Chemical Modification of Agro-Industrial Waste-Based Bioadsorbents for Enhanced Removal of Zn(II) Ions from Aqueous Solutions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bio-Adsorbent Preparation

2.3. Characterization

2.4. Adsorption Experiments

3. Results and Discussion

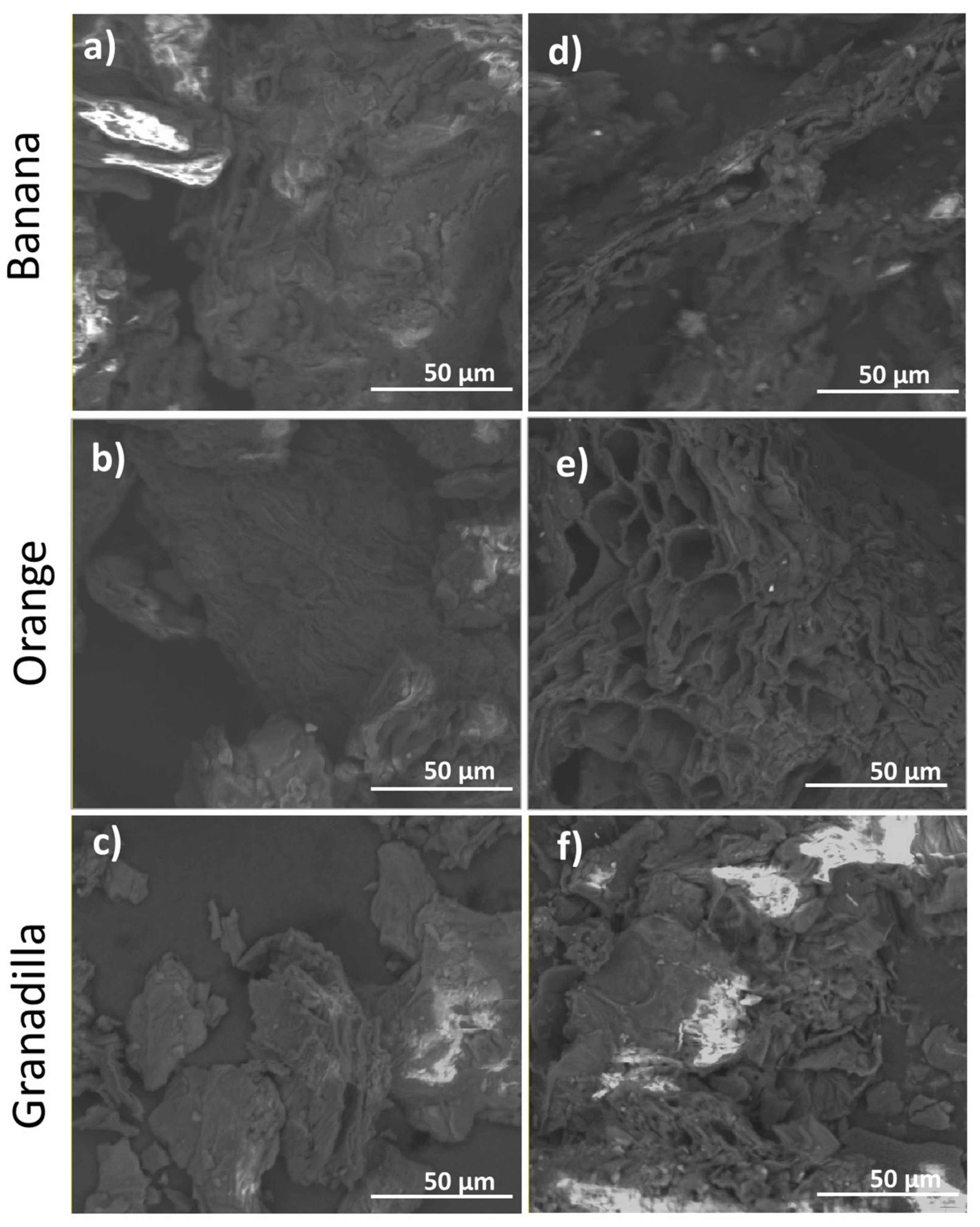

3.1. Characterization of the Adsorbents

3.2. Influence of Chemical Treatment on Zinc Adsorption

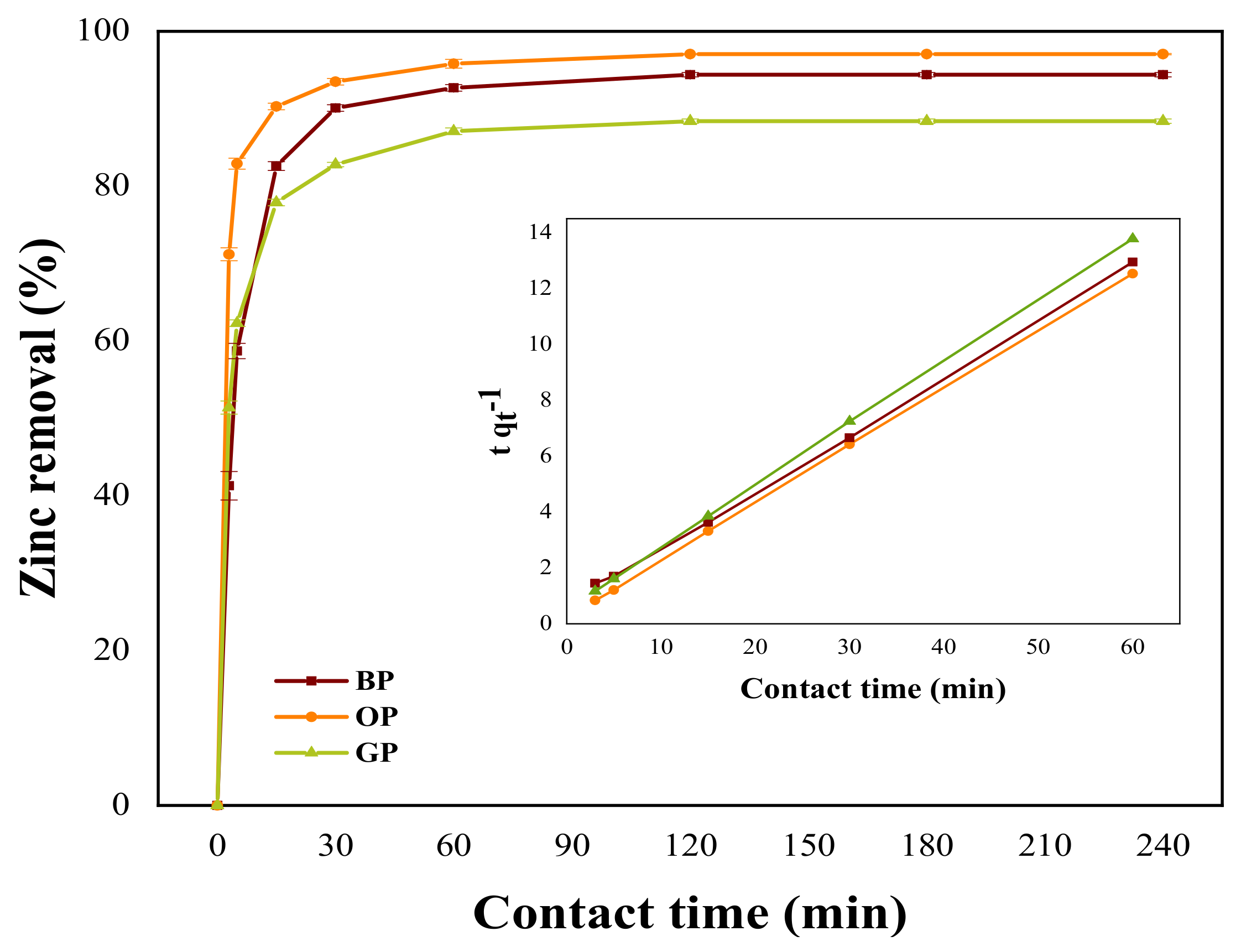

3.3. Adsorption Kinetics

3.4. Adsorption Isotherms

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klara, P.; de la Rosa, F.M.; Kovačić, M.; Kušić, H.; Štangar, U.L.; Fresno, F.; Dionysiou, D.D.; Bozic, A.L. Recent achievements in development of TiO2-based composite photocatalytic materials for solar driven water purification and water splitting. Materials 2020, 13, 1338. [Google Scholar]

- Hoang, H.G.; Lin, C.; Tran, H.T.; Chiang, C.F.; Bui, X.T.; Cheruiyot, N.K.; Shern, C.C.; Lee, C.W. Heavy metal contamination trends in surface water and sediments of a river in a highly-industrialized region. Environ. Technol. Innov. 