Control of Vapor Pressure Deficit (VPD) on Black Sesame Seed (Sesamum indicum L.) Sprout Production in a Micro-Greenhouse Using Intelligent Control

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Seed Preparation in Micro-Greenhouse and Traditional Technique

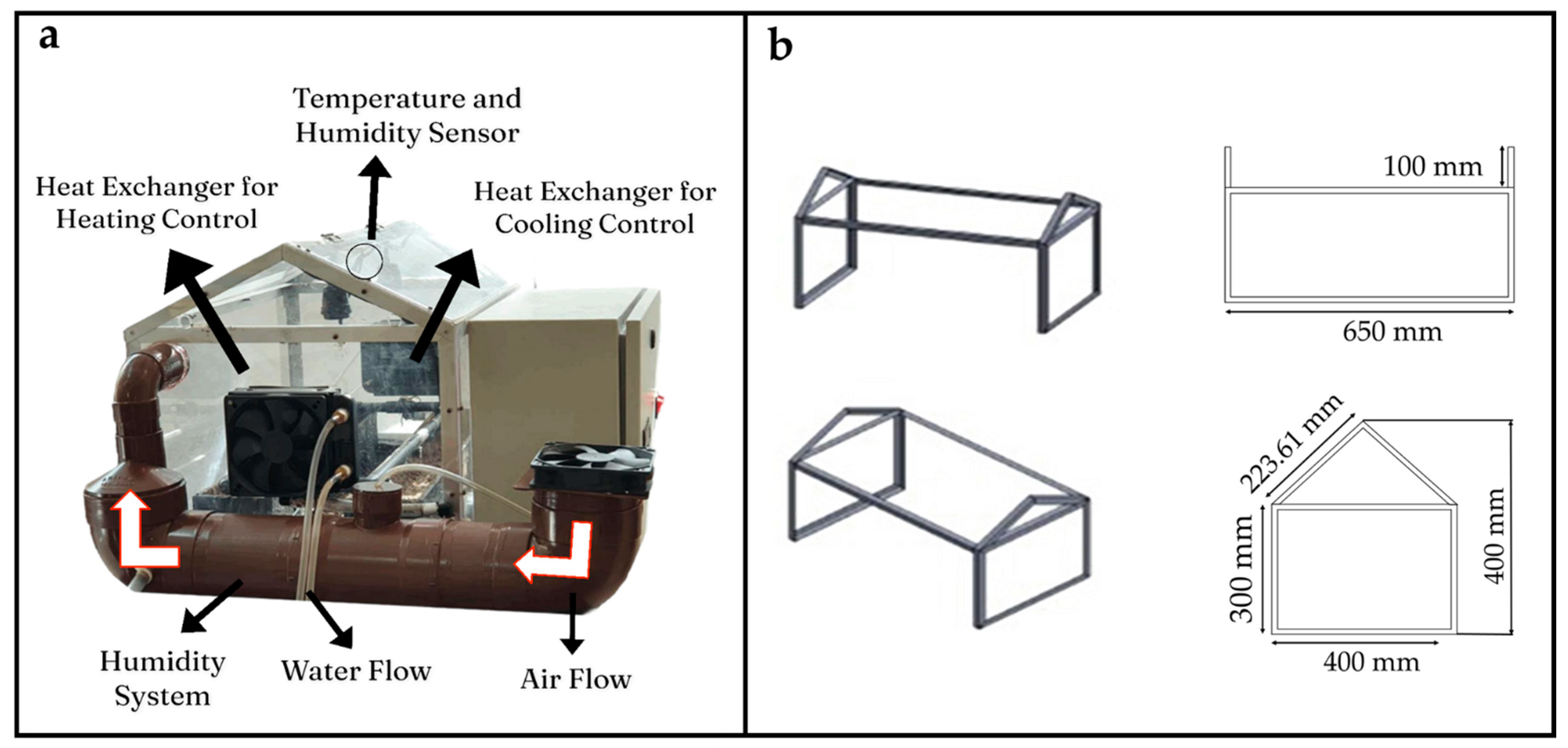

2.1.2. Prototype

2.2. Methods

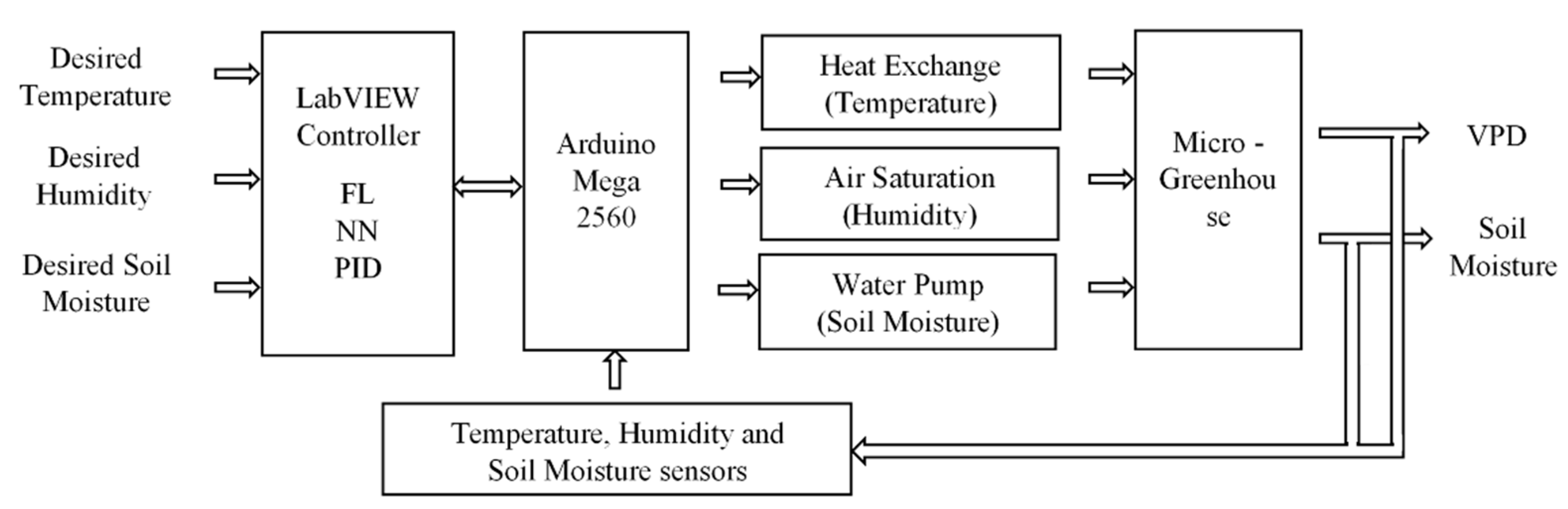

2.2.1. VPD Control Development

