A New Hybrid Stepper Motor, Compliant Piezoelectric Micro-Tweezer for Extended Stroke

Abstract

1. Introduction

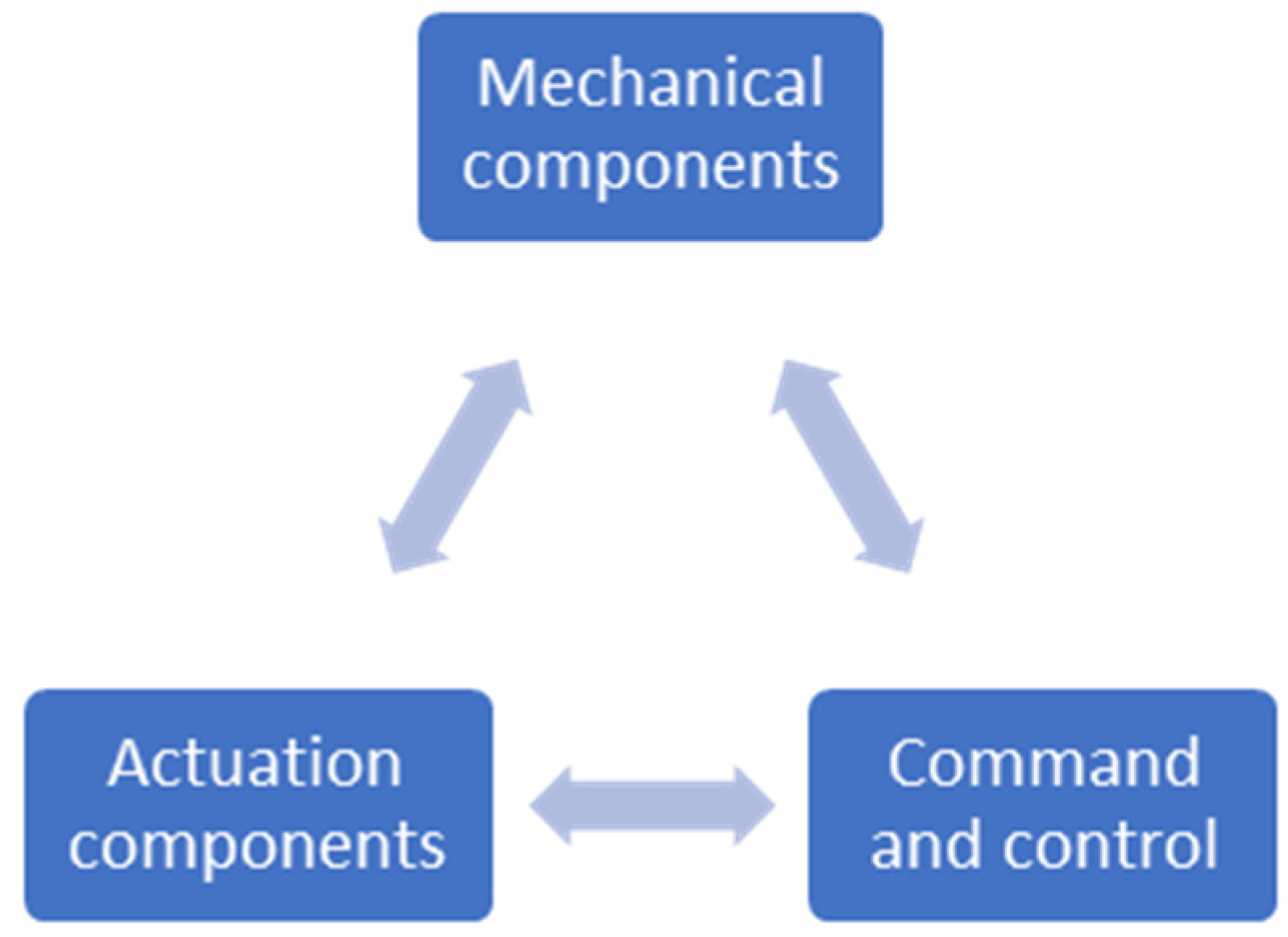

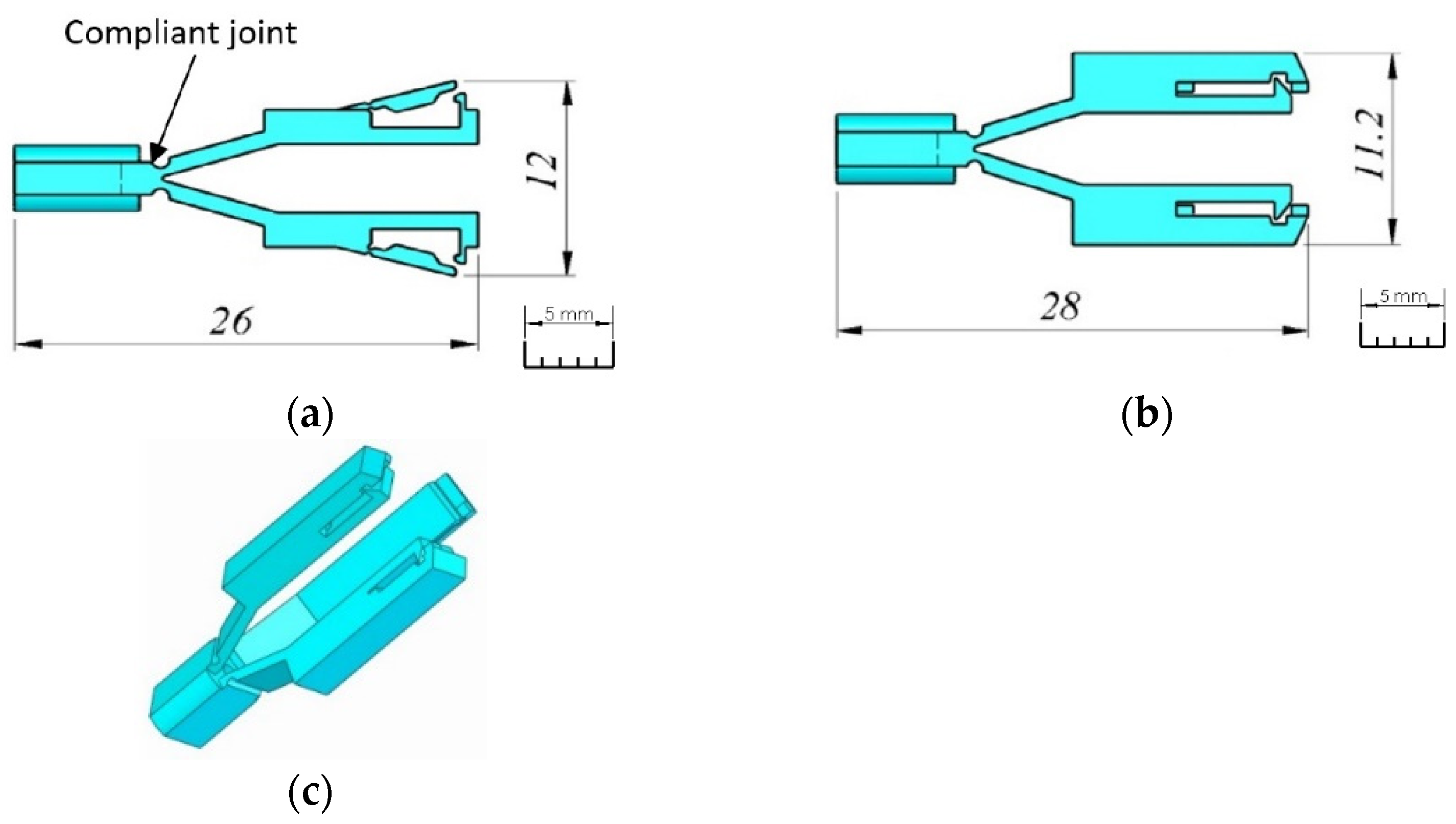

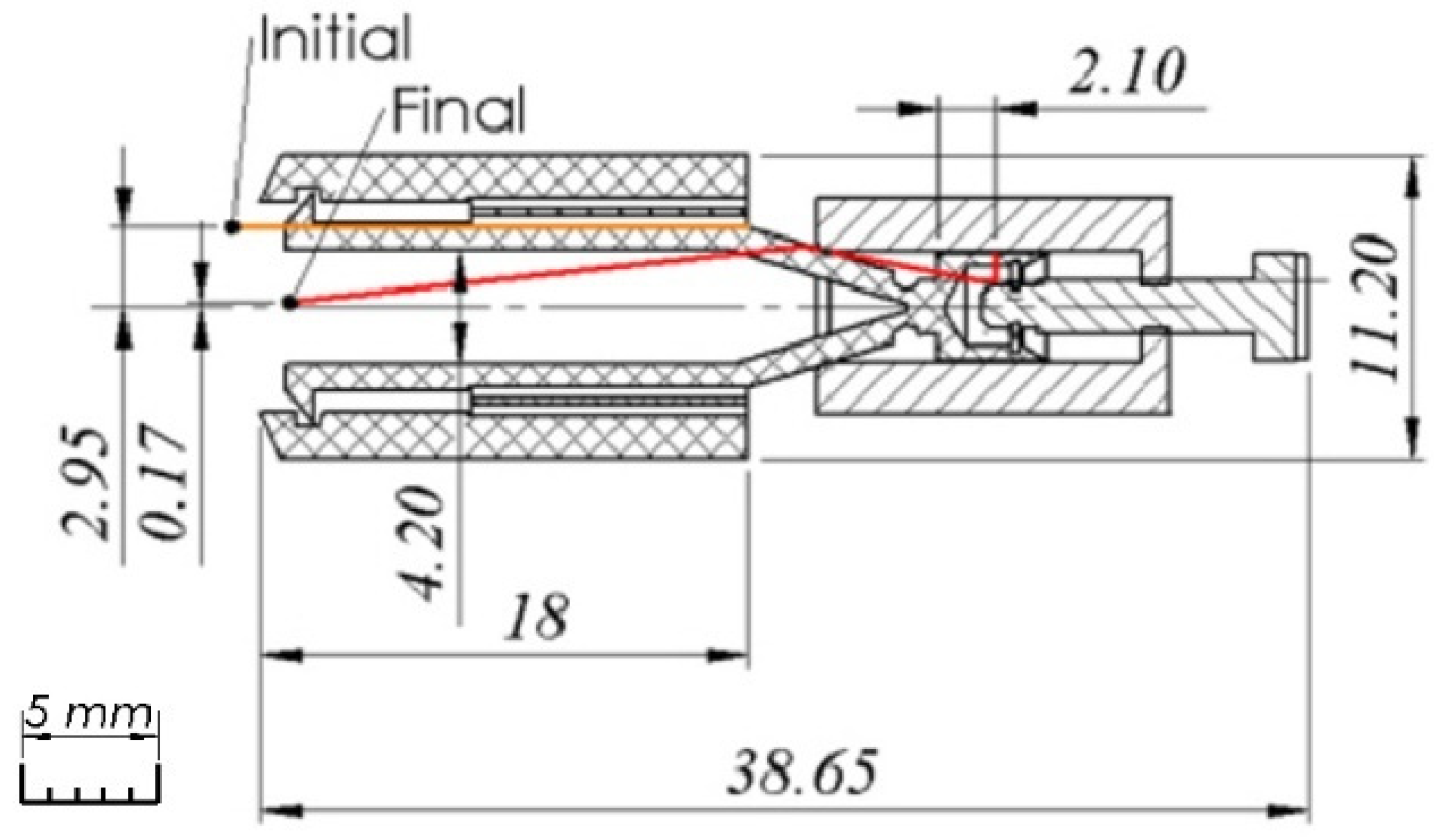

