Recent Progress in Hybrid Aluminum Composite: Manufacturing and Application

Abstract

:1. Introduction

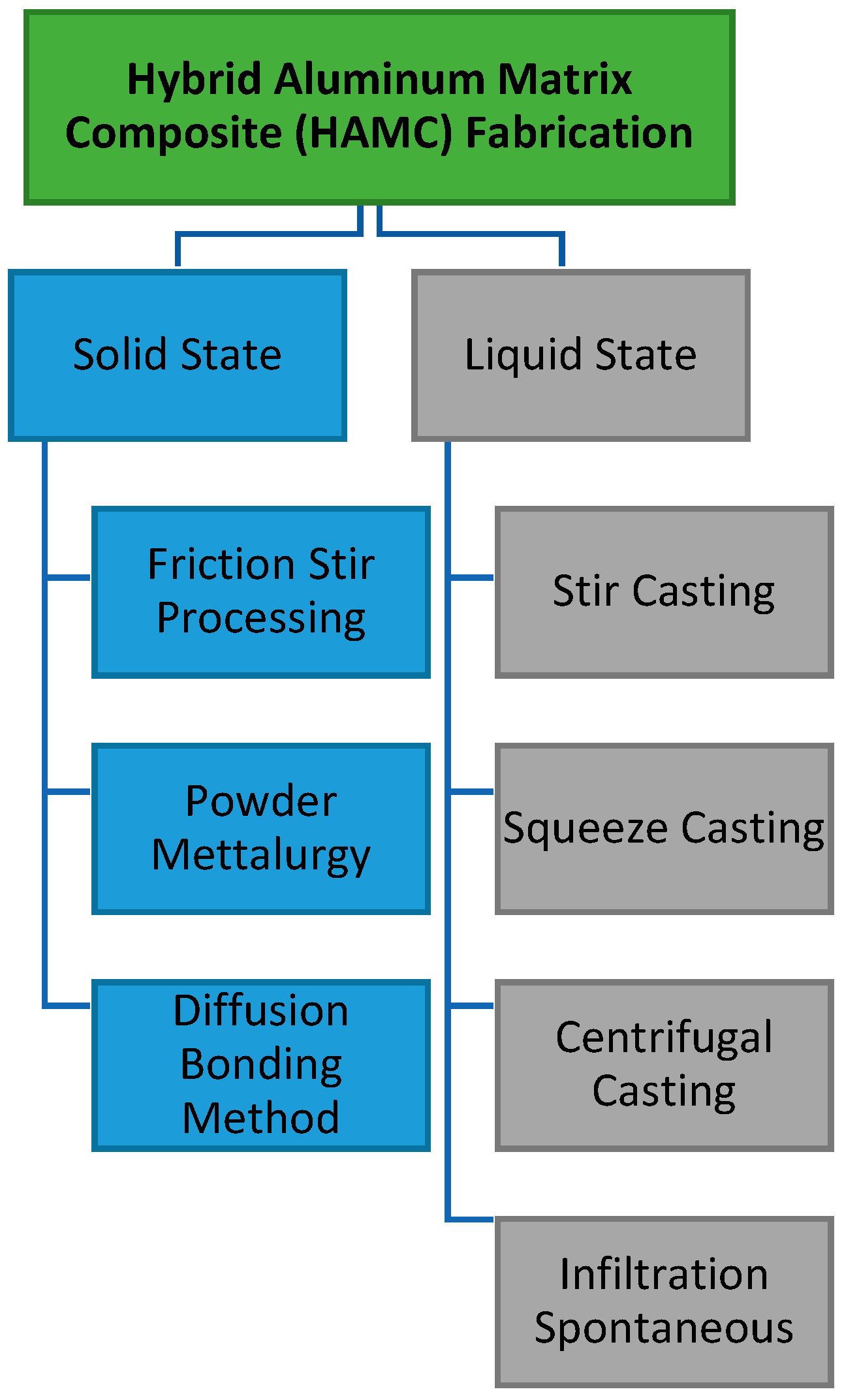

2. HAMC Fabrication Process

2.1. Solid-State Processing

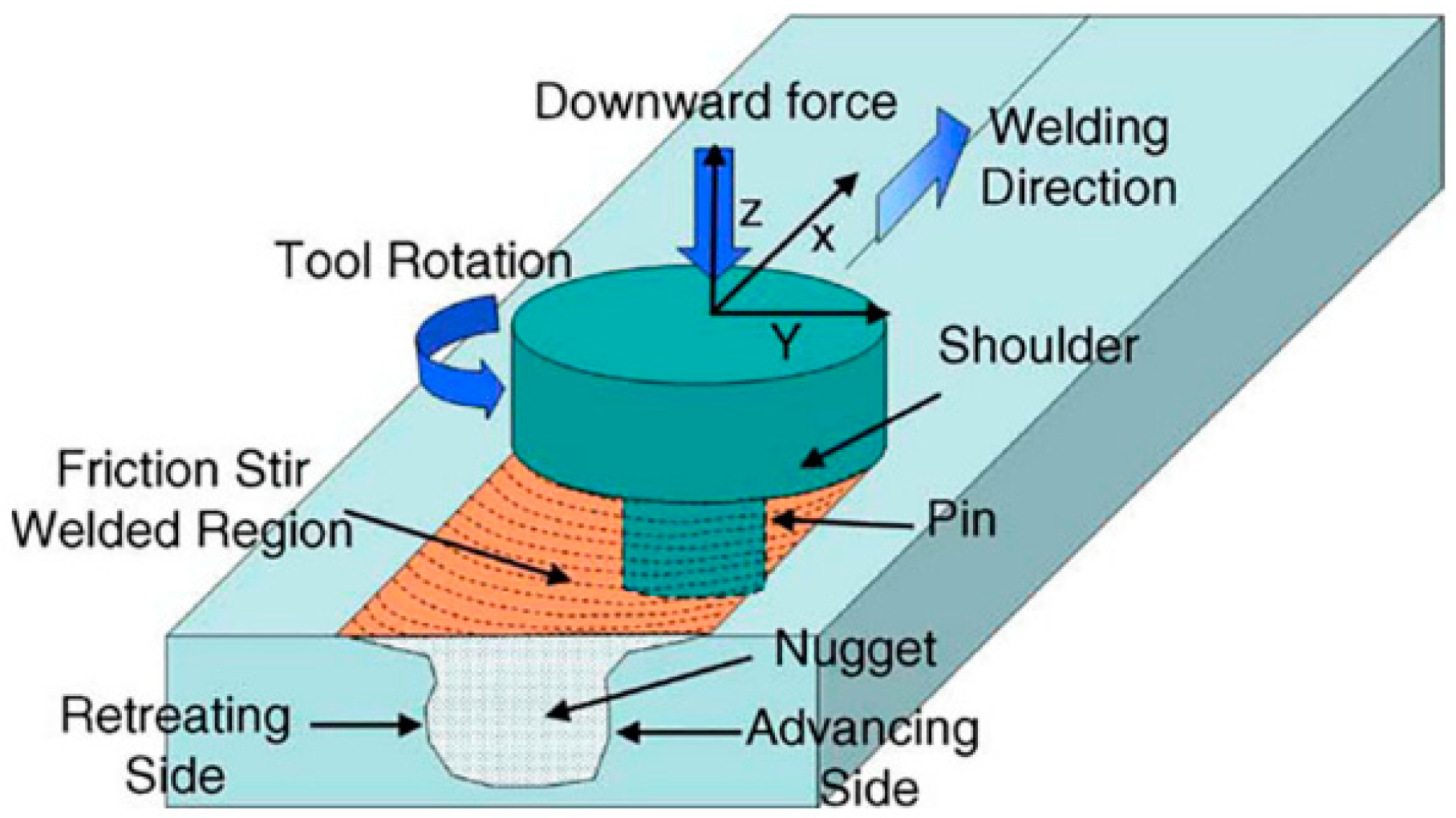

2.1.1. Friction Stir Processing (FSP)

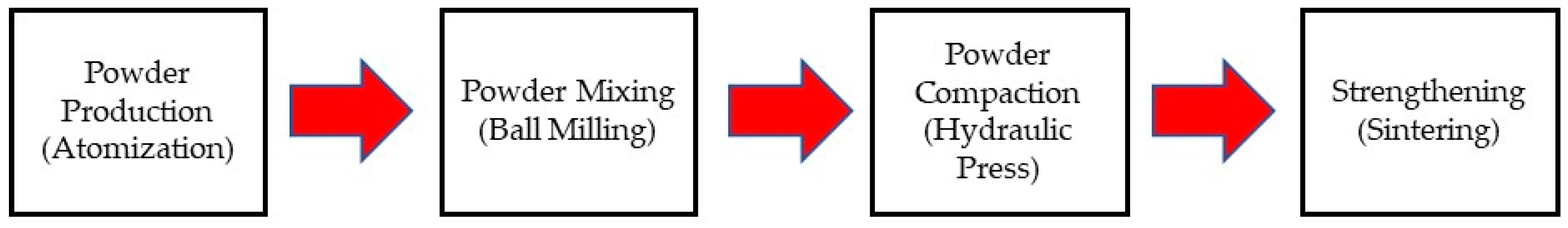

2.1.2. Powder Metallurgy

2.1.3. Diffusion Bonding Method

2.2. Liquid-State Processing

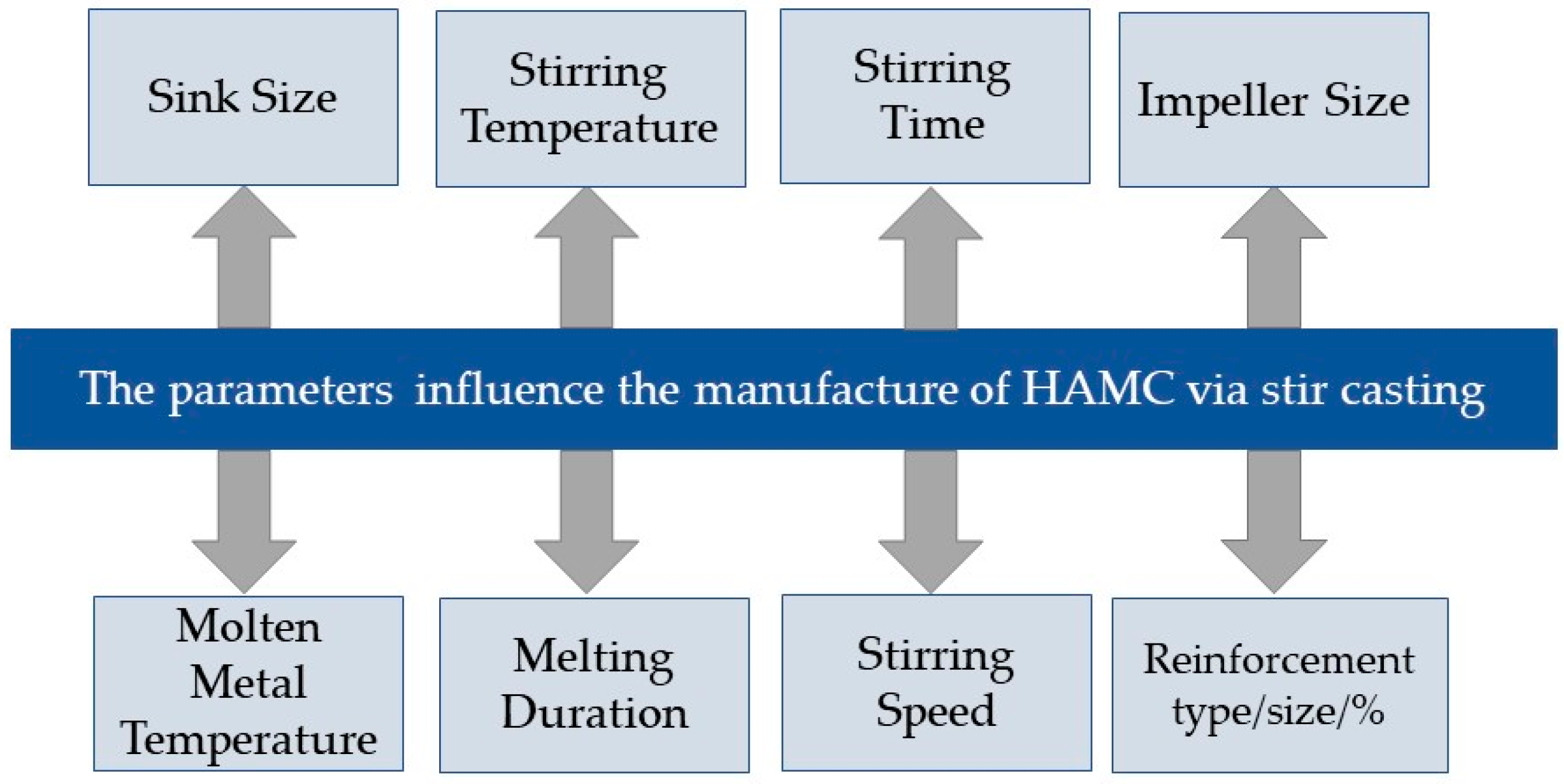

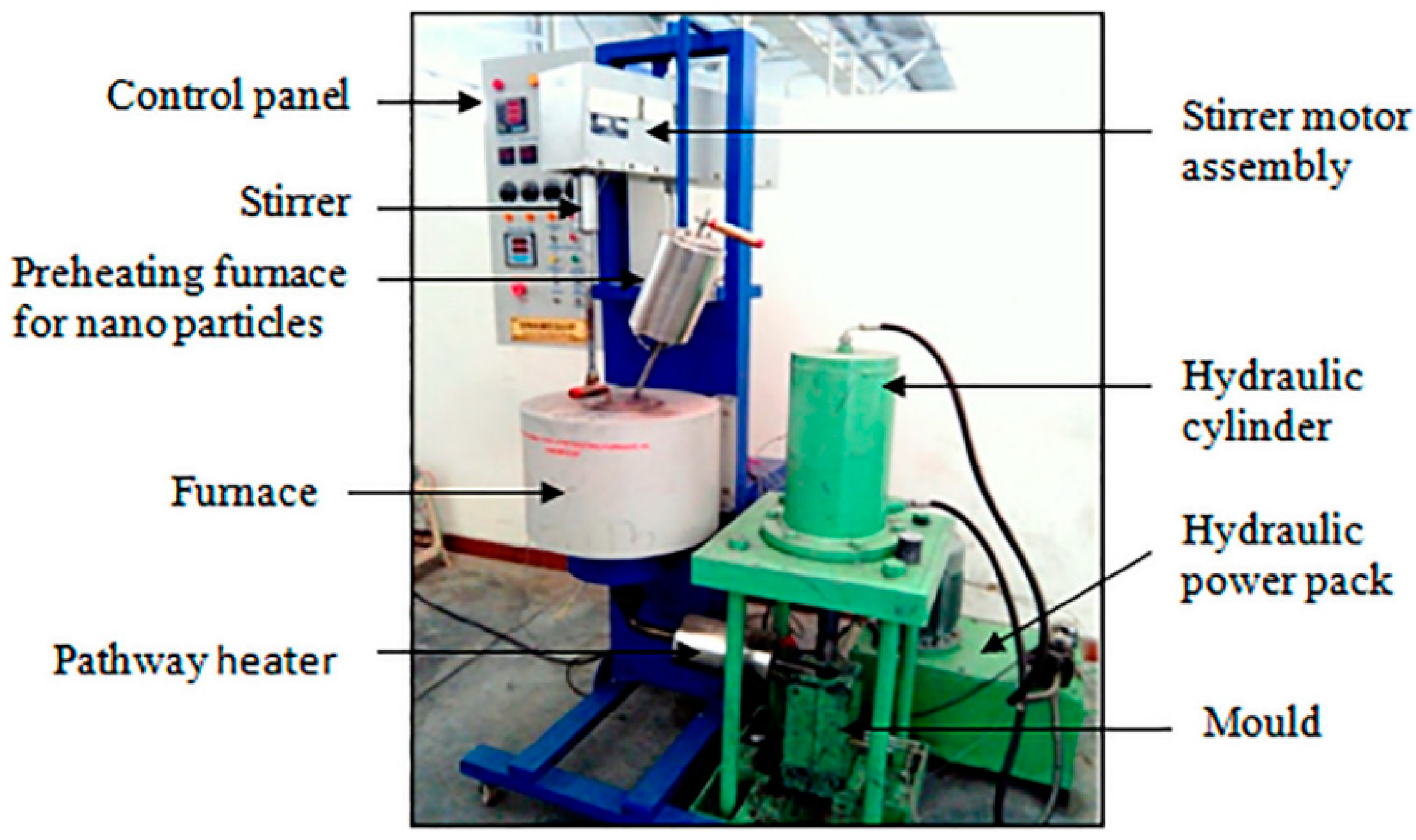

2.2.1. Stir Casting

2.2.2. Squeeze Casting

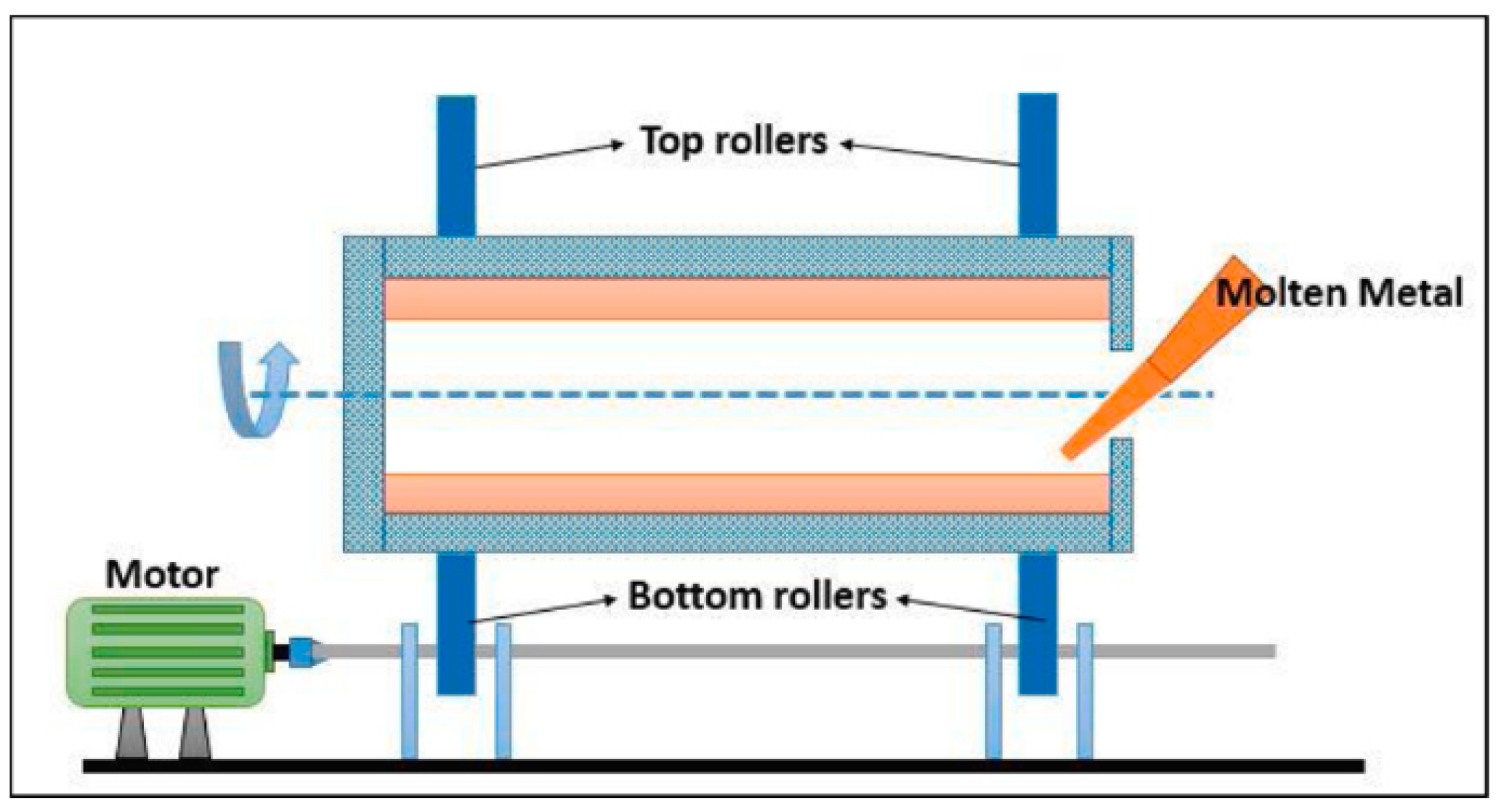

2.2.3. Centrifugal Casting

2.2.4. Spontaneous Infiltration

3. Properties of Hybrid Aluminum Composite

3.1. Physical Properties of HAMC

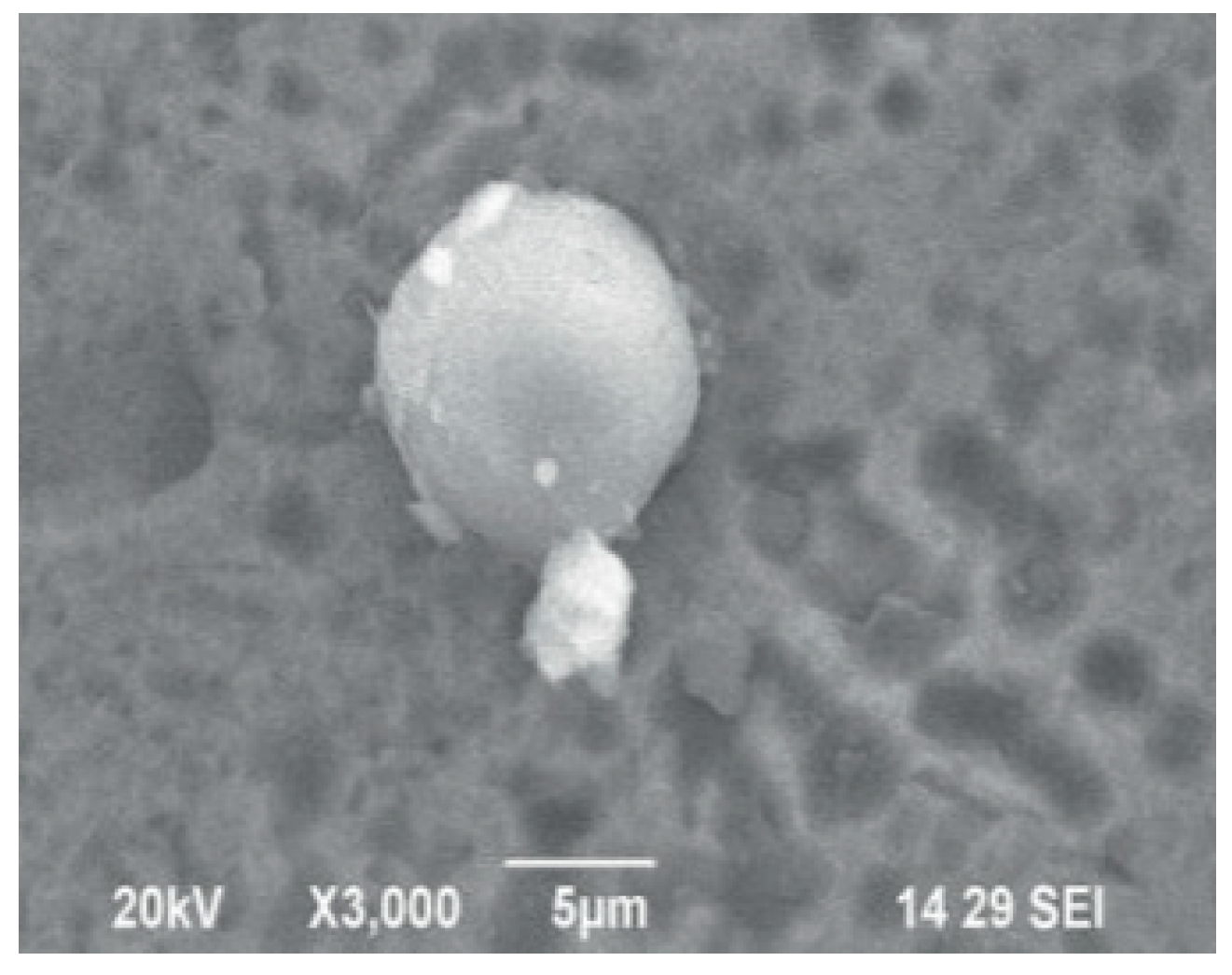

Density and Porosity

3.2. Mechanical Properties of HAMC

3.2.1. Yield Strength of HAMC

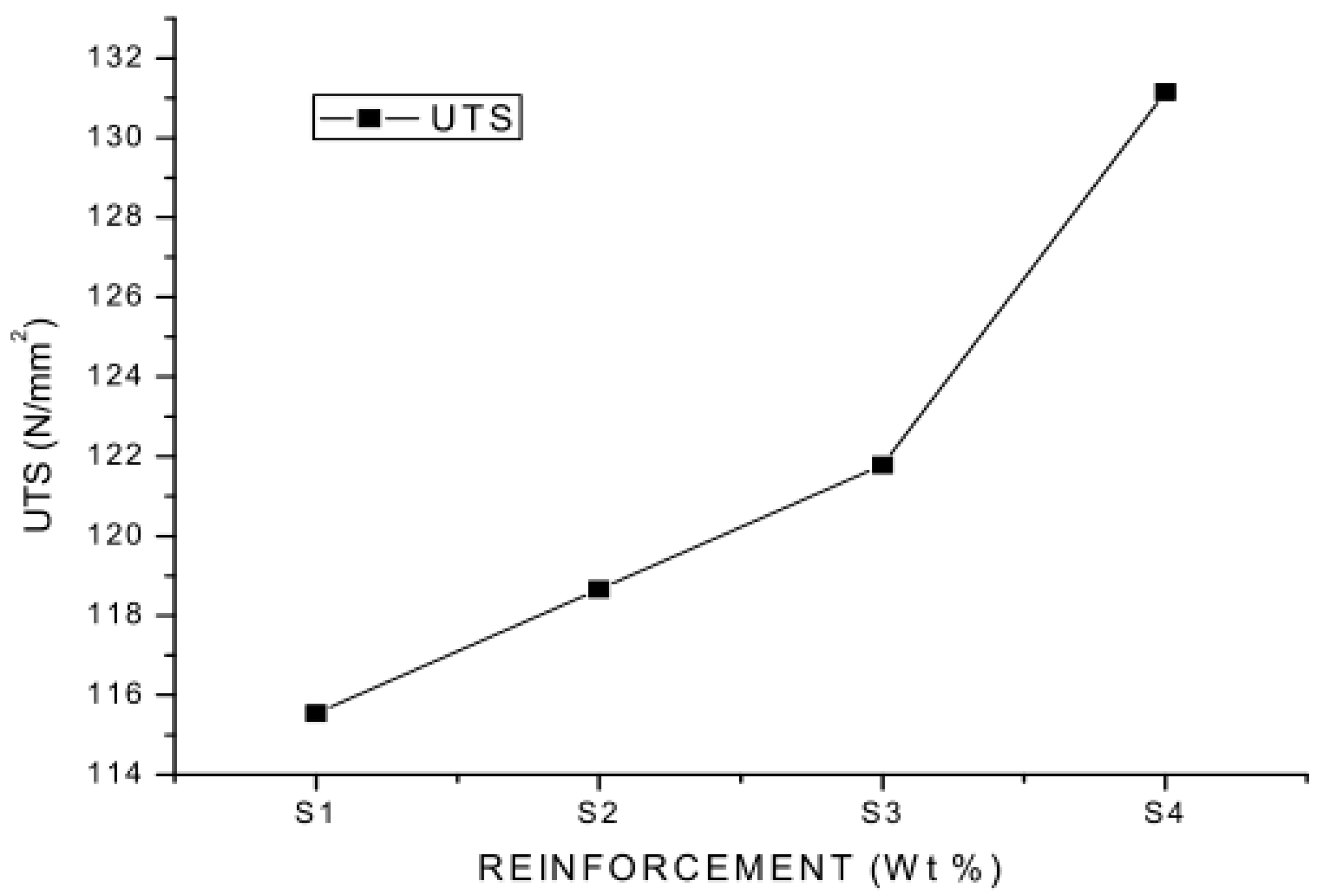

3.2.2. Tensile Strength of HAMC

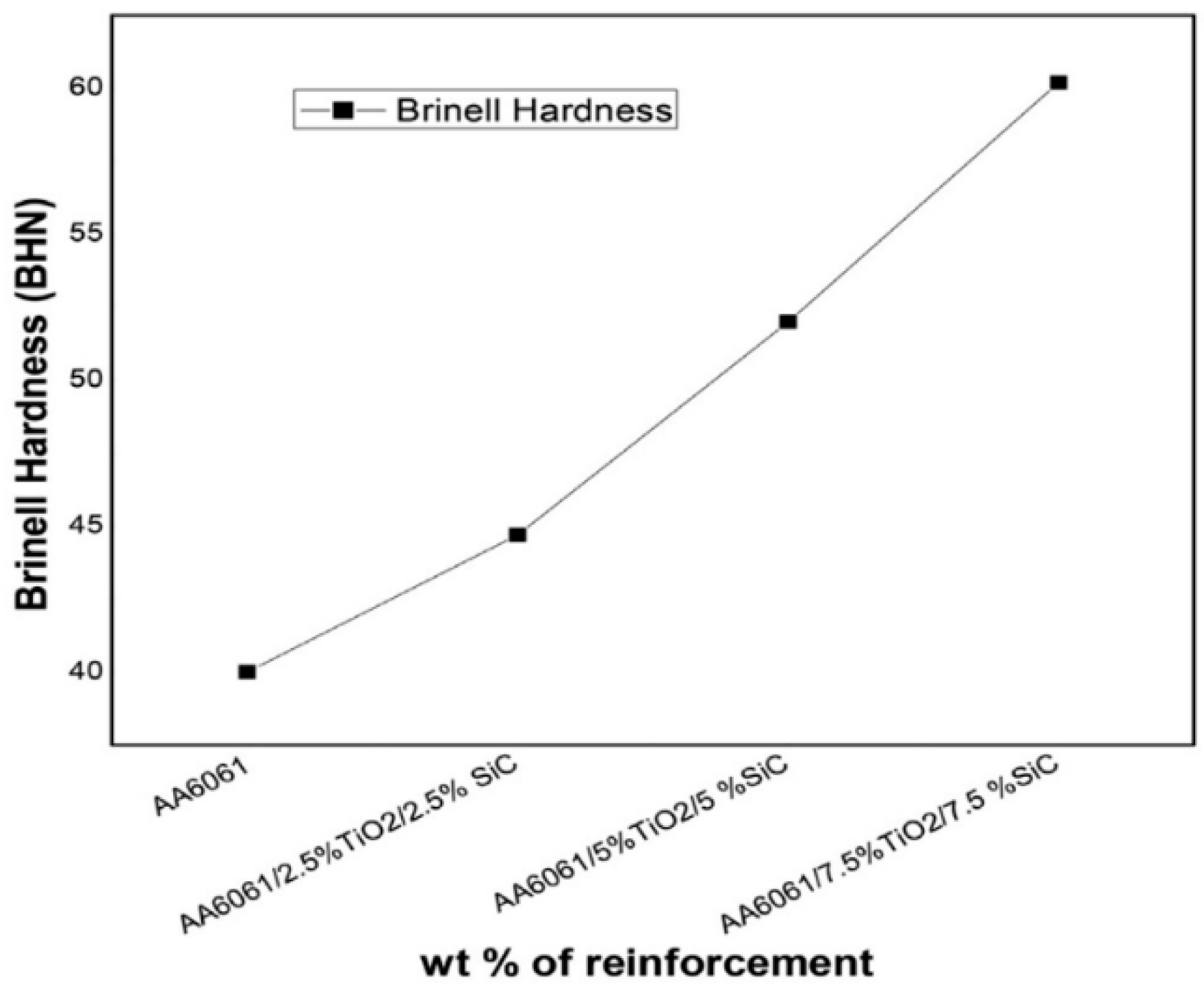

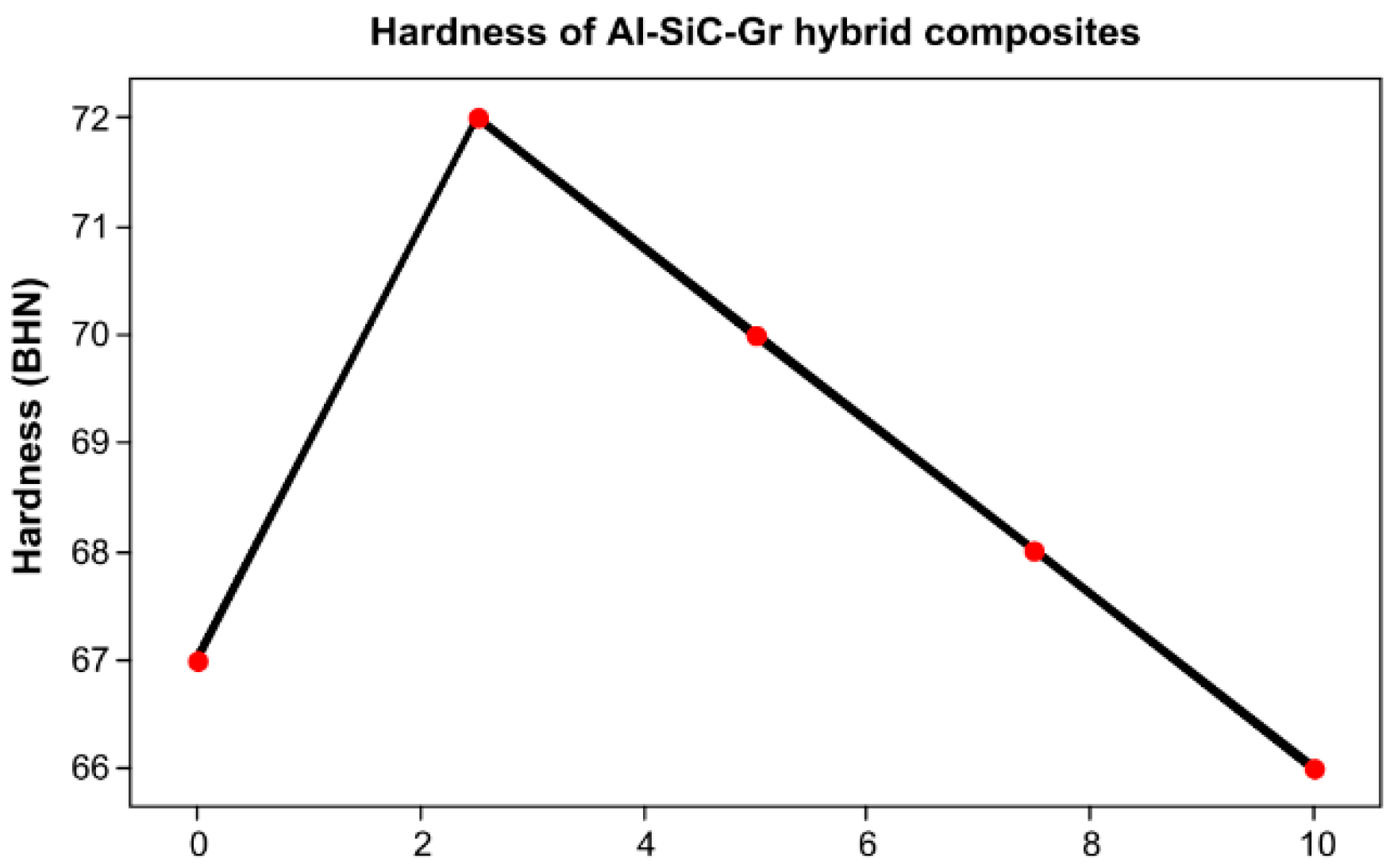

3.2.3. Hardness of HAMC

3.2.4. Ductility of HAMC

3.2.5. Toughness of HAMC

3.3. The Tribology Properties

4. Future Development and Application of Hybrid Aluminum Composite

4.1. Automotive

4.2. Aircraft

4.3. Rail Transport

4.4. Biomedical

4.5. Building and Construction

4.6. Sport and Recreations

4.7. Electrical Transmission

4.8. Packaging and Containerization

4.9. Marine

4.10. Defense

5. The Challenges of HAMC Development

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Padmanabham, K.C.A.; Mruthunjaya, M.; Shivakumar, B.P.; Yogesha, K.B.; Siddappa, P.N. Microstructure studies and mechanical characterisation of T6 heat treated aluminium and copper based alloy reinforced with zircon and graphite composite. J. Eng. Sci. Technol. 2019, 14, 2063–2073. [Google Scholar]

