First-Principles Design of Refractory High Entropy Alloy VMoNbTaW

Abstract

1. Introduction

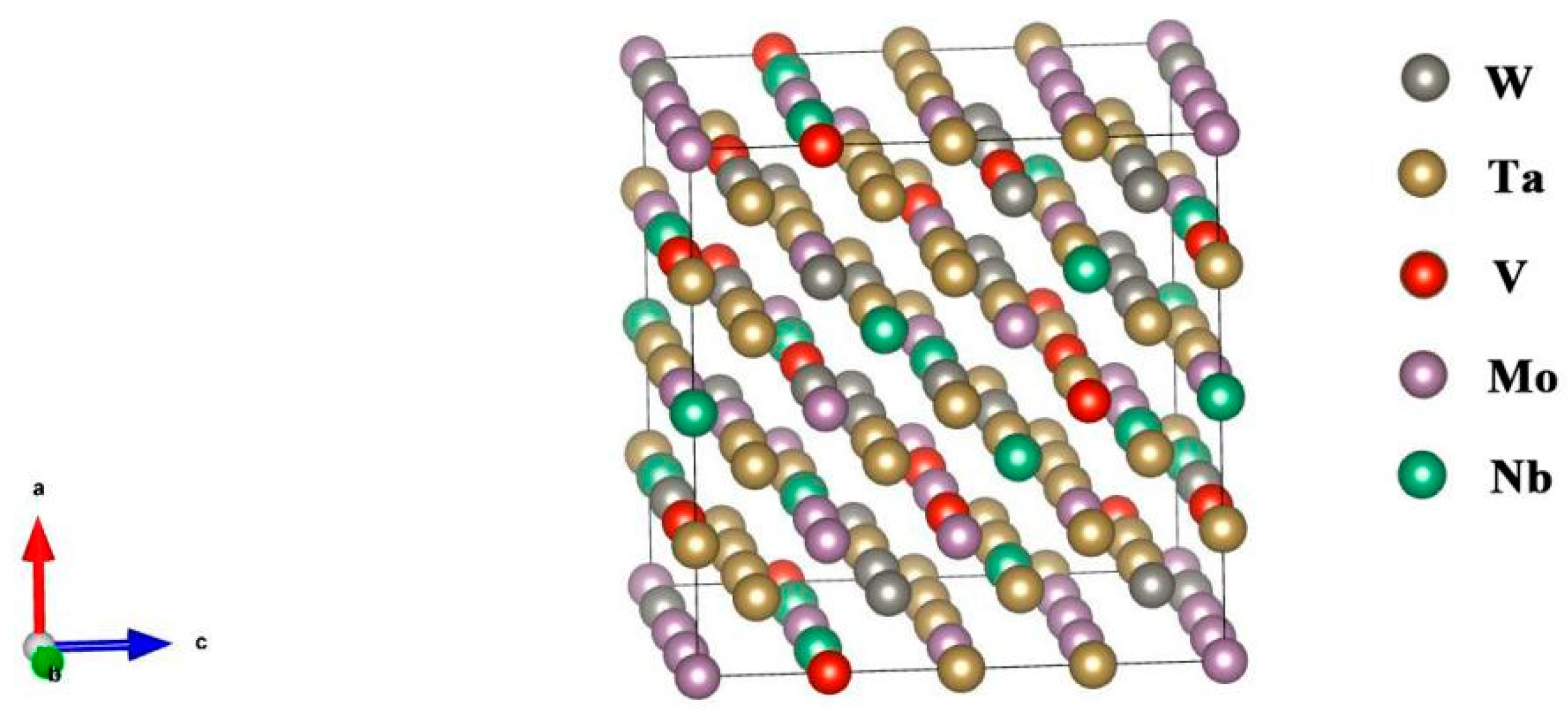

2. Methodology

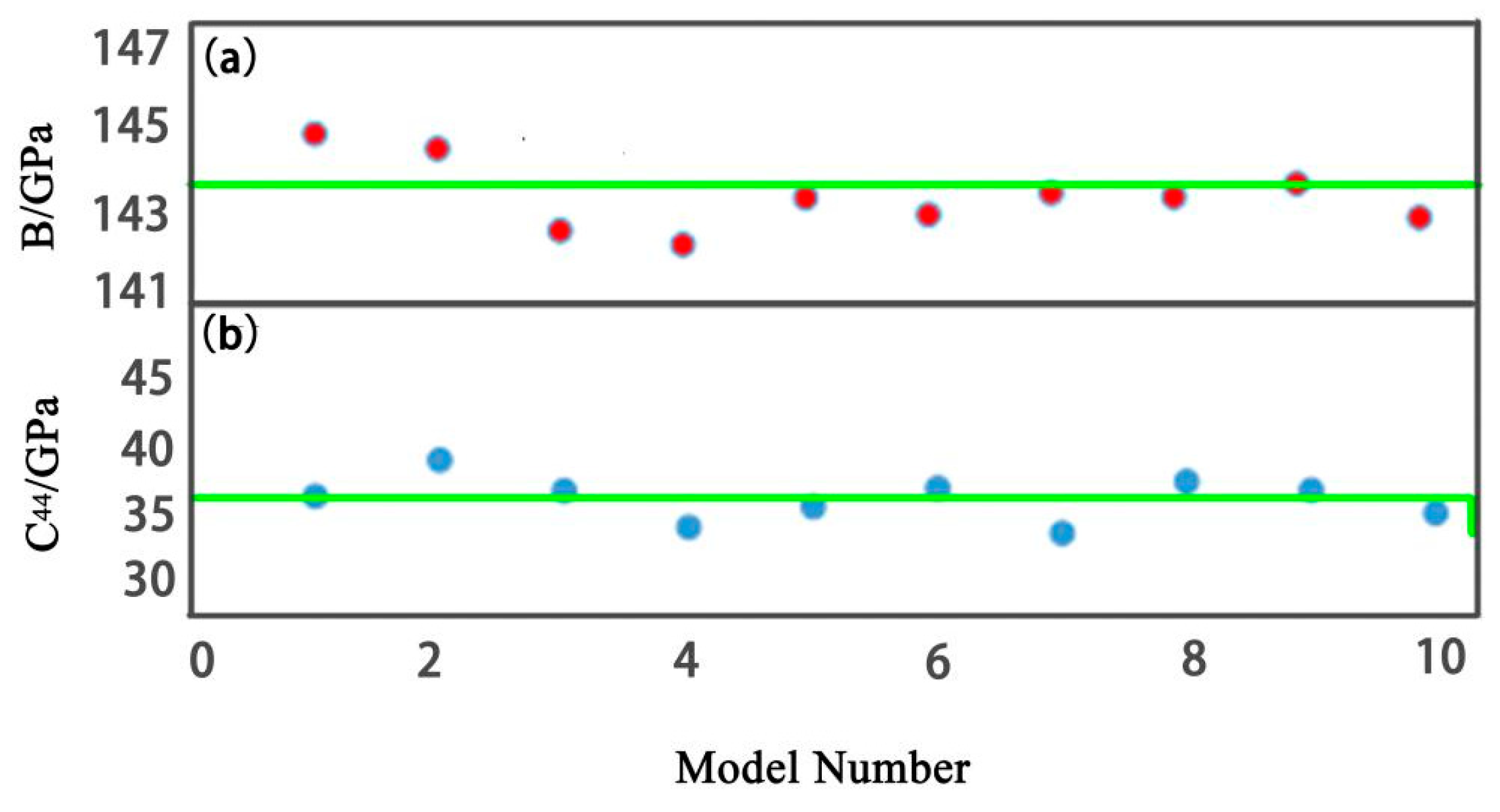

3. Maximum Entropy (MaxEnt) Model

4. Elastic Properties

5. Results and Discussion

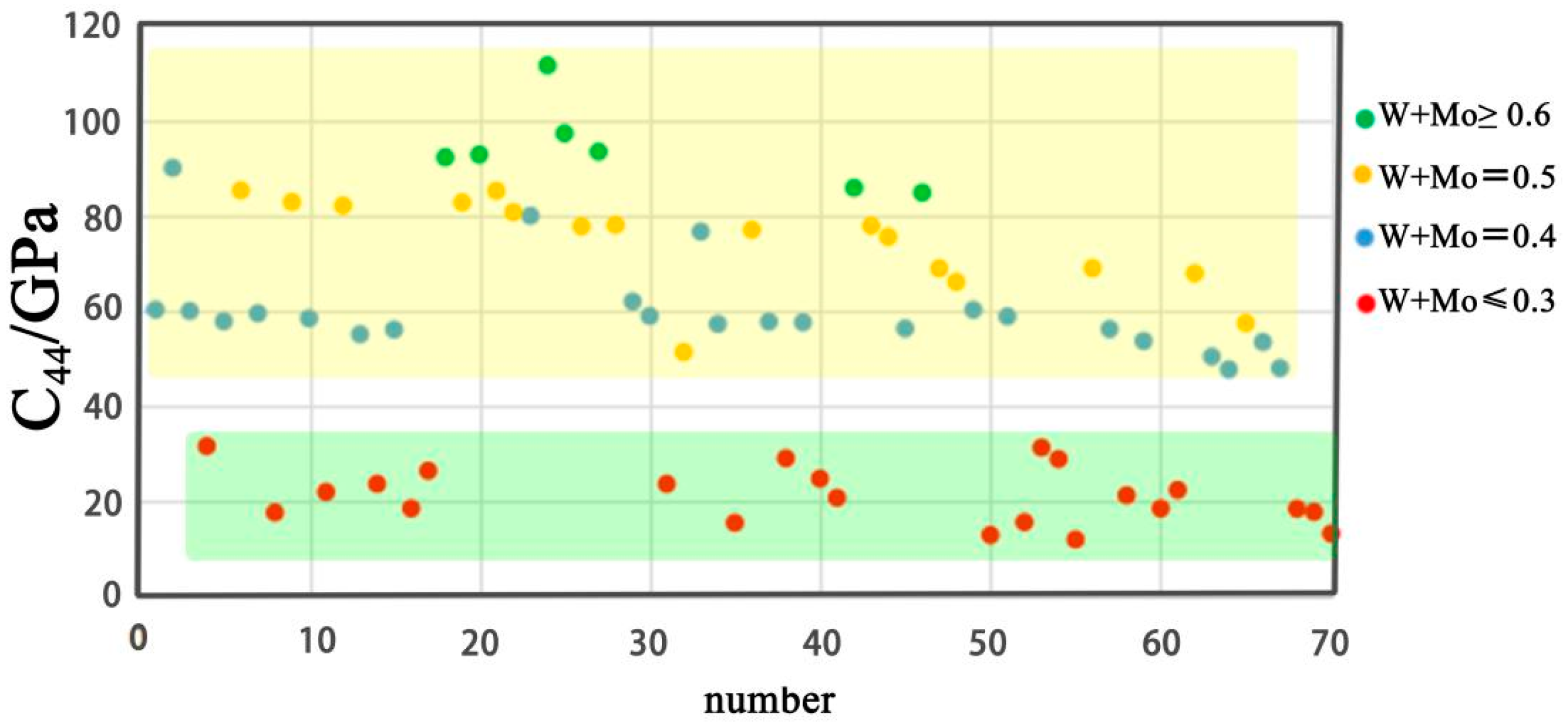

5.1. C44

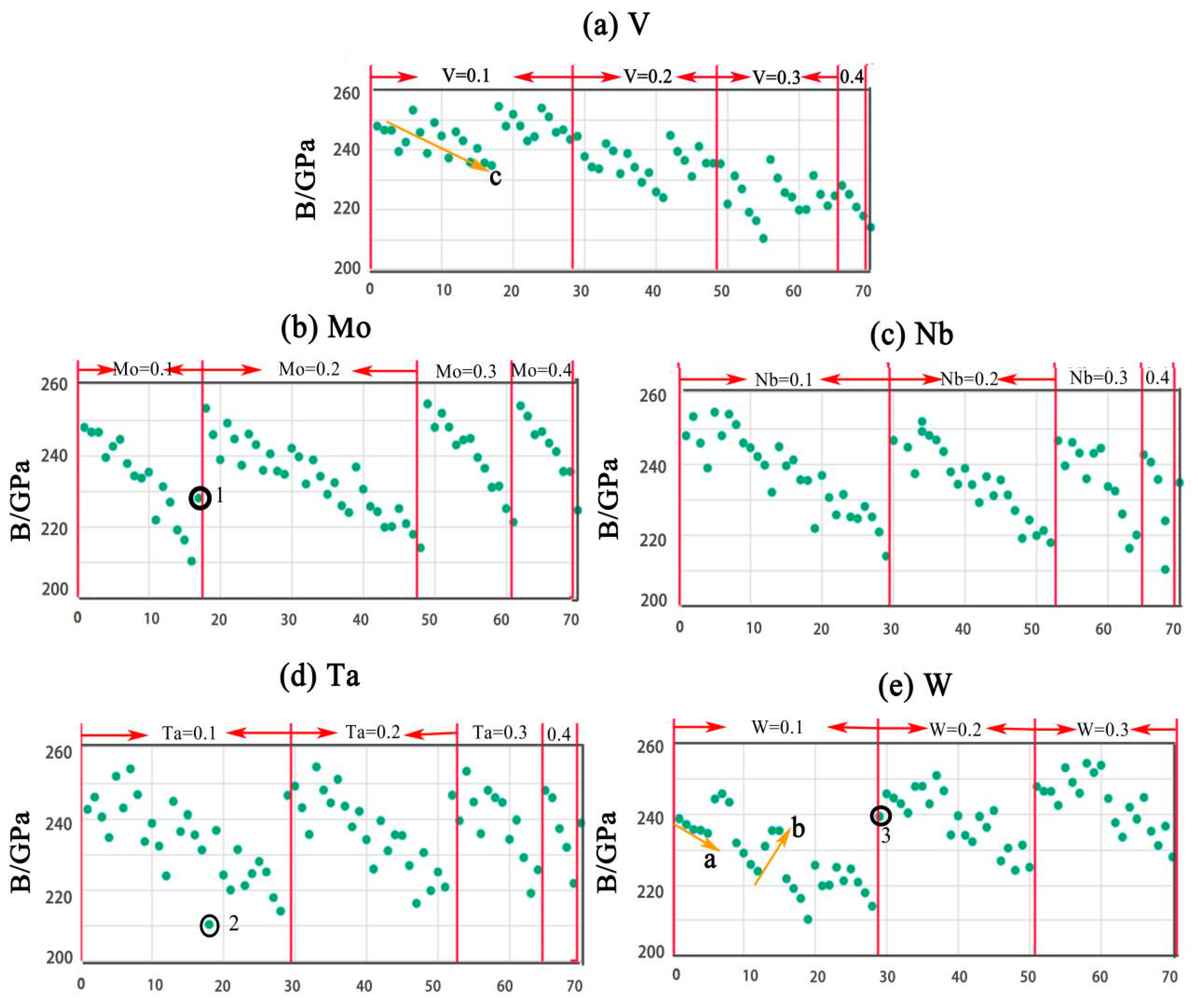

5.2. Bulk Modulus

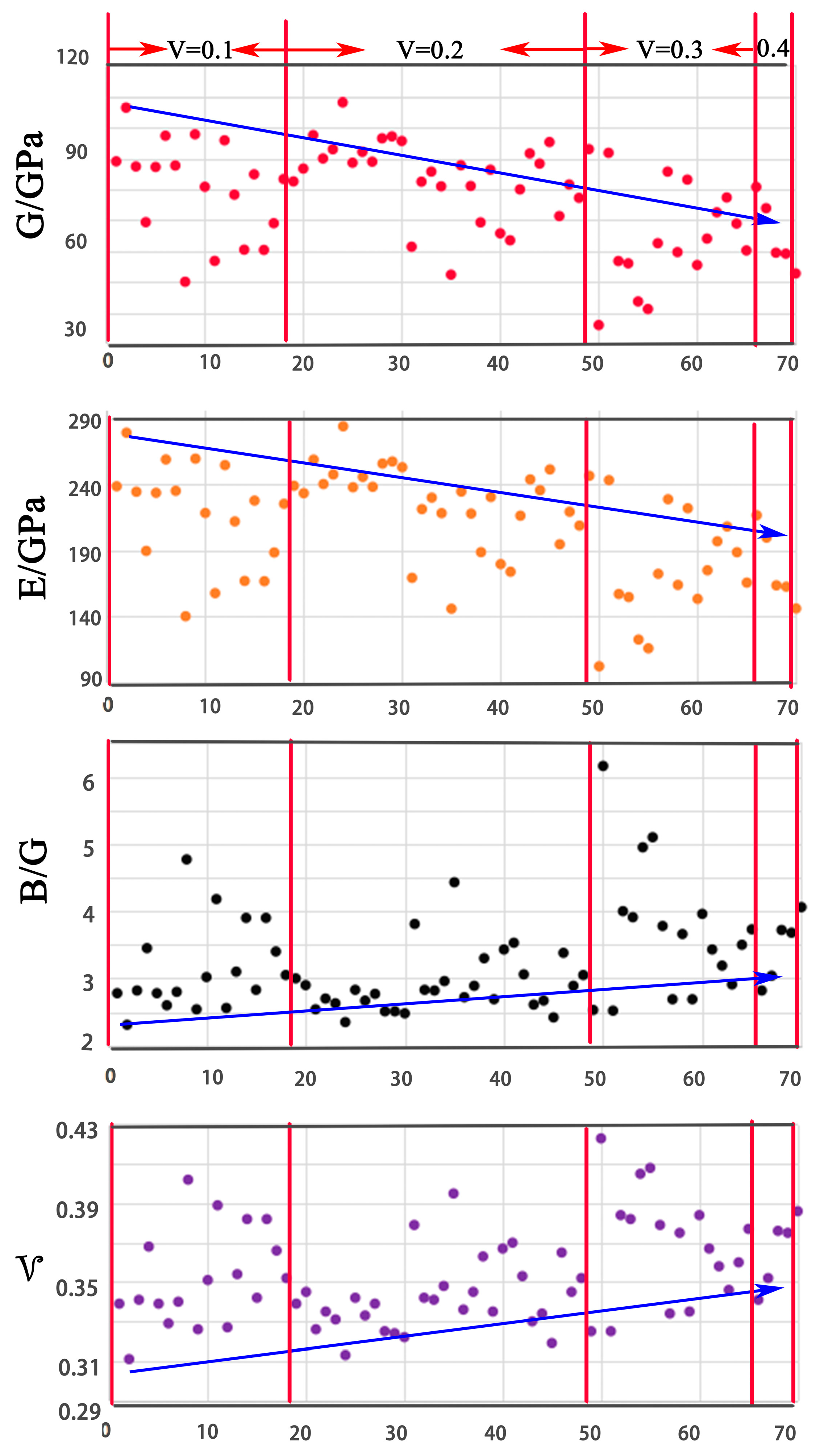

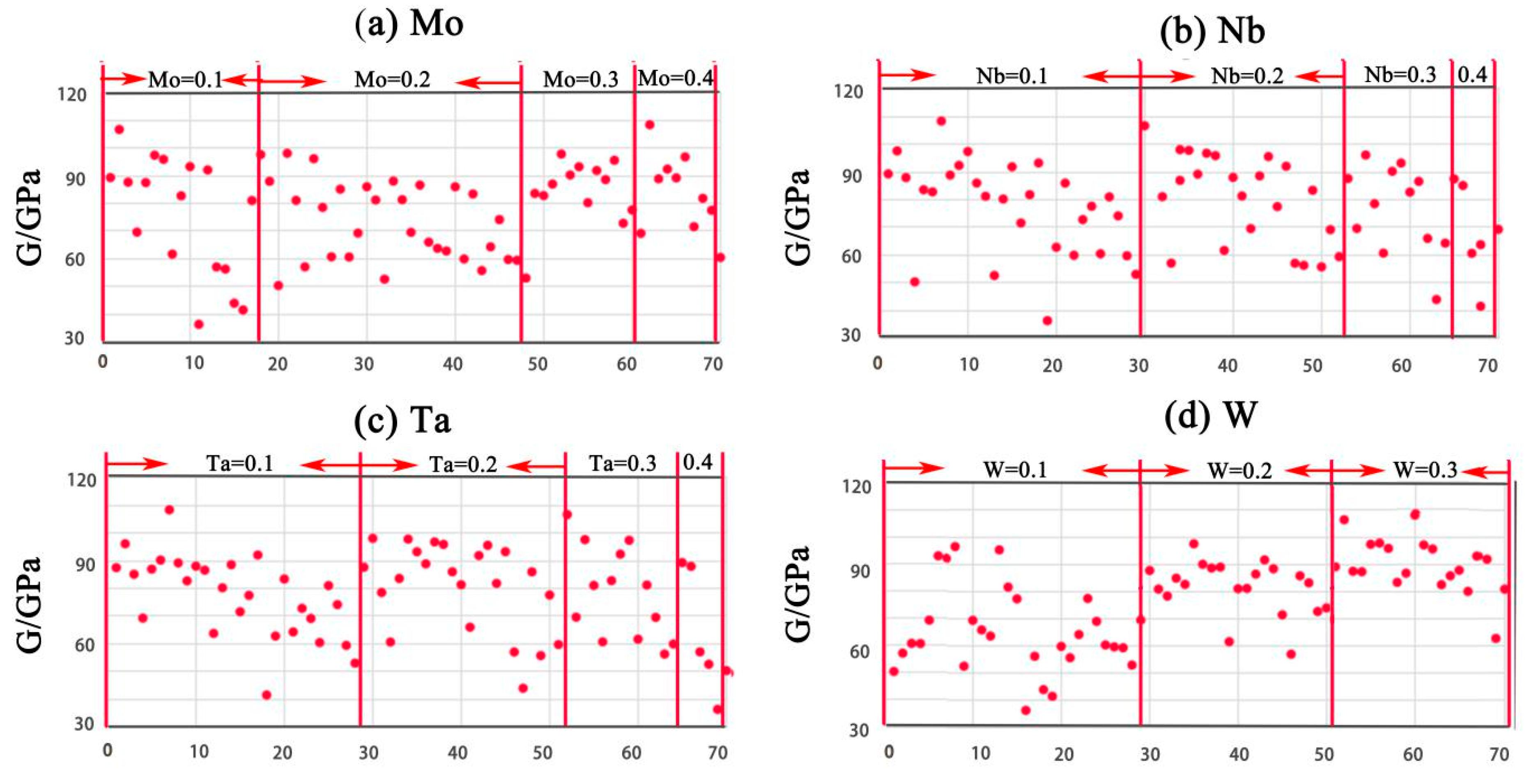

5.3. G, E, B/G, ν

6. Conclusions

- Mo and W are key elements in the V–Mo–Nb–Ta–W system. The V–Mo–Nb–Ta–W system has relatively high values of C44, B, E, and G, with high concentrations of Mo + W. The concentration of Mo + W shows the most prominent effect on C44. Due to the high density of W, element Mo can be used to substitute part of W. In this case, the concentration of W should be reduced.

