Friction Stir Welding of 2205 Duplex Stainless Steel: Feasibility of Butt Joint Groove Filling in Comparison to Gas Tungsten Arc Welding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

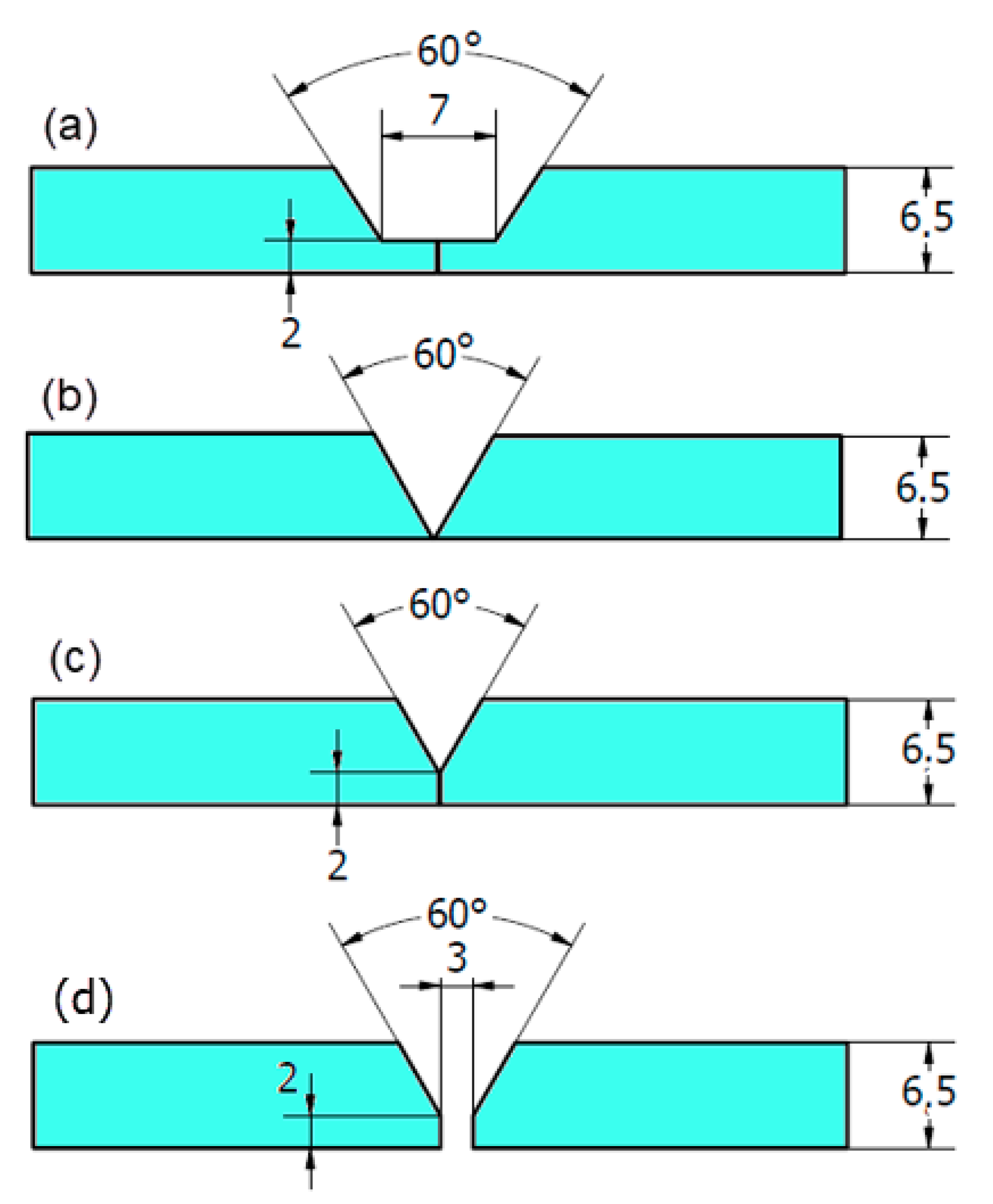

