Bearing Fault Diagnosis Considering the Effect of Imbalance Training Sample

Abstract

1. Introduction

2. Empirical Wavelet Transform

3. Construction and Classification Progress of RF

- (1)

- K sample sets selected randomly with replacement by bootstrap are used to build K decision trees, and the remaining samples after every selection are regarded as out-of-bag data.

- (2)

- features are selected from each node of the decision trees. The amount of discriminative information contained in the features is used to estimate the classification ability of the different features. The feature with the strongest classification ability is regarded as a segmentation feature of the node. Usually, , where M is the total number of features.

- (3)

- To obtain low-bias trees, no pruning operation is performed in each tree.

- (4)

- RF is constructed with K decision trees obtained through the above process. For the tested bearing samples, the final classification result of RF is determined by taking the voting results of all decision trees into account.

4. One-Class Support Vector

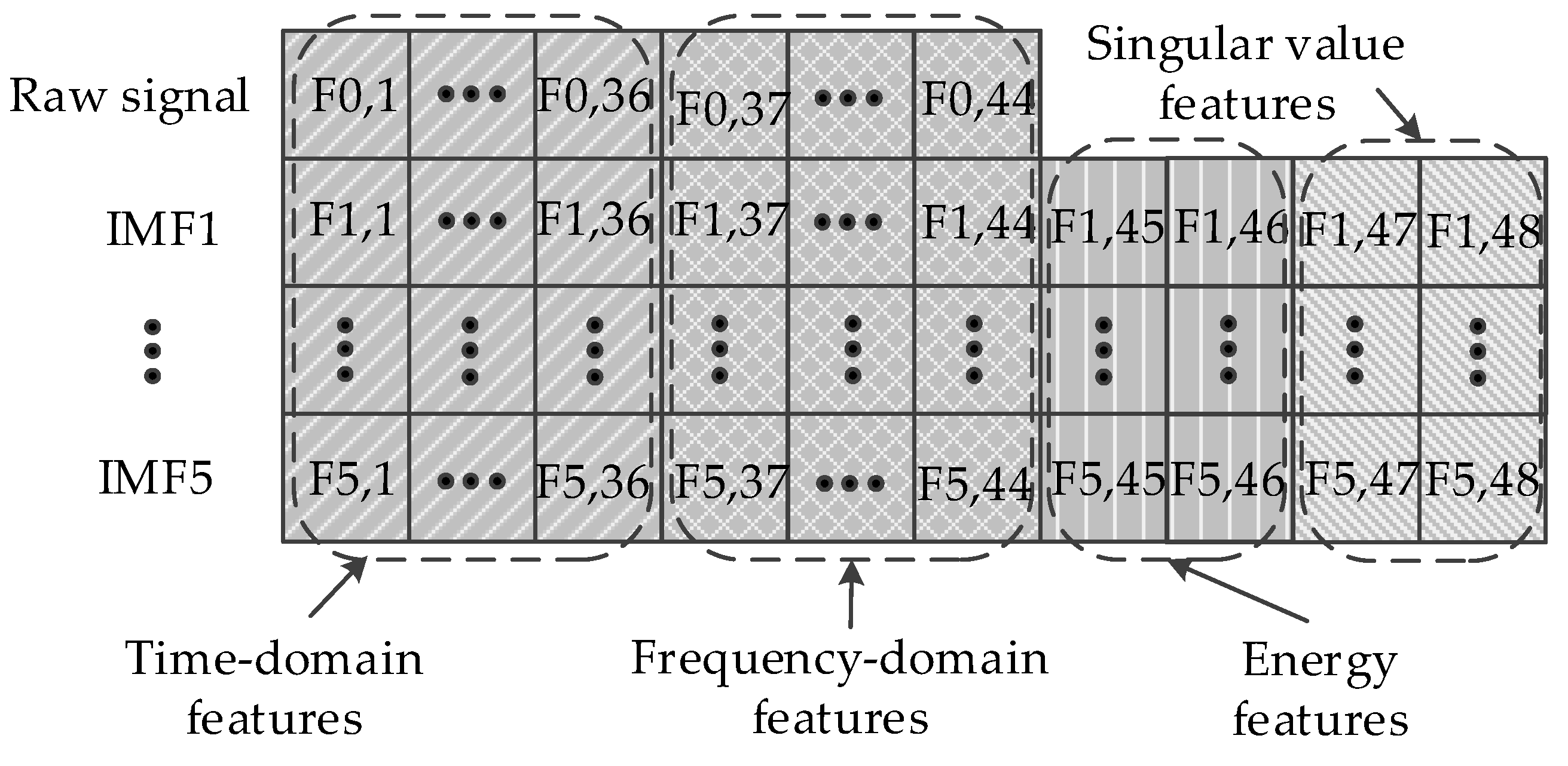

5. Construction of the Initial Feature Set

5.1. Condition Classes of the Experimental Data

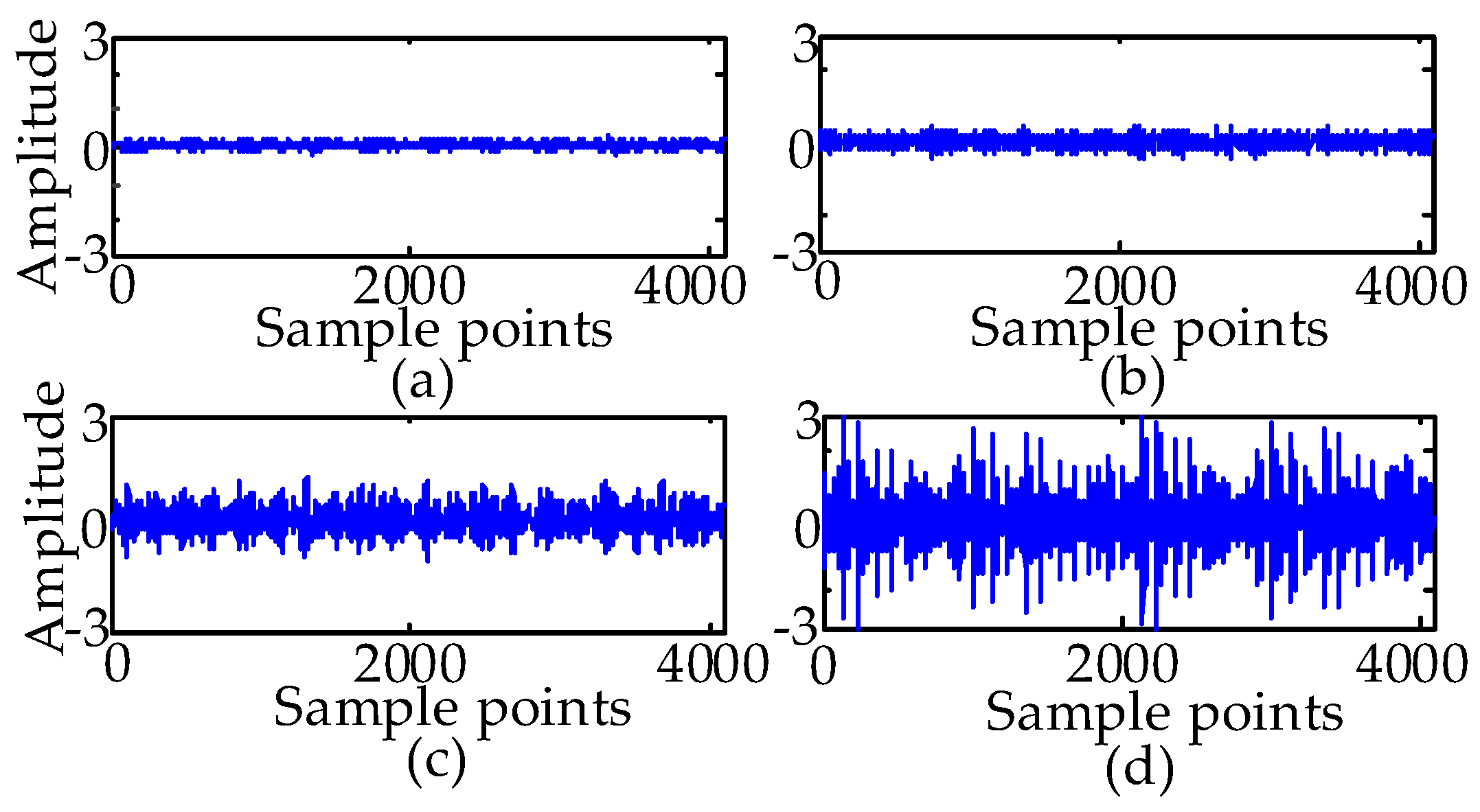

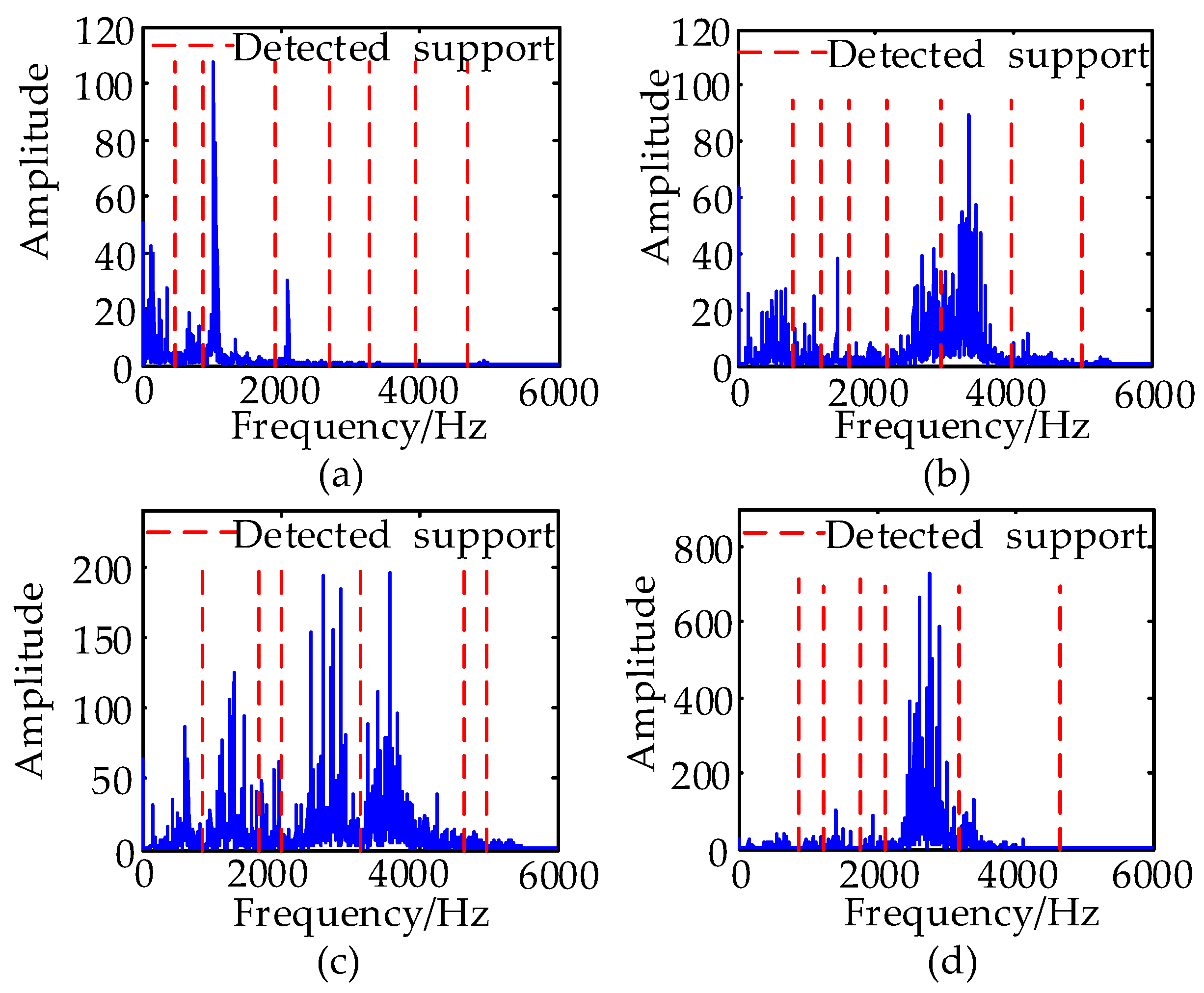

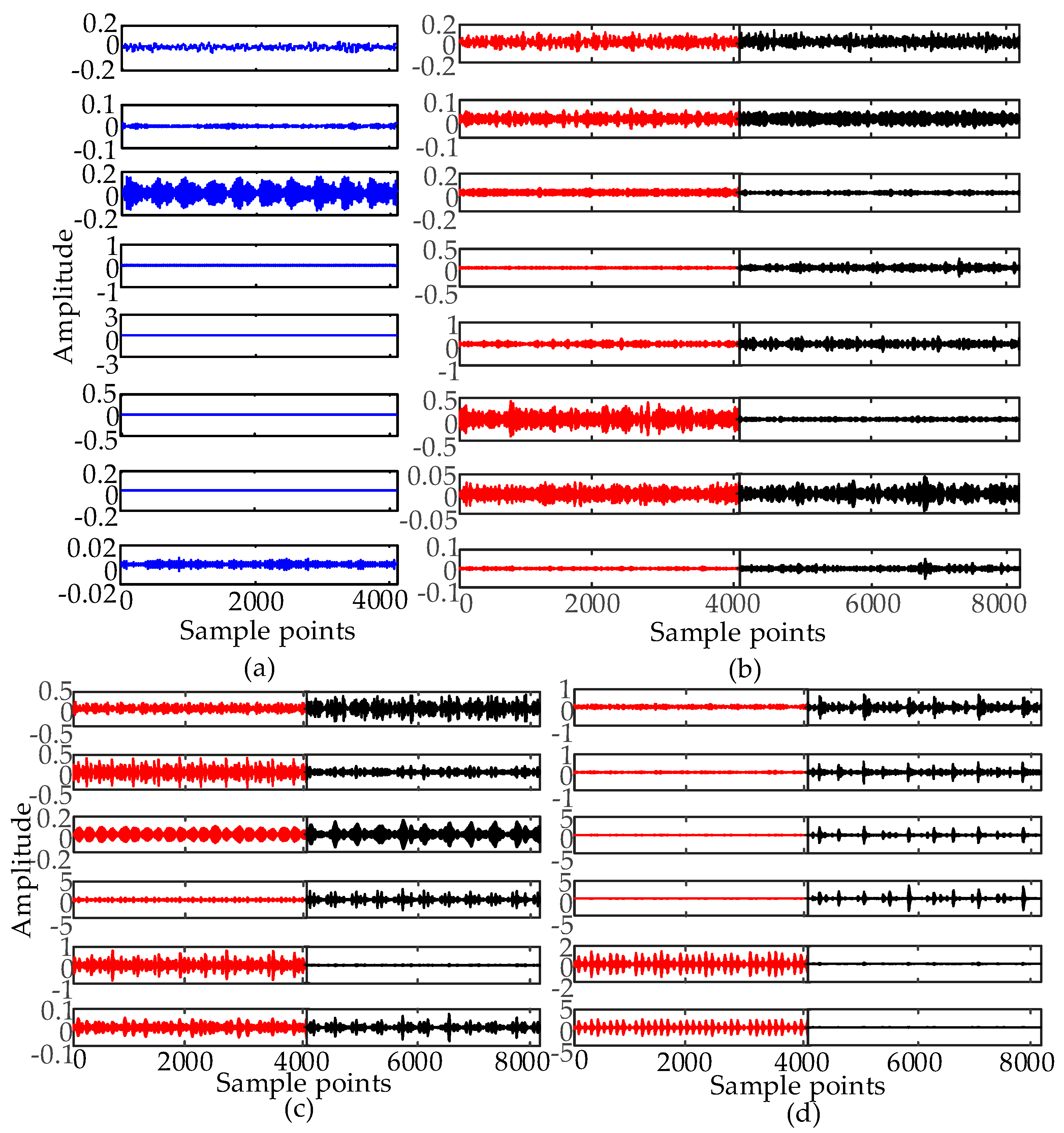

