Selective Leaching of Molybdenum from Bulk Concentrate by Electro-Oxidation

Abstract

:1. Introduction

(anode: 2Cl− → Cl2 + 2e−/cathode: 2H2O + 2e− → 2OH− + H2)

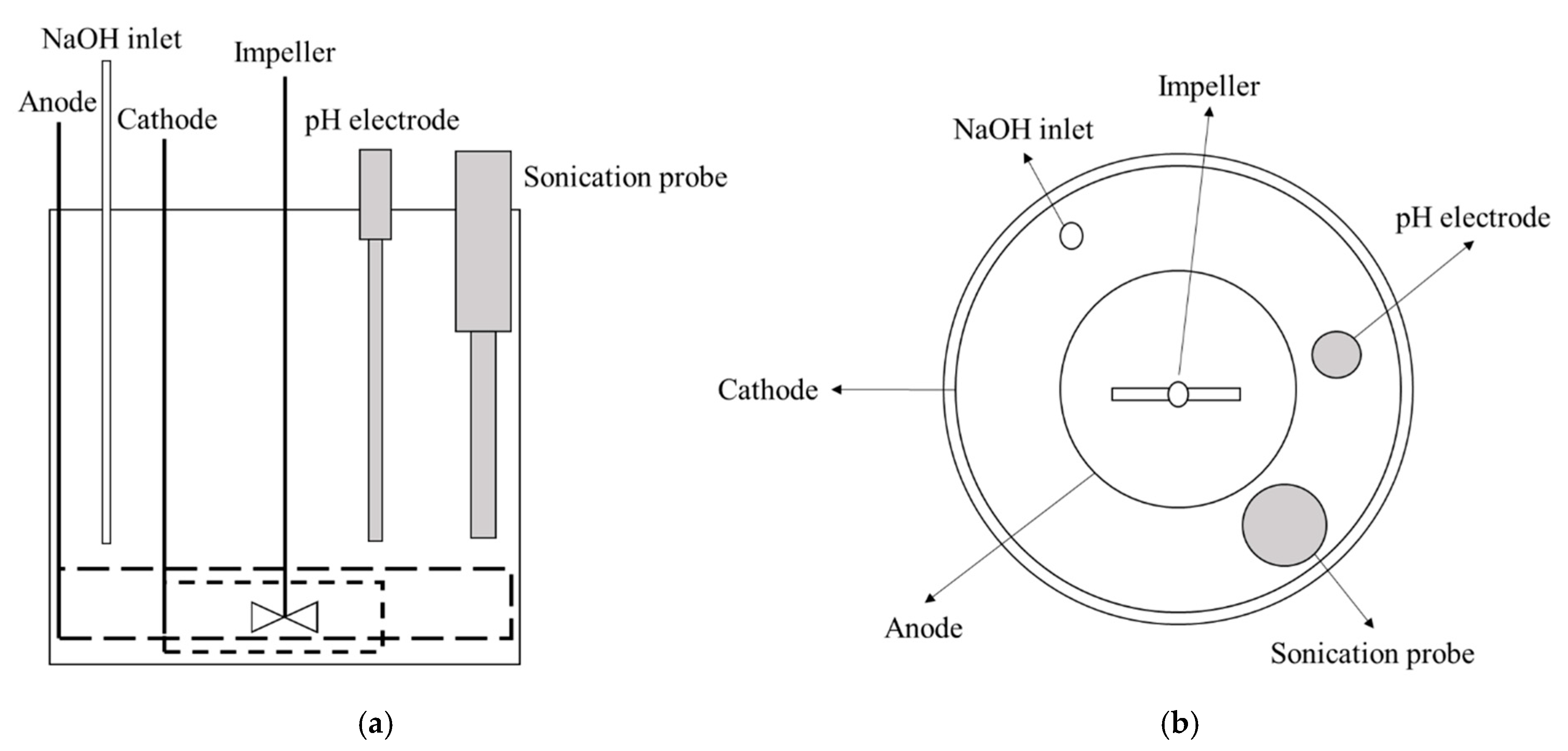

2. Experimental Section

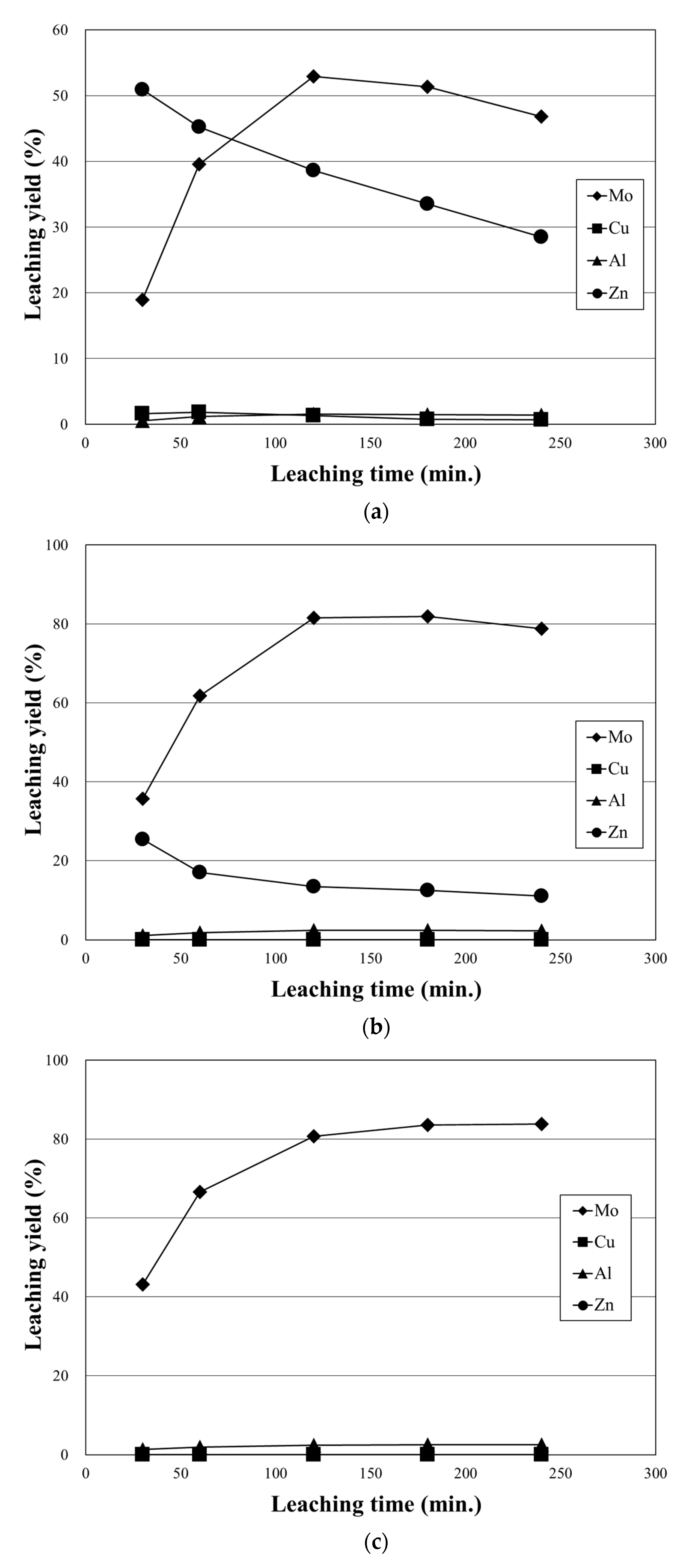

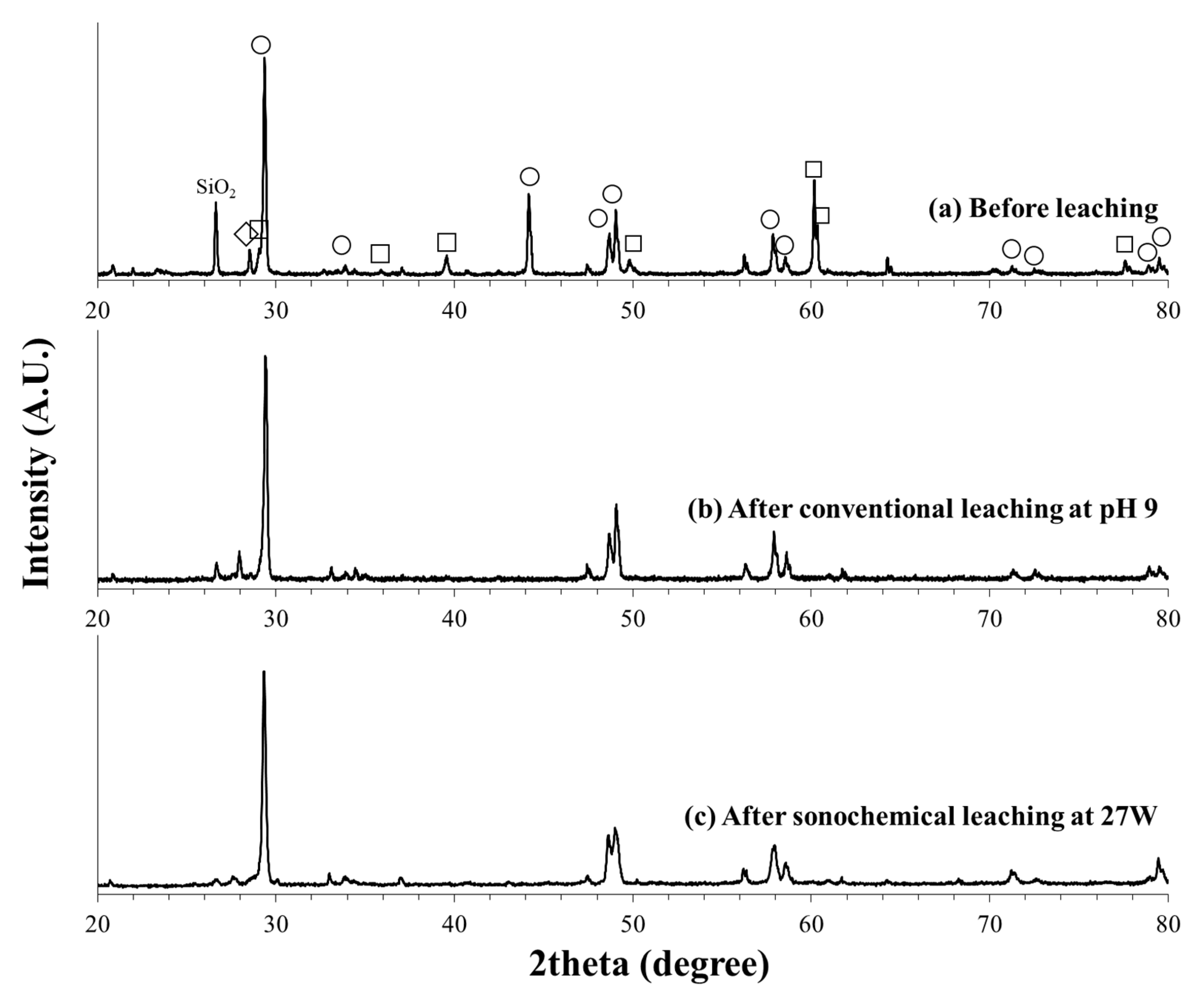

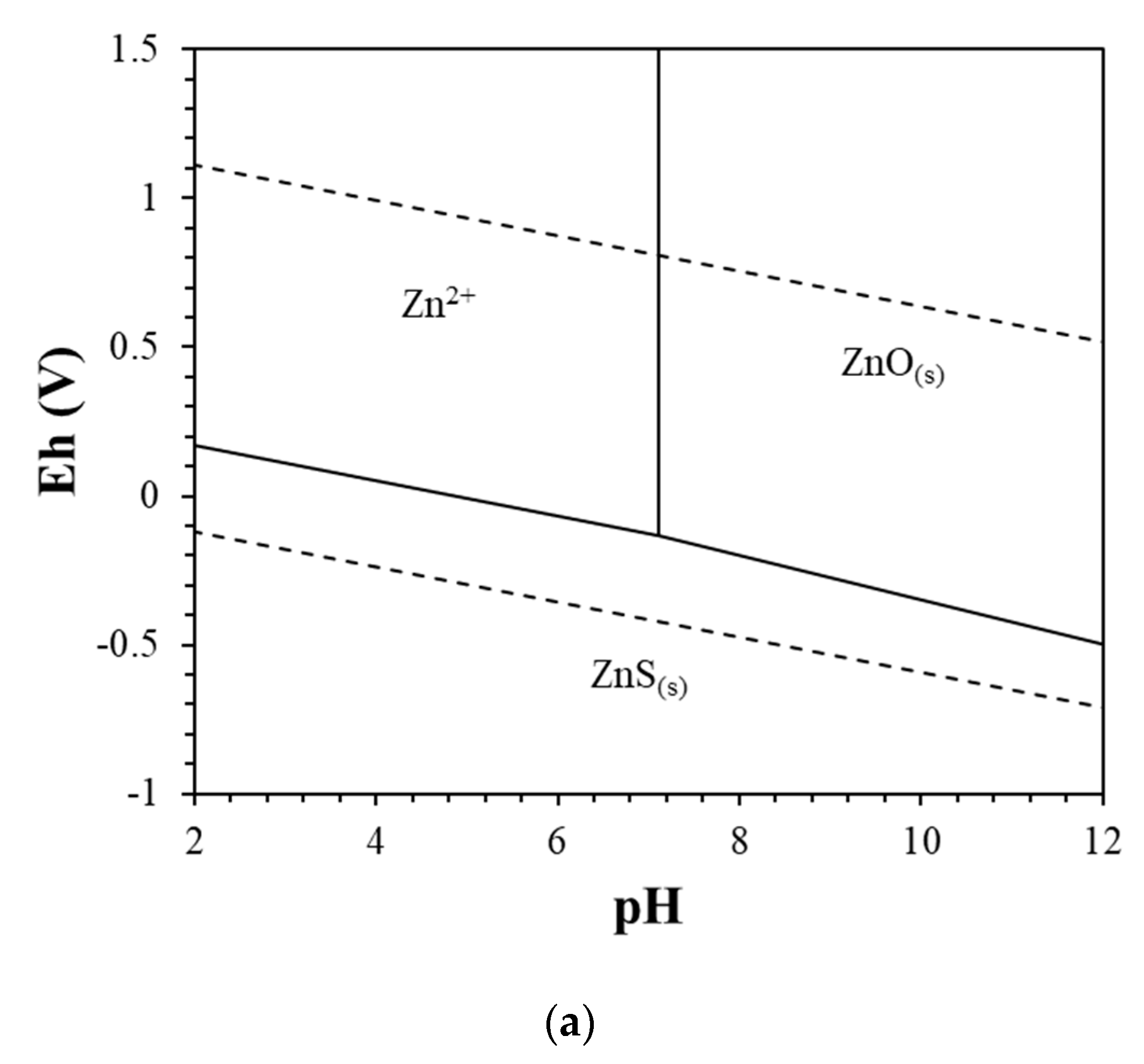

