Designing a Sustainable Supply Chain Network for Perishable Products Integrating Internet of Things and Mixed Fleets

Abstract

1. Introduction

2. Literature Review

2.1. Sustainable SCND for Perishable Products

2.2. SCND Integrating IoT

2.3. SCND Integrating Mixed Fleets

2.4. Research Gap

- To the best of our knowledge, this is the first mathematical model that integrates IoT technology and mixed fleets within a sustainable SCND framework specifically for perishable products.

- This is also the first time we have incorporated service levels—related to both quality and timely delivery—as an aspect of social sustainability within multi-objective location-inventory-routing models for sustainable SCND of perishable products. The model effectively balances three key dimensions of sustainability: economic performance, environmental impact, and service level.

- We analyze the effects of allocating service level weight coefficients on both total cost and service level in SCND. Our findings suggest that by strategically adjusting the emphasis on quality and delivery, the supply chain can achieve a competitive advantage in terms of both cost-effectiveness and service level.

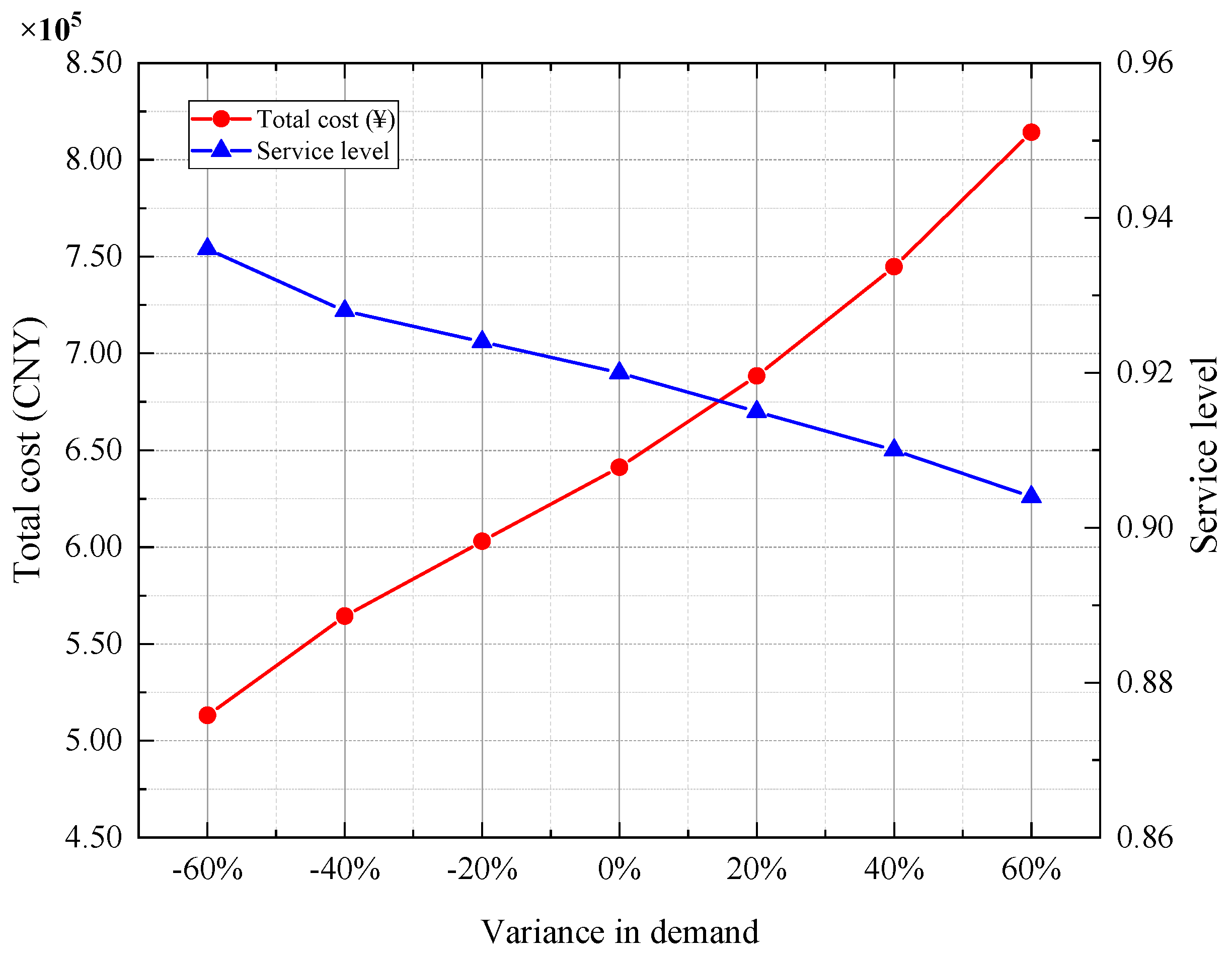

- Additionally, we discover that by moderately extending the shelf life of perishable products, total costs can be reduced while simultaneously improving service levels. However, if the extension exceeds a certain threshold, the effectiveness of this strategy significantly diminishes.

