Computation of Entropy Production in Stratified Flames Based on Chemistry Tabulation and an Eulerian Transported Probability Density Function Approach

Abstract

:1. Introduction

2. Methods

2.1. LES and Tabulated Chemistry

2.2. Modeling of the Turbulence Chemistry Interaction

2.3. Computation of the Entropy Generation Source Terms

3. Configuration and Numerical Setup

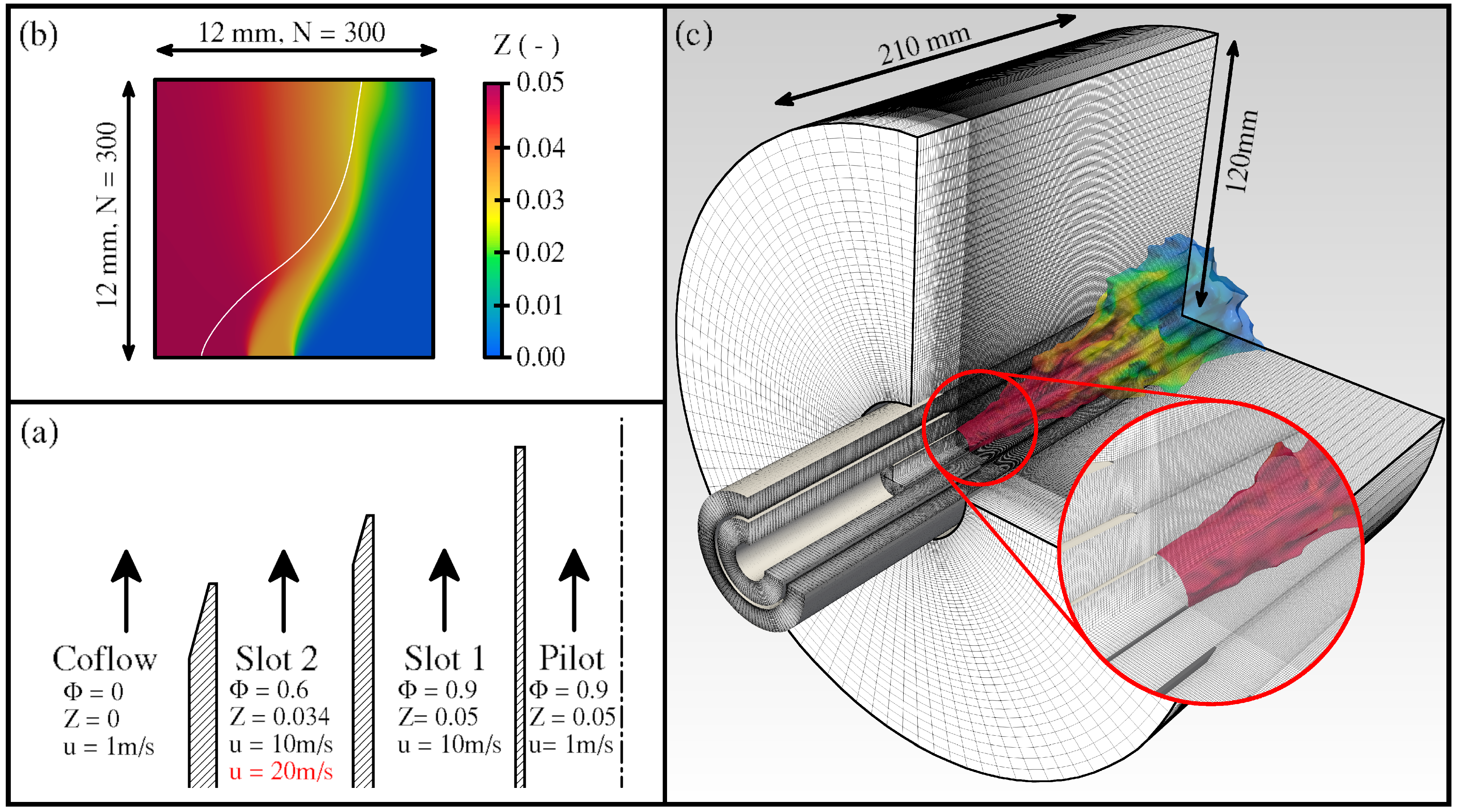

3.1. Experimental Configuration

3.2. Numerical Setup

4. Results

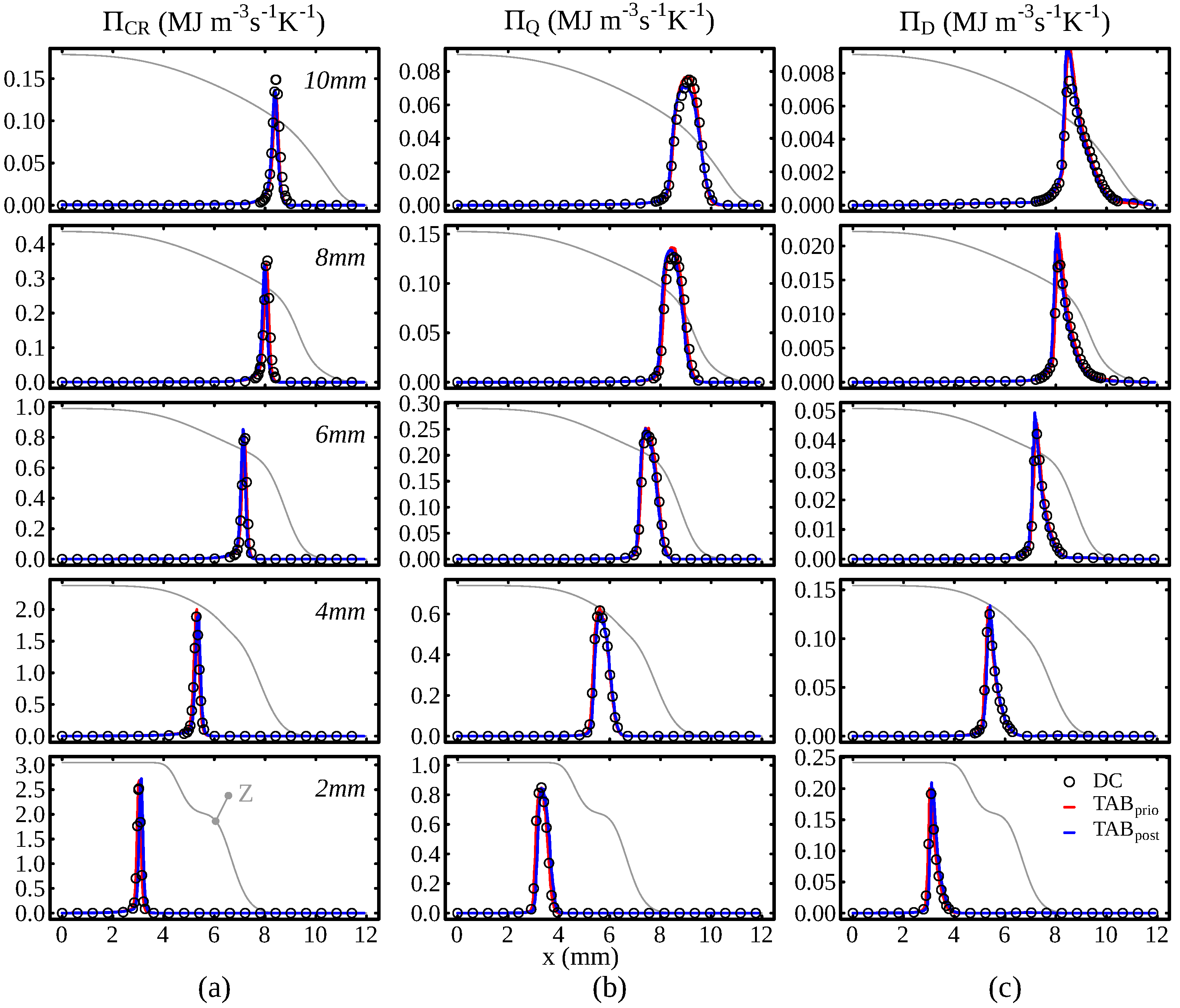

4.1. Entropy Generation in a Laminar Stratified Flame

