Multi-Fault Classification and Diagnosis of Rolling Bearing Based on Improved Convolution Neural Network

Abstract

:1. Introduction

2. Basic Theory

2.1. Convolution Neural Network

2.2. Batch Normalization

3. MFCNN Model

4. Fault Diagnosis Process

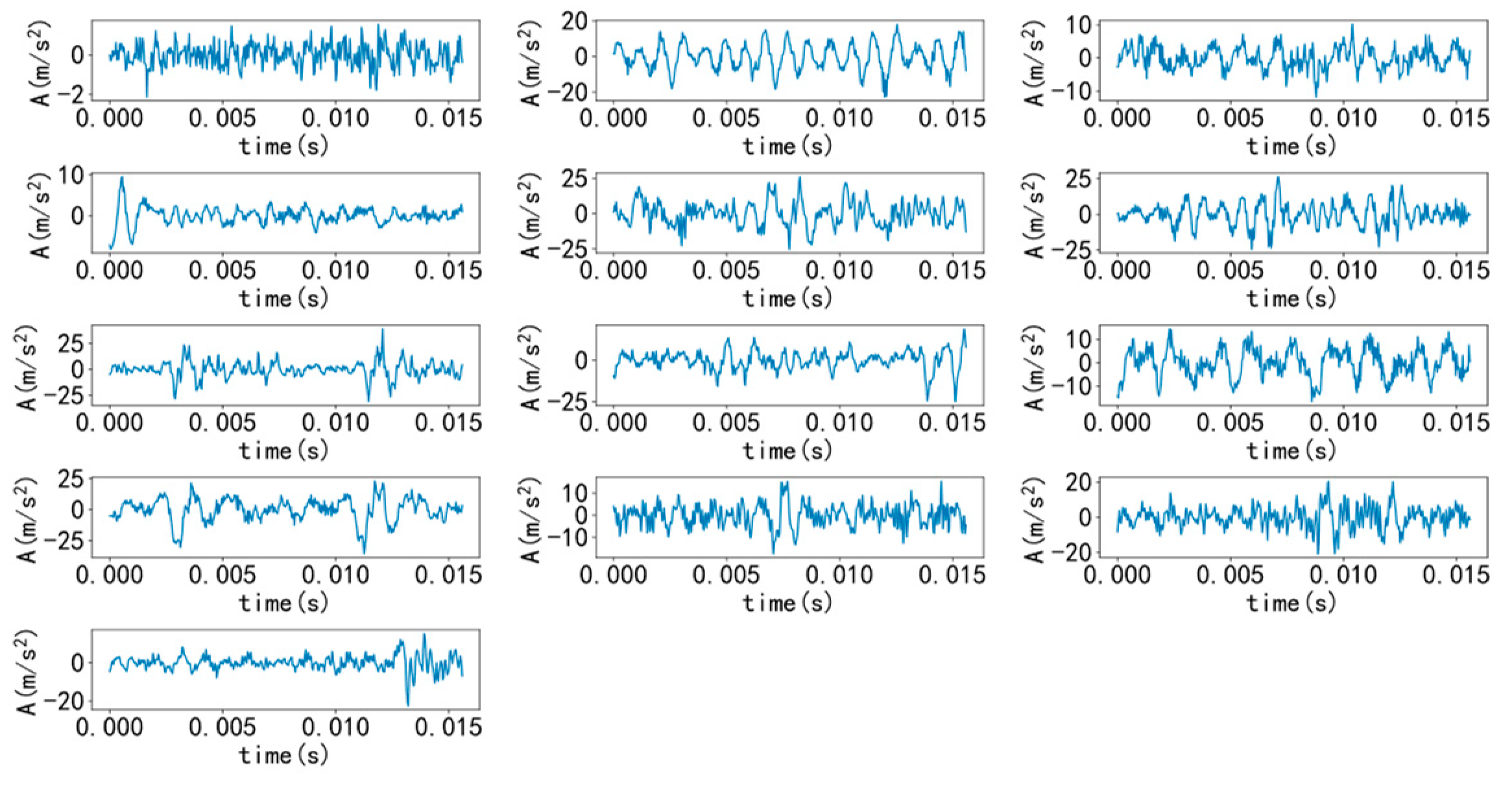

5. Experimental Data Analysis of XJTU-SY Bearing

5.1. Data Preprocessing

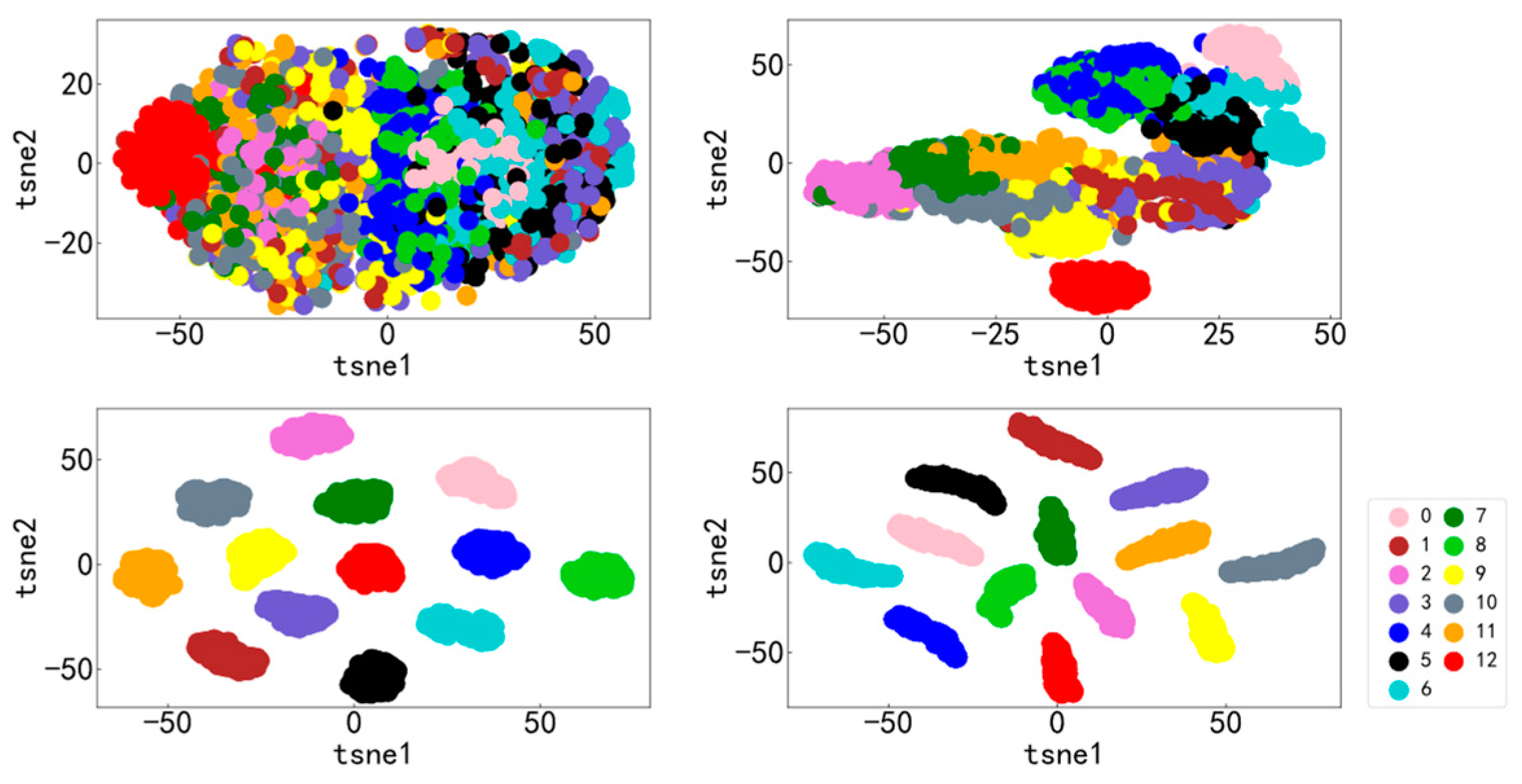

5.2. Experiment and Result Analysis

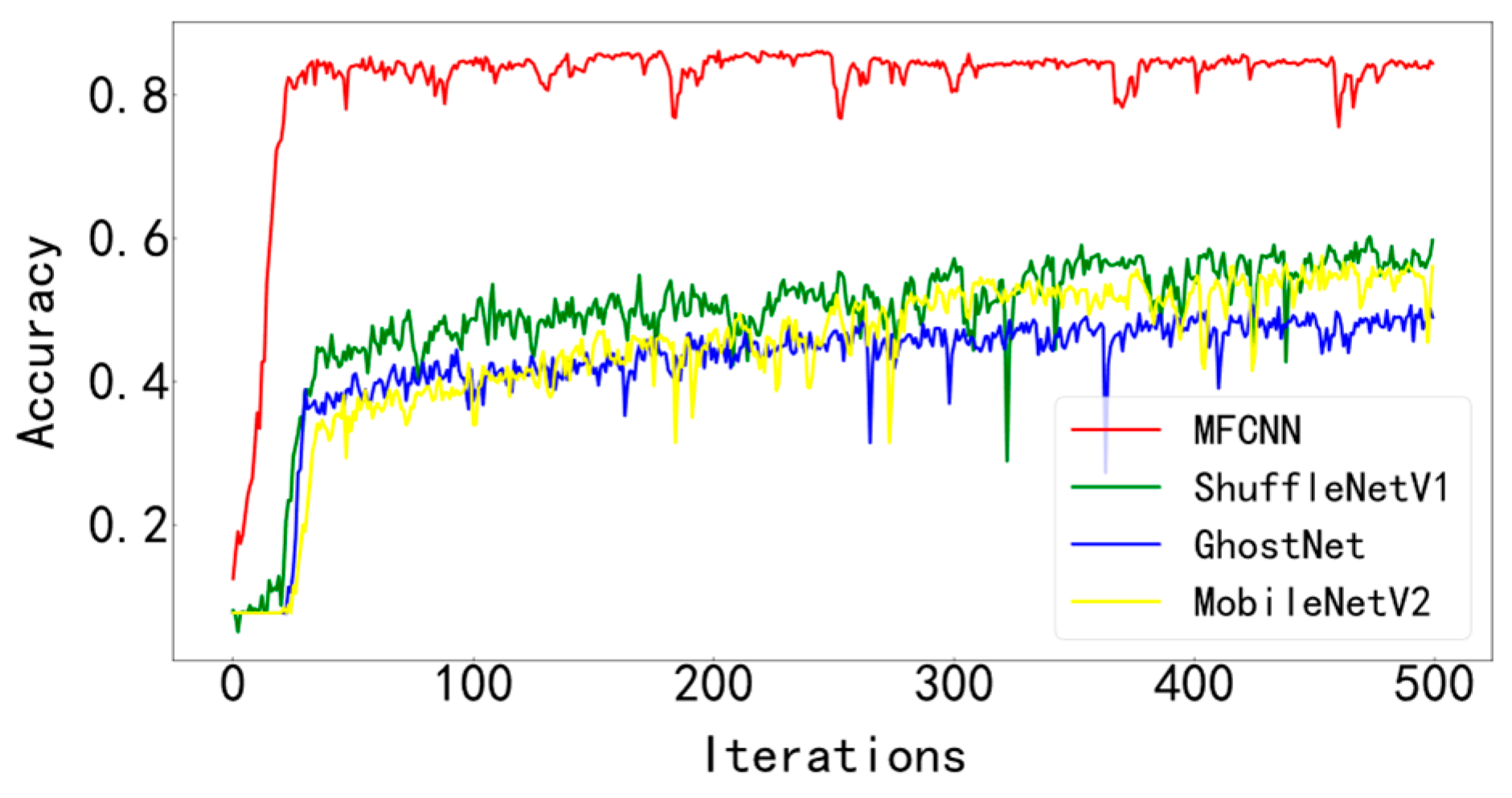

5.3. Comparison of Different Fault Diagnosis Methods

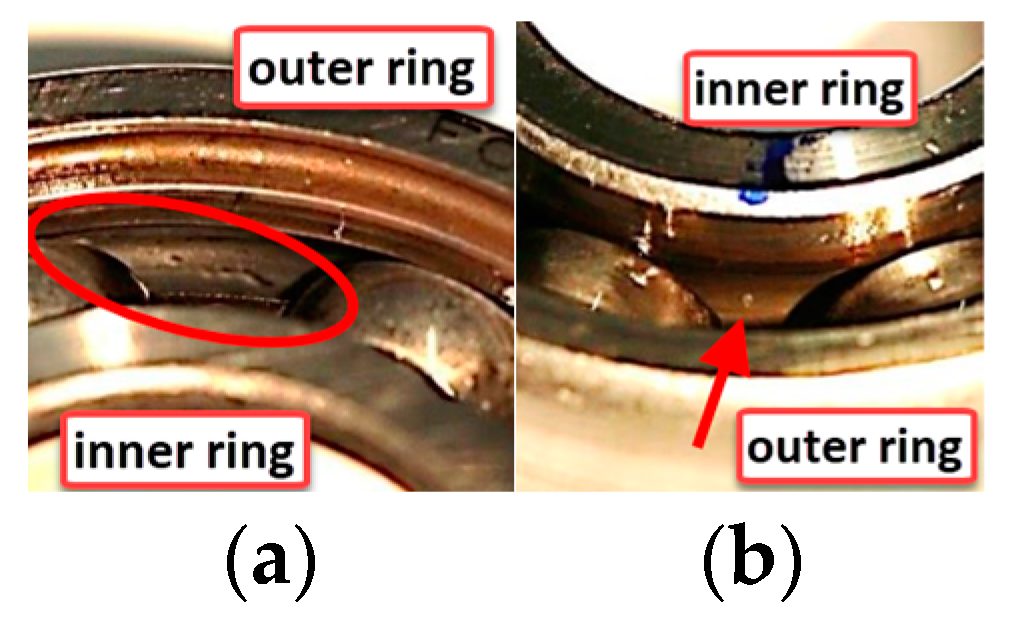

6. Analysis of Experimental Data on Paderborn University Bearings