5.2. Analysis of the Bearing Vibration Signal Using EWT

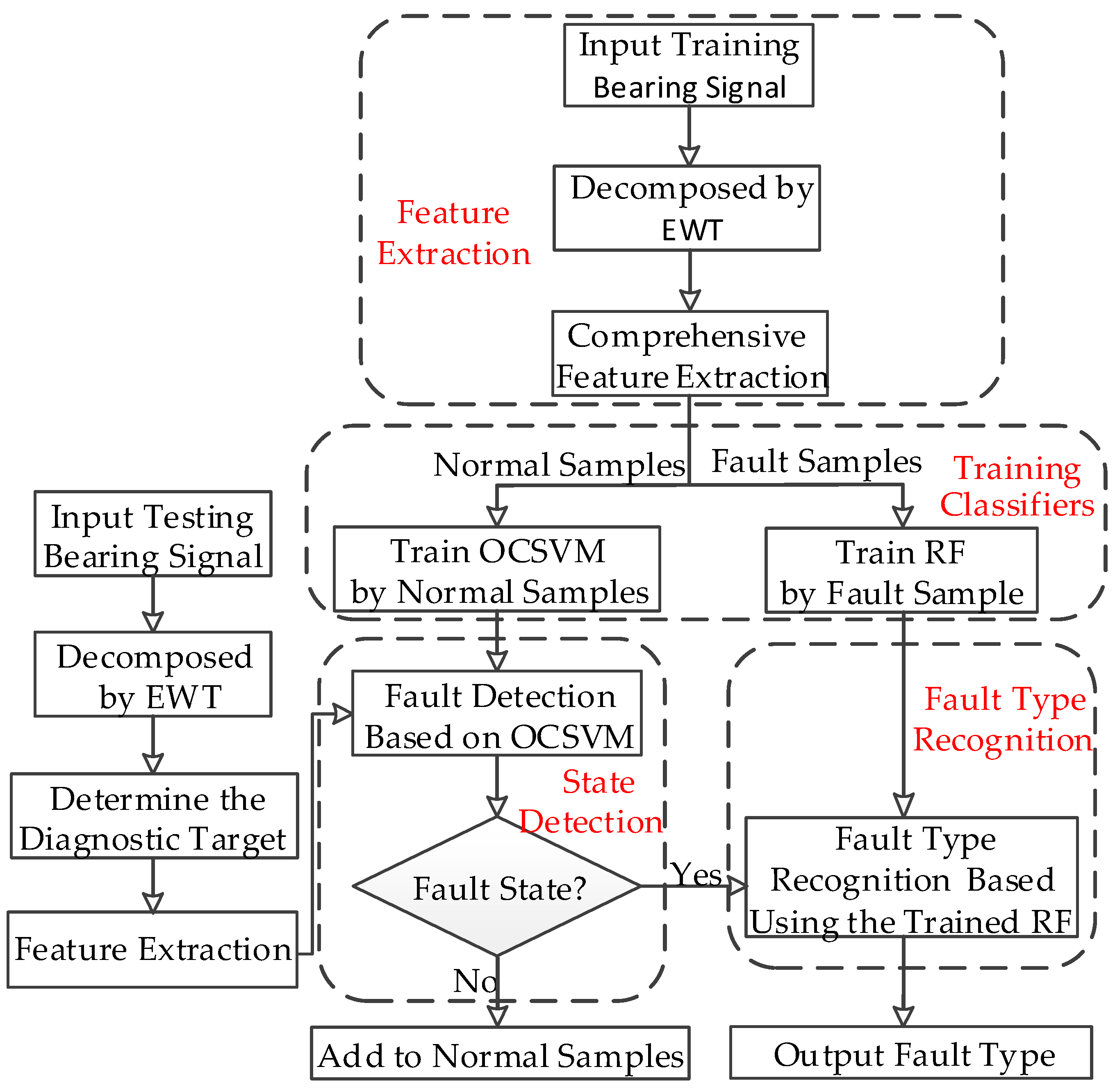

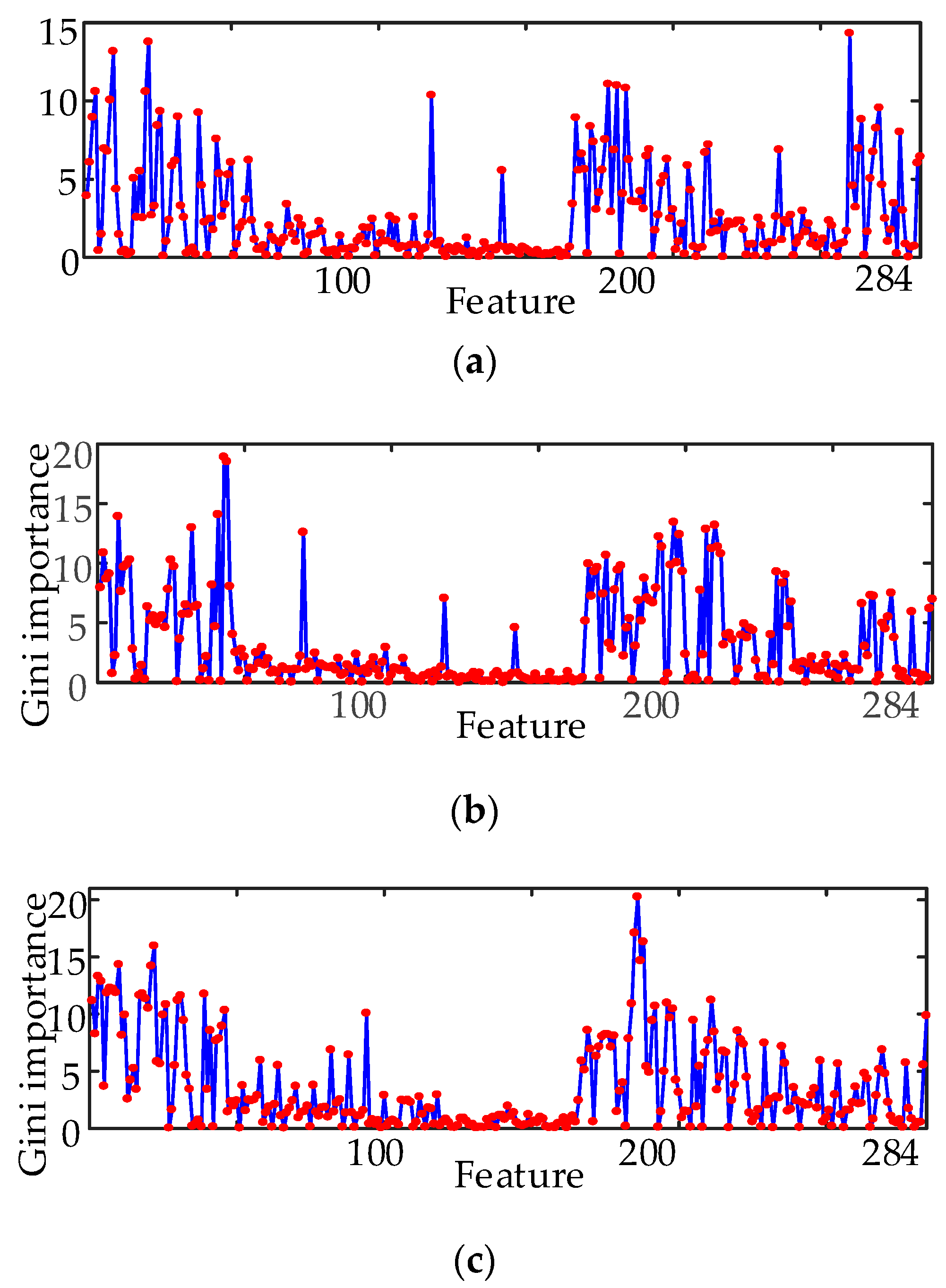

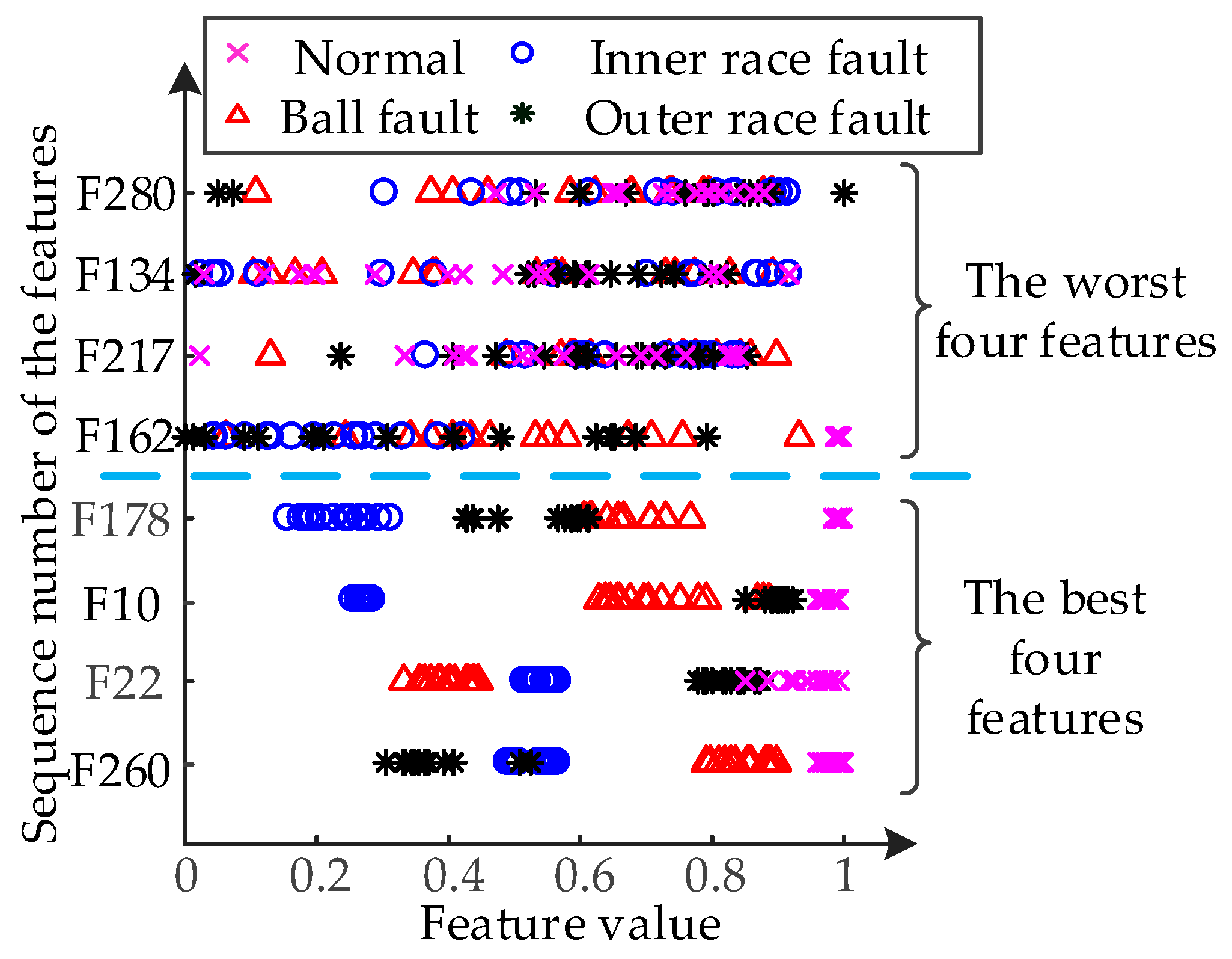

6. Feature Analysis and Classification Ability Analysis of OCSVM and RF

- (1)

- Target 1: 4 types, including normal signals, ball fault, inner race fault, outer race fault;

- (2)

- Target 2: 7 types, including normal signals and faults with different positions;

- (3)

- Target 3: 19 types, including normal signals and faults with different positions and severities.

7. Diagnosis Result of Various Scenarios

7.1. Fault Scenario 1: All Types are Included in the Training Set

