Microstructures and Mechanical Properties of Deposited Fe-8Cr-3V-2Mo-2W on SCM420 Substrate Using Directed Energy Deposition and Effect of Post-Heat Treatment

Abstract

1. Introduction

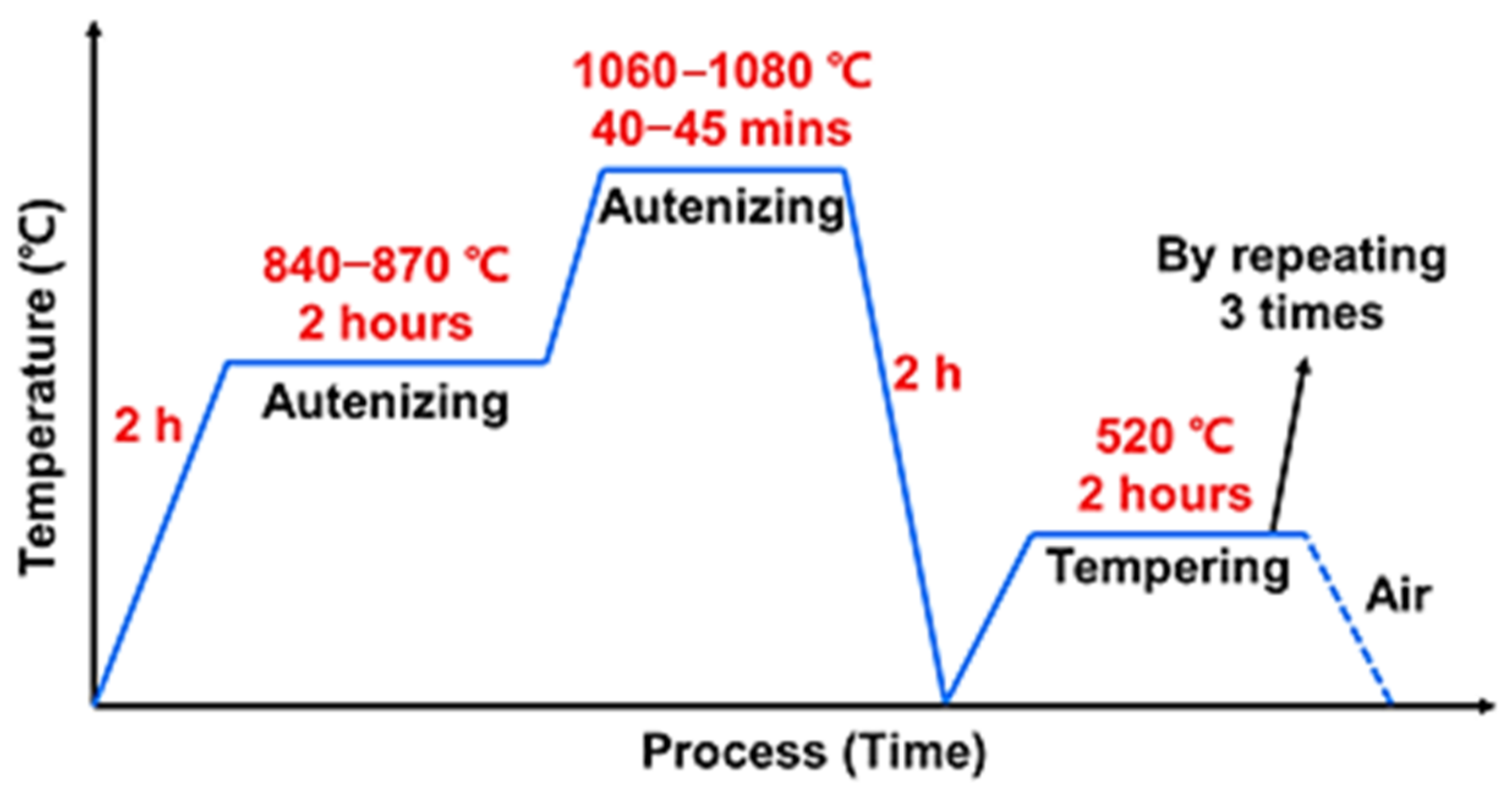

2. Materials and Methods

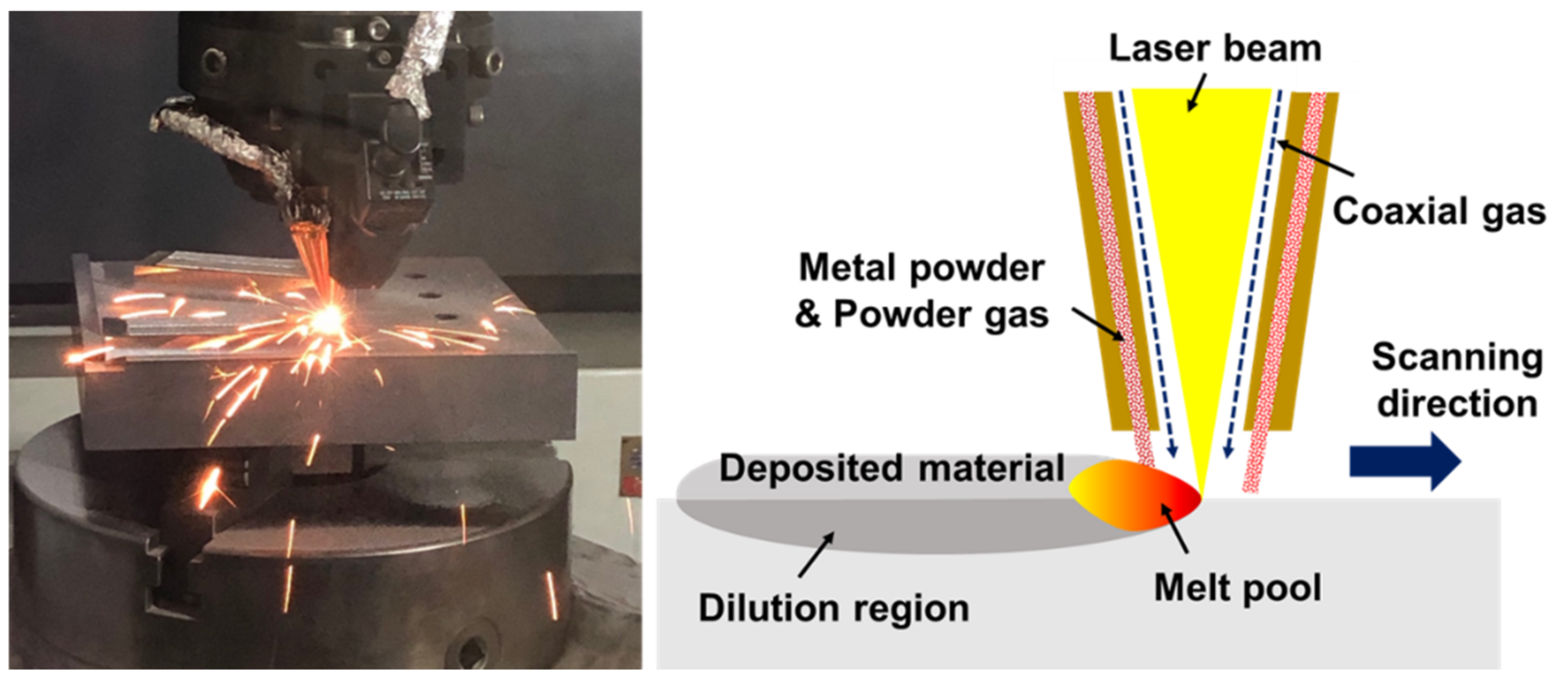

2.1. DED Process

2.2. Materials

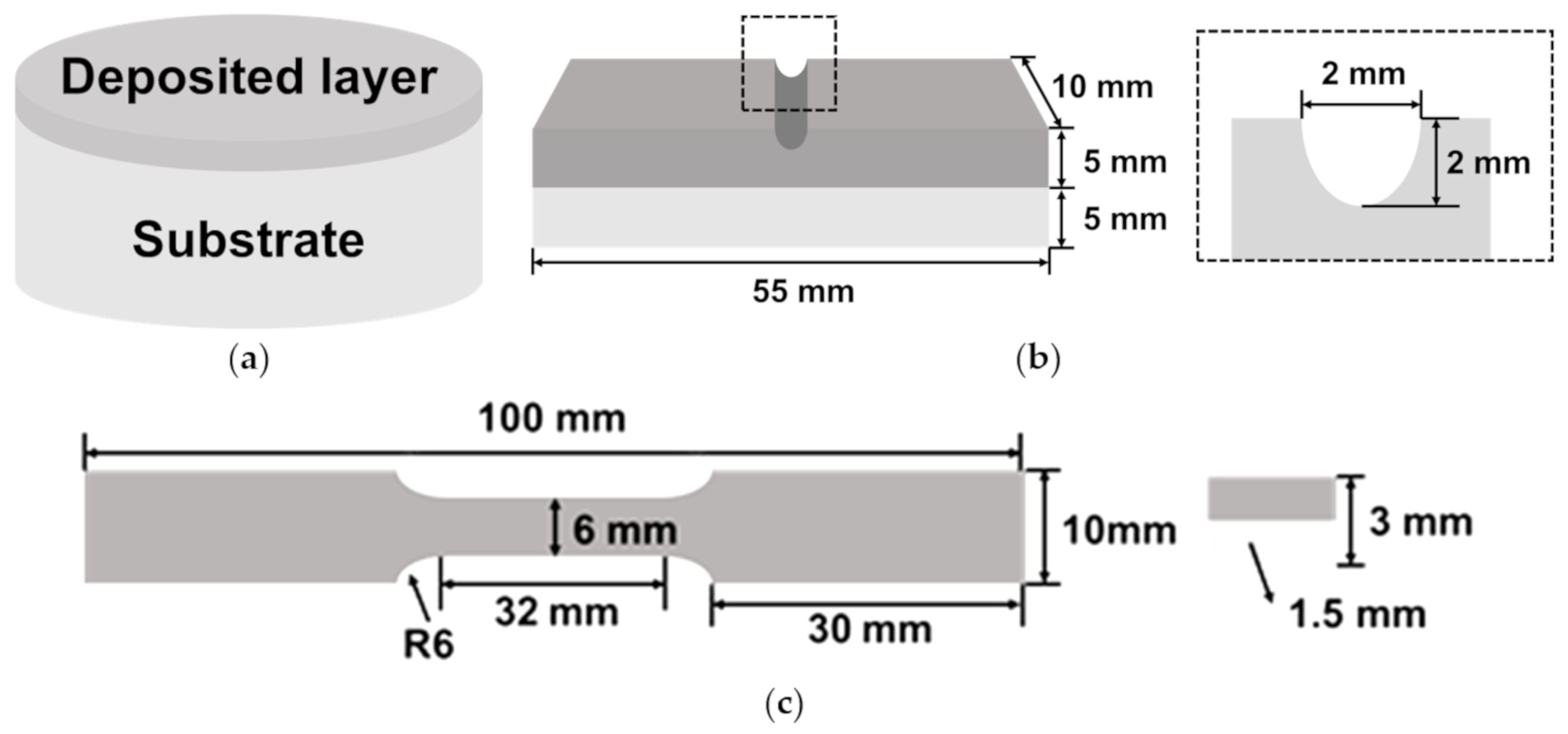

2.3. Specimen Preparation

2.4. Observation of Microstructures

2.5. Mechanical Testing

3. Results and Discussion

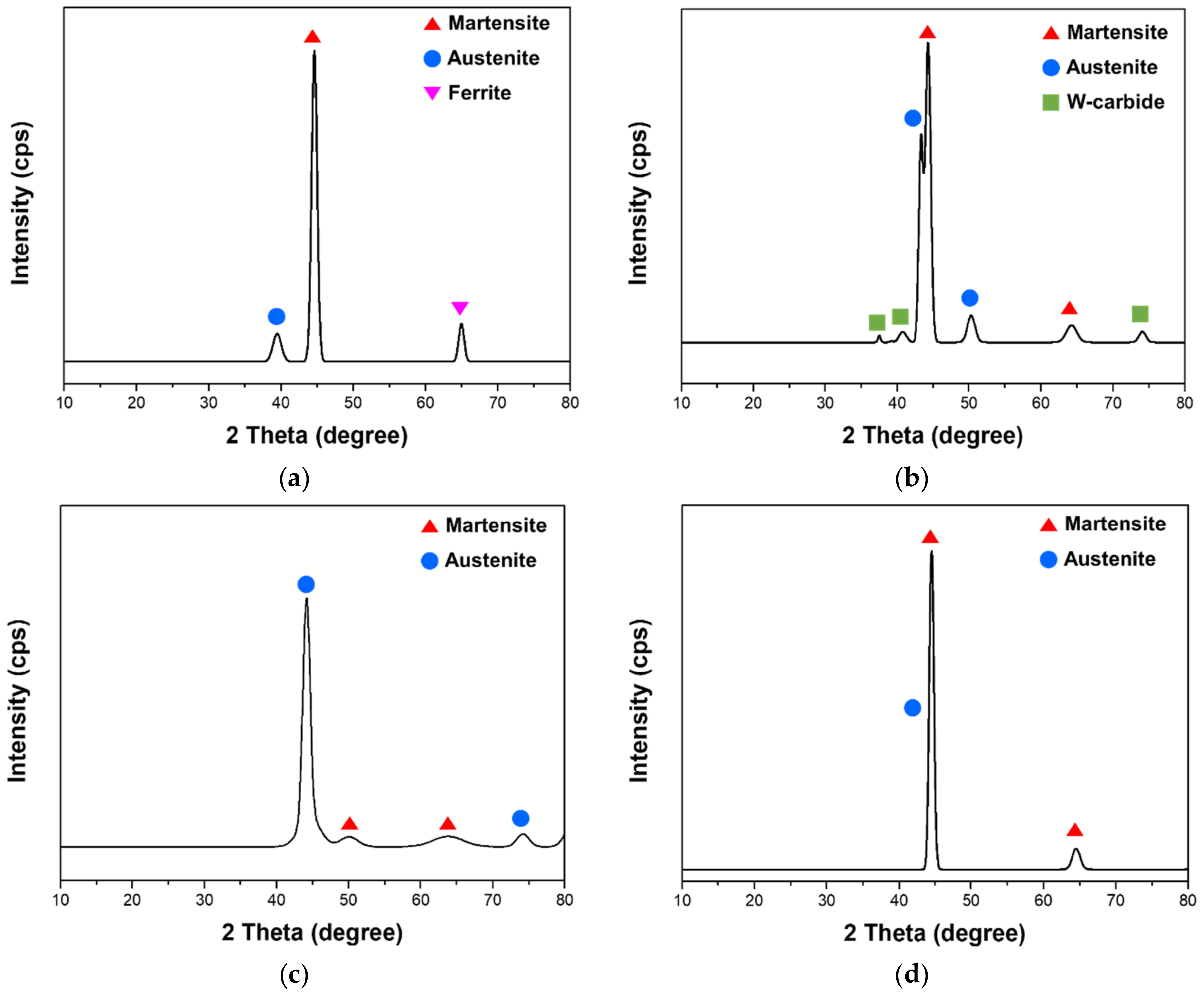