- Joseph, O.O.; Babaremu, K. Agricultural Waste as a Reinforcement Particulate for Aluminum Metal Matrix Composite (AMMCs): A Review. Fibers 2019, 7, 33. [Google Scholar] [CrossRef] [Green Version]

- Gurusamy, P.; Prabu, S.B.; Paskaramoorthy, R. Influence of Processing Temperatures on Mechanical Properties and Microstructure of Squeeze Cast Aluminum Alloy Composites. Mater. Manuf. Process. 2014, 30, 367–373. [Google Scholar] [CrossRef]

- Idusuyi, N.; Olayinka, J.I. Dry sliding wear characteristics of aluminium metal matrix composites: A brief overview. J. Mater. Res. Technol. 2019, 8, 3338–3346. [Google Scholar] [CrossRef]

- Akbar, H.I.; Surojo, E.; Ariawan, D.; Putra, G.A.; Wibowo, R.T. Effect of Reinforcement Material on Properties of Manufactured Aluminum Matrix Composite Using Stir Casting Route. Procedia Struct. Integr. 2020, 27, 62–68. [Google Scholar] [CrossRef]

- Christy, T.; Murugan, N.; Kumar, S. A Comparative Study on the Microstructures and Mechanical Properties of Al 6061 Alloy and the MMC Al 6061/TiB2/12p. J. Miner. Mater. Charact. Eng. 2010, 9, 57–65. [Google Scholar] [CrossRef]

- Mavhungu, S.; Akinlabi, E.; Onitiri, M.; Varachia, F. Aluminum Matrix Composites for Industrial Use: Advances and Trends. Procedia Manuf. 2017, 7, 178–182. [Google Scholar] [CrossRef]

- Abúndez, A.; Pereyra, I.; Campillo, B.; Serna, S.; Alcudia, E.; Molina, A.; Blanco, A.; Mayén, J. Improvement of ultimate tensile strength by artificial ageing and retrogression treatment of aluminium alloy 6061. Mater. Sci. Eng. A 2016, 668, 201–207. [Google Scholar] [CrossRef]

- Rohatgi, P.; Sobczak, J.; Asthana, R.; Kim, J. Inhomogeneities in silicon carbide distribution in stirred liquids—A water model study for synthesis of composites. Mater. Sci. Eng. A 1998, 252, 98–108. [Google Scholar] [CrossRef]

