The Application of Polysaccharides and Their Derivatives in Pigment, Barrier, and Functional Paper Coatings

Abstract

1. Introduction

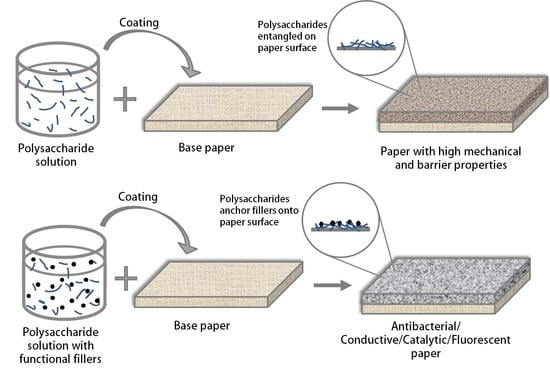

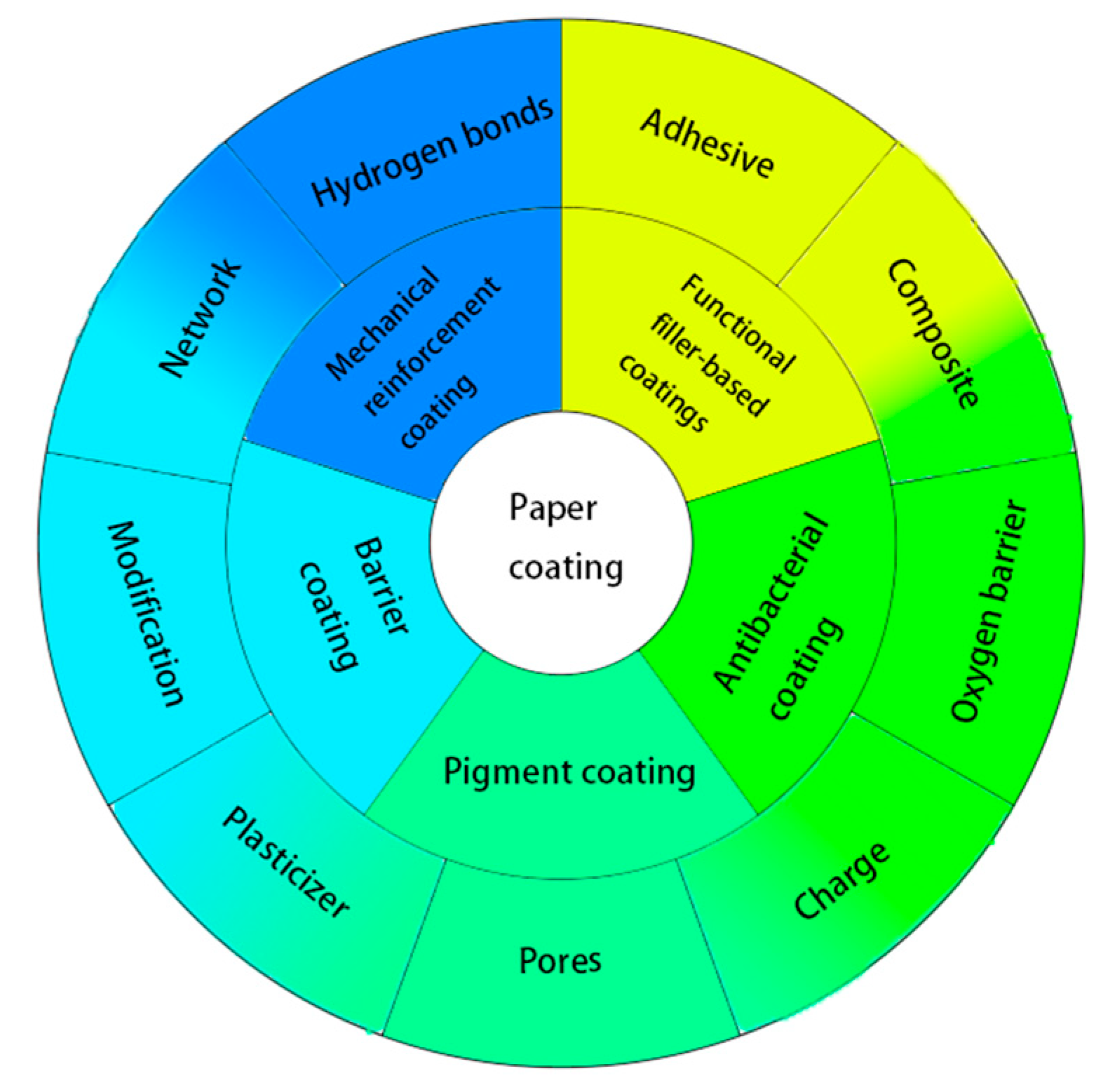

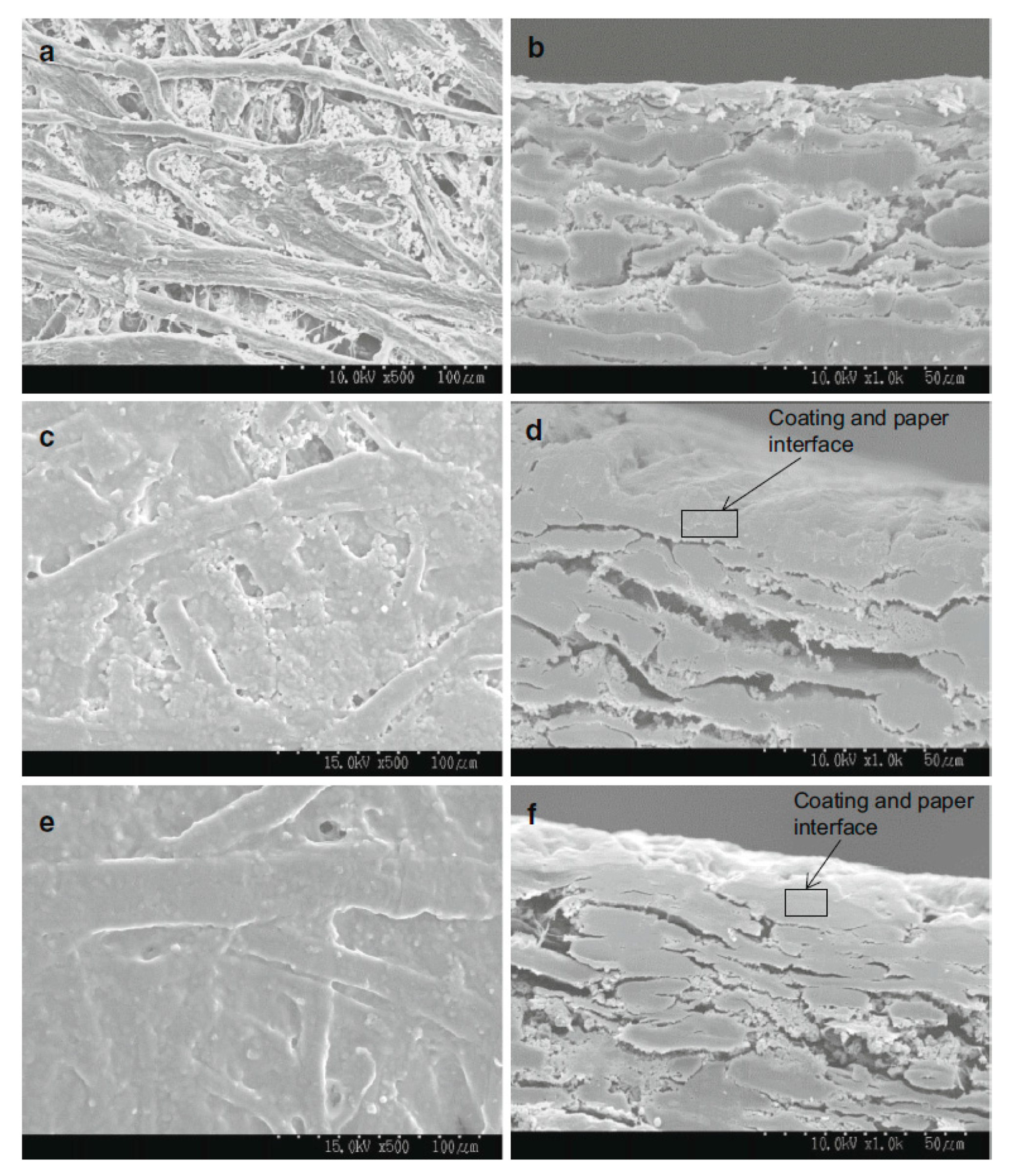

2. Mechanical Reinforcement Coating

3. Barrier Coating

3.1. Gas Barrier

3.2. Water Barrier

3.3. Oil Barrier

4. Pigment Coating

