Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

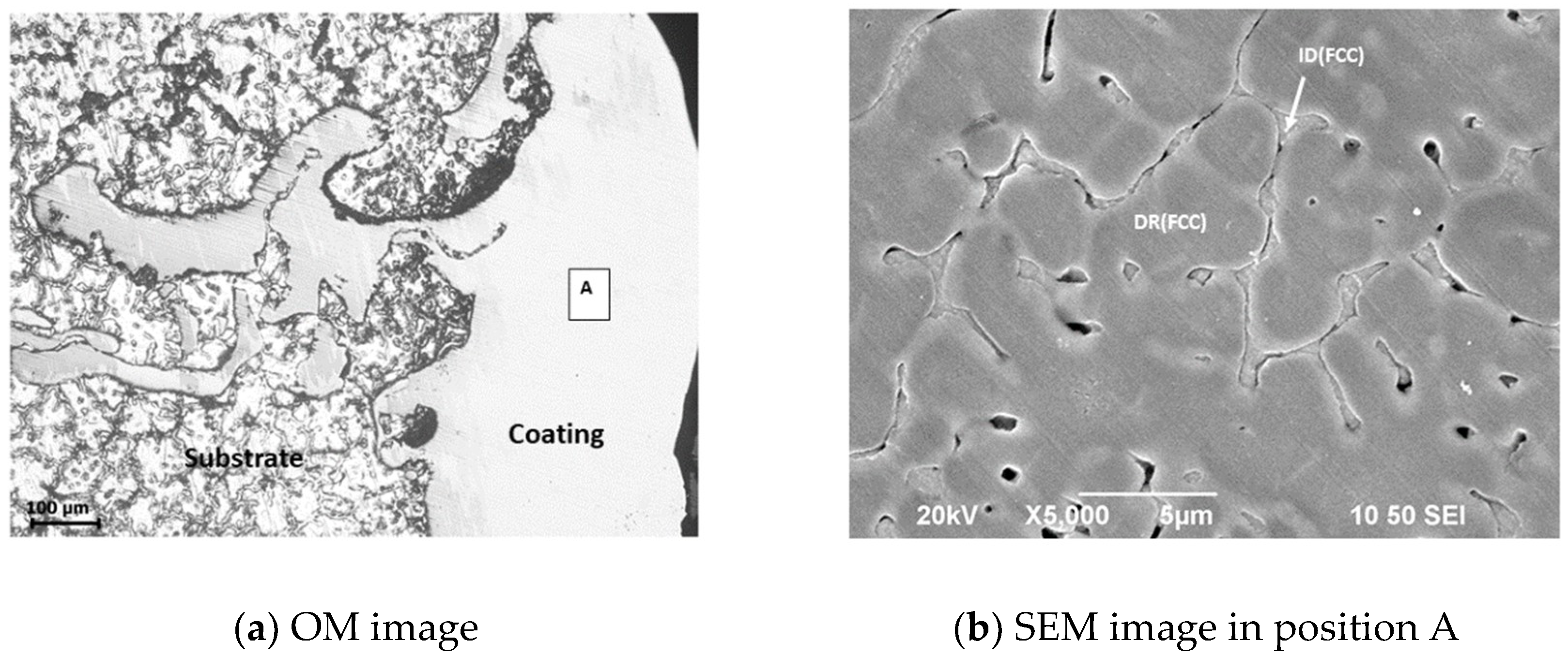

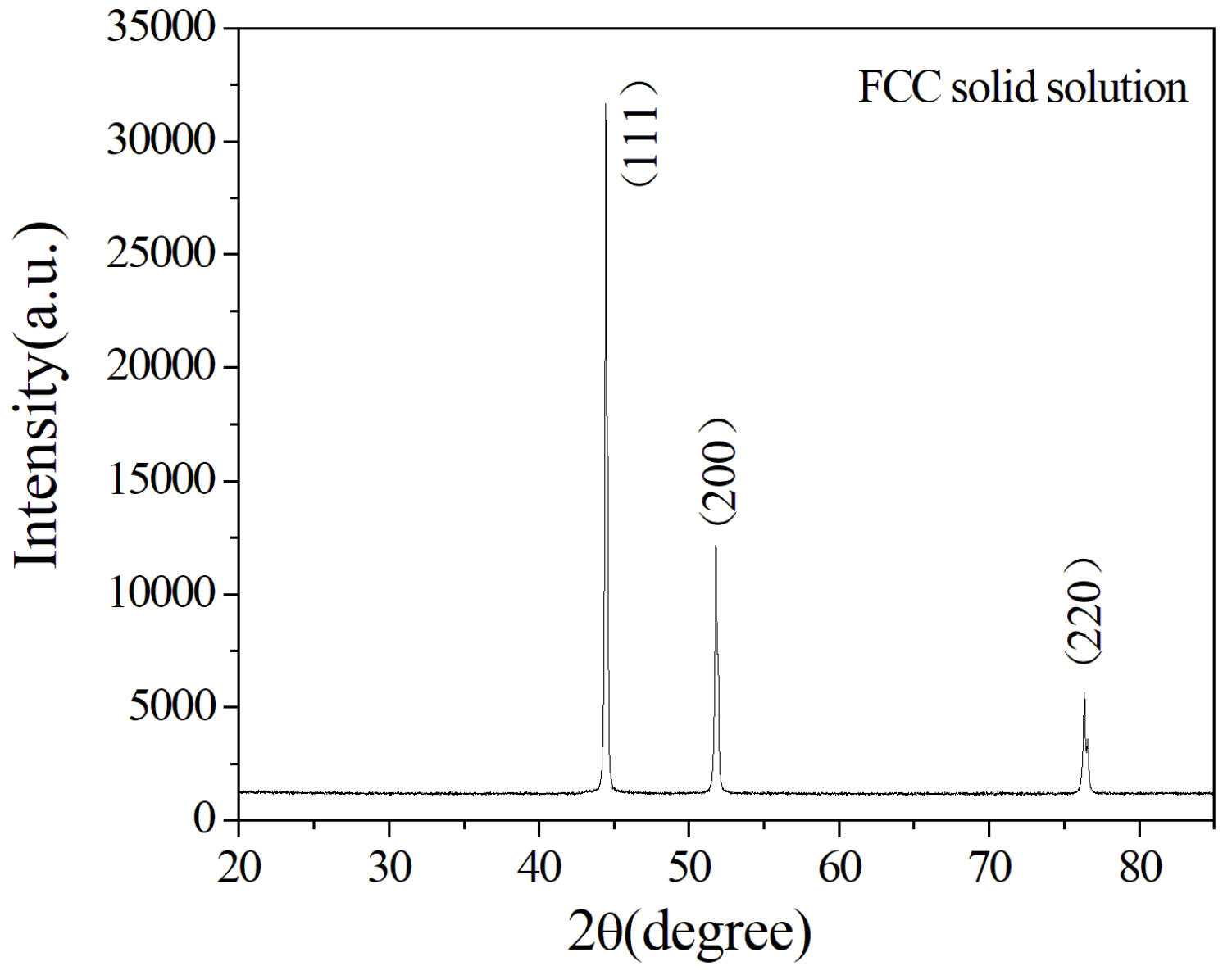

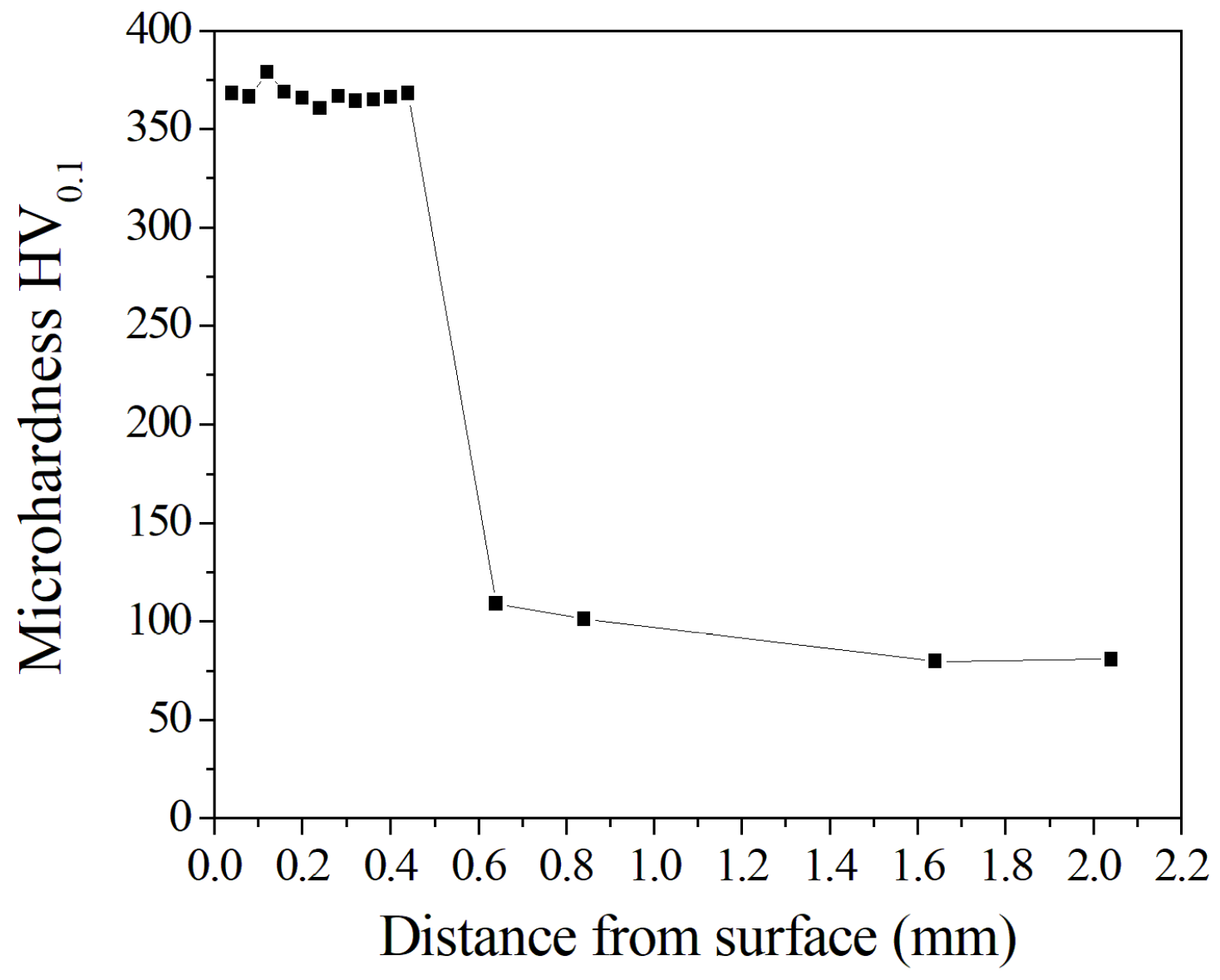

3.1. Microstructure and Microhardness

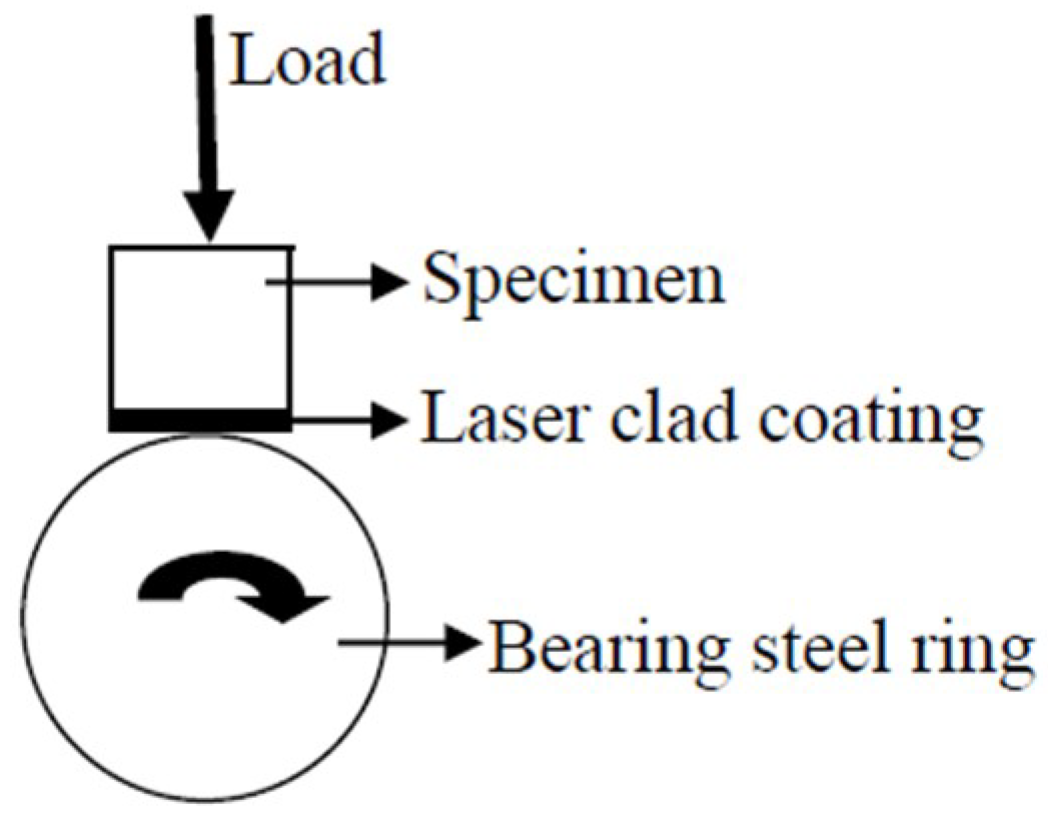

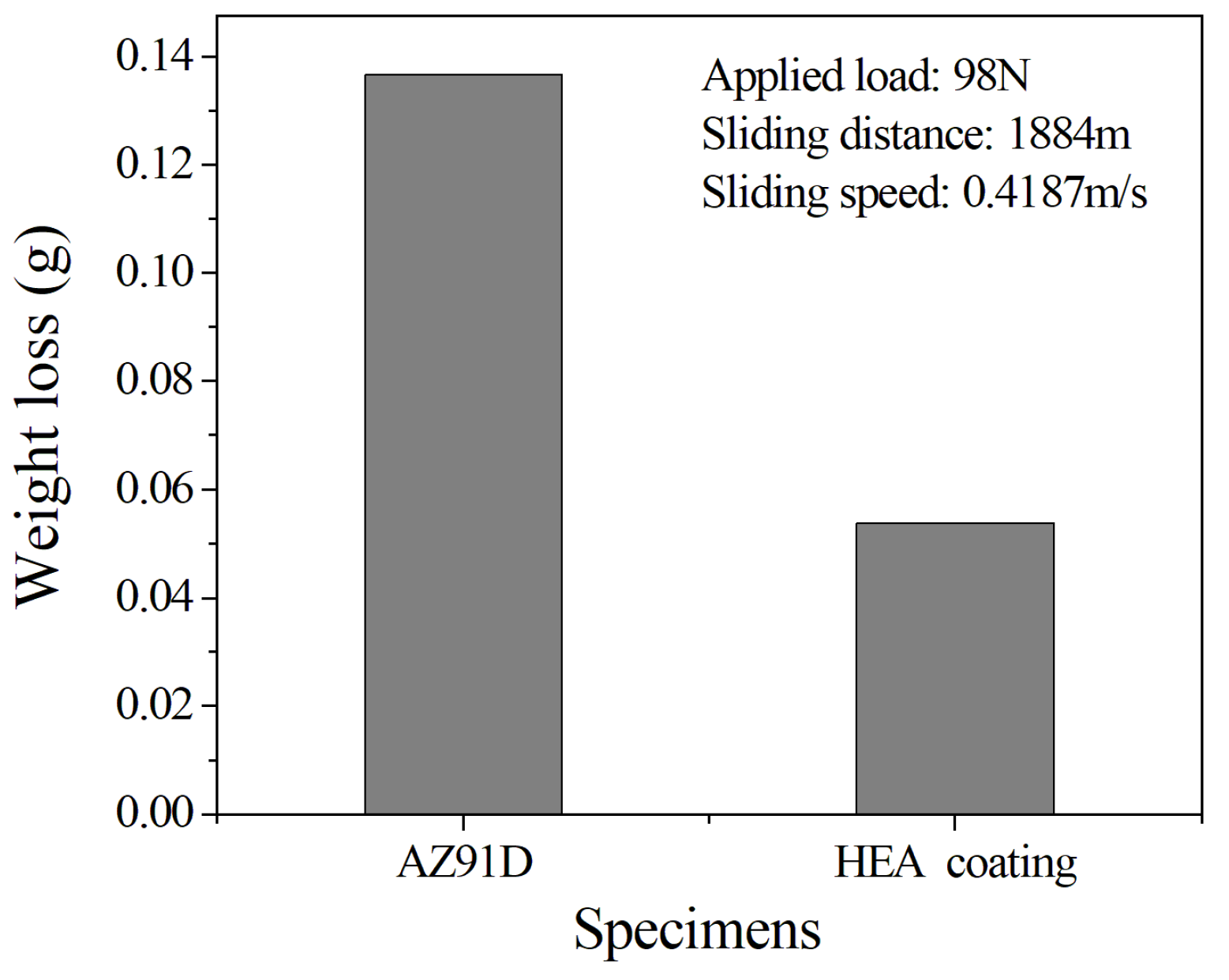

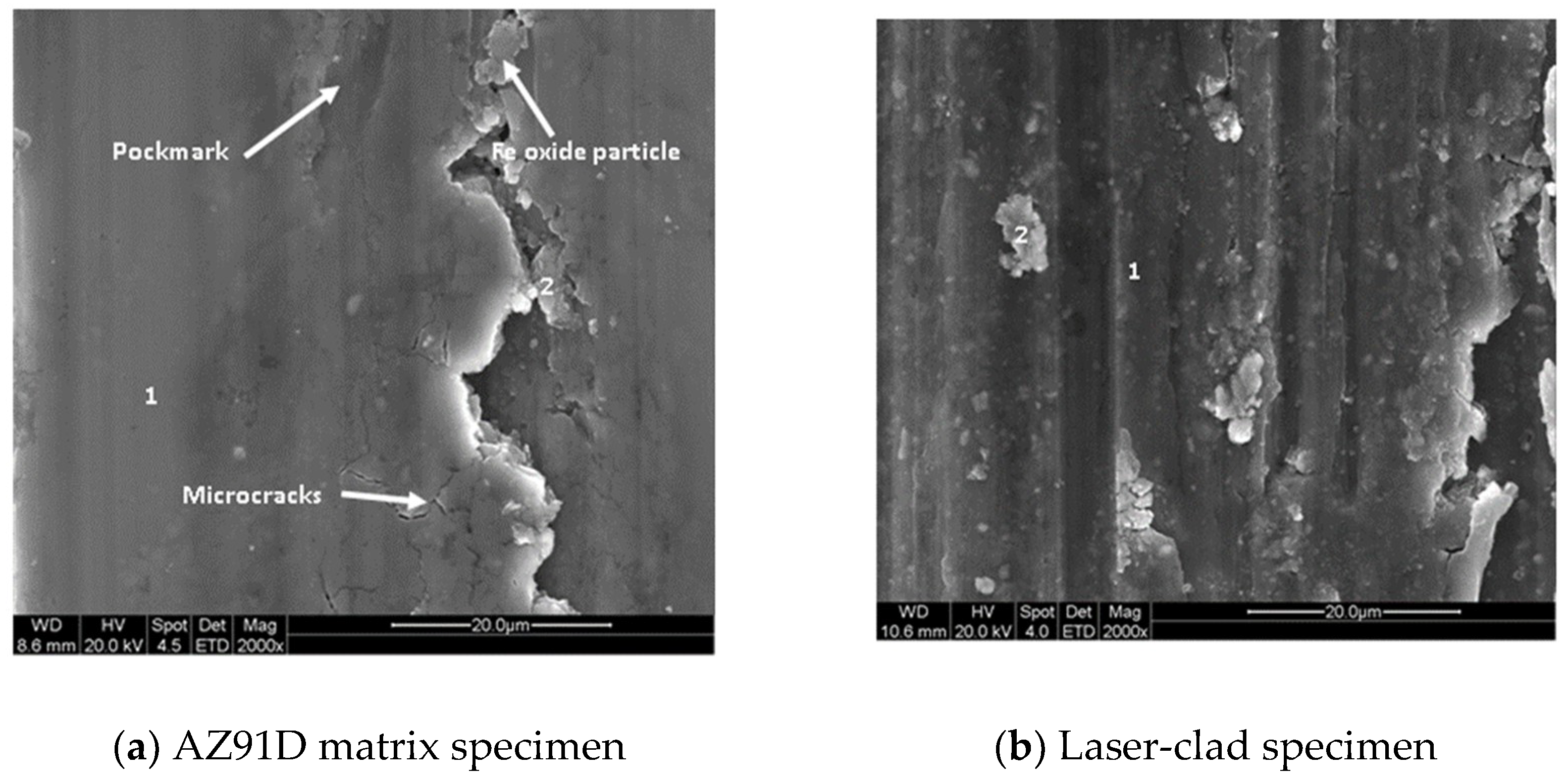

3.2. Wear Properties

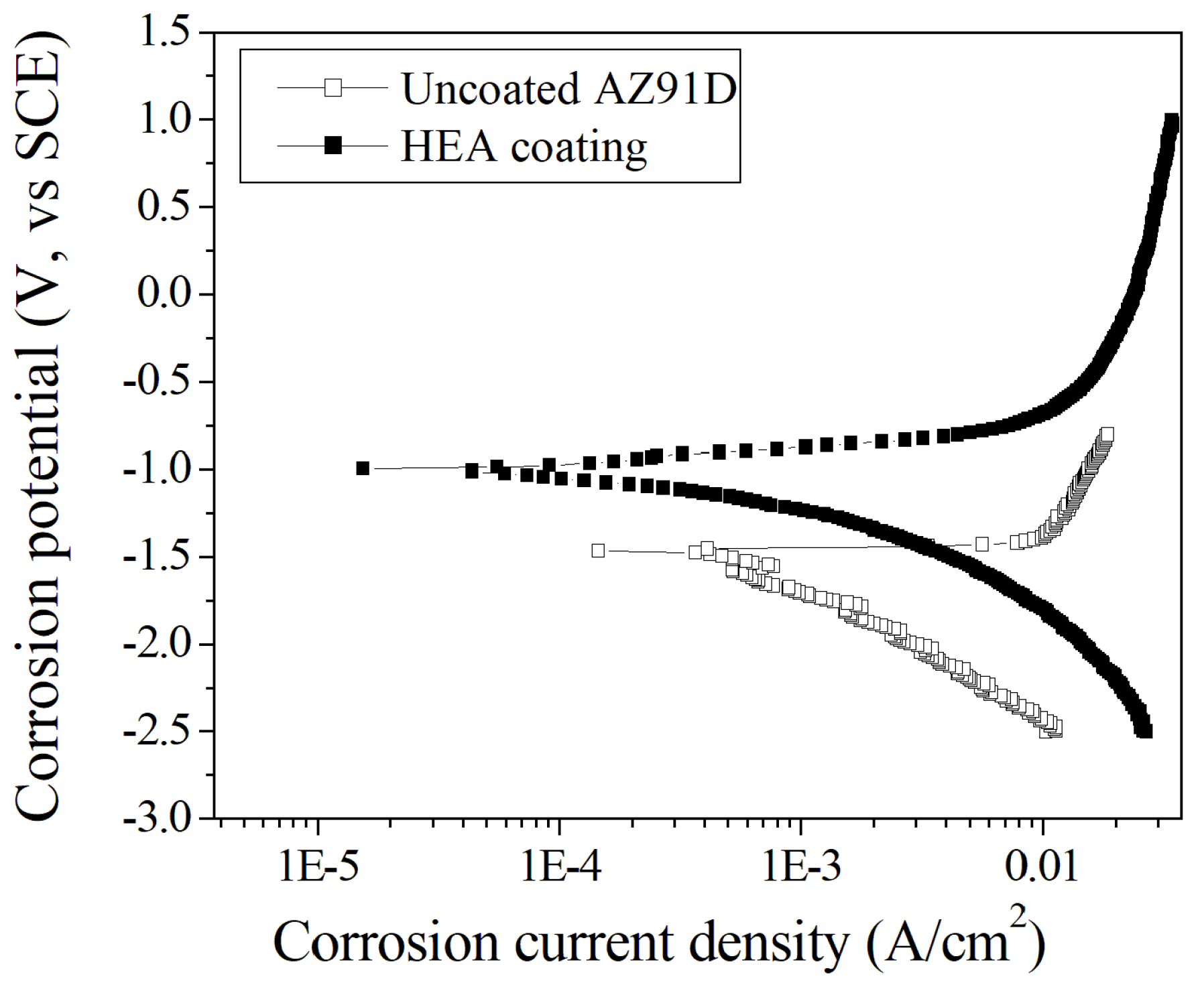

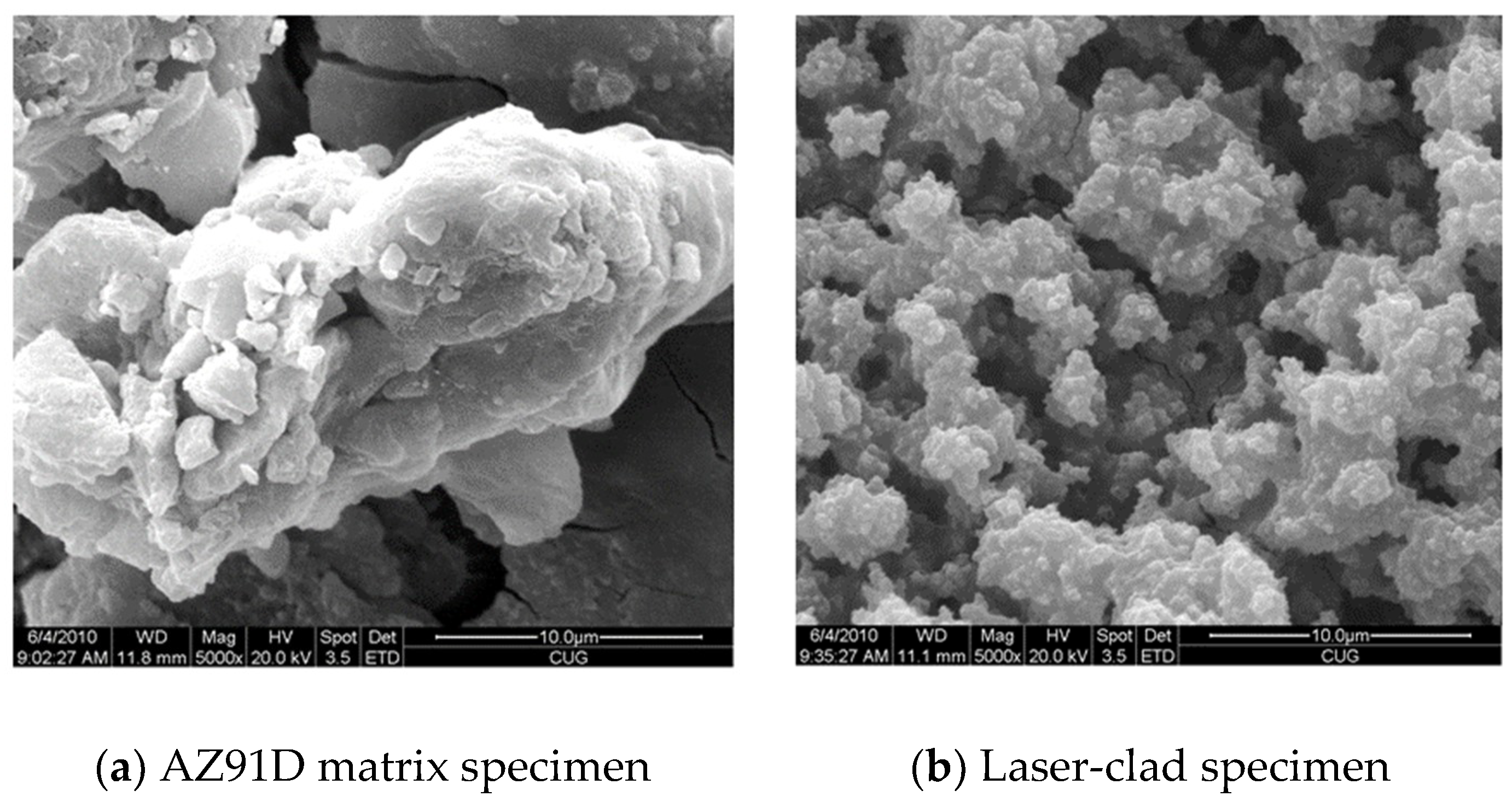