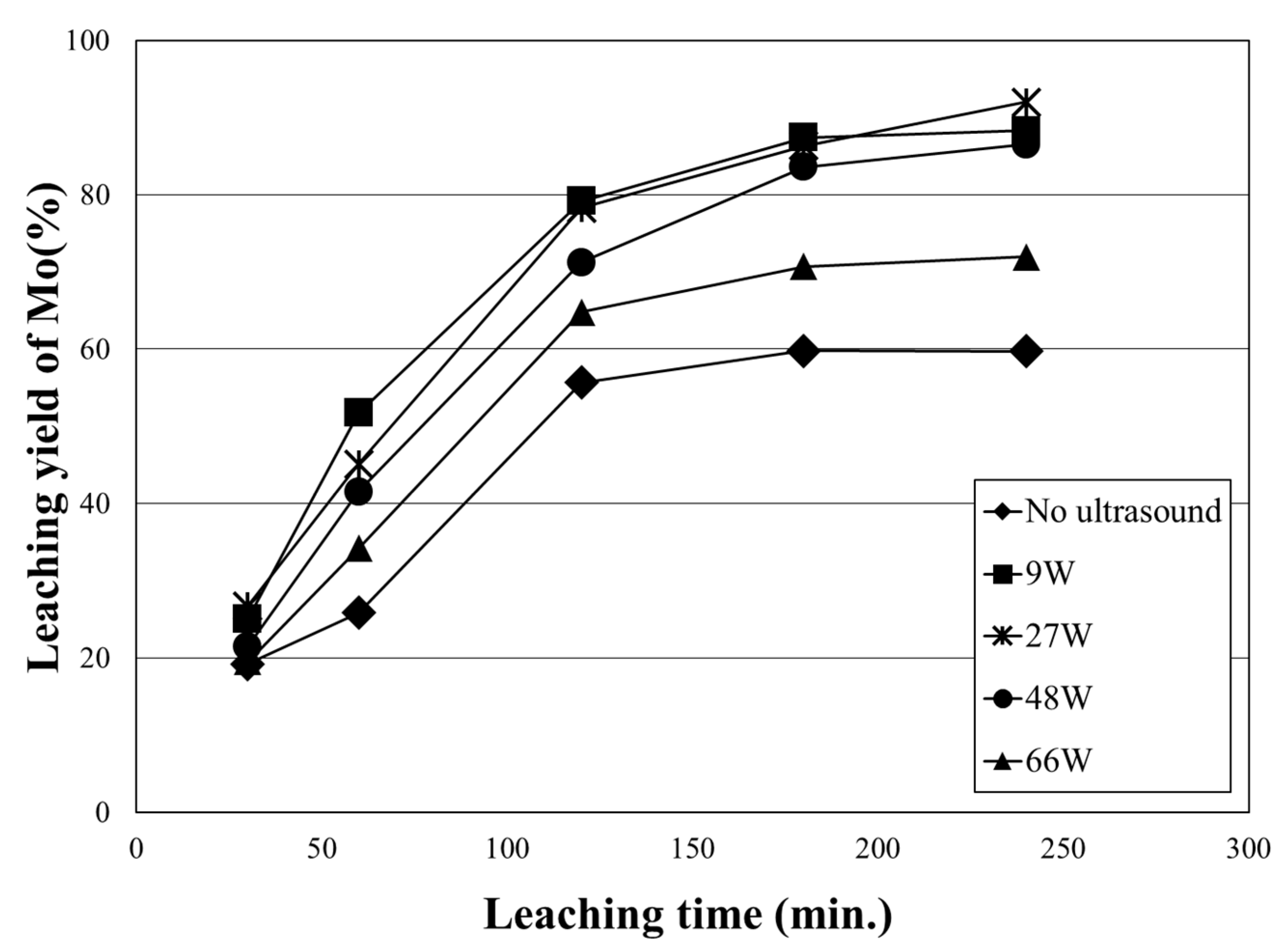

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lunk, H.-J.; Hartl, H. Discovery, Properties and Applications of Molybdenum and Its Compounds. ChemTexts 2017, 3, 13. [Google Scholar] [CrossRef]

- International Molybdenum Association. Molybdenum Metal & Alloys. Available online: