Optical Isomerization and Photo-Patternable Properties of GeO2/Ormosils Organic-Inorganic Composite Films Doped with Azobenzene

Abstract

:1. Introduction

2. Materials and Methods

2.1. Film Preparations

2.2. Patterned Film by UV Imprint Technique

2.3. Sample Characterizations

3. Results and Discussion

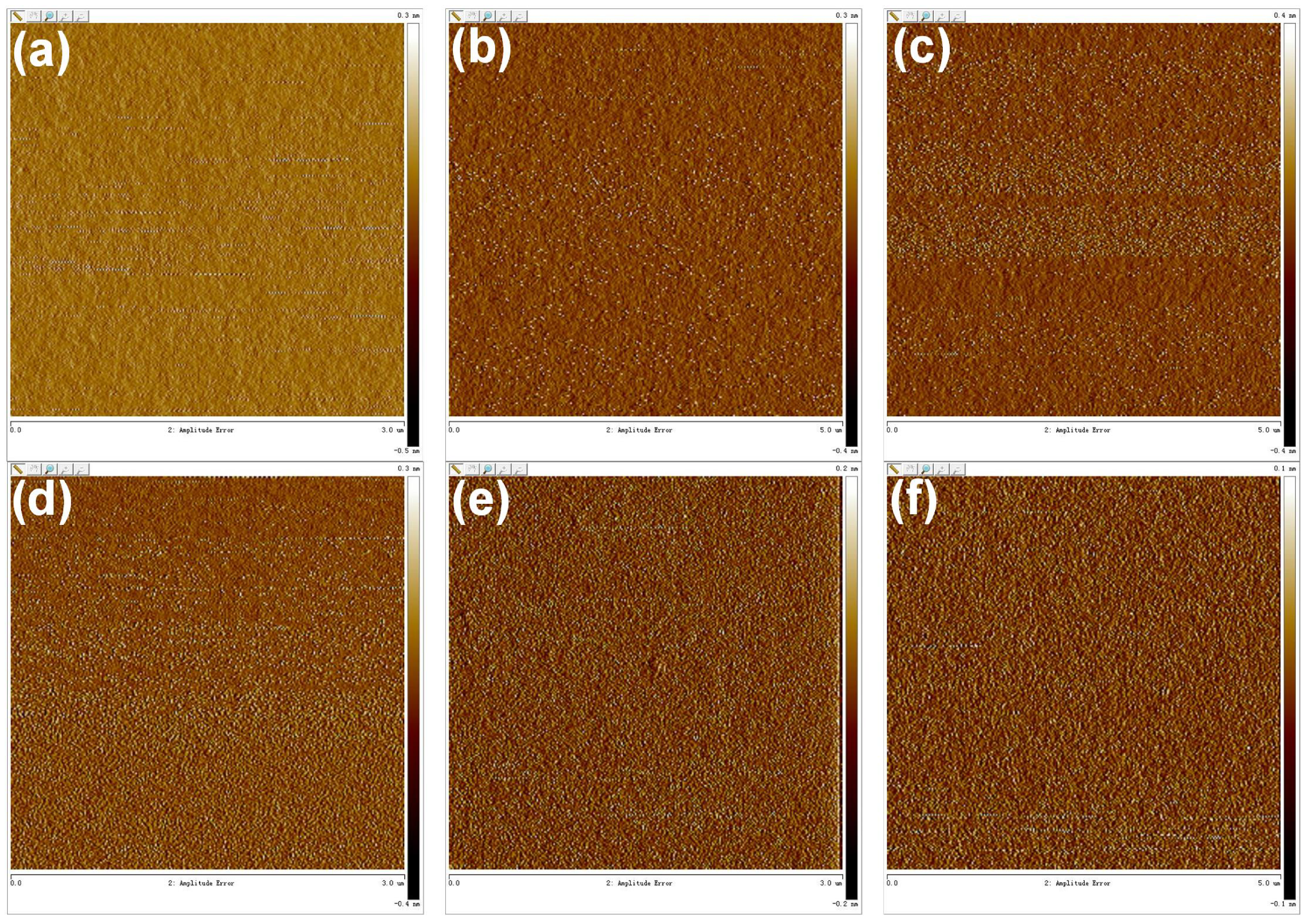

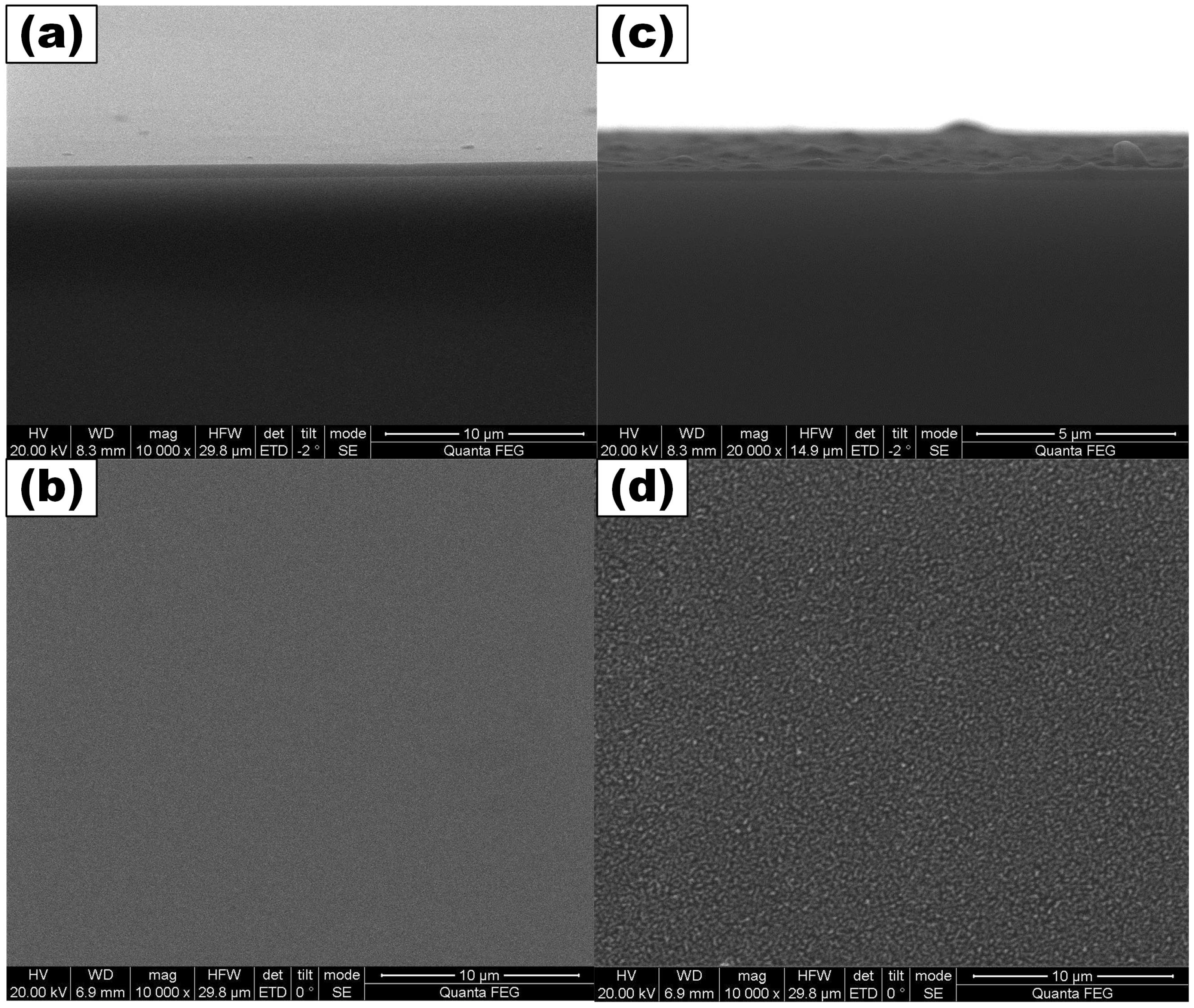

