Evaluation of the Infill Design on the Tensile Response of 3D Printed Polylactic Acid Polymer

Abstract

1. Introduction

2. Experimental Work

2.1. Materials

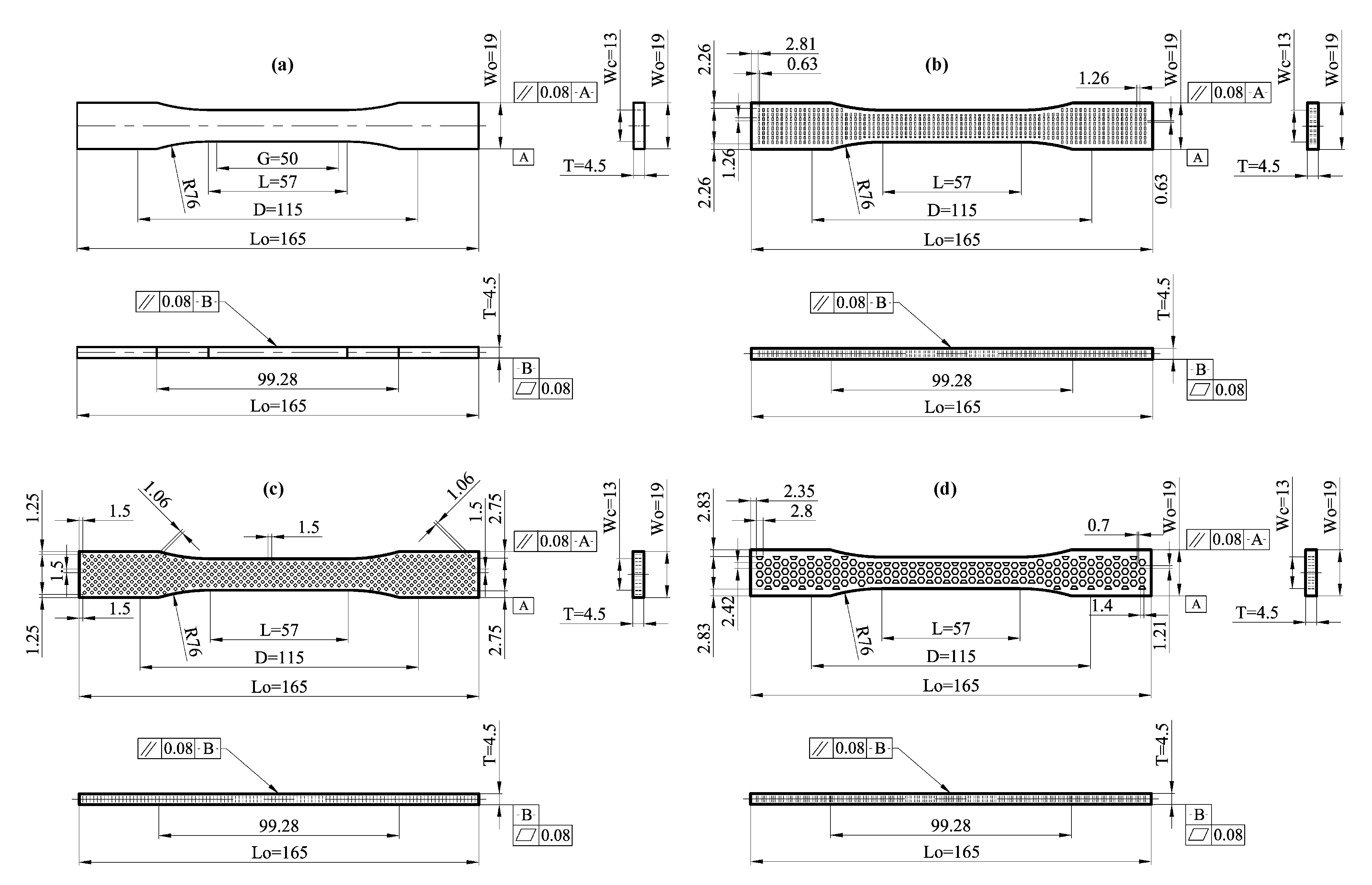

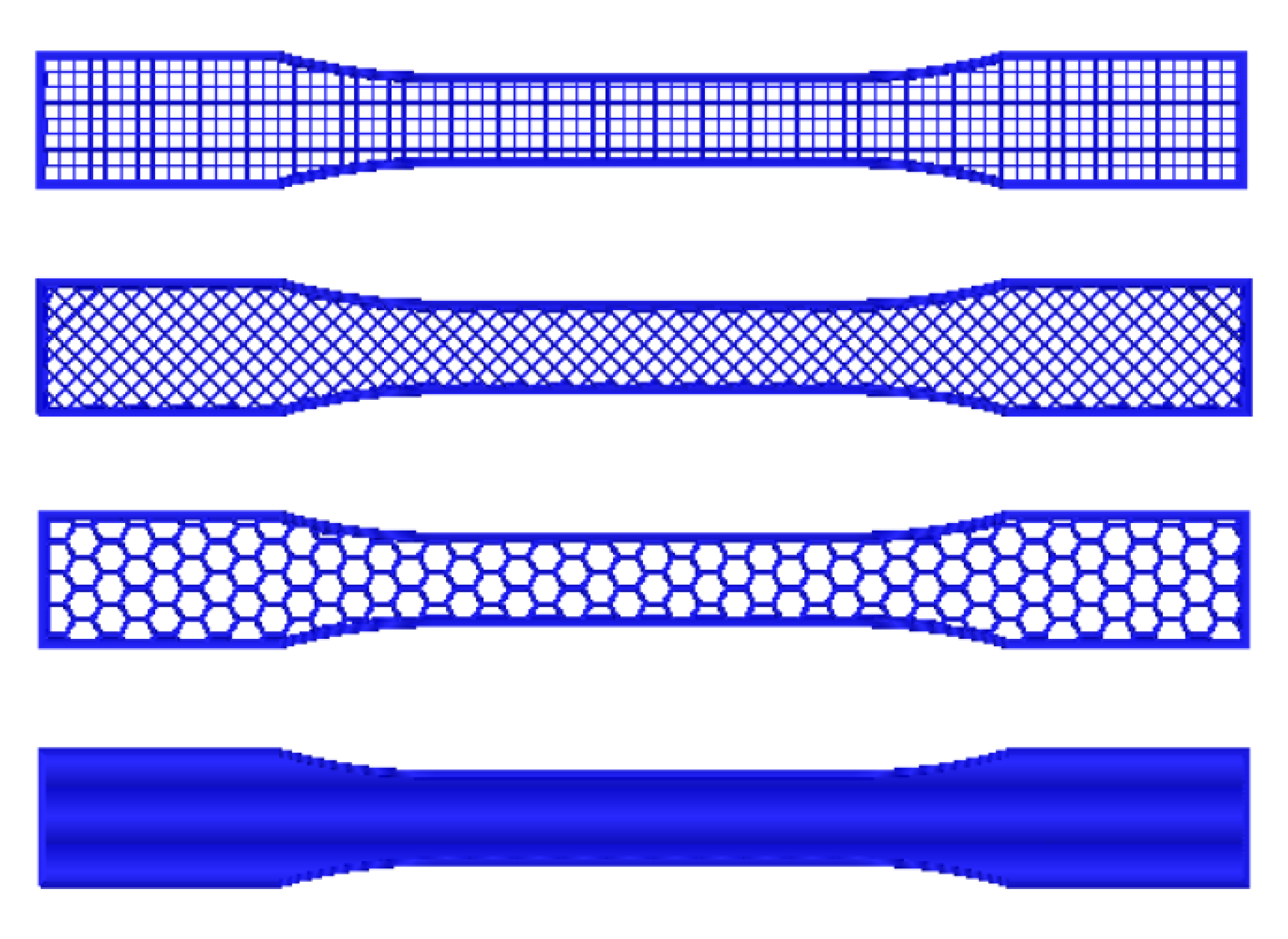

2.2. Preparation of Infill Shapes for Tensile Test

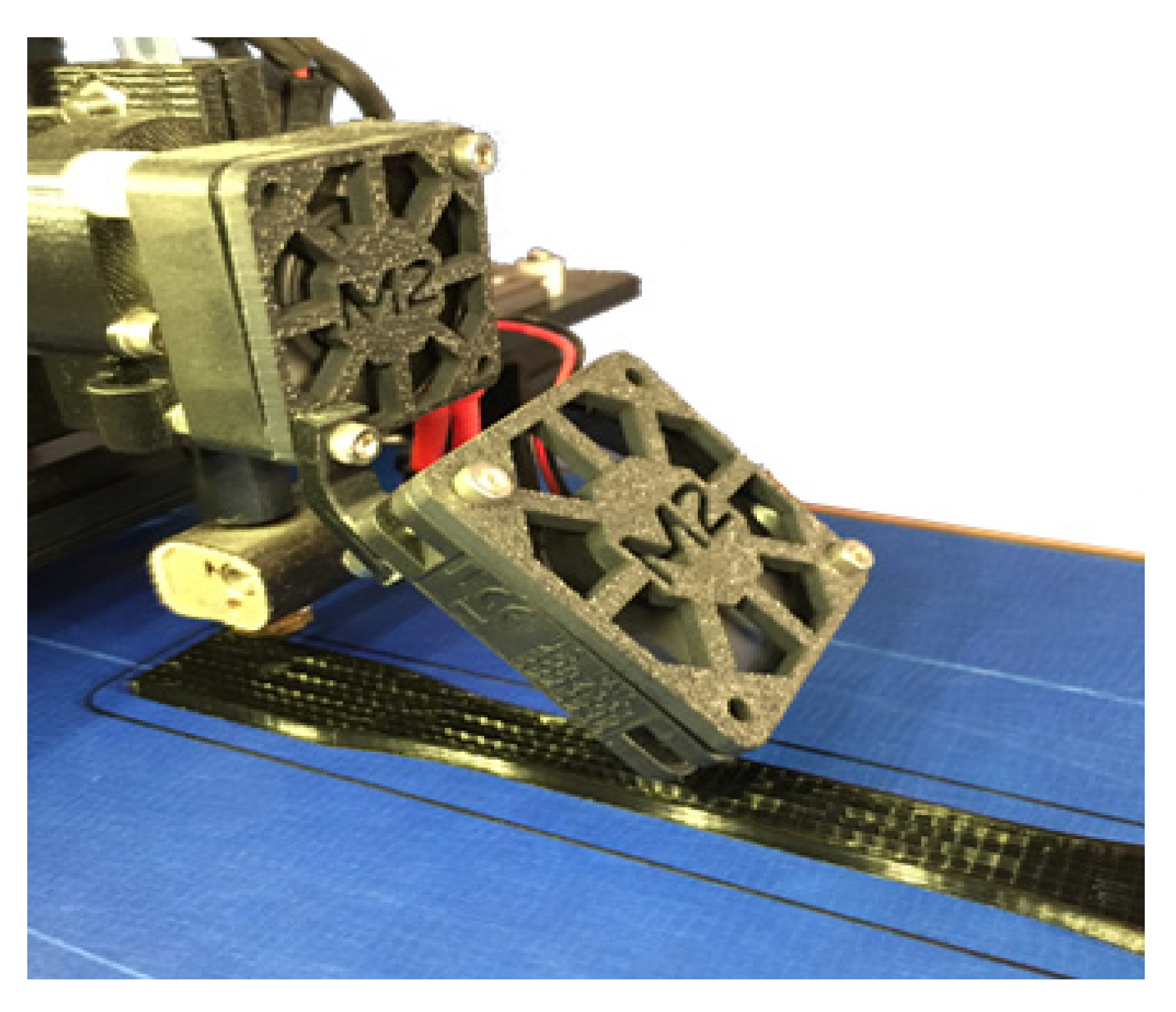

2.3. 3D Print Preparation

2.4. Finite Element Analysis

3. Results and Discussion

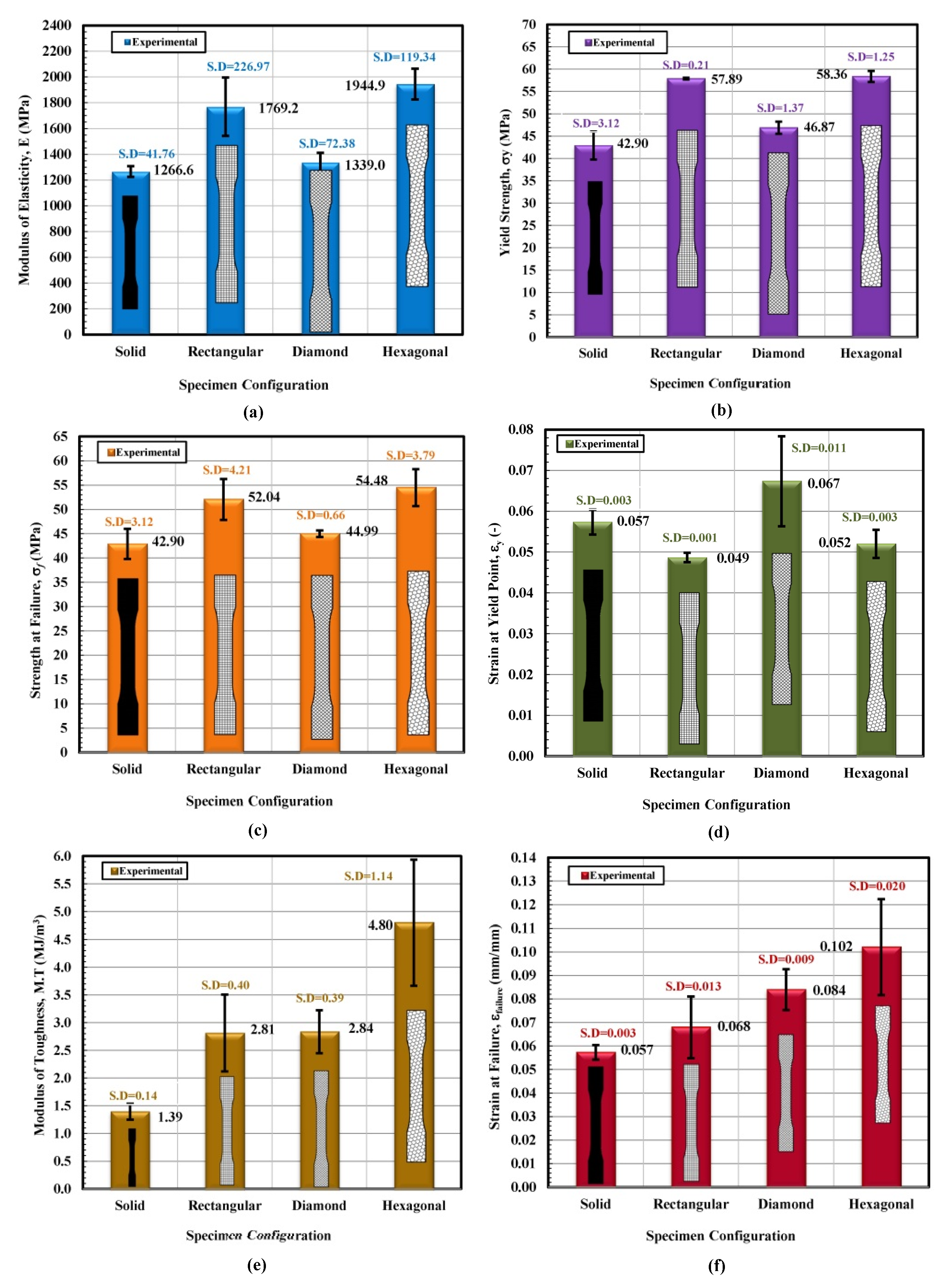

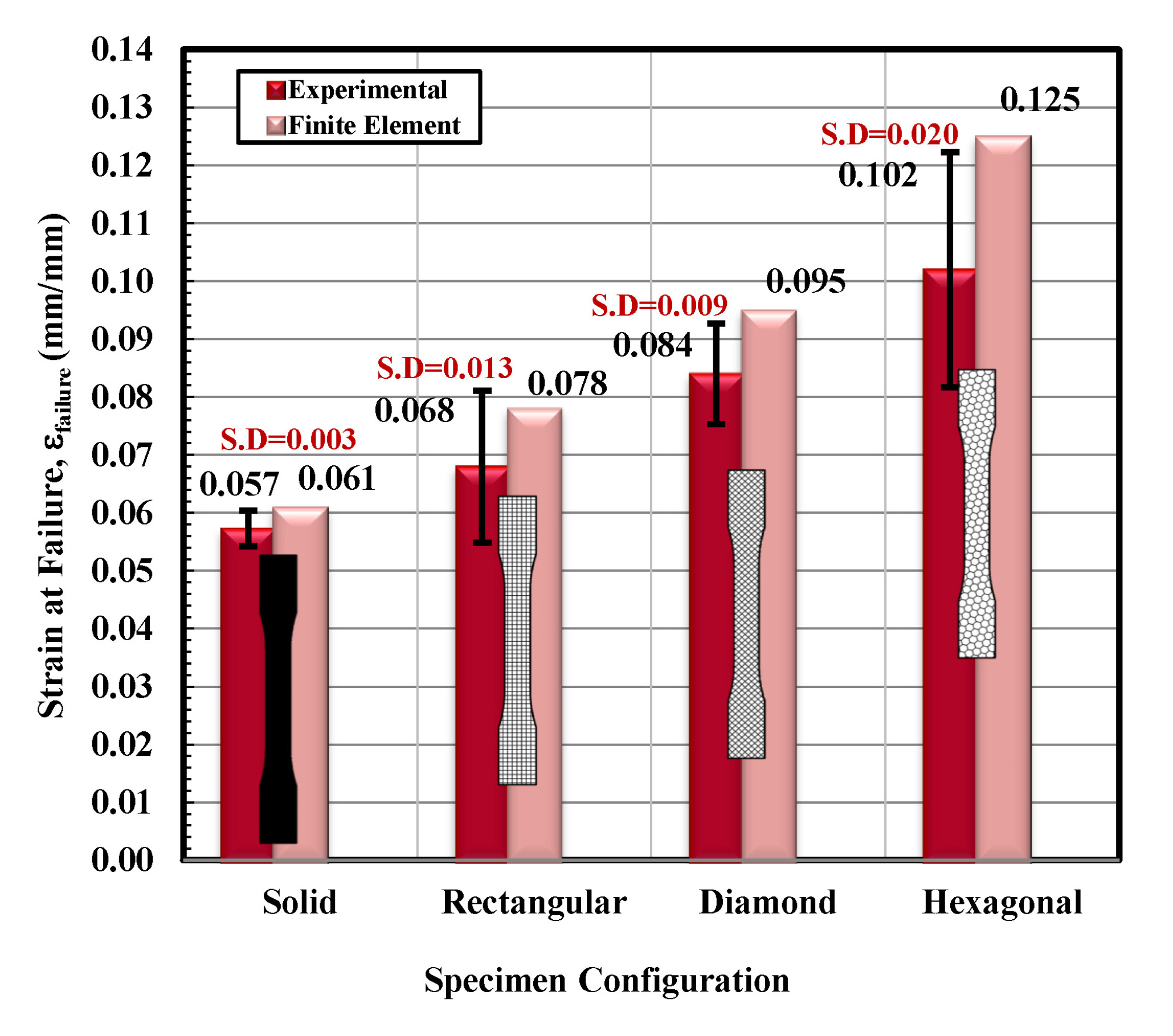

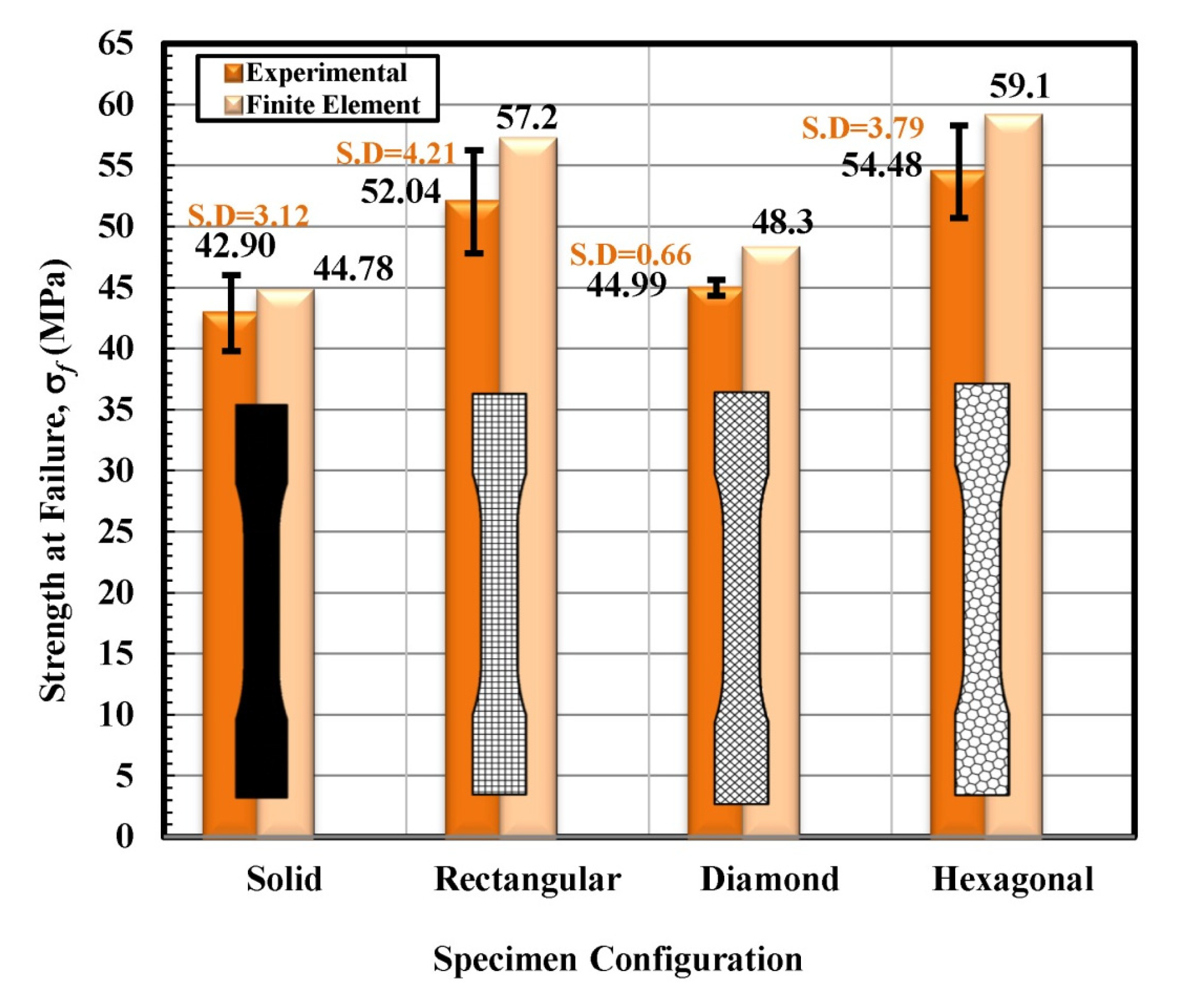

3.1. Tensile Testing Analysis

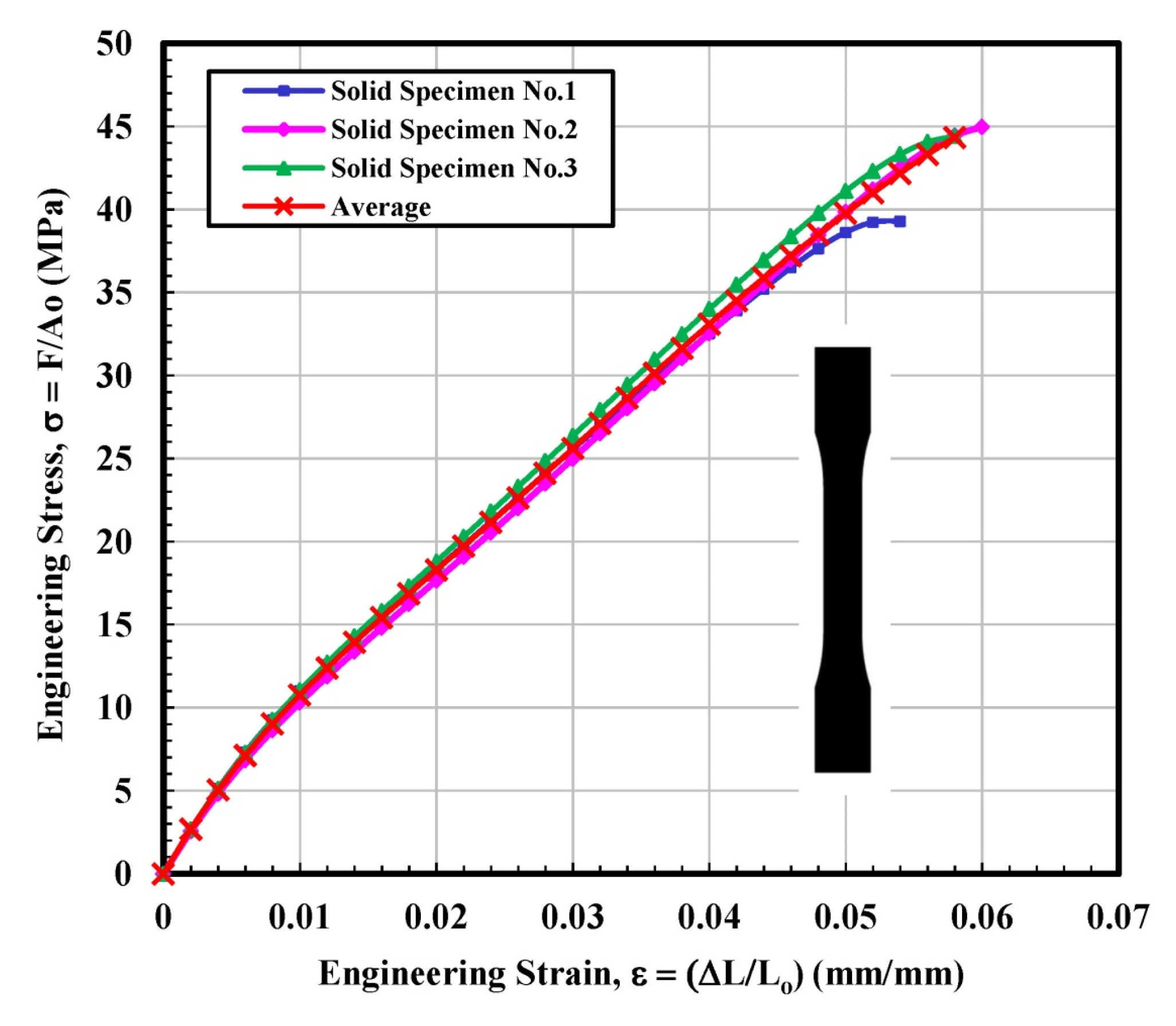

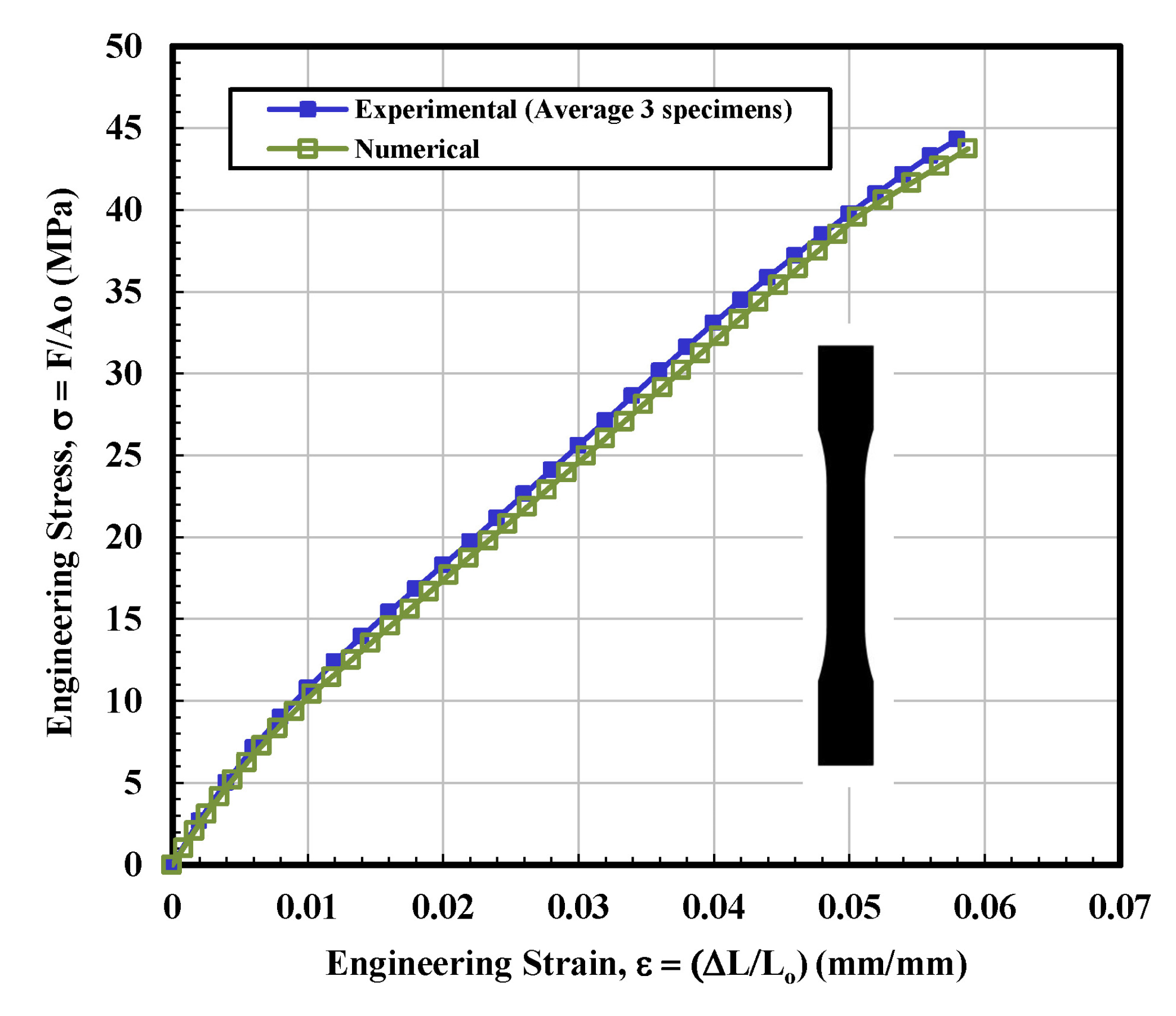

3.1.1. Solid Test Specimen

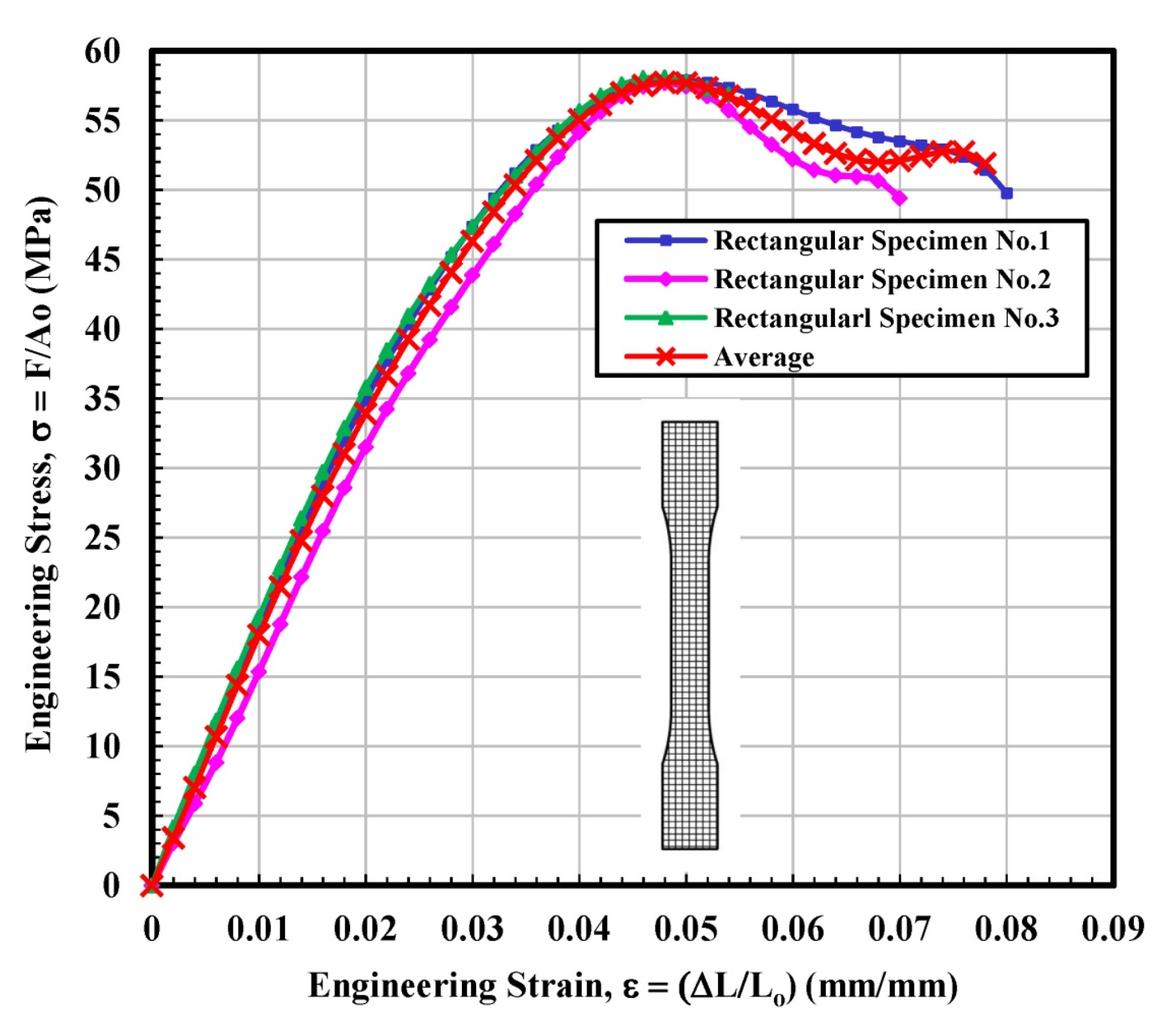

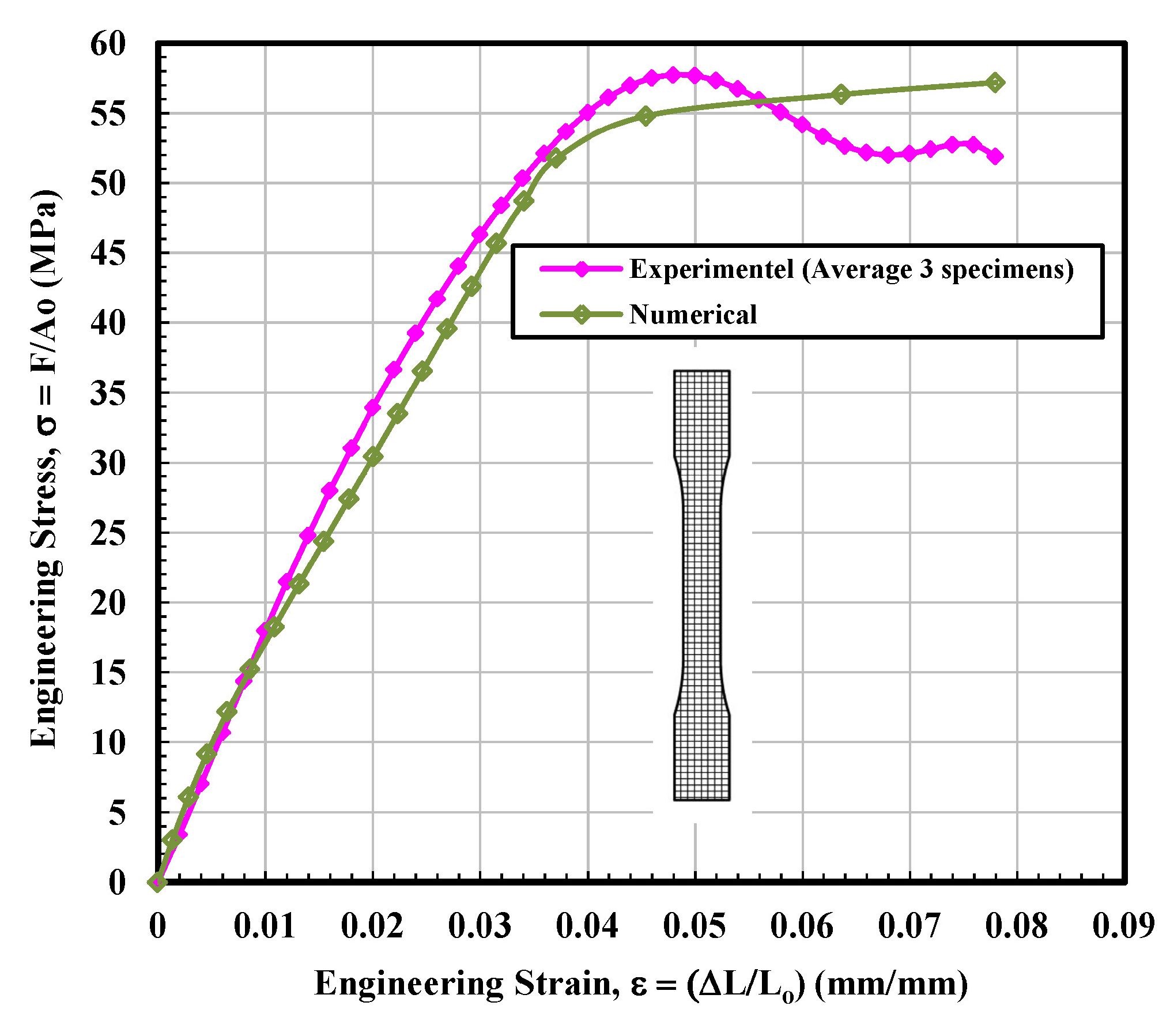

3.1.2. Rectangular Test Specimen

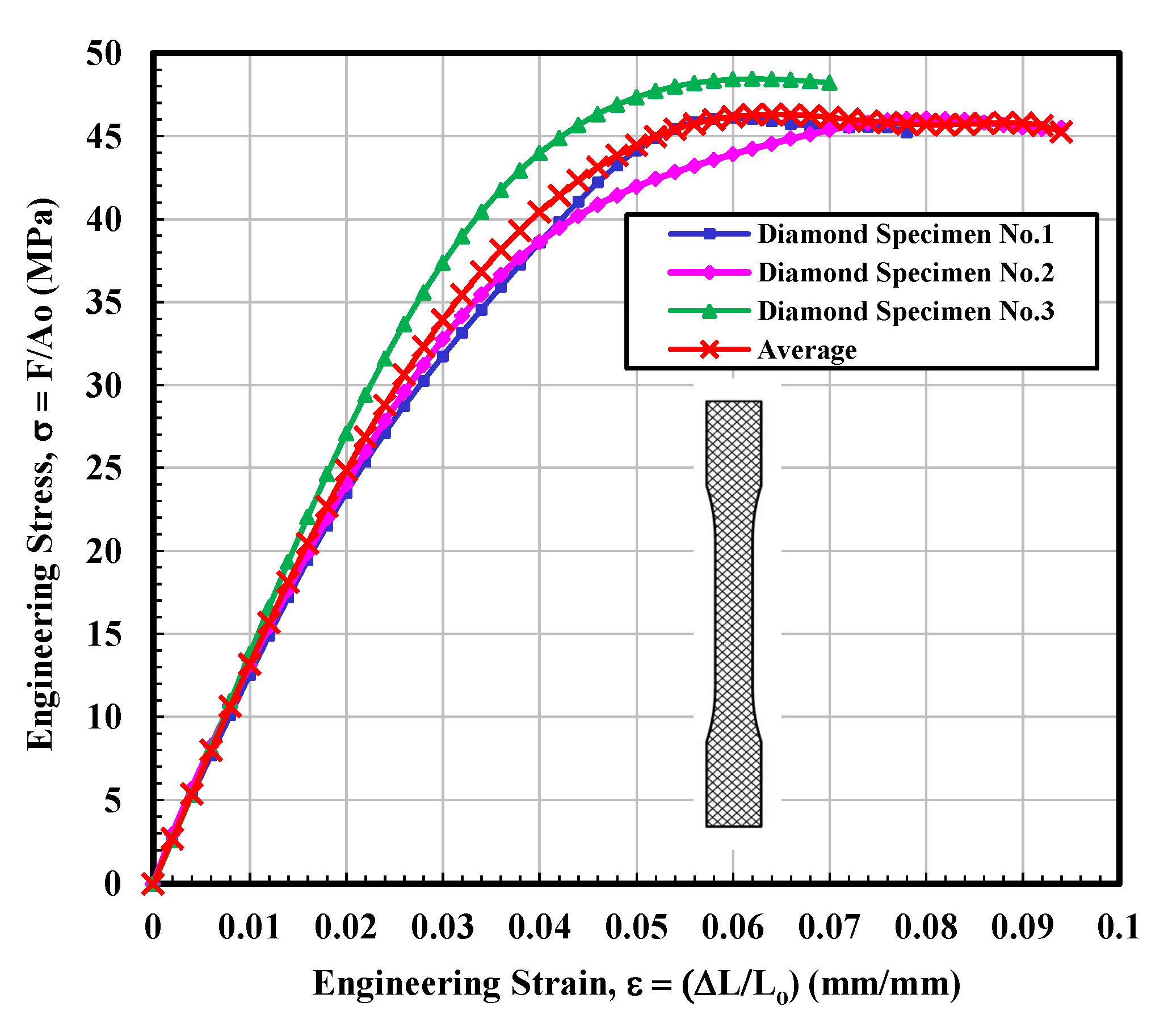

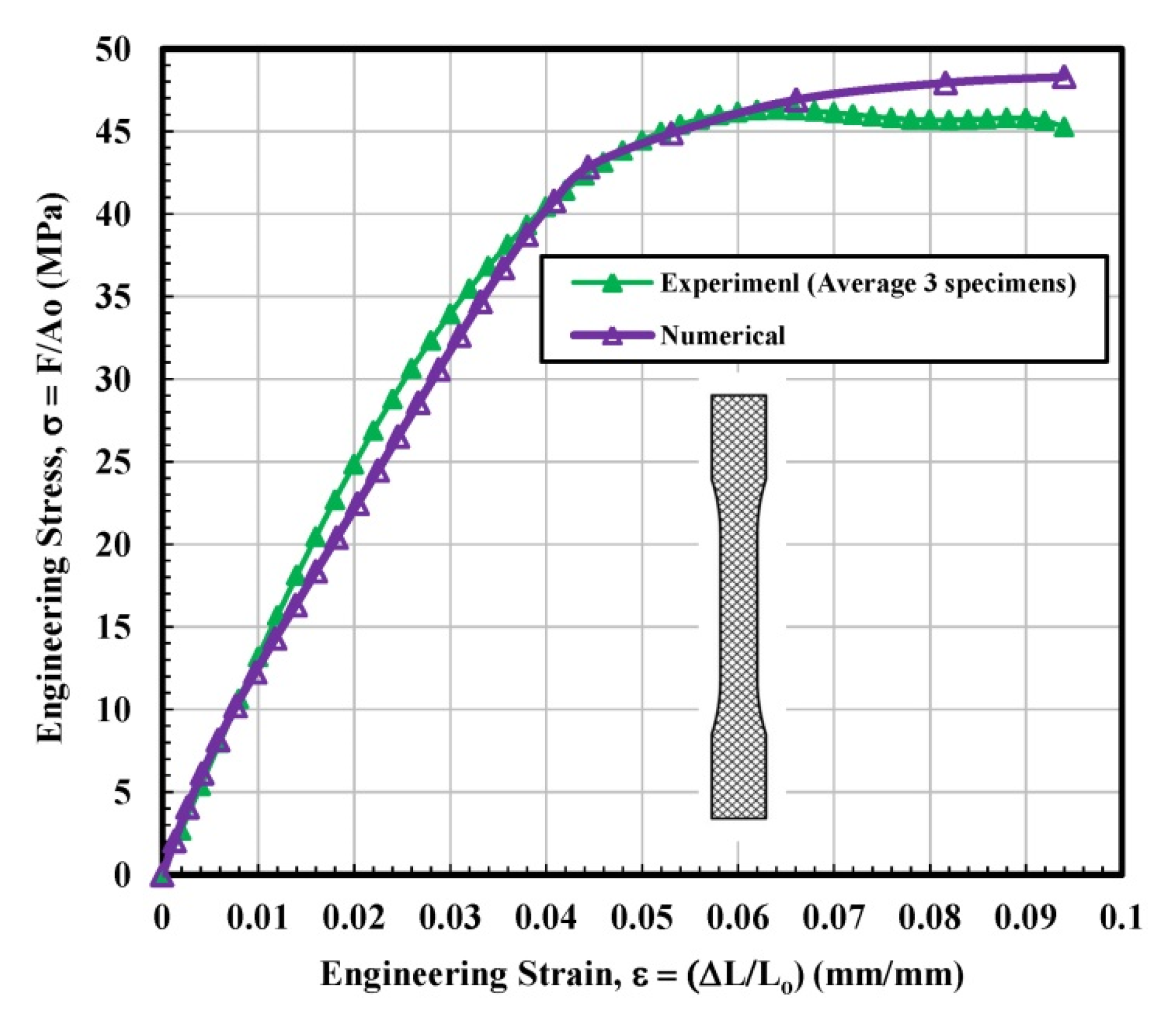

3.1.3. Diamond Test Specimen

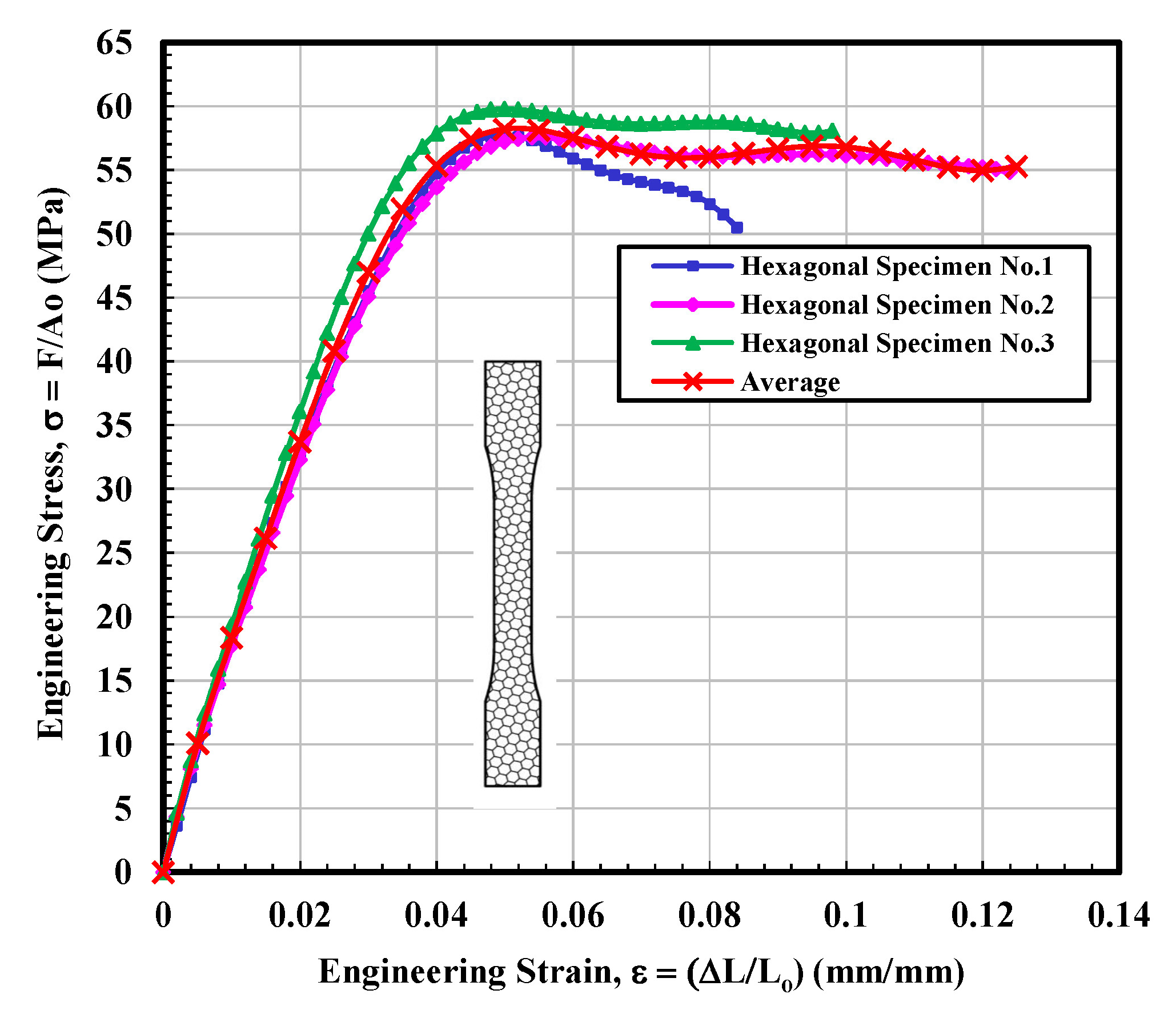

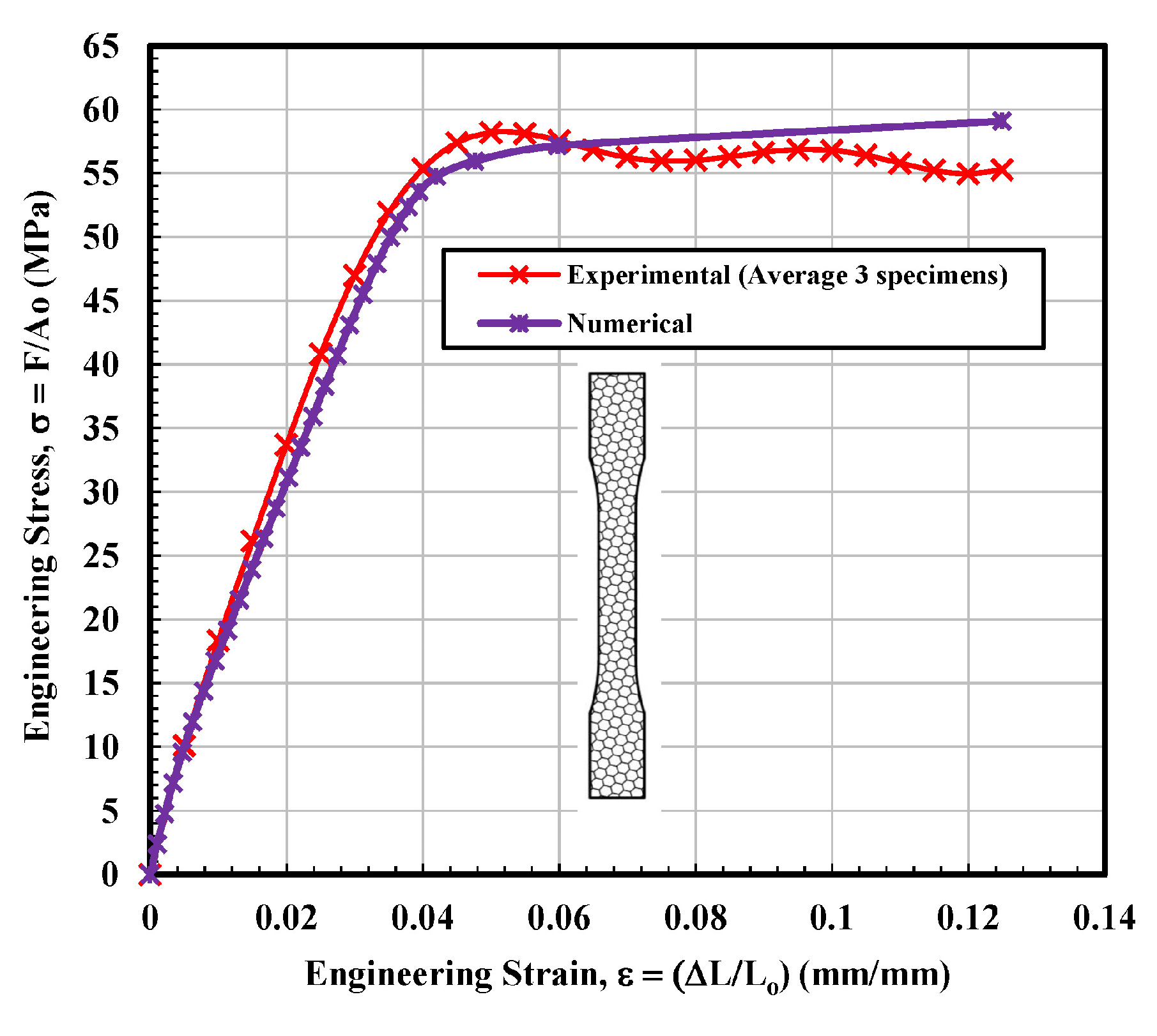

3.1.4. Hexagonal Test Specimen

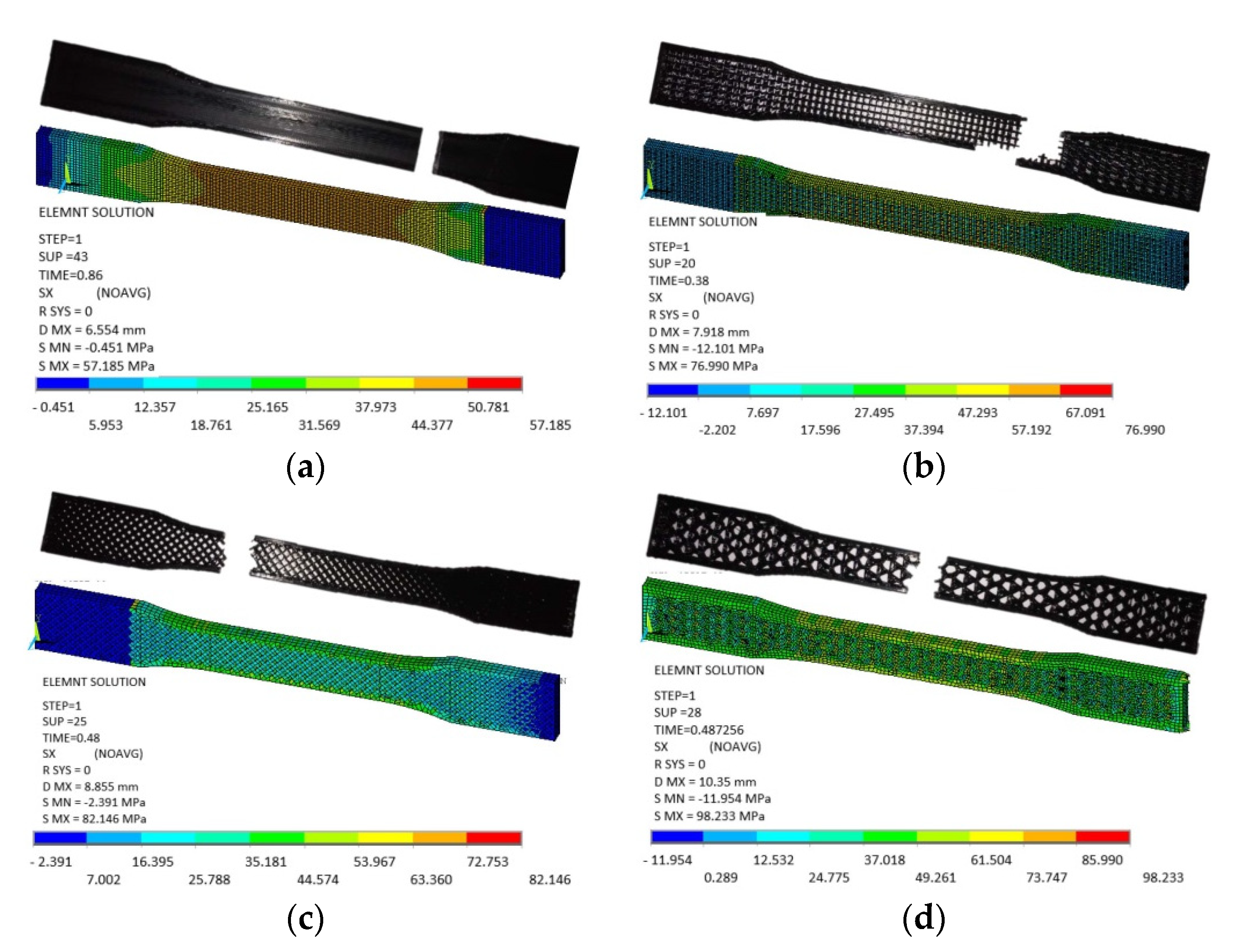