- Aigbodion, V.S. Bean pod ash nanoparticles a promising reinforcement for aluminium matrix biocomposites. J. Mater. Res. Technol. 2019, 8, 6011–6020. [Google Scholar] [CrossRef]

- Aybarc, U.; Dispinar, D.; Seydibeyoglu, M.O. Aluminum metal matrix composites with SiC, Al2O3 and grapheme—Review. Arch. Foundry Eng. 2018, 18, 5–10. [Google Scholar] [CrossRef]

- Purohit, R.; Qureshi, M.; Rana, R. The Effect of Hot Forging and Heat Treatment on Wear Properties of Al6061-Al2O3 Nano Composites. Mater. Today Proc. 2017, 4, 4042–4048. [Google Scholar] [CrossRef]

- Ramkumar, K.; Natarajan, S. Effects of TiO2 nanoparticles on the microstructural evolution and mechanical properties on accumulative roll bonded Al nanocomposites. J. Alloy. Compd. 2019, 793, 526–532. [Google Scholar] [CrossRef]

- Gowrishankar, T.P.; Manjunatha, L.H.; Sangmesh, B. Mechanical and Wear behaviour of Al6061 reinforced with Graphite and TiC Hybrid MMC’s. Mater. Res. Innov. 2019, 24, 179–185. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef] [Green Version]

- Seputro, H.; Ismail; Chang, S.H. Superplasticity of bottom ash reinforced aluminum metal matrix composite. Mater. Phys. Mech. 2018, 37, 205–211. [Google Scholar] [CrossRef]

- Verma, N.; Vettivel, S. Characterization and experimental analysis of boron carbide and rice husk ash reinforced AA7075 aluminium alloy hybrid composite. J. Alloy. Compd. 2018, 741, 981–998. [Google Scholar] [CrossRef]

- Kumar, B.P.; Birru, A.K. Microstructure and mechanical properties of aluminium metal matrix composites with addition of bamboo leaf ash by stir casting method. Trans. Nonferrous Met. Soc. China 2017, 27, 2555–2572. [Google Scholar] [CrossRef]

