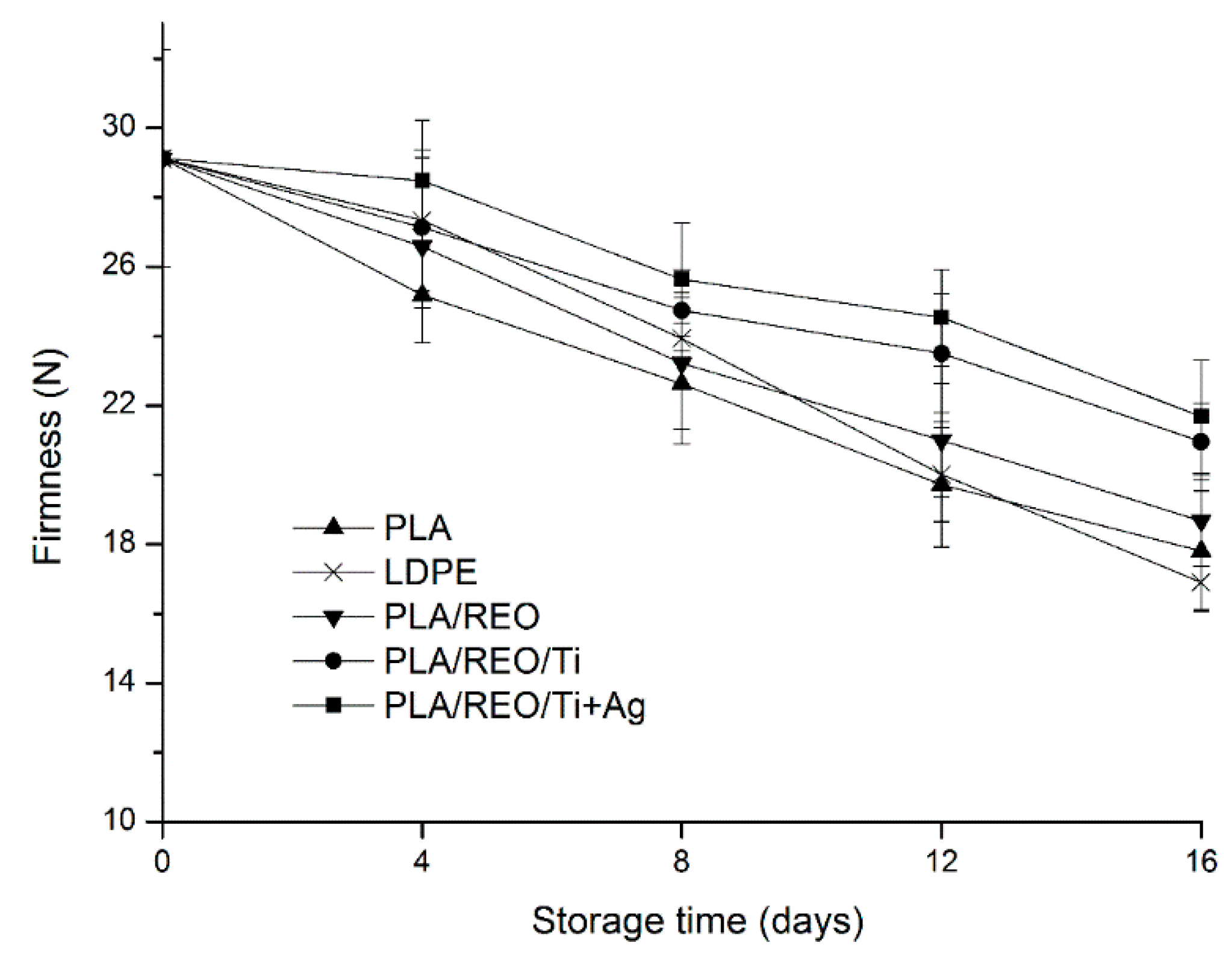

2.2. Firmness

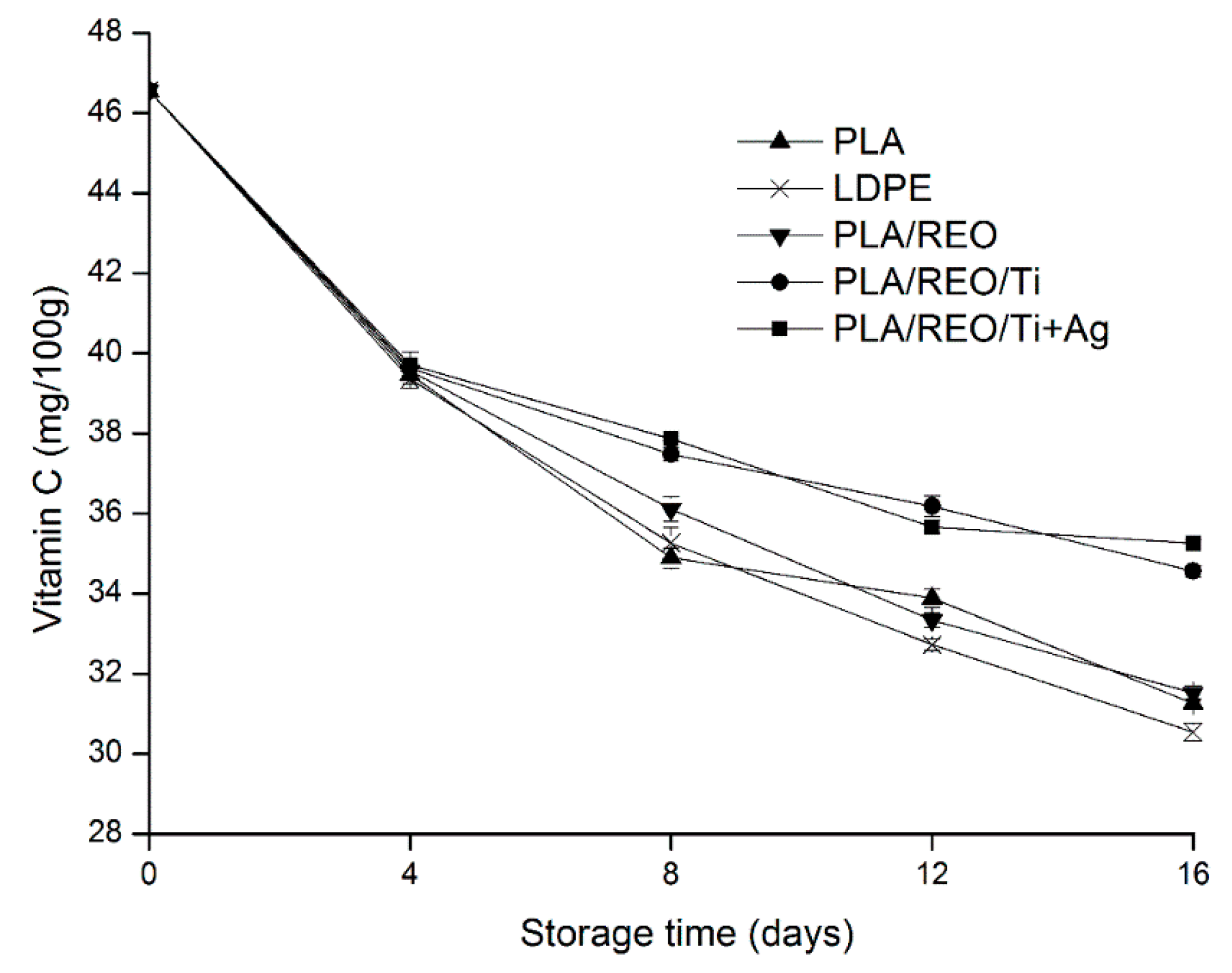

2.3. Vitamin C