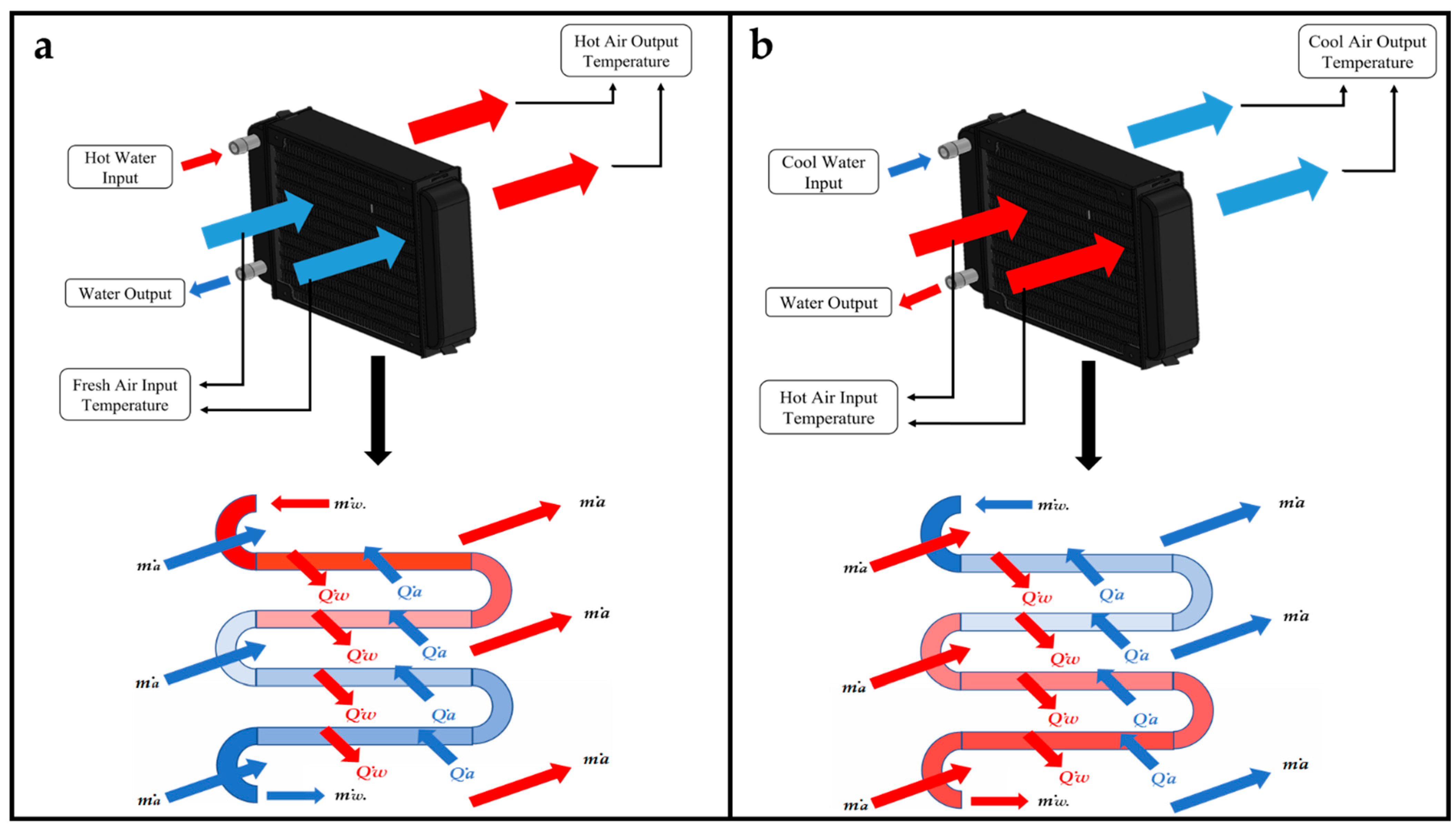

Temperature

Relative Humidity

Control

2.2.2. Treatment and Germination of Sesame Seeds

2.2.3. Determination of Germination Parameters

2.2.4. Measurement of Sprout Length

2.2.5. Nutritional Value Determination

2.2.6. Statistical Analysis

3. Results and Discussion

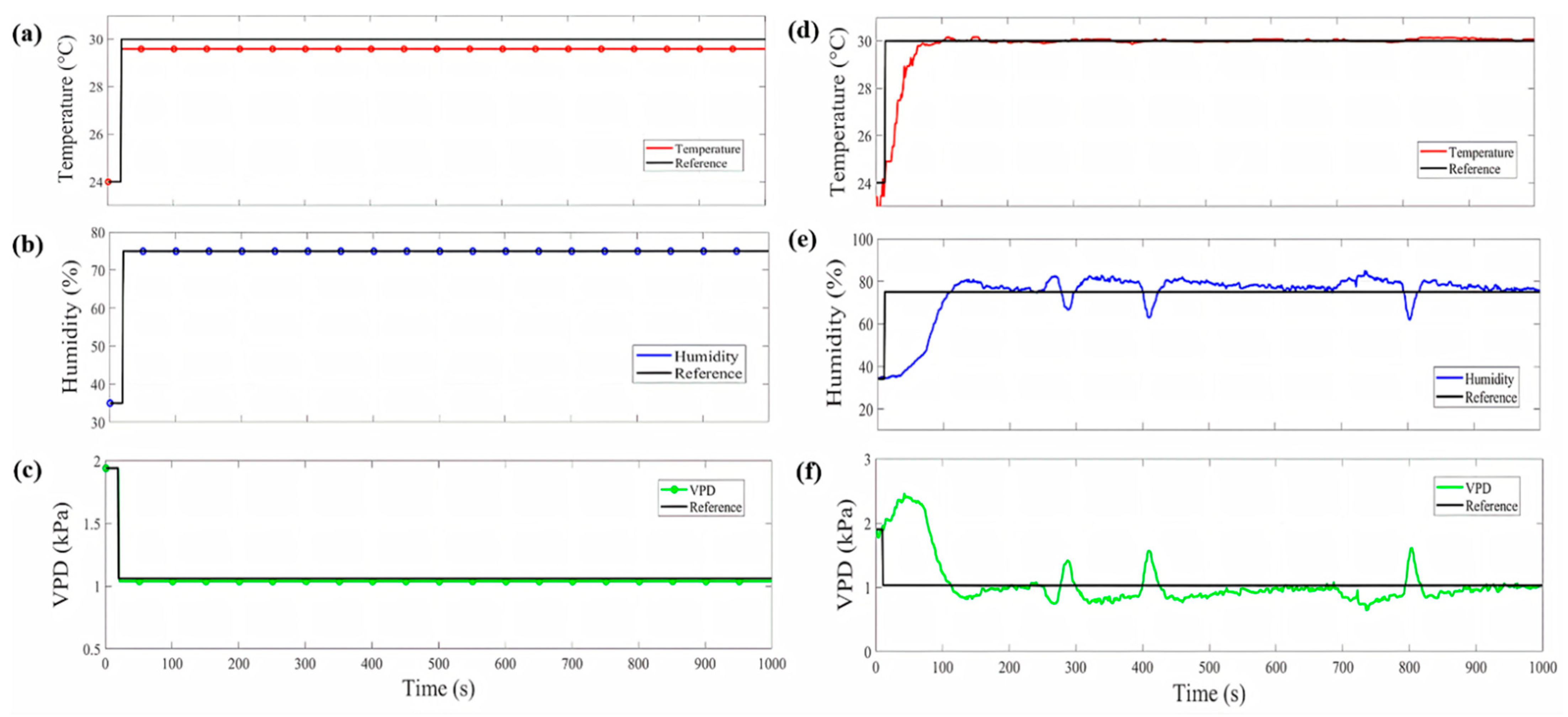

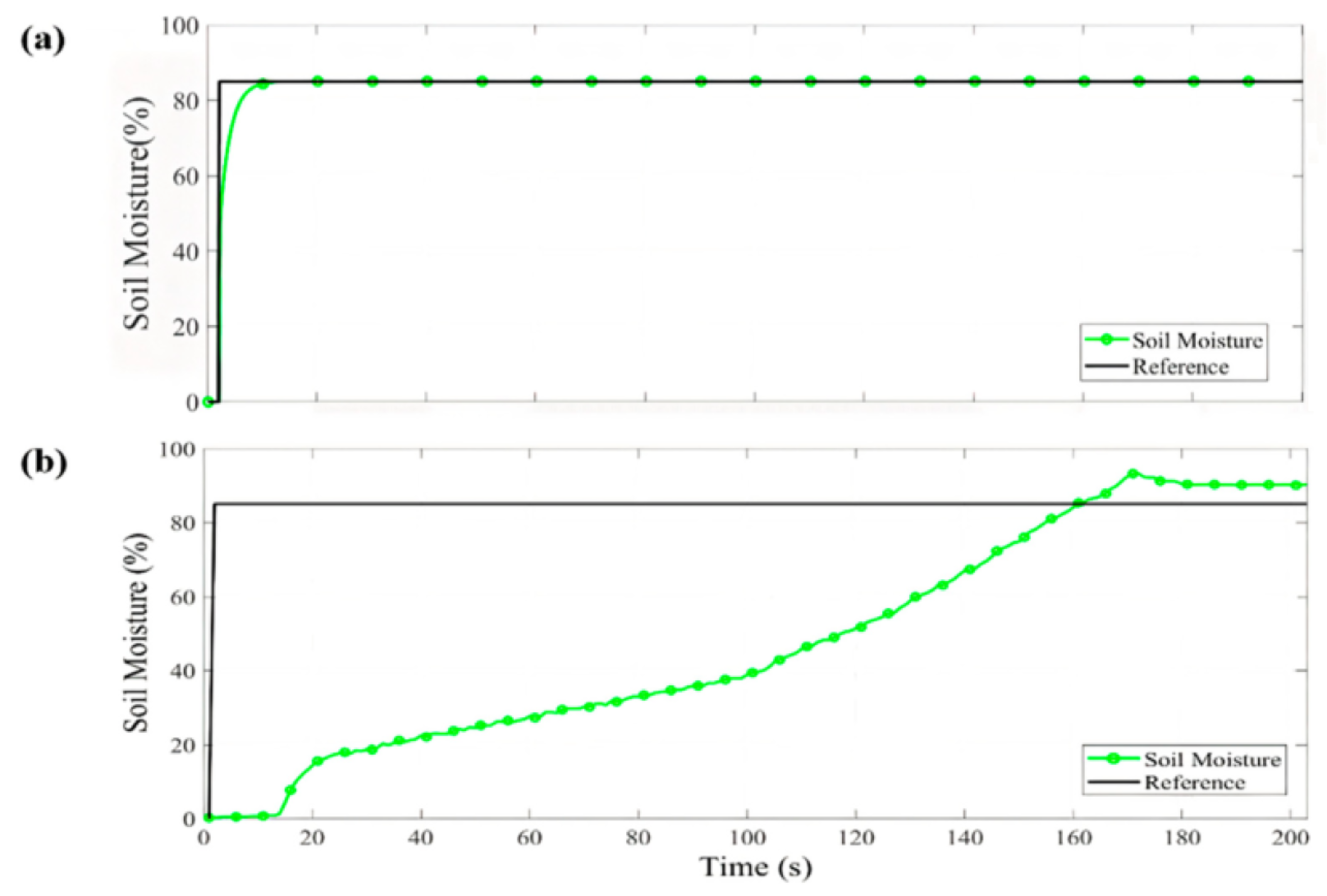

3.1. Control System

3.2. Germination Parameters

3.3. Sprout Length Measurement

3.4. Nutritional Value of the Sprout

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO. The State of Food Security and Nutrition in the World (SOFI). In Transforming Food Systems for Affordable Healthy Diets; FAO: Rome, Italy, 2020; pp. 1–320. [Google Scholar]

- Sivakanthan, A.; Prasantha, J.; Madhujith, T. Optimization of the Production of Structured Lipid by Enzymatic Interesterification from Coconut (Cocos nucifera) and Sesame (Sesamum indicum) Oil Using Response Surface Metholodogy; EJFST: Nigde, Turkey, 2018; Volume 6, pp. 43–55. [Google Scholar]

- Nadeem, A.; Kashani, S.; Ahmed, N.; Buriro, M.; Saeed, Z.; Mohammad, F.; Ahmed, S. Growth and yield of sesame (Sesamum indicum L.) under the influence of planting geometry and irrigation regimes. Am. J. Plant Sci. 2015, 6, 980–986. [Google Scholar] [CrossRef] [Green Version]