- Akbar, H.I.; Surojo, E.; Ariawan, D.; Prabowo, A.R. Technical investigation of sea sand reinforcement for novel al6061- sea sand composites: Identification of performance and mechanical properties. Periódico Tchê Química 2020, 17, 47–57. [Google Scholar] [CrossRef]

- Xue, S.; Feng, Z.; Kong, X.; Wu, C.; Huang, L.; Huang, N.; Hartley, W. A review of the characterization and revegetation of bauxite residues (Red mud). Environ. Sci. Pollut. Res. 2016, 23, 1120–1132. [Google Scholar] [CrossRef]

- Gireesh, C.H.; Prasad, K.D.; Ramji, K.; Vinay, P. Mechanical Characterization of Aluminium Metal Matrix Composite Reinforced with Aloe vera powder. Mater. Today Proc. 2018, 5, 3289–3297. [Google Scholar] [CrossRef]

- Ashrafi, N.; Ariff, A.H.M.; Sarraf, M.; Sulaiman, S.; Hong, T.S. Microstructural, thermal, electrical, and magnetic properties of optimized Fe3O4–SiC hybrid nano filler reinforced aluminium matrix composite. Mater. Chem. Phys. 2021, 258, 123895. [Google Scholar] [CrossRef]

- Sempros, G.; Kanari, K.; Gjoka, M.; Kalogirou, O.; Sarafidis, C. Synthesis, processing and characterization of Mn-based nanoparticles for permanent magnet applications. Mater. Today Proc. 2019, 19, 126–132. [Google Scholar] [CrossRef]

- Babu, K.A.; Venkataramaiah, P.; Reddy, K.D. Mechanical characterization of aluminium hybrid metal matrix composites synthesized by using stir casting process. Mater. Today Proc. 2018, 5, 28155–28163. [Google Scholar] [CrossRef]

- Awasthi, A.; Panwar, N.; Wadhwa, A.S.; Chauhan, A. Mechanical Characterization of hybrid aluminium composite-a review. Mater. Today Proc. 2018, 5, 27840–27844. [Google Scholar] [CrossRef]

- Singh, J.; Chauhan, A. Characterization of hybrid aluminum matrix composites for advanced applications—A review. J. Mater. Res. Technol. 2016, 5, 159–169. [Google Scholar] [CrossRef] [Green Version]