7.2. Fault Scenario 2: Samples of Various Fault Severities are Insufficient in the Training Set

8. The Comparisons of Diagnostic Results

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| EMD | empirical mode decomposition |

| WPT | wavelet packet transform |

| LMD | local mean decomposition |

| EEMD | ensemble empirical mode decomposition |

| EWT | empirical wavelet transform |

| IMFs | intrinsic mode functions |

| CART | Classification and Regression Tree |

| RF | random forest |

| SVMs | support vector machines |

| BPNNs | back propagation neural networks |

| ELMs | extreme learning machines |

| DNNs | deep neural networks |

| DBNs | deep belief networks |

| CNNs | convolutional neural network |

| CWRU | Case Western Reserve University |

| VSI | vibration spectrum imaging |

| FFT | Fast Fourier transform |

| OCSVM | One-class support vector machine |

| EDM | electro-discharge machining |

| DE | drive end |

| DAFD | domain adaptation in fault diagnosis |

| ACC | accuracy |

| FE | fan end |

| AM-FM | Amplitude modulated-frequency modulated |

| ANN | artificial neural network |

| LCN | local connection network |

| WKLFDA | wavelet kernel local fisher discriminant analysis |

References

- Rauber, T.W.; Boldt, F.D.A.; Varejão, F.M. Heterogeneous Feature Models and Feature Selection Applied to Bearing Fault Diagnosis. IEEE Trans. Ind. Electron. 2015, 62, 637–646. [Google Scholar] [CrossRef]

- Lu, W.; Liang, B.; Cheng, Y.; Meng, D.; Yang, J.; Zhang, T. Deep model based domain adaptation for fault diagnosis. IEEE Trans. Ind. Electron. 2017, 64, 2296–2305. [Google Scholar] [CrossRef]

- Castejon, C.; Lara, O.; Garcia, J.C. Automated diagnosis of rolling bearings using MRA and neural networks. Mech. Syst. Signal Process. 2010, 24, 289–299. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Guo, L.; Lin, J.; Xing, S. A neural network constructed by deep learning technique and its application to intelligent fault diagnosis of machines. Neurocomputing 2017, 272, 619–628. [Google Scholar] [CrossRef]