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Niu, G.X.; Wang, X.; Golda, M.; Mastro, S.; Zhang, B. An optimized adaptive PReLU-DBN for rolling element bearing fault diagnosis. Neurocomputing 2021, 445, 26–34. [Google Scholar] [CrossRef]

- Ayas, S.; Ayas, M.S. A novel bearing fault diagnosis method using deep residual learning network. Multimed. Tools Appl. 2022, 81, 22407–22423. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.L.; Wei, Y.; Zhang, H.L. A novel feature adaptive extraction method based on deep learning for bearing fault diagnosis. Measurement 2021, 185, 110030. [Google Scholar] [CrossRef]

- Ma, J.C.; Shang, J.A.; Zhao, X.; Zhong, P. Bayes-DCGRU with bayesian optimization for rolling bearing fault diagnosis. Appl. Intell. 2022, 52, 11172–11183. [Google Scholar]

- Wang, R.X.; Jiang, H.K.; Zhu, K.; Wang, Y.F.; Liu, C.Q. A deep feature enhanced reinforcement learning method for rolling bearing fault diagnosis. Adv. Eng. Inform. 2022, 54, 101750. [Google Scholar] [CrossRef]

- Guedidi, A.; Guettaf, A.; Cardoso, A.J.M.; Laala, W.; Arif, A. Bearing Faults Classification Based on Variational Mode Decomposition and Artificial Neural Network. In Proceedings of the 12th IEEE International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar]

- Huang, P.; Pan, Z.W.; Qi, X.L.; Lei, J.P. Bearing Fault Diagnosis Based on EMD and PSD. In Proceedings of the 8th World Congress on Intelligent Control and Automation (WCICA), Jinan, China, 6–9 July 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar]

- Wang, P.; Xiong, H.; He, H. Bearing fault diagnosis under various conditions using an incremental learning-based multi-task shared classifier. Knowl. Based Syst. 2023, 266, 110395. [Google Scholar] [CrossRef]

- Wang, X.; Mao, D.X.; Li, X.D. Bearing fault diagnosis based on vibro-acoustic data fusion and 1D-CNN network. Measurement 2021, 173, 108518. [Google Scholar] [CrossRef]

- Hoang, D.T.; Kang, H.J. Rolling element bearing fault diagnosis using convolutional neural network and vibration image. Cogn. Syst. Res. 2019, 53, 42–50. [Google Scholar] [CrossRef]