- Panwar, N.; Chauhan, A. Fabrication methods of particulate reinforced Aluminium metal matrix composite—A review. Mater. Today Proc. 2018, 5, 5933–5939. [Google Scholar] [CrossRef]

- Sharma, D.K.; Mahant, D.; Upadhyay, G. Manufacturing of metal matrix composites: A state of review. Mater. Today Proc. 2020, 26, 506–519. [Google Scholar] [CrossRef]

- Kumar, H.; Prasad, R.; Kumar, P.; Tewari, S.; Singh, J. Mechanical and tribological characterization of industrial wastes reinforced aluminum alloy composites fabricated via friction stir processing. J. Alloy. Compd. 2020, 831, 154832. [Google Scholar] [CrossRef]

- Arora, H.S.; Singh, H.; Dhindaw, B.K. Composite fabrication using friction stir processing—A review. Int. J. Adv. Manuf. Technol. 2012, 61, 1043–1055. [Google Scholar] [CrossRef]

- Dinaharan, I.; Nelson, R.; Vijay, S.; Akinlabi, E.T. Microstructure and wear characterization of aluminum matrix composites reinforced with industrial waste fly ash particulates synthesized by friction stir processing. Mater. Charact. 2016, 118, 149–158. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Patel, V.V.; Badheka, V.J.; Patel, U.; Patel, S.; Patel, S.; Zala, S.; Badheka, K. Experimental Investigation on Hybrid Friction Stir Processing using compressed air in Aluminum 7075 alloy. Mater. Today Proc. 2017, 4, 10025–10029. [Google Scholar] [CrossRef]

- Komarasamy, M.; Mishra, R.S.; Baumann, J.A.; Grant, G.; Hovanski, Y. Processing, Microstructure and Mechanical Property Correlation in Al-B4C Surface Composite Produced via Friction Stir Processing Welding. Frict. Stir Weld. Process. 2001, 7, 39–46. [Google Scholar] [CrossRef]

- Subramani, N.; Haridass, R.; Krishnan, R.; Manikandan, N.; Baskaran, A. Fabrication of hybrid (AA6061/SiCp/B4C) composites using FSP method and analysing the thermal behaviour in the weld region. Mater. Today Proc. 2021, 47, 4306–4311. [Google Scholar] [CrossRef]

- Harish, T.M.; Mathai, S.; Danty, G.; Govind, K.; Ben, A.; Paul, E. Development of Al5056/bagasse ash/SiC hybrid surface composite through friction stir processing. Mater. Today Proc. 2021, 47, 5121–5124. [Google Scholar] [CrossRef]

- Soleymani, S.; Abdollah-Zadeh, A.; Alidokht, S. Microstructural and tribological properties of Al5083 based surface hybrid composite produced by friction stir processing. Wear 2012, 278–279, 41–47. [Google Scholar] [CrossRef]

- Kumar, K.N.; Aravindkumar, N.; Eswaramoorthi, K. Fabrication of AA6016/(Al2O3 + AlN) hybrid surface composite using friction stir processing. Mater. Today Proc. 2020, 33, 315–319. [Google Scholar] [CrossRef]

- Devaraju, A.; Kumar, A.; Kotiveerachari, B. Influence of addition of Grp/Al2O3p with SiCp on wear properties of aluminum alloy 6061-T6 hybrid composites via friction stir processing. Trans. Nonferrous Met. Soc. China 2013, 23, 1275–1280. [Google Scholar] [CrossRef]

- Garg, P.; Jamwal, A.; Kumar, D.; Sadasivuni, K.K.; Hussain, C.M.; Gupta, P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. J. Mater. Res. Technol. 2019, 8, 4924–4939. [Google Scholar] [CrossRef]

- Mahmoud, E.R.I.; Tash, M.M. Characterization of Aluminum-Based-Surface Matrix Composites with Iron and Iron Oxide Fabricated by Friction Stir Processing. Materials 2016, 9, 505. [Google Scholar] [CrossRef] [Green Version]

- Bodukuri, A.K.; Eswaraiah, K.; Rajendar, K.; Sampath, V. Fabrication of Al–SiC–B4C metal matrix composite by powder metallurgy technique and evaluating mechanical properties. Perspect. Sci. 2016, 8, 428–431. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, Q.; Yang, S.; Chen, Z.; Jiang, Z. Microstructural evolution of hybrid aluminum matrix composites reinforced with SiC nanoparticles and graphene/graphite prepared by powder metallurgy. Prog. Nat. Sci. 2020, 30, 192–199. [Google Scholar] [CrossRef]

- Tang, S.; Shao, S.; Liu, H.; Jiang, F.; Fu, D.; Zhang, H.; Teng, J. Microstructure and mechanical behaviors of 6061 Al matrix hybrid composites reinforced with SiC and stainless steel particles. Mater. Sci. Eng. A 2021, 804, 140732. [Google Scholar] [CrossRef]

- Muratoğlu, M.; Yilmaz, O.; Aksoy, M. Investigation on diffusion bonding characteristics of aluminum metal matrix composites (Al/SiCp) with pure aluminum for different heat treatments. J. Mater. Process. Technol. 2006, 178, 211–217. [Google Scholar] [CrossRef]

- Baker, T.S.; Partridge, P.G. Diffusion Bonding; Pearce, R., Ed.; SIS: Cranfield, UK, 1987; pp. 73–90. [Google Scholar]

- Liu, W.S.; Long, L.P.; Ma, Y.Z.; Wu, L. Microstructure evolution and mechanical properties of Mg/Al diffusion bonded joints. J. Alloy. Compd. 2015, 643, 34–39. [Google Scholar] [CrossRef]

- Zan, Y.; Zhang, Q.; Zhou, Y.; Wang, Q.; Xiao, B.; Ma, Z. Enhancing high-temperature strength of B4C–6061Al neutron absorber material by in-situ Mg(Al)B2. J. Nucl. Mater. 2019, 526, 151788. [Google Scholar] [CrossRef]

- Senthil, S.; Raguraman, M.; Thamarai Manalan, D. Manufacturing processes & recent applications of aluminium metal matrix composite materials: A review. Mater. Today Proc. 2020, 45, 5934–5938. [Google Scholar] [CrossRef]

- Su, H.; Gao, W.; Feng, Z.; Lu, Z. Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites. Mater. Des. 2012, 36, 590–596. [Google Scholar] [CrossRef]

- Michaud, V.J. Chapter 1—Liquid-State Processing. In Fundamentals of Metal Matrix Composites; Butterworth-Heinemann: Boston, MA, USA, 1993; pp. 3–22. [Google Scholar]

- Naher, S.; Brabazon, D.; Looney, L. Simulation of the stir casting process. J. Mater. Process. Technol. 2003, 143–144, 567–571. [Google Scholar] [CrossRef] [Green Version]

- Ünlü, B.S. Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater. Des. 2008, 29, 2002–2008. [Google Scholar] [CrossRef]

- Shi, W.; Yuan, L.; Zheng, Z.; Shan, D. Effect of forging on the microstructure and tensile properties of 2024Al/Al18B4O33 w composite. Mater. Sci. Eng. A 2014, 615, 313–319. [Google Scholar] [CrossRef]

- Kandpal, B.C.; Kumar, J.; Singh, H. Manufacturing and technological challenges in Stir casting of metal matrix composites– A Review. Mater. Today Proc. 2018, 5, 5–10. [Google Scholar] [CrossRef]

- Ravindran, S.; Mani, N.; Balaji, S.; Abhijith, M.; Surendaran, K. Mechanical Behaviour of Aluminium Hybrid Metal Matrix Composites—A Review. Mater. Today Proc. 2019, 16, 1020–1033. [Google Scholar] [CrossRef]

- Arora, R.; Kumar, S.; Singh, G.; Pandey, O.P. Influence of particle size and temperature on the wear properties of rutile-reinforced aluminium metal matrix composite. J. Compos. Mater. 2015, 49, 843–852. [Google Scholar] [CrossRef]

- Jia, S.; Zhang, D.; Xuan, Y.; Nastac, L. An experimental and modeling investigation of aluminum-based alloys and nanocomposites processed by ultrasonic cavitation processing. Appl. Acoust. 2015, 103, 226–231. [Google Scholar] [CrossRef]

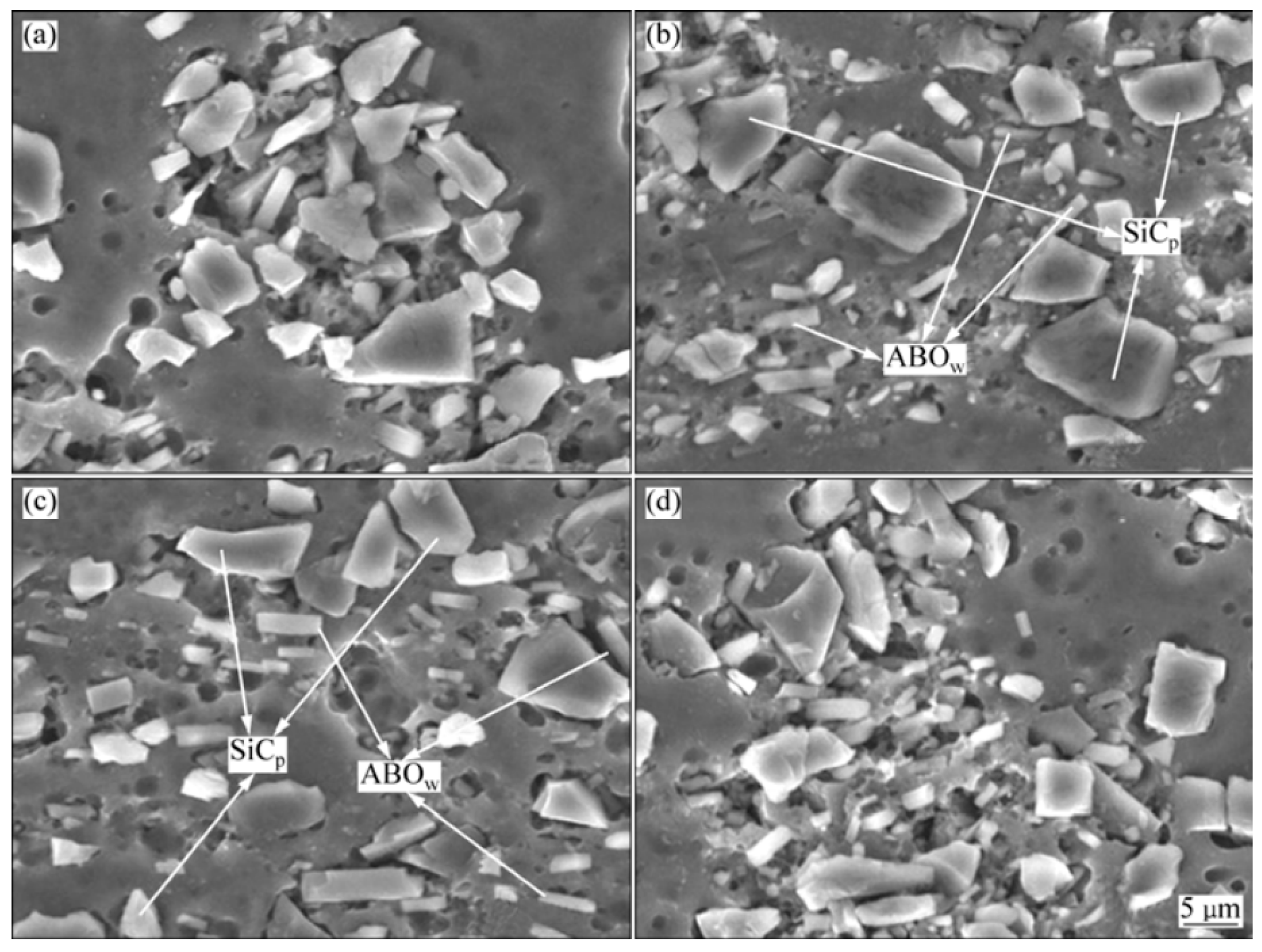

- Guan, L.-N.; Geng, L.; Zhang, H.-W.; Huang, L.-J. Effects of stirring parameters on microstructure and tensile properties of (ABOw+SiCp)/6061Al composites fabricated by semi-solid stirring technique. Trans. Nonferrous Met. Soc. China 2011, 21, s274–s279. [Google Scholar] [CrossRef]