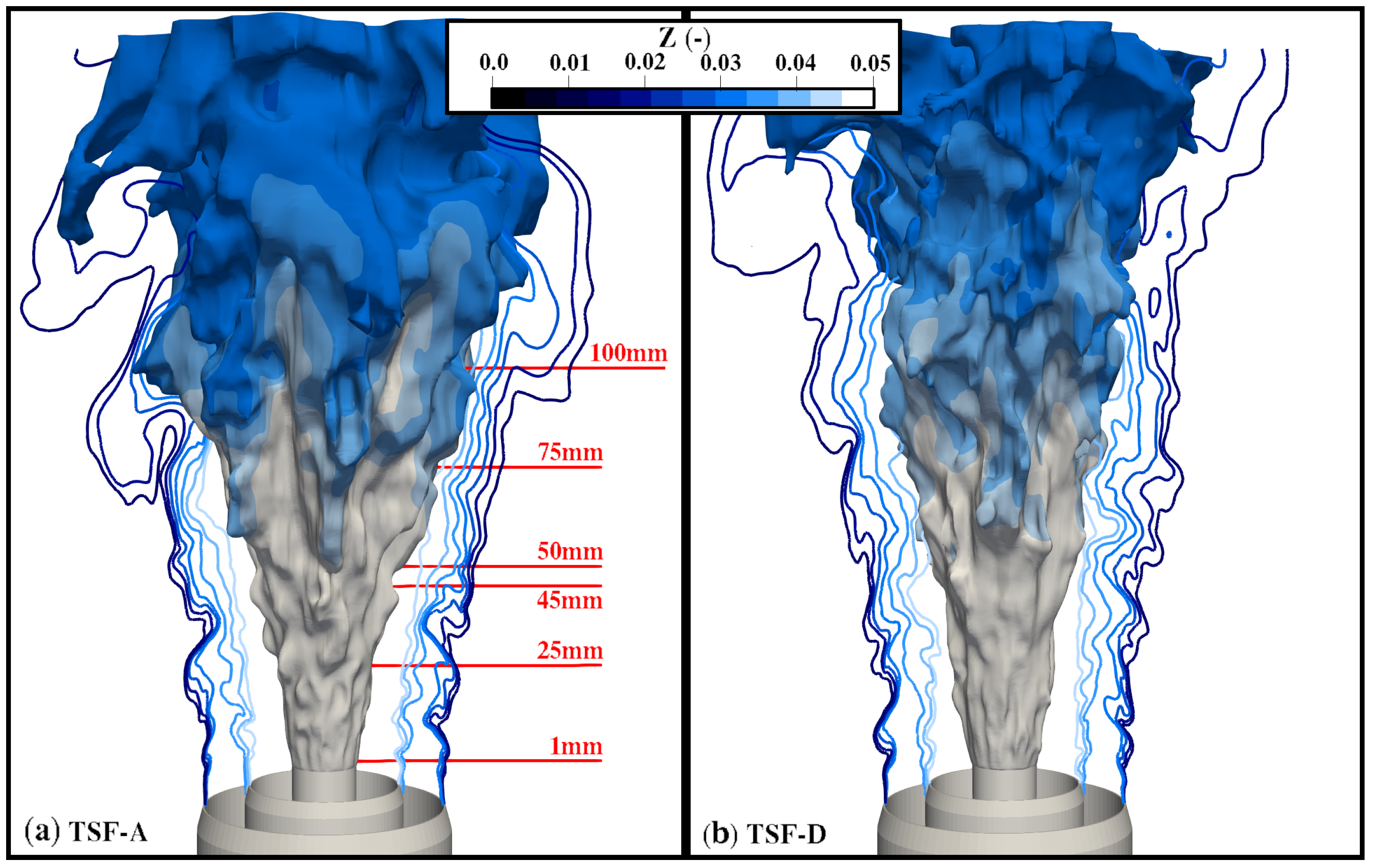

4.2. Entropy Generation in Turbulent Stratified Flames

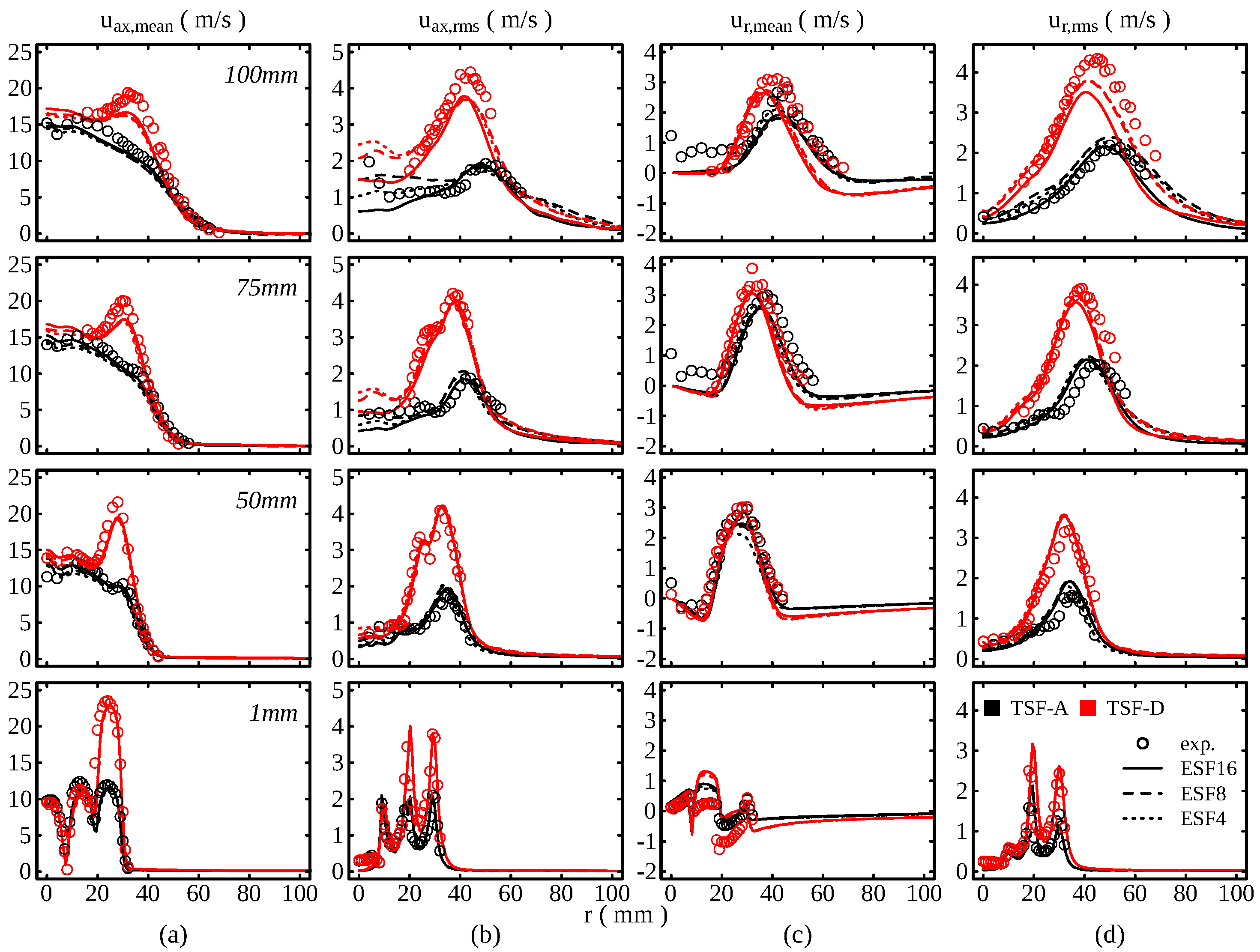

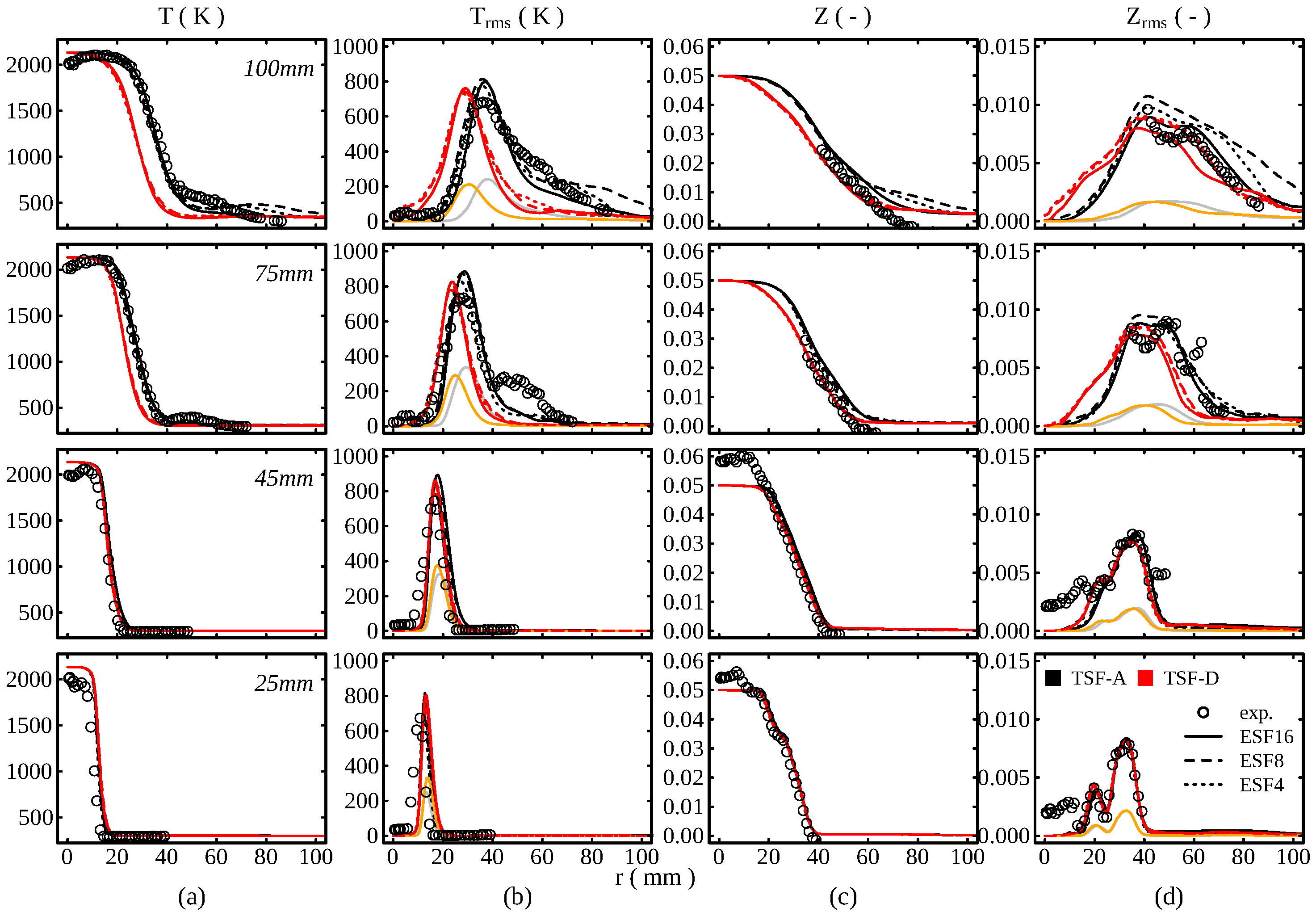

4.2.1. Comparison with Experimental Data

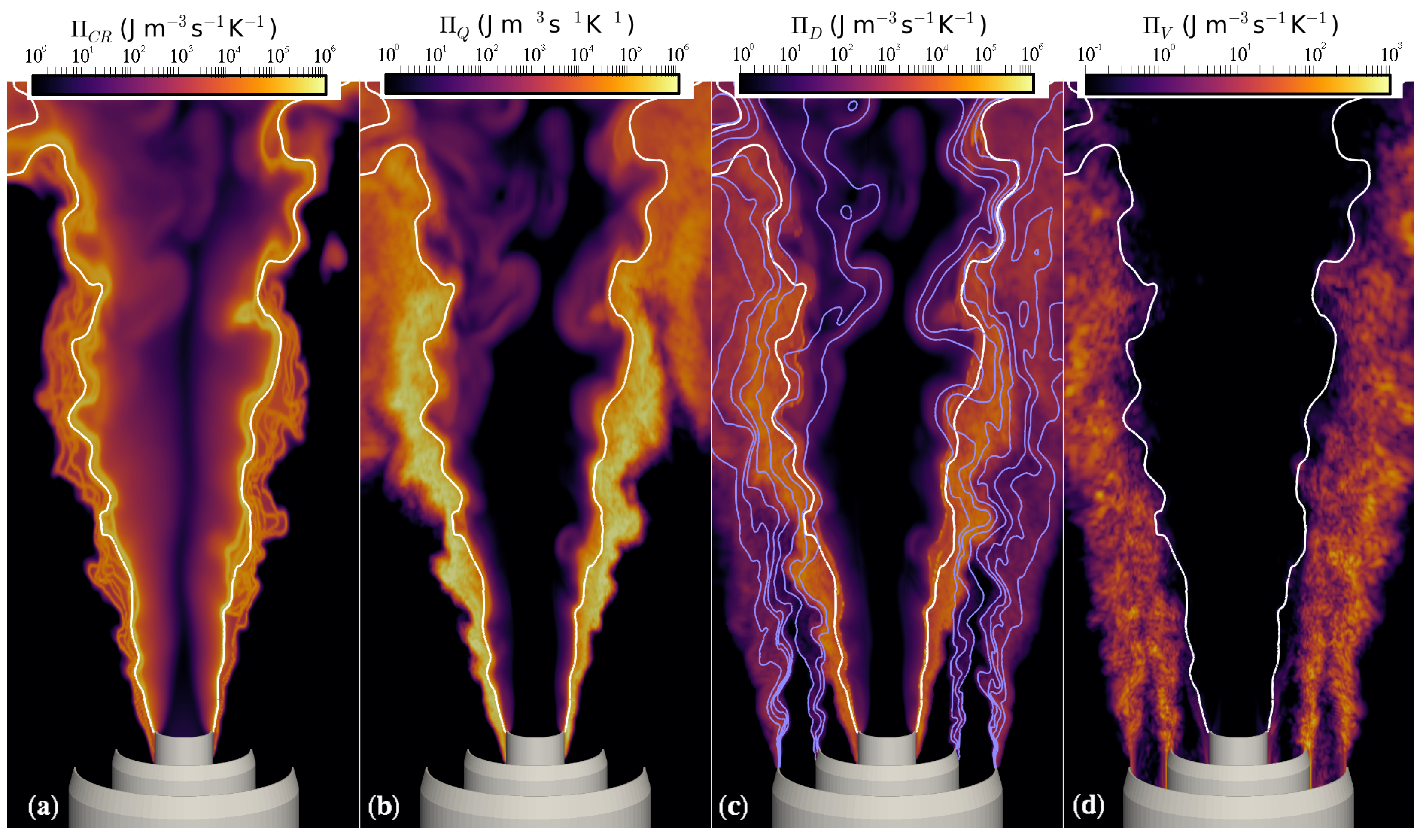

4.2.2. Entropy Production Analysis

5. Conclusions

- Through comparison with available experimental data it was demonstrated that the approach is able to represent the temporal flow field and scalar field statistics reasonably well for both operating conditions.