3.1. Surface Topography Characteristics

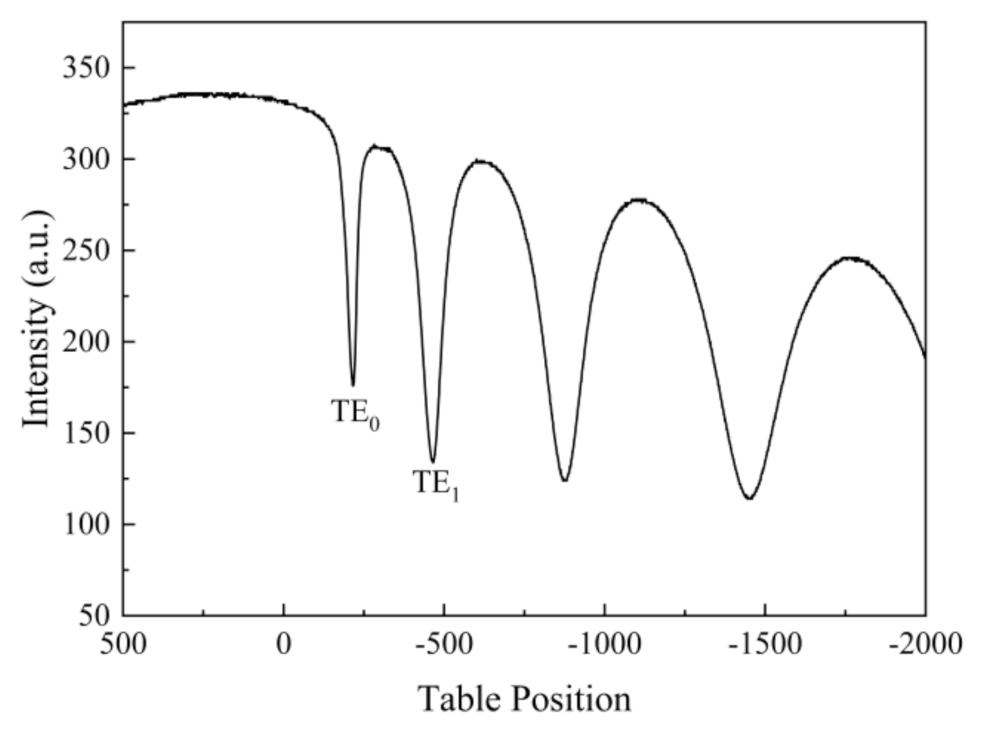

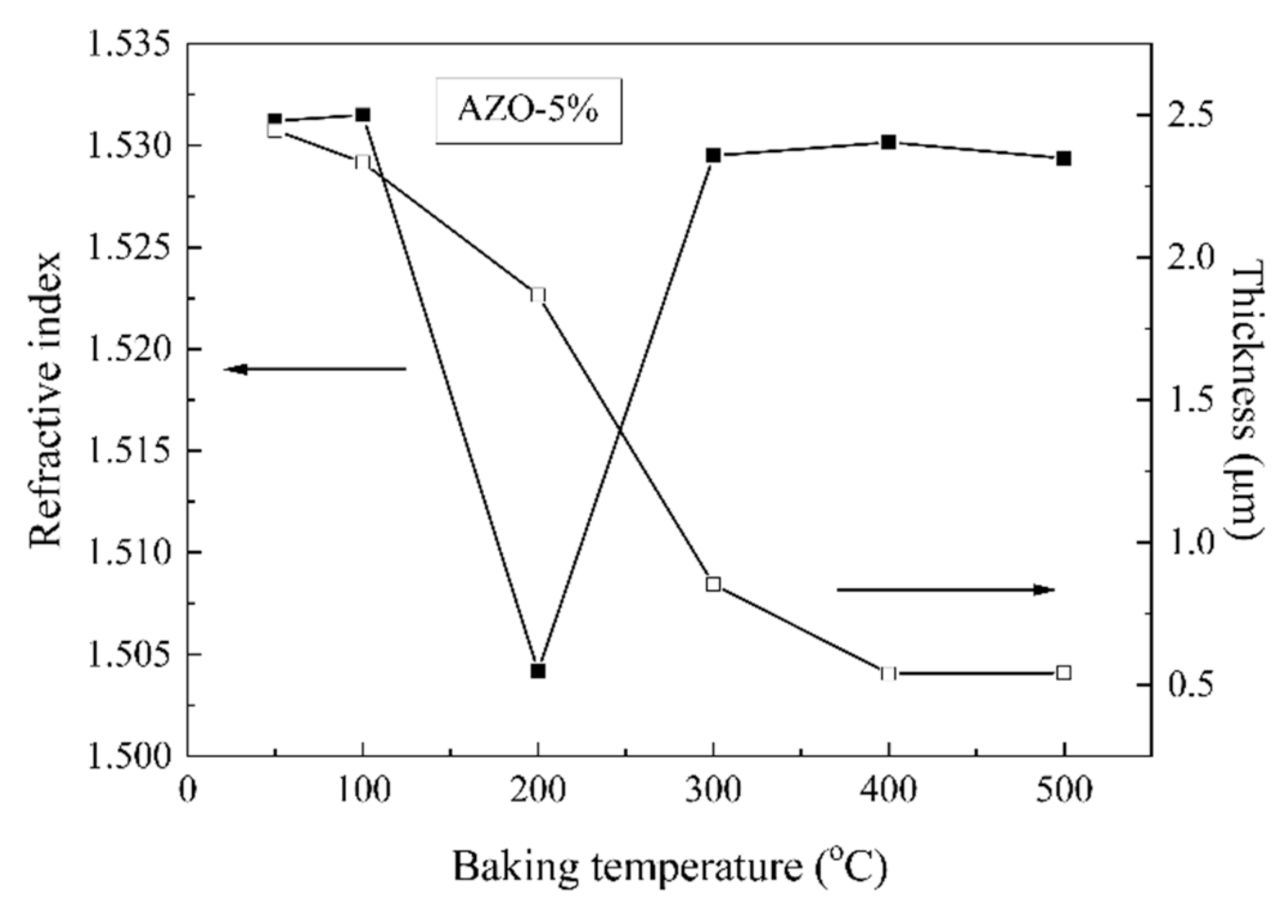

3.2. Optical Waveguide Characteristics

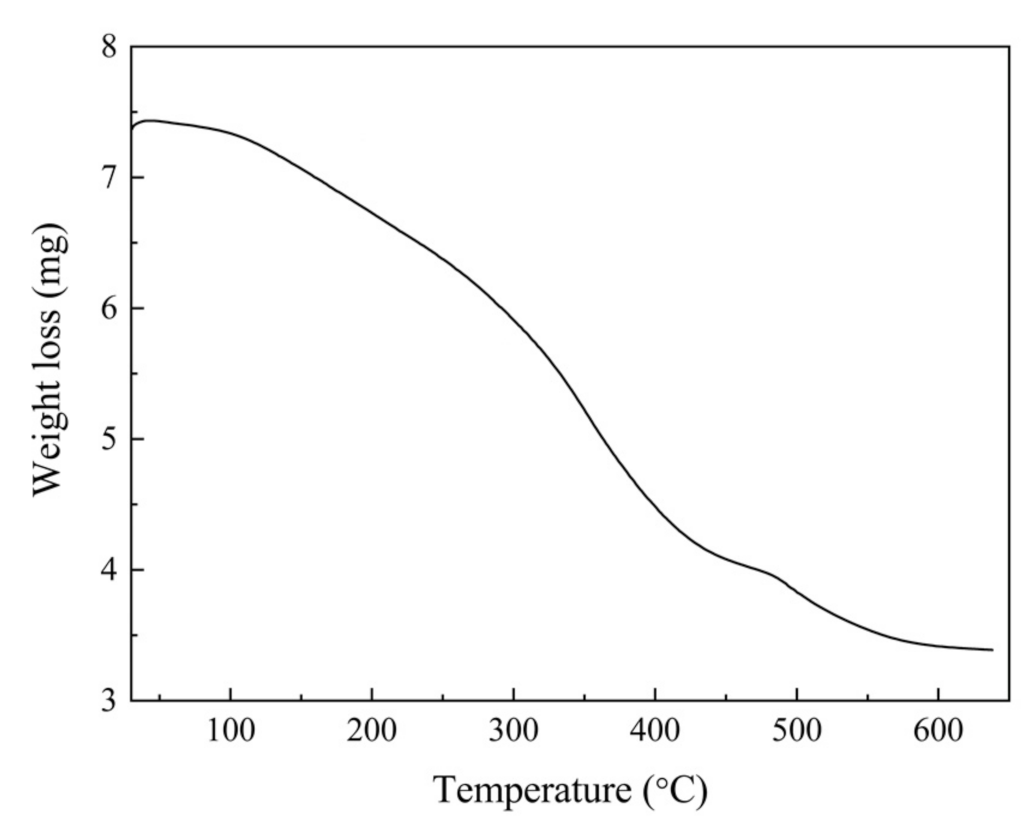