- Kumar, R.A.; Devaraju, A.; Arunkumar, S. Experimental Investigation on Mechanical Behaviour and Wear Parameters of TiC and Graphite Reinforced Aluminium Hybrid Composites. Mater. Today Proc. 2018, 5, 14244–14251. [Google Scholar] [CrossRef]

- Yashpal; Jawalkar, C.; Kant, S.; Panwar, N.; Sharma, M.D.; Pali, H.S. Effect of Particle Size Variation of Bagasse Ash on Mechanical Properties of Aluminium Hybrid Metal Matrix Composites. Mater. Today Proc. 2020, 21, 2024–2029. [Google Scholar] [CrossRef]

- Mathur, S.; Barnawal, A. Effect of process parameter of stir casting on metal matrix composites. Int. J. Sci. Res. 2013, 2, 395–398. [Google Scholar]

- Vijaybabu, G.; Prasadraju, K.; Raju, V.; Sunilkumar, K. Studies on effect of ash in aluminium hybrid metal matrix composites. Mater. Today Proc. 2019, 18, 2132–2136. [Google Scholar] [CrossRef]

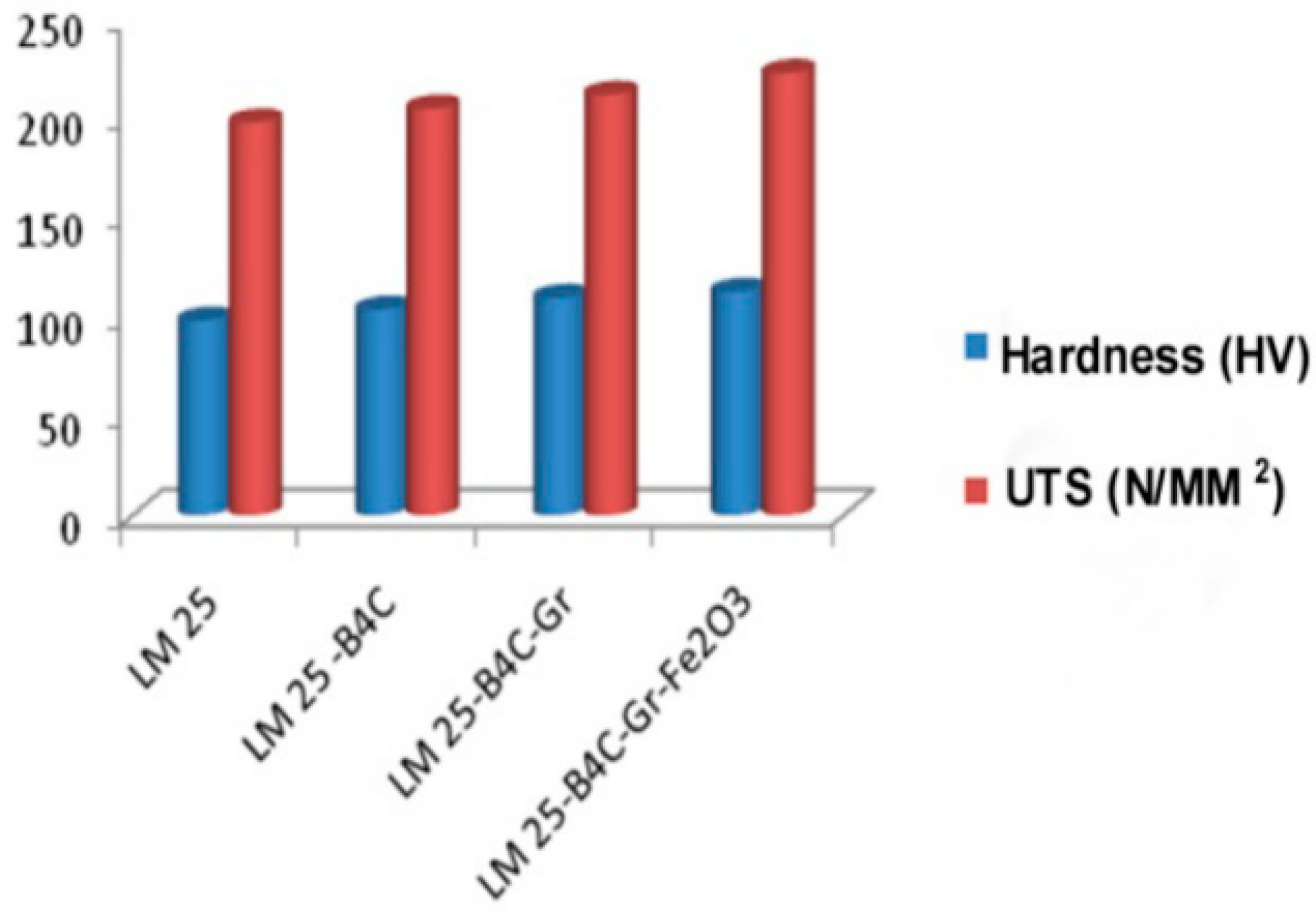

- Suresh, V.; Vikram, P.; Palanivel, R.; Laubscher, R. Mechanical and wear behavior of LM25 Aluminium matrix hybrid composite reinforced with Boron carbide, Graphite and Iron oxide. Mater. Today Proc. 2018, 5, 27852–27860. [Google Scholar] [CrossRef]

- Srinivasan, R.; Vignesh, S.; Veeramanipandi, P.; Sabarish, M.; Yuvaraj, C. Experimental investigation on aluminium hybrid metal matrix composites fabricated through stir casting technique. Mater. Today Proc. 2020, 27, 1884–1888. [Google Scholar] [CrossRef]

- Reddy, P.V.; Prasad, P.R.; Krishnudu, D.M.; Goud, E.V. An Investigation on Mechanical and Wear Characteristics of Al 6063/TiC Metal Matrix Composites Using RSM. J. Bio- Tribo-Corros. 2019, 5, 90. [Google Scholar] [CrossRef]

- Imran, M.; Khan, A.A. Characterization of Al-7075 metal matrix composites: A review. J. Mater. Res. Technol. 2019, 8, 3347–3356. [Google Scholar] [CrossRef]

- Ramanathan, A.; Krishnan, P.K.; Muraliraja, R. A review on the production of metal matrix composites through stir casting—Furnace design, properties, challenges, and research opportunities. J. Manuf. Process. 2019, 42, 213–245. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ramesh, A.; Athithanambi, A. Effect of Axial Force on Microstructure and Mechanical Properties of Friction Stir Welded Squeeze Cast A413 Aluminium Alloy. Mater. Today Proc. 2018, 5, 13486–13494. [Google Scholar] [CrossRef]

- Senthil, P.; Amirthagadeswaran, K.S. Optimization of squeeze casting parameters for non symmetrical AC2A aluminium alloy castings through Taguchi method. J. Mech. Sci. Technol. 2012, 26, 1141–1147. [Google Scholar] [CrossRef]

- Azhagan, M.T.; Mohan, B.; Rajadurai, A.; Maharajan, S. Influence of Squeeze Pressure on the Mechanical Properties of Squeeze Cast Aluminium Alloy AA6061. Adv. Mater. Res. 2014, 984–985, 350–354. [Google Scholar] [CrossRef]

- Sahin, I.; Eker, A.A. Analysis of Microstructures and Mechanical Properties of Particle Reinforced AlSi7Mg2 Matrix Composite Materials. J. Mater. Eng. Perform. 2011, 20, 1090–1096. [Google Scholar] [CrossRef]

- Vijayaram, T.; Sulaiman, S.; Hamouda, A.; Ahmad, M. Fabrication of fiber reinforced metal matrix composites by squeeze casting technology. J. Mater. Process. Technol. 2006, 178, 34–38. [Google Scholar] [CrossRef]

- Leng, J.; Wu, G.; Zhou, Q.; Dou, Z.; Huang, X. Mechanical properties of SiC/Gr/Al composites fabricated by squeeze casting technology. Scr. Mater. 2008, 59, 619–622. [Google Scholar] [CrossRef]

- Srinivasan, R.; Babu, B.S.; Shufiyan, M.M.; Thoufeeq, A.M.; Sanjay, S.M.; Varman, S.K. Experimental investigation on tribological behaviour of aluminium hybrid metal matrix composites processed through stir cum squeeze casting technique. Mater. Today Proc. 2020, 27, 1756–1760. [Google Scholar] [CrossRef]

- Jayakumar, E.; Rajan, T.P.D.; Pai, B.C. Effect of Mg on Solidification Microstructures of Homogenous and Functionally Graded A390 Aluminum Alloys. Trans. Indian Inst. Met. 2012, 65, 677–681. [Google Scholar] [CrossRef]

- Srinivasan, R.; Shrinivasan, B.H.; Prasath, K.J.; Saleth, R.J.; Anandhan, R. Experimental investigation of aluminium hybrid metal matrix composites processed through squeeze casting process. Mater. Today Proc. 2020, 27, 1821–1826. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Ademilua, B.O.; Bodunrin, M.O. Mechanical properties and corrosion behaviour of aluminium hybrid composites reinforced with silicon carbide and bamboo leaf ash. Tribol. Ind. 2013, 35, 25. [Google Scholar]

- Venugopal, S.; Karikalan, L. Microstructure and physical properties of hybrid metal matrix composites AA6061-TiO2-SiC via stir casting techniques. Mater. Today Proc. 2020, 37, 1289–1294. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Akintunde, I.B.; Olubambi, P.A.; Adewale, T.M. Fabrication characteristics and mechanical behaviour of rice husk ash—Alumina reinforced Al-Mg-Si alloy matrix hybrid composites. J. Mater. Res. Technol. 2013, 2, 60–67. [Google Scholar] [CrossRef] [Green Version]