https://www.imoa.info/molybdenum-uses/molybdenum-metal-alloys.php (accessed on 1 November 2021).

- Han, F.; Hwang, B.; Suh, D.-W.; Wang, Z.; Lee, D.L.; Kim, S.-J. Effect of Molybdenum and Chromium on Hardenability of Low-Carbon Boron-Added Steels. Met. Mater. Int. 2008, 6, 667–672. [Google Scholar] [CrossRef]

- Mordor Intelligence: Global Molybdenum Market Study Period (2016–2025); Mordor Intelligence: Hyderabad, India, 2019.

- Shalchian, H.; Ferella, F.; Birloaga, I.; Michelis, I.D.; Veglio, F. Recovery of Molybdenum from Leach Solution using Polyelectrolyte Extraction. Hydrometallurgy 2019, 190, 105167. [Google Scholar] [CrossRef]

- International Molybdenum Association. A Sustainable World with Molybdenum. Available online: https://www.imoa.info/download_files/sustainability/Sustainability-brochure-2015.pdf (accessed on 1 November 2021).

- Cha, J.; Lee, K. Towards Improved Circular Economy and Resource Security in South Korea. Sustainability 2021, 13, 17. [Google Scholar]

- USGS. Available online: https://pubs.usgs.gov/fs/2009/3106/pdf/fs2009-3106.pdf (accessed on 1 November 2021).