2020, 20, 101043. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, Q.; Ren, B.; Luo, J.; Yuan, J.; Ding, X.; Bian, H.; Yao, X. Trends and Health Risks of Dissolved Heavy Metal Pollution in Global River and Lake Water from 1970 to 2017. Rev. Environ. Contam. Toxicol. 2019, 238, 1–24. [Google Scholar]

- Häder, D.P.; Banaszak, A.T.; Villafañe, V.E.; Narvarte, M.A.; González, R.A.; Helbling, E.W. Anthropogenic pollution of aquatic ecosystems: Emerging problems with global implications. Sci. Total Environ. 2020, 713, 136586. [Google Scholar] [CrossRef]

- Basu, S.; Chanda, A.; Gogoi, P.; Bhattacharyya, S. Organochlorine pesticides and heavy metals in the zooplankton, fishes, and shrimps of tropical shallow tidal creeks and the associated human health risk. Mar. Pollut. Bull. 2021, 165, 112170. [Google Scholar] [CrossRef]

- Turan, F.; Eken, M.; Ozyilmaz, G.; Karan, S.; Uluca, H. Heavy metal bioaccumulation, oxidative stress and genotoxicity in African catfish Clarias gariepinus from Orontes river. Ecotoxicology 2020, 29, 1522–1537. [Google Scholar] [CrossRef] [PubMed]