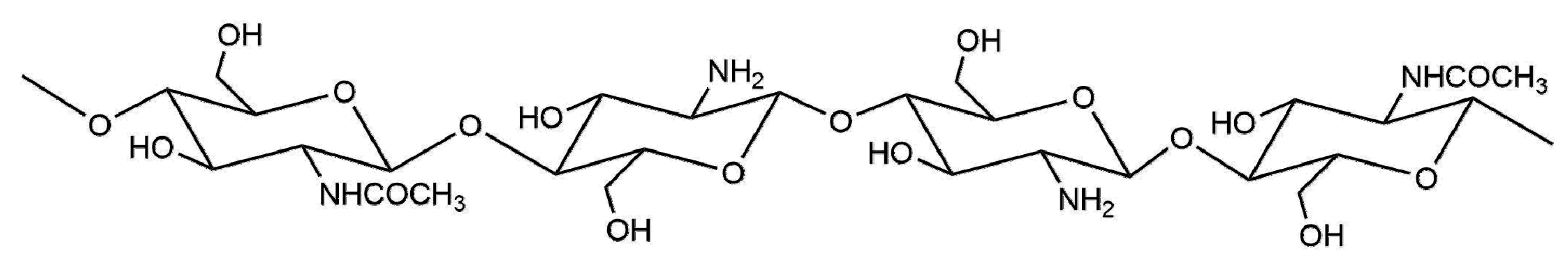

5. Antibacterial Coating

6. Functional Filler-Based Coatings

6.1. Conductive Coating

6.2. Catalytic Coating

6.3. Fluorescent Coating

7. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Liu, X.F.; Guan, Y.L.; Yang, D.Z.; Li, Z.; De Yao, K. Antibacterial action of chitosan and carboxymethylated chitosan. J. Appl. Polym. Sci. 2001, 79, 1324–1335. [Google Scholar]