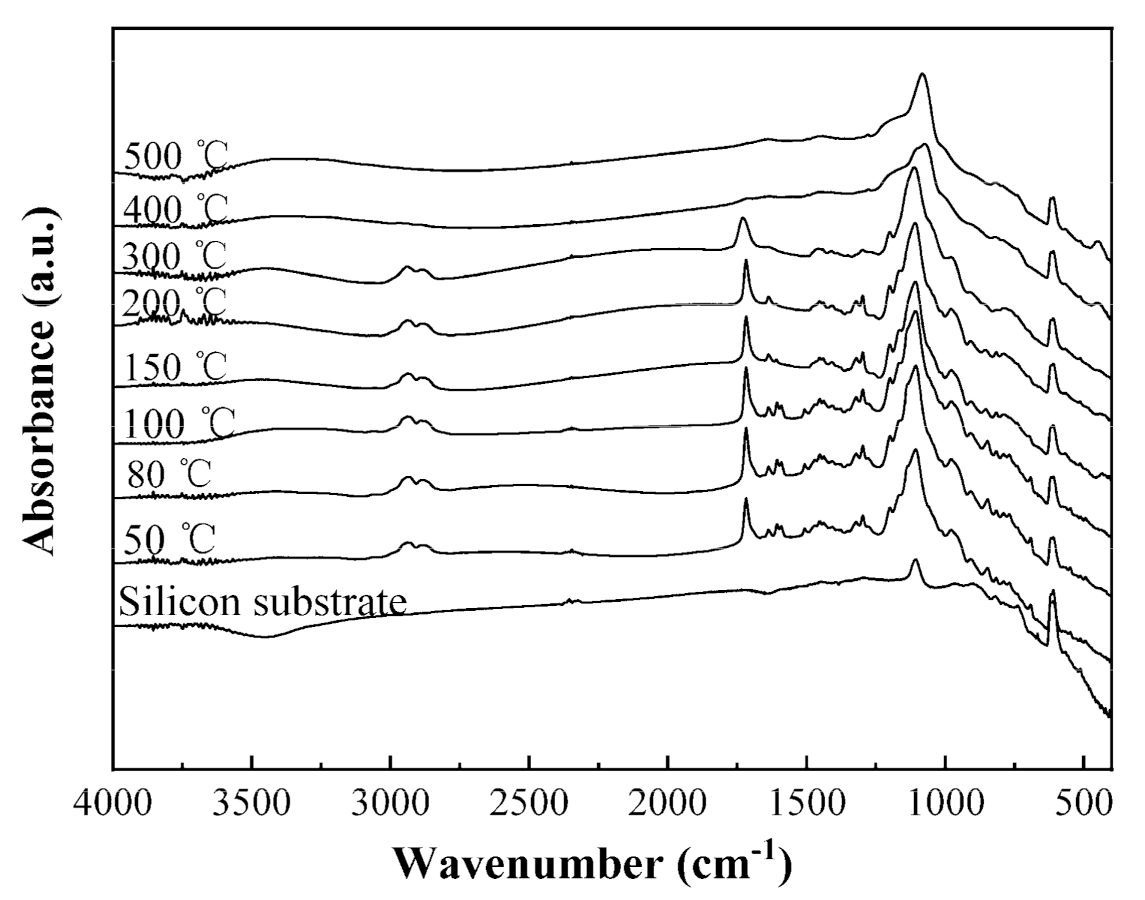

3.3. Structural Characteristics

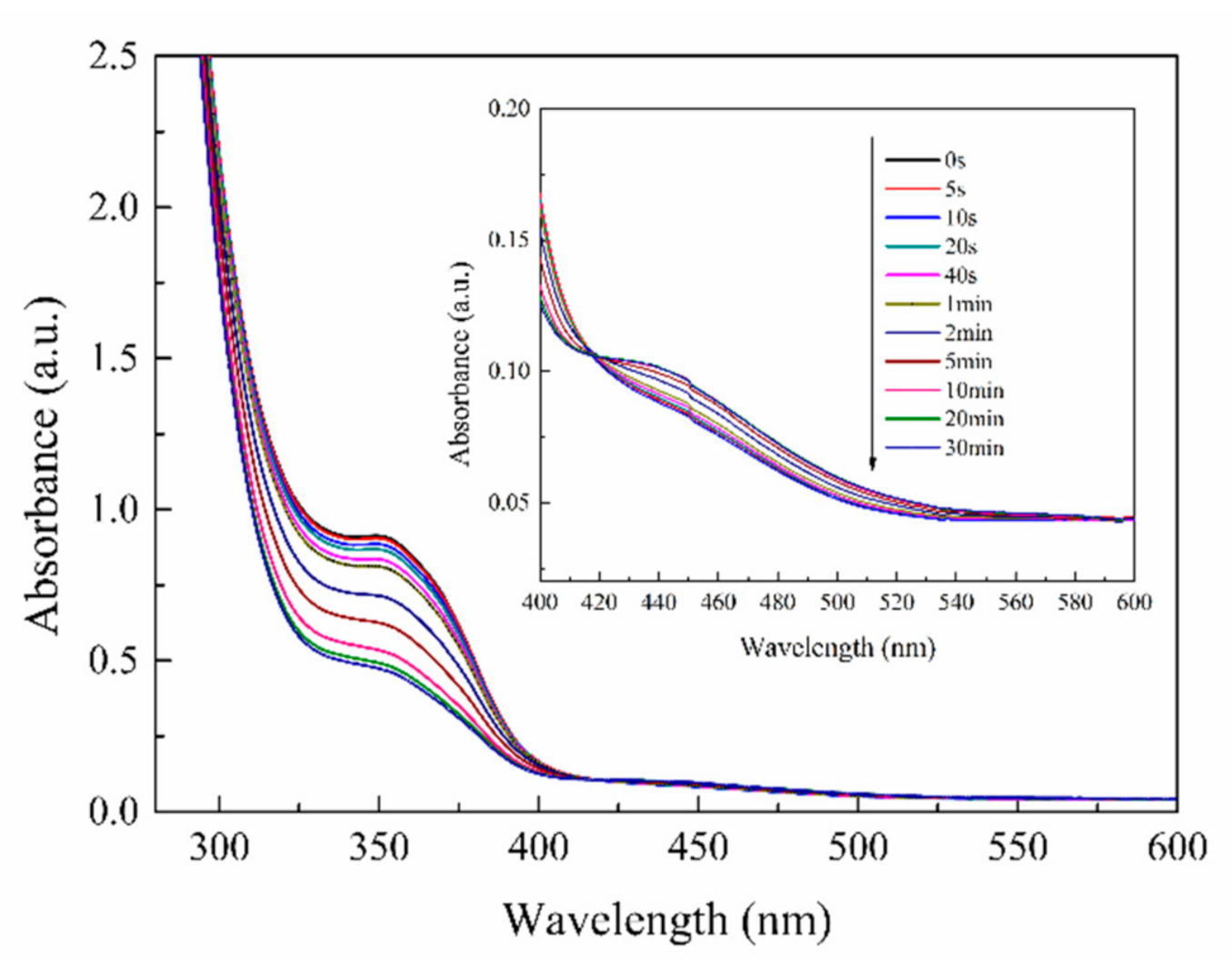

3.4. Photo-Isomerization Properties

