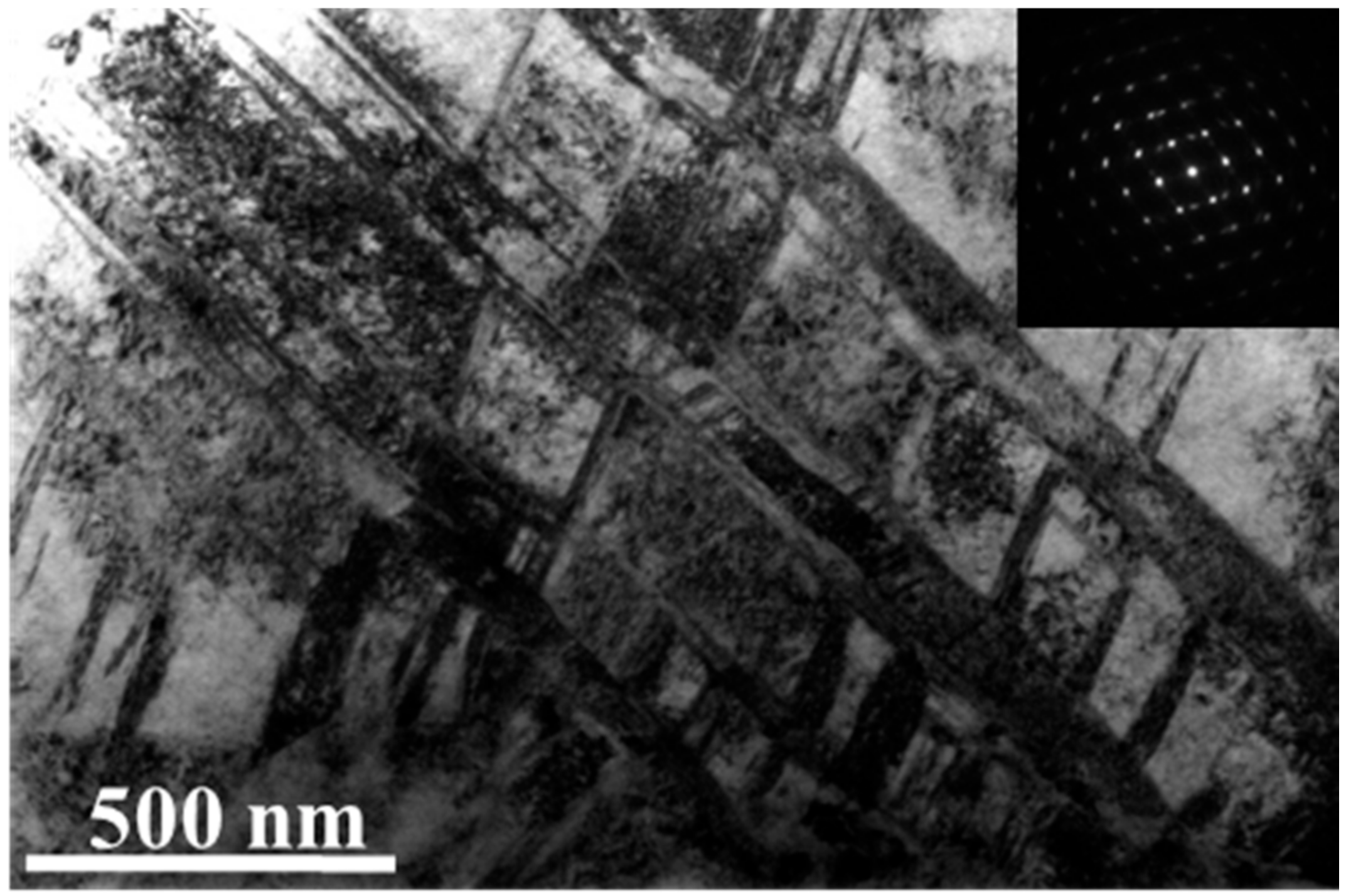

Effective Surface Nano-Crystallization of Ni2FeCoMo0.5V0.2 Medium Entropy Alloy by Rotationally Accelerated Shot Peening (RASP)