3.1. X-ray Diffraction

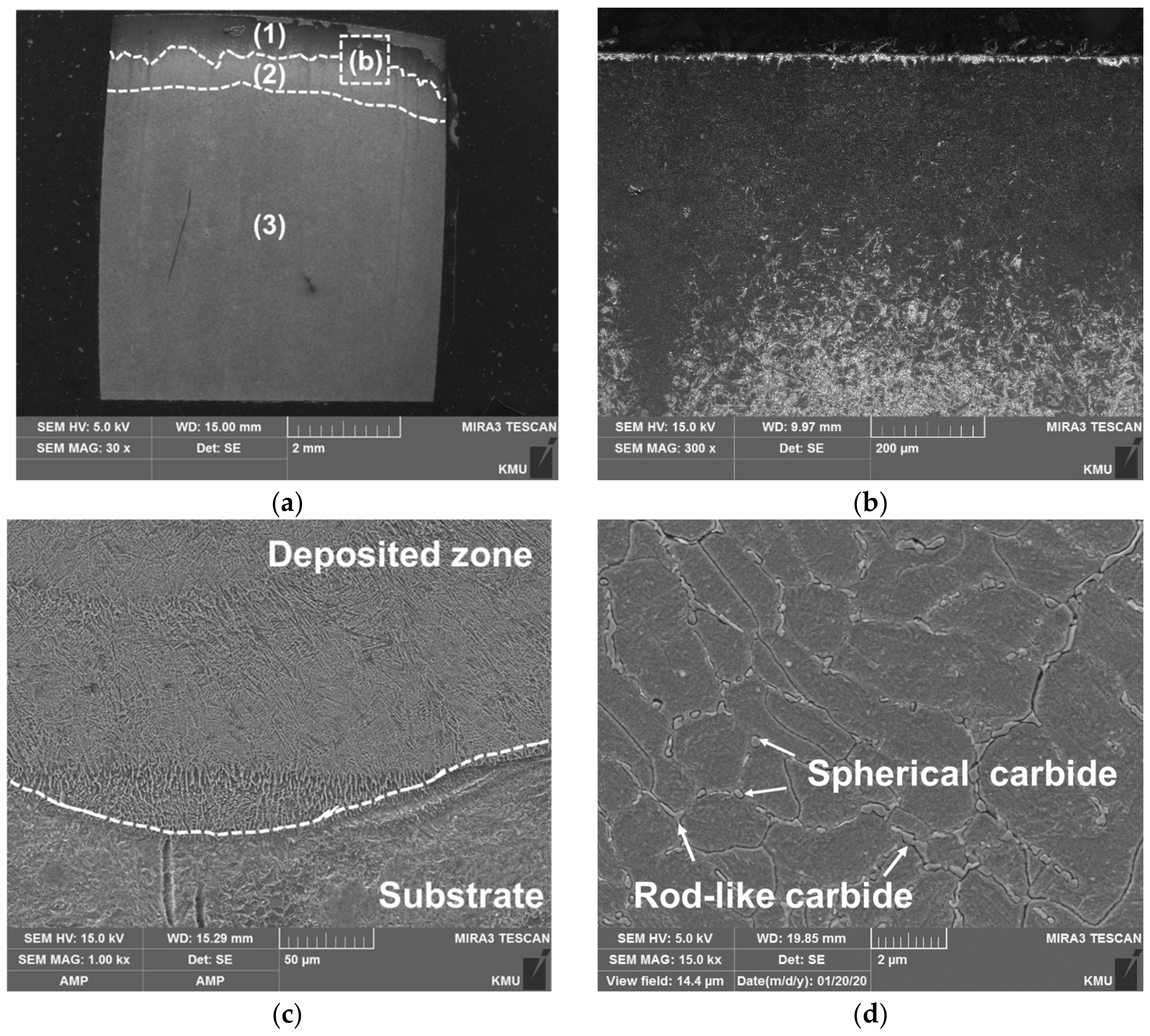

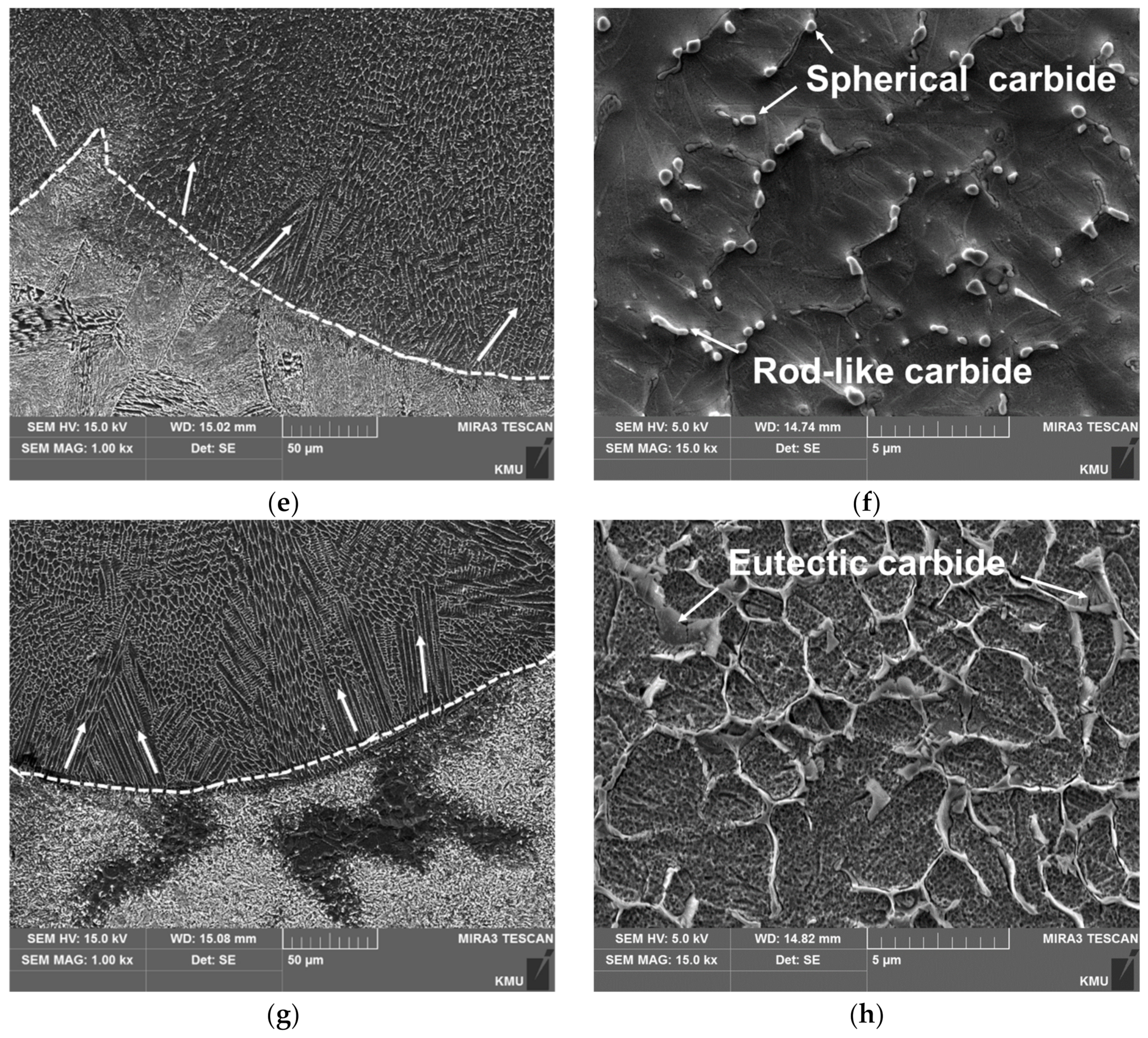

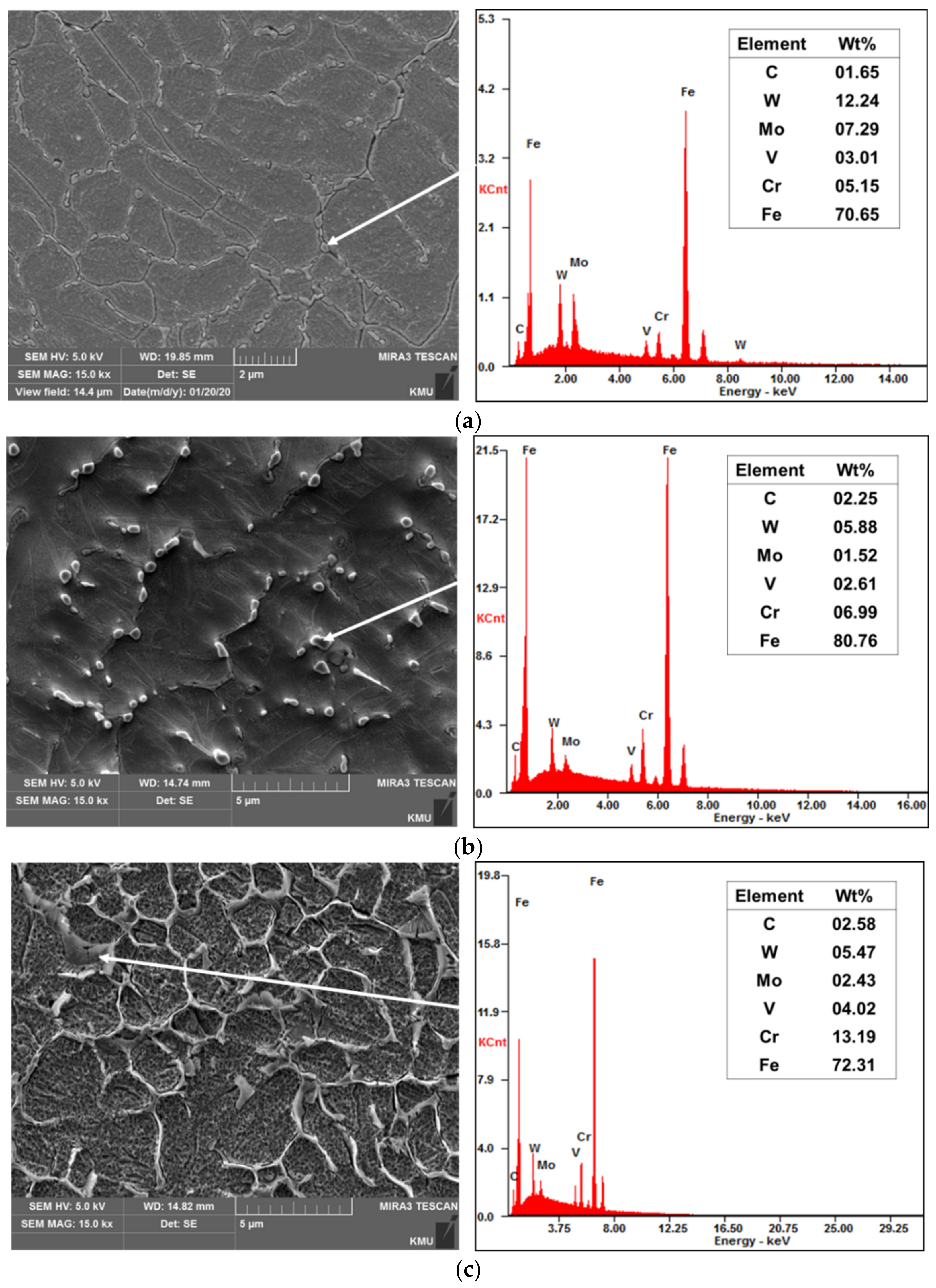

3.2. Microstructure

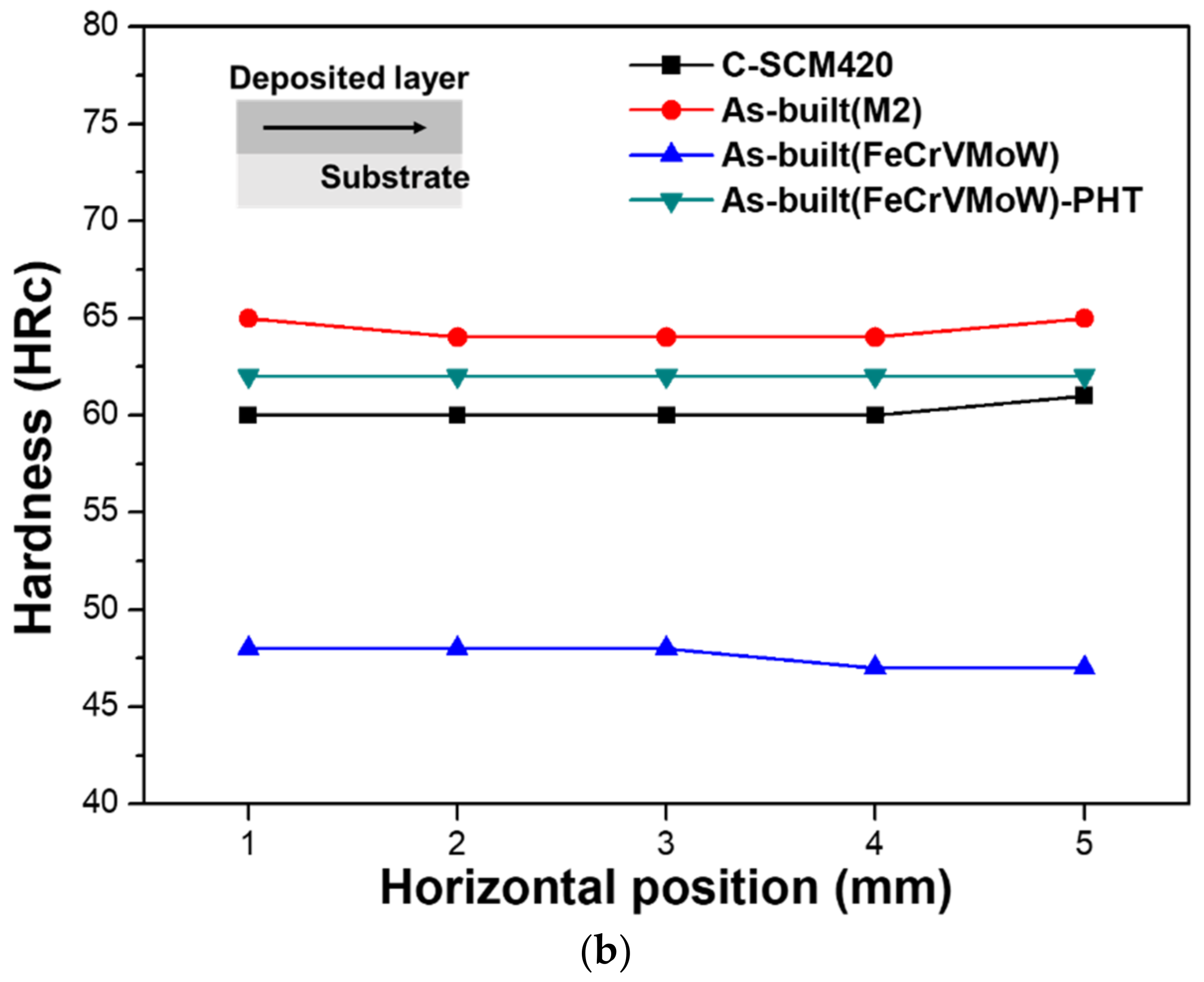

3.3. Microhardness

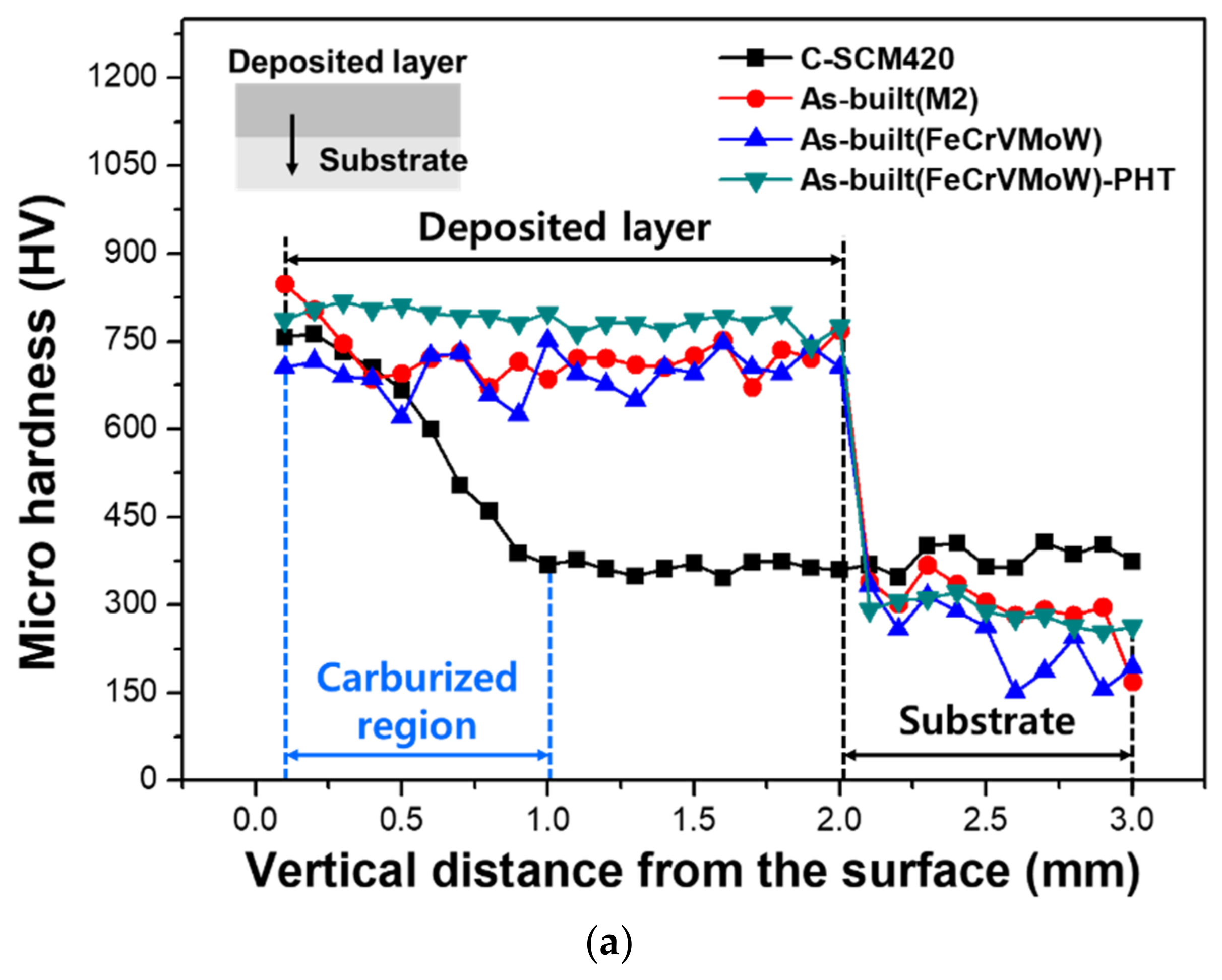

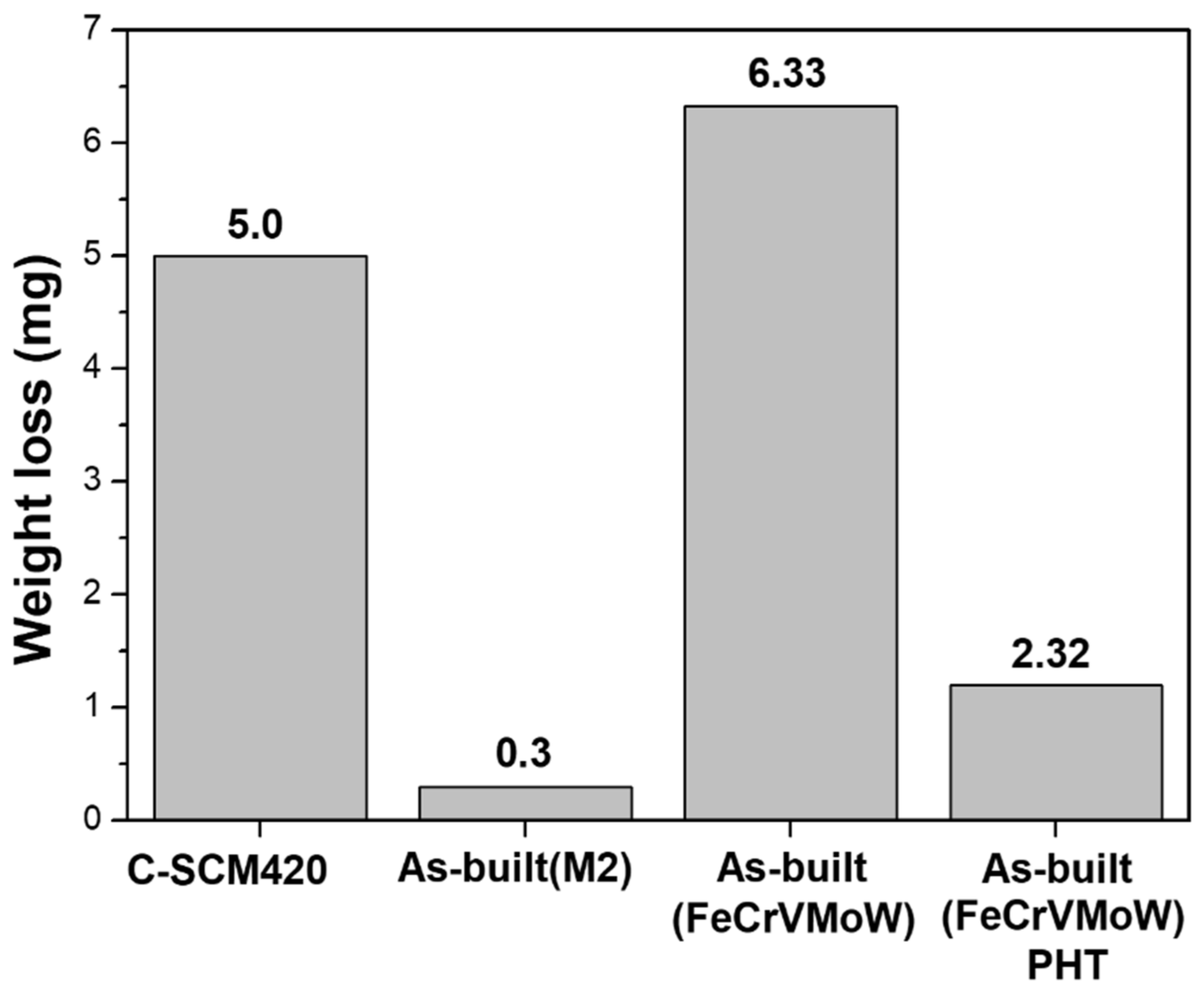

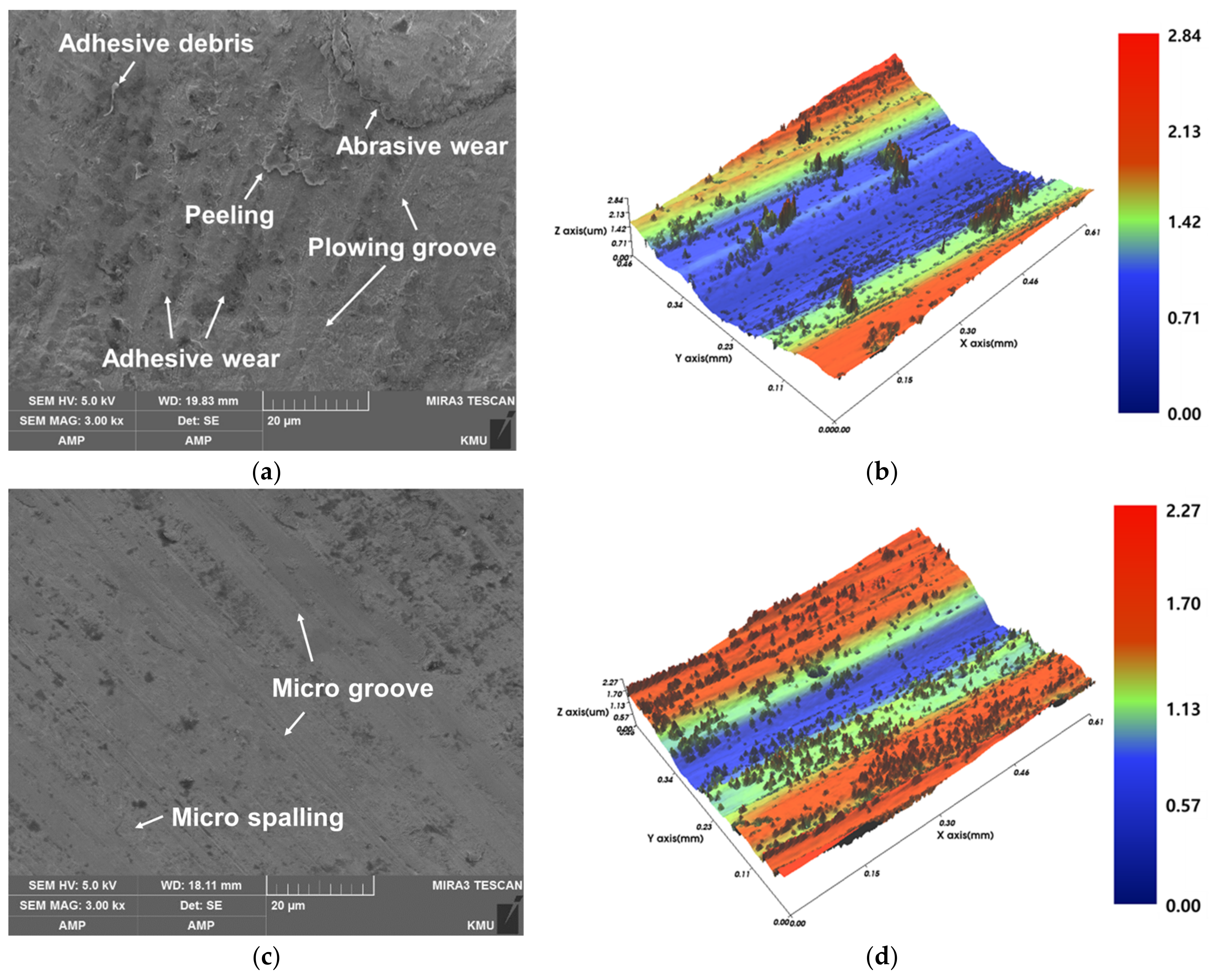

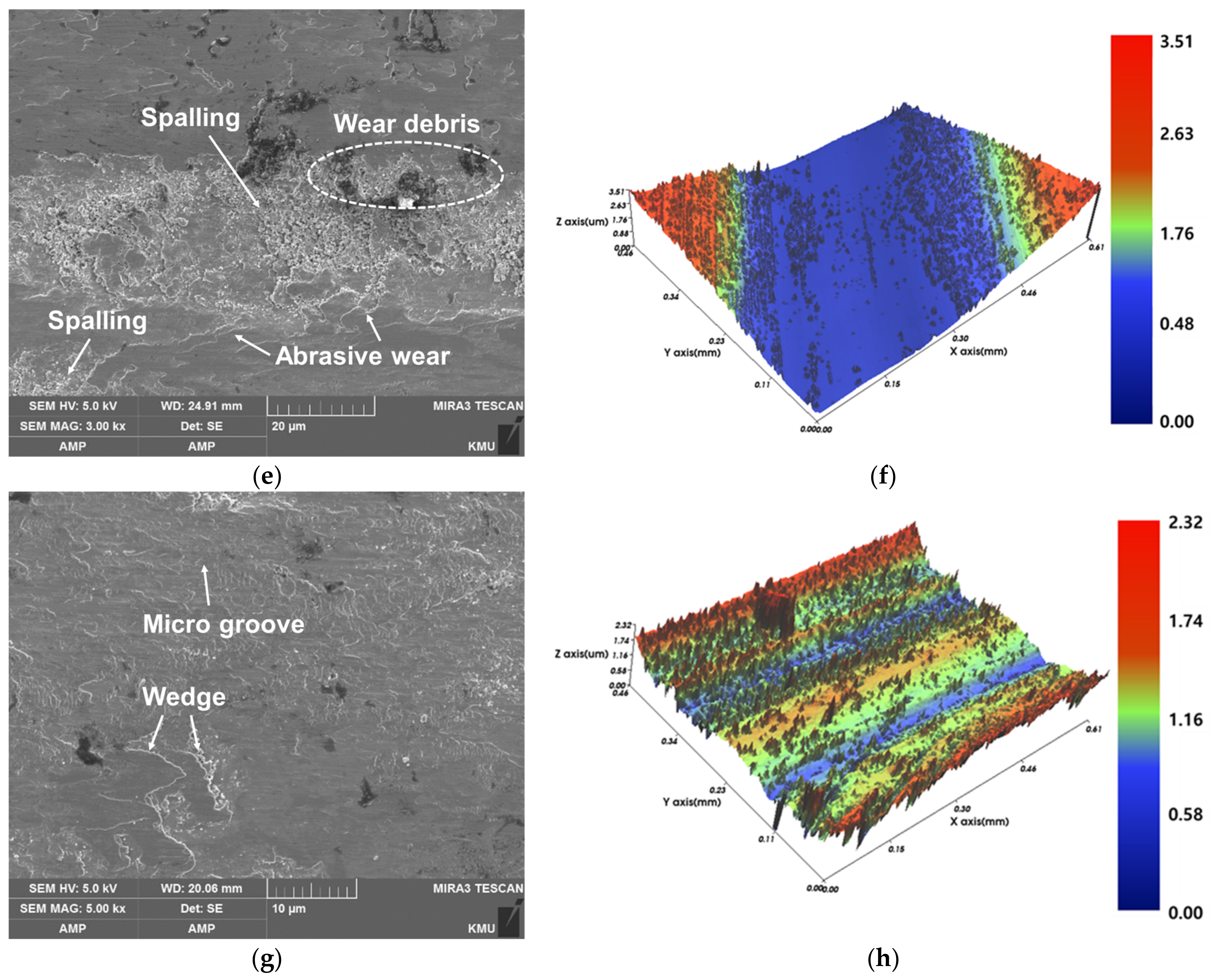

3.4. Wear Test

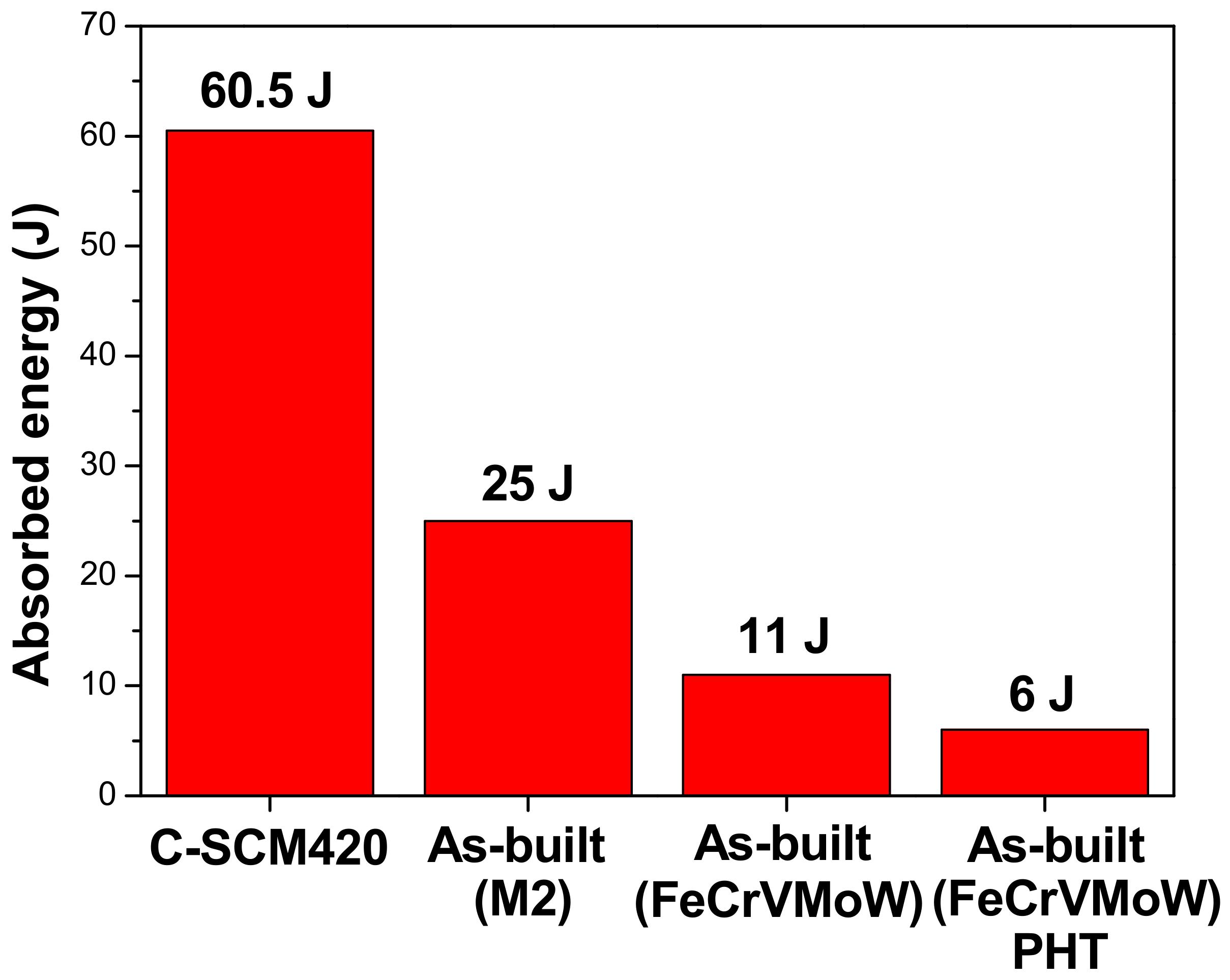

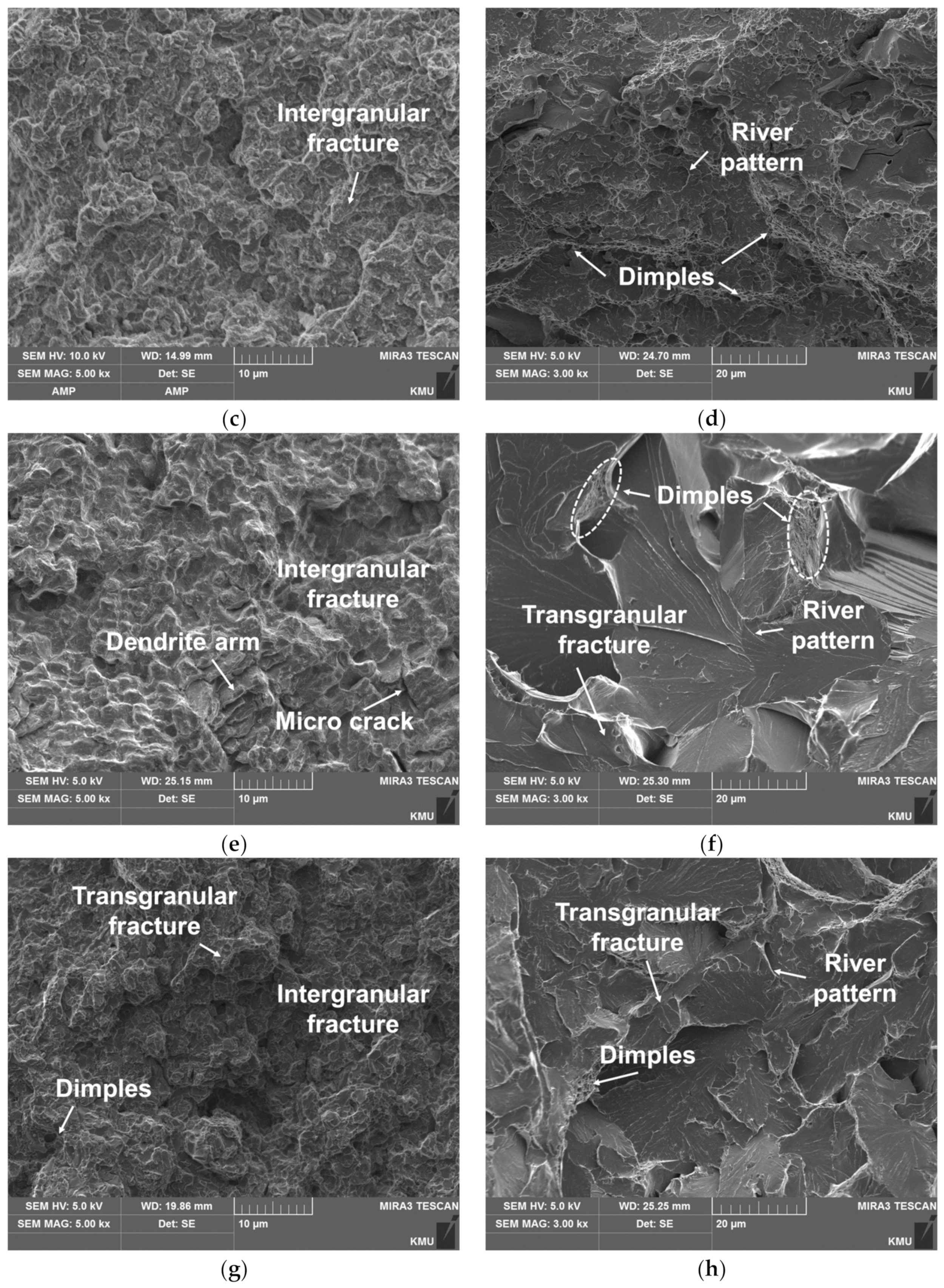

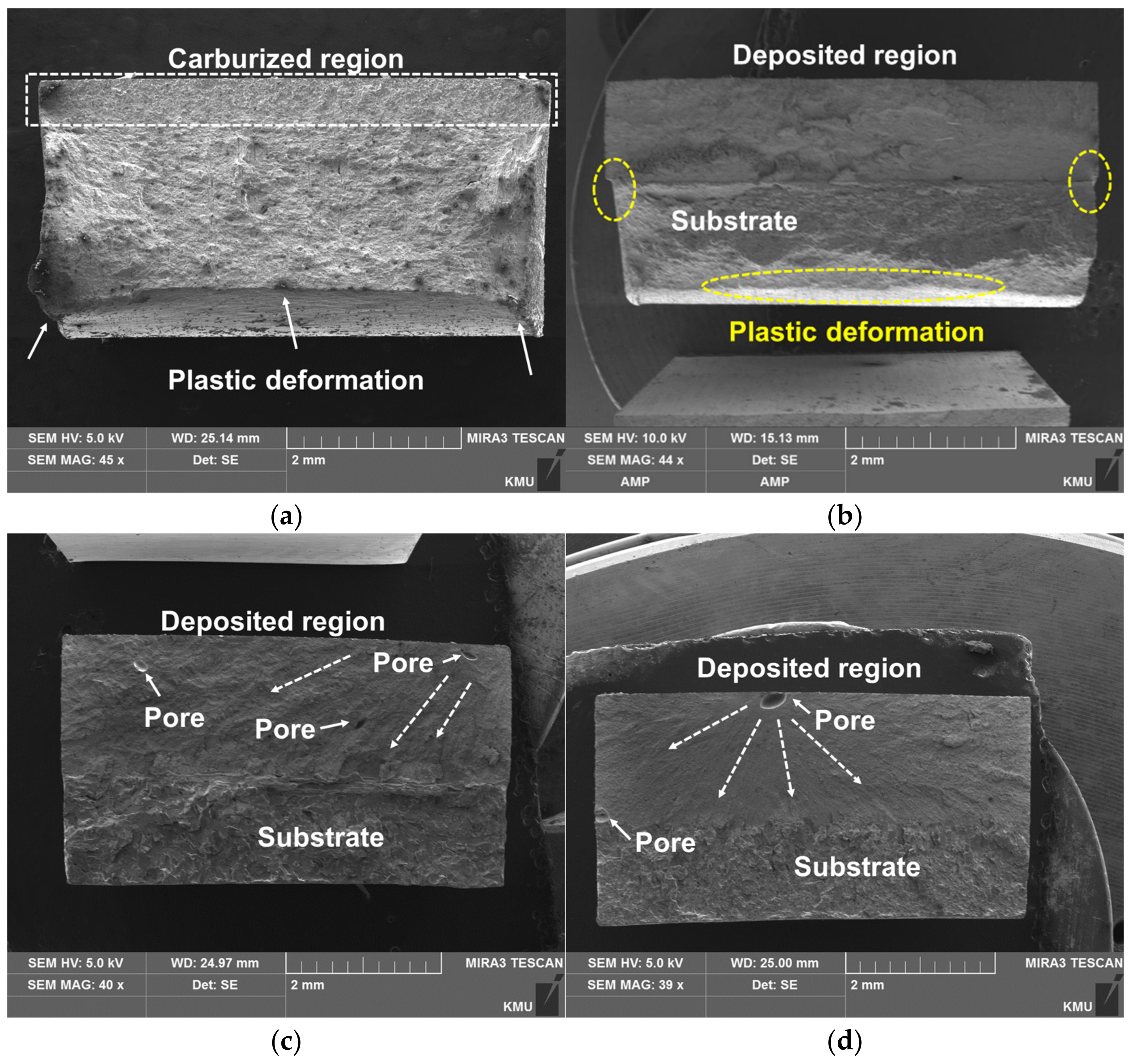