- Pujari, M.; Kapoor, D. Heavy metals in the ecosystem: Sources and their effects. In Heavy Metals in the Environment; Elsevier: Amsterdam, The Netherlands, 2021; pp. 1–7. [Google Scholar]

- Zamora-Ledezma, C.; Negrete-Bolagay, D.; Figueroa, F.; Zamora-Ledezma, E.; Ni, M.; Alexis, F.; Guerrero, V.H. Heavy metal water pollution: A fresh look about hazards, novel and conventional remediation methods. Press 2021, 22. [Google Scholar] [CrossRef]

- Briffa, J.; Sinagra, E.; Blundell, R. Heavy metal pollution in the environment and their toxicological effects on humans. Heliyon 2020, 6, e04691. [Google Scholar] [CrossRef]

- Kumar, V.; Parihar, R.D.; Sharma, A.; Bakshi, P.; Singh Sidhu, G.P.; Bali, A.S.; Karaouzas, I.; Bhardwaj, R.; Thukral, A.K.; Gyasi-Agyei, Y.; et al. Global evaluation of heavy metal content in surface water bodies: A meta-analysis using heavy metal pollution indices and multivariate statistical analyses. Chemosphere 2019, 236, 124364. [Google Scholar] [CrossRef]

- EPA. Ambient Water Quality Criteria for Zinc; United States Environmental Protection Agency: Washington, DC, USA, 1980.

- Borchers, N.; Clark, S.; Horstmann, B.; Jayasayee, K.; Juel, M.; Stevens, P. Innovative zinc-based batteries. J. Power Sources 2021, 484, 229309. [Google Scholar] [CrossRef]

- Hussain, A.K.; Seetharamaiah, N.; Pichumani, M.; Chakra, C.S. Research progress in organic zinc rich primer coatings for cathodic protection of metals—A comprehensive review. Prog. Org. Coatings 2021, 153, 106040. [Google Scholar] [CrossRef]

- Okereafor, U.; Makhatha, M.; Mekuto, L.; Uche-Okereafor, N.; Sebola, T.; Mavumengwana, V. Toxic metal implications on agricultural soils, plants, animals, aquatic life and human health. Int. J. Environ. Res. Public Health 2020, 17, 2204. [Google Scholar] [CrossRef] [Green Version]

- Plum, L.M.; Rink, L.; Hajo, H. The essential toxin: Impact of zinc on human health. Int. J. Environ. Res. Public Health 2010, 7, 1342–1365. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, Z.; Wu, H.; Zhao, J. Multifunctional roles of zinc in Alzheimer’s disease. Neurotoxicology 2020, 80, 112–123. [Google Scholar] [CrossRef] [PubMed]

- Senthil Murugan, S.; Karuppasamy, R.; Poongodi, K.; Puvaneswari, S. Bioaccumulation pattern of zinc in freshwater fish Channa punctatus (Bloch.) after chronic exposure. Turkish J. Fish. Aquat. Sci. 2008, 59, 55–59. [Google Scholar]

- Al-Shannag, M.; Al-Qodah, Z.; Bani-Melhem, K.; Qtaishat, M.R.; Alkasrawi, M. Heavy metal ions removal from metal plating wastewater using electrocoagulation: Kinetic study and process performance. Chem. Eng. J. 2015, 260, 749–756. [Google Scholar] [CrossRef]

- Dominighini, C.; Muscia, L.; Cataldi, Z.; Scurati, C.; Olivero, M.; Gottardo, M. Analysis of reverse osmosis membranes in the treatment of water for human consumption. Health Environ. World Congr. 2016, 1, 123–129. [Google Scholar]

- Ghosh, P.; Samanta, A.N.; Ray, S. Reduction of COD and removal of Zn2+ from rayon industry wastewater by combined electro-Fenton treatment and chemical precipitation. Desalination 2011, 266, 213–217. [Google Scholar] [CrossRef]

- Guo, S.; Jiao, P.; Dan, Z.; Duan, N.; Zhang, J.; Chen, G.; Gao, W. Synthesis of magnetic bioadsorbent for adsorption of Zn(II), Cd(II) and Pb(II) ions from aqueous solution. Chem. Eng. Res. Des. 2017, 126, 217–231. [Google Scholar] [CrossRef]

- Vidu, R.; Matei, E.; Predescu, A.M.; Alhalaili, B.; Pantilimon, C.; Tarcea, C.; Predescu, C. Removal of Heavy Metals from Wastewaters: A Challenge from Current Treatment Methods to Nanotechnology Applications. Toxics 2020, 8, 101. [Google Scholar] [CrossRef]

- Otunola, B.O.; Ololade, O.O. A review on the application of clay minerals as heavy metal adsorbents for remediation purposes. Environ. Technol. Innov. 2020, 18, 100692. [Google Scholar] [CrossRef]

- Beni, A.A.; Esmaeili, A. Biosorption an Efficient method for Removing Heavy Metals from Industrial Effluents: A Review. Environ. Technol. Innov. 2020, 17, 100503. [Google Scholar] [CrossRef]