- Amar, M.; Gondal, I.; Wilson, C. Vibration spectrum imaging: A novel bearing fault classification approach. IEEE Trans. Ind. Electron. 2015, 62, 494–502. [Google Scholar] [CrossRef]

- Tian, Y.; Ma, J.; Lu, C.; Wang, Z.L. Rolling bearing fault diagnosis under variable conditions using LMD-SVD and extreme learning machine. Mech. Mach. Theor. 2015, 90, 175–186. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W. Multisensor Feature Fusion for Bearing Fault Diagnosis Using Sparse Autoencoder and Deep Belief Network. IEEE Trans. Instrum. Meas. 2017, 66, 1693–1702. [Google Scholar] [CrossRef]

- Bustos, A.; Rubio, H.; Castejón, C.; García-Prada, J.C. EMD-Based Methodology for the Identification of a High-Speed Train Running in a Gear Operating State. Sensors 2018, 18, 793. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; He, Q. Energy-Fluctuated Multiscale Feature Learning With Deep ConvNet for Intelligent Spindle Bearing Fault Diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 1926–1935. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, J. Multi-fault diagnosis for rolling element bearings based on ensemble empirical mode decomposition and optimized support vector machines. Mech. Syst. Signal Process. 2013, 41, 127–140. [Google Scholar] [CrossRef]

- Wan, S.T.; Chen, L.; Dou, L.J.; Zhou, J.P. Mechanical Fault Diagnosis of HVCBs Based on Multi-Feature Entropy Fusion and Hybrid Classifier. Entropy 2018, 20, 847. [Google Scholar] [CrossRef]

- Gilles, J. Empirical wavelet transform. IEEE Trans. Signal Process. 2013, 61, 3999–4010. [Google Scholar] [CrossRef]

- Cao, H.R.; Fan, F.; Zhou, K.; He, Z.J. Wheel-bearing Fault Diagnosis of Trains using Empirical Wavelet Transform. Measurement 2016, 82, 439–449. [Google Scholar] [CrossRef]

- Chen, J.L.; Pan, J.; Li, Z.P.; Zi, Y.Y.; Chen, X.F. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Rai, A.; Upadhyay, S.H. Bearing performance degradation assessment based on a combination of empirical mode decomposition and k-medoids clustering. Mech. Syst. Signal Process. 2017, 93, 16–29. [Google Scholar] [CrossRef]

- Wu, S.D.; Wu, C.W.; Wu, T.Y.; Wang, C.C. Multi-scale analysis based ball bearing defect diagnostics using Mahalanobis distance and support vector machine. Entropy 2013, 15, 416–433. [Google Scholar] [CrossRef]

- Wei, Z.X.; Wang, Y.X.; He, S.L.; Bao, J.D. A novel intelligent method for bearing fault diagnosis based on affinity propagation clustering and adaptive feature selection. Knowl.-Based Syst. 2016, 116, 1–12. [Google Scholar] [CrossRef]

- Vong, C.M.; Wong, P.K.; Ip, W.F. A new framework of simultaneous-fault diagnosis using pairwise probabilistic multi-label classification for time-dependent patterns. IEEE Trans. Ind. Electron. 2013, 60, 3372–3385. [Google Scholar] [CrossRef]

- Van, M.; Kang, H.J. Bearing defect classification based on individual wavelet local fisher discriminant analysis with particle swarm optimization. IEEE Trans. Ind. Inform. 2016, 12, 124–135. [Google Scholar]

- Sreevani, C.; Murthy, A. Bridging Feature Selection and Extraction: Compound Feature Generation. IEEE Trans. Knowl. Data Eng. 2017, 18, 757–770. [Google Scholar]

- Guyon, I.; Elisseeff, A. An introduction to variable and feature selection. J. Mach. Learn. Res. 2003, 3, 1157–1182. [Google Scholar]

- Chandrashekar, G.; Sahin, F. A survey on feature selection methods. Comput. Electr. Eng. 2014, 40, 16–28. [Google Scholar] [CrossRef]

- Mursalin, M.; Zhang, Y.; Chen, Y.H.; Chawla, N.V. Automated epileptic seizure detection using improved correlation-based feature selection with random forest classifier. Neurocomputing 2017, 241, 204–214. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Cerrada, M.; Pacheco, F.; Cabrera, D.; Zurita, G.; Li, C. Hierarchical feature selection based on relative dependency for gear fault diagnosis. Appl. Intell. 2016, 44, 687–703. [Google Scholar] [CrossRef]

- Mahapatra, D. Analyzing training information from random forests for improved image segmentation. IEEE Trans. Image Process. 2014, 23, 1504–1512. [Google Scholar] [CrossRef]

- Kedadouche, M.; Liu, Z.H.; Vu, V.H. A new approach based on OMA-empirical wavelet transforms for bearing fault diagnosis. Measurement 2016, 90, 292–308. [Google Scholar] [CrossRef]

- Wang, J.; Peng, Y.Y.; Qiao, W. Current-Aided Order Tracking of Vibration Signals for Bearing Fault Diagnosis of Direct-Drive Wind Turbines. IEEE Trans. Ind. Electron. 2016, 63, 6336–6346. [Google Scholar] [CrossRef]