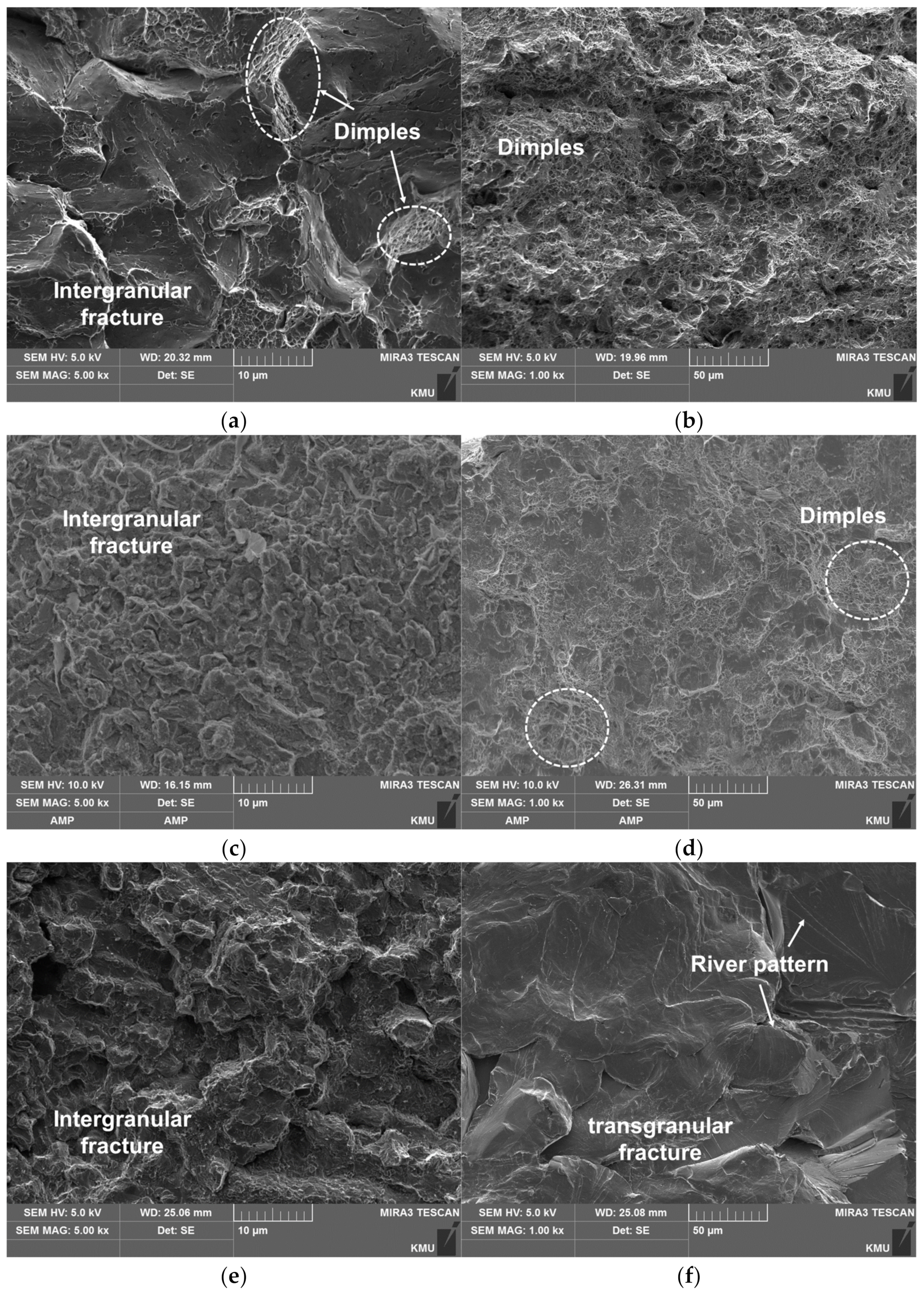

3.5. Impact Test

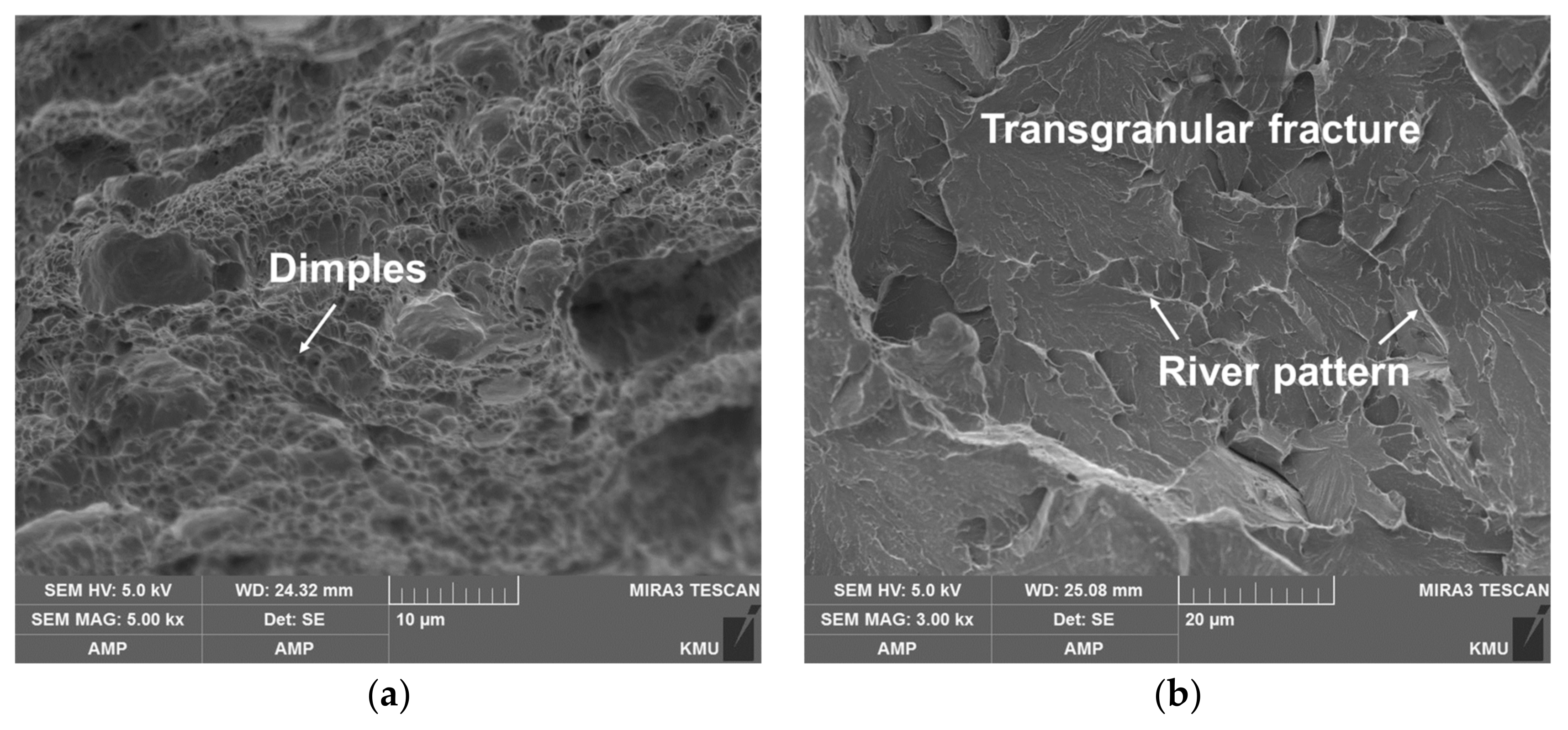

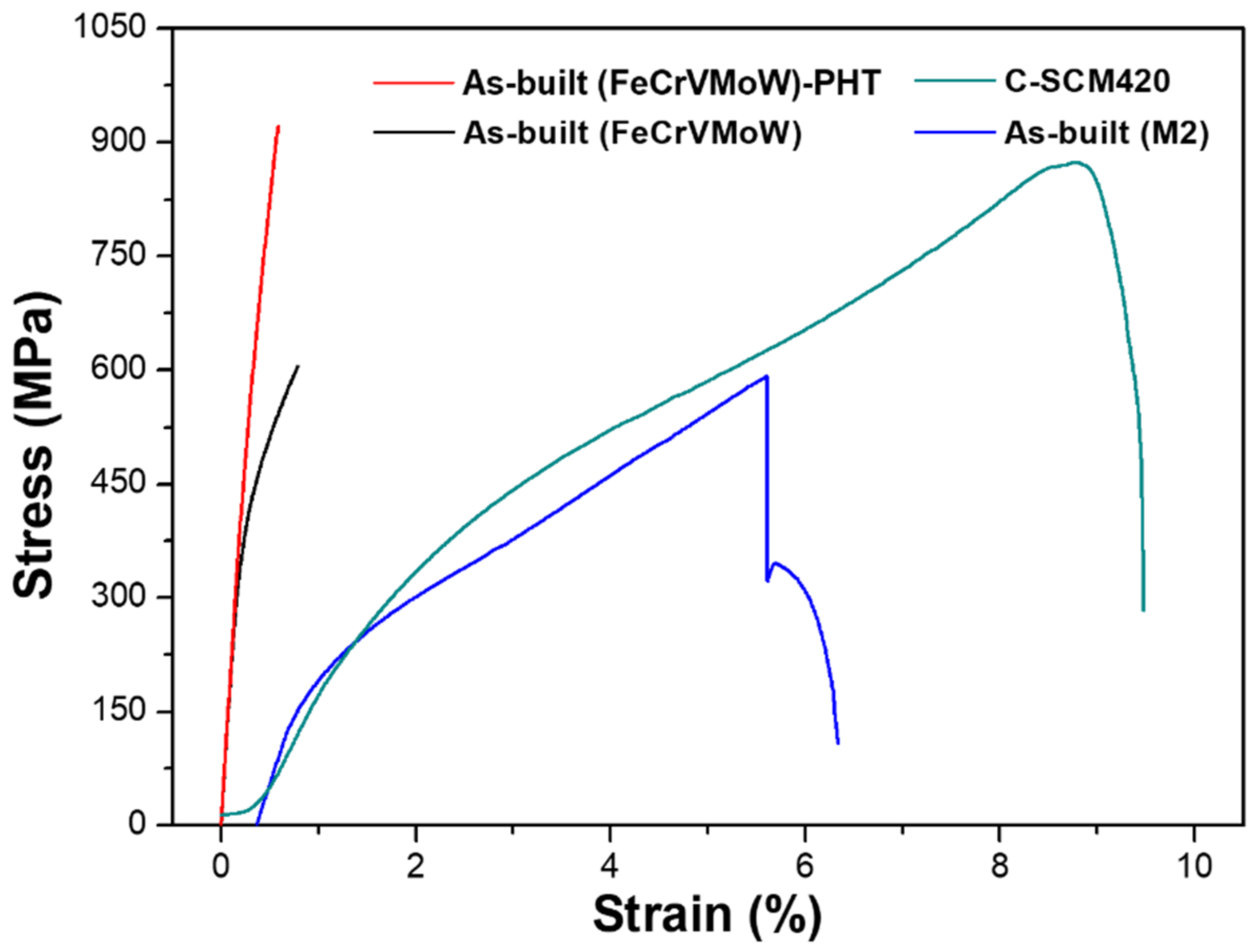

3.6. Tensile Test

4. Conclusions

- (1)

- The microstructure of the deposited Fe-8Cr-3V-2Mo-2W layer formed fine equiaxed grains because the melt pool was formed and cooled rapidly. During the heat treatment, a phase transformation occurred in the Fe-8Cr-3V-2Mo-2W layer, thereby decreasing the austenite fraction and increasing the martensite fraction.

- (2)