- Chai, W.S.; Cheun, J.Y.; Kumar, P.S.; Mubashir, M.; Majeed, Z.; Banat, F.; Ho, S.-H.; Show, P.L. A review on conventional and novel materials towards heavy metal adsorption in wastewater treatment application. J. Clean. Prod. 2021, 296, 126589. [Google Scholar] [CrossRef]

- Anoop Krishnan, K.; Sreejalekshmi, K.G.; Vimexen, V.; Dev, V.V. Evaluation of adsorption properties of sulphurised activated carbon for the effective and economically viable removal of Zn (II) from aqueous solutions. Ecotoxicol. Environ. Saf. 2016, 124, 418–425. [Google Scholar] [CrossRef]

- Kołodyńska, D.; Krukowska, J.; Thomas, P. Comparison of sorption and desorption studies of heavy metal ions from biochar and commercial active carbon. Chem. Eng. J. 2017, 307, 353–363. [Google Scholar] [CrossRef]

- Wang, J.; Chen, C. Biosorbents for heavy metals removal and their future. Biotechnol. Adv. 2009, 27, 195–226. [Google Scholar] [CrossRef]

- Boni, M.; Chiavola, A.; Marzeddu, S. Application of Biochar to the Remediation of Pb-Contaminated Solutions. Sustainability 2018, 10, 4440. [Google Scholar] [CrossRef] [Green Version]

- Hafshejani, L.D.; Nasab, S.B.; Gholami, R.M.; Moradzadeh, M.; Izadpanah, Z.; Hafshejani, S.B.; Bhatnagar, A. Removal of zinc and lead from aqueous solution by nanostructured cedar leaf ash as biosorbent. J. Mol. Liq. 2015, 211, 448–456. [Google Scholar] [CrossRef]

- Xu, M.; McKay, G. Removal of heavy metals, lead, cadmium, and zinc, using adsorption processes by cost-effective adsorbents. In Adsorption Processes for Water Treatment and Purification; Bonilla-Petriciolet, A., Mendoza-Castillo, D.I., Reynel-Ávila, H.E., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 109–138. ISBN 9783319581361. [Google Scholar]

- Paduraru, C.; Tofan, L.; Teodosiu, C.; Bunia, I.; Tudorachi, N.; Toma, O. Biosorption of zinc(II) on rapeseed waste: Equilibrium studies and thermogravimetric investigations. Process Saf. Environ. Prot. 2015, 94, 18–28. [Google Scholar] [CrossRef]

- Rajczykowski, K.; Sałasińska, O.; Loska, K. Zinc Removal from the Aqueous Solutions by the Chemically Modified Biosorbents. Water. Air. Soil Pollut. 2018, 229, 6. [Google Scholar] [CrossRef] [Green Version]

- Feng, N.C.; Guo, X.Y. Characterization of adsorptive capacity and mechanisms on adsorption of copper, lead and zinc by modified orange peel. Trans. Nonferrous Met. Soc. China 2012, 22, 1224–1231. [Google Scholar] [CrossRef]

- Malkoc, S.; Kaynak, E.; Guven, K. Biosorption of zinc (II) on dead and living biomass of Variovorax paradoxus and Arthrobacter viscosus. Desalin. Water Treat. 2016, 57, 15445–15454. [Google Scholar] [CrossRef]

- Kumari, P. Application of Sugarcane Bagasse for the Removal of Chromium (Vi) and Zinc (Ii) From Aqueous Solution. Int. Res. J. Eng. Technol. 2017, 04, 1670–1673. [Google Scholar]

- Ahmed, M.J.; Hameed, B.H.; Hummadi, E.H. Insight into the chemically modified crop straw adsorbents for the enhanced removal of water contaminants: A review. J. Mol. Liq. 2021, 330, 115616. [Google Scholar] [CrossRef]

- Cholico-González, D.; Ortiz Lara, N.; Fernández Macedo, A.M.; Chavez Salas, J. Adsorption Behavior of Pb (II), Cd (II), and Zn(II) onto Agave Bagasse, Characterization, and Mechanism. ACS Omega 2020, 5, 3302–3314. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Sillanpää, M. Utilization of agro-industrial and municipal waste materials as potential adsorbents for water treatment-A review. Chem. Eng. J. 2010, 157, 277–296. [Google Scholar] [CrossRef]

- Tran, H.N.; Nguyen, H.C.; Woo, S.H.; Nguyen, T.V.; Vigneswaran, S.; Hosseini-Bandegharaei, A.; Rinklebe, J.; Kumar Sarmah, A.; Ivanets, A.; Dotto, G.L.; et al. Removal of various contaminants from water by renewable lignocellulose-derived biosorbents: A comprehensive and critical review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 2155–2219. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Adeniyi, A.G. A mini-review of the morphological properties of biosorbents derived from plant leaves. SN Appl. Sci. 2020, 2, 509. [Google Scholar] [CrossRef] [Green Version]

- Yoo, C.G.; Meng, X.; Pu, Y.; Ragauskas, A.J. The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: A comprehensive review. Bioresour. Technol. 2020, 301, 122784. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Pashalidis, I.; Orfanos, A.G.; Manariotis, I.D.; Tatarchuk, T.; Sellaoui, L.; Bonilla-Petriciolet, A.; Mittal, A.; Núñez-Delgado, A. Removal of caffeine, nicotine and amoxicillin from (waste)waters by various adsorbents. A review. J. Environ. Manag. 2020, 261, 110236. [Google Scholar] [CrossRef]