- Cruz, T.; Rosa, L.; Proenca, J.; Maglaras, L.; Aubigny, M.; Lev, L.; Jiang, J.M.; Simoes, P. A Cyber Security Detection Framework for Supervisory Control and Data Acquisition Systems. IEEE Trans. Ind. Inform. 2016, 12, 2236–2245. [Google Scholar] [CrossRef]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64–65, 100–131. [Google Scholar] [CrossRef]

- Cohen, J. A coefficient of agreement for nominal scales. Educ. Psychol. Meas. 1960, 20, 37–46. [Google Scholar] [CrossRef]

- Potočnik, P.; Govekar, E. Semi-supervised vibration-based classification and condition monitoring of compressors. Mech. Syst. Signal Process. 2017, 93, 51–65. [Google Scholar] [CrossRef][Green Version]

| Diagnostic Target | Classifier | K | ACC/% | η/% |

|---|---|---|---|---|

| target 1 | OCSVM-RF | 1 | 100 | 100 |

| RF | 1 | 100 | 100 | |

| SVM BPNN | 0.9800 0.9750 | 97.50 97.50 | 97.750 97.500 | |

| target 2 | OCSVM-RF | 1 | 100 | 100 |

| RF | 1 | 100 | 100 | |

| SVM BPNN | 0.9667 0.9683 | 97 97.25 | 96.835 97.04 | |

| target 3 | OCSVM-RF | 1 | 100 | 100 |

| RF | 1 | 100 | 100 | |

| SVM BPNN | 0.9508 0.9250 | 95.75 95.25 | 95.415 93.875 |

| Classifier | Test Fault Type | Test (Missing) Fault Level | Diagnosis Result | ||

|---|---|---|---|---|---|

| BAF | Other Fault Type | Normal State | |||

| SVM | DE-BAF | 0.007, 0.014 | 79 | 17 | 4 |

| 0.007, 0.021 | 86 | 8 | 6 | ||

| 0.014, 0.021 | 82 | 18 | 0 | ||

| FE-BAF | 0.007, 0.014 | 85 | 10 | 5 | |

| 0.007, 0.021 | 86 | 11 | 3 | ||

| 0.014, 0.021 | 87 | 13 | 0 | ||

| BPNN | DE-BAF | 0.007, 0.014 | 79 | 10 | 11 |

| 0.007, 0.021 | 76 | 13 | 11 | ||

| 0.014, 0.021 | 80 | 20 | 0 | ||

| FE-BAF | 0.007, 0.014 | 81 | 7 | 12 | |

| 0.007, 0.021 | 80 | 10 | 10 | ||

| 0.014, 0.021 | 78 | 22 | 0 | ||

| RF | DE-BAF | 0.007, 0.014 | 93 | 3 | 4 |

| 0.007, 0.021 | 98 | 0 | 2 | ||

| 0.014, 0.021 | 100 | 0 | 0 | ||

| FE-BAF | 0.007, 0.014 | 94 | 2 | 4 | |

| 0.007, 0.021 | 98 | 0 | 2 | ||

| 0.014, 0.021 | 100 | 0 | 0 | ||

| OCSVM-RF | DE-BAF | 0.007, 0.014 | 97 | 3 | 0 |

| 0.007, 0.021 | 100 | 0 | 0 | ||

| 0.014, 0.021 | 100 | 0 | 0 | ||

| FE-BAF | 0.007, 0.014 | 98 | 2 | 0 | |

| 0.007, 0.012 | 100 | 0 | 0 | ||

| 0.014, 0.021 | 100 | 0 | 0 | ||

| Ref. | No. of Classes | ACC/% | No. of Diagnostic Targets | Imbalance of Samples |

|---|---|---|---|---|

| [1] | 19 | 98.13 | 1 | not considering |

| [2] | 4 | 94.73 | 1 | not considering |

| [4] | 4 | 96.90 | 1 | not considering |

| [3] | 10 | 99.92 | 1 | not considering |

| [8] | 6 | 97.04 | 1 | not considering |

| [16] | 10 | 98.80 | 1 | not considering |

| Proposed method | 4 | 100 | 3 | considering |

| 7 | 100 | |||

| 19 | 100 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, L.; Wang, B.; Qi, J.; Wang, D.; Huang, N. Bearing Fault Diagnosis Considering the Effect of Imbalance Training Sample. Entropy 2019, 21, 386. https://doi.org/10.3390/e21040386

Lin L, Wang B, Qi J, Wang D, Huang N. Bearing Fault Diagnosis Considering the Effect of Imbalance Training Sample. Entropy. 2019; 21(4):386. https://doi.org/10.3390/e21040386

Chicago/Turabian StyleLin, Lin, Bin Wang, Jiajin Qi, Da Wang, and Nantian Huang. 2019. "Bearing Fault Diagnosis Considering the Effect of Imbalance Training Sample" Entropy 21, no. 4: 386. https://doi.org/10.3390/e21040386

APA StyleLin, L., Wang, B., Qi, J., Wang, D., & Huang, N. (2019). Bearing Fault Diagnosis Considering the Effect of Imbalance Training Sample. Entropy, 21(4), 386. https://doi.org/10.3390/e21040386