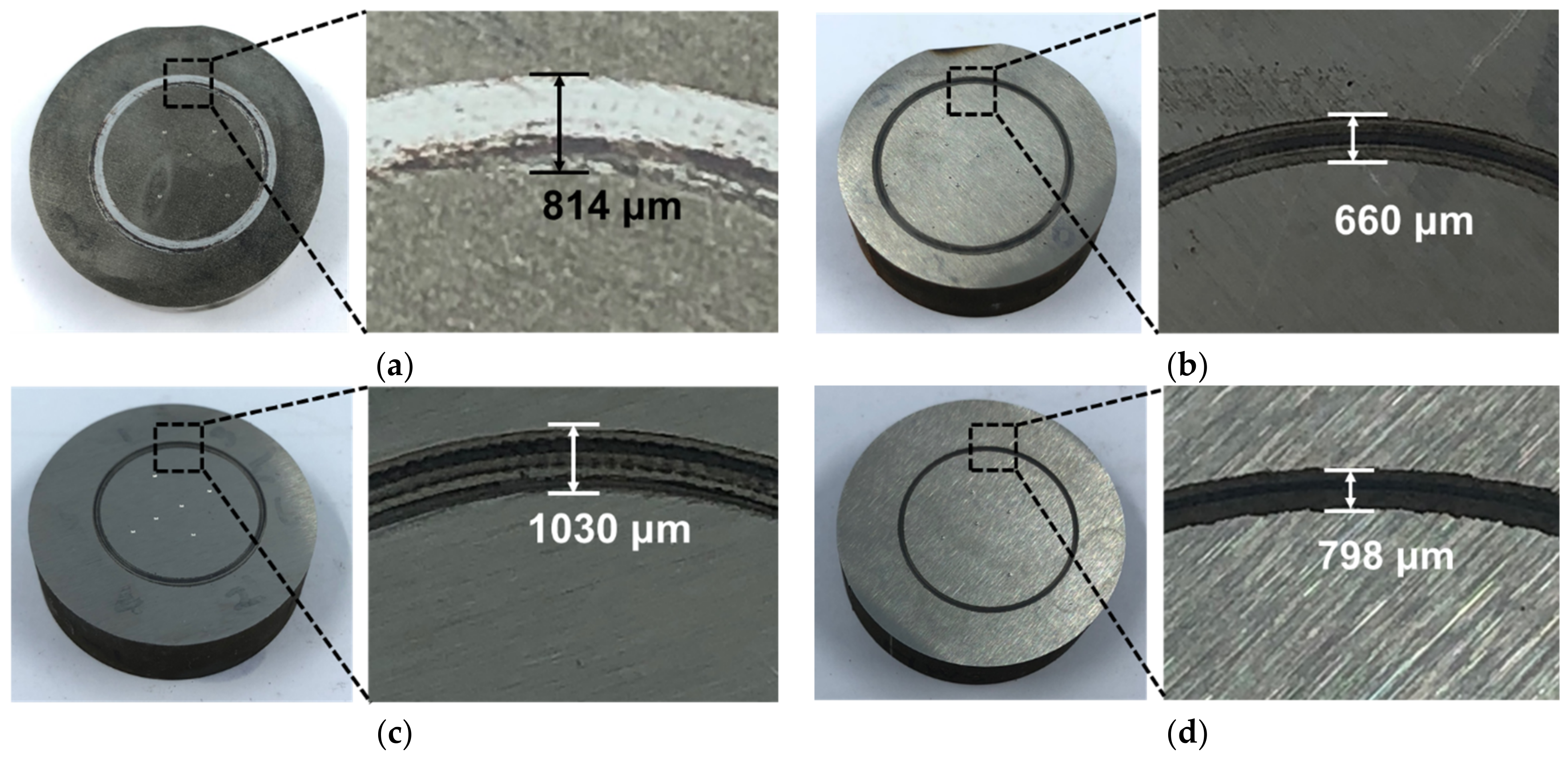

- The high hardness of the as-built (FeCrVMoW)-PHT also affected its wear resistance. The wear track of the as-built (FeCrVMoW)-PHT exhibited a lower value (798 μm) when compared to those of the as-built (FeCrVMoW) (1030 μm) and C-SCM420 (814 μm). This was due to the influence of the MC-type carbides present in the as-built (FeCrVMoW)-PHT and the generated carbides effectively protected the matrix.

- (3)