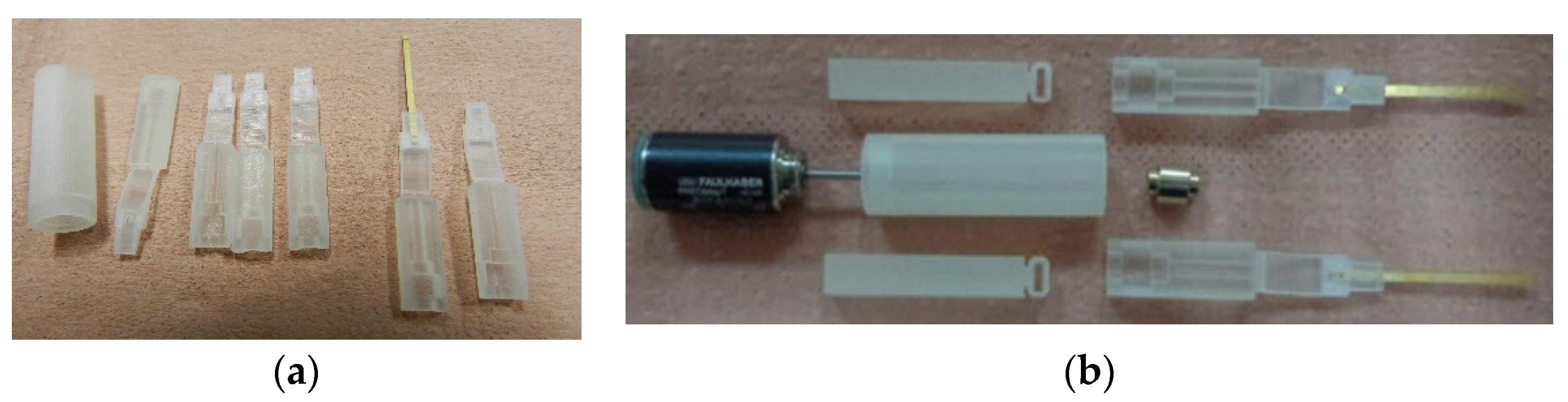

2. Design and Modelling of the Whole System

3. Kinematic Analysis for the Handling System

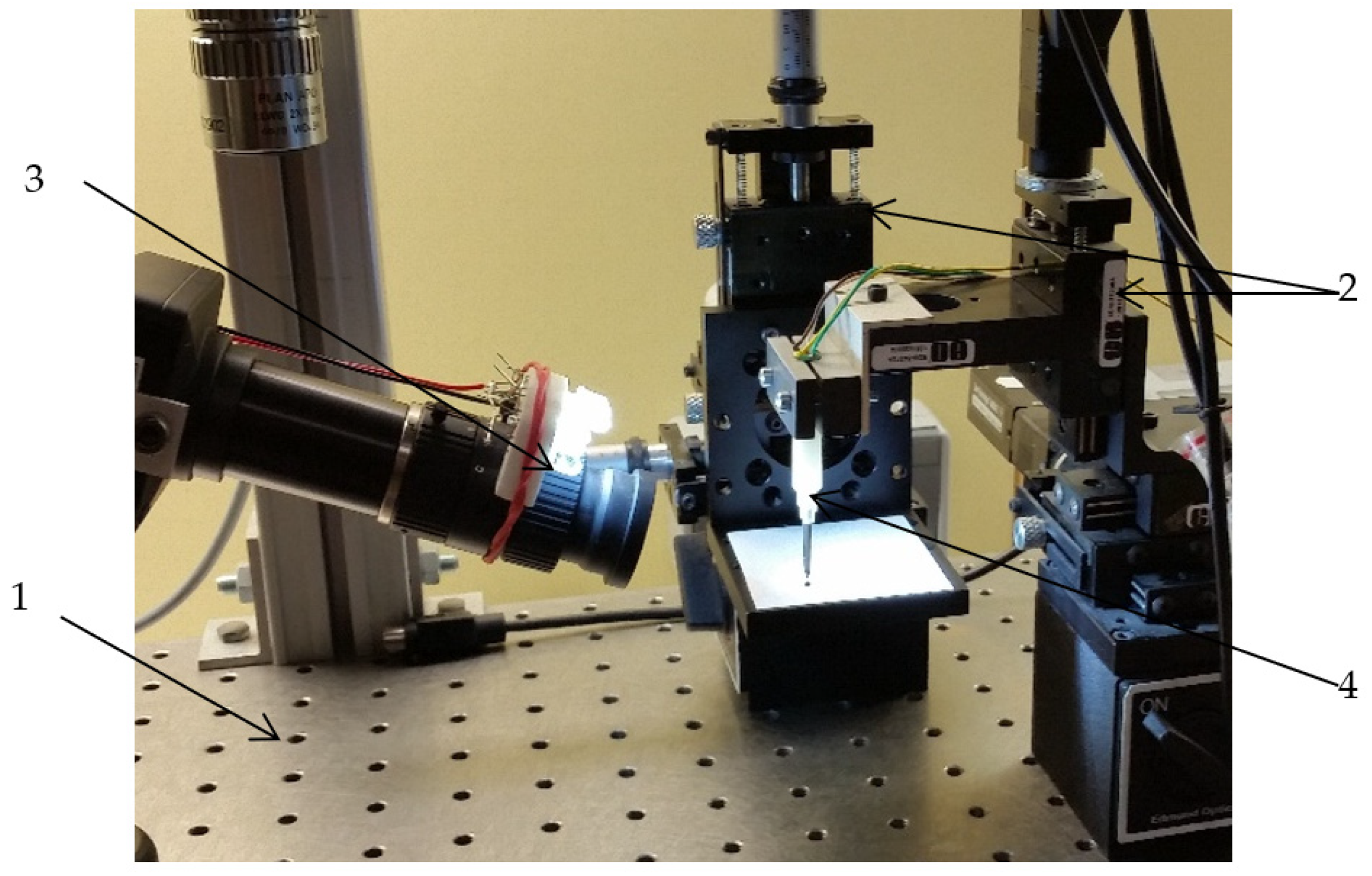

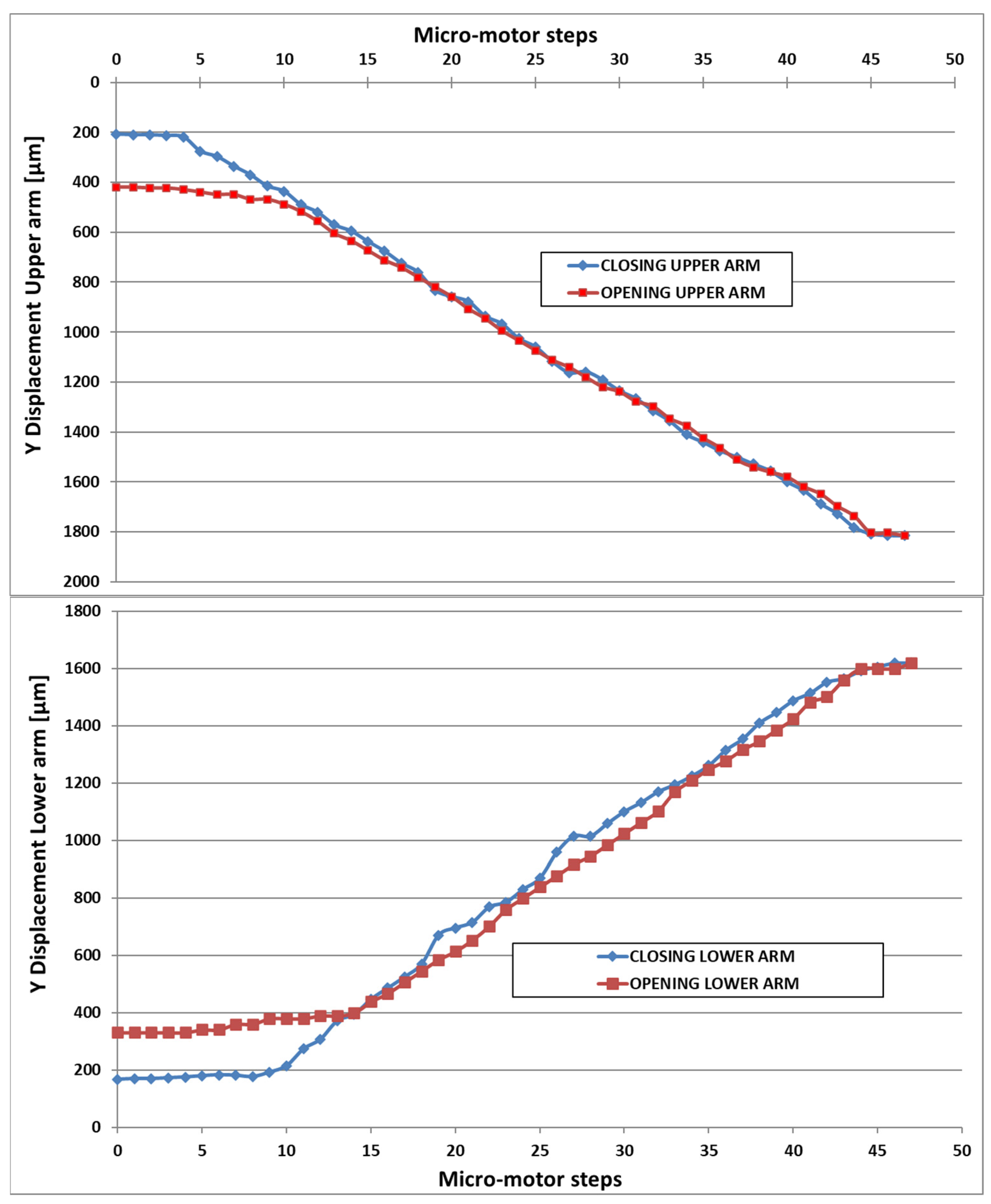

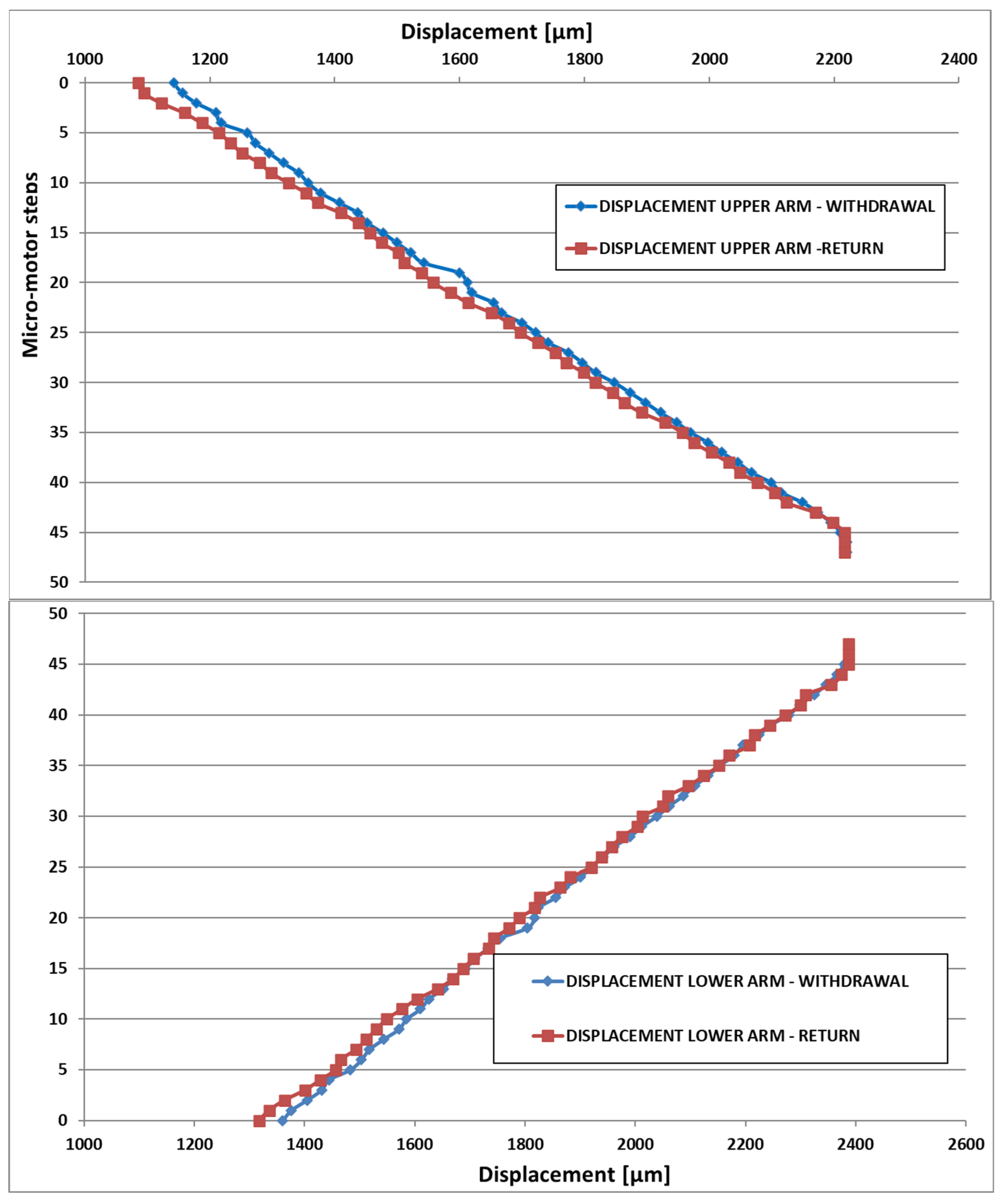