- Jiao, G.; Yu, G.; Zhang, J.; Ewart, H.S. Chemical Structures and Bioactivities of Sulfated Polysaccharides from Marine Algae. Mar. Drugs 2011, 9, 196–223. [Google Scholar] [CrossRef] [PubMed]

- Raposo, M.F.D.J.; Morais, A.M.M.B.; Morais, R. Marine Polysaccharides from Algae with Potential Biomedical Applications. Mar. Drugs 2015, 13, 2967–3028. [Google Scholar] [CrossRef] [PubMed]

- Laine, C.; Harlin, A.; Hartman, J.; Hyvarinen, S.; Kammiovirta, K.; Krogerus, B.; Pajari, H.; Rautkoski, H.; Setala, H.; Sievanen, J. Hydroxyalkylated xylans: Their synthesis and application in coatings for packaging and paper. Ind. Crop. Prod. 2013, 44, 692–704. [Google Scholar] [CrossRef]

- Barhoum, A.; Rahier, H.; Abouzaied, R.E.; Rehan, M.; Dufour, T.; Hill, G.; Dufresne, A. Effect of cationic and anionic surfactants on the application of calcium carbonate nanoparticles in paper coating. ACS Appl. Mater. Interfaces 2014, 6, 2734–2744. [Google Scholar] [CrossRef]

- Xiang, Z.; Anthony, R.; Lan, W.; Runge, T. Glutaraldehyde crosslinking of arabinoxylan produced from corn ethanol residuals. Cellulose 2016, 23, 307–321. [Google Scholar] [CrossRef]

- Molin, U.; Teder, A. Importance of cellulose/hemicellulose-ratio for pulp strength. Nord. Pulp Pap. Res. J. 2002, 17, 14–19. [Google Scholar] [CrossRef]

- Maruyama, H.; Terada, K.; Katayama, T. Paper Coating Agent. U.S. Patent No. 4,617,239, 30 August 1984. [Google Scholar]

- Hausman Mary, L.; Lenney William, E.; Miller Gerald, D. Vinyl Acetate/acrylate Copolymer Emulsions for Paper Coating Compositions. U.S. Patent No. 4,609,704, 9 November 1984. [Google Scholar]

- Hausman, M.L.B.; Gerald, M.D.; Wempe, L.K. Vinyl Acetate/Ethylene Copolymer Emulsions for Paper Coating Compositions. U.S. Patent No. 4,503,185, 22 June 1984. [Google Scholar]

- Hiroshi, W.; Seiichi, T.; Akira, S.; Naotaka, W. Toyo Koatsu Industries Inc. Ethylene-Vinyl Acetate Copolymer Paper Coating Composition. U.S. Patent No. 3,337,482, 20 September 1965. [Google Scholar]

- Aulin, C.; Lindström, T. Biopolymers: New Materials for Sustainable Films and Coatings; Wiley: Chichester, UK, 2011; pp. 255–276. [Google Scholar] [CrossRef]

- Tao, Y.; Huang, C.; Lai, C.; Huang, C.; Yong, Q. Biomimetic galactomannan/bentonite/graphene oxide film with superior mechanical and fire retardant properties by borate cross-linking. Carbohydr. Polym. 2020, 245, 116508. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef]

- Paakko, M.; Ankerfors, M.; Kosonen, H.; Nykanen, A.; Ahola, S.; Osterberg, M.; Ruokolainen, J.; Laine, J.; Larsson, P.T.; Ikkala, O. Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 2007, 8, 1934–1941. [Google Scholar] [CrossRef]

- Hassan, B.; Chatha, S.A.S.; Hussain, A.I.; Zia, K.M.; Akhtar, N. Recent advances on polysaccharides, lipids and protein based edible films and coatings: A review. Int. J. Biol. Macromol. 2017, 109, 1095–1107. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Xing, S.; Jin, Y.; Lu, X.; Huang, C.; Yong, Q. Insight into understanding the performance of deep eutectic solvent pretreatment on improving enzymatic digestibility of bamboo residues. Bioresour. Technol. 2020, 306, 123163. [Google Scholar] [CrossRef] [PubMed]

- Nešić, A.; Cabrera-Barjas, G.; Dimitrijević-Branković, S.; Davidović, S.; Radovanović, N.; Delattre, C. Prospect of Polysaccharide-Based Materials as Advanced Food Packaging. Molecules 2020, 25, 135. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Chen, K.; Guo, Y.; Liang, X. Application of Cellulose Derivative (CMC) in Paper Coating Color. Pap. Sci. Technol. 2001, 4, 24–28. [Google Scholar]

- Chen, Z.; Zhang, L. Modification of Papermaking Filler PCC with Cationic Chitosan and Carboxymethyl Cellulose. Bull. Chin. Ceram. Soc. 2016, 35, 1602–1605. [Google Scholar]

- Turbak, A.F.; Snyder, F.W.; Sandberg, K.R. Microfibrillated cellulose, a new cellulose product: Properties, uses, and commercial potential. J. Appl. Polym. Sci. Appl. Polym. Symp. 1983, 37, 815–827. [Google Scholar]