3. Problem Description and Mathematical Model

3.1. Problem Description

3.2. Problem Assumptions

- Candidate DCs are pre-determined and have finite inventory capacity constraints.

- During each planning period, a DC can source products from multiple manufacturers, while each customer is served by only one DC to meet their demand.

- Product quality deteriorates linearly over time, with a degradation rate of one unit per period, reflecting the perishable nature of the goods.

- All vehicles must depart from and return to their assigned DCs within specified time windows.

- Each customer may only be visited once per period.

- IoT technologies vary in complexity. Basic IoT solutions are low-cost and have limited functionality (e.g., temperature monitoring only), while advanced IoT solutions are more expensive and offer enhanced capabilities (e.g., real-time humidity control, geolocation tracking, and dynamic routing). This results in multiple types of IoT servers, each differing in deployment cost and energy consumption.

3.3. Notatio

3.4. Mathematical Model

4. Non-Dominated Sorting Genetic Algorithm II (NSGA-II)

5. Case Study

5.1. Case Description

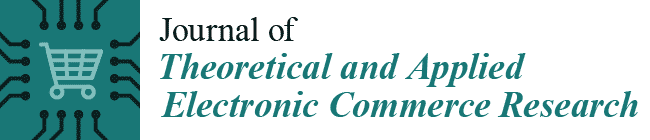

5.2. Pareto-Optimal Solutions Analysis

6. Sensitivity Analysis

6.1. The Effects of the Service Level Weight Allocation (: Product Quality vs. : On-Time Delivery)

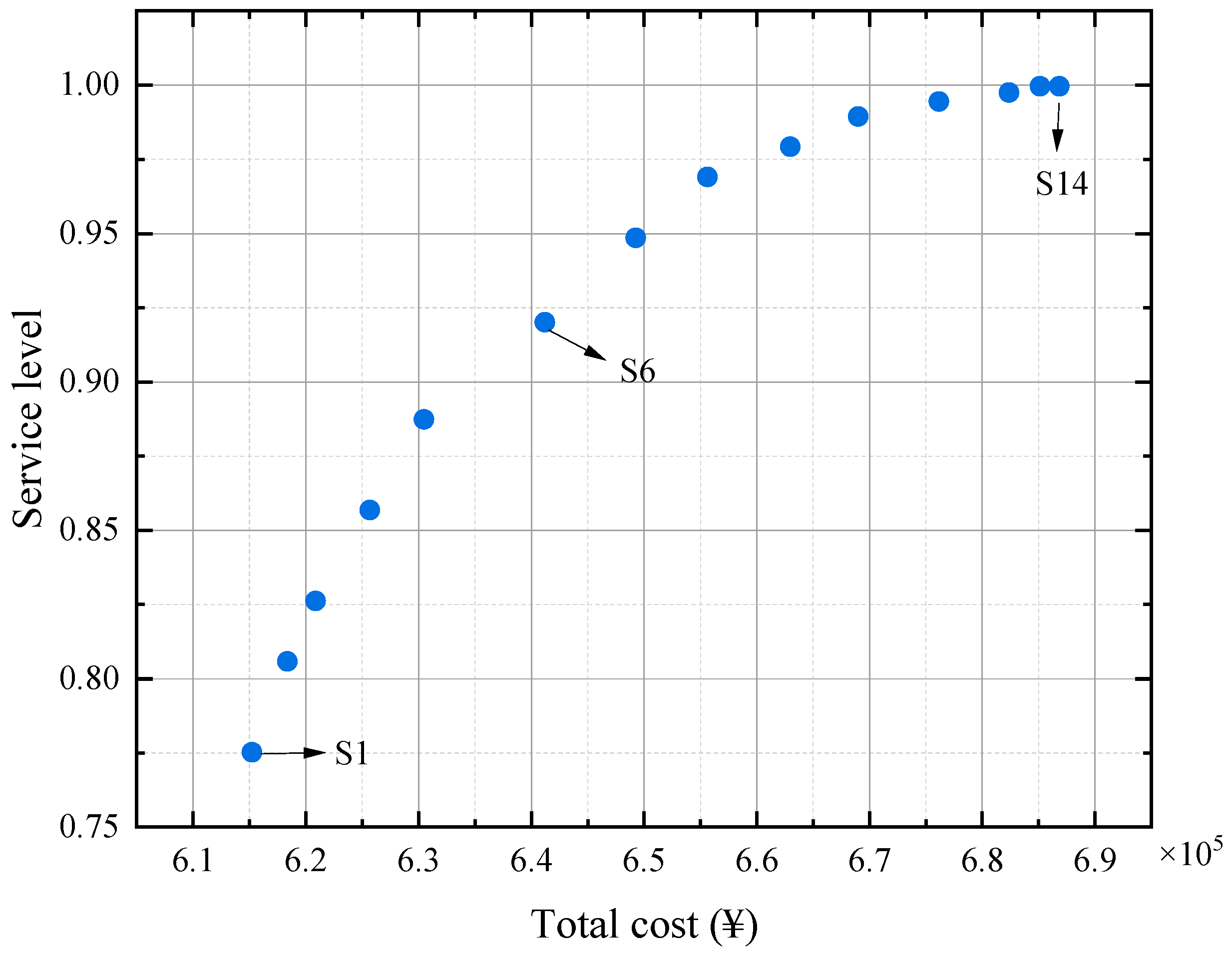

6.2. The Effects of the Demand Variation

6.3. The Effects of the Product Shelf Lives Variation

7. Conclusions and Future Research Directions

7.1. Theoretical Implications

7.2. Managerial Implications

- Managers can achieve a balance between economic efficiency and sustainability by carefully evaluating the trade-offs between minimizing costs and maximizing service levels. This approach ensures optimal operational performance while also meeting sustainability goals. The integration of IoT technologies for real-time monitoring, along with the use of mixed fleets of EVs and CVs, enhances operational efficiency, reduces waste, and lowers carbon emissions. This not only supports business goals but also aligns with broader sustainability efforts.

- Managers should prioritize costs and service levels while maintaining a reasonable quality balance. Placing too much emphasis on quality beyond a certain point can lead to diminishing returns, higher costs, and decreased service efficiency. By thoughtfully adjusting their focus on quality and delivery, managers can enhance operational performance and resource utilization. This approach ensures that the supply chain maintains a competitive edge in both cost-effectiveness and service level.

- To achieve supply chain resilience in the face of fluctuations, businesses can effectively manage cost variability while sustaining high service levels during periods of demand volatility. When confronted with significant changes in demand, managers can maintain operational stability by dynamically rerouting and optimizing inventories.