- Che, C.C.; Wang, H.W.; Ni, X.M.; Lin, R.G. Hybrid multimodal fusion with deep learning for rolling bearing fault diagnosis. Measurement 2021, 173, 108655. [Google Scholar] [CrossRef]

- Zou, Y.Y.; Zhang, Y.D.; Mao, H.C. Fault diagnosis on the bearing of traction motor in high-speed trains based on deep learning. Alex. Eng. J. 2021, 60, 1209–1219. [Google Scholar] [CrossRef]

- He, D.Q.; Liu, C.Y.; Jin, Z.Z.; Ma, R.; Chen, Y.J.; Shan, S. Fault diagnosis of flywheel bearing based on parameter optimization variational mode decomposition energy entropy and deep learning. Energy 2022, 239, 122108. [Google Scholar] [CrossRef]

- Li, X.Q.; Jiang, H.K.; Xie, M.; Wang, T.Q.; Wang, R.X.; Wu, Z.H. A reinforcement ensemble deep transfer learning network for rolling bearing fault diagnosis with Multi-source domains. Adv. Eng. Inform. 2022, 51, 101480. [Google Scholar] [CrossRef]

- Sinitsin, V.; Ibryaeva, O.; Sakovskaya, V.; Eremeeva, V. Intelligent bearing fault diagnosis method combining mixed input and hybrid CNN-MLP model. Mech. Syst. Signal Process. 2022, 180, 109454. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, B.; Gao, D. Bearing fault diagnosis base on multi-scale CNN and LSTM model. J. Intell. Manuf. 2021, 32, 971–987. [Google Scholar] [CrossRef]

- Kumar, P.; Hati, A.S. Deep convolutional neural network based on adaptive gradient optimizer for fault detection in SCIM. ISA Trans. 2021, 111, 350–359. [Google Scholar] [CrossRef]

- Huang, W.; Cheng, J.; Yang, Y.; Guo, G. An improved deep convolutional neural network with multi-scale information for bearing fault diagnosis. Neurocomputing 2019, 359, 77–92. [Google Scholar] [CrossRef]

- Xu, Y.; Yang, L. Based on Improved CNN Bearing Fault Detection. In Proceedings of the International Conference on Computer, Big Data and Artificial Intelligence (ICCBDAI 2021), Beihai, China, 12–14 November 2021. [Google Scholar]

- Gu, J.; Peng, Y.X.; Lu, H.; Chang, X.D.; Chen, G.A. A novel fault diagnosis method of rotating machinery via VMD, CWT and improved CNN. Measurement 2022, 200, 111635. [Google Scholar] [CrossRef]

- Xu, Q.S.; Zhu, B.; Huo, H.B.; Meng, Z.; Li, J.M.; Fan, F.J.; Cao, L.X. Fault diagnosis of rolling bearing based on online transfer convolutional neural network. Appl. Acoust. 2022, 192, 108703. [Google Scholar] [CrossRef]

- Cao, H.; Shao, H.; Zhong, X.; Deng, Q.; Yang, X.; Xuan, J. Unsupervised domain-share CNN for machine fault transfer diagnosis from steady speeds to time-varying speeds. J. Manuf. Syst. 2022, 62, 186–198. [Google Scholar] [CrossRef]

- Jin, T.; Yan, C.; Chen, C.; Yang, Z.; Tian, H.; Wang, S. Light neural network with fewer parameters based on CNN for fault diagnosis of rotating machinery. Measurement 2021, 181, 109639. [Google Scholar] [CrossRef]

- Ye, M.; Yan, X.; Chen, N.; Jia, M. Intelligent fault diagnosis of rolling bearing using variational mode extraction and improved one-dimensional convolutional neural network. Appl. Acoust. 2023, 202, 109143. [Google Scholar] [CrossRef]

- Hsiao, T.Y.; Chang, Y.C.; Chou, H.H.; Chiu, C.T. Filter-based deep-compression with global average pooling for convolutional networks. J. Syst. Archit. 2019, 95, 9–18. [Google Scholar] [CrossRef]