- Hassan, M.L.; Fadel, S.M.; Hassan, E.A. Acrylate/Nanofibrillated Cellulose Nanocomposites and Their Use for Paper Coating. J. Nanomater. 2018, 2018, 4953834. [Google Scholar] [CrossRef]

- Dimicmisic, K.; Gane, P.A.C.; Paltakari, J. Micro- and Nanofibrillated Cellulose as a Rheology Modifier Additive in CMC-Containing Pigment-Coating Formulations. Ind. Eng. Chem. Res. 2013, 52, 16066–16083. [Google Scholar] [CrossRef]

- Wang, C.; Chen, G.; Zhang, H. Preparation of Cellulose Nanofibrils and Its Application in Paper Coating. Pap. Sci. Technol. 2017, 36, 11–14. [Google Scholar]

- Khan, R.A.; Beck, S.; Dussault, D.; Salmieri, S.; Bouchard, J.; Lacroix, M. Mechanical and barrier properties of nanocrystalline cellulose reinforced poly(caprolactone) composites: Effect of gamma radiation. J. Appl. Polym. Sci. 2013, 129, 3038–3046. [Google Scholar] [CrossRef]

- Roohani, M.; Habibi, Y.; Belgacem, N.; Ebrahim, G.; Karimi, A.; Dufresne, A. Cellulose whiskers reinforced polyvinyl alcohol copolymers nanocomposites. Eur. Polym. J. 2008, 44, 2489–2498. [Google Scholar] [CrossRef]

- Paralikar, S.A.; Simonsen, J.; Lombardi, J. Poly(vinyl alcohol)/cellulose nanocrystal barrier membranes. J. Membr. Sci. 2008, 320, 248–258. [Google Scholar] [CrossRef]

- Gicquel, E.; Martin, C.; Yanez, J.G.; Bras, J. Cellulose nanocrystals as new bio-based coating layer for improving fiber-based mechanical and barrier properties. J. Mater. Sci. 2017, 52, 3048–3061. [Google Scholar] [CrossRef]

- Jin, X.; Xiang, Z.; Liu, Q.; Chen, Y.; Lu, F. Polyethyleneimine-bacterial cellulose bioadsorbent for effective removal of copper and lead ions from aqueous solution. Bioresour. Technol. 2017, 244, 844–849. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Z.; Jin, X.; Liu, Q.; Chen, Y.; Li, J.; Lu, F. The reinforcement mechanism of bacterial cellulose on paper made from woody and non-woody fiber sources. Cellulose 2017, 24, 5147–5156. [Google Scholar] [CrossRef]

- Xiang, Z.; Chen, Y.; Liu, Q.; Lu, F. A highly recyclable dip-catalyst produced from palladium nanoparticle-embedded bacterial cellulose and plant fibers. Green Chem. 2018, 20, 1085–1094. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, M.; Song, T.; Mou, H.; Xiang, Z.; Qi, H. Highly Durable and Flexible Paper Electrode with a Dual Fiber Matrix Structure for High-Performance Supercapacitors. ACS Appl. Mater. Interfaces 2020, 12, 13096–13106. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, X.; Hu, Z.; Xiang, Z.; Song, T.; Lu, F. A Highly Efficient and Durable Fluorescent Paper Produced from Bacterial Cellulose/Eu Complex and Cellulosic Fibers. Nanomaterials 2019, 9, 1322. [Google Scholar] [CrossRef]

- Ferreira, E.S.; Lanzoni, E.M.; Costa, C.A.R.; Deneke, C.; Bernardes, J.S.; Galembeck, F. Adhesive and Reinforcing Properties of Soluble Cellulose: A Repulpable Adhesive for Wet and Dry Cellulosic Substrates. ACS Appl. Mater. Interfaces 2015, 7, 18750–18758. [Google Scholar] [CrossRef]

- Jin, X.; Hu, Z.; Wu, S.; Song, T.; Yue, F.; Xiang, Z. Promoting the material properties of xylan-type hemicelluloses from the extraction step. Carbohydr. Polym. 2019, 215, 235–245. [Google Scholar] [CrossRef]

- Xiang, Z.; Jin, X.; Huang, C.; Li, L.; Wu, W.; Qi, H.; Nishiyama, Y. Water cast film formability of sugarcane bagasse xylans favored by side groups. Cellulose 2020. [Google Scholar] [CrossRef]

- Bai, L.; Hu, H.; Xu, J. Influences of configuration and molecular weight of hemicelluloses on their paper-strengthening effects. Carbohydr. Polym. 2012, 88, 1258–1263. [Google Scholar] [CrossRef]

- Xiang, Z.; Watson, J.; Tobimatsu, Y.; Runge, T. Film-forming polymers from distillers’ grains: Structural and material properties. Ind. Crop. Prod. 2014, 59, 282–289. [Google Scholar] [CrossRef]

- Fitt Larry, E.; Pienkowski James, J.; Wallace Jack, R. Starch-Hemicellulose Adhesive for High Speed Corrugating. U.S. Patent No. 5,358,559, 25 October 1994. [Google Scholar]

- Ramos, A.; Sousa, S.; Evtuguin, D.V.; Gamelas, J.A.F. Functionalized xylans in the production of xylan-coated paper laminates. React. Funct. Polym. 2017, 117, 89–96. [Google Scholar] [CrossRef]