- Extending shelf life can significantly lower costs and enhance service levels. However, after a certain point, the benefits begin to level off, suggesting diminishing returns. Managers should aim to optimize shelf life to find a balance between cost efficiency and service quality. Furthermore, understanding the trade-offs between short and long shelf lives can help in developing more targeted logistics strategies, ultimately improving cost control and operational efficiency.

7.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rezaali, Z.; Ghodratnama, A.; Amiri-Aref, M.; Tavakkoli-Moghaddam, R.; Wassan, N. Lagrangian relaxation method for solving a new time-dependent production–distribution planning model. Expert Syst. Appl. 2024, 255, 124669. [Google Scholar] [CrossRef]

- Biuki, M.; Kazemi, A.; Alinezhad, A. An integrated location-routing-inventory model for sustainable design of a perishable products supply chain network. J. Clean. Prod. 2020, 260, 120842. [Google Scholar] [CrossRef]

- Moshtagh, M.S.; Zhou, Y.; Verma, M. Optimal markdown policies for perishable products with fixed shelf life. Int. J. Prod. Res. 2025, 1–31. [Google Scholar] [CrossRef]

- Liu, A.J.; Zhu, Q.Y.; Xu, L.; Lu, Q.; Fan, Y.Q. Sustainable supply chain management for perishable products in emerging markets: An integrated location-inventory-routing model. Transp. Res. Part E-Logist. Transp. Rev. 2021, 150, 102319. [Google Scholar] [CrossRef]

- Shafiee, M.; Zare-Mehrjerdi, Y.; Govindan, K.; Dastgoshade, S. A causality analysis of risks to perishable product supply chain networks during the COVID-19 outbreak era: An extended DEMATEL method under Pythagorean fuzzy environment. Transp. Res. Part E-Logist. Transp. Rev. 2022, 163, 102759. [Google Scholar] [CrossRef]

- Sinha, A.K.; Anand, A. Optimizing supply chain network for perishable products using improved bacteria foraging algorithm. Appl. Soft Comput. 2020, 86, 105921. [Google Scholar] [CrossRef]

- Yuvaraj, M.; Basu, R.J.; Prabhu, B.V.; Boppana, S.B.; Kumar, C.G. Design of multi-echelon multi-fruit supply chain network considering multi-compartment reefer trucks to ensure food security. Br. Food J. 2024, 127, 1756–1787. [Google Scholar] [CrossRef]

- Song, L.Y.; Wu, Z.Q. An integrated approach for optimizing location-inventory and location-inventory-routing problem for perishable products. Int. J. Transp. Sci. Technol. 2023, 12, 148–172. [Google Scholar] [CrossRef]

- Christensen, F.M.M.; Solheim-Bojer, C.; Dukovska-Popovska, I.; Steger-Jensen, K. Developing new forecasting accuracy measure considering Product’s shelf life: Effect on availability and waste. J. Clean. Prod. 2021, 288, 125594. [Google Scholar] [CrossRef]

- Jin, X.Y.; Guo, L.Z.; Wang, Y.F.; Huang, W.T.; Wang, X. Flexible PEI functionalized CO 2 sensing system designed for climacteric fruit cold chain quality monitoring. Chem. Eng. J. 2025, 505, 159680. [Google Scholar] [CrossRef]