- Raeisi-Dehkordi, H.; Mohammadi, M.; Moghtaderi, F.; Salehi-Abargouei, A. Do sesame seed and its products affect body weight and composition? A systematic review and meta-analysis of controlled clinical trials. J. Funct. Foods 2018, 49, 324–332. [Google Scholar] [CrossRef]

- Akusu, O.; Kiin-Kabari, D.B.; Isah, E.M. Effects of processing methods on the nutrient composition and sensory attributes of cookies produced from wheat and sesame seed flour blends. Int. J. Food Sci. Technol. 2019, 5, 34–50. [Google Scholar]

- Turner, E.R.; Luo, Y.; Buchanan, R.L. Microgreen nutrition, food safety, and shelf life: A review. J. Food Sci. 2020, 85, 870–882. [Google Scholar] [CrossRef] [Green Version]

- Meyerowitz, S. Sprouts the Miracle Food; Quality Books: Buckingham, VA, USA, 2010. [Google Scholar]

- Ponce, P.; Molina, A.; Cepeda, P.; Lugo, E.; MacClery, B. Greenhouse Desing and Control; Taylor and Francis Group: Abingdon, UK; London, UK, 2015. [Google Scholar]

- Ottavini, D.; Pannacci, E.; Onofri, A.; Tei, F.; Kryger, P. Effects of light, temperature, and soil depth on the germination and emergence of Conyza canadensis (L.) Cronq. Agronomy 2019, 9, 533. [Google Scholar] [CrossRef] [Green Version]

- Limwiwattana, D.; Tongkhao, K.; Na, J.K. Effect of sprouting temperature and air relative humidity on metabolic profiles of sprouting black gram (Vigna Mungo L.). J. Food Process. Preserv. 2016, 40, 306–315. [Google Scholar]

- Gao, R.; Zhao, R.; Huang, Z.; Yang, X.; Wei, X.; He, Z.; Walck, J.L. Soil temperature and moisture regulate seed dormancy cycling of a dune annual in a temperate desert. Environ. Exp. Bot. 2018, 155, 688–694. [Google Scholar] [CrossRef]

- Amitrano, C.; Arena, C.; Rouphael, Y.; De Pascale, S.; De Micco, V. Vapour pressure deficit: The hidden driver behind plant morphofunctional traits in controlled environments. Ann. Appl. Biol. 2019, 175, 313–325. [Google Scholar] [CrossRef]

- Jambrak, A.R.; Nutrizio, M.; Djekić, I.; Pleslić, S.; Chemat, F. Internet of nonthermal food processing technologies (IoNTP): Food industry 4.0 and sustainability. Appl. Sci. 2021, 11, 686. [Google Scholar] [CrossRef]

- Riahi, J.; Vergura, S.; Mezghani, D.; Mami, A. Intelligent control of the microclimate of an agricultural greenhouse powered by a supporting pv system. Appl. Sci. 2020, 10, 1350. [Google Scholar] [CrossRef] [Green Version]

- Sriraman, A.; Mayorga, R.V.A. Fuzzy inference system approach for greenhouse climate control. Environ. Inform. Arch. 2004, 2, 630–641. [Google Scholar]

- Javadikia, P.; Tabatabaeefar, A.; Omid, M.; Fathi, M. Evaluation of intelligent greenhouse climate control system, based fuzzy logic in relation to conventional systems. In Proceedings of the International Conference on Artificial Intelligence and Computational Intelligence, Shanghai, China, 7–8 November 2009; pp. 146–150. [Google Scholar]

- Habib, S.; Akram, M.; Ashraf, A. Fuzzy climate decision support systems for tomatoes in high tunnels. Int. J. Fuzzy Syst. 2016, 19, 751–775. [Google Scholar] [CrossRef]

- Fletcher, A.; Sinclair, T.R.; Allen, L.H. Transpiration responses to vapor pressure deficit in well watered ‘slow-wilting’ and commercial soybean. Environ. Exp. Bot. 2007, 61, 145–151. [Google Scholar] [CrossRef]

- Ben-Asher, J.; García, A.G.Y.; Flitcroft, I.; Hoogenboom, G. Effect of atmospheric water vapor on photosynthesis, transpiration and canopy conductance: A case study in corn. Plant Soil Environ. 2013, 59, 549–555. [Google Scholar] [CrossRef] [Green Version]