- V has low density (6.110 g/cm3) and plays an important in decreasing the brittleness of the V–Mo–Nb–Ta–W system.

- In comparison, Nb and Ta have relatively small influence on elastic properties.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements; Noval Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A Fracture-resistant High-entrop Alloy for Cryogenic Applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed]

- Miracle, D.B.; Senkov, O.N. A Critical Review of High Entropy Alloys and Related. Acta. Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.; Miracle, D.B. Microstructure and Properties of Aluminum-Containing Refractory High-Entropy Alloys. JOM 2014, 66, 2030–2042. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Scott, J.M.; Miracle, D.B. Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Elloys. Intermetallics 2011, 19, 698–706. [Google Scholar] [CrossRef]

- Han, Z.D.; Luan, H.W.; Liu, X.; Chen, N.; Li, X.Y.; Shao, Y.; Yao, K.F. Microstructures and Mechanical Properties of TixNbMoTaW Refractory High Entropy Alloys. Mater. Sci. Eng. A 2018, 712, 380–385. [Google Scholar] [CrossRef]

- Yuan, L.; Yan, Z.; Heng, Z.; Naijuan, W.; Xiang, C.; Huawei, Z.; Yanxiang, L. Microstructure and mechanical properties of refractory HfMo0.5NbTiV0.5Six high-entropy composites. J. Alloy Compd. 2017, 694, 869–876. [Google Scholar]

- Senkov, O.N.; Isheim, D.; Seidman, D.N.; Pilchak, A.L. Development of a Refractory High Entropy Superalloy. Entropy 2016, 18, 102. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C. Effect of Aluminum on The Microstructure and Properties of Two Refractory High-Entropy Alloys. Acta Mater. 2014, 68, 214–228. [Google Scholar]

- Mina, Z.; Xianglin, Z.; Jinghao, L. Microstructure and Mechanical Properties of a Refractory CoCrMoNbTi High-Entropy Alloy. J. Mater. Eng. Perform. 2017, 26, 3657–3665. [Google Scholar]

- Shao-Ping, W.; Jian, X. (TiZrNbTa)-Mo High-entropy Alloys: Dependence of Microstructure and Mechanical Properties on Mo Concentration and Modeling of Solid Solution Strengthening. Intermetallic 2018, 95, 59–72. [Google Scholar]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Liam, X.Z. Metal Mixology. Nature 2016, 533, 306–307. [Google Scholar]

- Zaddach, A.J.; Niu, C.; Koch, C.C.; Irving, D.L. Mechanical Properties and Stacking Fault Energies of NiFeCrCoMn High-Entropy Alloy. JOM 2013, 65, 1780–1789. [Google Scholar] [CrossRef]

- Tian, F.Y.; Varga, L.K.; Chen, N.; Delczeg, L.; Vitos, L. Ab Initio Investigation of High-entropy Alloys of 3d Elements. Phys. Rev. B 2013, 87, 075144. [Google Scholar] [CrossRef]