- Bhat, M.A.; Rather, M.Y.; Singh, P.; Hassan, S.; Hussain, N. Advances in smart food authentication for enhanced safety and quality. Trends Food Sci. Technol. 2025, 155, 104800. [Google Scholar] [CrossRef]

- Taj, S.; Imran, A.S.; Kastrati, Z.; Daudpota, S.M.; Memon, R.A.; Ahmed, J. IoT-based supply chain management: A systematic literature review. Internet Things 2023, 24, 100982. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Nagarajan, S.M.; Deverajan, G.G.; Chatterjee, P.; Alnumay, W.; Muthukumaran, V. Integration of IoT based routing process for food supply chain management in sustainable smart cities. Sustain. Cities Soc. 2022, 76, 103448. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Wu, C.H.; Lam, H.Y.; Choy, K.L.; Ho, G.T.S. Integrating Internet of Things and multi-temperature delivery planning for perishable food E-commerce logistics: A model and application. Int. J. Prod. Res. 2021, 59, 1534–1556. [Google Scholar] [CrossRef]

- Chen, W.R.; Zhang, D.Z.; Van Woensel, T.; Xu, G.M.; Guo, J. Green vehicle routing using mixed fleets for cold chain distribution. Expert Syst. Appl. 2023, 233, 120979. [Google Scholar] [CrossRef]

- Tsao, Y.C.; Ai, H.T.T. Remanufacturing electric vehicle battery supply chain under government subsidies and carbon trading: Optimal pricing and return policy. Appl. Energy 2024, 375, 124063. [Google Scholar] [CrossRef]

- Farooq, A.; Cora, Ö. Current Status and Future Perspectives for Mobility Options Toward Sustainable Transportation With a Focus on Fuel Cells. Wiley Interdiscip. Rev. Energy Environ. 2024, 13, e539. [Google Scholar] [CrossRef]

- Yang, W.; Ma, J.H.; Fan, A.; Zhang, J.Y.; Pan, Y.C. Effectiveness of policies for electric commercial vehicle adoption and emission reduction in the logistics industry. Energy Policy 2024, 188, 114116. [Google Scholar] [CrossRef]

- Babagolzadeh, M.; Shrestha, A.; Abbasi, B.; Zhang, Y.H.; Woodhead, A.; Zhang, A.M. Sustainable cold supply chain management under demand uncertainty and carbon tax regulation. Transp. Res. Part D Transp. Environ. 2020, 80, 102245. [Google Scholar] [CrossRef]

- Cai, J.H.; Jiang, L.; Hu, X.Q.; Ma, X.Y. Supply chain contract design considering carbon tax policy under demand information asymmetry. Manag. Decis. Econ. 2024, 45, 1363–1378. [Google Scholar] [CrossRef]

- Kordasiabi, M.C.; Gholizadeh, H.; Khakifirooz, M.; Fathi, M. Robust-heuristic-based optimisation for an engine oil sustainable supply chain network under uncertainty. Int. J. Prod. Res. 2023, 61, 1313–1340. [Google Scholar] [CrossRef]

- Zhang, G.T.; Cheng, P.Y.; Sun, H.; Shi, Y.Y.; Zhang, G.Q.; Kadiane, A. Carbon reduction decisions under progressive carbon tax regulations: A new dual-channel supply chain network equilibrium model. Sustain. Prod. Consum. 2021, 27, 1077–1092. [Google Scholar] [CrossRef]

- Foroozesh, N.; Karimi, B.; Mousavi, S.M.; Mojtahedi, M. A hybrid decision-making method using robust programming and interval-valued fuzzy sets for sustainable-resilient supply chain network design considering circular economy and technology levels. J. Ind. Inf. Integr. 2023, 33, 100440. [Google Scholar] [CrossRef]

- Sogandi, F.; Shiri, M. Metaheuristic algorithms for a sustainable saffron supply chain network considering government policies and product quality under uncertainty. J. Comput. Des. Eng. 2023, 10, 1892–1929. [Google Scholar] [CrossRef]

- Fathi, M.R.; Zamanian, A.; Khosravi, A. Mathematical modeling for sustainable agri-food supply chain. Environ. Dev. Sustain. 2024, 26, 6879–6912. [Google Scholar] [CrossRef]

- Goodarzian, F.; Navaei, A.; Ehsani, B.; Ghasemi, P.; Muñuzuri, J. Designing an integrated responsive-green-cold vaccine supply chain network using Internet-of-Things: Artificial intelligence-based solutions. Ann. Oper. Res. 2023, 328, 531–575. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, T.; Sajadi, S.M.; Najafi, S.E.; Taghizadeh-Yazdi, M. Multi Objective and Multi-Product Perishable Supply Chain with Vendor-Managed Inventory and IoT-Related Technologies. Mathematics 2024, 12, 679. [Google Scholar] [CrossRef]