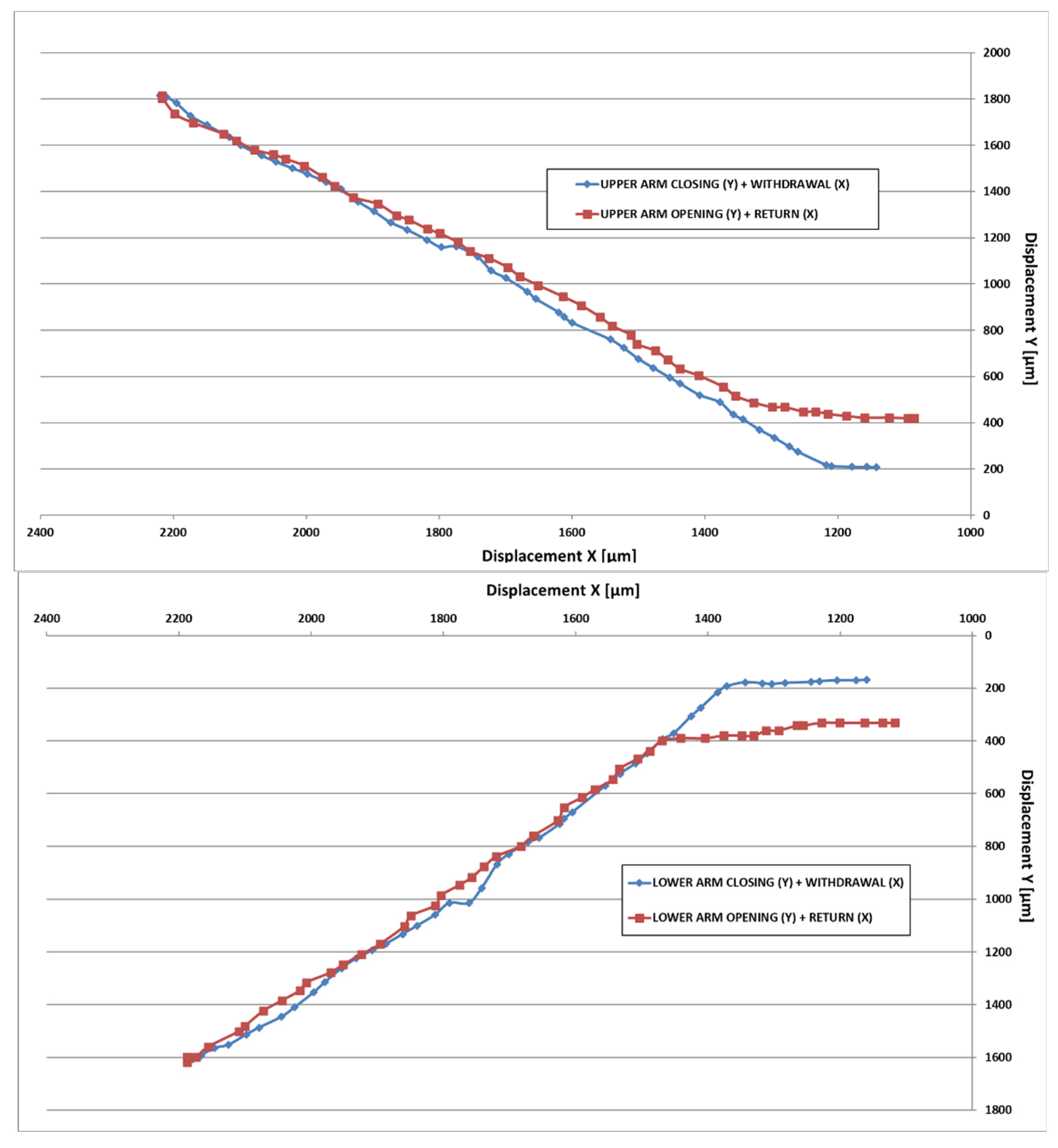

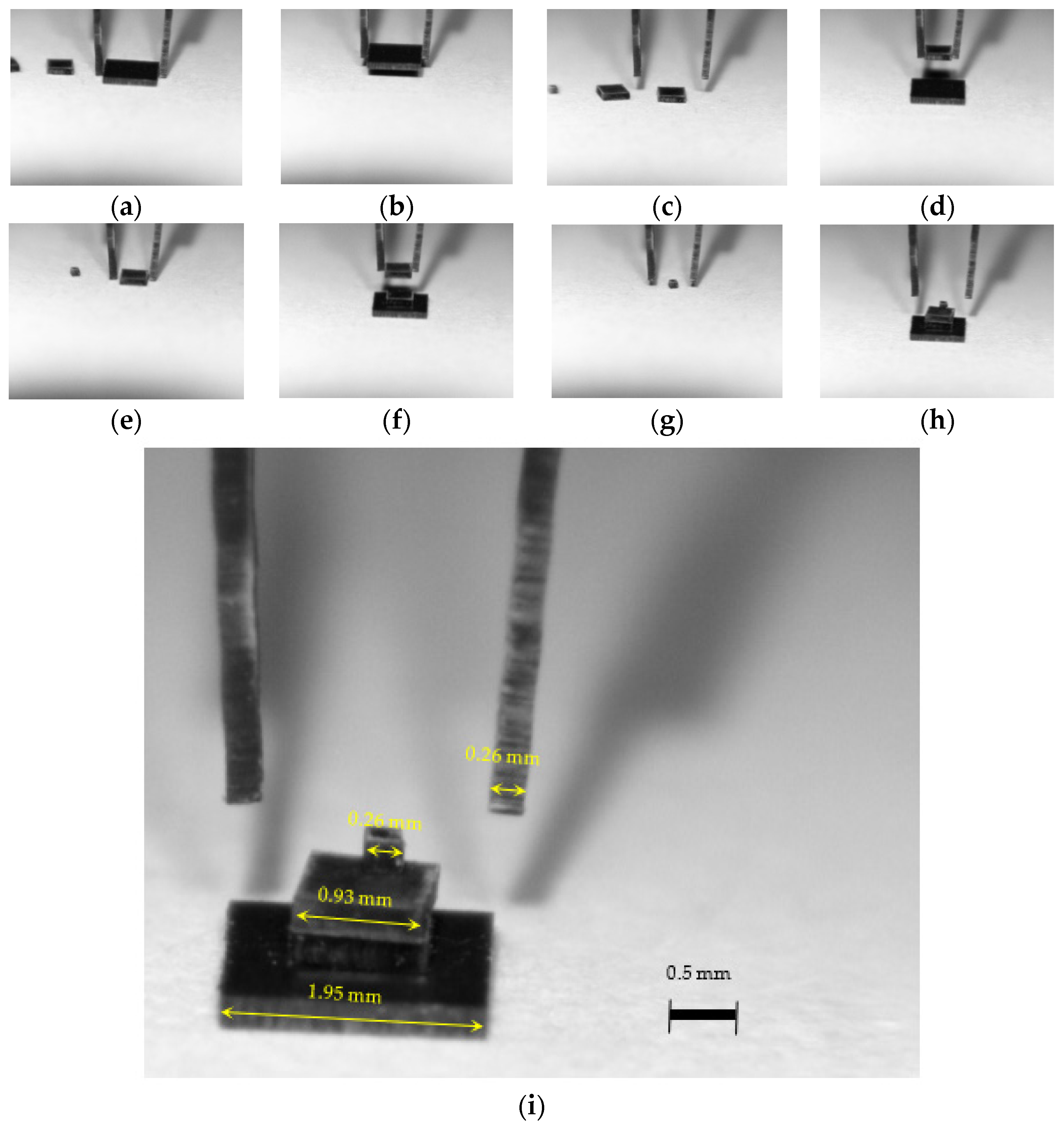

4. Experiments Set-Up, Procedure, and Results

- -

- The anti-vibration table (1) is made of stainless ferromagnetic steel and weighs 30kg. It is specially constructed to attenuate vibrations.