- VandeVondele, J.; Krack, M.; Mohamed, F.; Parrinello, M.; Chassaing, T.; Hutter, J. QUICKSTEP; Fast and Accurate Density Functional Calculations Using a Mixed Gaussian and Plane Waves Approach. Comput. Phys. Commun. 2005, 167, 103. [Google Scholar] [CrossRef]

- Wang, S.Q. Atomic Structure Modeling of Multi-Principal-Element Alloys by the Principle of Maximum Entropy. Entropy 2013, 15, 5536–5548. [Google Scholar] [CrossRef]

- Zheng, S.M.; Feng, W.Q.; Wang, S.Q. Elastic Properties of High Entropy Alloys by MaxEnt Approach. Comp. Mater. Sci. 2018, 142, 332–337. [Google Scholar] [CrossRef]

- Zheng, S.M.; Wang, S.Q. Elastic Properties of Face-centered Cubic, Body-centered Cubic and Hexagonal High Entropy Alloys by MaxEnt Approach. Mater. Res. Express. 2018, 5, 076503. [Google Scholar] [CrossRef]

- Dirras, G.; Lilensten, L.; Djemia, P.; Laurent-Brocq, M.; Tingaud, D.; Couzinié, J.P.; Perrière, L.; Chauveau, T.; Guillot, I. Elastic and Plastic Properties of As-cast Equimolar TiHfZrTaNb High-entropy Alloy. Mater. Sci. Eng. A 2016, 654, 30–38. [Google Scholar] [CrossRef]

- Laplanche, G.; Gadaud, P.; Horst, O.; Otto, F.; Eggeler, G.; George, E.P. Temperature Dependencies of The Elastic Moduli and Thermal Expansion Coefficient of An Equiatomic, Single-phase CoCrFeMnNi High-entropy Alloy. J. Alloy Compd. 2015, 623, 348–353. [Google Scholar] [CrossRef]

- Wang, S.Q.; Ye, H.Q. First-principles Study on Elastic Properties and Phase Stability of III–V Compounds. J. Phys. Condensed Matter 2003, 240, 45–54. [Google Scholar] [CrossRef]

- Meyers, M.A.; Chawla, K.K. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2008; pp. 112–114. [Google Scholar]

- Vitos, L. Computational Quantum Mechanics for Materials Engineers: The EMTO method and applications; Springer: Berlin, Germany, 2007; p. 129. [Google Scholar]

- Soderlind, P. Theory of Elastic Constants of Cubic Transition Metals and Alloys. Phys. Rev. B 1993, 48, 5844–5851. [Google Scholar] [CrossRef]

- Jhi, S.H.; Ihm, J.; Louie, S.G.; Cohen, M.L. Electronic Mechanism of Hardness Enhancement in Transition-metal Carbonitrides. Nature 1999, 399, 132–134. [Google Scholar] [CrossRef]

- Clerc, D.G.; Ledbetter, H.M. Mechanical Hardness; A Semiempirical Theory Based on Screened Eelctroatatics and Elasticshear. J. Phys. Chem. Solids 1998, 59, 1071–1095. [Google Scholar] [CrossRef]

- Chen, K.Y.; Zhao, L.R.; Rodgers, J.; Tse, J.S. Alloying Effects on Elastic Properties of TiN-based Nitrides. J. Phys. D Appl. Phys. 2003, 36, 2725–2729. [Google Scholar] [CrossRef]

- Pugh, S.F. XCII. Relations Between the elastic moduli and the plastic properties of polycrystalline pure metals. Philos. Mag. 1954, 45, 823–843. [Google Scholar] [CrossRef]

| Strain Vector e | The Corresponding Energy for Distorted Structure |

|---|---|

| Element | C11 (GPa) | C12 (GPa) | C44 (GPa) | B (GPa) | E (GPa) | G (GPa) | ν | ρ (g/cm3) | Tm (°C) | |

|---|---|---|---|---|---|---|---|---|---|---|

| V | expt. | 232.0 c | 119.0 c | 46.0 c | 155 b | 127.6 a | 46.7 a | 0.365 a | 6.11 | 1890 |

| present | 261.0 | 109.5 | 45.5 | 159.7 | 154.0 | 57.6 | 0.340 | |||

| other | 205.0 c | 130.0 c | 5.0 c | 194.0 b | ||||||

| Mo | expt. | 460.0 a/450.0 c | 176.0 a/173.0 c | 110.0 a/125.0 c | 261.0 b | 10.39 | 2622 | |||

| present | 407.8 | 150.0 | 135.5 | 236.0 | 335.3 | 132.7 | 0.263 | |||

| other | 406.0 c | 150.0 c | 107.0 c | 275.0 b | ||||||

| Nb | expt. | 242 b/253.0 c | 129 b/133.0 c | 31.0 c | 169.0 b | 8.57 | 2468 | |||

| present | 270.0 | 135.0 | 39.4 | 180.0 | 138.9 | 50.64 | 0.370 | |||

| other | 267.0 c | 147.0 c | 27.0 c | 171.0 b | ||||||

| Ta | expt. | 267.0 a/266.0 c | 161.0 a/158.0 c | 82.5 a/87.0 c | 191.0 b | 185.7 a | 69.2 a | 0.342 a | 16.65 | 2996 |

| present | 287.0 | 151.0 | 72.7 | 195.6 | 189.6 | 70.82 | 0.338 | |||

| other | 291.0 c | 162.0 c | 84.0 c | 183.0 b | ||||||

| W | expt. | 501.0 a/533.0 c | 198.0 a/205.0 c | 151.4 a/163.0 c | 308.0 b | 19.35 | 3410 | |||

| present | 558.0 | 181.5 | 173.8 | 307.9 | 451.0 | 179.6 | 0.256 | |||

| other | 553.0 c | 207.0 c | 178.0 c | 306.0 b | ||||||

| System | C11 | C12 | C44 | B | G | E | B/G | ν | a |

|---|---|---|---|---|---|---|---|---|---|

| (1)V0.1Mo0.1Nb0.1Ta0.4W0.3 | 424.5 | 159.4 | 60.1 | 247.7 | 89.0 | 238.6 | 2.78 | 0.339 | 3.199 |

| (2)V0.1Mo0.1Nb0.2Ta0.3W0.3 | 421.8 | 158.7 | 89.8 | 246.4 | 106.5 | 279.2 | 2.31 | 0.311 | 3.200 |

| (3)V0.1Mo0.1Nb0.3Ta0.2W0.3 | 418.1 | 160.5 | 59.8 | 246.3 | 87.4 | 234.5 | 2.82 | 0.341 | 3.200 |