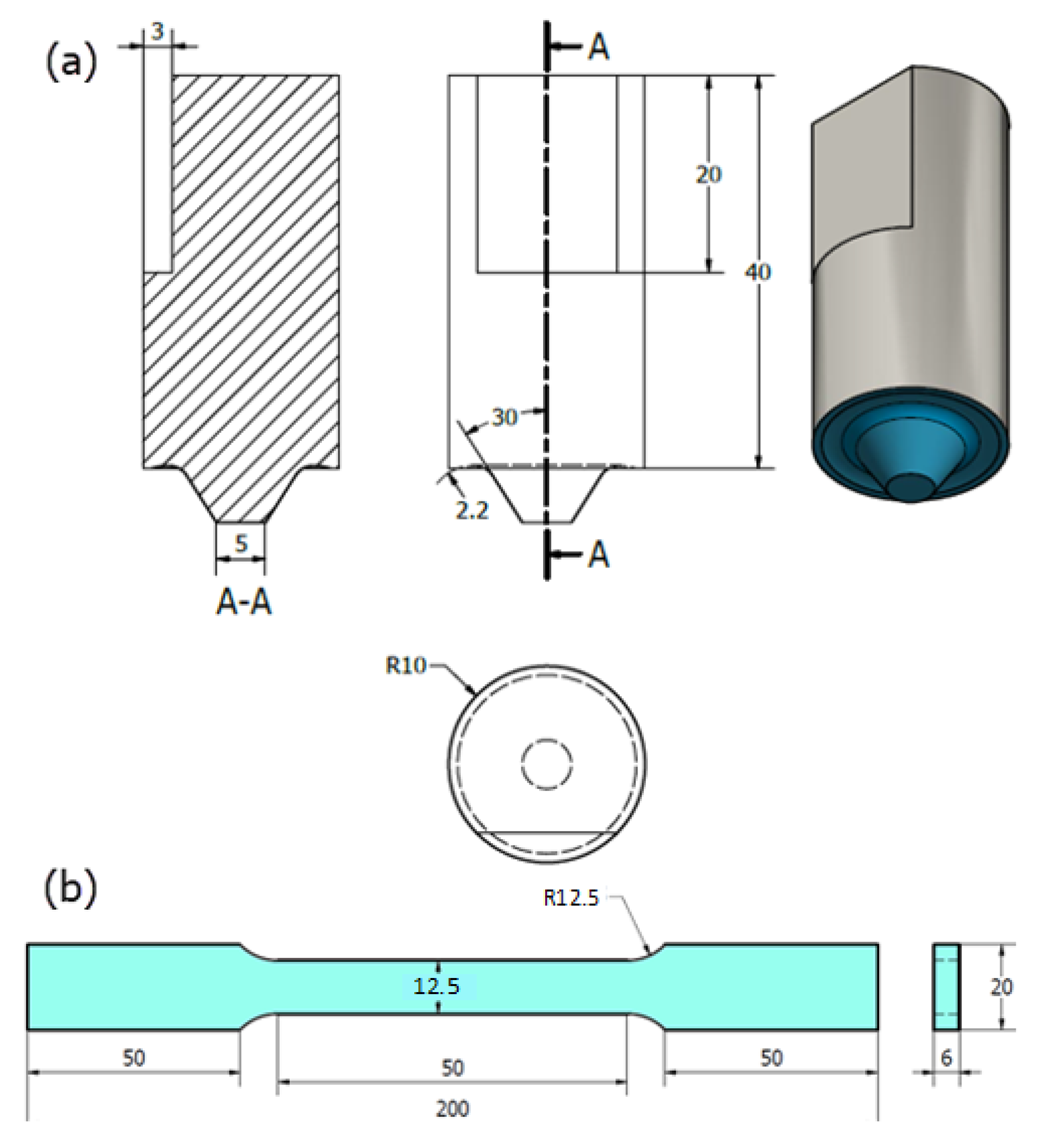

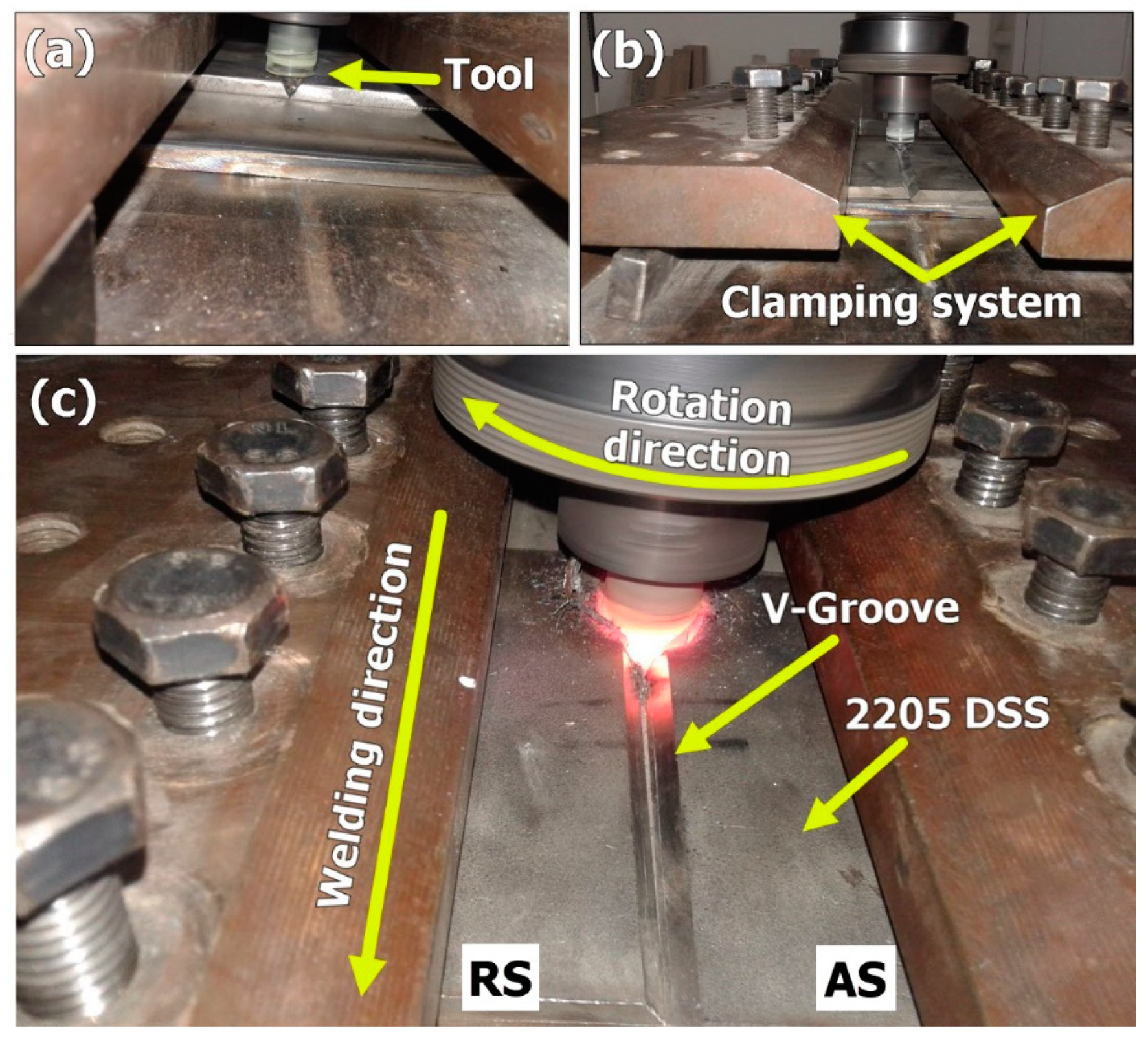

2.2. Welding Procedure

2.3. Joints Evaluation and Characteriztion

3. Results and Discussions

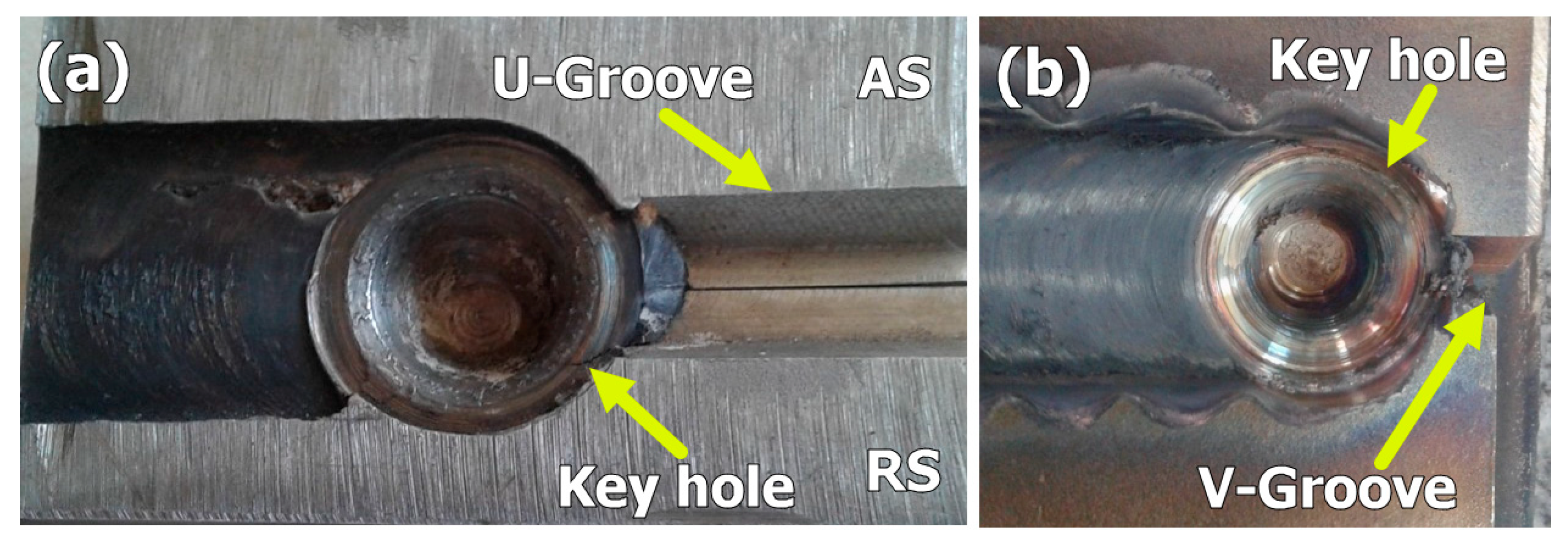