- The as-built (FeCrVMoW)-PHT exhibited a lower toughness value than the as-built (FeCrVMoW) because its brittleness increased due to the increased martensite after heat treatment. The as-built (FeCrVMoW) had a higher impact toughness because its small carbides made the crack propagation more complicated.

- (4)

- The tensile strength increased from 607 to 922 MPa after the post-deposition heat treatment. This is due to the finer grains as well as the decrease in the retained austenite and the increase in the martensite fraction described above.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, E.J.; Kim, K.S.; Kim, E.J.; Kim, J.Y. Influence of Carbide Formation on Tensile and Fatigue Properties of Carburized Steels. Appl. Microsc. 2013, 43, 81–87. [Google Scholar] [CrossRef][Green Version]

- Erdogan, M.; Tekeli, S. The effect of martensite volume fraction and particle size on the tensile properties of a surface-carburized AISI 8620 steel with a dual-phase core microstructure. Mater. Charact. 2002, 49, 445–454. [Google Scholar] [CrossRef]

- Vivek, C.M.; Vignesh Aravind, S.; Shriram, N.; Hari Vignesh, J. Investigating the mechanical and metallurgical properties of carburized 16MnCr5 steel. Int. J. Sci. Eng. Res. 2016, 7, 220–223. [Google Scholar]

- Fuller, A.J., Jr. Carburizing. In ASM Handbook Volume 18: Friction, Lubrication, and Wear Technology; George, E.T., Ed.; ASM International: Novelty, OH, USA, 1992; Volume 18, pp. 634–637. [Google Scholar]

- GEARSolutions. Available online: https://gearsolutions.com/departments/hot-seat-surface-engineering-of-steels-understanding-carburizing/ (accessed on 11 August 2017).