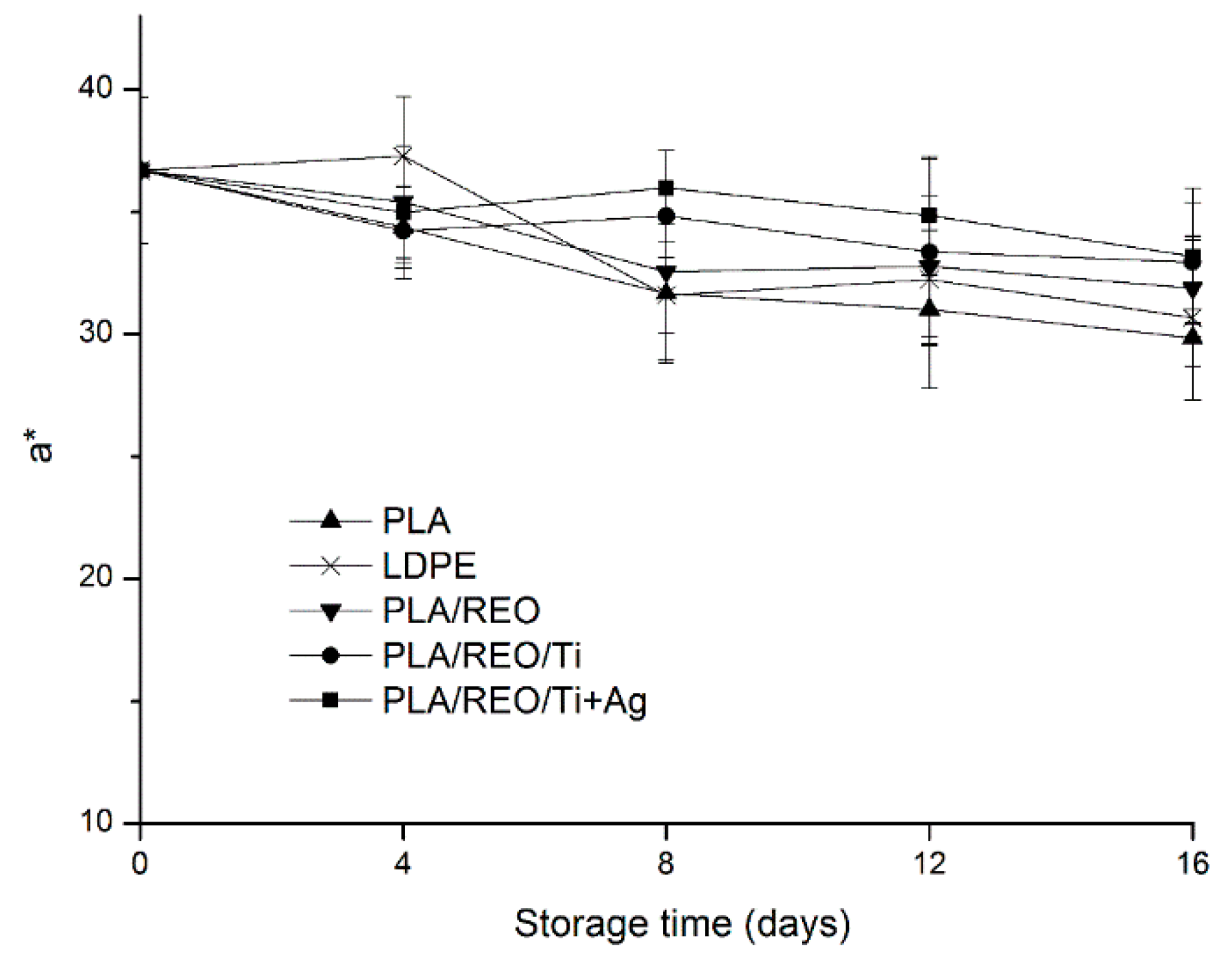

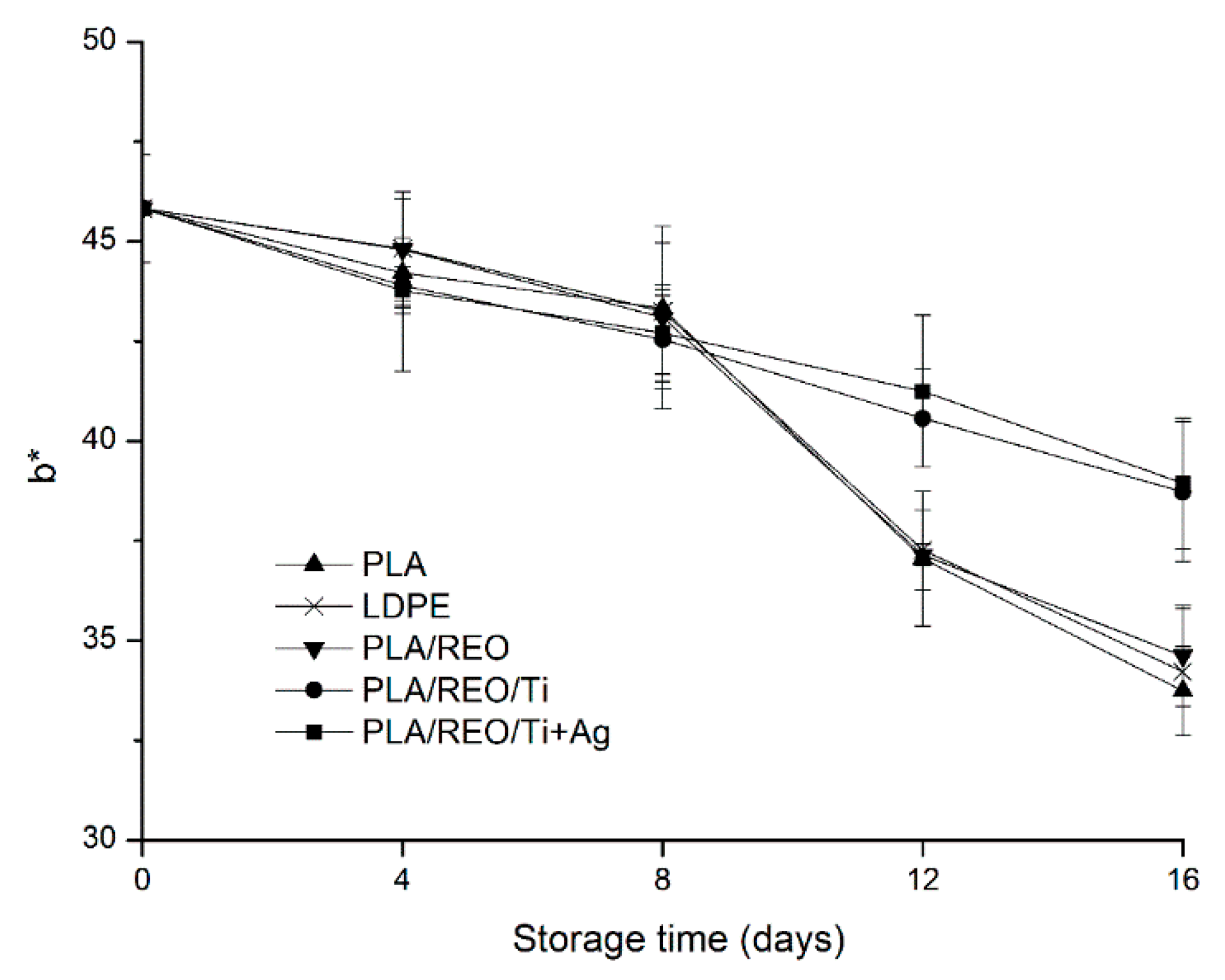

2.4. Color

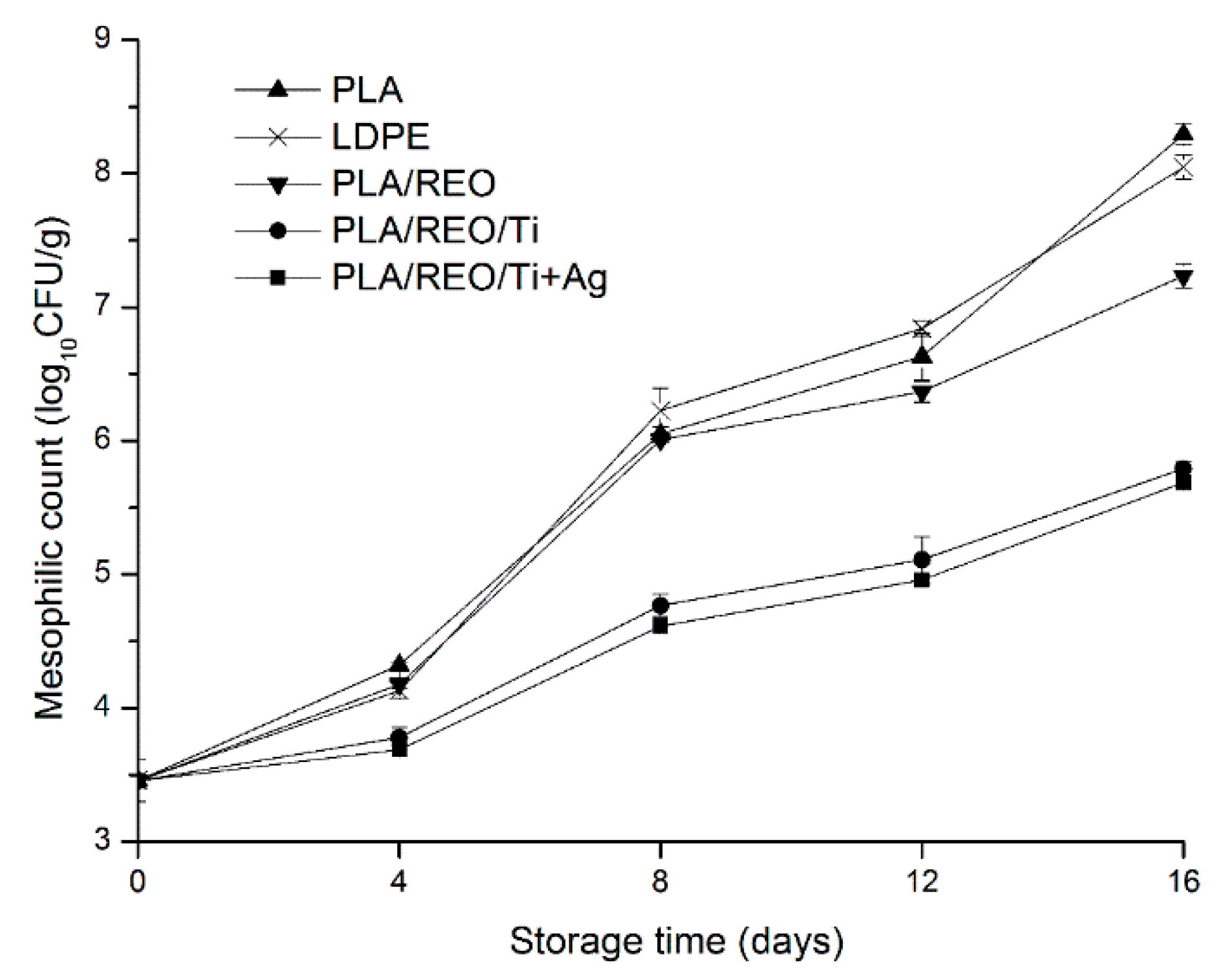