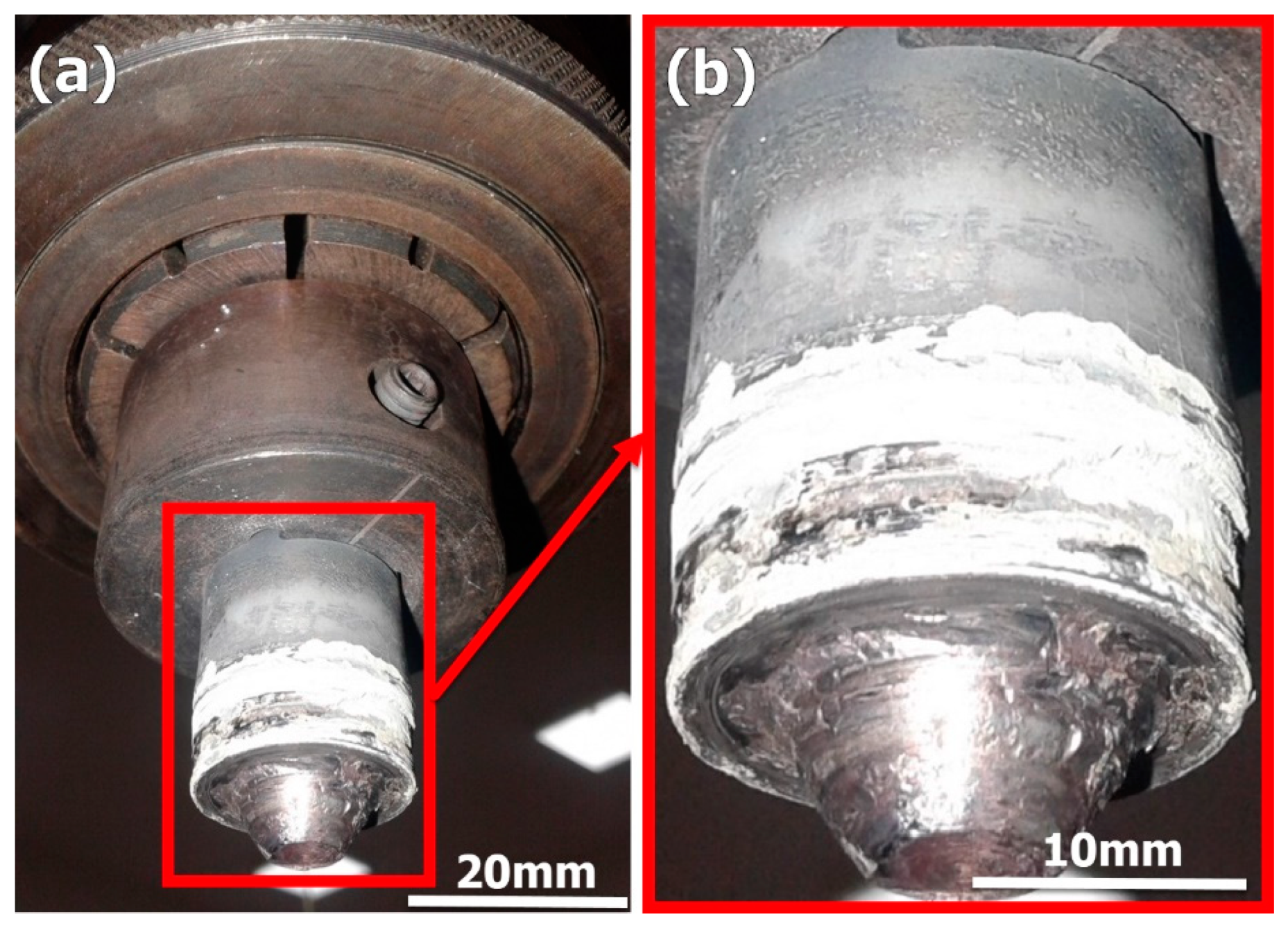

3.1. Mechanism of FSW with Groove Filling

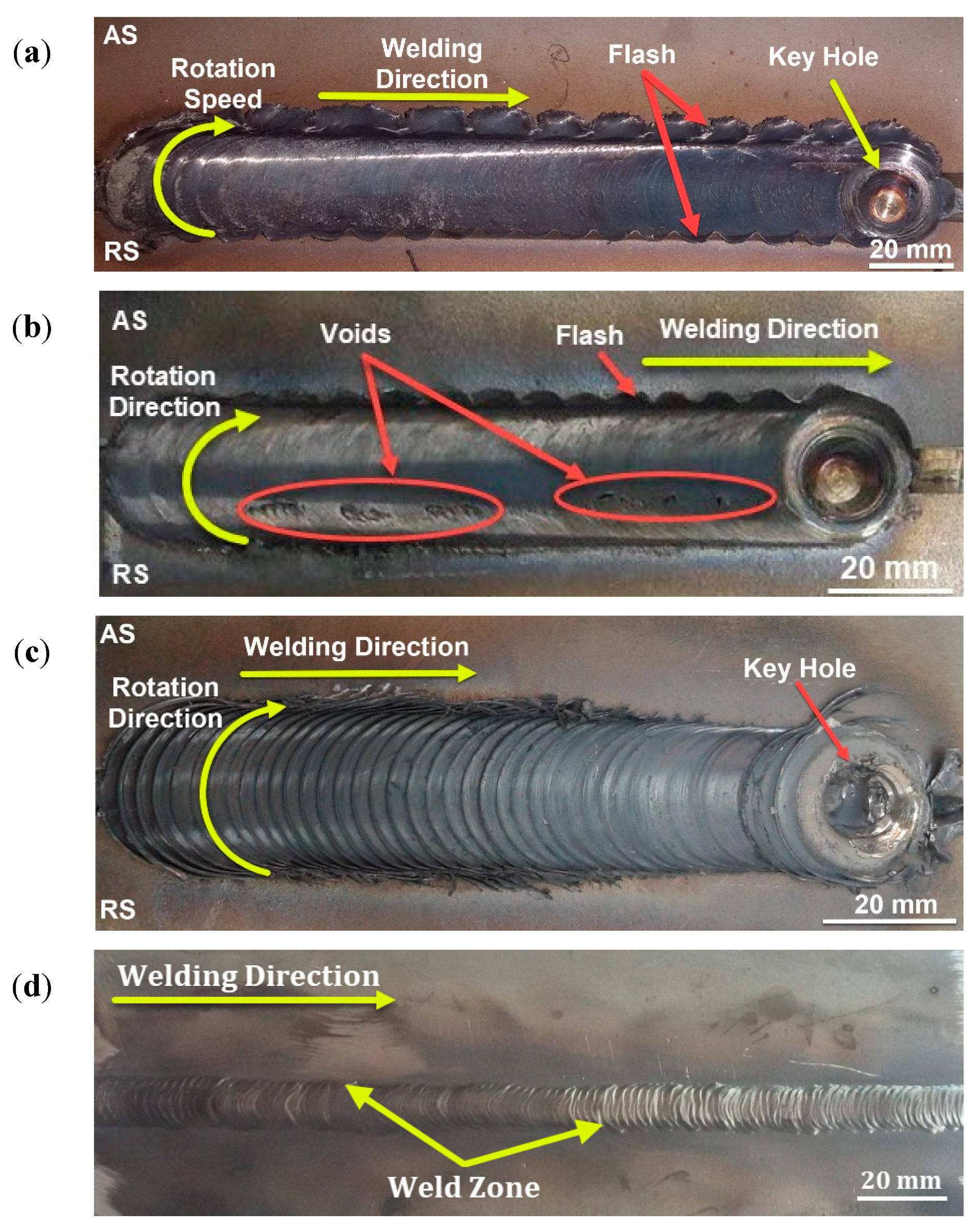

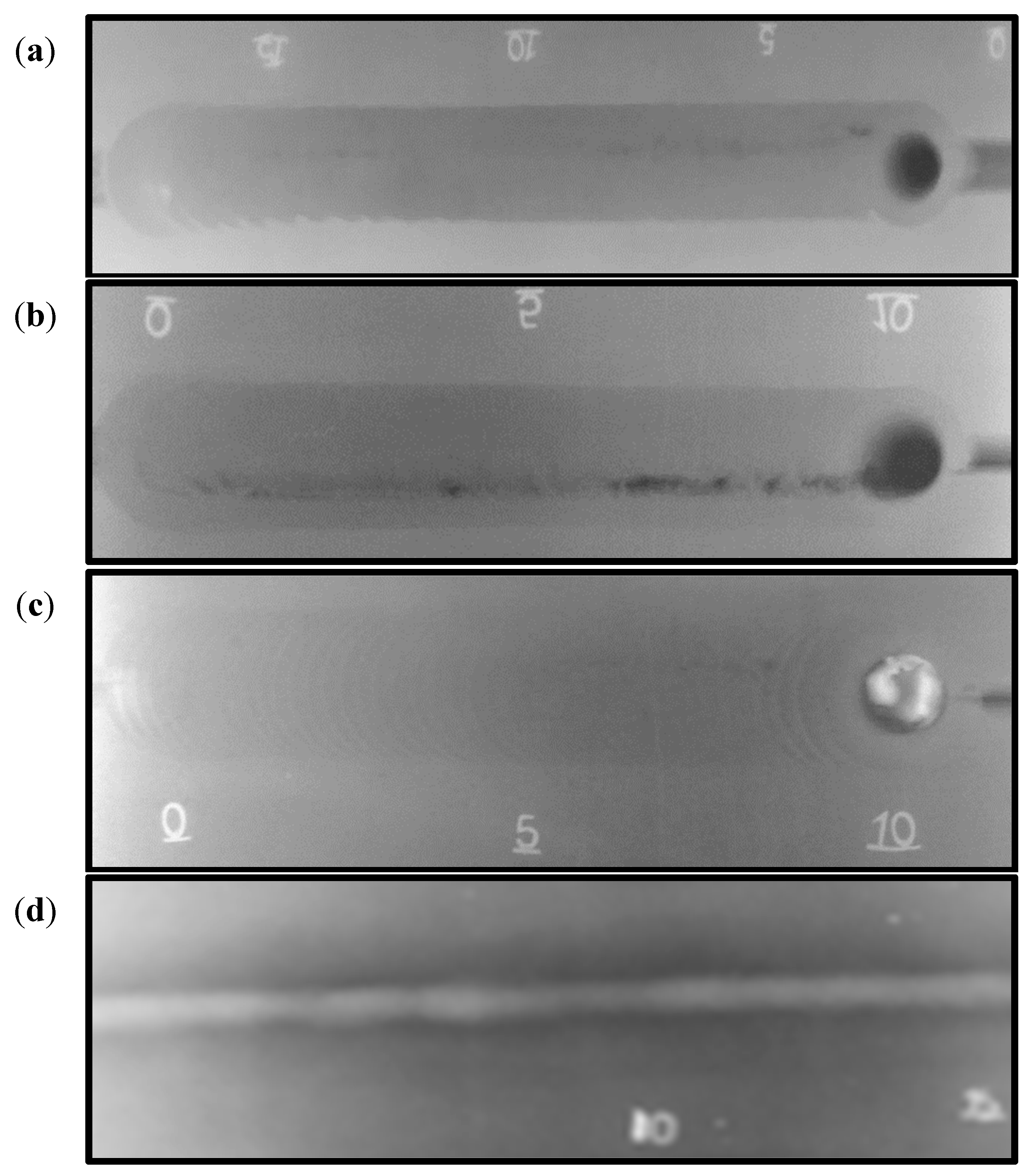

3.2. Visual and Radiographic Inspection