- From an analysis of the entropy production, qualitatively and quantitatively, the characterization of various entropy generation sources was achieved. It turned out that the main contribution is from heat transfer, followed by the chemical reaction.

- It was shown that the higher shear in slot 2 for TSF-D-r yields higher entropy production through heat, mixing and viscous dissipation and reduces the share by chemical reaction to the total entropy generated. The largest differences could be observed for the source term by heat transfer and the underlying phenomena could be identified, namely the stronger interaction of turbulent structures with the flame preheating zone.

Author Contributions

Funding

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CR | Chemical reaction |

| DC | Detailed chemistry |

| EMST | Euclidean minimum spanning tree |

| ESF | Eulerian stochastic fields |

| FDF | Filtered PDF |

| FP | Fokker-Planck |

| IEM | Interaction by exchange with the mean |

| LES | Large eddy simulation |

| LMSE | Linear mean square estimation |

| Probability density function | |

| RHS | Right-hand side |

| sgs | Subgrid-scale |

| TAB | Tabulated |

| TCI | Turbulence-chemistry interaction |

References

- Som, S.K.; Datta, A. Thermodynamic irreversibilities and exergy balance in combustion processes. Prog. Energy Combust. Sci. 2008, 34, 351–376. [Google Scholar] [CrossRef]

- Sciacovelli, A.; Verda, V.; Sciubba, E. Entropy generation analysis as a design tool—A review. Renew. Sustain. Energy Rev. 2015, 43, 1167–1181. [Google Scholar] [CrossRef]

- Bejan, A. Second-law analysis in heat transfer and thermal design. In Advances in Heat Transfer; Elsevier: Amsterdam, The Netherlands, 1982; Volume 15, pp. 1–58. [Google Scholar] [CrossRef]

- Sadiki, A.; Hutter, K. On Thermodynamics of Turbulence: Development of First Order Closure Models and Critical Evaluation of Existing Models; de Gruyter: Vienna, Austria, 2000; Volume 25, pp. 131–160. [Google Scholar] [CrossRef]

- Kwak, H.Y.; Kim, D.J.; Jeon, J.S. Exergetic and thermoeconomic analyses of power plants. Energy 2003, 28, 343–360. [Google Scholar] [CrossRef]

- Rakopoulos, C.D.; Giakoumis, E.G. Second-law analyses applied to internal combustion engines operation. Prog. Energy Combust. Sci. 2006, 32, 2–47. [Google Scholar] [CrossRef]

- Sanli, B.G.; Özcanli, M.; Serin, H. Assessment of thermodynamic performance of an IC engine using microalgae biodiesel at various ambient temperatures. Fuel 2020, 277, 118108. [Google Scholar] [CrossRef]

- Lior, N.; Sarmiento-Darkin, W.; Al-Sharqawi, H.S. The exergy fields in transport processes: Their calculation and use. Energy 2006, 31, 553–578. [Google Scholar] [CrossRef]

- Nishida, K.; Takagi, T.; Kinoshita, S. Analysis of entropy generation and exergy loss during combustion. Proc. Combust. Inst. 2002, 29, 869–874. [Google Scholar] [CrossRef]

- Datta, A. Entropy generation in a confined laminar diffusion flame. Combust. Sci. Technol. 2000, 159, 39–56. [Google Scholar] [CrossRef]

- Stanciu, D.; Isvoranu, D.; Marinescu, M.; Gogus, Y. Second law analysis of diffusion flames. Int. J. Thermodyn. 2001, 4, 1–18. [Google Scholar]

- Farran, R.; Chakraborty, N. A direct numerical simulation-based analysis of entropy generation in turbulent premixed flames. Entropy 2013, 15, 1540–1566. [Google Scholar] [CrossRef]

- Bazdidi-Tehrani, F.; Abedinejad, M.S.; Mohammadi, M. Analysis of relationship between entropy generation and soot formation in turbulent kerosene/air jet diffusion flames. Energy Fuels 2019, 33, 9184–9195. [Google Scholar] [CrossRef]

- Yapici, H.; Kayatas, N.; Albayrak, B.; Bastürk, G. Numerical calculation of local entropy generation in a methane–air burner. Energy Convers. Manag. 2005, 46, 1885–1919. [Google Scholar] [CrossRef]

- Safari, M.; Hadi, F.; Sheikhi, M.R.H. Progress in the prediction of entropy generation in turbulent reacting flows using large eddy simulation. Entropy 2014, 16, 5159–5177. [Google Scholar] [CrossRef] [Green Version]

- Safari, M.; Sheikhi, M.R.H.; Janbozorgi, M.; Metghalchi, H. Entropy transport equation in large eddy simulation for exergy analysis of turbulent combustion systems. Entropy 2010, 12, 434–444. [Google Scholar] [CrossRef]

- Barlow, R.S.; Frank, J.H.; Karpetis, A.N.; Chen, J.Y. Piloted methane/air jet flames: Transport effects and aspects of scalar structure. Combust. Flame 2005, 143, 433–449. [Google Scholar] [CrossRef]

- Agrebi, S.; Dressler, L.; Nicolai, H.; Ries, F.; Nishad, K.; Sadiki, A. Analysis of Local Exergy Losses in Combustion Systems Using a Hybrid Filtered Eulerian Stochastic Field Coupled with Detailed Chemistry Tabulation: Cases of Flames D and E. Energies 2021, 14, 6315. [Google Scholar] [CrossRef]

- Valiño, L. A field Monte Carlo formulation for calculating the probability density function of a single scalar in a turbulent flow. Flow Turbul. Combust. 1998, 60, 157–172. [Google Scholar] [CrossRef]

- Valiño, L.; Mustata, R.; Letaief, K.B. Consistent behavior of Eulerian Monte Carlo fields at low Reynolds numbers. Flow Turbul. Combust. 2016, 96, 503–512. [Google Scholar] [CrossRef]

- Pierce, C.D.; Moin, P. Progress-variable approach for large-eddy simulation of non-premixed turbulent combustion. J. Fluid Mech. 2004, 504, 73–97. [Google Scholar] [CrossRef]