- Leyva, R.; Aguilar, C.C.; Sánchez-Rodríguez, E.; Romero-Gámez, M.; Soriano, T. Cooling systems in screenhouses: Effect on microclimate, productivity and plant response in a tomato crop. Biosyst. Eng. 2015, 129, 100–111. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Z.; Li, J.; Chang, Y.; Du, Q.; Pan, T. Regulation of vapor pressure deficit by greenhouse micro-fog systems improved growth and productivity of tomato via enhancing photosynthesis during summer season. PLoS ONE 2015, 10, e0133919. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Nukaya, T.; Kamimura, T.; Zhang, D.; Kurimoto, I.; Takagaki, M.; Maruo, T.; Kozai, T.; Yamori, W. Control of vapor pressure deficit (VPD) in greenhouse enhanced tomato growth and productivity during the winter season. Sci. Hortic. 2015, 197, 17–23. [Google Scholar] [CrossRef]

- Prenger, J.J.; Ling, P.P. Greenhouse Condensation Control; Fact Sheet (Series) AEX-804: Wooster, OH, USA, 2000. [Google Scholar]

- Ramos-Fernández, J.C.; Jean-Francois, B.; Márquez-Vera, M.A.; Lafont, F.; Pessel, N.; Espinoza-Quesada, E.S. Fuzzy modeling vapor pressure deficit to monitoring microclimate in greenhouses. IFAC 2016, 49, 371–374. [Google Scholar] [CrossRef]

- Mendoza, C.P.; Fuentes, L.T.; Aguilera, L.A.; De Cristaldo, R.M.O. Effect of different temperatures on physiological quality of sesame seeds. Investig. Agrar. 2015, 17, 122–128. [Google Scholar] [CrossRef] [Green Version]

- Prabhakaran, J.; Kavitha, D. Allelopathic Influence of Trianthima Portulacastrum, L. on growth and developmental responses of sesame (Sesamum Indicum, L.). Kongunadu Res. J. 2017, 4, 183–186. [Google Scholar] [CrossRef]

- Nouriyani, H. Payame Noor University effect of seed priming on germination characteristics, biochemical changes and early seedling growth of sesame (Sesamum indicum). Iran. J. Seed Res. 2019, 5, 43–58. [Google Scholar] [CrossRef] [Green Version]

- Tizazu, Y.; Ayalew, D.; Terefe, G.; Assefa, F. Evaluation of seed priming and coating on germination and early seedling growth of sesame (Sesamum indicum L.) under laboratory condition at Gondar, Ethiopia. Cogent Food Agric. 2019, 5, 1–9. [Google Scholar] [CrossRef]

- Neme, K.; Tola, Y.B.; Mohammed, A.; Tadesse, E.; Astatkie, T. Effects of variety, storage container, and duration on the physical properties, oil content, germination capacity, and seed loss due to Plodia interpunctella infestation of Ethiopian sesame. J. Sci. Food Agric. 2020, 101, 843–852. [Google Scholar] [CrossRef]

- Megat, R.; Noraliza, C.W.; Azrina, A.; Zulkhairi, A. Nutritional changes in germinated legumes and rice varieties. Int. Food Res. J. 2011, 18, 705–713. [Google Scholar]

- Mares, L.F.D.M.; Passos, M.C.; Menezes, C.C. Interference of germination time on chemical composition and antioxidant capacity of white sesame (Sesamum Indicum). Food Sci. Technol. 2018, 38, 248–253. [Google Scholar] [CrossRef] [Green Version]

- Biswas, U.; Das, R.; Dutta, A. Growth, yield and seed quality parameters of sesame (Sesamum indicum L.) as influenced by seed priming and pinching. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 1112–1119. [Google Scholar] [CrossRef]

- Shamshiri, R.; Che Man, A.; Zakaria, A.; Beveren, P.; Wan Ismail, W.; Ahmad, D. Membership function model for defining optimality of vapor pressure deficit in closed-field cultivation of tomato. In Proceedings of the International Conference on Agricultural and Food Engineering, Kuala Lumpur, Malaysia, 21 March 2017; pp. 281–290. [Google Scholar]

- Terefe, G.; Wakjira, A.; Berhe, M.; Hagos, T. Sesame Production Manual; Ethiopian Institute of Agricultural Research: Adís Ababa, Ethiopia, 2012. [Google Scholar]

- Hahm, T.-S.; Park, S.-J.; Lo, Y.M. Effects of germination on chemical composition and functional properties of sesame (Sesamum indicum L.) seeds. Bioresour. Technol. 2009, 100, 1643–1647. [Google Scholar] [CrossRef] [PubMed]

- Murray, F.W. On the computation of saturation vapor pressure. J. Appl. Meteorol. 1967, 6, 203–204. [Google Scholar] [CrossRef]

- Cengel, Y.; Boles, M. Thermodynamics: An Engineering Approach; McGraw-Hill: New York, NY, USA, 2011. [Google Scholar]

- Kayacan, E.; Maslim, R. Type-2 fuzzy logic trajectory tracking control of quadrotor vtol aircraft with elliptic membership functions. IEEE/ASME Trans. Mechatron. 2016, 22, 339–348. [Google Scholar] [CrossRef]