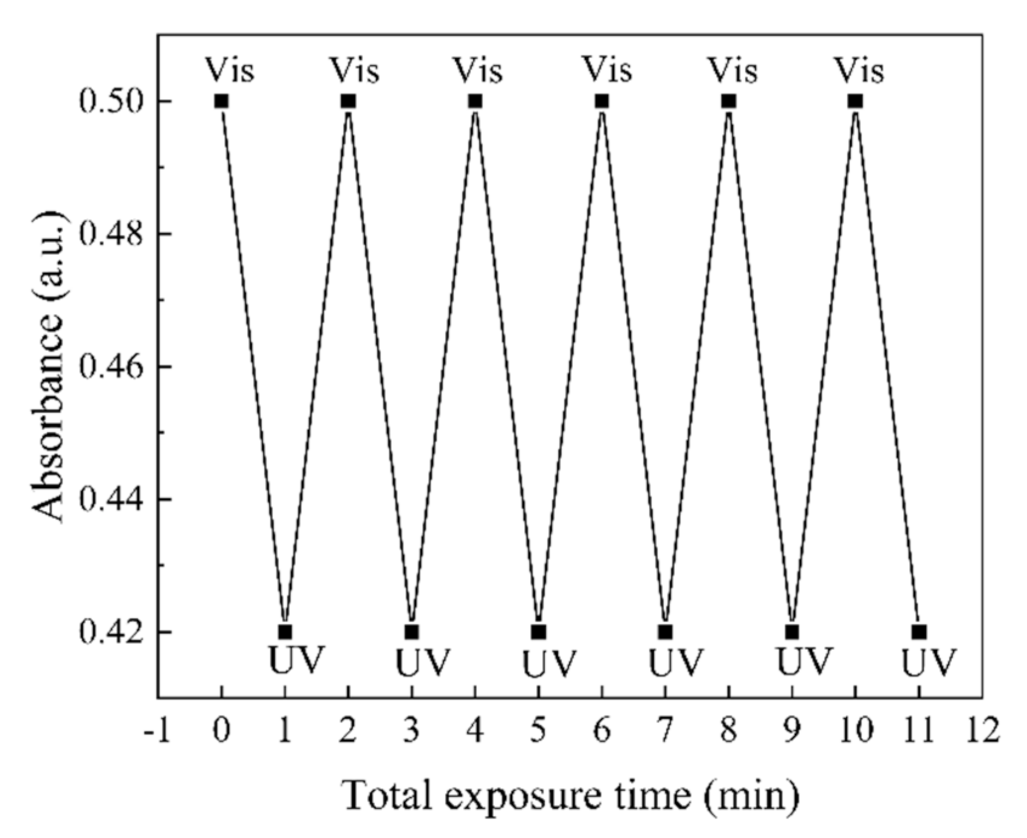

3.5. Optical Switch Performance

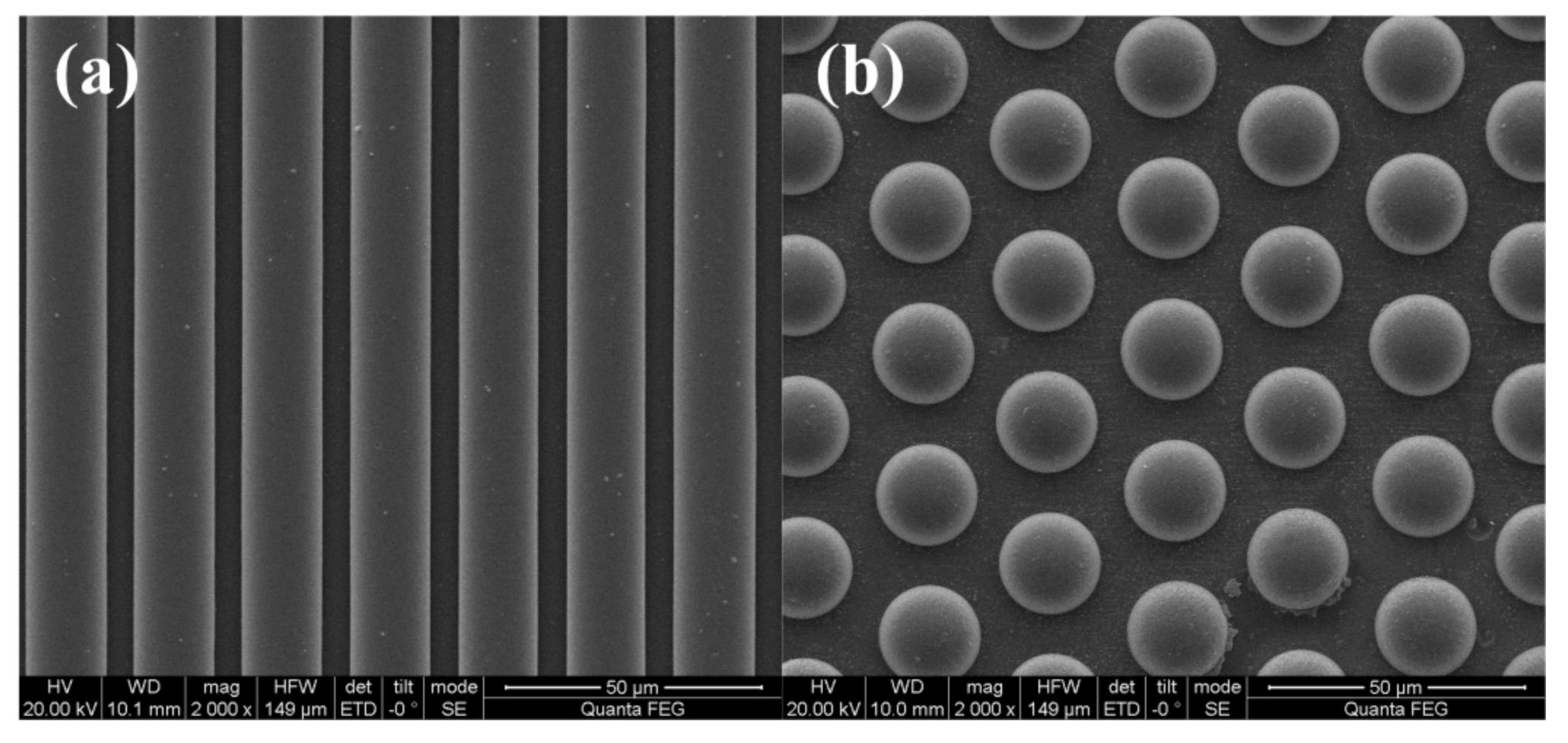

3.6. Surface Morphology of the Patterned Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marcaud, G.; Serna, S.; Panaghiotis, K. Third-order nonlinear optical susceptibility of crystalline oxide yttria-stabilized zirconia. Photonics Res. 2020, 8, 110–120. [Google Scholar] [CrossRef]