- Dacewicz, E.; Chmielowski, K. The Importance of Media in Wastewater Treatment. InTech Open 2018. [Google Scholar] [CrossRef] [Green Version]

- Tejedor, J.; Cóndor, V.; Almeida-Naranjo, C.E.; Guerrero, V.H.; Villamar, C.A. Performance of wood chips/peanut shells biofilters used to remove organic matter from domestic wastewater. Sci. Total Environ. 2020, 738. [Google Scholar] [CrossRef] [PubMed]

- Pathak, P.D.; Mandavgane, S.A.; Kulkarni, B.D. Fruit peel waste: Characterization and its potential uses. Curr. Sci. 2017, 113, 444–454. [Google Scholar] [CrossRef]

- Hossain, M.A. Removal of Copper from Water by Adsorption onto Banana Peel as Bioadsorbent. Int. J. Geomate 2012, 2, 227–234. [Google Scholar] [CrossRef]

- Chen, Y.W.; Hasanulbasori, M.A.; Chiat, P.F.; Lee, H.V. Pyrus pyrifolia fruit peel as sustainable source for spherical and porous network based nanocellulose synthesis via one-pot hydrolysis system. Int. J. Biol. Macromol. 2019, 123, 1305–1319. [Google Scholar] [CrossRef]

- Yeh, C.-H.; Yang, T.-C. Utilization of Waste Bamboo Fibers in Thermoplastic Composites: Influence of the Chemical Composition and Thermal Decomposition Behavior. Polymers 2020, 12, 636. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farinella, N.V.; Matos, G.D.; Lehmann, E.L.; Arruda, M.A.Z. Grape bagasse as an alternative natural adsorbent of cadmium and lead for effluent treatment. J. Hazard. Mater. 2008, 154, 1007–1012. [Google Scholar] [CrossRef] [PubMed]

- Kamsonlian, S.; Suresh, S.; Majumder, C.B.; Chand, S. Characterization of Banana and Orange Peels: Biosorption Mechanism. Int. J. Sci. Technol. Manag. 2011, 2, 1–7. [Google Scholar]

- Memon, J.R.; Memon, S.Q.; Bhanger, M.I.; Memon, G.Z.; El-Turki, A.; Allen, G.C. Characterization of banana peel by scanning electron microscopy and FT-IR spectroscopy and its use for cadmium removal. Colloids Surf. B Biointerfaces 2008, 66, 260–265. [Google Scholar] [CrossRef]

- Annadurai, G.; Juang, R.S.; Lee, D.J. Adsorption of heavy metals from water using banana and orange peels. Water Sci. Technol. 2003, 47, 185–190. [Google Scholar] [CrossRef]

- Cardona, A.F.; Cabañas, D.D.; Zepeda, A. Evaluación del poder biosorbente de cáscara de naranja para la eliminación de metales pesados, Pb (II) y Zn (II) Evaluation of the power of orange peel biosorbent for the removal of heavy metals, Pb (II) and Zn (II). Ingeniería 2013, 17, 1–9. [Google Scholar]

- Feng, N.C.; GUO, X.Y.; Liang, S. Kinetic and thermodynamic studies on biosorption of Cu (II) by chemically modified orange peel. Trans. Nonferrous Met. Soc. China 2009, 19, 1365–1370. [Google Scholar] [CrossRef]

- Yaneva, Z.L.; Koumanova, B.K.; Allen, S.J. Applicability comparison of different kinetic/diffusion models for 4-nitrophenol sorption on Rhizopus oryzae dead biomass. Bulg. Chem. Commun. 2013, 45, 161–168. [Google Scholar]

- Ho, Y.S. Selection of optimum sorption isotherm. Carbon N.Y. 2004, 42, 2115–2116. [Google Scholar] [CrossRef]

- Ngabura, M.; Hussain, S.A.; Ghani, W.A.W.A.; Jami, M.S.; Tan, Y.P. Utilization of renewable durian peels for biosorption of zinc from wastewater. J. Environ. Chem. Eng. 2018, 6, 2528–2539. [Google Scholar] [CrossRef]

- Weber, T.W.; Chakravorti, R.K. Pore and solid diffusion models for fixed-bed adsorbers. AIChE J. 1974, 20, 228–238. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Massas, I.; Ehaliotis, C. Use of residues and by-products of the olive-oil production chain for the removal of pollutants from environmental media: A review of batch biosorption approaches. J. Environ. Sci. Health Part A 2015, 50, 37–41. [Google Scholar] [CrossRef]

- Ashraf, M.; Wajid, A.; Mahmood, K.; Maah, M.; Yusoff, I. Low cost biosorbent banana peel (Musa sapientum) for the removal of heavy metals. Sci. Res. 2011, 6, 4055–4064. [Google Scholar]