Abstract

1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mat. Sci. Eng. A Struct. 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhy, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.S.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Miracle, D.B.; Miller, J.D.; Senkov, O.N.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Shi, P.; Ren, W.; Zheng, T.; Ren, Z.; Hou, X.; Peng, J.; Hu, P.; Gao, Y.; Zhong, Y.; Liaw, P.K. Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae. Nat. Commun. 2019, 10, 489. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Liu, K.M.; Komarasamy, M.; Gwalani, B.; Shukla, S.; Mishra, R.S. Fatigue behavior of ultrafine grained triplex Al0.3CoCrFeNi high entropy alloy. Scr. Mater. 2019, 158, 116–120. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Schuh, B.; Mendez-Martin, F.; Volker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Barr, C.M.; Nathaniel, J.E.; Unocic, K.A.; Liu, J.P.; Zhang, Y.; Wang, Y.Q.; Taheri, M.L. Exploring radiation induced segregation mechanisms at grain boundaries in equiatomic CoCrFeNiMn high entropy alloy under heavy ion irradiation. Scr. Mater. 2018, 156, 80–84. [Google Scholar] [CrossRef]

- Kumar, N.A.P.K.; Li, C.; Leonard, K.J.; Bei, H.; Zinkle, S.J. Microstructural stability and mechanical behavior of FeNiMnCr high entropy alloy under ion irradiation. Acta Mater. 2016, 113, 230–244. [Google Scholar] [CrossRef]

- Qiu, X.W.; Zhang, Y.P.; He, L.; Liu, C.G. Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy. J. Alloy. Compd. 2013, 549, 195–199. [Google Scholar] [CrossRef]

- Zhao, C.C.; Inoue, A.; Kong, F.L.; Zhang, J.Y.; Chen, C.J.; Shen, B.L.; Al-Marzouki, F.; Greer, A.L. Novel phase decomposition, good soft-magnetic and mechanical properties for high-entropy (fe0.25co0.25ni0.25cr0.125mn0.125)(100-x)b-x (x=9-13) amorphous alloys. J. Alloys Compd. 2020, 843, 155917. [Google Scholar] [CrossRef]

- Brechtl, J.; Chen, S.; Lee, C.; Shi, Y.; Feng, R.; Xie, X.; Hamblin, D.; Coleman, A.M.; Straka, B.; Shortt, H.; et al. A review of the serrated-flow phenomenon and its role in the deformation behavior of high-entropy alloys. Metals 2020, 10, 1101. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H.; Fan, Y.Z.; Zhang, W.W.; Wei, R.; Wang, T.; Zhang, T.; Li, F.S. A novel ultrafine-grained high entropy alloy with excellent combination of mechanical and soft magnetic properties. J. Magn. Magn. Mater. 2020, 502, 166513-1–166513-5. [Google Scholar] [CrossRef]

- Ding, Q.; Zhang, Y.; Chen, X.; Fu, X.; Chen, D.; Chen, S.; Gu, L.; Wei, F.; Bei, H.; Gao, Y.; et al. Tuning element distribution, structure and properties by composition in high-entropy alloys. Nature 2019, 574, 223–227. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Asta, M.; Ritchie, R.O.; Minor, A.M. Short-range order and its impact on the CrCoNi medium-entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef]

- Gao, X.Z.; Lu, Y.P.; Zhang, B.; Liang, N.N.; Wu, G.Z.; Sha, G.; Liu, J.Z.; Zhao, Y.H. Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy. Acta Mater. 2017, 141, 59–66. [Google Scholar] [CrossRef]

- Liu, J.B.; Chen, C.X.; Xu, Y.Q.; Wu, S.W.; Wang, G.; Wang, H.T.; Fang, Y.T.; Meng, L. Deformation twinning behaviors of the low stacking fault energy high-entropy alloy: An in-situ TEM study. Scr. Mater. 2017, 137, 9–12. [Google Scholar] [CrossRef]

- Deng, Y.; Tasan, C.C.; Pradeep, K.G.; Springer, H.; Kostka, A.; Raabe, D. Design of a twinning-induced plasticity high entropy alloy. Acta Mater. 2015, 94, 124–133. [Google Scholar] [CrossRef]

- Wu, W.; Song, M.; Ni, S.; Wang, J.; Liu, Y.; Liu, B.; Liao, X. Dual mechanisms of grain refinement in a FeCoCrNi high-entropy alloy processed by high-pressure torsion. Sci. Rep. 2017, 7, 46720. [Google Scholar] [CrossRef] [PubMed]