- Zhao, M.; Salminen, P.; Toivakka, M.; Kumar, V.; Xu, C.; Xu, W.; Korpinen, R.; Fu, S. Application of Acetylated Hemicelluloses in Improvement of Coated Paper. Pap. Sci. Technol. 2019, 38, 27–33. [Google Scholar]

- Hu, Z.; Xiang, Z.; Song, T.; Lu, F. Effects of Crosslinking Degree on the Coating Properties of Arabinoxylan. Bioresources 2019, 14, 70–86. [Google Scholar]

- Ghassemzadeh, J.; Hashemi, M.; Sartor, L.; Sahimi, M. Pore network simulation of imbibition into paper during coating: I. Model development. AIChE J. 2001, 47, 519–535. [Google Scholar] [CrossRef]

- Xiang, Z.; Runge, T. Emulsifying properties of succinylated arabinoxylan-protein gum produced from corn ethanol residuals. Food Hydrocoll. 2016, 52, 423–430. [Google Scholar] [CrossRef]

- Anthony, R.; Xiang, Z.; Runge, T. Paper coating performance of hemicellulose-rich natural polymer from distiller’s grains. Prog. Org. Coat. 2015, 89, 240–245. [Google Scholar] [CrossRef]

- Zhan, Z.; Tao, Z.; Liu, Z.; Chen, X. The Research of Microfibrillated cellulose and Its Appilcation in Paper Industry: A Review. China Pulp Pap. 2017, 36, 70–78. [Google Scholar]

- Hu, F.; Zhang, H.; Wang, L.; Tong, S. Preparation and Properties of Antibacterial Paper with Chitosan-starch Coating. China Pulp Pap. 2013, 32, 1–5. [Google Scholar]

- Cazón, P.; Velazquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-based films and coatings for food packaging: A review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Mousavi, S.M.M.; Afra, E.; Tajvidi, M.; Bousfield, D.W.; Dehghanifirouzabadi, M. Cellulose nanofiber/carboxymethyl cellulose blends as an efficient coating to improve the structure and barrier properties of paperboard. Cellulose 2017, 24, 3001–3014. [Google Scholar] [CrossRef]

- Mirmehdi, S.; Hein, P.R.G.; Sarantópoulos, C.I.G.D.L.; Dias, M.V.; Tonoli, G.H.D. Cellulose nanofibrils/nanoclay hybrid composite as a paper coating: Effects of spray time, nanoclay content and corona discharge on barrier and mechanical properties of the coated papers. Food Packag. Shelf Life 2018, 15, 87–94. [Google Scholar] [CrossRef]

- Hu, Y.; Wei, Z.; Li, F.; Du, W.; Yan, R. Preparation of cellulose nanocrystals coated soft packaging material and evaluation of its oxygen barrier performance. Trans. Chin. Soc. Agric. Eng. 2018, 34, 298–303. [Google Scholar]

- Grondahl, M.; Eriksson, L.; Gatenholm, P. Material Properties of Plasticized Hardwood Xylans for Potential Application as Oxygen Barrier Films. Biomacromolecules 2004, 5, 1528–1535. [Google Scholar] [CrossRef]

- Hartman, J.; Albertsson, A.; Lindblad, M.S.; Sjoberg, J. Oxygen barrier materials from renewable sources: Material properties of softwood hemicellulose-based films. J. Appl. Polym. Sci. 2006, 100, 2985–2991. [Google Scholar] [CrossRef]

- Mikkonen, K.S.; Heikkila, M.I.; Helen, H.; Hyvonen, L.; Tenkanen, M. Spruce galactoglucomannan films show promising barrier properties. Carbohydr. Polym. 2010, 79, 1107–1112. [Google Scholar] [CrossRef]

- Kisonen, V.; Xu, C.; Bollstrom, R.; Hartman, J.; Rautkoski, H.; Nurmi, M.; Hemming, J.; Eklund, P.; Willfor, S. O -acetyl galactoglucomannan esters for barrier coatings. Cellulose 2014, 21, 4497–4509. [Google Scholar] [CrossRef]

- Grondahl, M.; Gustafsson, A.; Gatenholm, P. Gas phase surface fluorination of arabinoxylan films. Macromolecules 2006, 39, 2718–2721. [Google Scholar] [CrossRef]

- Altuna, L.; Herrera, M.L.; Foresti, M.L. Synthesis and characterization of octenyl succinic anhydride modified starches for food applications. A review of recent literature. Food Hydrocoll. 2018, 80, 97–110. [Google Scholar] [CrossRef]

- Jansson, A.; Jarnstrom, L. Barrier and mechanical properties of modified starches. Cellulose 2005, 12, 423–433. [Google Scholar] [CrossRef]

- Koivula, H.; Jalkanen, L.; Saukkonen, E.; Ovaska, S.; Lahti, J.; Christophliemk, H.; Mikkonen, K.S. Machine-coated starch-based dispersion coatings prevent mineral oil migration from paperboard. Prog. Org. Coat. 2016, 99, 173–181. [Google Scholar] [CrossRef]

- Garcia, M.A.; Martino, M.N.; Zaritzky, N.E. Lipid Addition to Improve Barrier Properties of Edible Starch-based Films and Coatings. J. Food Sci. 2000, 65, 941–944. [Google Scholar] [CrossRef]