- Choi, S.-G.; Koo, M.-H.; Kang, H.-S.; Ahn, Y.H. Major Molybdenum Mineralization and Igneous Activity, South Korea. Econ. Environ. Geol. 2011, 44, 109–122, (Korean with English abstract). [Google Scholar] [CrossRef] [Green Version]

- Ahn, Y.H.; Choi, S.-G.; Lee, J.Y.; Kim, T.H.; Yoo, I.K. Genetic Environment of the Geumeum Mo(–Cu) mineralization in Korea. J. Geochem. Explor. 2009, 101, 1. [Google Scholar] [CrossRef]

- Jeon, H.-S.; Baek, S.-H.; Kim, S.-M.; Go, B.-H. Status of Reserves and Development Technology of Rare Earth Metals in Korea. J. Korean Soc. Miner. Energy Resour. Eng. 2018, 55, 67–82, (In Korean with English abstract). [Google Scholar] [CrossRef]

- Liu, G.-Y.; Lu, Y.-P.; Zhong, H.; Cao, Z.-F.; Xu, Z.-H. A Novel Approach for Preferential Flotation Recovery of Molybdenite from a Porphyry Copper–Molybdenum ore. Miner. Eng. 2012, 36–38, 37–44. [Google Scholar] [CrossRef]

- Yi, G.; Macha, E.; Van Dyke, J.; Macha, R.E.; McKay, T.; Free, M.L. Recent Progress on Research of Molybdenite Flotation: A review. J. Colloid Interface Sci. 2021, 295, 102466. [Google Scholar] [CrossRef]

- Timbillah, S.; LaDouceur, R.; Das, A.; Young, C.A. Theoretical and Experimental Investigation of Disodium Carboxymethyl Trithiocarbonate in Cu-Mo Flotation. Miner. Eng. 2021, 169, 106943. [Google Scholar] [CrossRef]

- Zanin, M.; Ametov, I.; Grano, S.; Zhou, L.; Skinner, W. A Study of Mechanisms Affecting Molybdenite Recovery in a Bulk Copper/Molybdenum Fotation Circuit. Int. J. Miner. Process. 2009, 93, 256–266. [Google Scholar] [CrossRef]

- Warren, I.H.; Isamy, A.; King, J. The Leaching of Molybdenite with Sodium Hypochlorite Solutions. Can. Metall. Q. 1977, 16, 11–20. [Google Scholar] [CrossRef]

- Van Den Stee, A.; Fuentes, J.E.; Salvo, C. Hydrometallurgical Recovery of Molybdenum from Low-Grade Molybdenite. Can. Metall. Q. 1977, 16, 16–17. [Google Scholar] [CrossRef]

- Cao, Z.-F.; Zhong, H.; Qiu, Z.-H.; Liu, G.-Y.; Zhang, W.-X. A Novel Technology for Molybdenum Extraction from Molybdenite Concentrate. Hydrometallurgy 2009, 99, 2–6. [Google Scholar] [CrossRef]

- Abdollahi, H.; Noaparast, M.; Shafaei, S.Z.; Manafi, Z.; Erust, E.; Akcil, A. Acidic Leaching with Chlorate as Oxidizing Agent to Extract Mo and Re from Molybdenite Flotation Concentrate in a Copper Plant. Sep. Purif. Methods 2015, 50, 2396–2404. [Google Scholar] [CrossRef]

- Liu, Y.; Zhong, H.; Cao, Z. Molybdenum Removal from Copper Ore Concentrate by Sodium Hypochlorite Leaching. Min. Sci. Technol. 2011, 21, 61–64. [Google Scholar]

- Warren, I.H.; Mounsey, D.M. Factors Influencing the Selective Leaching of Molybdenum with Sodium Hypochlorite from Copper/Molybdenum Sulphide Minerals. Hydrometallurgy 1983, 10, 343–357. [Google Scholar] [CrossRef]

- Barr, D.S.; Lindstrom, R.E.; Hendrix, J.L. Control of the Chlorate Factor in Electrooxidation Leaching of Molybdenum Concentrates. Int. J. Miner. Process. 1975, 2, 303–320. [Google Scholar] [CrossRef]