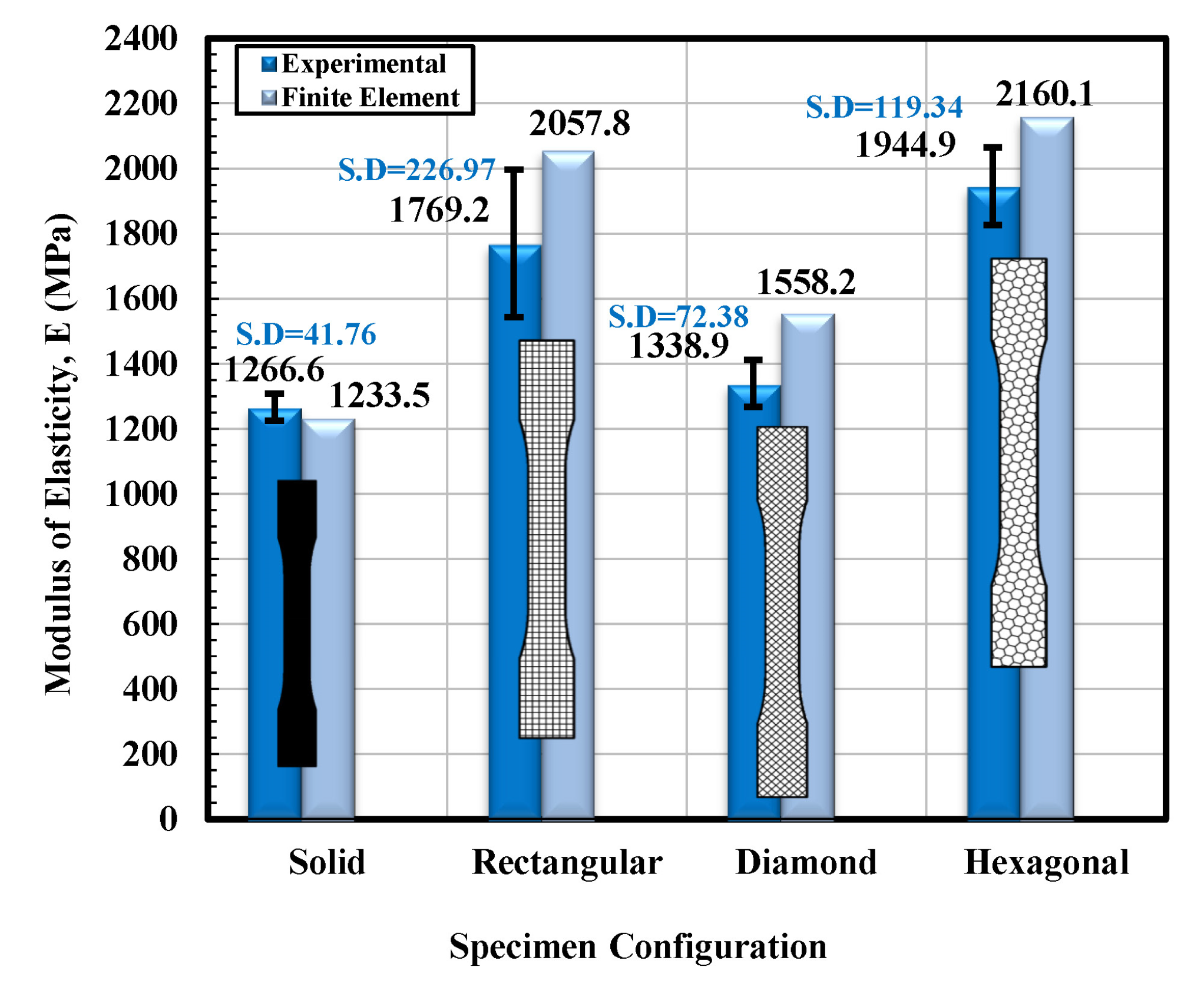

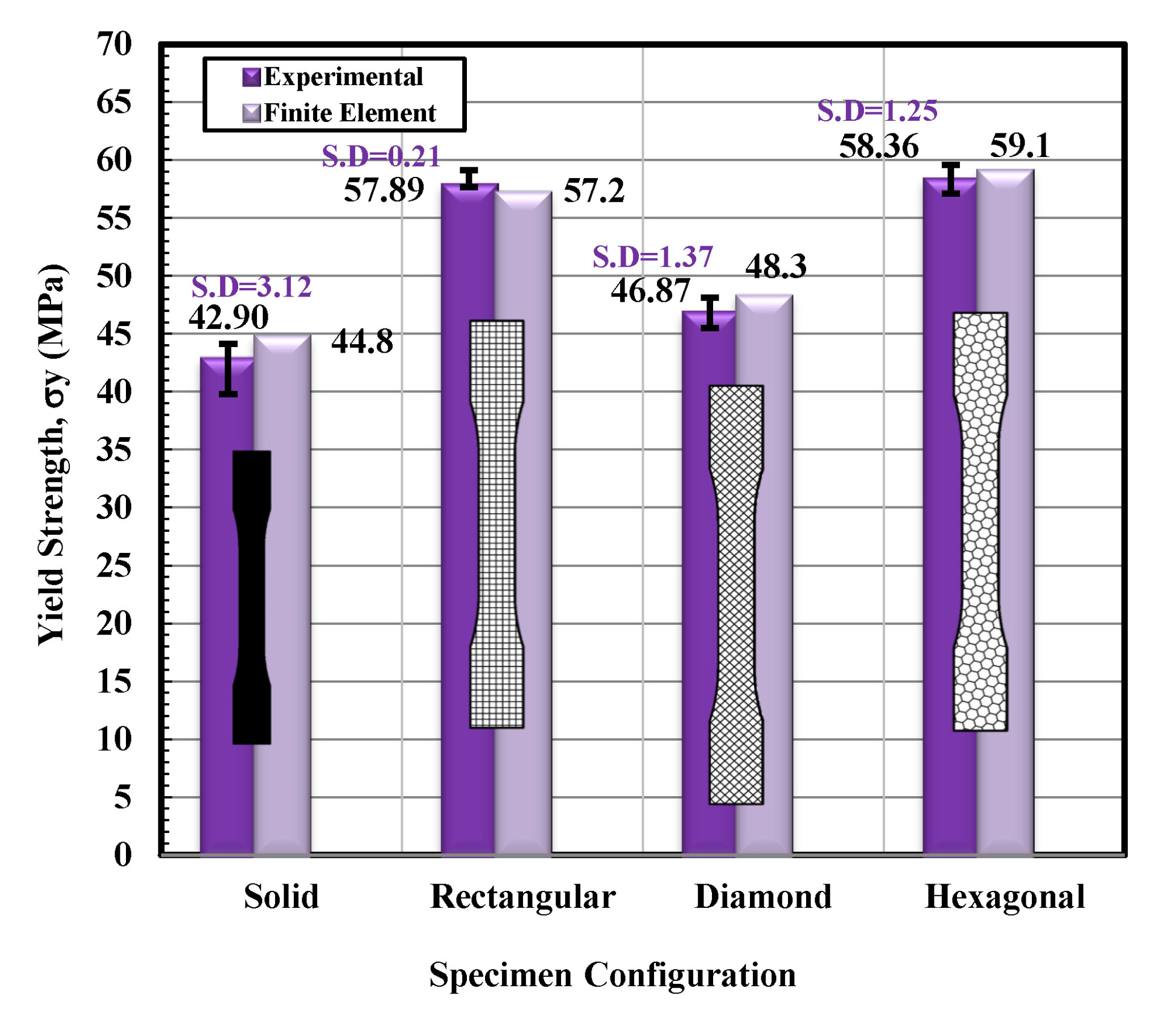

3.2. Finite Element Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Harpool, T.D. Observing the Effects of Infill Shapes on the Tensile Characteristics of 3D Printed Plastic Parts. Master’s Thesis, Department of Industrial Engineering, Wichita State University, Wichita, KS, USA, 2016. [Google Scholar]

- Page, C.; Kreuzer, S.; Ansari, F.; Eason, D.; Hamed, E.; Watson, H. Optimizing 3D printed components: A methodological approach to assessing print parameters on tensile properties. In Proceedings of the Annual Technical Conference—ANTEC, Conference Proceedings, Anaheim, CA, USA, 8–10 May 2017; Volume 2017. [Google Scholar]

- Baich, L. Impact of Infill Design on Mechanical Strength and Production Cost in Material Extrusion Based Additive Manufacturing. Master’s Thesis, Department of Industrial and Systems Engineering, Youngstown State University, Youngstown, OH, USA, 2016. [Google Scholar]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Melnikova, R.; Ehrmann, A.; Finsterbusch, K. 