- Oubehar, H.; Selmani, A.; Ed-Dahhak, A.; Lachhab, A.; Archidi, M.E.H.; Bouchikhi, B. ANFIS-based climate controller for computerized greenhouse system. Adv. Sci. Technol. Eng. Syst. J. 2020, 5, 8–12. [Google Scholar] [CrossRef]

- Izquierdo, S.; Izquierdo, L.R. Mamdani Fuzzy Systems for Modelling and Simulation: A Critical Assessment. J. Artif. Soc. Soc. Simul. 2018, 21. [Google Scholar] [CrossRef]

- Velandia, J.B.; Quintana, J.S.C.; Ayala, S.C.V. Environment humidity and temperature prediction in agriculture using Mamdani inference systems. Int. J. Electr. Comput. Eng. 2021, 11, 3502–3509. [Google Scholar] [CrossRef]

- Faouzi, D.; Bibi-Triki, N.; Draoui, B.; Abene, A. Modeling and simulation of fuzzy logic controller for optimization of the greenhouse microclimate management. Agric. Sci. Technol. 2017, 9, 132–139. [Google Scholar] [CrossRef]

- Singh, V.K.; Tiwari, K.N. Prediction of greenhouse micro-climate using artificial neural network. Appl. Ecol. Environ. Res. 2017, 15, 767–778. [Google Scholar] [CrossRef]

- Jung, D.-H.; Kim, H.S.; Jhin, C.; Kim, H.-J.; Park, S.H. Time-serial analysis of deep neural network models for prediction of climatic conditions inside a greenhouse. Comput. Electron. Agric. 2020, 173, 105402. [Google Scholar] [CrossRef]

- Hagan, M.; Demuth, H.; Beale, M.; De Jesús, O. Neural Network Design; Material: Oklahoma City, OK, USA, 2014. [Google Scholar]

- Mazzoleni, M.; Scandella, M.; Previdi, F. KBERG: A MatLab toolbox for nonlinear kernel-based regularization and system identification. IFAC-PapersOnLine 2020, 53, 1231–1236. [Google Scholar] [CrossRef]

- Wang, L.; Wang, B. Construction of greenhouse environment temperature adaptive model based on parameter identification. Comput. Electron. Agric. 2020, 174, 105477. [Google Scholar] [CrossRef]

- Taher Azar, A.; Hassan Ammar, H.; de Brito Silva, G.; Akmal Bin Razali, M.S. Optimal proportional integral derivative (PID) controller design for smart irrigation mobile robot with soil moisture sensor. In Proceedings of the International Conference on Advanced Machine Learning Technologies and Applications (AMLTA2019), Cairo, Egypt, 28–30 March 2019; pp. 349–359. [Google Scholar]

- Ogata, k. Modern Control Engineering; Pearson, Education: Madrid, Spain, 2010. [Google Scholar]

- Ziegler, J.; Nichols, G. Optimum settings for automatic controllers. Trans. ASME 1942, 64, 759–765. [Google Scholar] [CrossRef]

- Jain, R.; Joshi, I. Nutrient analysis of germinated sesame seeds and development of value added biscuits. Stud. Home Community Sci. 2015, 9, 61–64. [Google Scholar] [CrossRef]

- Kashani, S.-U.; Buriro, M.; Nadeem, A.; Ahmed, N.; Saeed, Z.; Mohammad, F.; Ahmed, S. Response of various sesame varieties under the influence of nitrogen and phosphorus doses. Am. J. Plant Sci. 2015, 6, 405–412. [Google Scholar] [CrossRef] [Green Version]

- Al-Ansari, F.; Ksiksi, T. A Quantitative assessment of germination parameters: The case of and. Open Ecol. J. 2016, 9, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Caliskan, O.; Mavi, K.; Polat, A. Influences of presowing treatments on the germination and emergence of fig seeds (Ficus carica L.). Acta Sci. Agron. 2012, 34, 293–297. [Google Scholar] [CrossRef] [Green Version]

- AOAC. Official Methods of Analysis; EUA/AOAC (Association of Official Analytical Chemists): Washinton, DC, SUA, 1999. [Google Scholar]

- Boureima, S.; Eyletters, M.; Diouf, M.; Diop, M.; Van Damme, P. Sensitivity of seed germination and seedling radicle growth to drought stress in sesame (Sesamum indicum L.). Res. J. Environ. Sci. 2011, 5, 557–564. [Google Scholar] [CrossRef]