- -

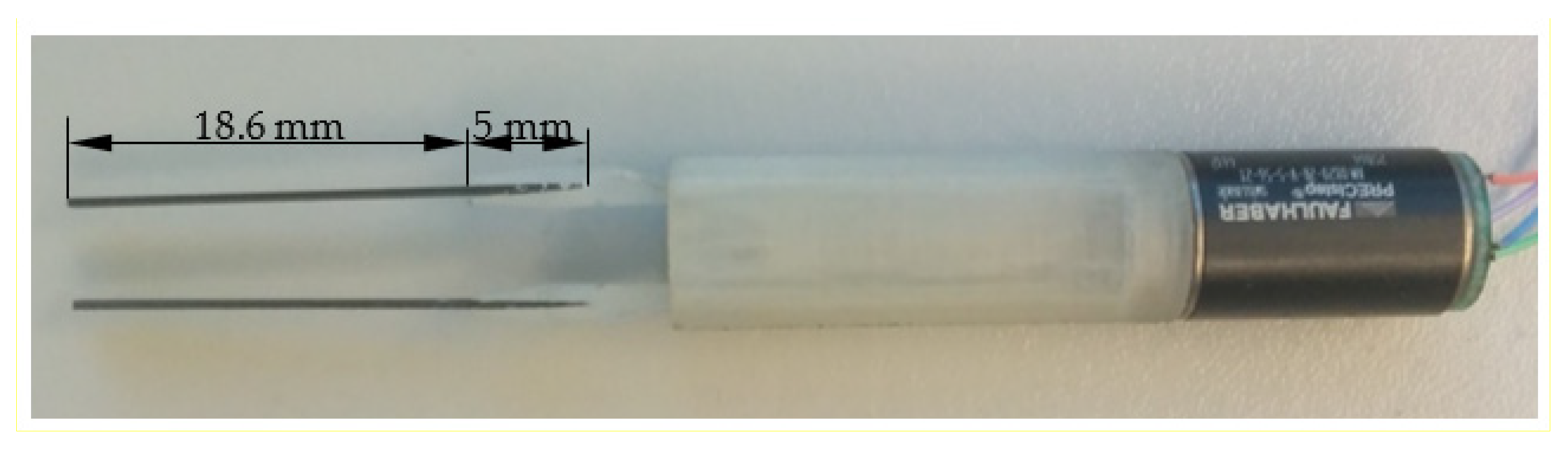

- The automatic micro-positioning system (2) can make displacements with a pitch of 0.047625 μm and a maximum speed of 8 mm/s. It consists of a mini stepper motor, a microcontroller, and a mechanical system that converts rotational movement into translational motion.

- -

- The video microscope (3) was essential for both the realization of the experiments and for obtaining a series of images captured for static processing. It features an optical system that allows viewing details up to 0.8 μm with internal lighting, a CMOS sensor with a size of 8.6 × 6.9 mm, a speed of 25 frames per second, and FireWire.A interface.

- -

- The system with micro-tweezers (4) for micro-objects and biomedical applications.