- Liu, Y.H.; Shi, X.L. Cold chain distribution network design with heterogeneous fleet under carbon reduction policy application effect. Transp. Plan. Technol. 2024, 1–24. [Google Scholar] [CrossRef]

- Leng, L.L.; Jin, Q.L.; Chen, T.; Wan, A.P.; Wang, Z. Energy-conserving cold chain with ambient temperature, path flexibility, and hybrid fleet: Formulation and heuristic approach. Int. J. Prod. Res. 2025, 63, 26–50. [Google Scholar] [CrossRef]

- Foroozesh, N.; Karimi, B.; Mousavi, S.M. Green-resilient supply chain network design for perishable products considering route risk and horizontal collaboration under robust interval-valued type-2 fuzzy uncertainty: A case study in food industry. J. Environ. Manag. 2022, 307, 114470. [Google Scholar] [CrossRef] [PubMed]

- Acevedo-Chedid, J.; Soto, M.C.; Ospina-Mateus, H.; Salas-Navarro, K.; Sana, S.S. An optimization model for routing-location of vehicles with time windows and cross-docking structures in a sustainable supply chain of perishable foods. Oper. Manag. Res. 2023, 16, 1742–1765. [Google Scholar] [CrossRef]

- Bortolini, M.; Galizia, F.G.; Mora, C.; Botti, L.; Rosano, M. Bi-objective design of fresh food supply chain networks with reusable and disposable packaging containers. J. Clean. Prod. 2018, 184, 375–388. [Google Scholar] [CrossRef]

- Govindan, K.; Jafarian, A.; Khodaverdi, R.; Devika, K. Two-echelon multiple-vehicle location-routing problem with time windows for optimization of sustainable supply chain network of perishable food. Int. J. Prod. Econ. 2014, 152, 9–28. [Google Scholar] [CrossRef]

- Diabat, A.; Jabbarzadeh, A.; Khosrojerdi, A. A perishable product supply chain network design problem with reliability and disruption considerations. Int. J. Prod. Econ. 2019, 212, 125–138. [Google Scholar] [CrossRef]

- Khazaeli, S.; Jabalameli, M.S.; Sahebi, H. Bi-objective model for multi-level supply chain by focusing on quality of agricultural products: A case study. Kybernetes 2024, 53, 3484–3521. [Google Scholar] [CrossRef]

- Seydanlou, P.; Jolai, F.; Tavakkoli-Moghaddam, R.; Fathollahi-Fard, A.M. A multi-objective optimization framework for a sustainable closed-loop supply chain network in the olive industry: Hybrid meta-heuristic algorithms. Expert Syst. Appl. 2022, 203, 117566. [Google Scholar] [CrossRef]

- Tolgari, F.S.; Zarrinpoor, N. A robust reverse pharmaceutical supply chain design considering perishability and sustainable development objectives. Ann. Oper. Res. 2024, 340, 981–1033. [Google Scholar] [CrossRef]

- Jouzdani, J.; Govindan, K. On the sustainable perishable food supply chain network design: A dairy products case to achieve sustainable development goals. J. Clean. Prod. 2021, 278, 123060. [Google Scholar] [CrossRef]

- Heidari, A.; Khalilzadeh, M.; Pamucar, D.; Ecer, F. Accelerating Benders Decomposition for sustainable food closed-loop supply chain network under uncertainty: A case study. Kybernetes 2025, 41. [Google Scholar] [CrossRef]

- Golestani, M.; Moosavirad, S.H.; Asadi, Y.; Biglari, S. A Multi-Objective Green Hub Location Problem with Multi Item-Multi Temperature Joint Distribution for Perishable Products in Cold Supply Chain. Sustain. Prod. Consum. 2021, 27, 1183–1194. [Google Scholar] [CrossRef]

- Seyedzadeh, Z.; Jabalameli, M.S.; Dehghani, E. Towards a sustainable viticultural supply chain under uncertainty: Integration of data envelopment analysis, artificial neural networks, and a multi-objective optimization model. Sci. Total Environ. 2025, 970, 178980. [Google Scholar] [CrossRef]

- Wang, C.N.; Nhieu, N.L.; Chung, Y.C.; Pham, H.T. Multi-Objective Optimization Models for Sustainable Perishable Intermodal Multi-Product Networks with Delivery Time Window. Mathematics 2021, 9, 379. [Google Scholar] [CrossRef]

- Meidute-Kavaliauskiene, I.; Yildirim, F.; Ghorbani, S.; Cincikaite, R. The Design of a Multi-Period and Multi-Echelon Perishable Goods Supply Network under Uncertainty. Sustainability 2022, 14, 2472. [Google Scholar] [CrossRef]

- Mohamed, N.H.; Khan, S.; Jagtap, S. Modernizing Medical Waste Management: Unleashing the Power of the Internet of Things (IoT). Sustainability 2023, 15, 9909. [Google Scholar] [CrossRef]