3.3. Corrosion Properties

4. Conclusions

- (1).

- An Al0.5CoCrCuFeNi high-entropy alloy coating was successfully fabricated on an AZ91D matrix by laser cladding using mixed powders of Cu, Ni, Al, Co, Cr, and Fe. The Al0.5CoCrCuFeNi high-entropy alloy coating consisted of fine dendrites with a simple FCC phase.

- (2).

- The dry sliding wear resistance of the Al0.5CoCrCuFeNi high-entropy alloy coating prepared by laser cladding was better than that of the AZ91D matrix, and the wear mechanisms of the two materials were different.

- (3).

- The Al0.5CoCrCuFeNi high-entropy alloy coating prepared by laser cladding had better corrosion resistance than did the AZ91D matrix in 3.5 wt % sodium chloride solution.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, W.R.; Liaw, P.K.; Zhang, Y. Science and technology in high-entropy alloys. Sci. China-Mater. 2018, 61, 2–22. [Google Scholar] [CrossRef]

- Liu, W.; Liu, P.; Liaw, P.K. Microstructure and properties of high-entropy alloy films and coatings: A review. Mater. Res. Lett. 2018, 6, 199–229. [Google Scholar] [CrossRef]

- Macdonald, B.E.; Fu, Z.; Zheng, B.; Chen, W.; Lin, Y.; Chen, F.; Zhang, L.; Ivanisenko, J.; Zhou, Y.; Hahn, H. Recent progress in high entropy alloy research. JOM. 2017, 69, 2024–2031. [Google Scholar] [CrossRef]

- Shi, Y.Z.; Yang, B.; Liaw, P.K. Corrosion-resistant high-entropy alloys: A review. Metals. 2017, 7. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructure and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Mat. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Chen, M.R.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Chuang, M.H. Effect of vanadium addition on the microstructure, hardness, and wear resistance of Al0.5CoCrCuFeNi high-entropy alloy. Metall. Mater. Trans. A 2006, 37, 1363–1369. [Google Scholar] [CrossRef]

- Huo, W.Y.; Shi, H.F.; Ren, X.; Zhang, J.Y. Microstructure and wear behavior of CoCrFeMnNbNi high entropy alloy coating by TIG cladding. Adv. Mater. Sci. Eng. 2015, 2015. [Google Scholar] [CrossRef]

- Abed, H.; Ghaini, F.M.; Shahverdi, H.R. Characterization of Fe49Cr18Mo7B16C4Nb6 high entropy hardfacing layers produced by gas tungsten arc welding (GTAW) process. Surf. Coat. Technol. 2018, 352, 360–369. [Google Scholar] [CrossRef]