3D printing of textile-based structures by Fused Deposition Modelling (FDM) with different polymer materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Jakarta, Indonesia, 29–31 March 2014; Volume 62. [Google Scholar]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3. [Google Scholar] [CrossRef]

- Padhi, S.K.; Sahu, R.K.; Mahapatra, S.S.; Das, H.C.; Sood, A.K.; Patro, B.; Mondal, A.K. Optimization of fused deposition modeling process parameters using a fuzzy inference system coupled with Taguchi philosophy. Adv. Manuf. 2017, 5. [Google Scholar] [CrossRef]

- Alhnan, M.A.; Okwuosa, T.C.; Sadia, M.; Wan, K.W.; Ahmed, W.; Arafat, B. Emergence of 3D Printed Dosage Forms: Opportunities and Challenges. Pharm. Res. 2016, 33, 1817–1832. [Google Scholar] [CrossRef]

- Bhushan, B.; Caspers, M. An overview of additive manufacturing (3D printing) for microfabrication. Microsyst. Technol. 2017, 23. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS with Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58. [Google Scholar] [CrossRef]

- Torrado, A.R.; Roberson, D.A. Failure Analysis and Anisotropy Evaluation of 3D-Printed Tensile Test Specimens of Different Geometries and Print Raster Patterns. J. Fail. Anal. Prev. 2016, 16. [Google Scholar] [CrossRef]

- Roberson, D.A.; Torrado Perez, A.R.; Shemelya, C.M.; Rivera, A.; MacDonald, E.; Wicker, R.B. Comparison of stress concentrator fabrication for 3D printed polymeric izod impact test specimens. Addit. Manuf. 2015, 7. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the mechanical properties of FFF structures and materials: A review on the experimental, computational and theoretical approaches. Materials 2019, 16, 895. [Google Scholar] [CrossRef]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of material and process specific factors on the strength of printed parts in fused filament fabrication: A review of recent developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef]

- Wang, L.; Gramlich, W.M.; Gardner, D.J. Improving the impact strength of Poly (lactic acid) (PLA) in fused layer modeling (FLM). Polymer 2017, 114. [Google Scholar] [CrossRef]