- Mosallanezhad, B.; Gholian-Jouybari, F.; Cárdenas-Barrón, L.E.; Hajiaghaei-Keshteli, M. The IoT-enabled sustainable reverse supply chain for COVID-19 Pandemic Wastes (CPW). Eng. Appl. Artif. Intell. 2023, 120, 105903. [Google Scholar] [CrossRef] [PubMed]

- Salehi-Amiri, A.; Jabbarzadeh, A.; Hajiaghaei-Keshteli, M.; Chaabane, A. Utilizing the Internet of Things (IoT) to address uncertain home health care supply chain network. Expert Syst. Appl. 2022, 208, 118239. [Google Scholar] [CrossRef]

- Tavana, M.; Sohrabi, M.; Rezaei, H.; Sorooshian, S.; Mina, H. A sustainable circular supply chain network design model for electric vehicle battery production using internet of things and big data. Expert Syst. 2024, 41, e13395. [Google Scholar] [CrossRef]

- Sorooshian, S.; Khiavi, S.F.; Karimi, F.; Mina, H. Link between sustainable circular supply chain and Internet of Things technology in electric vehicle battery manufacturing industry: A business strategy optimization for pickup and delivery. Bus. Strategy Environ. 2024, 33, 8211–8232. [Google Scholar] [CrossRef]

- Ekren, B.Y.; Mangla, S.K.; Turhanlar, E.E.; Kazancoglu, Y.; Li, G. Lateral inventory share-based models for IoT-enabled E-commerce sustainable food supply networks. Comput. Oper. Res. 2021, 130, 105237. [Google Scholar] [CrossRef]

- Govindan, K.; Salehian, F.; Kian, H.; Hosseini, S.T.; Mina, H. A location-inventory-routing problem to design a circular closed-loop supply chain network with carbon tax policy for achieving circular economy: An augmented epsilon-constraint approach. Int. J. Prod. Econ. 2023, 257, 108771. [Google Scholar] [CrossRef]

- Goodarzian, F.; Wamba, S.F.; Mathiyazhagan, K.; Taghipour, A. A new bi-objective green medicine supply chain network design under fuzzy environment: Hybrid metaheuristic algorithms. Comput. Ind. Eng. 2021, 160, 107535. [Google Scholar] [CrossRef]

- Tsao, Y.C.; Balo, H.T.; Lee, C.K.H. Resilient and sustainable semiconductor supply chain network design under trade credit and uncertainty of supply and demand. Int. J. Prod. Econ. 2024, 274, 109318. [Google Scholar] [CrossRef]

- Jochem, P.; Doll, C.; Fichtner, W. External costs of electric vehicles. Transp. Res. Part D Transp. Environ. 2016, 42, 60–76. [Google Scholar] [CrossRef]

- Hammam, A.H.; Nayel, M.A.; Mohamed, M.A. Optimal design of sizing and allocations for highway electric vehicle charging stations based on a PV system. Appl. Energy 2024, 376, 124284. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Guan, C.L.; Qiu, Y.G.; Wu, N.J. Multi-objective route optimization of urban cold chain distribution using electric and diesel powered vehicles. Res. Transp. Bus. Manag. 2023, 49, 100969. [Google Scholar] [CrossRef]

- Soysal, M.; Belbag, S.; Sel, Ç. A closed vendor managed inventory system under a mixed fleet of electric and conventional vehicles. Comput. Ind. Eng. 2021, 156, 107210. [Google Scholar] [CrossRef]

- Xu, X.; Li, F.; Wu, T.; Huang, X.R.; Guan, X.L.; Zheng, T.Y.; Shen, L. Location-routing optimization problem of pharmaceutical cold chain logistics with oil-electric mixed fleets under uncertainties. Comput. Ind. Eng. 2025, 201, 110932. [Google Scholar] [CrossRef]

- Leng, L.L.; Wang, Z.; Wan, A.P.; Zhao, Y.W.; Liu, Y.Z.; Zuo, Q. Joint impacts of ambient temperature, path flexibility, and hybrid fleet on energy-conserving supply chain network. J. Clean. Prod. 2023, 423, 138685. [Google Scholar] [CrossRef]

- Goli, A.; Tirkolaee, E.B.; Golmohammadi, A.M.; Atan, Z.; Weber, G.W.; Ali, S.S. A robust optimization model to design an IoT-based sustainable supply chain network with flexibility. Cent. Eur. J. Oper. Res. 2023, 1–22. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, N.; Wang, J.; Li, J.Z. Research on location-inventory-routing optimization of emergency logistics based on multiple reliability under uncertainty. Comput. Ind. Eng. 2025, 200, 110826. [Google Scholar] [CrossRef]

- Roshani, A.; Gholamian, M.R.; Arabi, M. Integrating the triple bottom line of sustainability, resilience strategies, and product perishability consideration to design a pharmaceutical supply chain network: A COVID-19 case study. Rairo-Oper. Res. 2024, 58, 5121–5158. [Google Scholar] [CrossRef]