- Gu, J.; Song, M. Annealing-induced abnormal hardening in a cold rolled CrMnFeCoNi high entropy alloy. Scr. Mater. 2019, 162, 345–349. [Google Scholar] [CrossRef]

- Yao, M.J.; Pradeep, K.G.; Tasan, C.C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Porgress Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Cao, Y.; Ni, S.; Liao, X.Z.; Song, M.; Zhu, Y.T. Structural evolutions of metallic materials processed by severe plastic deformation. Mater. Sci. Eng. R-Rep. 2018, 133, 1–59. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Porgress Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Porgress Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Ovid’ko, I.A.; Valiev, R.Z.; Zhu, Y.T. Review on superior strength and enhanced ductility of metallic nanomaterials. Porgress Mater. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Zhu, Y.T.; Lavernia, E.J. Strategies for improving tensile ductility of bulk nanostructured materials. Adv. Eng. Mater. 2010, 12, 769–778. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Wan, Y.C.; Tang, B.; Gao, Y.H.; Tang, L.L.; Sha, G.; Zhang, B.; Liang, N.N.; Liu, C.M.; Jiang, S.N.; Chen, Z.Y.; et al. Bulk nanocrystalline high-strength magnesium alloys prepared via rotary swaging. Acta Mater. 2020, 200, 274–286. [Google Scholar] [CrossRef]

- Wang, K.; Tao, N.R.; Liu, G.; Lu, J.; Lu, K. Plastic strain-induced grain refinement at the nanometer scale in copper. Acta Mater. 2006, 54, 5281–5291. [Google Scholar] [CrossRef]

- Lu, K. The future of metals. Science 2010, 328, 319–320. [Google Scholar] [CrossRef] [PubMed]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Han, Z.; Wang, K.; Lu, K. Friction and wear behaviors of nanocrystalline surface layer of pure copper. Wear 2006, 260, 942–948. [Google Scholar] [CrossRef]

- Won, J.W.; Lee, S.; Park, S.H.; Kang, M.; Lim, K.R.; Park, C.H.; Na, Y.S. Ultrafine-grained CoCrFeMnNi high-entropy alloy produced by cryogenic multi-pass caliber rolling. J. Alloys Compd. 2018, 742, 290–295. [Google Scholar] [CrossRef]

- Ma, Y.; Yuan, F.P.; Yang, M.X.; Jiang, P.; Ma, E.; Wu, X.L. Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures. Acta Mater. 2018, 148, 407–418. [Google Scholar] [CrossRef]

- Gao, X.Z.; Jiang, L.; Lu, Y.P.; Cao, Z.Q.; Wen, B.; Gang, G.; Liang, N.N.; Wang, T.M.; Li, T.J.; Zhao, Y.H. Extraordinary hardening and ductility in Ni2Co1Fe1V0.5Mo0.2 high entropy alloy by unique nano-scale planar slips. Nature 2020, in press. [Google Scholar]

- Wang, X.; Li, Y.S.; Zhang, Q.; Zhao, Y.H.; Zhu, Y.T. Gradient Structured Copper by Rotationally Accelerated Shot Peening. J. Mater. Sci. Technol. 2017, 33, 758–761. [Google Scholar] [CrossRef]

- Wang, Z.W.; Guo, L.; Xia, W.Z.; Yuan, Z.; Cao, Y.; Ni, S.; Song, M. An SEM-based approach to characterize the microstructural evolution in a gradient CoCrFeNiMo0.15 high-entropy alloy. Mater. Charact. 2020, 161, 110169. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.B.; An, X.H.; Liao, X.Z.; Kawasaki, M.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Concurrent microstructural evolution of ferrite and austenite in a duplex stainless steel processed by high-pressure torsion. Acta Mater. 2014, 63, 16–29. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation twinning in nanocrystalline materials. Pro. Mater. Sci. 2012, 57, 1–62. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X.Y.; Lu, K. Enhanced thermal stability of nanograined metals below a critical grain size. Science 2018, 360, 526–530. [Google Scholar] [CrossRef]