- Dong, Y.; Milentis, J.; Pramanik, A. Additive manufacturing of mechanical testing samples based on virgin poly (lactic acid) (PLA) and PLA/wood fibre composites. Adv. Manuf. 2018, 6. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Flexural strength of fused filament fabricated (FFF) PLA parts on an open-source 3D printer. Adv. Manuf. 2018, 6. [Google Scholar] [CrossRef]

- Mishra, S.B.; Malik, R.; Mahapatra, S.S. Effect of External Perimeter on Flexural Strength of FDM Build Parts. Arab. J. Sci. Eng. 2017, 42. [Google Scholar] [CrossRef]

- Luzanin, O.; Guduric, V.; Ristic, I.; Muhic, S. Investigating impact of five build parameters on the maximum flexural force in FDM specimens—A definitive screening design approach. Rapid Prototyp. J. 2017, 23. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. Failure investigation of fused deposition modelling parts fabricated at different raster angles under tensile and flexural loading. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231. [Google Scholar] [CrossRef]

- Motaparti, K.P.; Taylor, G.; Leu, M.C.; Chandrashekhara, K.; Castle, J.; Matlack, M. Experimental investigation of effects of build parameters on flexural properties in fused deposition modelling parts. Virtual Phys. Prototyp. 2017, 12. [Google Scholar] [CrossRef]

- Rahman, K.M.; Letcher, T.; Reese, R. Mechanical properties of additively manufactured peek components using fused filament fabrication. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Montreal, QC, Canada, 13–19 November 2015; Volume 2A. [Google Scholar]

- Bakarich, S.E.; Gorkin, R.; Panhuis, M.; Spinks, G.M. Three-dimensional printing fiber reinforced hydrogel composites. ACS Appl. Mater. Interfaces 2014, 6. [Google Scholar] [CrossRef]

- Rane, K.; Strano, M. A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv. Manuf. 2019, 7. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Iovenitti, P.; Nikzad, M.; Sbarski, I. Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog. Addit. Manuf. 2016, 1. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Tensile Properties of Plastics (Metric); Annual Book of ASTM Standards, Part 08.01, Plastics-General Test Method; American Society for Testing and Materials, ASTM International 638-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Ghanbarzadeh, B.; Almasi, H.; Entezami, A.A. Physical properties of edible modified starch/carboxymethyl cellulose films. Innov. Food Sci. Emerg. Technol. 2010, 11. [Google Scholar] [CrossRef]

- Harpool, T.D.; Alamir, M.; Asmatulu, R. Effects of infill shapes on mechanical behaviors of 3D printed plastics. In Proceedings of the CAMX 2017—Composites and Advanced Materials Expo, Orlando, FL, USA, 11–14 December 2017; Volume 2017. [Google Scholar]

- Giordano, R.A.; Wu, B.M.; Borland, S.W.; Cima, L.G.; Sachs, E.M.; Cima, M.J. Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing. J. Biomater. Sci. Polym. Ed. 1997, 8. [Google Scholar] [CrossRef]

- Costa, S.F.; Duarte, F.M.; Covas, J.A. Estimation of filament temperature and adhesion development in fused deposition techniques. J. Mater. Process. Technol. 2017, 245. [Google Scholar] [CrossRef]

- TestWorks 4; Vers. 4.12 Build 1012; MTS Systems Corporation: Eden Prairie, MN, USA, 1995–2010.