| (4)V0.1Mo0.1Nb0.3Ta0.3W0.2 | 407.4 | 155.2 | 31.5 | 239.3 | 69.3 | 189.5 | 3.45 | 0.368 | 3.212 |

| (5)V0.1Mo0.1Nb0.4Ta0.1W0.3 | 417.9 | 154.6 | 57.6 | 242.4 | 87.2 | 233.7 | 2.78 | 0.339 | 3.202 |

| (6)V0.1Mo0.2Nb0.1Ta0.3W0.3 | 407.0 | 176.1 | 85.1 | 253.1 | 97.4 | 259.0 | 2.60 | 0.329 | 3.187 |

| (7)V0.1Mo0.2Nb0.1Ta0.4W0.2 | 419.5 | 158.8 | 59.3 | 245.7 | 87.7 | 235.2 | 2.80 | 0.340 | 3.199 |

| (8)V0.1Mo0.2Nb0.1Ta0.5W0.1 | 370.2 | 172.9 | 17.6 | 238.6 | 50.0 | 140.2 | 4.77 | 0.402 | 3.212 |

| (9)V0.1Mo0.2Nb0.2Ta0.2W0.3 | 409.8 | 168.5 | 82.6 | 248.9 | 97.8 | 259.5 | 2.54 | 0.326 | 3.190 |

| (10)V0.1Mo0.2Nb0.2Ta0.3W0.2 | 397.4 | 168.5 | 58.2 | 244.5 | 80.8 | 218.4 | 3.02 | 0.351 | 3.200 |

| (11)V0.1Mo0.2Nb0.2Ta0.4W0.1 | 382.5 | 164.3 | 21.9 | 237.1 | 56.7 | 157.7 | 4.18 | 0.389 | 3.212 |

| (12)V0.1Mo0.2Nb0.3Ta0.1W0.3 | 401.7 | 167.9 | 81.9 | 245.8 | 95.9 | 254.7 | 2.56 | 0.327 | 3.190 |

| (13)V0.1Mo0.2Nb0.3Ta0.2W0.2 | 393.9 | 167.3 | 54.9 | 242.9 | 78.2 | 212.0 | 3.10 | 0.354 | 3.201 |

| (14)V0.1Mo0.2Nb0.3Ta0.3W0.1 | 389.9 | 158.5 | 23.6 | 235.6 | 60.4 | 167.0 | 3.90 | 0.382 | 3.212 |

| (15)V0.1Mo0.2Nb0.4Ta0.2W0.2 | 411.4 | 154.7 | 55.9 | 240.3 | 84.8 | 227.8 | 2.83 | 0.342 | 3.201 |

| (16)V0.1Mo0.2Nb0.4Ta0.2W0.1 | 399.9 | 153.5 | 18.4 | 235.4 | 60.3 | 166.8 | 3.90 | 0.382 | 3.214 |

| (17)V0.1Mo0.2Nb0.5Ta0.1W0.1 | 411.9 | 145.9 | 26.3 | 234.5 | 69.0 | 188.5 | 3.40 | 0.366 | 3.214 |

| (18)V0.1Mo0.3Nb0.1Ta0.2W0.3 | 348.1 | 207.5 | 92.0 | 254.3 | 83.3 | 225.4 | 3.05 | 0.352 | 3.176 |

| (19)V0.1Mo0.3Nb0.1Ta0.3W0.2 | 380.1 | 181.6 | 82.5 | 247.7 | 82.5 | 239.0 | 3.00 | 0.339 | 3.188 |

| (20)V0.1Mo0.3Nb0.2Ta0.1W0.3 | 355.6 | 199.7 | 92.6 | 251.7 | 86.7 | 233.4 | 2.90 | 0.345 | 3.177 |

| (21)V0.1Mo0.3Nb0.2Ta0.2W0.2 | 403.1 | 170.1 | 85.0 | 247.8 | 97.6 | 258.8 | 2.54 | 0326 | 3.189 |

| (22)V0.1Mo0.3Nb0.3Ta0.1W0.2 | 381.8 | 173.3 | 80.5 | 242.8 | 90.0 | 240.3 | 2.70 | 0.335 | 3.190 |

| (23)V0.1Mo0.3Nb0.3Ta0.2W0.1 | 394.7 | 169.0 | 79.7 | 244.2 | 93.0 | 247.6 | 2.63 | 0.331 | 3.190 |

| (24)V0.1Mo0.4Nb0.1Ta0.1W0.3 | 391.7 | 184.8 | 111.3 | 253.8 | 108.2 | 284.1 | 2.35 | 0.313 | 3.167 |

| (25)V0.1Mo0.4Nb0.1Ta0.2W0.2 | 352.2 | 200.2 | 97.0 | 250.9 | 88.6 | 237.9 | 2.83 | 0.342 | 3.176 |

| (26)V0.1Mo0.4Nb0.1Ta0.3W0.1 | 397.8 | 169.6 | 77.5 | 245.7 | 92.1 | 245.7 | 2.67 | 0.333 | 3.188 |

| (27)V0.1Mo0.4Nb0.2Ta0.1W0.2 | 356.7 | 191.4 | 93.2 | 246.5 | 88.9 | 238.2 | 2.77 | 0.339 | 3.178 |

| (28)V0.1Mo0.4Nb0.2Ta0.2W0.1 | 409.4 | 160.2 | 77.8 | 243.3 | 96.5 | 255.8 | 2.51 | 0.325 | 3.189 |

| (29)V0.2Mo0.1Nb0.1Ta0.3W0.3 | 444.7 | 144.2 | 61.8 | 244.3 | 97.1 | 257.4 | 2.51 | 0.324 | 3.174 |

| (30)V0.2Mo0.1Nb0.2Ta0.2W0.3 | 439.0 | 136.8 | 58.7 | 237.6 | 95. | 253.1 | 2.48 | 0.322 | 3.177 |

| (31)V0.2Mo0.1Nb0.2Ta0.3W0.2 | 391.6 | 155.3 | 23.5 | 234.1 | 61.3 | 169.3 | 3.81 | 0.379 | 3.188 |

| (32)V0.2Mo0.1Nb0.3Ta0.1W0.3 | 406.0 | 147.2 | 51.2 | 233.4 | 82.4 | 221.4 | 2.83 | 0.342 | 3.179 |

| (33)V0.2Mo0.1Nb0.2Ta0.2W0.3 | 374.8 | 175.4 | 76.4 | 241.9 | 85.7 | 230.1 | 2.82 | 0.341 | 3.165 |