- Babarinde, A.; Ogundipe, K.; Sangosanya, K.T.; Akintola, B.D.; Hassan, A.-O.E. Comparative study on the biosorption of Pb (II), Cd (II) and Zn (II) using Lemon grass (Cymbopogon citratus): Kinetics, isotherms and thermodynamics. Chem. Int. 2016, 2, 89–102. [Google Scholar]

- Hung, K.-C.; Yeh, H.; Yang, T.-C.; Wu, T.-L.; Xu, J.-W.; Wu, J.-H. Characterization of Wood-Plastic Composites Made with Different Lignocellulosic Materials that Vary in Their Morphology, Chemical Composition and Thermal Stability. Polymers 2017, 9, 726. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carvajal de Pabon, L.; Turbay Ceballos, S.; Marelly Álvarez, L.; Rodríguez, A.; Álvarez, M.; Bonilla, K.; Restrepo Escobar, S.; Parra, M. Relación entre los usos populares de la granadilla (passiflora ligularis juss) y su composición fitoquímica. Biotecnol. Sect. Agropecu. Agroind. BSAA 2014, 12, 191–202. [Google Scholar]

- Pyar, H.; Peh, K.K. Chemical Compositions of Banana Peels (Musa sapientum) Fruits cultivated in Malaysia using proximate analysis. Res. J. Chem. Environ. 2018, 22, 108. [Google Scholar]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sustain. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef] [Green Version]

- Palacios, S.; Ruiz, H.A.; Ramos-Gonzalez, R.; Martínez, J.; Segura, E.; Aguilar, M.; Aguilera, A.; Michelena, G.; Aguilar, C.; Ilyina, A. Comparison of physicochemical pretreatments of banana peels for bioethanol production. Food Sci. Biotechnol. 2017, 26, 993–1001. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, T.Í.S.; Rosa, M.F.; Cavalcante, F.L.; Pereira, P.H.F.; Moates, G.K.; Wellner, N.; Mazzetto, S.E.; Waldron, K.W.; Azeredo, H.M.C. Optimization of pectin extraction from banana peels with citric acid by using response surface methodology. Food Chem. 2016, 198, 113–118. [Google Scholar] [CrossRef]

- Boumediene, M.; Benaïssa, H.; George, B.; Molina, S.; Merlin, A. Characterization of two cellulosic waste materials (orange and almond peels) and their use for the removal of methylene blue from aqueous solutions. Maderas. Cienc. Tecnol. 2014, 17. [Google Scholar] [CrossRef] [Green Version]

- Rodriguez-Amaya, D.B. Passion Fruits. In Encyclopedia of Food Sciences and Nutrition; Elsevier: Amsterdam, The Netherlands, 2003; pp. 4368–4373. [Google Scholar]

- Khawas, P.; Deka, S.C. Comparative Nutritional, Functional, Morphological, and Diffractogram Study on Culinary Banana (Musa ABB) Peel at Various Stages of Development. Int. J. Food Prop. 2016, 19, 2832–2853. [Google Scholar] [CrossRef] [Green Version]

- El-Sayed, A.A.; Salama, M.; El-Rafie, M.H.; Emam, H.E. Modified Rice Straw as a Template in Syntheses of Nano TiO2 Loaded on Wool Fibers for Wastewater Treatment. J. Nat. Fibers 2017, 14, 297–309. [Google Scholar] [CrossRef]

- Pereira, M.A.F.; Monteiro, C.R.M.; Pereira, G.N.; Júnior, S.E.B.; Zanella, E.; Ávila, P.F.; Stambuk, B.U.; Goldbeck, R.; de Oliveira, D.; Poletto, P. Deconstruction of banana peel for carbohydrate fractionation. Bioprocess Biosyst. Eng. 2020, 1, 3. [Google Scholar] [CrossRef]

- Jaramillo, P.M.D.; Andreaus, J.; Neto, G.P.D.S.; Castro, C.F.D.S.; Filho, E.X.F. The characterization of a pectin-degrading enzyme from Aspergillus oryzae grown on passion fruit peel as the carbon source and the evaluation of its potential for industrial applications. Biocatal. Biotransform. 2015, 33, 310–322. [Google Scholar] [CrossRef]

- López, G.J.; Cuarán, C.J.; Arenas, G.L.; Flórez, P.L. Usos potenciales de la cáscara de banano: Elaboración de un bioplástico. Rev. Colomb. Investig. Agroind. 2014, 1, 7–21. [Google Scholar] [CrossRef] [Green Version]

- Pholosi, A.; Ofomaja, A.E.; Naidoo, E.B. Effect of chemical extractants on the biosorptive properties of pine cone powder: Influence on lead(II) removal mechanism. J. Saudi Chem. Soc. 2013, 17, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Kabenge, I.; Omulo, G.; Banadda, N.; Seay, J.; Zziwa, A.; Kiggundu, N. Characterization of Banana Peels Wastes as Potential Slow Pyrolysis Feedstock. J. Sustain. Dev. 2018, 11, 14. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Wang, B.; Xue, M.; Lu, Y. Kinetics of thermal oxidative degradation of poly (vinyl chloride) containing Ca and Sn at low temperature. Waste Manag. 2021, 121, 52–58. [Google Scholar] [CrossRef]