- Boopathi, M.M.; Arulshri, K.P.; Iyandurai, N. Evaluation of mechanical properties of aluminium alloy 2024 reinforced with silicon carbide and fly ash hybrid metal matrix composites. Am. J. Appl. Sci. 2013, 10, 219–229. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K.; Ranganathan, S. Evaluation of mechanical and wear properties of hybrid aluminium matrix composites. Trans. Nonferrous Met. Soc. China 2013, 23, 2509–2517. [Google Scholar] [CrossRef]

- Aqida, S.N.; Ghazali, M.I.; Hashim, J. Effect of Porosity on Mechanical Properties of Metal Matrix Composite: An Overview. J. Teknol. 2012, 40, 17–32. [Google Scholar] [CrossRef] [Green Version]

- Askeland, D.R. The Science and Engineering of Materials; PWS Publishing Company: Boston, MA, USA, 1994. [Google Scholar]

- Prasad, D.S.; Shoba, C.; Ramanaiah, N. Investigations on mechanical properties of aluminum hybrid composites. J. Mater. Res. Technol. 2014, 3, 79–85. [Google Scholar] [CrossRef] [Green Version]

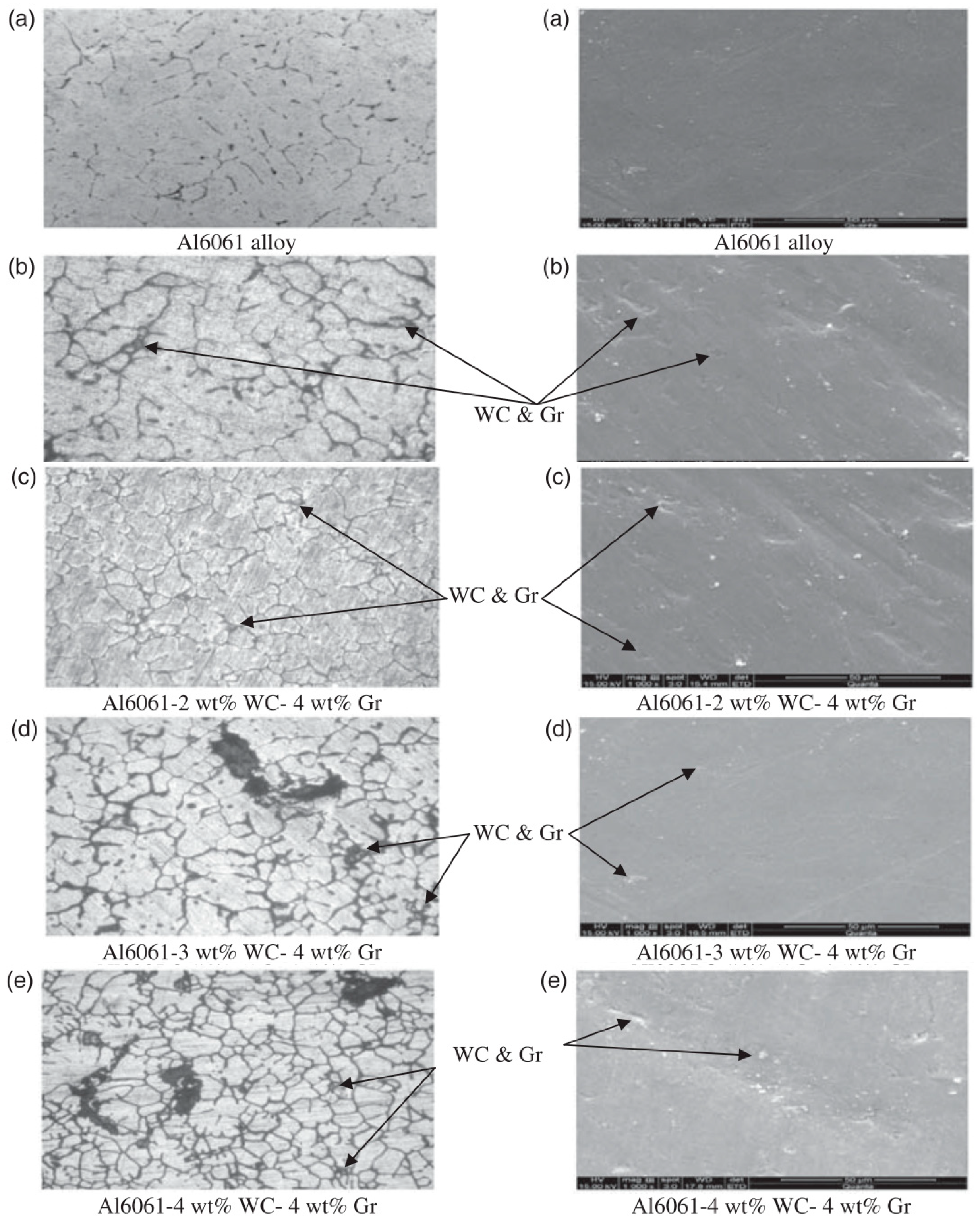

- Kumar, G.V.; Swamy, A.; Ramesha, A. Studies on properties of as-cast Al6061-WC-Gr hybrid MMCs. J. Compos. Mater. 2011, 46, 2111–2122. [Google Scholar] [CrossRef]

- Sarraf, M.; Razak, A.B.; Crum, R.; Gámez, C.; Ramirez, B.; Abu Kasim, N.H.B.; Nasiri-Tabrizi, B.; Gupta, V.; Sukiman, N.L.; Basirun, W.J. Adhesion measurement of highly-ordered TiO2 nanotubes on Ti-6Al-4V alloy. Process. Appl. Ceram. 2017, 11, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Eftekharinia, H.; Amadeh, A.A.; Khodabandeh, A.; Paidar, M. Microstructure and wear behavior of AA6061/SiC surface composite fabricated via friction stir processing with different pins and passes. Rare Met. 2020, 39, 429–435. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Perumal, A.E. Study on mechanical and wear properties of Al 7075/Al2O3/graphite hybrid composites. Compos. Part B Eng. 2014, 56, 464–471. [Google Scholar] [CrossRef]

- Narasaraju, G.; Raju, D.L. Characterization of Hybrid Rice Husk and Fly ash-Reinforced Aluminium alloy (AlSi10Mg) Composites. Mater. Today Proc. 2015, 2, 3056–3064. [Google Scholar] [CrossRef]

- Nathan, V.; Soundararajan, R.; Abraham, C.; Rahman, A.F. Evaluation of Mechanical and Metallurgical Properties on Aluminium Hybrid Metal Matrix Composites. Mater. Today Proc. 2019, 18, 2520–2529. [Google Scholar] [CrossRef]

- Dhanalakshmi, S.; Mohanasundararaju, N.; Venkatakrishnan, P. Preparation and Mechanical Characterization of Stir Cast Hybrid Al7075-Al2O3-B4C Metal Matrix Composites. Appl. Mech. Mater. 2014, 592–594, 705–710. [Google Scholar] [CrossRef]

- Selvam, J.D.R.; Smart, D.R.; Dinaharan, I. Synthesis and Characterization of Al6061-Fly Ashp-SiCp Composites by Stir Casting and Compocasting Methods. Energy Procedia 2013, 34, 637–646. [Google Scholar] [CrossRef] [Green Version]

- Pawar, S.Y.; Kharde, Y.R. Tribological characterization of LM26/SiC/Ni.-Gr. Hybrid aluminium matrix composites (HAMCs) for high temperature applications. Mater. Today Proc. 2020, 37, 793–800. [Google Scholar] [CrossRef]

- Kumar, G.M. Characterization of Al-6063/TiB2/Gr hybrid composite fabricated by stir casting process. Met. Powder Rep. 2020. [Google Scholar] [CrossRef]

- Suresha, S.; Sridhara, B. Friction characteristics of aluminium silicon carbide graphite hybrid composites. Mater. Des. 2012, 34, 576–583. [Google Scholar] [CrossRef]

- Mohanavel, V.; Rajan, K.; Senthil, P.; Arul, S. Mechanical behaviour of hybrid composite (AA6351+Al2O3 +Gr) fabricated by stir casting method. Mater. Today Proc. 2017, 4, 3093–3101. [Google Scholar] [CrossRef]

- James, J.; Venkatesan, K.; Kuppan, P.; Ramanujam, R. Hybrid Aluminium Metal Matrix Composite Reinforced with SiC and TiB2. Procedia Eng. 2014, 97, 1018–1026. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Cui, Z.; Chen, Z.; Chen, D.; Wang, H. Investigation on the high-temperature ductility and fracture mechanisms of an in-situ particle reinforced Al matrix composite 7075Al/TiB2. Mater. Sci. Eng. A 2019, 764, 138263. [Google Scholar] [CrossRef]

- Ravesh, S.K.; Garg, T.K. Preparation & analysis for some mechanical property of aluminium based metal matrix composite reinforced with SiC & fly ash. Int. J. Eng. Res. Appl. 2012, 2, 727–731. [Google Scholar]

- Kumar, K.R.; Pridhar, T.; Balaji, V.S. Mechanical properties and characterization of zirconium oxide (ZrO2) and coconut shell ash(CSA) reinforced aluminium (Al 6082) matrix hybrid composite. J. Alloy. Compd. 2018, 765, 171–179. [Google Scholar] [CrossRef]

- Lia, F.; Zammit-Mangion, M.; Farrugia, C. A First Description of the Phenolic Profile of EVOOs from the Maltese Islands Using SPE and HPLC: Pedo-Climatic Conditions Modulate Genetic Factors. Agriculture 2019, 9, 107. [Google Scholar] [CrossRef] [Green Version]

- Fayomi, J.; Popoola, A.; Oladijo, O.; Popoola, O.; Fayomi, O. Experimental study of ZrB2-Si3N4 on the microstructure, mechanical and electrical properties of high grade AA8011 metal matrix composites. J. Alloy. Compd. 2019, 790, 610–615. [Google Scholar] [CrossRef]

- Kumar, N.; Irfan, G. Mechanical, microstructural properties and wear characteristics of hybrid aluminium matrix nano composites (HAMNCs)—Review. Mater. Today Proc. 2020, 45, 619–625. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Mahadevan, A.; Thangavelu, M.; Subramanian, R.; Gopalakrishnan, P. Influence of sliding speed on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite. Wear 2007, 262, 1007–1012. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Vettivel, S.; Perumal, A.E.; Selvakumar, N.; Issac, F. Experimental investigation on mechanical behaviour, modelling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater. Des. 2014, 63, 620–632. [Google Scholar] [CrossRef]

- Mahdavi, S.; Akhlaghi, F. Effect of the Graphite Content on the Tribological Behavior of Al/Gr and Al/30SiC/Gr Composites Processed by In Situ Powder Metallurgy (IPM) Method. Tribol. Lett. 2011, 44, 1–12. [Google Scholar] [CrossRef]

- Umanath, K.; Palanikumar, K.; Selvamani, S. Analysis of dry sliding wear behaviour of Al6061/SiC/Al2O3 hybrid metal matrix composites. Compos. Part B Eng. 2013, 53, 159–168. [Google Scholar] [CrossRef]