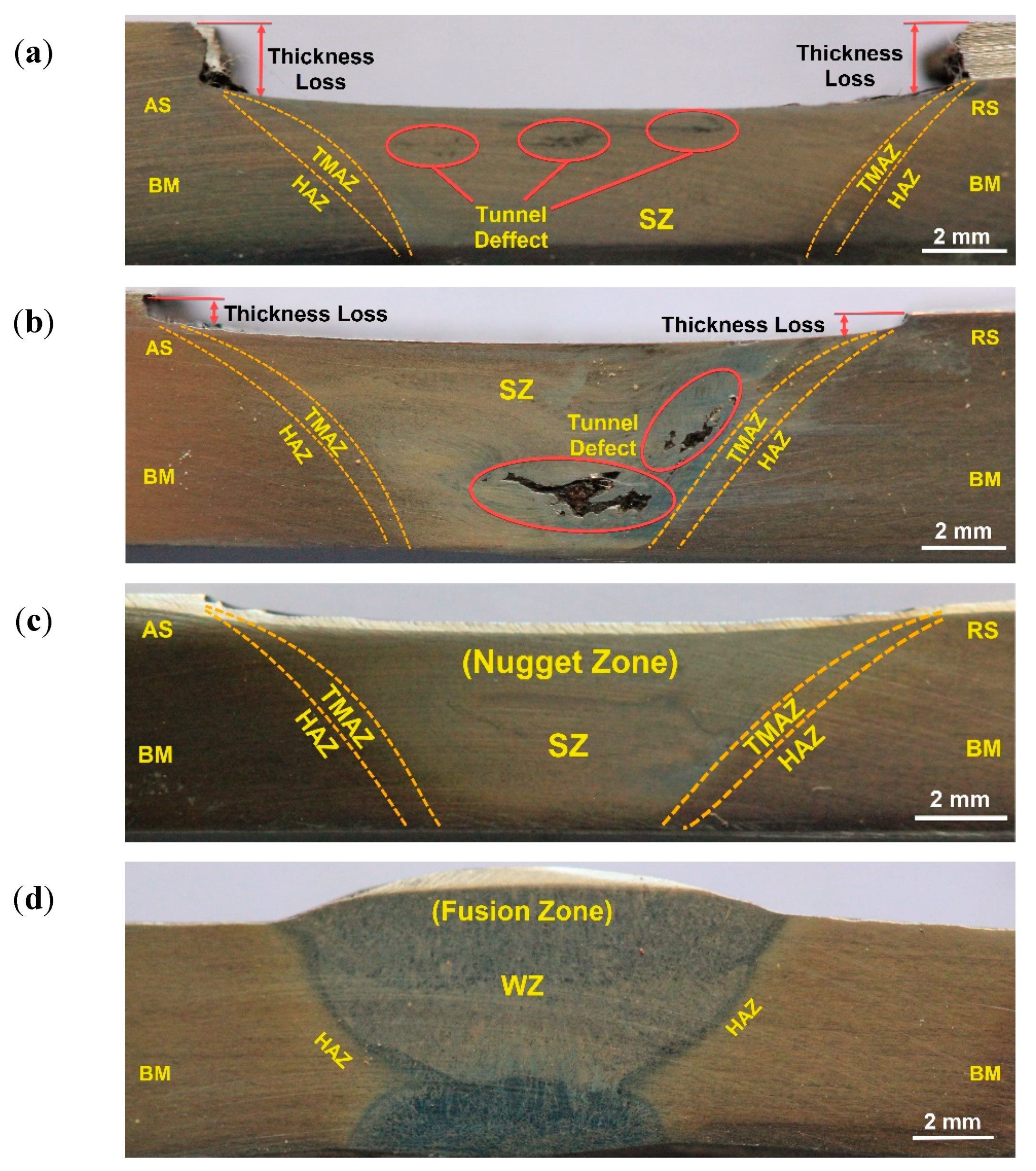

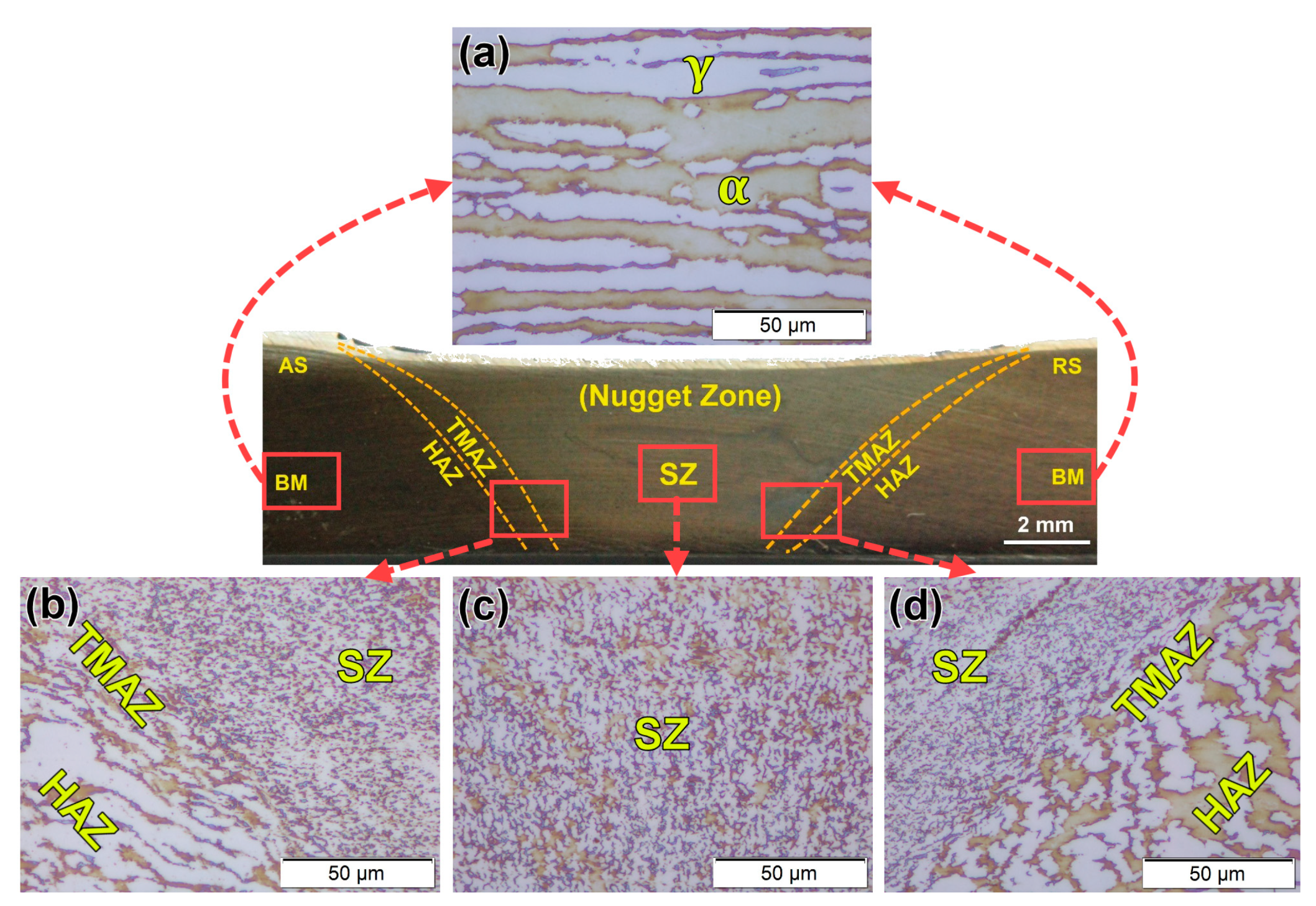

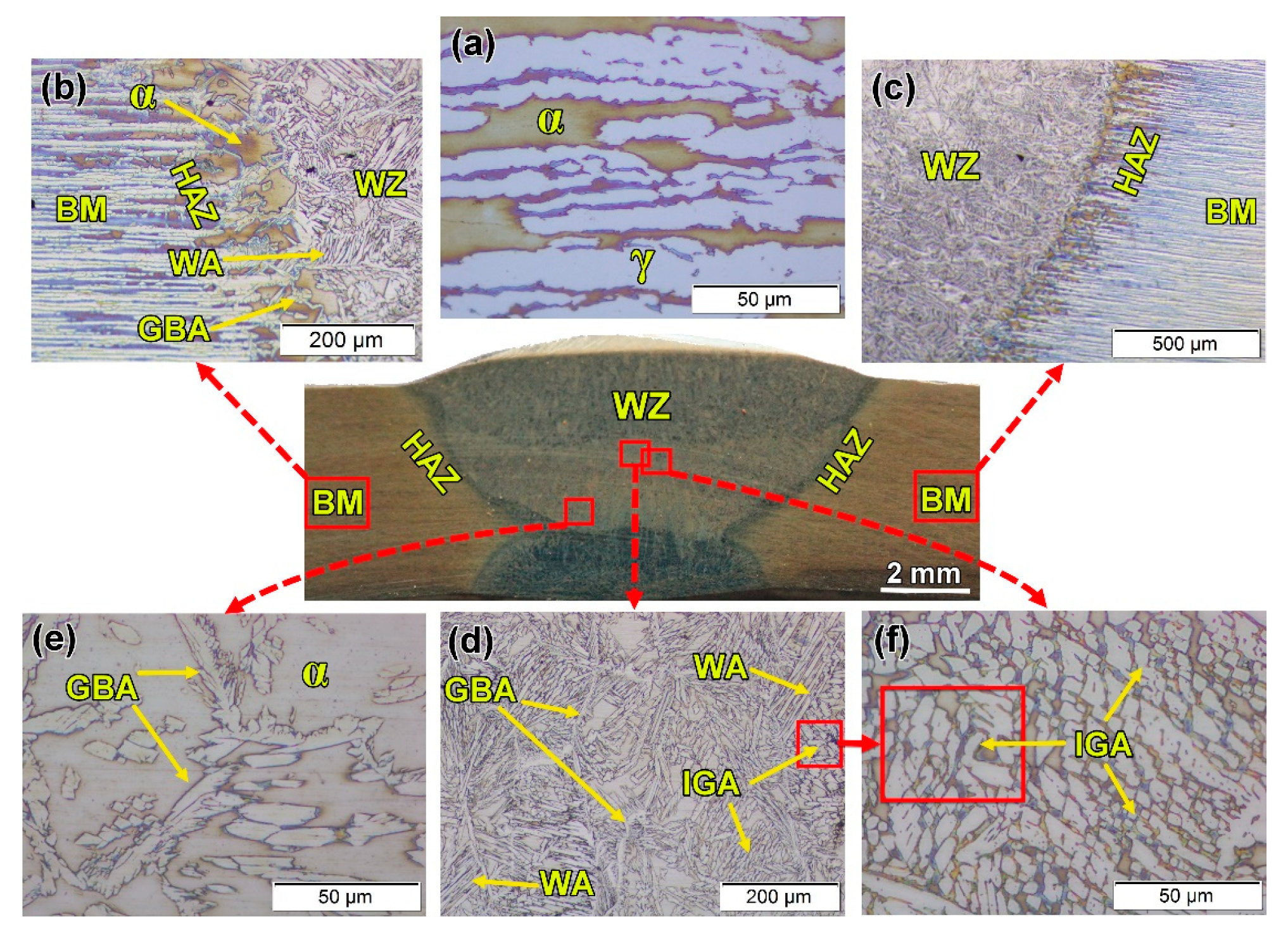

3.3. Macrostructure and Microstructure

3.4. XRD Assessment

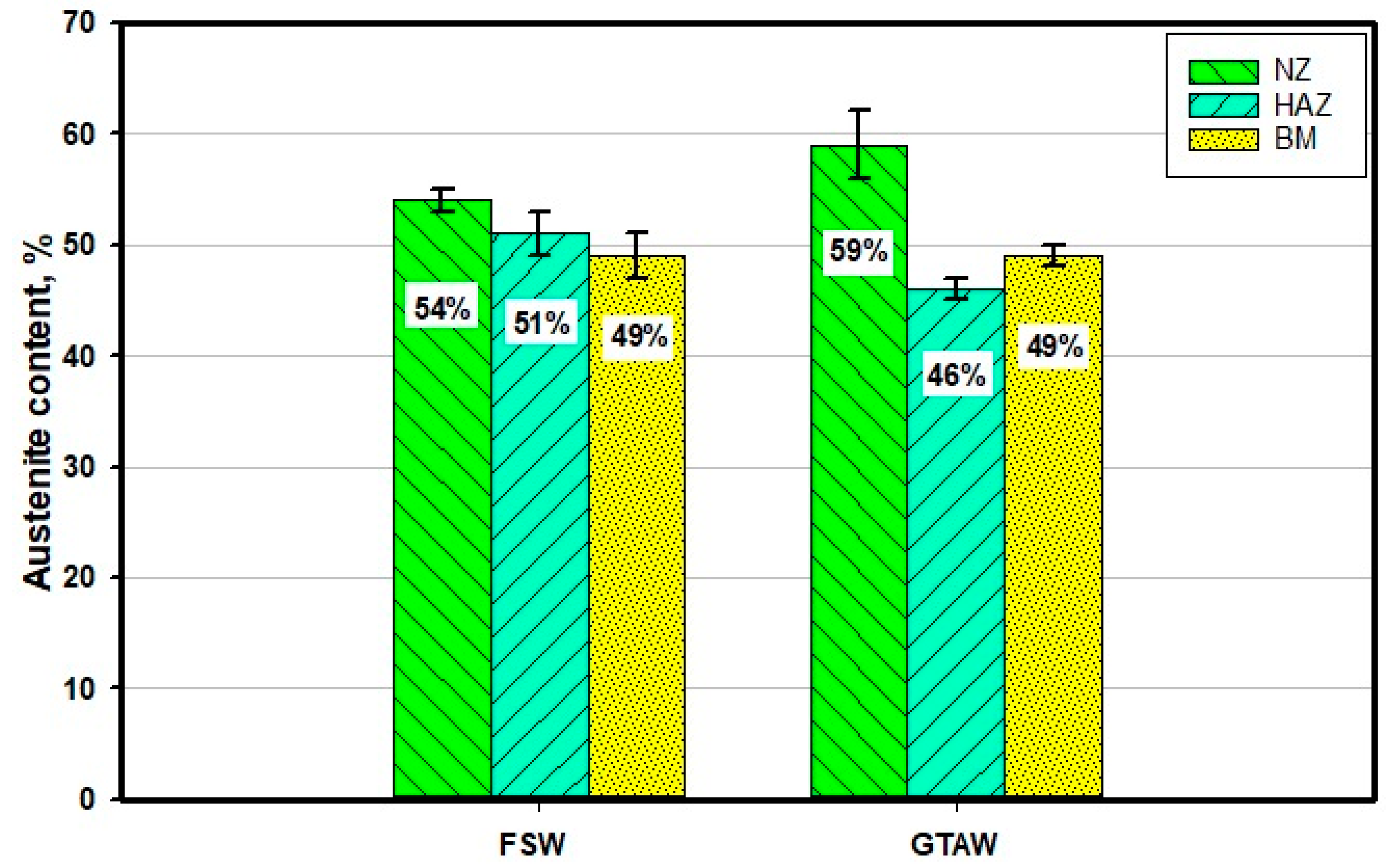

3.5. Measured Austenite Content