- Gustavo, G.; Michael, P.N.; Paul, D.; Yi, L.; Rupert, F.O.; Stefan, A.M. Ultrafast sub–30-fs all-optical switching based on gallium phosphide. Sci. Adv. 2019, 5, eaaw3262. [Google Scholar]

- Nguyen, D.T.; Freitag, M.; Gutheil, C.; Sotthewes, K.; Tyler, B.J.; Böckmann, M.; Das, M.; Schlüter, F.; Doltsinis, N.L.; Arlinghaus, H.F.; et al. An Arylazopyrazole Based N-Heterocyclic Carbene as a Photoswitch on Gold Surfaces: Light-Switchable Wettability, Work Function, and Conductance. Angew. Chem. Int. Ed. 2020, 59, 13651–13656. [Google Scholar] [CrossRef] [PubMed]

- Wu, K.; Sun, J.; Ma, Y.Z.; Wei, D.; Lee, O.; Luo, H.R.; Fan, H.S. Spatiotemporal regulation of dynamic cell microenvironment signals based on an azobenzene photoswitch. J. Mater. Chem. B 2020, 8, 9212–9226. [Google Scholar] [CrossRef] [PubMed]

- Kellner, S.; Berlin, S. Two-Photon Excitation of Azobenzene Photoswitches for Synthetic Optogenetics. Appl. Sci. 2020, 10, 805. [Google Scholar] [CrossRef] [Green Version]

- Ochi, R.; Perur, N.; Yoshida, K.; Nobuyuki, T. Fast thermal cis-trans isomerization depending on pH and metal ions of water-soluble azobenzene derivatives containing a phosphate group. Tetrahedron 2015, 71, 3500–3506. [Google Scholar] [CrossRef]

- Ludwanowski, S.; Ari, M.; Parison, K.; Kalthoum, S.; Straub, P.; Pompe, N.; Weber, S.; Walter, P.D.; Walther, A. pH Tuning of Water-Soluble Arylazopyrazole Photoswitches. Chem. Eur. J. 2020, 26, 13203–13212. [Google Scholar] [CrossRef]

- Pang, J.; Kong, J.Y.; Xu, J.L.; Mao, X.C.; Hu, X.H. Synthesis and Investigation of Macromolecular Photoswitches. Front. Mater. 2020, 7, 120. [Google Scholar] [CrossRef]

- Fitz, J.; Mammana, A. Spectroscopic study of the pH dependence of the optical properties of a water-soluble molecular photo-switch. Spectrochim. Acta A 2020, 227, 117576. [Google Scholar] [CrossRef] [PubMed]

- Paterno, G.M.; Colombo, E.; Vurro, V.; Lodola, F.; Cimò, S.; Sesti, V.; Molotokaite, E.; Bramini, M.; Ganzer, L.; Fazzi, D.; et al. Membrane Environment Enables Ultrafast Isomerization of Amphiphilic Azobenzene. Adv. Sci. 2020, 7, 1903241. [Google Scholar] [CrossRef]

- Gindre, D.; Boeglin, A.; Fort, A.; Mager, L.; Dorkenoo, K.D. Rewritable optical data storage in azobenzene copolymers. Opt. Express 2006, 14, 9896–9901. [Google Scholar] [CrossRef]

- Kondo, M.; Sugimoto, M.; Yamada, M.; Naka, Y.; Mamiya, J.; Kinoshita, M.; Shishido, A.; Yu, Y.L.; Ikeda, T. Effect of concentration of photoactive chromophores on photomechanical properties of crosslinked azobenzene liquid-crystalline polymers. J. Mater. Chem. 2010, 20, 117–122. [Google Scholar] [CrossRef]

- Tang, Q.; Gong, C.B.; Lam, M.H.; Fu, X.K. Photoregulated uptake and release of drug by an organic-inorganic composite sol-gel material. J. Sol-Gel Sci. Technol. 2011, 59, 495–504. [Google Scholar] [CrossRef]

- Que, W.X.; Sun, Z.; Wang, L.L.; Chen, T. Photo-isomerization properties and heating-induced surface relief patterns from azobenzene-doped GeO2/gamma-glycidoxypropyltrimethoxy-silane organic-inorganic composite films. Opt. Express 2007, 15, 6868–6873. [Google Scholar] [CrossRef] [PubMed]

- Wankar, S.; Pandit, U.J.; Khan, I. Composite material derived via embedding ternary lanthanide complexes in inorganic/organic matrix. J. Lumin. 2019, 215, 116705. [Google Scholar] [CrossRef]

- Pianowski, Z.L. Recent implementations of molecular photoswitches into smart materials and biological systems. Chem. Eur. J. 2019, 25, 5128–5144. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Dokhanian, M.; Kassu, A.; Parekh, A.N. Photoinduced grating formation in azo-dye-labeled phospholipids thin film by 244-nm light. Opt. Lett. 2005, 30, 501–503. [Google Scholar] [CrossRef]