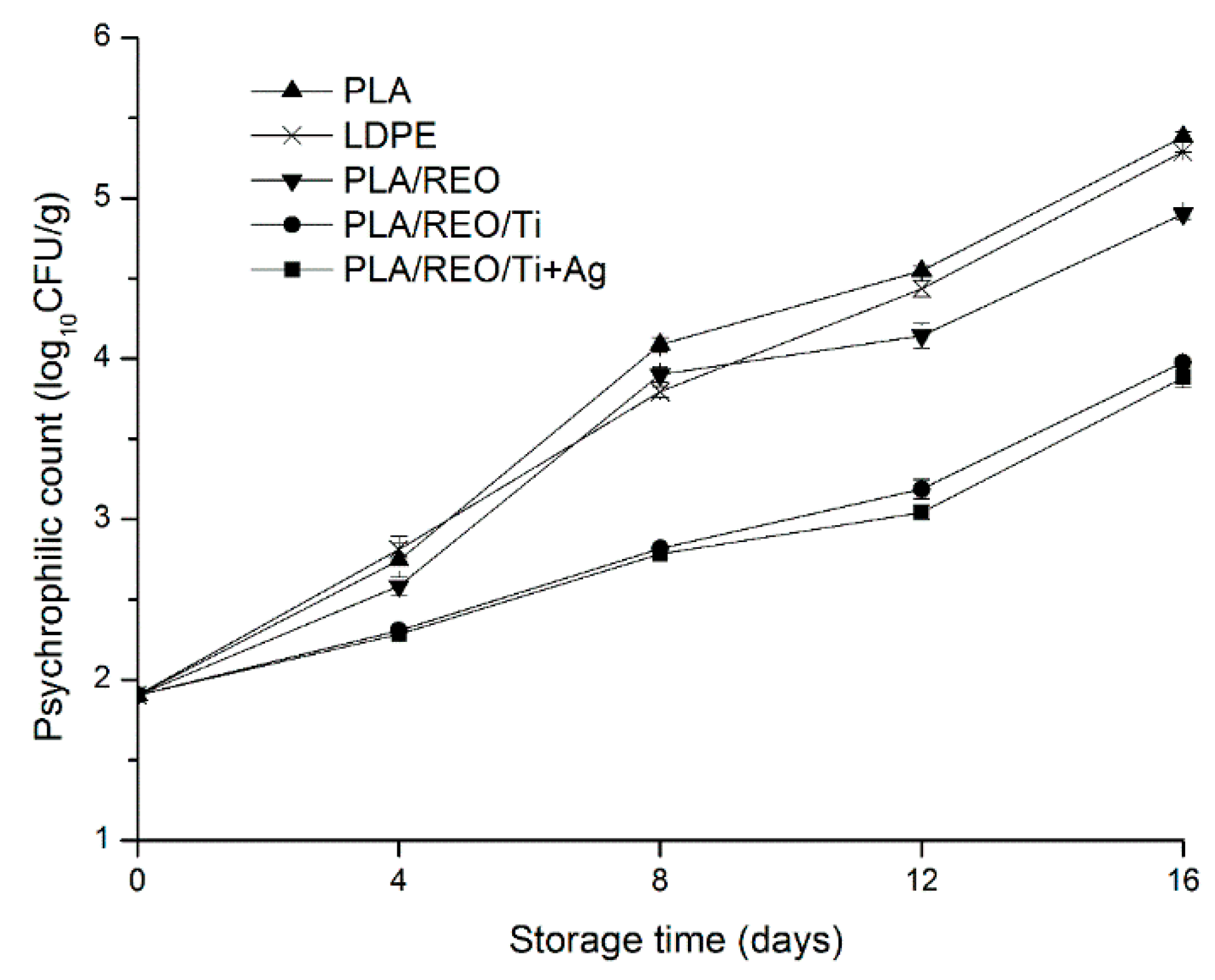

2.5. Microbiological Analysis

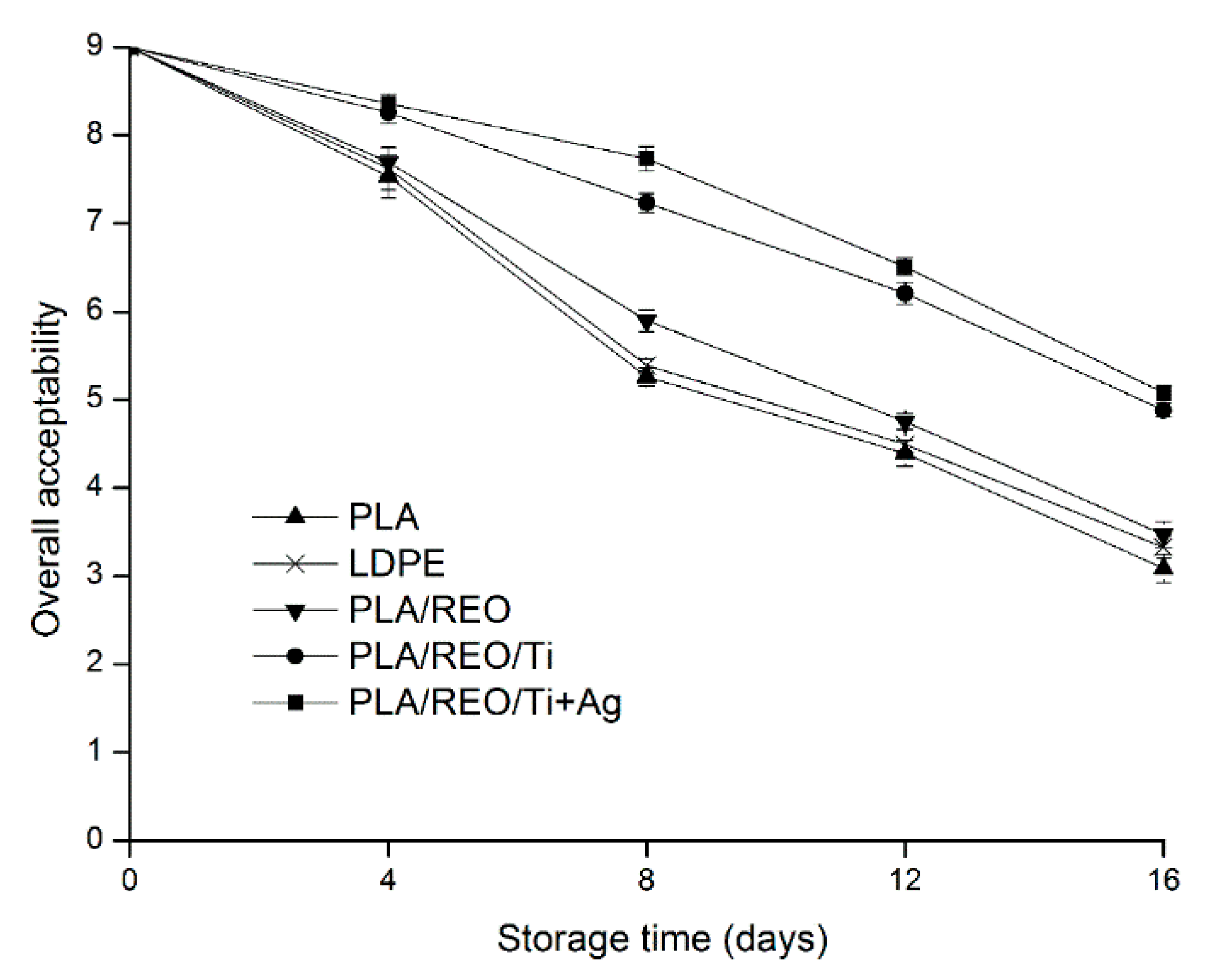

2.6. Overall Acceptability

3. Materials and Methods

3.1. Materials

3.2. Sample Preparation

3.3. Weight Loss

3.4. Firmness Measurement

3.5. Vitamin C

3.6. Color

3.7. Microbiological Analysis

3.8. Overall Acceptability

3.9. Statistical Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bandoni, R.J.; Zang, M. On an undescribed Tremella from China. Mycologia 1990, 82, 270–273. [Google Scholar] [CrossRef]