- Huang, Y.J.; Liao, A.H.; Hu, D.Y.; Shi, W.; Zheng, S.B. Multi-scale convolutional network with channel attention mechanism for rolling bearing fault diagnosis. Measurement 2022, 203, 111935. [Google Scholar] [CrossRef]

| MFCNN Network Structure | Parameter Setting |

|---|---|

| Convolution layer | 16 × 16 × 16 |

| Batch normalization layer | / |

| Average pooling layer | Pooled window 3 × 3, Stride 2 |

| Convolution layer | 3 × 3 × 32 |

| Batch normalization layer | / |

| Average pooling layer | Pooled window 3 × 3, Stride 2 |

| Convolution layer | 3 × 3 × 64 |

| Batch normalization layer | / |

| Average pooling layer | Pooled window 3 × 3, Stride 2 |

| Global average pooling layer | / |

| Output layer | 13 × 1 |

| Parameter Type | Parameter Value |

|---|---|

| Inner race raceway diameter (mm) | 29.30 |

| Outer ring raceway diameter (mm) | 39.80 |

| Bearing pitch diameter (mm) | 34.55 |

| Basic dynamic load rating (N) | 12,820 |

| Ball diameter (mm) | 7.92 |

| Number of balls | 8 |

| contact angle (°) | 0 |

| Basic static load rating (KN) | 6.65 |

| Data Type | Tag Number |

|---|---|

| Normal data | 0 |

| Outer ring fault 1 | 1 |

| Outer ring fault 2 | 2 |

| Holder fault 1 | 3 |

| Mixed fault of inner ring and outer ring | 4 |

| Inner ring fault 1 | 5 |

| Outer ring fault 3 | 6 |

| Holder fault 2 | 7 |

| Outer ring fault 4 | 8 |

| Outer ring fault 5 | 9 |

| Mixed failure of inner ring, rolling element, holder, and outer ring | 10 |

| Inner ring fault 2 | 11 |

| Inner ring fault 3 | 12 |

| Diagnostic Method | Number of Parameters |

|---|---|

| MFCNN | 28,429 |

| ShuffleNetV1 | 952,549 |

| GhostNet | 2,605,480 |

| MobileNetV2 | 2,282,981 |

| Data Type | Tag Number |

|---|---|

| healthy bearing data | 0 |

| Outer ring damage; Pitting; Single point damage; Damage level 1 | 1 |

| Outer ring damage; Plastic deform; Single point damage; Damage level 1 | 2 |

| Outer ring damage; Pitting; Single point damage; Damage level 2 | 3 |

| Outer ring damage; Plastic deform; Distributed damage; Damage level 1 | 4 |

| Mixed damage of outer and inner rings; Pitting; Single point damage; Damage level 2 | 5 |

| Mixed damage of outer and inner rings; Pitting; Distributed damage; Damage level 3 | 6 |

| Mixed fault of outer ring and inner ring; Plastic deform; Distributed damage; Damage level 1 | 7 |

| Inner ring damage; Pitting; Single point damage; Damage level 1 | 8 |

| Inner ring damage; Pitting; Single point damage; Damage level 3 | 9 |

| Inner ring damage; Pitting; Single point damage; Damage level 1 | 10 |

| Inner ring damage; Pitting; Single point damage; Damage level 2 | 11 |

| Inner ring damage; Pitting; Single point damage; Damage level 1 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, J.; Wu, W.; Dong, F.; Wan, S. Multi-Fault Classification and Diagnosis of Rolling Bearing Based on Improved Convolution Neural Network. Entropy 2023, 25, 737. https://doi.org/10.3390/e25050737

Zhang X, Li J, Wu W, Dong F, Wan S. Multi-Fault Classification and Diagnosis of Rolling Bearing Based on Improved Convolution Neural Network. Entropy. 2023; 25(5):737. https://doi.org/10.3390/e25050737

Chicago/Turabian StyleZhang, Xiong, Jialu Li, Wenbo Wu, Fan Dong, and Shuting Wan. 2023. "Multi-Fault Classification and Diagnosis of Rolling Bearing Based on Improved Convolution Neural Network" Entropy 25, no. 5: 737. https://doi.org/10.3390/e25050737

APA StyleZhang, X., Li, J., Wu, W., Dong, F., & Wan, S. (2023). Multi-Fault Classification and Diagnosis of Rolling Bearing Based on Improved Convolution Neural Network. Entropy, 25(5), 737. https://doi.org/10.3390/e25050737