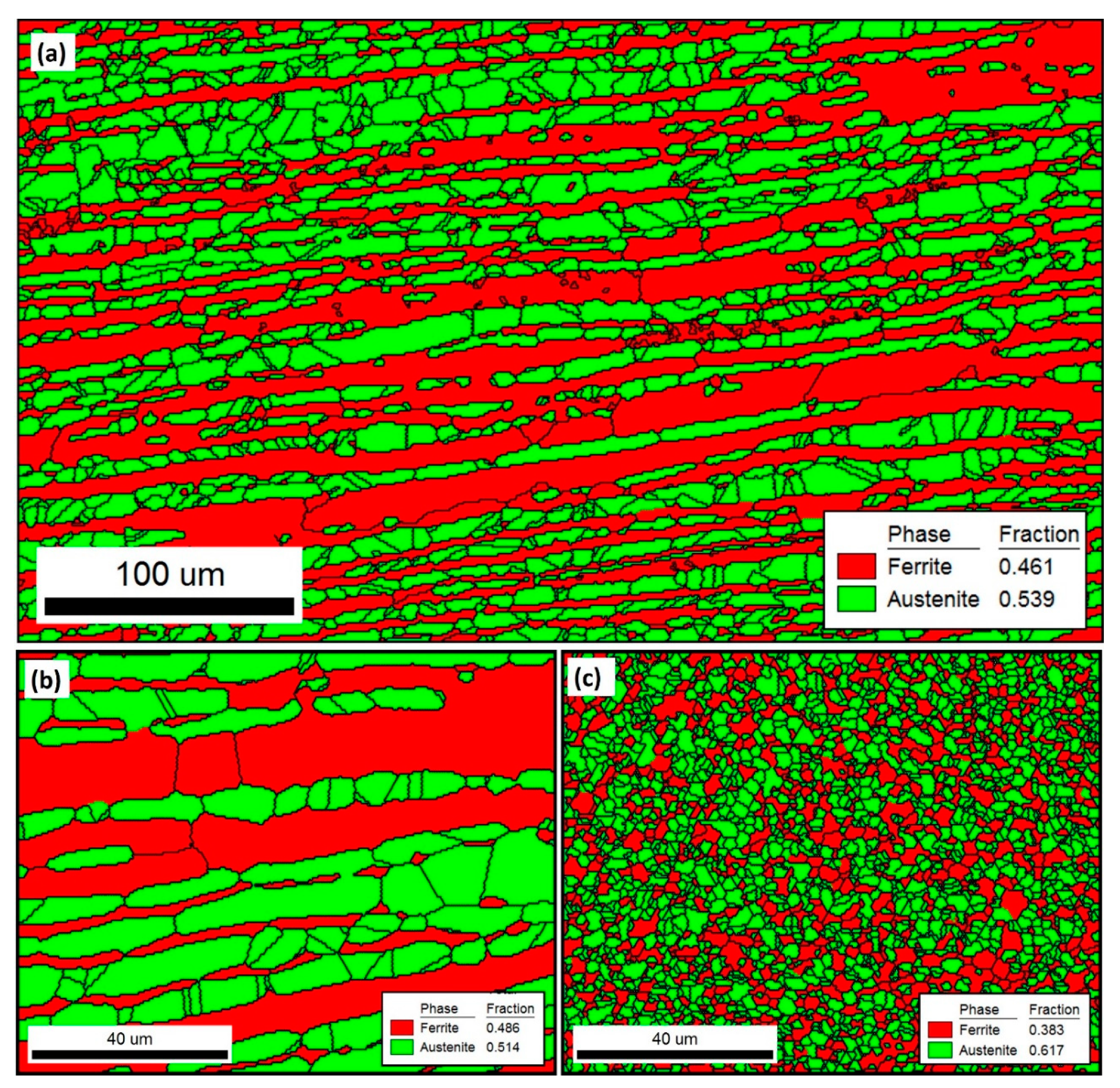

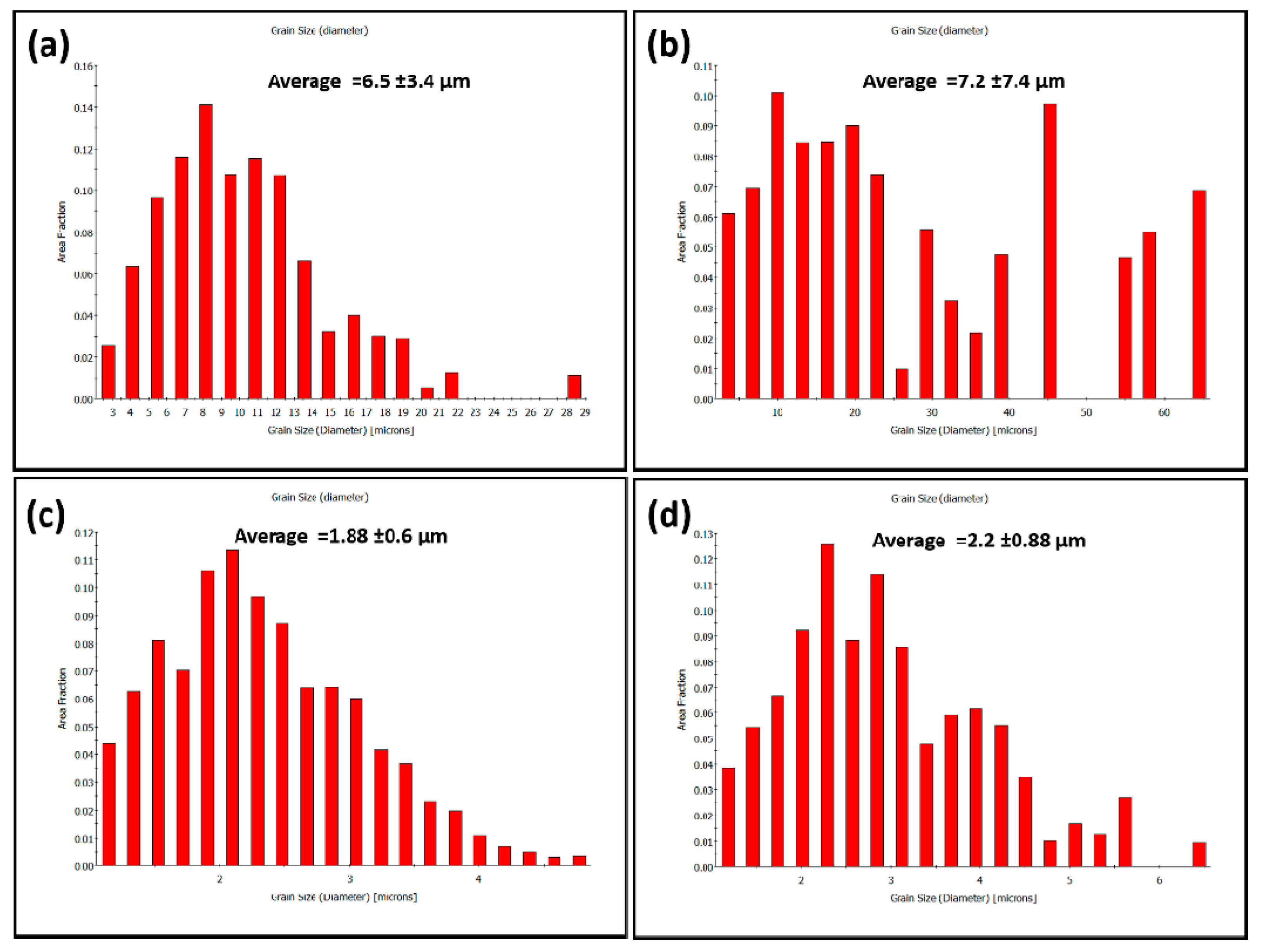

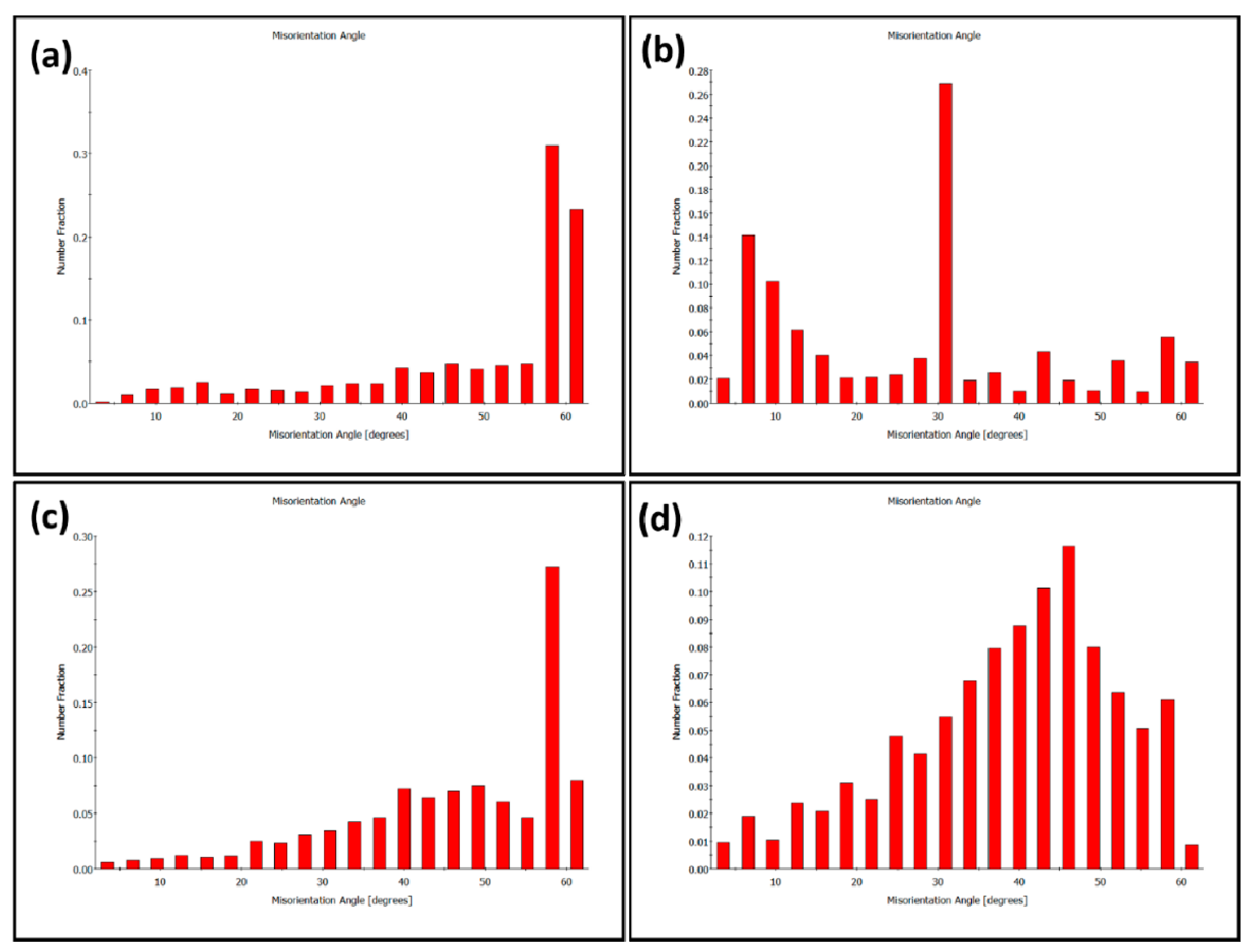

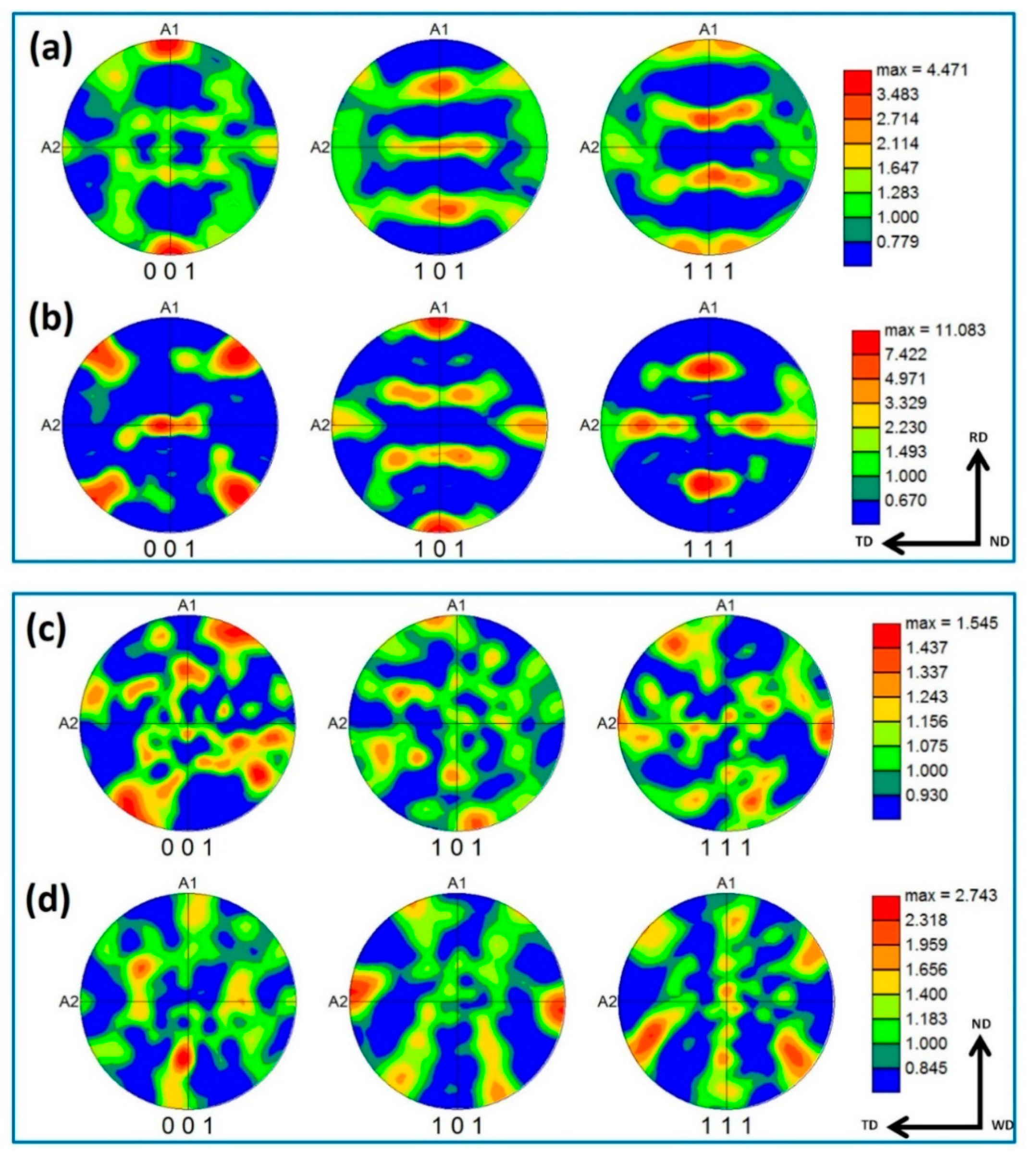

3.6. EBSD Investigation