- Gholian-Jouybari, F.; Hajiaghaei-Keshteli, M.; Smith, N.R.; Calvo, E.Z.R.; Mejía-Argueta, C.; Mosallanezhad, B. An in-depth metaheuristic approach to design a sustainable closed-loop agri-food supply chain network. Appl. Soft Comput. 2024, 150, 111017. [Google Scholar] [CrossRef]

- Navaei, A.; Taleizadeh, A.A.; Goodarzian, F. Designing a new sustainable Test Kit supply chain network utilizing Internet of Things. Eng. Appl. Artif. Intell. 2023, 124, 106585. [Google Scholar] [CrossRef]

- Sadati-Keneti, Y.; Sebt, M.V.; Tavakkoli-Moghaddam, R.; Rahbari, M.; Jafari, M.J. Risk assessment in the supply chain of hazardous materials with carbon cap and trade mechanism: Multi-objective red deer algorithm. Ann. Oper. Res. 2023, 1–41. [Google Scholar] [CrossRef]

| Authors | Perishability | Sustainability | Decisions | IoT | Mixed Fleets | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ec | En | So-Quality | So-Delivery | L | I | R | ||||

| [2] | √ | √ | √ | √ | √ | √ | ||||

| [37] | √ | √ | √ | √ | ||||||

| [38] | √ | √ | √ | √ | √ | |||||

| [39] | √ | √ | √ | √ | √ | |||||

| [40] | √ | √ | √ | √ | √ | |||||

| [4] | √ | √ | √ | √ | √ | √ | √ | |||

| [41] | √ | √ | √ | √ | √ | |||||

| [25] | √ | √ | √ | √ | √ | |||||

| [42] | √ | √ | √ | √ | √ | |||||

| [43] | √ | √ | √ | √ | √ | √ | ||||

| [44] | √ | √ | √ | √ | √ | √ | ||||

| [26] | √ | √ | √ | √ | √ | |||||

| [45] | √ | √ | √ | √ | ||||||

| [47] | √ | √ | √ | √ | √ | |||||

| [48] | √ | √ | √ | √ | √ | |||||

| [49] | √ | √ | √ | √ | √ | |||||

| [60] | √ | √ | √ | √ | ||||||

| [28] | √ | √ | √ | √ | √ | √ | ||||

| [27] | √ | √ | √ | √ | √ | |||||

| [16] | √ | √ | √ | √ | ||||||

| [56] | √ | √ | √ | √ | ||||||

| [57] | √ | √ | √ | √ | √ | |||||

| [58] | √ | √ | √ | √ | √ | √ | ||||

| [29] | √ | √ | √ | √ | √ | |||||

| [59] | √ | √ | √ | √ | √ | |||||

| [30] | √ | √ | √ | √ | √ | √ | √ | |||

| This study | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| Symbol | Definition |

|---|---|

| C | |

| where 0 represents the freshest product | |

| where 0 indicates that no IoT technology is deployed | |

| Vehicles type index | |

| Travel arc index | |

| Period index | |

| Parameters: | |

| . | |

| in the system | |

| Price of one unit of energy | |

| Shelf life of perishable product | |

| per trip | |

| T | |

| Carbon emissions per unit of consumed energy | |

| A sufficiently large number | |

| Decision Variables: | |

| ; 0, otherwise | |

| operates; 0, otherwise | |

| is deployed in the system; 0 otherwise | |

| ; 0, otherwise | |

| ; 0, otherwise | |

| ; 0, otherwise | |

| is utilized; 0, otherwise | |

| Number | (Longitude, Latitude) | Time Window (a.m.) | Demand (kg) Per Period (1–5) | ||||