- Masri, A.R. Partial premixing and stratification in turbulent flames. Proc. Combust. Inst. 2015, 35, 1115–1136. [Google Scholar] [CrossRef]

- Lipatnikov, A.N. Stratified turbulent flames: Recent advances in understanding the influence of mixture inhomogeneities on premixed combustion and modeling challenges. Prog. Energy Combust. Sci. 2017, 62, 87–132. [Google Scholar] [CrossRef]

- Seffrin, F.; Fuest, F.; Geyer, D.; Dreizler, A. Flow field studies of a new series of turbulent premixed stratified flames. Combust. Flame 2010, 157, 384–396. [Google Scholar] [CrossRef]

- Kuenne, G.; Seffrin, F.; Fuest, F.; Stahler, T.; Ketelheun, A.; Geyer, D.; Janicka, J.; Dreizler, A. Experimental and numerical analysis of a lean premixed stratified burner using 1D Raman/Rayleigh scattering and large eddy simulation. Combust. Flame 2012, 159, 2669–2689. [Google Scholar] [CrossRef]

- Avdić, A.; Kuenne, G.; Ketelheun, A.; Sadiki, A.; Jakirlić, S.; Janicka, J. High performance computing of the Darmstadt stratified burner by means of large eddy simulation and a joint ATF-FGM approach. Comput. Vis. Sci. 2013, 16, 77–88. [Google Scholar] [CrossRef]

- Dressler, L.; Ries, F.; Kuenne, G.; Janicka, J.; Sadiki, A. Analysis of Shear Effects on Mixing and Reaction Layers in Premixed Turbulent Stratified Flames using LES coupled to Tabulated Chemistry. Combust. Sci. Technol. 2019, 194, 242–257. [Google Scholar] [CrossRef]

- Straub, C.; Kronenburg, A.; Stein, O.T.; Barlow, R.S.; Geyer, D. Modeling stratified flames with and without shear using multiple mapping conditioning. Proc. Combust. Inst. 2018, 37, 2317–2324. [Google Scholar] [CrossRef]

- Fiorina, B.; Mercier, R.; Kuenne, G.; Ketelheun, A.; Avdić, A.; Janicka, J.; Geyer, D.; Dreizler, A.; Alenius, E.; Duwig, C.; et al. Challenging modeling strategies for LES of non-adiabatic turbulent stratified combustion. Combust. Flame 2015, 162, 4264–4282. [Google Scholar] [CrossRef] [Green Version]

- Böhm, B.; Frank, J.; Dreizler, A. Temperature and mixing field measurements in stratified lean premixed turbulent flames. Proc. Combust. Inst. 2011, 33, 1583–1590. [Google Scholar] [CrossRef]

- Maas, U.; Pope, S.B. Simplifying chemical kinetics: Intrinsic low-dimensional manifolds in composition space. Combust. Flame 1992, 88, 239–264. [Google Scholar] [CrossRef]

- Bykov, V.; Maas, U. The extension of the ILDM concept to reaction–diffusion manifolds. Combust. Theory Model. 2007, 11, 839–862. [Google Scholar] [CrossRef]

- Van Oijen, J.A.; De Goey, L.P.H. Modelling of premixed laminar flames using flamelet-generated manifolds. Combust. Sci. Technol. 2000, 161, 113–137. [Google Scholar] [CrossRef] [Green Version]

- Fiorina, B.; Gicquel, O.; Vervisch, L.; Carpentier, S.; Darabiha, N. Approximating the chemical structure of partially premixed and diffusion counterflow flames using FPI flamelet tabulation. Combust. Flame 2005, 140, 147–160. [Google Scholar] [CrossRef]

- De Swart, J.; Groot, G.; Van Oijen, J.A.; ten Thije Boonkkamp, J.H.M.; De Goey, L.P.H. Detailed analysis of the mass burning rate of stretched flames including preferential diffusion effects. Combust. Flame 2006, 145, 245–258. [Google Scholar] [CrossRef]

- Nicoud, F.; Toda, H.B.; Cabrit, O.; Bose, S.; Lee, J. Using singular values to build a subgrid-scale model for large eddy simulations. Phys. Fluids 2011, 23, 085106. [Google Scholar] [CrossRef] [Green Version]

- Avdić, A.; Kuenne, G.; di Mare, F.; Janicka, J. LES combustion modeling using the Eulerian stochastic field method coupled with tabulated chemistry. Combust. Flame 2017, 175, 201–219. [Google Scholar] [CrossRef]

- Janicka, J.; Sadiki, A. Large eddy simulation of turbulent combustion systems. Proc. Combust. Inst. 2005, 30, 537–547. [Google Scholar] [CrossRef]

- Pitsch, H. Large Eddy Simulation of Turbulent Combustion. Annu. Rev. Fluid Mech. 2006, 38, 453–482. [Google Scholar] [CrossRef] [Green Version]

- Peters, N. Turbulent Combustion; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Kerstein, A.R.; Ashurst, W.T.; Williams, F.A. Field equation for interface propagation in an unsteady homogeneous flow field. Phys. Rev. A 1988, 37, 2728. [Google Scholar] [CrossRef]

- Butler, T.D.; O’rourke, P.J. A numerical method for two dimensional unsteady reacting flows. In Symposium (International) on Combustion; Elsevier: Amsterdam, The Netherlands, 1977; Volume 16, pp. 1503–1515. [Google Scholar] [CrossRef] [Green Version]

- Legier, J.P.; Poinsot, T.; Veynante, D. Dynamically thickened flame LES model for premixed and non-premixed turbulent combustion. In Proceedings of the Summer Program; Center for Turbulence Research: Stanford, CA, USA, 2000; Volume 12. [Google Scholar]

- Fiorina, B.; Vicquelin, R.; Auzillon, P.; Darabiha, N.; Gicquel, O.; Veynante, D. A filtered tabulated chemistry model for LES of premixed combustion. Combust. Flame 2010, 157, 465–475. [Google Scholar] [CrossRef] [Green Version]