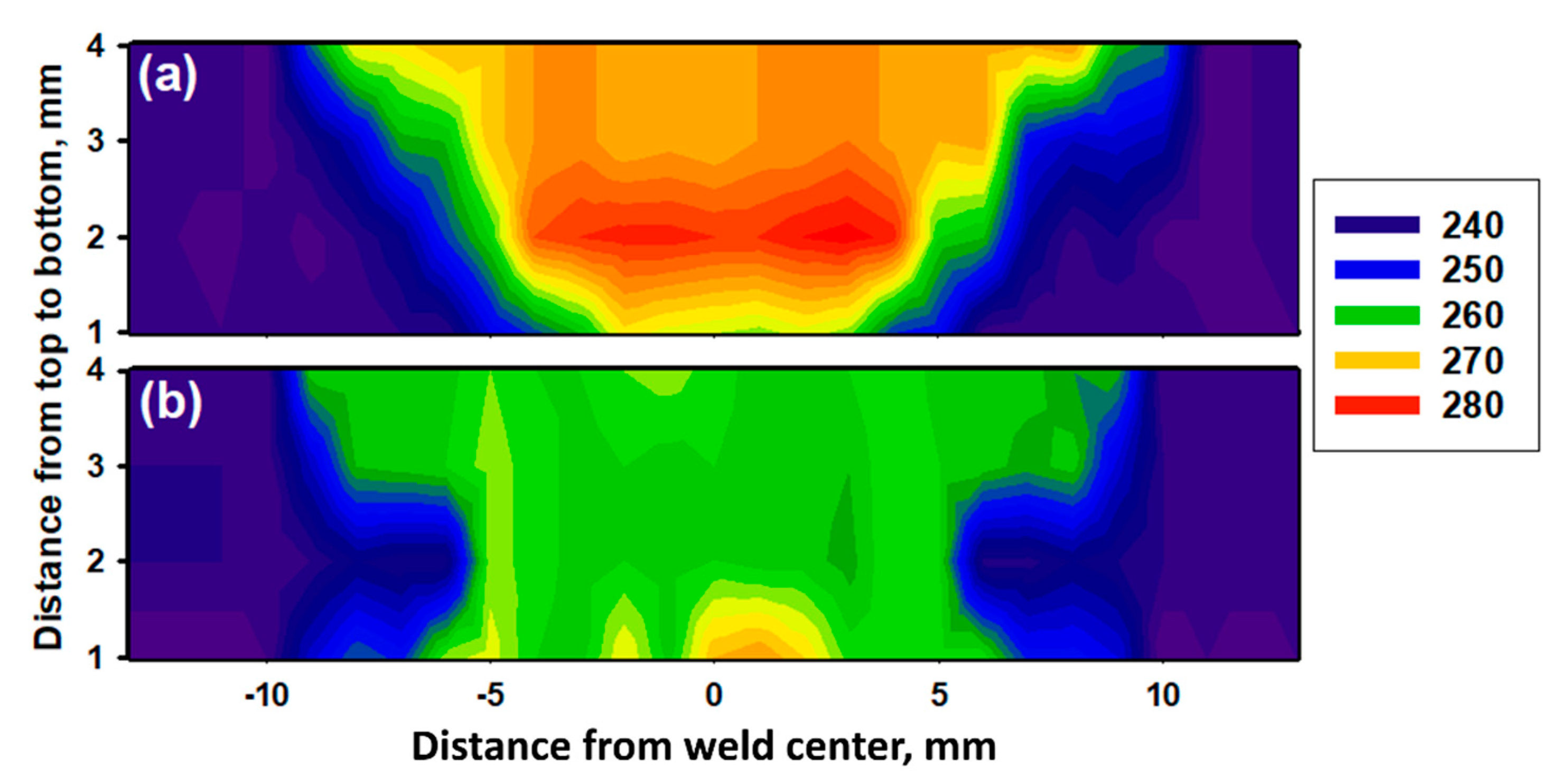

3.7. Hardness Distribution

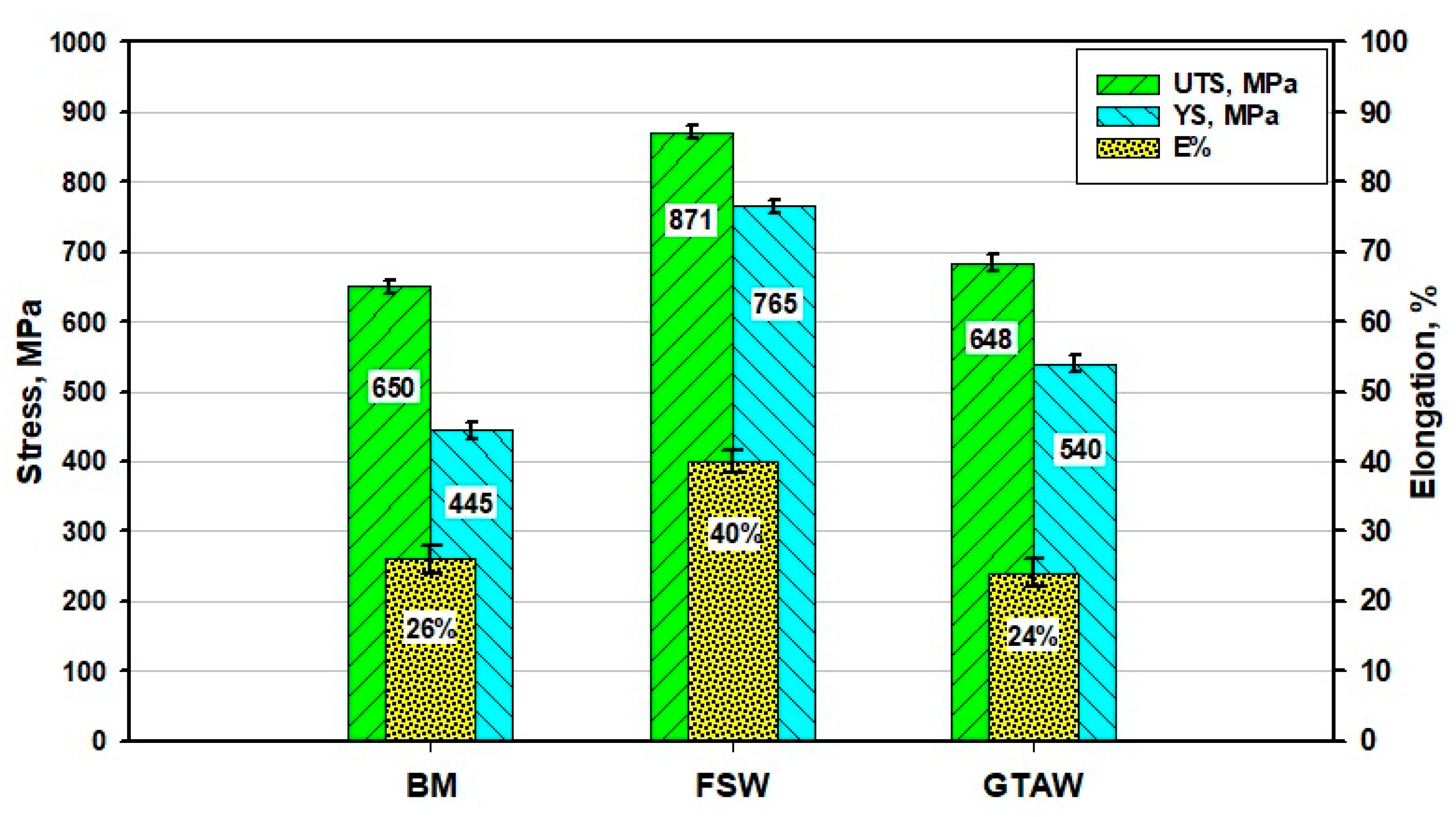

3.8. Tensile Properties

4. Conclusions

- The FSW used to weld 2205 DSS of 6.5 mm thick with groove filling is shown to be feasible.