- ANSYS. User’s Manual; Version (15); Swanson Analysis Systems, Inc.: Cannonsburg, PA, USA, 2015. [Google Scholar]

- Menčík, P.; Přikryl, R.; Stehnová, I.; Melčová, V.; Kontárová, S.; Figalla, S.; Alexy, P.; Bočkaj, J. Effect of selected commercial plasticizers on mechanical, thermal, and morphological properties of poly(3-hydroxybutyrate)/Poly(lactic acid)/plasticizer biodegradable blends for three-dimensional (3D) print. Materials 2018, 11, 1893. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Anakhu, P.I.; Bolu, C.C.; Abioye, A.A.; Onyiagha, G.; Boyo, H.; Jolayemi, K.; Azeta, J. Innovative foundry technology and material using fused deposition modeling and polylactic acid material in sand casing. Arch. Foundry Eng. 2018, 18. [Google Scholar] [CrossRef]

- Aloyaydi, B.; Sivasankaran, S.; Mustafa, A. Investigation of infill-patterns on mechanical response of 3D printed poly-lactic-acid. Polym. Test. 2020, 87. [Google Scholar] [CrossRef]

- Shao, J.; Zhang, Z.; Zhao, S.; Wang, S.; Guo, Z.; Xie, H.; Hu, Y. Self-Healing Hydrogel of Poly (Vinyl Alcohol)/Agarose with Robust Mechanical Property. Starch/Staerke 2019, 71. [Google Scholar] [CrossRef]

- Polylactic Acid (PLA) Typical Properties. Prospector. ULProspector, Web. 20 August 2016. Available online: https://plastics.ulprospector.com/generics/34/c/t/polylactic-acid-pla-properties-processing (accessed on 24 March 2021).

- Srinivasan, R.; Prathap, P.; Raj, A.; Kannan, S.A.; Deepak, V. Influence of fused deposition modeling process parameters on the mechanical properties of PETG parts. Mater. Today Proc. 2020, 27, 1877–1883. [Google Scholar] [CrossRef]

- Masood, S.H.; Mau, K.; Song, W.Q. Tensile properties of processed FDM polycarbonate material. In Materials Science Forum; Scientific.net: Zurich, Switzerland, 2010; Volume 654–656. [Google Scholar]

- Hossain, M.S.; Ramos, J.; Espalin, D.; Perez, M.; Wicker, R. Improving tensile mechanical properties of FDM-manufactured specimens via modifying build parameters. In Proceedings of the 24th International SFF Symposium—An Additive Manufacturing Conference, SFF 2013, Austin, TX, USA, 12 August 2013. [Google Scholar]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The influence of manufacturing parameters on the mechanical behaviour of PLA and ABS pieces manufactured by FDM: A comparative analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Goh, G.D.; Dikshit, V.; An, J.; Yeong, W.Y. Process-structure-property of additively manufactured continuous carbon fiber reinforced thermoplastic: An investigation of mode I interlaminar fracture toughness. Mech. Adv. Mater. Struct. 2020. [Google Scholar] [CrossRef]

- Luis, E.; Pan, H.M.; Sing, S.L.; Bastola, A.K.; Goh, G.D.; Goh, G.L.; Tan, H.K.J.; Bajpai, R.; Song, J.; Yeong, W.Y. Silicone 3D Printing: Process Optimization, Product Biocompatibility, and Reliability of Silicone Meniscus Implants. 3D Print. Addit. Manuf. 2019, 6. [Google Scholar] [CrossRef]

- Bakis, C.E.; Haluza, R.T.; Bartolai, J.; Kim, J.J.; Simpson, T.W. Assessment of anisotropic mechanical properties of a 3D printed carbon whisker reinforced composite. Adv. Compos. Mater. 2019, 28. [Google Scholar] [CrossRef]

- Goh, G.D.; Toh, W.; Yap, Y.L.; Ng, T.Y.; Yeong, W.Y. Additively manufactured continuous carbon fiber-reinforced thermoplastic for topology optimized unmanned aerial vehicle structures. Compos. Part B Eng. 2021, 216. [Google Scholar] [CrossRef]

- Christiyan, K.G.J.; Chandrasekhar, U.; Venkateswarlu, K. A study on the influence of process parameters on the Mechanical Properties of 3D printed ABS composite. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114. [Google Scholar] [CrossRef]

| Mechanical Properties | Specimen No. 1 | Specimen No. 2 | Specimen No. 3 | Average Value ± (Standard Deviation, S.D.) | Average Value According to Fitting Curve |

|---|---|---|---|---|---|

| E (MPa) | 1291.9 | 1218.4 | 1289.5 | 1267 ± 42.0 | 1275.5 |

| σy = σUTS (MPa) | 39.31 | 44.97 | 44.41 | 43.0 ± 3.0 | 44.34 |

| εy (mm/mm) | 0.054 | 0.06 | 0.058 | 0.06 ± 0.003 | 0.058 |

| σf (MPa) | 39.31 | 44.97 | 44.41 | 43.0 ± 3.0 | 44.34 |

| εfailure (mm/mm) | 0.054 | 0.060 | 0.058 | 0.06 ± 0.003 | 0.058 |

| M.T (MJ/m3) | 1.23 | 1.49 | 1.46 | 1.0 ± 0.14 | 1.42 |

| Mechanical Properties | Specimen No. 1 | Specimen No. 2 | Specimen No. 3 | Average Value ± (Standard Deviation, S.D.) | Average Value According to Fitting Curve |

|---|---|---|---|---|---|

| E (MPa) | 1867.4 | 1509.7 | 1930.6 | 1769 ± 227 | 1759.4 |

| σy = σUTS (MPa] | 57.90 | 57.68 | 58.09 | 58.0 ± 0.21 | 57.74 |

| εy (mm/mm) | 0.05 | 0.048 | 0.048 | 0.05 ± 0.001 | 0.048 |

| σf (MPa) | 49.80 | 49.42 | 56.90 | 52.0 ± 4.0 | 51.91 |

| εfailure (mm/mm) | 0.08 | 0.07 | 0.054 | 0.07 ± 0.013 | 0.078 |

| M.T (MJ/m3) | 3.51 | 2.81 | 2.12 | 3.0 ± 0.70 | 3.34 |

| Mechanical Properties | Specimen No. 1 | Specimen No. 2 | Specimen No. 3 | Average Value ± (Standard Deviation, S.D.) | Average Value According to Fitting Curve |

|---|---|---|---|---|---|

| E (MPa) | 1258.1 | 1397.7 | 1361.1 | 1339 ± 72 | 1300 |

| σy = σUTS (MPa) | 46.11 | 46.06 | 48.45 | 47 ± 1 | 46.32 |

| εy (mm/mm) | 0.06 | 0.08 | 0.062 | 0.07 ± 0.011 | 0.064 |

| σf (MPa) | 44.25 | 45.49 | 45.24 | 45 ± 0.66 | 45.26 |

| εfailure (mm/mm) | 0.08 | 0.094 | 0.078 | 0.080 ± 0.01 | 0.094 |

| M.T (MJ/m3) | 2.66 | 3.28 | 2.57 | 3.0 ± 0.40 | 3.0 |

| Mechanical Properties | Specimen No. 1 | Specimen No. 2 | Specimen No. 3 | Average Value ± (Standard Deviation, S.D.) | Average Value According to Fitting Curve |

|---|---|---|---|---|---|

| E (MPa) | 1816.9 | 1964.7 | 2053.1 | 1945 ± 119 | 2016.8 |

| σy = σUTS (MPa) | 57.72 | 57.56 | 59.80 | 58 ± 1.0 | 58.25 |

| εy (-) | 0.05 | 0.056 | 0.05 | 0.050 ± 0.003 | 0.052 |

| σf (MPa) | 50.52 | 54.84 | 58.08 | 54.0 ± 4.0 | 55.18 |

| εfailure (-) | 0.084 | 0.124 | 0.098 | 0.10 ± 0.020 | 0.124 |

| M.T (MJ/m3) | 3.68 | 5.95 | 4.77 | 5.0 ± 1.0 | 6.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harpool, T.D.; Alarifi, I.M.; Alshammari, B.A.; Aabid, A.; Baig, M.; Malik, R.A.; Mohamed Sayed, A.; Asmatulu, R.; EL-Bagory, T.M.A.A. Evaluation of the Infill Design on the Tensile Response of 3D Printed Polylactic Acid Polymer. Materials 2021, 14, 2195. https://doi.org/10.3390/ma14092195

Harpool TD, Alarifi IM, Alshammari BA, Aabid A, Baig M, Malik RA, Mohamed Sayed A, Asmatulu R, EL-Bagory TMAA. Evaluation of the Infill Design on the Tensile Response of 3D Printed Polylactic Acid Polymer. Materials. 2021; 14(9):2195. https://doi.org/10.3390/ma14092195

Chicago/Turabian StyleHarpool, Tanner David, Ibrahim Mohammed Alarifi, Basheer A. Alshammari, Abdul Aabid, Muneer Baig, Rizwan Ahmed Malik, Ahmed Mohamed Sayed, Ramazan Asmatulu, and Tarek Mohamed Ahmed Ali EL-Bagory. 2021. "Evaluation of the Infill Design on the Tensile Response of 3D Printed Polylactic Acid Polymer" Materials 14, no. 9: 2195. https://doi.org/10.3390/ma14092195

APA StyleHarpool, T. D., Alarifi, I. M., Alshammari, B. A., Aabid, A., Baig, M., Malik, R. A., Mohamed Sayed, A., Asmatulu, R., & EL-Bagory, T. M. A. A. (2021). Evaluation of the Infill Design on the Tensile Response of 3D Printed Polylactic Acid Polymer. Materials, 14(9), 2195. https://doi.org/10.3390/ma14092195