- Barr, D.S.; Scheiner, B.J.; Hendrix, J.L. Examination of the Chlorate factor in Electro-oxidation Leaching of Molybdenum Concentrates using Flow-Through Cells. Int. J. Miner. Process. 1977, 4, 83–88. [Google Scholar] [CrossRef]

- Cao, Z.-F.; Wang, M.-M.; Zhong, H.; Chen, N.; Xia, L.-Y.; Fan, F.; Liu, G.Y.; Wang, S. Purification of Bismuthinite Concentrate by Selective Electro-oxidation of Molybdenite. Hydrometallurgy 2015, 154, 95–101. [Google Scholar] [CrossRef]

- Li, L.-F.; Cao, Z.-F.; Zhong, H.; Wang, M.-M.; Liu, G.-Y.; Wang, S.; Cao, X.-Y. The Selective Leaching and Separation of Molybdenum from Complex Molybdenite Concentrate Containing Copper. Miner. Metall. Process. 2013, 30, 233–237. [Google Scholar] [CrossRef]

- Liu, Z.-X.; Sun, L.; Hu, J.; Wu, X.-W.; Xiao, Y.; Xiang, Y.-H.; He, Z.-J.; Yin, Z.L. Selective Extraction of Molybdenum from Copper Concentrate by Air Oxidation in Alkaline Solution. Hydrometallurgy 2017, 169, 9–15. [Google Scholar] [CrossRef]

- Aleksandrov, P.V.; Medvedev, A.S.; Milovanov, M.F.; Imideev, V.A.; Kotova, S.A.; Moskovskikh, D.O. Molybdenum Recovery from Molybdenite Concentrates by Low-Temperature Roasting with Sodium Chloride. Int. J. Miner. Process. 2017, 161, 13–20. [Google Scholar] [CrossRef]

- Liu, Z.-X.; Sun, L.; Tang, L.D.; Hu, J.; Xiao, Y.; Chen, Y.-G.; Yin, Z.L. Removal of Metallic Impurities from Off-Grade Copper Concentrate in Alkaline Solution. Int. J. Nonferrous Metall. 2018, 7, 9–23. [Google Scholar] [CrossRef] [Green Version]

- Darjaa, T.; Okabe, T.H.; Waseda, Y.; Umetsu, Y. Recovery of Molybdenum from Sulfide Concentrate by Electro-Oxidation and Precipitation. J. Min. Mater. Proc. Inst. Jpn. 2000, 116, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.-F.; Zhong, H.; Liu, G.-Y.; Qiu, Y.-R.; Wang, S. Molybdenum Extraction from Molybdenite Concentrate in NaCl Electrolyte. J. Taiwan Inst. Chem. Eng. 2010, 41, 338–343. [Google Scholar] [CrossRef]

- Cao, Z.-F.; Wan, M.-M.; Zhong, H.; Qiu, Z.-H.; Qiu, P.; Yue, Y.-J.; Liu, G.-Y.; Wang, S. Electro-oxidation of Sphalerite in Weak Alkaline Sodium Chloride Solution. Hydrometallurgy 2015, 157, 127–132. [Google Scholar] [CrossRef]

- Cho, E.H. Leaching Studies of Chalcopyrite and Sphalerite with Hypochlorous Acid. Metall. Trans. B 1987, 18B, 315–323. [Google Scholar] [CrossRef]

- Garlapalli, R.K.; Cho, E.H.; Yang, R.Y.K. Leaching of Chalcopyrite with Sodium Hypochlorite. Metall. Mater. Trans. B 2010, 41B, 308–317. [Google Scholar] [CrossRef]

- Choubey, P.K.; Lee, J.-C.; Kim, M.-S.; Kim, H.-S. Conversion of Chalcopyrite to Copper Oxide in Hypochlorite Solution for Selective Leaching of Copper in Dilute Sulfuric Acid Solution. Hydrometallurgy 2018, 178, 224–230. [Google Scholar] [CrossRef]

- Shahri, Z.; Bazarganipour, M.; Salavati-Niasari, M. Controllable Synthesis of Novel Zinc Molybdate Rod-like Nanostructures via Simple Surfactant-free Precipitation Route. Superlattices Microstruct. 2013, 63, 258–266. [Google Scholar] [CrossRef]