- Le Corre, D.; Bras, J.; Dufresne, A. Starch Nanoparticles: A Review. Biomacromolecules 2010, 11, 1139–1153. [Google Scholar] [CrossRef] [PubMed]

- Garcia, N.L.; Ribba, L.; Dufresne, A.; Aranguren, M.I.; Goyanes, S. Physico-Mechanical Properties of Biodegradable Starch Nanocomposites. Macromol. Mater. Eng. 2009, 294, 169–177. [Google Scholar] [CrossRef]

- Kjellgren, H.; Gällstedt, M.; Engström, G.; Järnström, L. Barrier and surface properties of chitosan-coated greaseproof paper. Carbohydr. Polym. 2006, 65, 453–460. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, C.; Coelhoso, I.M.; Fernando, A.L. Chitosan Composites in Packaging Industry—Current Trends and Future Challenges. Polymers 2020, 12, 417. [Google Scholar] [CrossRef]

- Khwaldia, K.; Basta, A.H.; Aloui, H.; Elsaied, H. Chitosan-caseinate bilayer coatings for paper packaging materials. Carbohydr. Polym. 2014, 99, 508–516. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, H.; Qian, L. Beeswax–chitosan emulsion coated paper with enhanced water vapor barrier efficiency. Appl. Surf. Sci. 2014, 300, 80–85. [Google Scholar] [CrossRef]

- West, E.R.; Xu, M.; Woodruff, T.K.; Shea, L.D. Physical properties of alginate hydrogels and their effects on in vitro follicle development. Biomaterials 2007, 28, 4439–4448. [Google Scholar] [CrossRef] [PubMed]

- Gao, C.; Liu, M.; Lu, S.; Chen, C.; Yinjuan, H.; Chen, Y.; Gao, C.; Liu, M.; Lu, S.; Chen, C. Preparation of Sodium Alginate Hydrogel and Its Application in Drug Release. Prog. Chem. 2013, 25, 1012–1022. [Google Scholar]

- Kopacic, S.; Walzl, A.; Zankel, A.; Leitner, E.; Bauer, W. Alginate and Chitosan as a Functional Barrier for Paper-Based Packaging Materials. Coatings 2018, 8, 235. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Lee, J.-H.; Hong, S.-I. Water resistance and mechanical properties of biopolymer (alginate and soy protein) coated paperboards. LWT Food Sci. Technol. 2006, 39, 806–813. [Google Scholar] [CrossRef]

- Wang, W.; Qin, C.; Li, W.; Ge, J.; Feng, C. Improving moisture barrier properties of paper sheets by cellulose stearoyl ester-based coatings. Carbohydr. Polym. 2020, 235, 115924. [Google Scholar] [CrossRef]

- Bordenave, N.; Grelier, S.; Coma, V. Hydrophobization and Antimicrobial Activity of Chitosan and Paper-Based Packaging Material. Biomacromolecules 2010, 11, 88–96. [Google Scholar] [CrossRef]

- Hartman, J.; Albertsson, A.-C.; Sjoberg, J. Surface- and bulk-modified galactoglucomannan hemicellulose films and film laminates for versatile oxygen barriers. Biomacromolecules 2006, 7, 1983–1989. [Google Scholar] [CrossRef]

- Zhang, S.; Li, W.; Wang, W.; Wang, S.; Qin, C. Reactive superhydrophobic paper from one-step spray-coating of cellulose-based derivative. Appl. Surf. Sci. 2019, 497, 143816. [Google Scholar] [CrossRef]

- Ma, Z.; Sun, M.; Li, A.; Zhu, G.; Zhang, Y. Anticorrosion behavior of polyvinyl butyral (PVB)/polymethylhydrosiloxane (PMHS)/chitosan (Ch) environment-friendly assembled coatings. Prog. Org. Coat. 2020, 144, 105662. [Google Scholar] [CrossRef]

- Farhat, W.; Venditti, R.A.; Quick, A.; Taha, M.; Mignard, N.; Becquart, F.; Ayoub, A. Hemicellulose extraction and characterization for applications in paper coatings and adhesives. Ind. Crop. Prod. 2017, 107, 370–377. [Google Scholar] [CrossRef]

- Chi, K.; Wang, H.; Catchmark, J.M. Sustainable starch-based barrier coatings for packaging applications. Food Hydrocoll. 2020, 103, 105696. [Google Scholar] [CrossRef]

- Lin, W.; Chen, D.; Yong, Q.; Huang, C.; Huang, S. Improving enzymatic hydrolysis of acid-pretreated bamboo residues using amphiphilic surfactant derived from dehydroabietic acid. Bioresour. Technol. 2019, 293, 122055. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yang, Z.; Li, H.; Long, X.; Zhao, L.; Zhang, J. Effect of Particle Size Distribution of Titanium Dioxide and Pigment Volume Concentration on Pigment Properties. China Coat. 2017, 32, 60–63. [Google Scholar]

- Laudone, G.M.; Matthews, G.P.; Gane, P.A.C. Effect of Latex Volumetric Concentration on Void Structure, Particle Packing, and Effective Particle Size Distribution in a Pigmented Paper Coating Layer. Ind. Eng. Chem. Res. 2006, 45, 1918–1923. [Google Scholar] [CrossRef]