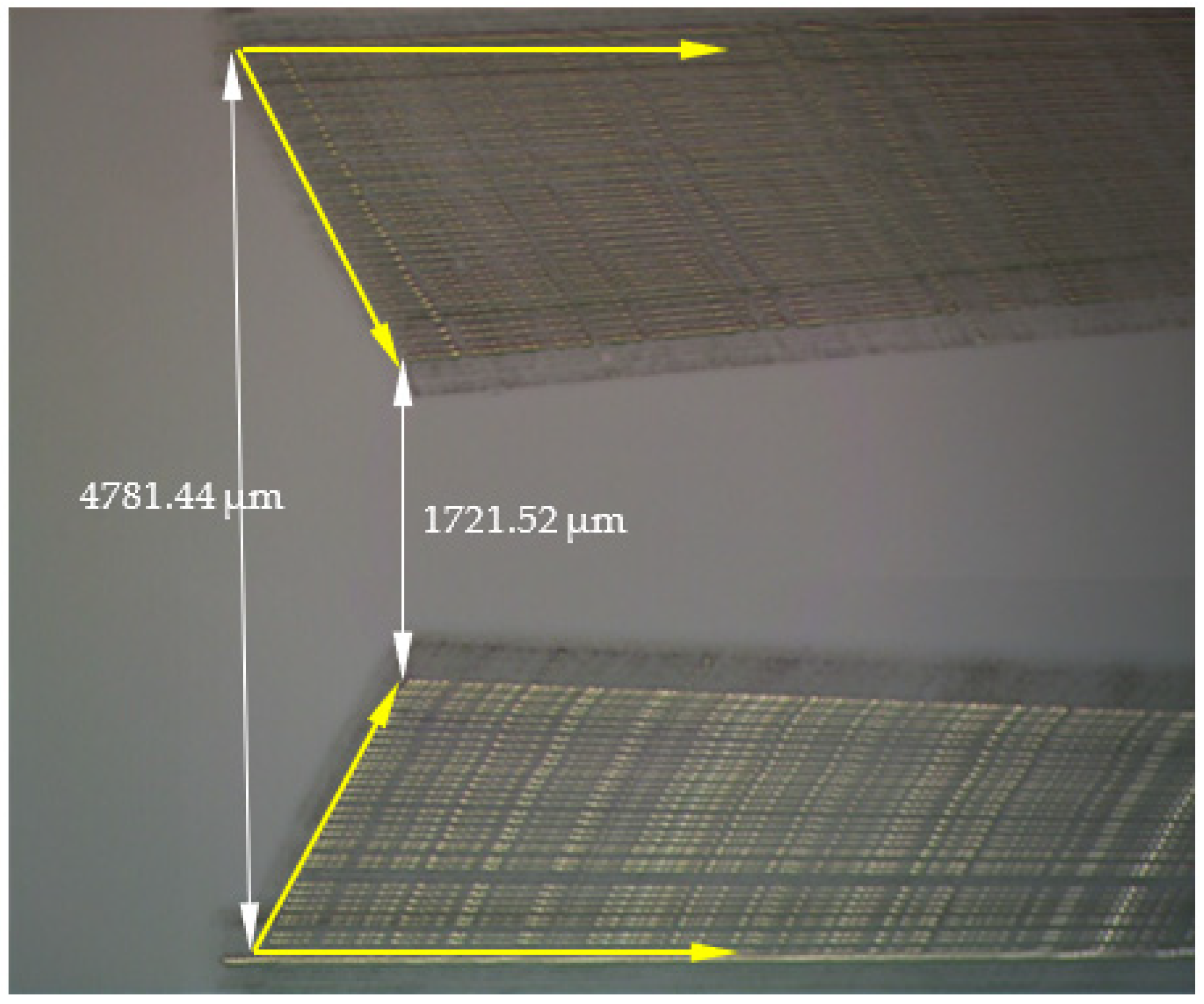

- Piezoceramic plate thickness 191.62 µm

- Electroconductive adhesive thickness ~23.95 µm

- Piezoelectric element thickness 407.19 µm (191.62 × 2 = 383.24 + 23.95 = 407.19)

- Thickness of the end = effector 263.47 µm

5. Conclusions

- Allows for higher accuracy and more precise control over the applied force;

- The design offers greater flexibility when compared to traditional microgripper designs due to the ability to adjust the end-effectors using piezoelectric actuators;

- Extended stroke of up to 2.7 mm with minimal costs and without compromising the pretension resolution;

- High adaptability and versatility to handle a wide range of objects of various shapes and sizes;

- Robust construction for reliable operation in harsh environments;

- Safe and efficient operation, even at small-scale operations.

- -

- The material from which a micromanipulator/microgripper is built is also determined by the different environmental conditions in which it operates, such as air, liquids, biological media, clean rooms, and sterile environments.

- -

- The precise grip of objects of different shapes imposes certain conditions on the tightening forces applied by the mechanical structure, which is provided with terminal elements corresponding to the arms.

- -

- Objects manipulated in non-industrial applications, particularly in biological applications, are extremely fragile, necessitating fine control of the clamping force and a reduced gauge comparable to that of manipulated objects.

- -

- The biocompatibility of materials is an important factor in determining the choice of drive for a microgripper.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rakotondrabe, M. Bouc-Wen modeling and inverse multiplicative structure to compensate hysteresis nonlinearity in piezoelectric actuators. IEEE Trans. Autom. Sci. 2011, 8, 428–431. [Google Scholar] [CrossRef][Green Version]

- Nah, S.K.; Zhong, Z.W. A microgripper using piezoelectric actuation for micro-object manipulation. Sens. Actuator A Phys. 2007, 133, 218–224. [Google Scholar] [CrossRef]

- Noveanu, S.; Noveanu, D. Compliant Mini-Gripper with High Flexibility. Patent Application OSIM RO 00103, 26 February 2020. [Google Scholar]

- Zheng, X.; Chen, X.; Kim, J.-K.; Lee, D.-W. Analysis on microfinger with grooved patterns and its application in electric–thermal microgripper. Int. J. Adv. Manuf. Technol. 2011, 56, 505–513. [Google Scholar] [CrossRef]

- Voicu, R.; Tibeica, C.; Muller, R. Design and simulation study for an electrothermally actuated micromanipulator. In Proceedings of the EuroSimE 2009—10th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, Delft, The Netherlands, 26–29 April 2009; pp. 429–433. [Google Scholar]

- Millet, O.; Bernardoni, P.; Régnier, S.; Bidaud, P.; Tsitsiris, E.; Collard, D.; Buchaillot, L. Electrostatic actuated micro gripper using an amplification mechanism. Sens. Actuator A Phys. 2004, 114, 371–378. [Google Scholar] [CrossRef]

- Varona, J.; Saenz, E.; Fiscal-Woodhouse, S.; Hamoui, A.A. Design and fabrication of a novel microgripper based on electrostatic actuation. In Proceedings of the 52nd IEEE International Midwest Symposium on Circuits and Systems, Cancun, Mexico, 2–5 August 2009; pp. 827–832. [Google Scholar]

- Dong, D.; Lam, W.S.; Sun, D. Electromagnetic Actuation of Microrobots in a Simulated Vascular Structure with a Position Estimator Based Motion Controller. IEEE Robot. Autom. Lett. 2020, 5, 6255–6261. [Google Scholar] [CrossRef]

- Yuan, G.; Yuan, W.; Hao, Y.; Li, X.; Chang, H. A Microgripper with a Post-Assembly Self-Locking Mechanism. Sensors 2015, 15, 20140–20151. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Calin, M.; Chaillet, N.; Agnus, J.; Bourjault, A.; Bertsch, A.; Zissi, S.; Thiery, L. Shape Memory Alloy Compliant Microrobots. In Proceedings of the 9th IFAC Symposium on Information Control in Manufacturing 1998 (INCOM’98), Nancy, France, 24–26 June 1998; Volume 31, pp. 241–248. [Google Scholar] [CrossRef]

- Kim, B.; Lee, M.G.; Lee, Y.P.; Kim, Y.I.; Lee, G.H. An earthworm-like micro robot using shape memory alloy actuator. Sens. Actuator A Phys. 2006, 125, 429–437. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Q. Survey on Recent Designs of Compliant Micro-/Nano-Positioning Stages. Actuators 2018, 7, 5. [Google Scholar] [CrossRef][Green Version]