- Gao, M.; Feng, L.; Jiang, T. Browning inhibition and quality preservation of button mushroom (Agaricus bisporus) by essential oils fumigation treatment. Food Chem. 2014, 149, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.; Feng, L.; Zheng, X.; Li, J. Physicochemical responses and microbial characteristics of shiitake mushroom (Lentinus edodes) to gum arabic coating enriched with natamycin during storage. Food Chem. 2013, 138, 1992–1997. [Google Scholar] [CrossRef] [PubMed]

- Villaescusa, R.; Gil, M.I. Quality improvement of Pleurotus mushrooms by modified atmosphere packaging and moisture absorbers. Postharvest Biol. Technol. 2003, 28, 169–179. [Google Scholar] [CrossRef]

- Jafri, M.; Jha, A.; Bunkar, D.S.; Ram, R.C. Quality retention of oyster mushrooms (Pleurotus florida) by a combination of chemical treatments and modified atmosphere packaging. Postharvest Biol. Technol. 2013, 76, 112–118. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E.; Gadzinowska, K.; Stasiak, M. Plasticization of Poly(l-lactide) with Poly(propylene glycol). BioMacromol. 2006, 7, 2128–2135. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Peng, H.; Yu, X.; Zheng, X.; Cui, W.; Zhang, Z.; Li, X.; Wang, J.; Weng, J.; Jia, W. Preparation and characterization of a novel electrospun spider silk fibroin/poly(d,l-lactide) composite fiber. J. Phys. Chem. B 2008, 112, 11209–11216. [Google Scholar] [CrossRef] [PubMed]

- Wnek, G.E.; Carr, M.E.; Simpson, D.G.; Bowlin, G.L. Electrospinning of nanofiber fibrinogen structures. Nano Lett. 2002, 3, 213–216. [Google Scholar] [CrossRef]

- An, K.J.; Liu, H.Y.; Guo, S.D.; Kumar, D.N.T.; Wang, Q.Q. Preparation of fish gelatin and fish gelatin/poly(l-lactide) nanofibers by electrospinning. Int. J. Biol. Macromol. 2010, 47, 380–388. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.; Li, W.; Liu, D.; Yuan, M.; Li, L. Development of active packaging film made from poly (lactic acid) incorporated essential oil. Prog. Organ. Coat. 2016, 103, 76–82. [Google Scholar] [CrossRef]

- Ramos, M.; Jiménez, A.; Peltzer, M.; Garrigós, M.C. Development of novel nano-biocomposite antioxidant films based on poly (lactic acid) and thymol for active packaging. Food Chem. 2014, 162, 149–155. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Chen, Y.; Yu, S.; Chen, S.; Yin, Y. Preparation and antibacterial behavior of Fe3+-doped nanostructured TiO2 thin films. Thin Solid Films 2008, 516, 4690–4694. [Google Scholar] [CrossRef]

- Azlin-Hasim, S.; Cruz-Romero, M.C.; Ghoshal, T.; Morris, M.A.; Cummins, E.; Kerry, J.P. Application of silver nanodots for potential use in antimicrobial packaging applications. Innov. Food Sci. Emerg. Technol. 2015, 27, 136–143. [Google Scholar] [CrossRef]

- Bodaghi, H.; Mostofi, Y.; Oromiehie, A.; Zamani, Z.; Ghanbarzadeh, B.; Costa, C.; Conte, A.; Nobile, M.A.D. Evaluation of the photocatalytic antimicrobial effects of a TiO2 nanocomposite food packaging film by invitro and invivo tests. LWT Food Sci. Technol. 2013, 50, 702–706. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, D.; Wu, Y.; Yuan, M.; Li, L.; Yang, J. Effect of PLA/PCL/cinnamaldehyde antimicrobial packaging on physicochemical and microbial quality of button mushroom (Agaricus bisporus). Postharvest Biol. Technol. 2015, 99, 73–79. [Google Scholar] [CrossRef]

- Antmann, G.; Ares, G.; Lema, P.; Lareo, C. Influence of modified atmosphere packaging on sensory quality of shiitake mushrooms. Postharvest Biol. Technol. 2008, 49, 164–170. [Google Scholar] [CrossRef]

- Qin, Y.; Zhuang, Y.; Wu, Y.; Li, L. Quality evaluation of hot peppers stored in biodegradable poly(lactic acid)-based active packaging. Sci. Hortic. 2016, 202, 1–8. [Google Scholar] [CrossRef]