- Varalakshmi, S.; Kamaraj, M.; Murty, B.S. Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloy. J. Alloys Compd. 2008, 460, 253–257. [Google Scholar] [CrossRef]

- Chen, T.K.; Wong, M.S.; Shun, T.T.; Yeh, J.W. Nanostructured nitride films of multi-element high entropy alloys by reactive DC sputtering. Surf. Coat. Technol. 2005, 200, 1361–1365. [Google Scholar] [CrossRef]

- Huang, P.K.; Yeh, J.W.; Shun, T.T.; Chen, S.K. Multi-principle-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv. Eng. Mater. 2004, 6, 74–78. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.Z.; Shen, J.Y.; Vilar, R. Thermal stability and oxidation resistance of laser clad TiVCrAlSi high entropy alloy coatings on Ti-6A1-4V alloy. Surf. Coat. Technol. 2011, 206, 1389–1395. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.Z.; Vilar, R.; Shen, J.Y. Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti-6Al-4V substrate. Mater. Des. 2012, 41, 338–343. [Google Scholar] [CrossRef]

- Qiu, X.W. Microstructure, hardness and corrosion resistance of Al2CoCrCuFeNiTix high entropy alloy coatings prepared by rapid solidification. J. Alloys Compd. 2018, 735, 359–364. [Google Scholar] [CrossRef]

- Zhao, J.H.; Ma, A.B.; Ji, X.L.; Jiang, J.H.; Bao, Y.Y. Slurry erosion behavior of AlxCoCrFeNiTi0.5 high-entropy alloy coatings fabricated by laser cladding. Metals. 2018, 8. [Google Scholar] [CrossRef]

- Guo, Y.X.; Liu, Q.B.; Zhou, F. Microstructure and properties of Fe5Cr5SiTiCoNbMoW coating by laser cladding. Surf. Eng. 2018, 34, 283–288. [Google Scholar] [CrossRef]

- Qiu, X.W.; Zhang, Y.P.; He, L.; Liu, C.G. Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy. J. Alloys Compd. 2013, 549, 195–199. [Google Scholar] [CrossRef]

- Ye, X.Y.; Ma, M.X.; Cao, Y.X.L.; Liu, W.J.; Ye, X.H.; Gu, Y. The property research on high-entropy alloy AlxFeCoNiCuCr coating by laser cladding. Phys. Procedia. 2011, 12, 303–312. [Google Scholar] [CrossRef]

- Zhang, H.; Pan, Y.; He, Y.Z.; Jiao, H.S. Microstructure and properties of 6FeNiCoSiCrAlTi high-entropy alloy coating prepared by laser cladding. Appl. Surf. Sci. 2011, 257, 2259–2263. [Google Scholar] [CrossRef]

- Guo, Y.X.; Shang, X.J.; Liu, Q.B. Microstructure and properties of in-situ TiN reinforced laser cladding CoCr2FeNiTix high entropy alloy composite coatings. Surf. Coat. Technol. 2018, 344, 353–358. [Google Scholar] [CrossRef]

- Jiang, L.; Wu, W.; Cao, Z.Q.; Deng, D.W.; Li, T.J. Microstructure evolution and wear behavior of the laser cladded CoFeNi2V0.5Nb0.75 and CoFeNi2V0.5Nb high entropy alloy coatings. J. Therm. Spray Technol. 2016, 25, 806–814. [Google Scholar] [CrossRef]

- Wu, W.; Jiang, L.; Jiang, H.; Pan, X.M.; Cao, Z.Q.; Deng, D.W.; Wang, T.M. Phase evolution and properties of Al2CrFeNiMox high entropy alloys coatings by laser cladding. J. Therm. Spray Technol. 2015, 24, 1333–1340. [Google Scholar] [CrossRef]

- Shang, X.J.; Liu, Q.B.; Guo, Y.X.; Xu, P.; Zhou, F. Laser cladding of a Fe5Cr5SiTiCoNbMoW high entropy alloy coating onto a tool steel substrate. Laser. Eng. 2018, 41, 305–316. [Google Scholar]

- Wang, W.M.; Zhang, B.H.; Liu, B.H.; Liu, C.S.; Cui, J.Z. Laser cladding of high entropy alloy on H13 steel. Rare Metals. 2014, 33, 727–730. [Google Scholar]

- Shi, Y.; Ni, C.; Liu, J.; Huang, G.Z. Microstructure and properties of laser clad high entropy alloy coating on aluminum. Mater. Sci. Technol. 2018, 34, 1239–1245. [Google Scholar] [CrossRef]

- Yue, T.M.; Xie, H.; Lin, X.; Yang, H.O.; Meng, G.H. Microstructure of laser re-melted AlCoCrCuFeNi high entropy alloy coatings produced by plasma spraying. Entropy 2013, 15, 2833–2845. [Google Scholar] [CrossRef]

- Yue, T.M.; Xie, H.; Lin, X.; Yang, H.O.; Meng, G.H. Solidification behavior in laser cladding of AlCoCrCuFeNi high entropy on magnesium substrates. J. Alloys Compd. 2014, 587, 588–593. [Google Scholar] [CrossRef]

- Meng, G.H.; Liu, X.T.; Qiu, J.; Wang, B.; Zhao, K. Growth morphology of CuMg2 in laser forming of AlCoCrCuFeNi coating on Mg. Adv. Eng. Res. 2017, 146, 162–165. [Google Scholar]