- The optimum groove design to produce a sound joint with groove filling is the V-shaped with 60o groove angle and 2 mm root face.

- The use of the groove in the butt joint of DSS 2205 extended WC tool life due to the reduction in tool resistance forces during plunging and welding.

- The heat input and 2209 filler rod used in the GTAW process produce different γ-phase morphologies, such as GBA, IGA, and WA, besides the α phase in the WZ. In comparison, the friction stir weld has only two-phase microstructures: α and γ with significant grain refining.

- The α/γ ratio in the weld zone is influenced by welding techniques (solid-state welding and fusion welding) and their parameters in terms of welding temperature, joint groove design, and the presence or absence of filler rod. Compared with the BM that attains an α/γ ratio of 51/49, GTAW promotes a ratio of 41/59 while FSW produces a ratio of 44/56.

- Grain refining in the NG zone of the FSWed joint has been quantified to be 1.88 µm for austenite and 2.2 µm for ferrite from about 6.5 µm and 7.2 µm in the BM phases, respectively.

- Significant hardness improvements have been detected for the weld joint produced by FSW than that produced by GTAW.

- The FSWed 2205 DSS butt joint shows higher tensile properties than both BM and GTAWed joints. The Ys, UTS, and E% of the FSWed joint are enhanced over BM by 65%, 33%, and 54%, and over the GTAW weldment by 21%, 41%, and 66%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Chaudhari, A.N.; Dixit, K.; Bhatia, G.S.; Singh, B.; Singhal, P.; Saxena, K.K. Welding Behaviour of Duplex Stainless Steel AISI 2205: A Review. Mater. Today Proc. 2019, 18, 2731–2737. [Google Scholar] [CrossRef]

- Vinoth Jebaraj, A.; Ajaykumar, L.; Deepak, C.R.; Aditya, K.V.V. Weldability, Machinability and Surfacing of Commercial Duplex Stainless Steel AISI2205 for Marine Applications—A Recent Review. J. Adv. Res. 2017, 8, 183–199. [Google Scholar] [CrossRef]

- Verma, J.; Taiwade, R.V. Effect of Welding Processes and Conditions on the Microstructure, Mechanical Properties and Corrosion Resistance of Duplex Stainless Steel Weldments—A Review. J. Manuf. Process. 2017, 25, 134–152. [Google Scholar] [CrossRef]

- Rahimi, S.; Konkova, T.N.; Violatos, I.; Baker, T.N. Evolution of Microstructure and Crystallographic Texture During Dissimilar Friction Stir Welding of Duplex Stainless Steel to Low Carbon-Manganese Structural Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 664–687. [Google Scholar] [CrossRef] [Green Version]

- Shokri, V.; Sadeghi, A.; Sadeghi, M.H. Effect of Friction Stir Welding Parameters on Microstructure and Mechanical Properties of DSS–Cu Joints. Mater. Sci. Eng. A 2017, 693, 111–120. [Google Scholar] [CrossRef] [Green Version]

- Antony, P.J.; Singh Raman, R.K.; Kumar, P.; Raman, R. Corrosion of 2205 Duplex Stainless Steel Weldment in Chloride Medium Containing Sulfate-Reducing Bacteria. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 2689–2697. [Google Scholar] [CrossRef]

- Múnez, C.J.; Utrilla, M.V.; Ureña, A.; Otero, E. Influence of the Filler Material on Pitting Corrosion in Welded Duplex Stainless Steel 2205. Weld. Int. 2010, 24, 105–110. [Google Scholar] [CrossRef]

- Using, S.; Metallography, C. Duplex Stainless Steels Represent an Important and Expanding Class of Superior to Those of the 300-Series Austenitic Stainless Steels Such Property Combinations Have Led to an Increased Application of These Alloys Cations in Which Duplex Stainless. Current 1998, 225, 215–225. [Google Scholar]

- Muthupandi, V.; Bala Srinivasan, P.; Seshadri, S.K.; Sundaresan, S. Effect of Weld Metal Chemistry and Heat Input on the Structure and Properties of Duplex Stainless Steel Welds. Mater. Sci. Eng. A 2003, 358, 9–16. [Google Scholar] [CrossRef]

- Geng, S.; Sun, J.; Guo, L.; Wang, H. Evolution of Microstructure and Corrosion Behavior in 2205 Duplex Stainless Steel GTA-Welding Joint. J. Manuf. Process. 2015, 19, 32–37. [Google Scholar] [CrossRef]

- Devakumar, D.; Jabaraj, D.B.; Bupesh Raja, V.K.; Periyasamy, P. Characterization of Duplex Stainless Steel/Cold Reduced Low Carbon Steel Dissimilar Weld Joints by GTAW. Appl. Mech. Mater. 2015, 766, 780–788. [Google Scholar] [CrossRef]

- Magudeeswaran, G.; Nair, S.R.; Sundar, L.; Harikannan, N. Optimization of Process Parameters of the Activated Tungsten Inert Gas Welding for Aspect Ratio of UNS S32205 Duplex Stainless Steel Welds. Def. Technol. 2014, 10, 251–260. [Google Scholar] [CrossRef] [Green Version]

- Mourad, A.H.I.; Khourshid, A.; Sharef, T. Gas Tungsten Arc and Laser Beam Welding Processes Effects on Duplex Stainless Steel 2205 Properties. Mater. Sci. Eng. A 2012, 549, 105–113. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Singh, P.M. Stress Corrosion Cracking of Welded 2205 Duplex Stainless Steel in Sulfide-Containing Caustic Solution. J. Fail. Anal. Prev. 2007, 7, 371–377. [Google Scholar] [CrossRef]

- Emami, S.; Saeid, T.; Abdollah-zadeh, A. Effect of Friction Stir Welding Parameters on the Microstructure and Microtexture Evolution of SAF 2205 Stainless Steel. J. Alloys Compd. 2019, 810, 151797. [Google Scholar] [CrossRef]

- Emami, S.; Saeid, T.; Khosroshahi, R.A. Microstructural Evolution of Friction Stir Welded SAF 2205 Duplex Stainless Steel. J. Alloys Compd. 2018, 739, 678–689. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-zadeh, A.; Assadi, H.; Malek Ghaini, F. Effect of Friction Stir Welding Speed on the Microstructure and Mechanical Properties of a Duplex Stainless Steel. Mater. Sci. Eng. A 2008, 496, 262–268. [Google Scholar] [CrossRef]

- Gideon, B.; Ward, L.; Biddle, G. Duplex Stainless Steel Welds and Their Susceptibility to Intergranular Corrosion. J. Miner. Mater. Charact. Eng. 2008, 7, 247–263. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat Input and Mechanical Properties Investigation of Friction Stir Welded AA5083/AA5754 and AA5083/AA7020. Metals 2021, 11, 68. [Google Scholar] [CrossRef]

- Cui, L.; Fujii, H.; Nogi, K. Friction Stir Welding of a High Carbon Steel. Scr. Mater. 2007, 56, 637–640. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Rainforth, W.M.; Addison, A.; Martin, J.P.; Threadgill, P.L. Effect of Tool Geometry and Heat Input on the Hardness, Grain Structure, and Crystallographic Texture of Thick-Section Friction Stir-Welded Aluminium. Metall. Mater. Trans. A 2019, 50, 271–284. [Google Scholar] [CrossRef]

- Shazly, M.; Ahmed, M.M.Z.; El-Raey, M. Friction stir welding of polycarbonate sheets. In Characterization of Minerals, Metals, and Materials 2014; John Wiley& Sons: Hoboken, NJ, USA, 2014; ISBN 9781118887868. [Google Scholar]

- Ahmed, M.M.Z.; Seleman, M.M.E.S.; Shazly, M.; Attallah, M.M.; Ahmed, E. Microstructural Development and Mechanical Propertiesof Friction Stir Welded Ferritic Stainless Steel AISI 40. J. Mater. Eng. Perform. 2019, 28, 6391–6406. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; Martin, J.P. Effect of Friction Stir Welding Speed on Mechanical Properties and Microstructure of Nickel Based Super Alloy Inconel 718. Sci. Technol. Weld. Join. 2013, 18, 680–687. [Google Scholar] [CrossRef]

- Rai, R.; De, A.; Bhadeshia, H.K.D.H.; DebRoy, T. Review: Friction Stir Welding Tools. Sci. Technol. Weld. Join. 2011, 16, 325–342. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Barakat, W.S.; Mohamed, A.Y.A.; Alsaleh, N.A. The Development of WC-Based Composite Tools for Friction Stir Welding of High-Softening-Temperature Materials. Metals 2021, 11, 285. [Google Scholar] [CrossRef]

- Ragab, M.; Liu, H.; Yang, G.; Ahmed, M.M.Z. Applied Sciences Friction Stir Welding of 1Cr11Ni2W2MoV Martensitic Stainless Steel: Numerical Simulation Based on Coupled Eulerian Lagrangian Approach Supported with Experimental Work. Appl. Sci. 2021, 11, 3049. [Google Scholar] [CrossRef]

- Zhang, Y.; Sato, Y.S.; Kokawa, H.; Hwan, S.; Park, C.; Hirano, S. Stir Zone Microstructure of Commercial Purity Titanium Friction Stir Welded Using PcBN Tool. Mater. Sci. Eng. A 2008, 488, 25–30. [Google Scholar] [CrossRef]