- Singh, P.; Langowski, H.C.; Wani, A.A.; Saengerlaub, S. Recent advances in extending the shelf life of fresh Agaricus mushrooms: A review. J. Sci. Food Agric. 2010, 90, 1393–1402. [Google Scholar] [CrossRef] [PubMed]

- Zivanovic, S.; Busher, R.W.; Kim, K.S. Textural changes in mushrooms (Agaricus bisporus) associated with tissue ultrastructure and composition. J. Food Sci. 2000, 65, 1404–1408. [Google Scholar] [CrossRef]

- Mcerlain, L.; Marson, H.; Ainsworth, P.; Burnett, S.A. Ascorbic acid loss in vegetables: Adequacy of a hospital cook-chill system. Int. J. Food Sci. Nutr. 2001, 52, 205–211. [Google Scholar] [PubMed]

- Kays, S.J. Preharvest factors affecting appearance. Postharvest Biol. Technol. 1999, 15, 233–247. [Google Scholar] [CrossRef]

- Du, J.; Fu, Y.; Wang, N. Effects of aqueous chlorine dioxide treatment on browning of fresh-cut lotus root. LWT Food Sci.Technol. 2009, 42, 654–659. [Google Scholar] [CrossRef]

- Cholnoky, L.; Györgyfy, C.; Nagy, E.; Pánczél, M. Function of carotenoids in chlorophy II-containing organs. Adv. Drug Deliv. Rev. 1956, 178, 410–411. [Google Scholar]

- Eastwood, D.; Burton, K. Mushrooms—A Matter Of Choice and Spoiling Oneself. MicroBiol. Today 2002, 29, 18–19. [Google Scholar]

- Abdollahi, M.; Rezaei, M.; Farzi, G. A novel active bionanocomposite film incorporating rosemary essential oil and nanoclay into chitosan. J. Food Eng. 2012, 111, 343–350. [Google Scholar] [CrossRef]

- Kim, J.S.; Kuk, E.; Yu, K.N.; Kim, J.H.; Park, S.J.; Hu, J.L.; Kim, S.H.; Park, Y.K.; Yong, H.P.; Hwang, C.Y. Antimicrobial effects of silver nanoparticles. Nanomed. Nanotechnol. Biol. Med. 2007, 3, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Sunada, K.; Watanabe, T.; Hashimoto, K. Studies on photokilling of bacteria on TiO2 thin film. J. Photochem. Photobiol. A 2003, 156, 227–233. [Google Scholar] [CrossRef]

- Lian, Z.; Zhang, Y.; Zhao, Y. Nano-TiO2 particles and high hydrostatic pressure treatment for improving functionality of polyvinyl alcohol and chitosan composite films and nano-TiO2 migration from film matrix in food simulants. Innov. Food Sci. Emerg. Technol. 2015, 33, 145–153. [Google Scholar] [CrossRef]

- Khan, M.M.R.; Rahman, M.M.; Islam, M.S.; Begum, S.A. A simple UV-spectrophotometric method for the determination of vitamin C content in various fruits and vegetables at Sylhet area in Bangladesh. J. Biol. Sci. 2006, 6, 388–392. [Google Scholar] [CrossRef]

- Sample Availability: Samples of the compounds are not available from the authors.

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Chu, Z.; Li, L.; Zhao, T.; Yin, M.; Qin, Y. Physicochemical Properties and Microbial Quality of Tremella aurantialba Packed in Antimicrobial Composite Films. Molecules 2017, 22, 500. https://doi.org/10.3390/molecules22030500

Fan J, Chu Z, Li L, Zhao T, Yin M, Qin Y. Physicochemical Properties and Microbial Quality of Tremella aurantialba Packed in Antimicrobial Composite Films. Molecules. 2017; 22(3):500. https://doi.org/10.3390/molecules22030500

Chicago/Turabian StyleFan, Jian, Zhuangzhuang Chu, Lin Li, Tianrui Zhao, Min Yin, and Yuyue Qin. 2017. "Physicochemical Properties and Microbial Quality of Tremella aurantialba Packed in Antimicrobial Composite Films" Molecules 22, no. 3: 500. https://doi.org/10.3390/molecules22030500

APA StyleFan, J., Chu, Z., Li, L., Zhao, T., Yin, M., & Qin, Y. (2017). Physicochemical Properties and Microbial Quality of Tremella aurantialba Packed in Antimicrobial Composite Films. Molecules, 22(3), 500. https://doi.org/10.3390/molecules22030500