- Yue, T.M.; Zhang, H. Laser cladding of FeCoNiCrAlCuxSi0.5 high entropy alloys on AZ31 Mg alloy substrates. Mater. Res. Innovations. 2014, 18, 624–628. [Google Scholar] [CrossRef]

- Huang, K.J.; Lin, X.; Wang, Y.Y.; Xie, C.S.; Yue, T.M. Microstructure and corrosion resistance of Cu0.9NiAlCoCrFe high entropy alloy coating on AZ91D magnesium alloy by laser cladding. Mater. Res. Innovations. 2014, 18, 1008–1011. [Google Scholar] [CrossRef]

- Liu, J.L.; Yu, H.J.; Chen, C.Z.; Weng, F.; Dai, J.J. Research and development status of laser cladding on magnesium alloys: A review. Opt. Laser. Eng. 2017, 93, 195–210. [Google Scholar] [CrossRef]

- Yue, T.M.; Su, Y.P.; Yang, H.O. Laser cladding of Zr65Al7.5Ni10Cu17.5 amorphous alloy on magnesium. Mater. Lett. 2007, 61, 209–212. [Google Scholar] [CrossRef]

- Chen, M.R.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Chuang, M.H. Effect of vanadium addition on the microstructure, hardness, and wear resistance of Al0.5CoCrCuFeNi high-entropy alloy. Metall. Mater. Trans. A 2006, 37, 1363–1369. [Google Scholar] [CrossRef]

- Wu, J.M.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Chen, H.C. Adhesive wear behavior of AlxCoCrCuFeNi high-entropy alloys as a function of aluminum content. Wear 2006, 261, 513–519. [Google Scholar] [CrossRef]

- Chen, M.R.; Lin, S.J.; Yeh, J.W.; Chen, S.K.; Huang, Y.S.; Tu, C.P. Microstructure and properties of Al0.5CoCrCuFeNiTix (x = 0–2.0) high-entropy alloys. Mater. Trans. 2006, 47, 1395–1401. [Google Scholar] [CrossRef]

- Tong, C.J.; Chen, Y.L.; Chen, S.K.; Yeh, J.W.; Shun, T.T.; Tsau, C.H.; Lin, S.J.; Chang, S.Y. Microstructure characterization of AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall. Mater. Trans. A 2005, 36, 881–893. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Classification of bulk metallic glasses by atomic size differences, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater. Trans. 2005, 46, 2817–2829. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials. 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

| Elements | Al | Co | Cr | Cu | Fe | Ni | Results |

|---|---|---|---|---|---|---|---|

| DR | 9.9 | 18.7 | 20.1 | 12.1 | 22.0 | 17.2 | poor in Cu element |

| ID | 12.7 | 5.7 | 3.5 | 60.7 | 3.1 | 14.3 | rich in Cu element |

| Raw powders | 9.0 | 18.2 | 18.2 | 18.2 | 18.2 | 18.2 |

| Mixing Enthalpy | Al | Co | Cr | Cu | Fe | Ni |

|---|---|---|---|---|---|---|

| Al | - | −19 | −10 | −1 | −11 | −22 |

| Co | - | −4 | 6 | −1 | 0 | |

| Cr | - | 12 | −1 | −7 | ||

| Cu | - | 13 | 4 | |||

| Fe | - | −2 | ||||

| Ni | - |

| Samples | Position | C | O | Mg | Al | Zn | Fe | Ni | Cu | Cr | Co | Mn |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AZ91D | 1 | 2.2 | 6.5 | 83.8 | 6.8 | 0.7 | - | - | - | - | - | - |

| AZ91D | 2 | 1.8 | 44.5 | 1.3 | 1.3 | 0.3 | 50.8 | - | - | - | - | - |

| Coating | 1 | 1.1 | 8.9 | - | 4.7 | - | 18.7 | 19.9 | 12.4 | 17.3 | 17.0 | - |

| Coating | 2 | 1.2 | 33.7 | - | 3.4 | - | 34.8 | 5.3 | 7.2 | 7.1 | 7.3 | - |

| AZ91D | Raw | - | - | 90.2 | 8.9 | 0.6 | - | - | - | - | - | 0.3 |

| Specimen | Ecorr (V) | Icorr (A/cm2) |

|---|---|---|

| AZ91D | −1.46 | 6.20×10−4 |

| Laser-clad coating | −0.998 | 1.60×10−4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, K.; Chen, L.; Lin, X.; Huang, H.; Tang, S.; Du, F. Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding. Entropy 2018, 20, 915. https://doi.org/10.3390/e20120915

Huang K, Chen L, Lin X, Huang H, Tang S, Du F. Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding. Entropy. 2018; 20(12):915. https://doi.org/10.3390/e20120915

Chicago/Turabian StyleHuang, Kaijin, Lin Chen, Xin Lin, Haisong Huang, Shihao Tang, and Feilong Du. 2018. "Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding" Entropy 20, no. 12: 915. https://doi.org/10.3390/e20120915

APA StyleHuang, K., Chen, L., Lin, X., Huang, H., Tang, S., & Du, F. (2018). Wear and Corrosion Resistance of Al0.5CoCrCuFeNi High-Entropy Alloy Coating Deposited on AZ91D Magnesium Alloy by Laser Cladding. Entropy, 20(12), 915. https://doi.org/10.3390/e20120915