- Pope, S.B. PDF methods for turbulent reactive flows. Prog. Energy Combust. Sci. 1985, 11, 119–192. [Google Scholar] [CrossRef]

- Sabel’nikov, V.; Soulard, O. Eulerian (Field) Monte Carlo Methods for Solving PDF Transport Equations in Turbulent Reacting Flows. In Handbook of Combustion; American Cancer Society: Atlanta, GA, USA, 2010; Chapter 4; pp. 75–119. [Google Scholar] [CrossRef]

- Subramaniam, S.; Pope, S.B. A mixing model for turbulent reactive flows based on Euclidean minimum spanning trees. Combust. Flame 1998, 115, 487–514. [Google Scholar] [CrossRef]

- Villermaux, J.; Falk, L. A generalized mixing model for initial contacting of reactive fluids. Chem. Eng. Sci. 1994, 49, 5127–5140. [Google Scholar] [CrossRef]

- Borghi, R. Turbulent combustion modelling. Prog. Energy Combust. Sci. 1988, 14, 245–292. [Google Scholar] [CrossRef]

- Frost, V.A. Model of a turbulent, diffusion-controlled flame jet. Fluid Mech. Sov. Res. 1975, 4, 124–133. [Google Scholar]

- Dopazo, C.; O’Brien, E.E. An approach to the autoignition of a turbulent mixture. Acta Astronaut. 1974, 1, 1239–1266. [Google Scholar] [CrossRef]

- Jaberi, F.A.; Colucci, P.J.; James, S.; Givi, P.; Pope, S.B. Filtered mass density function for large-eddy simulation of turbulent reacting flows. J. Fluid Mech. 1999, 401, 85–121. [Google Scholar] [CrossRef] [Green Version]

- Mahmoud, R.; Jangi, M.; Ries, F.; Fiorina, B.; Janicka, J.; Sadiki, A. Combustion Characteristics of a Non-Premixed Oxy-Flame Applying a Hybrid Filtered Eulerian Stochastic Field/Flamelet Progress Variable Approach. Appl. Sci. 2019, 9, 1320. [Google Scholar] [CrossRef] [Green Version]

- Dressler, L.J. Towards Predictive Large-Eddy-Simulation-Based Modeling of Reactive Multiphase Flows Using Tabulated Chemistry. Ph.D. Thesis, Technische Universität Darmstadt, Darmstadt, Germany, 2021. [Google Scholar] [CrossRef]

- Fredrich, D.; Jones, W.P.; Marquis, A.J. The stochastic fields method applied to a partially premixed swirl flame with wall heat transfer. Combust. Flame 2019, 205, 446–456. [Google Scholar] [CrossRef]

- Hansinger, M.; Zirwes, T.; Zips, J.; Pfitzner, M.; Zhang, F.; Habisreuther, P.; Bockhorn, H. The Eulerian stochastic fields method applied to large eddy simulations of a piloted flame with inhomogeneous inlet. Flow Turbul. Combust. 2020, 105, 837–867. [Google Scholar] [CrossRef]

- Jones, W.P.; Navarro-Martinez, S.; Röhl, O. Large eddy simulation of hydrogen auto-ignition with a probability density function method. Proc. Combust. Inst. 2007, 31, 1765–1771. [Google Scholar] [CrossRef]

- Dressler, L.; Sacomano Filho, F.L.; Ries, F.; Nicolai, H.; Janicka, J.; Sadiki, A. Numerical prediction of turbulent spray flame characteristics using the filtered eulerian stochastic field approach coupled to tabulated chemistry. Fluids 2021, 6, 50. [Google Scholar] [CrossRef]

- Picciani, M.A. Investigation of Numerical Resolution Requirements of the Eulerian Stochastic Fields and the Thickened Stochastic Field Approach. Ph.D. Thesis, University of Southampton, Southampton, UK, 2018. [Google Scholar]

- Kloeden, P.E.; Platen, E. Numerical Solution of Stochastic Differential Equations; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1992. [Google Scholar] [CrossRef] [Green Version]

- Muradoglu, M.; Jenny, P.; Pope, S.B.; Caughey, D.A. A consistent hybrid finite-volume/particle method for the PDF equations of turbulent reactive flows. J. Comput. Phys. 1999, 154, 342–371. [Google Scholar] [CrossRef] [Green Version]

- James, S.; Zhu, J.; Anand, M.S. Large eddy simulations of turbulent flames using the filtered density function model. Proc. Combust. Inst. 2007, 31, 1737–1745. [Google Scholar] [CrossRef]

- Raman, V.; Pitsch, H.; Fox, R.O. Hybrid large-eddy simulation/Lagrangian filtered-density-function approach for simulating turbulent combustion. Combust. Flame 2005, 143, 56–78. [Google Scholar] [CrossRef]

- Raman, V.; Pitsch, H. A consistent LES/filtered-density function formulation for the simulation of turbulent flames with detailed chemistry. Proc. Combust. Inst. 2007, 31, 1711–1719. [Google Scholar] [CrossRef]

- Prasad, V.N. Large Eddy Simulation of Partially Premixed Turbulent Combustion. Ph.D. Thesis, Imperial College London (University of London), London, UK, 2011. [Google Scholar]

- Bejan, A. Entropy Generation Minimization: The Method of Thermodynamic Optimization of Finite-Size Systems and Finite-Time Processes, 1st ed.; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Bejan, A. Advanced Engineering Thermodynamics; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Hirschfelder, J.O.; Curtiss, C.F.; Bird, R.B. Molecular Theory of Gases and Liquids, 2nd ed.; John Wiley and Sons, Inc.: New York, NY, USA, 1964. [Google Scholar]

- Ries, F.; Nishad, K.; Janicka, J.; Sadiki, A. Entropy generation analysis and thermodynamic optimization of jet impingement cooling using large eddy simulation. Entropy 2019, 19, 129. [Google Scholar] [CrossRef] [Green Version]