| (34)V0.2Mo0.2Nb0.1Ta0.3W0.2 | 395.2 | 161.6 | 57.1 | 239.5 | 80.9 | 218.3 | 2.96 | 0.348 | 3.175 |

| (35)V0.2Mo0.2Nb0.1Ta0.4W0.1 | 375.4 | 160.9 | 15.4 | 231.8 | 52.3 | 145.9 | 4.43 | 0.395 | 3.188 |

| (36)V0.2Mo0.2Nb0.2Ta0.1W0.3 | 377.5 | 169.1 | 76.8 | 238.6 | 87.8 | 234.6 | 2.72 | 0.336 | 3.167 |

| (37)V0.2Mo0.2Nb0.2Ta0.2W0.2 | 392.7 | 160.0 | 57.6 | 234.0 | 81.1 | 218.0 | 2.89 | 0.345 | 3.189 |

| (38)V0.2Mo0.2Nb0.2Ta0.3W0.1 | 402.0 | 142.4 | 28.9 | 228.9 | 69.2 | 188.8 | 3.30 | 0.363 | 3.189 |

| (39)V0.2Mo0.2Nb0.3Ta0.1W0.2 | 405.2 | 145.7 | 57.4 | 232.2 | 86.3 | 230.5 | 2.69 | 0.335 | 3.177 |

| (40)V0.2Mo0.2Nb0.3Ta0.2W0.1 | 395.1 | 141.0 | 24.7 | 225.7 | 65.7 | 179.7 | 3.43 | 0.367 | 3.190 |

| (41)V0.2Mo0.2Nb0.4Ta0.1W0.1 | 394.2 | 138.2 | 20.6 | 223.8 | 63.4 | 173.9 | 3.53 | 0.370 | 3.191 |

| (42)V0.2Mo0.3Nb0.1Ta0.1W0.3 | 340.0 | 196.9 | 85.6 | 244.6 | 79.9 | 216.3 | 3.06 | 0.353 | 3.153 |

| (43)V0.2Mo0.3Nb0.1Ta0.2W0.2 | 389.4 | 164.2 | 77.7 | 239.3 | 91.6 | 243.8 | 2.61 | 0.330 | 3.164 |

| (44)V0.2Mo0.3Nb0.2Ta0.1W0.2 | 380.0 | 164.3 | 75.3 | 236.2 | 88.3 | 235.7 | 2.67 | 0.334 | 3.165 |

| (45)V0.2Mo0.3Nb0.2Ta0.2W0.1 | 436.4 | 128.1 | 56.1 | 230.9 | 95.3 | 251.4 | 2.42 | 0.319 | 3.177 |

| (46)V0.2Mo0.4Nb0.1Ta0.1W0.2 | 309.4 | 206.7 | 84.6 | 241.0 | 71.3 | 194.7 | 3.38 | 0.365 | 3.152 |

| (47)V0.2Mo0.4Nb0.1Ta0.2W0.1 | 369.7 | 168.1 | 68.7 | 235.3 | 81.5 | 219.3 | 2.89 | 0.345 | 3.164 |

| (48)V0.2Mo0.4Nb0.2Ta0.1W0.1 | 361.0 | 172.5 | 65.9 | 235.3 | 77.2 | 208.8 | 3.05 | 0.352 | 3.165 |

| (49)V0.3Mo0.1Nb0.1Ta0.2W0.3 | 425.1 | 140.1 | 60.0 | 235.1 | 93.0 | 246.6 | 2.53 | 0.325 | 3.152 |

| (50)V0.3Mo0.1Nb0.1Ta0.4W0.1 | 315.8 | 174.6 | 12.8 | 221.7 | 35.9 | 102.4 | 6.16 | 0.423 | 3.177 |

| (51)V0.3Mo0.1Nb0.2Ta0.1W0.3 | 419.9 | 136.7 | 58.6 | 231.1 | 91.8 | 243.3 | 2.52 | 0.325 | 3.153 |

| (52)V0.3Mo0.1Nb0.2Ta0.2W0.2 | 384.7 | 147.7 | 15.5 | 226.7 | 56.7 | 157.1 | 4.00 | 0.384 | 3.164 |

| (53)V0.3Mo0.1Nb0.2Ta0.3W0.1 | 343.1 | 156.7 | 31.2 | 218.9 | 56.0 | 154.8 | 3.91 | 0.382 | 3.177 |

| (54)V0.3Mo0.1Nb0.3Ta0.2W0.1 | 303.9 | 172.1 | 28.8 | 216.0 | 43.6 | 122.6 | 4.95 | 0.405 | 3.178 |

| (55)V0.3Mo0.1Nb0.4Ta0.1W0.1 | 323.5 | 153.4 | 11.9 | 210.1 | 41.1 | 115.9 | 5.10 | 0.408 | 3.180 |

| (56)V0.3Mo0.2Nb0.1Ta0.1W0.3 | 307.4 | 201.1 | 68.8 | 236.6 | 62.5 | 172.4 | 3.78 | 0.379 | 3.139 |

| (57)V0.3Mo0.2Nb0.1Ta0.2W0.2 | 404.2 | 143.4 | 56.0 | 230.3 | 85.7 | 228.8 | 2.69 | 0.334 | 3.155 |

| (58)V0.3Mo0.2Nb0.1Ta0.3W0.1 | 374.1 | 140.7 | 21.2 | 225.5 | 59.6 | 164.0 | 3.66 | 0.375 | 3.164 |

| (59)V0.3Mo0.2Nb0.2Ta0.1W0.2 | 394.2 | 138.9 | 53.5 | 224.0 | 83.1 | 222.0 | 2.69 | 0.335 | 3.156 |

| (60)V0.3Mo0.2Nb0.2Ta0.2W0.1 | 367.6 | 145.6 | 18.4 | 219.6 | 55.4 | 153.4 | 3.96 | 0.384 | 3.169 |

| (61)V0.3Mo0.2Nb0.3Ta0.1W0.1 | 388.6 | 135.4 | 22.3 | 219.8 | 64.0 | 175.0 | 3.43 | 0.367 | 3.165 |

| (62)V0.3Mo0.3Nb0.1Ta0.1W0.2 | 337.5 | 178.0 | 67.7 | 231.2 | 72.5 | 197.0 | 3.19 | 0.358 | 3.141 |

| (63)V0.3Mo0.3Nb0.1Ta0.2W0.1 | 382.2 | 146.2 | 50.2 | 224.9 | 77.3 | 208.2 | 2.91 | 0.346 | 3.151 |

| (64)V0.3Mo0.3Nb0.2Ta0.1W0.1 | 375.9 | 174.2 | 47.6 | 221.1 | 68.9 | 188.0 | 3.50 | 0.360 | 3.156 |