- Fonseca, J.; Albis, A.; Montenegro, A.R. Evaluation of zinc adsorption using cassava peels (Manihot esculenta) modified with citric acid. Contemp. Eng. Sci. 2018, 11, 3575–3585. [Google Scholar] [CrossRef] [Green Version]

- Feng, N.; Guo, X.; Liang, S. Adsorption study of copper (II) by chemically modified orange peel. J. Hazard. Mater. 2009, 164, 1286–1292. [Google Scholar] [CrossRef]

- Lahlali, R.; Song, T.; Chu, M.; Yu, F.; Kumar, S.; Karunakaran, C.; Peng, G. Evaluating changes in cell-wall components associated with clubroot resistance using fourier transform infrared spectroscopy and RT-PCR. Int. J. Mol. Sci. 2017, 18, 2058. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, X.; Tang, Y.; Cao, X.; Lu, D.; Luo, F.; Shao, W. Preparation and evaluation of orange peel cellulose adsorbents for effective removal of cadmium, zinc, cobalt and nickel. Colloids Surf. Physicochem. Eng. Asp. 2008, 317, 512–521. [Google Scholar] [CrossRef]

- Gupta, H.; Gogate, P.R. Intensified removal of copper from waste water using activated watermelon based biosorbent in the presence of ultrasound. Ultrason. Sonochem. 2016, 30, 113–122. [Google Scholar] [CrossRef]

- Afroze, S.; Sen, T.K.; Ang, H.M. Adsorption removal of zinc (II) from aqueous phase by raw and base modified Eucalyptus sheathiana bark: Kinetics, mechanism and equilibrium study. Process Saf. Environ. Prot. 2016, 102, 336–352. [Google Scholar] [CrossRef]

- Assifaoui, A.; Loupiac, C.; Chambin, O.; Cayot, P. Structure of calcium and zinc pectinate films investigated by FTIR spectroscopy. Carbohydr. Res. 2010, 345, 929–933. [Google Scholar] [CrossRef]

- Sari, A.; Tuzen, M.; Uluözlü, O.D.; Soylak, M. Biosorption of Pb (II) and Ni (II) from aqueous solution by lichen (Cladonia furcata) biomass. Biochem. Eng. J. 2007, 37, 151–158. [Google Scholar] [CrossRef]

- Negro, V.; Ruggeri, B.; Mancini, G.; Fino, D. Recovery of D-limonene through moderate temperature extraction and pyrolytic products from orange peels. J. Chem. Technol. Biotechnol. 2017, 92, 1186–1191. [Google Scholar] [CrossRef]

- De Carvalho, H.P.; Huang, J.; Zhao, M.; Liu, G.; Dong, L.; Liu, X. Improvement of Methylene Blue removal by electrocoagulation/banana peel adsorption coupling in a batch system. Alex. Eng. J. 2015, 54, 777–786. [Google Scholar] [CrossRef] [Green Version]

- Wurm, F.; Rietzler, B.; Pham, T.; Bechtold, T. Multivalent Ions as Reactive Crosslinkers for Biopolymers—A Review. Molecules 2020, 25, 1840. [Google Scholar] [CrossRef]

- Gawkowska, D.; Cybulska, J.; Zdunek, A. Structure-Related Gelling of Pectins and Linking with Other Natural Compounds: A Review. Polymers 2018, 10, 762. [Google Scholar] [CrossRef] [Green Version]

- Sirilamduan, C.; Umpuch, C.; Kaewsarn, P. Removal of copper from aqueous solutions by adsorption using modify Zalacca edulis peel modify. Songklanakarin J. Sci. Technol. 2011, 33, 725–732. [Google Scholar]

- Dada, A.O.; Olalekan, A. Langmuir, Freundlich, Temkin and Dubinin–Radushkevich Isotherms Studies of Equilibrium Sorption of Zn 2+ Unto Phosphoric Acid Modified Rice Husk. IOSR J. Appl. Chem. 2012, 3, 38–45. [Google Scholar]

- Tran, H.N.; You, S.; Hosseini-bandegharaei, A.; Chao, H. Mistakes and inconsistencies regarding adsorption of contaminants from aqueous solutions: A critical review. Water Res. 2017, 120, 88–116. [Google Scholar] [CrossRef]

- Kalyani, G.; Kumar, P.; King, P. Use of novel biosorbent mimusops elengi for removing zinc ions from aqueous solutions—Process optimization using central composite design. Rasayan J. Chem. 2016, 9, 510–525. [Google Scholar]