|---|---|---|---|---|---|---|---|

| 1st | 2nd | 3rd | 4th | 5th | |||

| C 1 | (112.989, 28.123) | [8:00, 8:50] | 278.94 | 302.09 | 282.97 | 275.57 | 273.62 |

| C 2 | (112.927, 28.153) | [8:20, 9:40] | 272.01 | 298.60 | 282.34 | 293.19 | 294.78 |

| C 3 | (113.943, 28.175) | [7:00, 7:45] | 227.01 | 190.16 | 221.50 | 230.48 | 202.35 |

| C 4 | (112.977, 28.192) | [8:00, 8:50] | 296.48 | 321.37 | 308.60 | 304.63 | 308.71 |

| C 5 | (112.995, 28.171) | [7:30, 8:20] | 240.24 | 262.10 | 265.92 | 246.29 | 259.15 |

| C 6 | (113.969, 28.179) | [8:00, 8:50] | 268.83 | 282.21 | 261.24 | 277.18 | 274.39 |

| C 7 | (113.007, 28.187) | [7:20, 7:55] | 257.99 | 253.38 | 267.58 | 267.38 | 257.66 |

| C 8 | (113.032, 28.203) | [6:45, 7:15] | 308.46 | 310.55 | 295.12 | 316.70 | 298.04 |

| C 9 | (112.972, 28.200) | [8:00, 9:30] | 209.79 | 176.90 | 206.26 | 179.25 | 190.80 |

| C 10 | (112.889, 28.217) | [6:30, 7:30] | 295.32 | 282.44 | 293.29 | 292.45 | 295.54 |

| Distances | DC 1 | DC 2 | DC 3 | DC 4 | DC 5 |

|---|---|---|---|---|---|

| M 1 | 344 | 327 | 358 | 366 | 351 |

| M 2 | 458 | 474 | 438 | 444 | 457 |

| Distances | C 1 | C 2 | C 3 | C 4 | C 5 | C 6 | C 7 | C 8 | C 9 | C 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| DC 1 | 19.21 | 30.31 | 28.89 | 15.17 | 11.34 | 17.86 | 13.45 | 13.00 | 17.65 | 34.77 |

| DC 2 | 21.77 | 34.84 | 28.09 | 14.98 | 13.18 | 16.69 | 14.59 | 11.36 | 17.62 | 21.41 |

| DC 3 | 8.93 | 14.90 | 21.63 | 15.71 | 18.05 | 14.31 | 17.44 | 20.85 | 16.23 | 23.96 |

| DC 4 | 9.48 | 23.52 | 24.13 | 10.10 | 8.43 | 10.82 | 7.98 | 5.04 | 11.16 | 23.27 |

| DC 5 | 11.67 | 15.60 | 25.35 | 9.51 | 8.80 | 9.97 | 6.16 | 5.73 | 10.51 | 24.66 |

| Metric | S1 (Cost-Optimal) | S6 (Compromise) | S14 (Service-Optimal) |

|---|---|---|---|

| Total Cost (¥) | 615,229.03 | 641,223.15 | 686,847.03 |

| Service Level | 0.775 | 0.920 | 0.996 |

| CO2 Emissions (tons) | 40.31 | 37.63 | 35.98 |

| EVs Utilization (%) | 29% | 43% | 78% |

| Advanced IoT Deployed (%) | 64% | 87% | 99% |

| Expected quality level | 3.5 | 1.2 | 0.1 |

| Expected on-time delivery rate | 81.63% | 93.33% | 99.64% |

| Total Cost (¥) | Service Level | |

|---|---|---|

| 0 | 654,603.88 | 0.789 |

| 0.1 | 647,426.92 | 0.829 |

| 0.2 | 642,223.75 | 0.861 |

| 0.3 | 639,151.16 | 0.886 |

| 0.4 | 638,148.31 | 0.904 |

| 0.5 | 639,181.56 | 0.915 |

| 0.6 | 641,223.15 | 0.920 |

| 0.7 | 647,354.8 | 0.916 |

| 0.8 | 654,642.15 | 0.906 |

| 0.9 | 663,843.93 | 0.893 |

| 1.0 | 675,233.59 | 0.879 |

| Variance in Demand | Total Cost | Service Level |

|---|---|---|

| −60% | 513,146.15 | 0.936 |

| −40% | 564,285.83 | 0.928 |

| −20% | 602,993.59 | 0.924 |

| 0% | 641,223.15 | 0.920 |

| 20% | 688,370.52 | 0.915 |

| 40% | 744,844.96 | 0.910 |

| 60% | 814,215.12 | 0.904 |

| Variance in Product Shelf Life | Total Cost | Service Level |

|---|---|---|

| 3 | 719,373.13 | 0.902 |

| 5 | 677,050.8 | 0.911 |

| 7 | 641,223.15 | 0.92 |

| 9 | 623,953.52 | 0.928 |

| 11 | 613,313.84 | 0.934 |

| 13 | 607,824.26 | 0.937 |

| 15 | 606,412.98 | 0.939 |

| 17 | 605,629.95 | 0.939 |

| 19 | 605,125.71 | 0.940 |

| 21 | 605,125.22 | 0.940 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Li, X.; Shan, M. Designing a Sustainable Supply Chain Network for Perishable Products Integrating Internet of Things and Mixed Fleets. J. Theor. Appl. Electron. Commer. Res. 2025, 20, 137. https://doi.org/10.3390/jtaer20020137

Pan L, Li X, Shan M. Designing a Sustainable Supply Chain Network for Perishable Products Integrating Internet of Things and Mixed Fleets. Journal of Theoretical and Applied Electronic Commerce Research. 2025; 20(2):137. https://doi.org/10.3390/jtaer20020137

Chicago/Turabian StylePan, Lihong, Xialian Li, and Miyuan Shan. 2025. "Designing a Sustainable Supply Chain Network for Perishable Products Integrating Internet of Things and Mixed Fleets" Journal of Theoretical and Applied Electronic Commerce Research 20, no. 2: 137. https://doi.org/10.3390/jtaer20020137

APA StylePan, L., Li, X., & Shan, M. (2025). Designing a Sustainable Supply Chain Network for Perishable Products Integrating Internet of Things and Mixed Fleets. Journal of Theoretical and Applied Electronic Commerce Research, 20(2), 137. https://doi.org/10.3390/jtaer20020137