- Kugge, C.; Craig, V.S.J.; Daicic, J. A scanning electron microscope study of the surface structure of mineral pigments, latices and thickeners used for paper coating on non-absorbent substrates. Colloids Surf. A Physicochem. Eng. Asp. 2004, 238, 1–11. [Google Scholar] [CrossRef]

- Oh, K.; Lee, J.-H.; Im, W.; Rajabi Abhari, A.; Lee, H.L. Role of Cellulose Nanofibrils in Structure Formation of Pigment Coating Layers. Ind. Eng. Chem. Res. 2017, 56, 9569–9577. [Google Scholar] [CrossRef]

- Xu, H.; Zhu, Y.; Dai, H. Properties of Carboxymethyl Modified Nanofibrillated Cellulose and Its Influence on Pigment Dispersi and Coating Property. Trans. China Pulp Pap. 2017, 32, 16–21. [Google Scholar]

- Yan, J.; Chen, K. Effect of Binders on the Rheological Properties of Coating Colors. Trans. China Pulp Pap. 1999, 14, 82–87. [Google Scholar]

- Verlee, A.; Mincke, S.; Stevens, C.V. Recent developments in antibacterial and antifungal chitosan and its derivatives. Carbohydr. Polym. 2017, 164, 268–283. [Google Scholar] [CrossRef]

- Zakaria, S.; Chia, C.H.; Ahmad, W.H.W.; Kaco, H.; Chook, S.W.; Chan, C.H. Mechanical and antibacterial properties of paper coated with chitosan. Sains Malays. 2015, 44, 905–911. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S.; Wootthikanokkhan, J.; Srimarut, Y.; Woraprayote, W.; Malila, Y. Mechanical and antibacterial properties of the chitosan coated cellulose paper for packaging applications: Effects of molecular weight types and concentrations of chitosan. Int. J. Biol. Macromol. 2019, 155, 1510–1519. [Google Scholar] [CrossRef]

- Li, Z.; Yang, L.; Du, F.; Yu, Z.; Li, J. Preparation of Antibacterial Paper with Chitosan/Nano Silver and Its Antibacterial Effect. China Pulp Pap. 2019, 38, 22–28. [Google Scholar]

- Li, Y.; Qian, J.; Bian, Y. Preparation and Application of Nano-ZnO / O-CMC Coating. Pap. Sci. Technol. 2018, 37, 22–25. [Google Scholar]

- Qu, M.; Jiang, W. Investigation of the antibacterial mechanism of nanometer zinc oxide. Text. Aux. 2004, 6, 45–46. [Google Scholar]

- Elhamshary, H.; Fouda, M.M.G.; Moydeen, M.; Elnewehy, M.H.; Aldeyab, S.S.; Abdelmegeed, A. Synthesis and antibacterial of carboxymethyl starch-grafted poly(vinyl imidazole) against some plant pathogens. Int. J. Biol. Macromol. 2015, 72, 1466–1472. [Google Scholar] [CrossRef]

- Naushad, M.; Ahamad, T.; Sharma, G.; Al-Muhtaseb, A.a.H.; Albadarin, A.B.; Alam, M.M.; Alothman, Z.A.; Alshehri, S.M.; Ghfar, A.A. Synthesis and characterization of a new starch/SnO2 nanocomposite for efficient adsorption of toxic Hg2+ metal ion. Chem. Eng. J. 2016, 300, 306–316. [Google Scholar] [CrossRef]

- Prasad, V.; Shaikh, A.J.; Kathe, A.A.; Bisoyi, D.K.; Verma, A.K.; Vigneshwaran, N. Functional behaviour of paper coated with zinc oxide–soluble starch nanocomposites. J. Mater. Process. Technol. 2010, 210, 1962–1967. [Google Scholar] [CrossRef]

- Arfa, A.B.; Preziosibelloy, L.; Chalier, P.; Gontard, N. Antimicrobial paper based on a soy protein isolate or modified starch coating including carvacrol and cinnamaldehyde. J. Agric. Food Chem. 2007, 55, 2155–2162. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Zhou, S.; Sun, Q. Preservation effect of degradable chitosan starch antibacterial composite membrane on red grape. J. Food Saf. Qual. 2017, 8, 1579–1584. [Google Scholar]

- Gong, Z.; Chen, N.; Hu, Z. Study on the Coating and the Performance of Handsheet with Carbon Conductive Filler. Pap. Sci. Technol. 2015, 34, 20–24. [Google Scholar]

- Li, H.; Qian, X.; Li, T.; Ni, Y. Percolation for Coated Conductive Paper: Electrical Conductivity as a Function of Volume Fraction of Graphite and Carbon Black. Bioresources 2015, 10, 4877–4885. [Google Scholar] [CrossRef][Green Version]

- Jabbour, L.; Chaussy, D.; Eyraud, B.; Beneventi, D. Highly conductive graphite/carbon fiber/cellulose composite papers. Compos. Sci. Technol. 2012, 72, 616–623. [Google Scholar] [CrossRef]