- Marín, A.B.P.; Aguilar, M.I.; Ortuño, J.F.; Meseguer, V.F.; Sáez, J.; Lloréns, M. Biosorption of Zn (II) by orange waste in batch and packed-bed systems. J. Chem. Technol. Biotechnol. 2010, 85, 1310–1318. [Google Scholar] [CrossRef]

| Parameter (%) | Banana Peels | Orange Peels | Granadilla Peels |

|---|---|---|---|

| Lignin * | 16.6 ± 1.1 | 7.9 ± 0.2 | 16.9 ± 0.6 |

| Hemicellulose * | 15.9 ± 0.1 | 15.4 ± 0.3 | 10.1 ± 0.7 |

| Cellulose * | 62.5 ± 1.0 | 55.7 ± 0.9 | 24.6 ± 1.3 |

| Ethanol-toluene extractives * | 4.7 ± 0.6 | 21.1 ± 1.2 | 48.5 ± 0.7 |

| Moisture | 89.1 ± 0.3 | 68.7 ± 0.4 | 68.8 ± 0.5 |

| Adsorbent | Zn Removal (%) | Adsorbent | Zn Removal (%) | Adsorbent | Zn Removal (%) |

|---|---|---|---|---|---|

| BP | 85.5 ± 0.5 | OP | 91.9 ± 0.1 | GP | 74.5 ± 1.1 |

| BP0.2 | 87.4 ± 0.2 | OP0.2 | 93.4 ± 0.1 | GP0.2 | 83.1 ± 0.8 |

| BP0.5 | 90.2 ± 0.3 | OP0.5 | 96.2 ± 0.3 | GP0.5 | 85.6 ± 0.2 |

| BP0.8 | 92.6 ± 0.2 | OP0.8 | 97.1 ± 0.2 | GP0.8 | 88.2 ± 0.4 |

| Peel Adsorbents | Pseudo First Order | Pseudo Second Order | |||||

|---|---|---|---|---|---|---|---|

| R2 | R2 | ||||||

| BP0.8 | 2.65 | 0.058 | 0.9145 | 4.81 | 0.09 | 2.06 | 0.9997 |

| OP0.8 | 0.96 | 0.049 | 0.9303 | 4.83 | 0.27 | 6.49 | 0.9999 |

| GP0.8 | 1.67 | 0.056 | 0.9720 | 4.44 | 0.14 | 2.73 | 0.9998 |

| Isotherm | BP0.8 | OP0.8 | GP0.8 |

|---|---|---|---|

| Linear Langmuir | |||

| qm (mg/g) | 25.59 | 27.48 | 16.61 |

| KL (L/mg) | 0.046 | 0.099 | 0.049 |

| R2 | 0.9925 | 0.9945 | 0.9949 |

| Linear Freundlich | |||

| KF (mg/g) (L/mg)1/n | 2.14 | 3.72 | 1.97 |

| n | 1.94 | 2.16 | 2.42 |

| R2 | 0.9738 | 0.9679 | 0.9763 |

| Non-Linear Langmuir | |||

| qm (mg/g) | 29.25 | 29.12 | 17.28 |

| KL (L/mg) | 0.024 | 0.055 | 0.034 |

| SSE | 12.47 | 19.11 | 9.42 |

| R2 | 0.9932 | 0.9950 | 0.9945 |

| Non-Linear Freundlich | |||

| KF (mg/g) (L/mg)1/n | 2.41 | 3.99 | 2.56 |

| n | 2.14 | 2.39 | 2.86 |

| SSE | 2.87 | 2.85 | 5.30 |

| R2 | 0.9925 | 0.9990 | 0.9940 |

| Adsorbent | Modification | Adsorbent Dose (g L−1) | Contact Time (h) | pH | Ref. | |

|---|---|---|---|---|---|---|

| Mimusops Elengi | without | 1 | 1.5 | 5 | 16.39 | [94] |

| Rapeseed waste | without | 1 | 24 | 5 | 13.86 | [32] |

| Durian | Acid-treated HCl | 5 | 4 | 8 | 36.75 | [58] |

| BP0.8 | NaOH and Ca(CH3COO)2 | 1 | 2 | 5 | 25.59 | This work |

| Orange | without | 4 | 3 | 5 | 33.08 | [95] |

| OP0.8 | NaOH and Ca(CH3COO)2 | 1 | 2 | 5 | 27.48 | This work |

| GP0.8 | NaOH and Ca(CH3COO)2 | 1 | 2 | 5 | 16.61 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castro, D.; Rosas-Laverde, N.M.; Aldás, M.B.; Almeida-Naranjo, C.E.; Guerrero, V.H.; Pruna, A.I. Chemical Modification of Agro-Industrial Waste-Based Bioadsorbents for Enhanced Removal of Zn(II) Ions from Aqueous Solutions. Materials 2021, 14, 2134. https://doi.org/10.3390/ma14092134

Castro D, Rosas-Laverde NM, Aldás MB, Almeida-Naranjo CE, Guerrero VH, Pruna AI. Chemical Modification of Agro-Industrial Waste-Based Bioadsorbents for Enhanced Removal of Zn(II) Ions from Aqueous Solutions. Materials. 2021; 14(9):2134. https://doi.org/10.3390/ma14092134

Chicago/Turabian StyleCastro, David, Nelly Ma. Rosas-Laverde, María Belén Aldás, Cristina E. Almeida-Naranjo, Víctor H. Guerrero, and Alina Iuliana Pruna. 2021. "Chemical Modification of Agro-Industrial Waste-Based Bioadsorbents for Enhanced Removal of Zn(II) Ions from Aqueous Solutions" Materials 14, no. 9: 2134. https://doi.org/10.3390/ma14092134