- Miladinov, Z.; Balešević-Tubić, S.; Đukić, V.; Ilić, A.; Čobanović, L.; Dozet, G.; Merkulov-Popadić, L. Effect of priming on soybean seed germination parameters. Acta Agric. Serbica 2018, 23, 15–26. [Google Scholar] [CrossRef] [Green Version]

| ErrorTempInt | ||||

|---|---|---|---|---|

| Set | Vertex 1 | Vertex 2 | Vertex 3 | Vertex 4 (Trapeze) |

| High Negative | −20 | −20 | −4 | −1.3 |

| Normal Negative | −2 | −1.3 | −0.6 | N/A |

| Low Negative | −1.4 | −0.6 | −0.2 | N/A |

| Normal | −0.2 | 0 | 0.5 | N/A |

| Low Positive | 0 | 1 | 2 | N/A |

| Normal Positive | 1 | 2 | 3 | N/A |

| High Positive | 2 | 5 | 15 | 15 |

| ErrorTempExt | ||||

| Normal | −2.5 | 0 | 2.5 | N/A |

| Very Low Positive Difference | 1 | 2.5 | 4 | N/A |

| Low Positive Difference | 2.5 | 4.2 | 6 | N/A |

| Normal Positive Difference | 4 | 6 | 8 | N/A |

| High Normal Positive Difference | 6 | 8 | 17 | 17 |

| VarTempInt | ||||

| High Descent | −255 | −255 | −170 | N/A |

| Normal Descent | −240 | −170 | −100 | N/A |

| Low Descent | −170 | −100 | −30 | N/A |

| Hold | −30 | −1 | 1 | 30 |

| Very Small Ascent | 0 | 30 | 60 | N/A |

| Small Ascent | 30 | 70 | 115 | N/A |

| Normal Low Ascent | 60 | 115 | 170 | N/A |

| Normal High Ascent | 115 | 170 | 230 | N/A |

| High Ascent | 170 | 255 | 255 | N/A |

| Errorint | |||||

|---|---|---|---|---|---|

| Normal | Very Low Positive Difference | Low Positive Difference | Normal Positive Difference | High Normal Positive Difference | |

| Normal | HLD | HLD | HLD | VSA | SA |

| Low Positive | NLA | NHA | HA | HA | HA |

| Normal Positive | NHA | HA | HA | HA | HA |

| High Positive | HA | HA | HA | HA | HA |

| Error Temp Int | Control Action |

|---|---|

| Low Negative | LD |

| Normal Negative | ND |

| High Negative | HD |

| Control | Simulation | Implementation | |

|---|---|---|---|

| SE | MAE | ||

| FL Temperature Control (°C) | 0.4 | 30.02 ± 0.002 | 30.02 ± 0.08 |

| NN Humidity Control (%) | 0.05 | 77 ± 0.11 | 77 ± 3.90 |

| PID Soil Moisture Control (%) | 0.1 | 87 ± 0.55 | 87 ± 3.95 |

| VPD Control (kPa) | 1.03 | 0.93 ± 0.004 | 0.93 ± 0.09 |

| Technique | G% | GI (Days) | CVG (%) | T50 (Days) |

|---|---|---|---|---|

| Micro-Greenhouse | 88 ± 3.51 a | 3.62 ± 1.52 a | 19.71 ± 2.52 a | 4.63 ± 2.52 a |

| Traditional | 32 ± 3.44 b | 1.03 ± 2.20 b | 16.40 ± 2.70 b | 5.79 ± 3.6 a |

| Technique | Protein (%) | Lipids (%) | Ash (%) | Moisture (%) |

|---|---|---|---|---|

| Whole grain | 22.3 ± 1.5 b | 54.3 ± 2.1 a | 4.8 ± 1.1 c | 10.2 ± 1.5 c |

| Micro-Greenhouse | 25.4 ± 2.2 a | 37.5 ± 2.1 b | 6.7 ± 1.3 a | 90.1 ± 1.2 a |

| Traditional | 15.7 ± 1.7 c | 22.8 ± 1.8 c | 5.6 ± 1.1 b | 83.3 ± 1.6 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barreto-Salazar, L.E.; Rochín-Medina, J.J.; Picos-Ponce, J.C.; Castro-Palazuelos, D.E.; Rubio-Astorga, G.J. Control of Vapor Pressure Deficit (VPD) on Black Sesame Seed (Sesamum indicum L.) Sprout Production in a Micro-Greenhouse Using Intelligent Control. Appl. Sci. 2021, 11, 7957. https://doi.org/10.3390/app11177957

Barreto-Salazar LE, Rochín-Medina JJ, Picos-Ponce JC, Castro-Palazuelos DE, Rubio-Astorga GJ. Control of Vapor Pressure Deficit (VPD) on Black Sesame Seed (Sesamum indicum L.) Sprout Production in a Micro-Greenhouse Using Intelligent Control. Applied Sciences. 2021; 11(17):7957. https://doi.org/10.3390/app11177957

Chicago/Turabian StyleBarreto-Salazar, Luis E., Jesús J. Rochín-Medina, Julio C. Picos-Ponce, David E. Castro-Palazuelos, and Guillermo J. Rubio-Astorga. 2021. "Control of Vapor Pressure Deficit (VPD) on Black Sesame Seed (Sesamum indicum L.) Sprout Production in a Micro-Greenhouse Using Intelligent Control" Applied Sciences 11, no. 17: 7957. https://doi.org/10.3390/app11177957