- Sharifi, E.M.; Karimzadeh, F. Wear behavior of aluminum matrix hybrid nanocomposites fabricated by powder metallurgy. Wear 2011, 271, 1072–1079. [Google Scholar] [CrossRef]

- Ravindran, P.; Manisekar, K.; Narayanasamy, P.; Selvakumar, N. Application of factorial techniques to study the wear of Al hybrid composites with graphite addition. Mater. Des. 2012, 39, 42–54. [Google Scholar] [CrossRef]

- Suresha, S.; Sridhara, B. Wear characteristics of hybrid aluminium matrix composites reinforced with graphite and silicon carbide particulates. Compos. Sci. Technol. 2010, 70, 1652–1659. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Rambabu, P.; Prasad, N.E.; Kutumbarao, V.V.; Wanhill, R.J. Aluminium Alloys for Aerospace Applications. Aerospace Mater. Mater. Technol. 2017, 1, 29–52. [Google Scholar] [CrossRef]

- Zhu, J.; Jiang, W.; Li, G.; Guan, F.; Yu, Y.; Fan, Z. Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J. Mater. Process. Technol. 2020, 283, 116699. [Google Scholar] [CrossRef]

- Kainer, K.U. Basics of Metal Matrix Composites in Metal Matrix Composite: Custom-Made Materials for Automotive and Aerospace Engineering; Kainer, K.U., Ed.; Verlag GmbH & Co. KGaA: Weinheim, Germany, 2006; p. 2. [Google Scholar]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Sahoo, P.; Das, S.K. Tribology of electroless nickel coatings—A review. Mater. Des. 2010, 32, 1760–1775. [Google Scholar] [CrossRef]

- Gopalakrishnan, S.; Murugan, N. Production and wear characterisation of AA 6061 matrix titanium carbide particulate reinforced composite by enhanced stir casting method. Compos. Part B Eng. 2011, 43, 302–308. [Google Scholar] [CrossRef]

| Specimen | Microhardness (HRB) | |||

|---|---|---|---|---|

| Base Metal | Average | Stir Zone | Average | |

| 1. FSP of AA6061 | B-89 | B-87.33 | B-91 | B-89.33 |

| B-85 | B-88 | |||

| B-88 | B-89 | |||

| 2. 75% Al2O3 & 25% AlN | B-87 | B-87.66 | B-93 | B-91.33 |

| B-91 | B-87 | |||

| B-85 | B-94 | |||

| 3. 50% Al2O3 & 50% AlN | B-89 | B-87 | B-94 | B-93 |

| B-87 | B-92 | |||

| B-85 | B-93 | |||

| 4. 25% Al2O3 & 75% AlN | B-88 | B-88 | B-89 | B-88.66 |

| B-85 | B-87 | |||

| B-91 | B-91 | |||

| Year | Writers | Matrix | Reinforcement | Findings |

|---|---|---|---|---|

| 2021 [35] | Subramani et al. | Al6061 | B4C and SiCp | The uniform distribution of SiCp/B4C components in A6061 matrix achieved through the FSP method and heat treatment can improve mechanical properties. |

| 2021 [36] | Harish et al. | AL5056 | Bagasse ash (3, 4, 6, and 9 wt.%) and SiC (3 wt.%) | When the bagasse ash concentration was increased to 6%, the characteristics improved. |

| 2016 [33] | Patel et al. | Aluminum 7075 | - | The compressed-air cooling Hybrid FSP provided a perfectly matched granular microstructure within the SZ. |

| 2013 [39] | Devaraju et al. | 6061-T6 | (SiC+Gr) and (SiC+ Al2O3) particles of 20 μm | Microstructures and worn micrographs are connected to microhardness and wear characteristics. |

| 2012 [37] | Soleymani et al. | Al5083 | SiC and MoS2 | The hybrids were used concurrently with the light delamination and the light abrasion mechanisms. Wear mechanisms confirmed that hybrid composite production may reduce wear damage greatly at the surface and increase alloy wear resistance. |

| Year | Writers | Matrix | Reinforcement | Findings |

|---|---|---|---|---|

| 2021 [22] | Ashrafi et al. | Al | Fe3O4–SiC | Adding Fe3O4 nanoparticles and SiC hybrid reinforcements in the aluminum matrix improved the magnetic permeability; increasing the SiC improved the thermal conductivity of aluminum by 37%. |

| 2021 [44] | Tang et al. | 6061-Al | SiC and stainless-steel particles | The composite hybrid reinforced with SiC and stainless-steel particles could successfully increase ductility without sacrificing strength. |

| 2020 [43] | Zhang et al. | A355 | SiC–graphite and SiC–graphene nanosheets (GNSs) | The addition of SiC–GNSs particle intensifies the deformation of the aluminum particles compared with SiC–graphite. |

| 2016 [42] | Bodukuri et al. | Al | SiC–B4C | The hardness of composite increased significantly as the percentage of B4C increased. |

| Manufacturing Method | Method | Influential Variables | Advantages |

|---|---|---|---|

| FSP |

| Rotational speed, axial load, speed of power travel, hole pattern and geometry, and the number of FSP passes [34,38]. | High reproducibility, fast production time, low energy input, refined grain structure, the surface composite layer appears to be very well bonded to the aluminum alloy substrate, no defects are visible at the interface, eradication of porosity, fragmentation of a-Al dendrites, breakage and redistribution of Si particles [29,35,38]. |

| Powder Metallurgy | Fine powders are mixed and blended together in the powder metallurgy process, then degassed in a vacuum and compacted in the desired shape before sintering in a controlled atmosphere. Powder metallurgy is recommended for the manufacture of complex shaped precision components with superior mechanical and structural qualities and high homogeneity. | Volume fraction of reinforcements, green density, compact pressure, sintered density, hot pressing temperature [28,48]. | Economical process for complex part production with high strength, dimensional accuracy, minimum scrap loss, high homogeneity, better mechanical and structural properties, and less subsequent machining operations [28]. |

| Diffusion Bonding Method | The technique is used to apply the required pressure to combine comparable or different metal layers and fibers into sandwich metal. | Bonding temperature, pressure, holding duration and surface roughness, temperature, pressure, and the diffusion timing [49] | With various metal matrix composites, it is possible to regulate fiber orientation by varying the metal volume fraction. |

| Year | Writers | Matrix | Reinforcement | Findings |

|---|---|---|---|---|

| 2020 [61] | Yashpal et al. | Al6061 | Bagasse ash (37 µm, 53 µm and 75 µm) | As the particle size of bagasse ash rose, the tensile strength, hardness, and impact strength decreased. |

| 2019 [63] | Vijaybabu et al. | Al7075 | B4C constant (2%), and fly ash (2%, 4%, 6%) | The hardness, elongation, density, and tensile strength increased with the increase in fly ash content in the base alloy. |

| 2019 [65] | Srinivasan et al. | AA6063 | Graphite (3%wt), ZrO2 (2%, 4%, 6%) | Addition of reinforcement particles increases the mechanical properties such as hardness and tensile strength. |

| 2018 [64] | Suresh et al. | LM25 | Boron carbide (B4C), graphite (Gr) and iron oxide (Fe3O4) | Adding reinforcement improves the wear resistance and increases the hardness and UTS. |

| 2018 [60] | Kumar et al. | Al7075 | Graphite and varying TiC content (1–4 wt.%) | TiC and graphite-reinforced AHCs outperformed standard Al7075 in terms of hardness, tensile strength, and wear resistance. |

| Manufacturing Method | Method | Influential Variables | Advantages |

|---|---|---|---|

| Stir Casting | The suitable reinforcement is added in molten metal at the melting temperature. Then, with the help of external device, the stirring process is carried out to distribute the reinforcement thoroughly throughout the molten metal to avoid the heterogeneous distribution and to reduce the porosity. | Applied load, sliding time, sliding velocity, sink size, stirring time, impeller capacity and size, molten metal temperature, melting duration, stirring speed, reinforcement type/size/%, melting rate, mold temperature, and heat treatment [28,56]. | Large production, most effective, simple, low cost, flexible production [49]. |

| Squeeze Casting | By using the closed die, metal undergoes solidification under pressure. Due to the movement of mold parts, pressure is applied over the molten metal, and it penetrates over the dispersed phase. | Stirring speed, squeeze pressure, pressure holding time [77]. | Near net shape, good castability, removal of porosities, reduced material waste due to the absence of a gating system, high dimensional accuracy, and improved mechanical properties, Other benefits of squeeze casting are due to increased mechanical properties: no shrinkage, no metal waste, good castability of squeeze cast components, high weldability, high temperature resistance, good surface finish, high corrosion resistance, and high dimensional accuracy [49,73,74]. |

| Centrifugal Casting | The process used is to combine comparable or different metal layers and fibers into sandwich metal at the required pressure. | Bonding temperature, pressure, holding duration, and surface roughness, temperature, pressure and the diffusion timing [49]. | Controlling fiber orientation with metal volume fraction in various metal matrix composites. |

| Spontaneous Infiltration | The pressure-less infiltration process is another name for the spontaneous infiltration process. External pressure or forces are not used in this procedure when the liquid metal enters cavities. | Temperature and gaseous atmosphere [40]. | Low cost, high precision with complexity in fabrication [40]. |

| No | Sample Designation | UTS (MPa) |

|---|---|---|

| 1 | AlSi10Mg | 350 |

| 2 | AlSi10Mg + 15% fly ash + 5% rice husk ash | 392 |

| 3 | AlSi10Mg + 10% fly ash + 10% rice husk | 410 |

| 4 | Ash AlSi10Mg + 5% fly ash + 15% rice husk ash | 386 |

| Sample Details | Al7075 (%) | SiC (%) | ZrO2 (%) |

|---|---|---|---|

| S1 | 100 | - | - |

| S2 | 95 | 2 | 3 |

| S3 | 93 | 4 | 3 |

| S4 | 91 | 6 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fanani, E.W.A.; Surojo, E.; Prabowo, A.R.; Akbar, H.I. Recent Progress in Hybrid Aluminum Composite: Manufacturing and Application. Metals 2021, 11, 1919. https://doi.org/10.3390/met11121919

Fanani EWA, Surojo E, Prabowo AR, Akbar HI. Recent Progress in Hybrid Aluminum Composite: Manufacturing and Application. Metals. 2021; 11(12):1919. https://doi.org/10.3390/met11121919

Chicago/Turabian StyleFanani, Elvira Wahyu Arum, Eko Surojo, Aditya Rio Prabowo, and Hammar Ilham Akbar. 2021. "Recent Progress in Hybrid Aluminum Composite: Manufacturing and Application" Metals 11, no. 12: 1919. https://doi.org/10.3390/met11121919

APA StyleFanani, E. W. A., Surojo, E., Prabowo, A. R., & Akbar, H. I. (2021). Recent Progress in Hybrid Aluminum Composite: Manufacturing and Application. Metals, 11(12), 1919. https://doi.org/10.3390/met11121919