- Lobontiu, N. Compliant Mechanisms: Design of Flexure Hinges; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Lobontiu, N.; Cullin, M.; Petersen, T.; Alcazar, J.A.; Noveanu, S. Planar Compliances of Symmetric Notch Flexure Hinges: The Right Circularly Corner-Filleted Parabolic Design. IEEE Trans. Autom. Sci. Eng. 2014, 11, 169–176. [Google Scholar] [CrossRef]

- Lobontiu, N.; Garcia, E. Mechanics of Microelectromechanical Systems; Springer: New York, NY, USA, 2005. [Google Scholar]

- Gusev, E.; Garfunkel, E.; Dideikin, A. Advanced Materials and Technologies for Micro/Nano-Devices, Sensors and Actuators; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Matsuzaki, Y.; Inoue, K.; Suwoong, L. Manipulation of Micro-Scale Objects Using Micro Hand with Two Rotational Fingers. In Proceedings of the 2009 International Symposium on Micro-NanoMechatronics and Human Science, Nagoya, Japan, 9–11 November 2009; pp. 438–443. [Google Scholar] [CrossRef]

- Jain, R.K.; Datta, S.; Majumder, S.; Dutta, A. Two IPMC Fingers Based Micro Gripper for Handling. Int. J. Adv. Robot 2011, 8, 13. [Google Scholar] [CrossRef][Green Version]

- Dafflon, M.; Lorent, B.; Clavel, R. A micromanipulation setup for comparative tests of microgrippers. In Proceedings of the International Symposium on Robotics, Münich, Germany, 15–17 May 2006; pp. 141–142. [Google Scholar]

- Cecchi, R.; Verotti, M.; Capata, R.; Dochshanov, A.; Broggiato, G.B.; Crescenzi, R.; Balucani, M.; Natali, S.; Razzano, G.; Lucchese, F.; et al. Development of Micro-Grippers for Tissue and Cell Manipulation with Direct Morphological Comparison. Micromachines 2015, 6, 1710–1728. [Google Scholar] [CrossRef][Green Version]

- Noveanu, D.; Noveanu, S.; Ivan, I.A. Influence of the Flexure Hinge Shape on Compliant Gripper Small Displacements. Rom. J. Tech. Sci. Appl. Mech. 2022, 67, 97–111. [Google Scholar]

- Ciubotariu, D.A.; Ivan, I.A.; Clévy, C.; Lutz, P. Piezoelectric 3D actuator for micro-manipulation based on [011]-poled PMN-PT single crystal. Sens. Actuators 2016, 252, 242–252. [Google Scholar] [CrossRef]

- Alogla, A.; Scanlan, P.; Shu, W.; Reuben, R.L. A Scalable Syringe-Actuated Microgripper for Biological Manipulation. In Proceedings of the Eurosensors XXVI, Kraków, Poland, 9–12 September 2012; pp. 882–885. [Google Scholar]

- Noveanu, S.; Ivan, I.A.; Noveanu, D.C.; Rusu, C.; Lates, D. SiMFlex Micromanipulation Cell with Modular Structure. Appl. Sci. 2020, 10, 2861. [Google Scholar] [CrossRef][Green Version]

- Rakotondrabe, M.; Ivan, I.A. Development and Force/Position Control of a New Hybrid Thermo-Piezoelectric MicroGripper Dedicated to Micromanipulation Tasks. IEEE Trans. Autom. Sci. Eng. 2011, 8, 824–834. [Google Scholar] [CrossRef][Green Version]

- Lates, D.; Noveanu, S.; Csibi, V. Design and Application of Compliant Mini-Grippers for Handling Chemicals. Arch. Mech. Eng. 2015, 62, 205–216. [Google Scholar] [CrossRef]

- Gurgu, I.V.; Ionita, M.G.; Vasile, I.; Coltuc, D.; Ivan, I.A.; Andrei, H. Simulation method and measurement system of electromagnetic force used in micromanipulation systems. In Proceedings of the 9th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Targoviste, Romania, 29 June–1 July 2017. [Google Scholar] [CrossRef]

- Rakotondrabe, M.; Ivan, I.A.; Khadraoui, S.; Lutz, P.; Chaillet, N. Simultaneous Displacement/Force Self-Sensing in Piezoelectric Actuators and Applications to Robust Control. IEEE ASME Trans. Mechatron. 2015, 20, 519–531. [Google Scholar] [CrossRef][Green Version]

- Ivan, I.A.; Agnus, J.; Rakotondrabe, M.; Lutz, P.; Chaillet, N. Microfabricated PMN-PT on silicon cantilevers with improved static and dynamic piezoelectric actuation: Development, characterization and control. In Proceedings of the 2011 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Budapest, Hungary, 3–7 July 2011; pp. 403–408. [Google Scholar] [CrossRef]

- Lyu, Z.; Xu, Q. Design and Testing of a New Piezoelectric-Actuated Symmetric Compliant Microgripper. Actuators 2022, 11, 77. [Google Scholar] [CrossRef]

- Liu, X.; Su, Y. Micro and Nano Systems for Biophysical Studies of Cells and Small Organisms; Academic Press: London, UK, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivan, I.A.; Noveanu, D.C.; Gurgu, V.I.; Despa, V.; Noveanu, S. A New Hybrid Stepper Motor, Compliant Piezoelectric Micro-Tweezer for Extended Stroke. Micromachines 2023, 14, 1112. https://doi.org/10.3390/mi14061112

Ivan IA, Noveanu DC, Gurgu VI, Despa V, Noveanu S. A New Hybrid Stepper Motor, Compliant Piezoelectric Micro-Tweezer for Extended Stroke. Micromachines. 2023; 14(6):1112. https://doi.org/10.3390/mi14061112

Chicago/Turabian StyleIvan, Ioan Alexandru, Dan Cristian Noveanu, Valentin Ion Gurgu, Veronica Despa, and Simona Noveanu. 2023. "A New Hybrid Stepper Motor, Compliant Piezoelectric Micro-Tweezer for Extended Stroke" Micromachines 14, no. 6: 1112. https://doi.org/10.3390/mi14061112

APA StyleIvan, I. A., Noveanu, D. C., Gurgu, V. I., Despa, V., & Noveanu, S. (2023). A New Hybrid Stepper Motor, Compliant Piezoelectric Micro-Tweezer for Extended Stroke. Micromachines, 14(6), 1112. https://doi.org/10.3390/mi14061112