- Zelenyak, T.Y.; Rakhmonov, K.R.; Kholmurodov, K.T.; Gladyshev, P.P.; Tameev, A.R. Comparative Characterization of Relaxed Organic-Inorganic Composite Perovskite Structures Using Molecular Dynamic Simulation and X-ray Diffraction Data. High Energy Chem. 2018, 52, 433–439. [Google Scholar] [CrossRef]

- Innocenzi, P.; Kidchob, T.; Yoko, T. Composite organic-inorganic sol-gel materials based on epoxy-amine systems. J. Sol-Gel Sci. Technol. 2005, 35, 225–235. [Google Scholar] [CrossRef]

- El Hadad, A.A.; Barranco, V.; Jimenez-Morales, A.; Peón, E.; Hickman, G.J.; Perry, C.C.; Galván, J.C. Enhancing in vitro biocompatibility and corrosion protection of organic-inorganic composite sol-gel films with nanocrystalline hydroxyapatite. J. Mater. Chem. B 2014, 2, 3886–3896. [Google Scholar] [CrossRef] [Green Version]

- Parola, S.; Julián-López, B.; Carlos, L.D.; Sanchez, C. Optical Properties of Composite Organic-Inorganic Materials and their Applications. Adv. Funct. Mater. 2016, 26, 6506–6544. [Google Scholar] [CrossRef]

- Gu, Y.L.; Chen, C.M.; Zheng, Y.; Shi, Z.S.; Wang, X.B.; Yi, Y.J.; Jiang, T.C.; Sun, X.Q.; Wang, F.; Cui, Z.C.; et al. Heat-induced multimode interference variable optical attenuator based on novel organic-inorganic composite materials. J. Opt. 2015, 17, 85802. [Google Scholar] [CrossRef]

- Zhang, X.; Xue, C.; Zhang, W.; Yu, L.; Wang, Q.; Que, W.; Wang, Y.; Hu, F. Multifunctional TiO2/ormosils organic-inorganic composite films derived by a sol-gel process for photonics and UV nanoimprint applications. Opt. Mater. Express 2019, 9, 304–314. [Google Scholar] [CrossRef]

- Zhang, X.H.; Que, W.X.; Hu, J.X.; Chen, J.; Zhang, J.; Liu, W.G. Fabrication of Nanoporous Arrays from Photosensitive Organic–Inorganic Hybrid Materials by Using an UV Soft Nanoimprint Technique. J. Nanosci. Nanotechnol. 2013, 13, 1241–1245. [Google Scholar] [CrossRef]

- Que, W.X.; Hu, X. Optical switch and luminescence properties of sol-gel composite organic-inorganic materials containing azobenzene groups and doped with neodymium ions. Appl. Phys. B 2007, 88, 557–661. [Google Scholar] [CrossRef]

- Que, W.X.; Zhou, Y.; Lam, Y.L.; Chan, Y.C.; Kam, C.H. Optical and microstructural properties of sol-gel derived titania/organically modified silane thin films. Thin Solid Films 2000, 358, 16–21. [Google Scholar] [CrossRef]

- Sun, M.; Que, W.X.; Hu, X. Preparation and trans-cis isomerization of azobenzene-containing TiO2/ormosils hybrid films derived at a low temperature sol-gel process for photonic applications. J. Sol-Gel Sci. Technol. 2009, 50, 415–420. [Google Scholar] [CrossRef]

- Que, W.X.; Yao, X.; Liu, W.G. Azobenzene-containing small molecules organic-inorganic hybrid sol-gel materials for photonic applications. Appl. Phys. B 2008, 91, 539–543. [Google Scholar] [CrossRef]

- Que, W.X.; Hu, X.; Zhang, Q.Y. Germania/ormosil composite materials derived at low temperature for photonic applications. Appl. Phys. B 2003, 76, 423–427. [Google Scholar] [CrossRef]

- Xu, G.F.; Li, S.X.; Liu, C.W.; Wu, S. Photoswitchable Adhesives Using Azobenzene-Containing Materials. Chem. Asian J. 2020, 15, 547–554. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wang, Q.; Liu, S.; Zhang, W.; Hu, F.; Wang, Y. Optical Isomerization and Photo-Patternable Properties of GeO2/Ormosils Organic-Inorganic Composite Films Doped with Azobenzene. Coatings 2021, 11, 818. https://doi.org/10.3390/coatings11070818

Zhang X, Wang Q, Liu S, Zhang W, Hu F, Wang Y. Optical Isomerization and Photo-Patternable Properties of GeO2/Ormosils Organic-Inorganic Composite Films Doped with Azobenzene. Coatings. 2021; 11(7):818. https://doi.org/10.3390/coatings11070818

Chicago/Turabian StyleZhang, Xuehua, Qian Wang, Shun Liu, Wei Zhang, Fangren Hu, and Yongjin Wang. 2021. "Optical Isomerization and Photo-Patternable Properties of GeO2/Ormosils Organic-Inorganic Composite Films Doped with Azobenzene" Coatings 11, no. 7: 818. https://doi.org/10.3390/coatings11070818