- Ries, F.; Sadiki, A. Supercritical and transcritical turbulent injection processes: Consistency of numerical modeling. At. Sprays 2021, 31, 37–71. [Google Scholar] [CrossRef]

- Corrsin, S. On the spectrum of isotropic temperature fluctuations in an isotropic turbulence. J. Appl. Phys. 1951, 22, 469–473. [Google Scholar] [CrossRef]

- Schneider, S.; Geyer, D.; Magnotti, G.; Dunn, M.J.; Barlow, R.S.; Dreizler, A. Structure of a stratified CH4 flame with H2 addition. Proc. Combust. Inst. 2019, 37, 2307–2315. [Google Scholar] [CrossRef]

- Smith, G.P.; Golden, D.M.; Frenklach, M.; Moriarty, N.W.; Eiteneer, B.; Goldenberg, M.; Bowman, C.T.; Hanson, R.K.; Song, S.; Gardiner, W.C., Jr.; et al. GRI-Mech 3.0. 1999. Available online: http://www.me.berkeley.edu/gri_mech (accessed on 6 October 2011).

- Spalding, D. A single formula for the “law of the wall”. J. Appl. Mech. 1961, 28, 455–458. [Google Scholar] [CrossRef]

- Weller, H.G.; Tabor, G.; Jasak, H.; Fureby, C. A tensorial approach to computational continuum mechanics using object-oriented techniques. Comput. Phys. 1998, 12, 620–631. [Google Scholar] [CrossRef]

- Issa, R.I. Solution of the implicitly discretised fluid flow equations by operator-splitting. J. Comput. Phys. 1986, 62, 40–65. [Google Scholar] [CrossRef]

- Patankar, S.V.; Spalding, D.B. A calculation procedure for heat, mass and momentum transfer in three-dimensional parabolic flows. In Numerical Prediction of Flow, Heat Transfer, Turbulence and Combustion; Pergamon Press: Oxford, UK, 1983; pp. 54–73. [Google Scholar]

- Ries, F.; Obando, P.; Shevchuck, I.; Janicka, J.; Sadiki, A. Numerical analysis of turbulent flow dynamics and heat transport in a round jet at supercritical conditions. Int. J. Heat Fluid Flow 2017, 66, 172–184. [Google Scholar] [CrossRef]

- Greenshields, C.J. OpenFOAM Programmer’s Guide; OpenFOAM Foundation Ltd.: London, UK, 2015. [Google Scholar]

- Roe, P.L. Characteristic-based schemes for the Euler equations. Annu. Rev. Fluid Mech. 1986, 18, 337–365. [Google Scholar] [CrossRef]

- Kuenne, G.; Ketelheun, A.; Janicka, J. LES modeling of premixed combustion using a thickened flame approach coupled with FGM tabulated chemistry. Combust. Flame 2011, 158, 1750–1767. [Google Scholar] [CrossRef]

- Ketelheun, A.; Olbricht, C.; Hahn, F.; Janicka, J. NO prediction in turbulent flames using LES/FGM with additional transport equations. Proc. Combust. Inst. 2011, 33, 2975–2982. [Google Scholar] [CrossRef]

- Popp, S.; Hartl, S.; Butz, D.; Geyer, D.; Dreizler, A.; Vervisch, L.; Hasse, C. Assessing multi-regime combustion in a novel burner configuration with large eddy simulations using tabulated chemistry. Proc. Combust. Inst. 2021, 38, 2551–2558. [Google Scholar] [CrossRef]

- Peters, N. The turbulent burning velocity for large-scale and small-scale turbulence. J. Fluid Mech. 1999, 384, 107–132. [Google Scholar] [CrossRef]

- Borghi, R. On the structure and morphology of turbulent premixed flames. In Recent Advances in the Aerospace Sciences; Springer: Berlin/Heidelberg, Germany, 1985; pp. 117–138. [Google Scholar] [CrossRef]

- Poinsot, T.; Veynante, D. Theoretical and Numerical Combustion; RT Edwards, Inc.: Dallas, TX, USA, 2012. [Google Scholar]

- Kuenne, G.; Euler, M.; Ketelheun, A.; Avdić, A.; Dreizler, A.; Janicka, J. A numerical study of the flame stabilization mechanism being determined by chemical reaction rates submitted to heat transfer processes. Z. Phys. Chem. 2015, 229, 643–662. [Google Scholar] [CrossRef]

| Approach | Transported Quantities | Computation of via |

|---|---|---|

| DC | , h | transported |

| TAB,prio | , h | tabulated |

| TAB,post | Z, | tabulated |

| TSF-A-r | TSF-D-r | |

|---|---|---|

| 69.557% | 71.780% | |

| 26.523% | 23.935% | |

| 3.917% | 4.262% | |

| 0.004% | 0.023% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dressler, L.; Nicolai, H.; Agrebi, S.; Ries, F.; Sadiki, A. Computation of Entropy Production in Stratified Flames Based on Chemistry Tabulation and an Eulerian Transported Probability Density Function Approach. Entropy 2022, 24, 615. https://doi.org/10.3390/e24050615

Dressler L, Nicolai H, Agrebi S, Ries F, Sadiki A. Computation of Entropy Production in Stratified Flames Based on Chemistry Tabulation and an Eulerian Transported Probability Density Function Approach. Entropy. 2022; 24(5):615. https://doi.org/10.3390/e24050615

Chicago/Turabian StyleDressler, Louis, Hendrik Nicolai, Senda Agrebi, Florian Ries, and Amsini Sadiki. 2022. "Computation of Entropy Production in Stratified Flames Based on Chemistry Tabulation and an Eulerian Transported Probability Density Function Approach" Entropy 24, no. 5: 615. https://doi.org/10.3390/e24050615

APA StyleDressler, L., Nicolai, H., Agrebi, S., Ries, F., & Sadiki, A. (2022). Computation of Entropy Production in Stratified Flames Based on Chemistry Tabulation and an Eulerian Transported Probability Density Function Approach. Entropy, 24(5), 615. https://doi.org/10.3390/e24050615