- Ray, S.K.; Dhakal, D.; Lee, S.W. Insight into Malachite Green Degradation, Mechanism and Pathways by Morphology-Tuned a-NiMoO4, Photocatalyst. Photochem. Photobiol. 2018, 94, 552–563. [Google Scholar] [CrossRef] [PubMed]

- Pedroza, F.R.C.; Aguilar, M.J.S.; Trvioño, T.P.; Luévanos, A.M.; Castillo, M.S. Treatment of Sulfide Minerals by Oxidative Leaching with Ozone. Miner. Process. Extr. Metall. Rev. 2012, 33, 269–279. [Google Scholar] [CrossRef]

- Yoon, H.-S.; Kim, C.-J.; Chung, K.W.; Lee, J.-U.; Shin, S.M.; Kim, S.-R.; Jang, M.-H.; Kim, J.-H.; Lee, S.-I.; Yoo, S.-J. Ultrasonic-assisted Leaching Kinetics in Aqueous FeCl3-HCl Solution for The Recovery of Copper by Hydrometallurgy from poorly Soluble Chalcopyrite. Korean J. Chem. Eng. 2017, 34, 1748–1755. [Google Scholar]

- Speight, J.G. Lange’s Handbook of Chemistry, 6th ed.; McGraw-Hill: Seoul, Korea, 2005; pp. 1.312–1.404. [Google Scholar]

- Adam, L.C.; Fabian, I.; Suzuk, K.; Cordon, G. Hypochlorous Acid Decomposition in the pH 5-8 Region. Inorg. Chem. 1992, 31, 3535–3541. [Google Scholar] [CrossRef]

- Awakura, Y.; Yoshitake, S.; Majima, H. Solubility of Cl2 Gas in Aqueous Chloride Solution. Mater. Trans. 1990, 8, 697–702. [Google Scholar] [CrossRef] [Green Version]

- Adewuyi, Y.G. Sonochemistry: Environmental Science and Engineering Applications. Ind. Eng. Chem. Res. 2001, 40, 4681–4715. [Google Scholar] [CrossRef]

- Held, A.M.; Halko, D.J.; Hurst, J.K. Mechanisms of Chlorine Oxidation of Hydrogen Peroxide. J. Am. Chem. Soc. 1978, 100, 5732–5740. [Google Scholar] [CrossRef]

| Element | MoS2 | CuFeS2 | ZnS | Pb | Mg | Al | Ca | SiO2 | Mean Dia. (um) |

|---|---|---|---|---|---|---|---|---|---|

| Concentrate (wt%) | 10.14 | 62.08 | 1.88 | 1.96 | 0.33 | 1.05 | 1.73 | 5.44 | 52.2 |

| Pulp Density | Input Amount of Feed | Electrons Required (C) | Electrons Input (C) | The Ratio of Electron Required to that Input | |

|---|---|---|---|---|---|

| Weight (g) | Mole (M) | ||||

| 1 | 5 | 0.003167 | 5501 | 21,024 | 3.822 |

| 5 | 25 | 0.01584 | 27,504 | 105,120 | 3.822 |

| 10 | 50 | 0.03167 | 55,008 | 210,240 | 3.822 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chung, K.W.; Yoon, H.-S.; Kim, C.-J.; Jeon, H.-S. Selective Leaching of Molybdenum from Bulk Concentrate by Electro-Oxidation. Metals 2021, 11, 1904. https://doi.org/10.3390/met11121904

Chung KW, Yoon H-S, Kim C-J, Jeon H-S. Selective Leaching of Molybdenum from Bulk Concentrate by Electro-Oxidation. Metals. 2021; 11(12):1904. https://doi.org/10.3390/met11121904

Chicago/Turabian StyleChung, Kyeong Woo, Ho-Sung Yoon, Chul-Joo Kim, and Ho-Seok Jeon. 2021. "Selective Leaching of Molybdenum from Bulk Concentrate by Electro-Oxidation" Metals 11, no. 12: 1904. https://doi.org/10.3390/met11121904

APA StyleChung, K. W., Yoon, H.-S., Kim, C.-J., & Jeon, H.-S. (2021). Selective Leaching of Molybdenum from Bulk Concentrate by Electro-Oxidation. Metals, 11(12), 1904. https://doi.org/10.3390/met11121904