- Lee, D.H.; Choi, I.C.; Yang, G.H.; Lu, Z.P.; Kawasaki, M.; Ramamurty, U.; Schwaiger, R.; Jang, J.I. Activation energy for plastic flow in nanocrystalline CoCrFeMnNi high-entropy alloy: A high temperature nanoindentation study. Scr. Mater. 2018, 156, 129–133. [Google Scholar] [CrossRef]

- Qiang, J.; Tsuchiya, K.; Diao, H.Y.; Liaw, P.K. Vanishing of room-temperature slip avalanches in a face-centered-cubic high-entropy alloy by ultrafine grain formation. Scr. Mater. 2018, 155, 99–103. [Google Scholar] [CrossRef]

- Jiang, L.; Lu, Y.P.; Song, M.; Lu, C.; Sun, K.; Cao, Z.Q.; Wang, T.M.; Gao, F.; Wang, L.M. A promising CoFeNi2V0.5Mo0.2 high entropy alloy with exceptional ductility. Scr. Mater. 2019, 165, 128–133. [Google Scholar] [CrossRef]

- Li, Y.S.; Tao, N.R.; Lu, K. Microstructural evolution and nanostructure formation in copper during dynamic plastic deformation at cryogenic temperatures. Acta Mater. 2008, 56, 230–241. [Google Scholar] [CrossRef]

- Liu, Y.F.; Cao, Y.; Zhou, H.; Chen, X.F.; Liu, Y.; Xiao, L.R.; Huan, X.W.; Zhao, Y.H.; Zhu, Y.T. Mechanical Properties and Microstructures of Commercial-Purity Aluminum Processed by Rotational Accelerated Shot Peening Plus Cold Rolling. Adv. Eng. Mater. 2020, 22, 1900478. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Y.B.; Figueiredo, R.B.; Chang, L.; Liao, X.Z.; Kawasaki, M.; Zheng, W.L.; Ringer, S.P.; Langdon, T.G.; Zhu, Y.T. Three-dimensional shear-strain patterns induced by high-pressure torsion and their impact on hardness evolution. Acta Mater. 2011, 59, 3903–3914. [Google Scholar] [CrossRef]

- Liu, Y.F.; Cao, Y.; Mao, Q.Z.; Zhou, H.; Zhao, Y.H.; Jiang, W.; Liu, Y.; Wang, J.T.; You, Z.S.; Zhu, Y.T. Critical microstructures and defects in heterostructured materials and their effects on mechanical properties. Acta Mater. 2020, 189, 129–144. [Google Scholar] [CrossRef]

- Liu, Y.F.; Wang, F.; Cao, Y.; Nie, J.F.; Zhou, H.; Yang, H.B.; Liu, X.F.; An, X.H.; Liao, X.Z.; Zhao, Y.H.; et al. Unique defect evolution during the plastic deformation of a metal matrix composite. Scr. Mater. 2019, 162, 316–320. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, N.; Wang, X.; Cao, Y.; Li, Y.; Zhu, Y.; Zhao, Y. Effective Surface Nano-Crystallization of Ni2FeCoMo0.5V0.2 Medium Entropy Alloy by Rotationally Accelerated Shot Peening (RASP). Entropy 2020, 22, 1074. https://doi.org/10.3390/e22101074

Liang N, Wang X, Cao Y, Li Y, Zhu Y, Zhao Y. Effective Surface Nano-Crystallization of Ni2FeCoMo0.5V0.2 Medium Entropy Alloy by Rotationally Accelerated Shot Peening (RASP). Entropy. 2020; 22(10):1074. https://doi.org/10.3390/e22101074

Chicago/Turabian StyleLiang, Ningning, Xiang Wang, Yang Cao, Yusheng Li, Yuntian Zhu, and Yonghao Zhao. 2020. "Effective Surface Nano-Crystallization of Ni2FeCoMo0.5V0.2 Medium Entropy Alloy by Rotationally Accelerated Shot Peening (RASP)" Entropy 22, no. 10: 1074. https://doi.org/10.3390/e22101074

APA StyleLiang, N., Wang, X., Cao, Y., Li, Y., Zhu, Y., & Zhao, Y. (2020). Effective Surface Nano-Crystallization of Ni2FeCoMo0.5V0.2 Medium Entropy Alloy by Rotationally Accelerated Shot Peening (RASP). Entropy, 22(10), 1074. https://doi.org/10.3390/e22101074