- Tonelli, L.; Morri, A.; Toschi, S.; Shaaban, M.; Ammar, H.R.; Ahmed, M.M.Z.; Ramadan, R.M. Effect of FSP Parameters and Tool Geometry on Microstructure, Hardness, and Wear Properties of AA7075 with and without Reinforcing B 4 C Ceramic Particles. Int. J. Adv. Manuf. Technol. 2019, 102, 3945–3961. [Google Scholar] [CrossRef]

- Bakkar, A.; Ahmed, M.M.Z.; Alsaleh, N.A.; Seleman, M.M.E.; Ataya, S. Microstructure, Wear, and Corrosion Characterization of High TiC Content Inconel 625 Matrix Composites. J. Mater. Res. Technol. 2019, 8, 1102–1110. [Google Scholar] [CrossRef]

- Janeczek, A. The Influence of Tool Shape and Process Parameters on the Mechanical Properties of AW-3004 Aluminium Alloy Friction Stir Welded Joints. Materials 2021, 14, 3244. [Google Scholar] [CrossRef]

- Zhang, R.; Buchanan, C.; Matilainen, V.; Daskalaki-mountanou, D.; Britton, T.B.; Piili, H.; Salminen, A.; Gardner, L. Mechanical Properties and Microstructure of Additively Manufactured Stainless Steel with Laser Welded Joints. Mater. Des. 2021, 208, 109921. [Google Scholar] [CrossRef]

- Abdelazem, K.A.; El-aziz, H.M.A.; Ahmed, M.M.Z. Characterization of Mechanical Properties and Corrosion Resistance of SAF 2205 Duplex Stainless Steel Groove Joints Welded Using Friction Stir Welding Process. Int. J. Recent Technol. Eng. 2020, 8, 3428–3435. [Google Scholar] [CrossRef]

- Trinh, D.; Frappart, S.; Rückert, G.; Cortial, F.; Touzain, S. Effect of Friction Stir Welding Process on Microstructural Characteristics and Corrosion Properties of Steels for Naval Applications. Corros. Eng. Sci. Technol. 2019, 54, 353–361. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welded AA2024-T4/AA7075-T6 T-Butt Joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Moreira, P.M.G.P.; Santos, T.; Tavares, S.M.O.; Richter-Trummer, V.; Vilaça, P.; de Castro, P.M.S.T. Mechanical and Metallurgical Characterization of Friction Stir Welding Joints of AA6061-T6 with AA6082-T6. Mater. Des. 2009, 30, 180–187. [Google Scholar] [CrossRef]

- Balaram Naik, A.; Chennakesava Reddy, A. Macro and Microstructure Evaluation of TIG Weld on DSS (2304) with Bead Geometry at Three Positions. Mater. Today Proc. 2020, in press. [Google Scholar] [CrossRef]

- Ghadar, S.; Momeni, A.; Khademi, E.; Kazemi, S. Effect of Rotation and Traverse Speeds on the Microstructure and Mechanical Properties of Friction Stir Processed 2205 Duplex Stainless Steel. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 263, 114813. [Google Scholar] [CrossRef]

- Hamada, A.S.; Järvenpää, A.; Ahmed, M.M.Z.; Jaskari, M.; Wynne, B.P.; Porter, D.A.; Karjalainen, L.P. The Microstructural Evolution of Friction Stir Welded AA6082-T6 Aluminum Alloy during Cyclic Deformation. Mater. Sci. Eng. A 2015, 642, 366–376. [Google Scholar] [CrossRef]

- El-Mahallawi, I.; Ahmed, M.M.Z.; Mahdy, A.A.; Abdelmotagaly, A.M.M.; Hoziefa, W.; Refat, M. Effect of Heat Treatment on Friction-Stir-Processed Nanodispersed AA7075 and 2024 Al Alloys. In Friction Stir Welding and Processing IX; The Minerals, Metals & Materials Series; Hovanski, Y., Mishra, R., Sato, Y., Upadhyay, P., Yan, D., Eds.; Springer: Cham, Switzerland, 2017; pp. 297–309. [Google Scholar] [CrossRef]

- Makhdoom, M.A.; Ahmad, A.; Kamran, M.; Abid, K.; Haider, W. Microstructural and Electrochemical Behavior of 2205 Duplex Stainless Steel Weldments. Surf. Interfaces 2017, 9, 189–195. [Google Scholar] [CrossRef]

- Xie, X.F.; Li, J.; Jiang, W.; Dong, Z.; Tu, S.T.; Zhai, X.; Zhao, X. Nonhomogeneous Microstructure Formation and Its Role on Tensile and Fatigue Performance of Duplex Stainless Steel 2205 Multi-Pass Weld Joints. Mater. Sci. Eng. A 2020, 786, 139426. [Google Scholar] [CrossRef]

- Eghlimi, A.; Shamanian, M.; Raeissi, K. Effect of Current Type on Microstructure and Corrosion Resistance of Super Duplex Stainless Steel Claddings Produced by the Gas Tungsten Arc Welding Process. Surf. Coat. Technol. 2014, 244, 45–51. [Google Scholar] [CrossRef]

- Ramirez, A.J.; Lippold, J.C.; Brandi, S.D. The Relationship between Chromium Nitride and Secondary Austenite Precipitation in Duplex Stainless Steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2003, 34, 1575–1597. [Google Scholar] [CrossRef]

- Luo, J.; Yuan, Y.; Wang, X.; Yao, Z. Double-Sided Single-Pass Submerged Arc Welding for 2205 Duplex Stainless Steel. J. Mater. Eng. Perform. 2013, 22, 2477–2486. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, P.; Pan, J.; Tan, L.; Zhu, K. Investigation on Microstructure and Mechanical Properties of Double-Sided Synchronous TIP TIG Arc Butt Welded Duplex Stainless Steel. Int. J. Adv. Manuf. Technol. 2021, 112, 303–312. [Google Scholar] [CrossRef]

- Calliari, I.; Breda, M.; Gennari, C.; Pezzato, L.; Pellizzari, M.; Zambon, A. Investigation on Solid-State Phase Transformations in a 2510 Duplex Stainless Steel Grade. Metals 2020, 10, 967. [Google Scholar] [CrossRef]

- Zayed, E.M.; El-Tayeb, N.S.M.; Ahmed, M.M.Z.; Rashad, R.M. Development and Characterization of AA5083 Reinforced with SiC and Al2O3 Particles by Friction Stir Processing; Springer International Publishing: New York, NY, USA, 2019; Volume 92. [Google Scholar]

- Wang, W.; Hu, Y.; Zhang, M.; Zhao, H. Microstructure and Mechanical Properties of Dissimilar Friction Stir Welds in Austenitic-Duplex Stainless Steels. Mater. Sci. Eng. A 2020, 787, 139477. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Wynne, B.P.; El-Sayed Seleman, M.M.; Rainforth, W.M. A Comparison of Crystallographic Texture and Grain Structure Development in Aluminum Generated by Friction Stir Welding and High Strain Torsion. Mater. Des. 2016, 103, 259–267. [Google Scholar] [CrossRef]

- Santos, T.F.A.; Idagawa, H.S.; Ramirez, A.J. Thermal History in UNS S32205 Duplex Stainless Steel Friction Stir Welds. Sci. Technol. Weld. Join. 2014, 19, 150–156. [Google Scholar] [CrossRef]

- Nowacki, J.; Łukojć, A. Structure and Properties of the Heat-Affected Zone of Duplex Steels Welded Joints. J. Mater. Process. Technol. 2005, 164, 1074–1081. [Google Scholar] [CrossRef]

- Sorger, G.; Sarikka, T.; Vilaça, P.; Santos, T.G. Effect of Processing Temperatures on the Properties of a High-Strength Steel Welded by FSW. Weld. World 2018, 62, 1173–1185. [Google Scholar] [CrossRef] [Green Version]

| Cr | Ni | Mo | Mn | Si | N | C | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 22.43 | 5.74 | 3.15 | 1.51 | 0.38 | 0.17 | 0.015 | 0.025 | 0.001 | Bal. |

| Cr | Ni | Mo | Mn | Si | N | C | P | S | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| 22.10 | 9.42 | 3.03 | 0.76 | 0.86 | 0.14 | 0.022 | 0.015 | 0.016 | 0.05 | Bal. |

| Pass | Filler rod | Ampere (A) | Volt (V) | Travel Speed (mm/min) | Heat Input (kJ/mm) |

|---|---|---|---|---|---|

| 1st | ER2209 | 116 | 10 | 90 | 0.733 |

| 2nd | 159 | 13 | 90 | 1.378 | |

| 3rd | 155 | 13.5 | 81 | 1.550 | |

| Cap1 | 150 | 14.5 | 76 | 1.717 | |

| Cap2 | 116 | 10 | 135 | 0.516 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; Abdelazem, K.A.; El-Sayed Seleman, M.M.; Alzahrani, B.; Touileb, K.; Jouini, N.; El-Batanony, I.G.; Abd El-Aziz, H.M. Friction Stir Welding of 2205 Duplex Stainless Steel: Feasibility of Butt Joint Groove Filling in Comparison to Gas Tungsten Arc Welding. Materials 2021, 14, 4597. https://doi.org/10.3390/ma14164597

Ahmed MMZ, Abdelazem KA, El-Sayed Seleman MM, Alzahrani B, Touileb K, Jouini N, El-Batanony IG, Abd El-Aziz HM. Friction Stir Welding of 2205 Duplex Stainless Steel: Feasibility of Butt Joint Groove Filling in Comparison to Gas Tungsten Arc Welding. Materials. 2021; 14(16):4597. https://doi.org/10.3390/ma14164597

Chicago/Turabian StyleAhmed, Mohamed M. Z., Khaled A. Abdelazem, Mohamed M. El-Sayed Seleman, Bandar Alzahrani, Kamel Touileb, Nabil Jouini, Ismail G. El-Batanony, and Hussein M. Abd El-Aziz. 2021. "Friction Stir Welding of 2205 Duplex Stainless Steel: Feasibility of Butt Joint Groove Filling in Comparison to Gas Tungsten Arc Welding" Materials 14, no. 16: 4597. https://doi.org/10.3390/ma14164597

APA StyleAhmed, M. M. Z., Abdelazem, K. A., El-Sayed Seleman, M. M., Alzahrani, B., Touileb, K., Jouini, N., El-Batanony, I. G., & Abd El-Aziz, H. M. (2021). Friction Stir Welding of 2205 Duplex Stainless Steel: Feasibility of Butt Joint Groove Filling in Comparison to Gas Tungsten Arc Welding. Materials, 14(16), 4597. https://doi.org/10.3390/ma14164597