| (65)V0.3Mo0.4Nb0.1Ta0.1W0.1 | 310.4 | 181.4 | 57.2 | 224.4 | 60.1 | 165.7 | 3.73 | 0.377 | 3.140 |

| (66)V0.4Mo0.1Nb0.1Ta0.1W0.3 | 390.5 | 146.4 | 53.3 | 227.8 | 80.7 | 216.7 | 2.82 | 0.341 | 3.127 |

| (67)V0.4Mo0.2Nb0.1Ta0.1W0.2 | 375.5 | 149.6 | 47.8 | 224.9 | 73.9 | 199.8 | 3.04 | 0.352 | 3.128 |

| (68)V0.4Mo0.2Nb0.1Ta0.2W0.1 | 382.1 | 139.9 | 18.3 | 220.6 | 59.4 | 163.6 | 3.72 | 0.376 | 3.140 |

| (69)V0.4Mo0.2Nb0.2Ta0.1W0.1 | 378.7 | 136.1 | 17.7 | 217.7 | 59.1 | 162.6 | 3.68 | 0.375 | 3.141 |

| (70)V0.5Mo0.2Nb0.1Ta0.1W0.1 | 363.3 | 139.1 | 13.1 | 213.8 | 52.7 | 146.1 | 4.06 | 0.386 | 3.115 |

| Table 2 | V | Mo | Nb | Ta | W | Table 2 | V | Mo | Nb | Ta | W | Table 2 | V | Mo | Nb | Ta | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 65 | 51 | 25 | 25 | 63 | 8 | 36 | 37 | 49 | 49 | 10 | 18 | 45 | 67 |

| 2 | 2 | 2 | 30 | 52 | 52 | 26 | 26 | 64 | 9 | 58 | 7 | 50 | 50 | 11 | 19 | 69 | 16 |

| 3 | 3 | 3 | 53 | 29 | 53 | 27 | 27 | 65 | 36 | 8 | 38 | 51 | 51 | 12 | 46 | 17 | 68 |

| 4 | 4 | 4 | 54 | 53 | 29 | 28 | 28 | 66 | 37 | 37 | 8 | 52 | 52 | 13 | 47 | 46 | 46 |

| 5 | 5 | 5 | 65 | 1 | 54 | 29 | 29 | 6 | 10 | 59 | 61 | 53 | 53 | 14 | 48 | 63 | 17 |

| 6 | 6 | 18 | 2 | 54 | 55 | 30 | 30 | 7 | 38 | 38 | 62 | 54 | 54 | 15 | 63 | 47 | 18 |

| 7 | 7 | 19 | 3 | 66 | 30 | 31 | 31 | 8 | 39 | 60 | 39 | 55 | 55 | 16 | 69 | 18 | 19 |

| 8 | 8 | 20 | 4 | 70 | 1 | 32 | 32 | 9 | 60 | 9 | 63 | 56 | 56 | 39 | 20 | 19 | 69 |

| 9 | 9 | 21 | 34 | 30 | 56 | 33 | 33 | 30 | 11 | 39 | 64 | 57 | 57 | 40 | 21 | 48 | 47 |

| 10 | 10 | 22 | 32 | 55 | 31 | 34 | 34 | 31 | 12 | 61 | 40 | 58 | 58 | 41 | 22 | 64 | 20 |

| 11 | 11 | 23 | 33 | 67 | 2 | 35 | 35 | 32 | 13 | 68 | 9 | 59 | 59 | 42 | 49 | 20 | 48 |

| 12 | 12 | 24 | 55 | 2 | 57 | 36 | 36 | 33 | 40 | 10 | 65 | 60 | 60 | 43 | 50 | 49 | 21 |

| 13 | 13 | 25 | 56 | 31 | 32 | 37 | 37 | 34 | 41 | 40 | 41 | 61 | 61 | 44 | 64 | 21 | 22 |

| 14 | 14 | 26 | 57 | 56 | 3 | 38 | 38 | 35 | 42 | 62 | 10 | 62 | 62 | 59 | 23 | 22 | 49 |

| 15 | 15 | 27 | 66 | 3 | 33 | 39 | 39 | 36 | 61 | 11 | 42 | 63 | 63 | 60 | 24 | 50 | 23 |

| 16 | 16 | 28 | 67 | 32 | 4 | 40 | 40 | 37 | 62 | 41 | 11 | 64 | 64 | 61 | 51 | 23 | 24 |

| 17 | 17 | 29 | 70 | 4 | 5 | 41 | 41 | 38 | 68 | 12 | 12 | 65 | 65 | 70 | 25 | 24 | 25 |

| 18 | 18 | 49 | 5 | 33 | 58 | 42 | 42 | 55 | 14 | 13 | 66 | 66 | 66 | 17 | 26 | 25 | 70 |

| 19 | 19 | 50 | 6 | 57 | 34 | 43 | 43 | 56 | 15 | 42 | 43 | 67 | 67 | 45 | 27 | 26 | 50 |

| 20 | 20 | 51 | 34 | 5 | 59 | 44 | 44 | 57 | 43 | 14 | 44 | 68 | 68 | 46 | 28 | 51 | 26 |

| 21 | 21 | 52 | 35 | 34 | 35 | 45 | 45 | 58 | 44 | 43 | 13 | 69 | 69 | 47 | 52 | 27 | 27 |

| 22 | 22 | 53 | 58 | 6 | 36 | 46 | 46 | 67 | 16 | 15 | 45 | 70 | 70 | 48 | 29 | 28 | 28 |

| 23 | 23 | 54 | 59 | 35 | 6 | 47 | 47 | 68 | 17 | 44 | 14 | ||||||

| 24 | 24 | 62 | 7 | 7 | 60 | 48 | 48 | 69 | 45 | 16 | 15 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, S.; Wang, S. First-Principles Design of Refractory High Entropy Alloy VMoNbTaW. Entropy 2018, 20, 965. https://doi.org/10.3390/e20120965

Zheng S, Wang S. First-Principles Design of Refractory High Entropy Alloy VMoNbTaW. Entropy. 2018; 20(12):965. https://doi.org/10.3390/e20120965

Chicago/Turabian StyleZheng, Shumin, and Shaoqing Wang. 2018. "First-Principles Design of Refractory High Entropy Alloy VMoNbTaW" Entropy 20, no. 12: 965. https://doi.org/10.3390/e20120965

APA StyleZheng, S., & Wang, S. (2018). First-Principles Design of Refractory High Entropy Alloy VMoNbTaW. Entropy, 20(12), 965. https://doi.org/10.3390/e20120965