- Gao, M.; Feng, X.; Zhang, Z.; Ji, P.; Lu, P.; Yang, J.; Dong, Y.; Lu, C.; Li, M.; Nie, C. Application Research of Cellulose Paper Loading Graphene Oxide Used in Filter Rods. Pap. Pap. Mak. 2015, 34, 54–57. [Google Scholar]

- Ling, Y.; Li, X.; Zhou, S.; Wang, X.; Sun, R. Multifunctional cellulosic paper based on quaternized chitosan and gold nanoparticle–reduced graphene oxide via electrostatic self-assembly. J. Mater. Chem. 2015, 3, 7422–7428. [Google Scholar] [CrossRef]

- Tiitu, M.; Laine, J.; Serimaa, R.; Ikkala, O. Ionically self-assembled carboxymethyl cellulose/surfactant complexes for antistatic paper coatings. J. Colloid Interface Sci. 2006, 301, 92–97. [Google Scholar] [CrossRef]

- Pang, Z.; Sun, X.; Wu, X.; Nie, Y.; Liu, Z.; Yue, L. Fabrication and application of carbon nanotubes/cellulose composite paper. Vacuum 2015, 122, 135–142. [Google Scholar] [CrossRef]

- Tharun, J.; Hwang, Y.; Roshan, R.; Ahn, S.; Kathalikkattil, A.C.; Park, D. A novel approach of utilizing quaternized chitosan as a catalyst for the eco-friendly cycloaddition of epoxides with CO2. Catal. Sci. Technol. 2012, 2, 1674–1680. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, S.; Luo, J.; Wang, X.; Sun, R. Green synthesis of silver nanoparticles in xylan solution via Tollens reaction and their detection for Hg2+. Nanoscale 2015, 7, 690–700. [Google Scholar] [CrossRef]

- Kamal, T.; Khan, S.B.; Asiri, A.M. Nickel nanoparticles-chitosan composite coated cellulose filter paper: An efficient and easily recoverable dip-catalyst for pollutants degradation. Environ. Pollut. 2016, 218, 625–633. [Google Scholar] [CrossRef]

- Wei, D.; Ye, Y.; Jia, X.; Yuan, C.; Qian, W. Chitosan as an active support for assembly of metal nanoparticles and application of the resultant bioconjugates in catalysis. Carbohydr. Res. 2010, 345, 74–81. [Google Scholar] [CrossRef]

- Venkatesham, M.; Ayodhya, D.; Madhusudhan, A.; Babu, N.V.; Veerabhadram, G. A novel green one-step synthesis of silver nanoparticles using chitosan: Catalytic activity and antimicrobial studies. Appl. Nanosci. 2014, 4, 113–119. [Google Scholar] [CrossRef]

- Ahmad, I.; Kamal, T.; Khan, S.B.; Asiri, A.M. An efficient and easily retrievable dip catalyst based on silver nanoparticles/chitosan-coated cellulose filter paper. Cellulose 2016, 23, 3577–3588. [Google Scholar] [CrossRef]

- Kamal, T.; Khan, S.B.; Asiri, A.M. Synthesis of zero-valent Cu nanoparticles in the chitosan coating layer on cellulose microfibers: Evaluation of azo dyes catalytic reduction. Cellulose 2016, 23, 1911–1923. [Google Scholar] [CrossRef]

- Qi, H.; Chang, C.; Zhang, L. Properties and applications of biodegradable transparent and photoluminescent cellulose films prepared via a green process. Green Chem. 2009, 11, 177–184. [Google Scholar] [CrossRef]

- Jin, L.; Li, W.; Xu, Q.; Sun, Q. Amino-functionalized nanocrystalline cellulose as an adsorbent for anionic dyes. Cellulose 2015, 22, 2443–2456. [Google Scholar] [CrossRef]

- Purington, E.; Bousfield, D.W.; Gramlich, W.M. Fluorescent dye adsorption in aqueous suspension to produce tagged cellulose nanofibers for visualization on paper. Cellulose 2019, 26, 5117–5131. [Google Scholar] [CrossRef]

- Patel, S.; Seet, J.; Li, L.; Duhamel, J. Detection of Nitroaromatics by Pyrene-Labeled Starch Nanoparticles. Langmuir 2019, 35, 13145–13156. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Wang, S.; Jin, X.; Huang, C.; Xiang, Z. The Application of Polysaccharides and Their Derivatives in Pigment, Barrier, and Functional Paper Coatings. Polymers 2020, 12, 1837. https://doi.org/10.3390/polym12081837

Li Q, Wang S, Jin X, Huang C, Xiang Z. The Application of Polysaccharides and Their Derivatives in Pigment, Barrier, and Functional Paper Coatings. Polymers. 2020; 12(8):1837. https://doi.org/10.3390/polym12081837

Chicago/Turabian StyleLi, Qianlong, Shanyong Wang, Xuchen Jin, Caoxing Huang, and Zhouyang Xiang. 2020. "The Application of Polysaccharides and Their Derivatives in Pigment, Barrier, and Functional Paper Coatings" Polymers 12, no. 8: 1837. https://doi.org/10.3390/polym12081837

APA StyleLi, Q., Wang, S., Jin, X., Huang, C., & Xiang, Z. (2020). The Application of Polysaccharides and Their Derivatives in Pigment, Barrier, and Functional Paper Coatings. Polymers, 12(8), 1837. https://doi.org/10.3390/polym12081837