- Bonora, R.G.; Voorwald, H.J.C.; Cioffi, M.O.H.; Junior, G.S.; Santos, L.F.V. Fatigue in AISI 4340 steel thermal spray coating by HVOF for aeronautic application. Procedia Eng. 2010, 2, 1617–1623. [Google Scholar] [CrossRef]

- Ojo, O.A.; Chaturvedi, M.C. Liquation Microfissuring in the Weld Heat-Affected Zone of an Overaged Precipitation-Hardened Nickel-Base Superalloy. Metall. Mater. Trans. A 2007, 38A, 356–369. [Google Scholar] [CrossRef]

- Henderson, M.B.; Arrell, D.; Larsson, R.; Heobel, M.; Marchant, G. Nickel based superalloy welding practices for industrial gas turbine applications. Sci. Technol. Weld. Join. 2004, 9, 13–21. [Google Scholar] [CrossRef]

- Liu, D.; Lippold, J.C.; Li, J.; Rohklin, S.R.; Vollbrecht, J.; Grylls, R. Laser Engineered Net Shape (LENS) Technology for the Repair of Ni-Base Superalloy Turbine Components. Metall. Mater. Trans. A 2014, 45A, 4454–4469. [Google Scholar] [CrossRef]

- Pinkerton, A.J.; Wang, W.; Li, L. Component repair using laser direct metal deposition. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 827–836. [Google Scholar] [CrossRef]

- Nowotny, S.; Scharek, S.; Beyer, E.; Richter, K.H. Laser beam build-up welding: Precision in repair, surface cladding, and direct 3D metal deposition. J. Therm. Spray Technol. 2007, 16, 344–348. [Google Scholar] [CrossRef]

- Roy, T.; Abrahams, R.; Paradowska, A.; Lai, Q.; Mutton, P.; Soodi, M.; Fasihi, P.; Yan, W. Evaluation of the mechanical properties of laser cladded hypereutectoid steel rails. Wear 2019, 432–433, 202930. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding, 1st ed.; CRC Press: Boca Raton, FL, USA, 2004; pp. 8–12. [Google Scholar]

- Baufeld, B.; Brandl, E.; Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Sun, S.D.; Liu, Q.; Brandt, M.; Luzin, V.; Cottam, R.; Janardhana, M.; Clark, G. Effect of laser clad repair on the fatigue behaviour of ultra-high strength AISI 4340 steel. Mater. Sci. Eng. A 2014, 606, 46–57. [Google Scholar] [CrossRef]

- Mazumder, J.; Dutta, D.; Kikuchi, N.; Ghosh, A. Closed loop direct metal deposition: Art to part. Opt. Lasers Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Kim, W.H.; Jung, B.H.; Park, I.D.; Oh, M.H.; Choi, S.W.; Kang, D.M. Surface Hardness as a Function of Laser Metal Deposition Parameters. Trans. Mater. Process. 2015, 24, 272–279. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, I.K.; Jeong, M.S.; Lee, J.W.; Lee, S.B.; Lee, S.K. Evaluation of Wear Characteristics of AISI H13 Tool Steel Repaired by Metal 3D Printing. J. Korean Soc. Manuf. Process Eng. 2017, 16, 9–15. [Google Scholar] [CrossRef]

- Hu, Y.P.; Chen, C.W.; Mukherjee, K. Development of a new laser cladding process for manufacturing cutting and stamping dies. J. Mater. Sci. 1998, 33, 1287–1292. [Google Scholar] [CrossRef]

- Wang, S.H.; Chen, J.Y.; Xue, L. A study of the abrasive wear behaviour of laser-clad tool steel coatings. Surf. Coat. Technol. 2006, 200, 3446–3458. [Google Scholar] [CrossRef]

- Leunda, J.; Soriano, C.; Sanz, C.; Navas, V.G. Laser cladding of vanadium-carbide tool steels for die repair. Phys. Procedia 2011, 12, 345–352. [Google Scholar] [CrossRef]

- Chen, J.Y.; Wang, S.H.; Xue, L. On the development of microstructures and residual stresses during laser cladding and post-heat treatments. J. Mater. Sci. 2012, 47, 779–791. [Google Scholar] [CrossRef]

- Junker, D.; Hentschel, O.; Schmidt, M.; Merklein, M. Investigation of Heat Treatment Strategies for Additively-Manufactured Tools of X37CrMoV5-1. Metals 2018, 8, 854. [Google Scholar] [CrossRef]

- Pleterski, M.; Muhic, T.; Podgornik, B.; Tušek, J. Blanking punch life improvement by laser cladding. Eng. Fail. Anal. 2011, 18, 1527–1537. [Google Scholar] [CrossRef]

- Kattire, P.; Paul, S.; Singh, R.; Yan, W. Experimental characterization of laser cladding of CPM 9V on H13 tool steel for die repair applications. J. Manuf. Process. 2015, 20, 492–499. [Google Scholar] [CrossRef]

- Fukaura, K.; Yokoyama, Y.; Yokoi, D.; Tsujii, N.; Ono, K. Fatigue of cold-work tool steels: Effect of heat treatment and carbide morphology on fatigue crack formation, life, and fracture surface observations. Metall. Mater. Trans. A 2004, 35A, 1289–1300. [Google Scholar] [CrossRef]

- Liu, S.; Farahmand, P.; Kovacevic, R. Optical monitoring of high power direct diode laser cladding. Opt. Laser Technol. 2014, 64, 363–376. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Long, R. Effects of substrate preheating on the thin-wall part built by laser metal deposition shaping. Appl. Surf. Sci. 2014, 317, 839–855. [Google Scholar] [CrossRef]

- Shim, D.S.; Baek, G.Y.; Lee, S.B.; Yu, J.H.; Choi, Y.S.; Park, S.H. Influence of heat treatment on wear behavior and impact toughness of AISI M4 coated by laser melting deposition. Surf. Coat. Technol. 2017, 328, 219–230. [Google Scholar] [CrossRef]

- Zeisig, J.; Schädlich, N.; Giebeler, L.; Sander, J.; Eckert, J.; Kühn, U.; Hufenbach, J. Microstructure and abrasive wear behavior of a novel FeCrMoVC laser cladding alloy for high-performance tool steels. Wear 2017, 382–383, 107–112. [Google Scholar] [CrossRef]

- Chen, J.; Xue, L. Laser Cladding of CPM Tool Steels on Hardened H13 Hot-Work Steel for Low-Cost High-Performance Automotive Tooling. J. Miner. Met. Mater. Soc. 2012, 64, 688–693. [Google Scholar] [CrossRef]

- Navas, C.; Conde, A.; Fernández, B.J.; Zubiri, F.; de Damborenea, J. Laser coatings to improve wear resistance of mould steel. Surf. Coat. Technol. 2005, 194, 136–142. [Google Scholar] [CrossRef]

- Chen, J.Y.; Conlon, K.; Xue, L.; Rogge, R. Experimental study of residual stresses in laser clad AISI P20 tool steel on pre-hardened wrought P20 substrate. Mater. Sci. Eng. A 2010, 527, 7265–7273. [Google Scholar] [CrossRef]

- Gururaj, T.; Jyotsna, D.M.; Nitin, W.; Padmanabham, G.; Indranil, M. Microstructure and Mechanical Properties of Laser Clad and Post-cladding Tempered AISI H13 Tool Steel. Mater. Trans. A 2015, 46, 2309–2321. [Google Scholar] [CrossRef]

- Choi, B.Y.; Gub, Y.S. Characteristics of Carburized Surface Layers in 0.18C-3.5Ni-1.5Cr-0.2Mo Steels for Main Shaft Bearings of Wind Turbines. J. Korean Inst. Surf. Eng. 2012, 45, 226–231. [Google Scholar] [CrossRef]

- Kąc, S.; Kusiński, J. SEM and TEM microstructural investigation of high-speed tool steel after laser melting. Mater. Chem. Phys. 2003, 81, 510–512. [Google Scholar] [CrossRef]

- Grosch, J. Microstructure and Properties of Gas Carburized Steels. In Comprehensive Materials Processing, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 379–411. [Google Scholar]

- Kim, W.H.; Song, M.H.; Park, I.D.; Kang, D.M. The Characteristics Analysis of Track of Laser Metal Deposition Using AISI M2 Powder. Trans. Korean Soc. Automot. Eng. 2016, 24, 463–470. [Google Scholar] [CrossRef][Green Version]

- Leunda, J.; García Navas, J.; Soriano, C.; Sanz, C. Improvement of Laser Deposited High Alloyed Powder Metallurgical Tool Steel by a Post-tempering Treatment. Phys. Procedia 2012, 39, 392–400. [Google Scholar] [CrossRef]

- Guitar, M.A.; Suárez, S.; Prat, O.; Guigou, M.D.; Gari, V.; Pereira, G.; Mucklich, F. High Chromium Cast Irons: Destabilized-Subcritical Secondary Carbide Precipitation and Its Effect on Hardness and Wear Properties. J. Mater. Eng. Perform. 2018, 27, 3877–3885. [Google Scholar] [CrossRef]

- Carpenter, S.D.; Carpenter, D. X-ray diffraction study of M7C3 carbide within a high chromium white iron. Mater. Lett. 2003, 57, 4456–4459. [Google Scholar] [CrossRef]

- Choi, S.W.; Lee, K.H.; Suh, J.; Oh, M.H.; Kang, J.Y. Effects of Powder Feeding Rate on the Crack Formation in Laser-Surface Alloying-Hardened SKD61 Hot Die Steel using SKH51 Powder. Korean J. Met. Mater. 2016, 54, 194–203. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wang, S.W.; Chen, T.M. A study on the wear behavior of hardened medium carbon steel. J. Mater. Process. Technol. 2002, 120, 126–132. [Google Scholar] [CrossRef]

| Laser Power (W) | Scanning Speed (mm/min) | Powder Feed Rate (g/min) | Coaxial Gas (L/min) | Shielding Gas (L/min) |

|---|---|---|---|---|

| 800 | 850 | 5 | 8.0 | 2.5 |

| C | Si | Mn | Mo | Cr | V | W | P | S | Ni | Cu | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Fe-8Cr-3V-2Mo-2W (Powder) | 1.08 | 1.38 | 0.34 | 1.86 | 7.80 | 2.66 | 1.73 | - | - | - | - |

| AISI M2 (Powder) | 0.803 | 0.16 | 0.29 | 4.84 | 3.98 | 0.90 | 5.84 | 0.018 | 0.013 | 0.07 | - |

| SCM420 (Substrate) | 0.19 | 0.23 | 0.80 | 0.17 | 1.00 | - | - | - | - | 0.02 | 0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, Y.E.; Lee, J.Y.; Lee, E.K.; Shim, D.S. Microstructures and Mechanical Properties of Deposited Fe-8Cr-3V-2Mo-2W on SCM420 Substrate Using Directed Energy Deposition and Effect of Post-Heat Treatment. Materials 2021, 14, 1231. https://doi.org/10.3390/ma14051231

Jeong YE, Lee JY, Lee EK, Shim DS. Microstructures and Mechanical Properties of Deposited Fe-8Cr-3V-2Mo-2W on SCM420 Substrate Using Directed Energy Deposition and Effect of Post-Heat Treatment. Materials. 2021; 14(5):1231. https://doi.org/10.3390/ma14051231

Chicago/Turabian StyleJeong, Ye Eun, Jun Yeop Lee, Eun Kyung Lee, and Do Sik Shim. 2021. "Microstructures and Mechanical Properties of Deposited Fe-8Cr-3V-2Mo-2W on SCM420 Substrate Using Directed Energy Deposition and Effect of Post-Heat Treatment" Materials 14, no. 5: 1231. https://doi.org/10.3390/ma14051231

APA StyleJeong, Y. E., Lee, J. Y., Lee, E. K., & Shim, D. S. (2021). Microstructures and Mechanical Properties of Deposited Fe-8Cr-3V-2Mo-2W on SCM420 Substrate Using Directed Energy Deposition and Effect of Post-Heat Treatment. Materials, 14(5), 1231. https://doi.org/10.3390/ma14051231