Constitutive Analysis of the Deformation Behavior of Al-Mg-Si Alloy Under Various Forming Conditions Using Several Modeling Approaches

Highlights

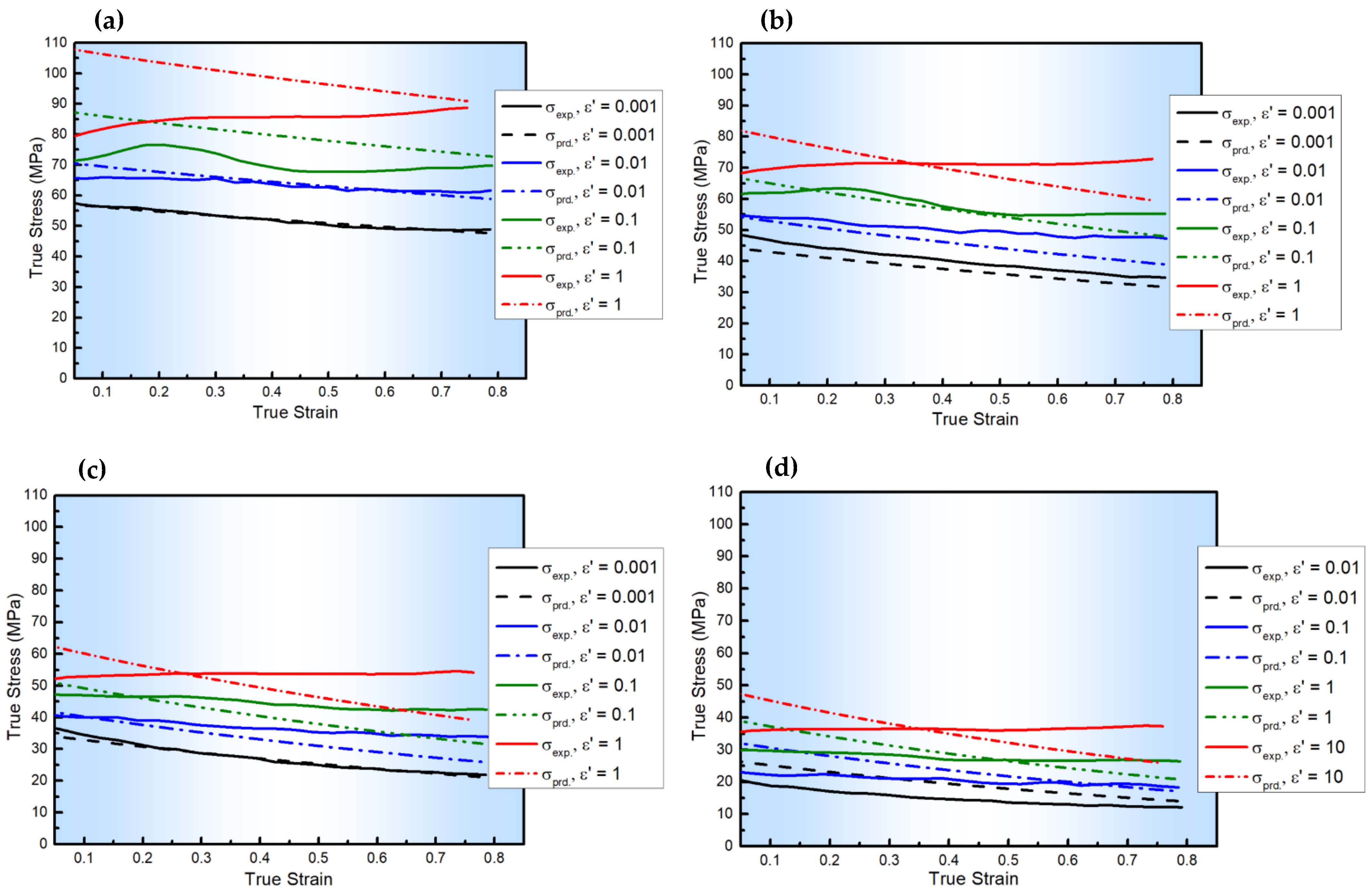

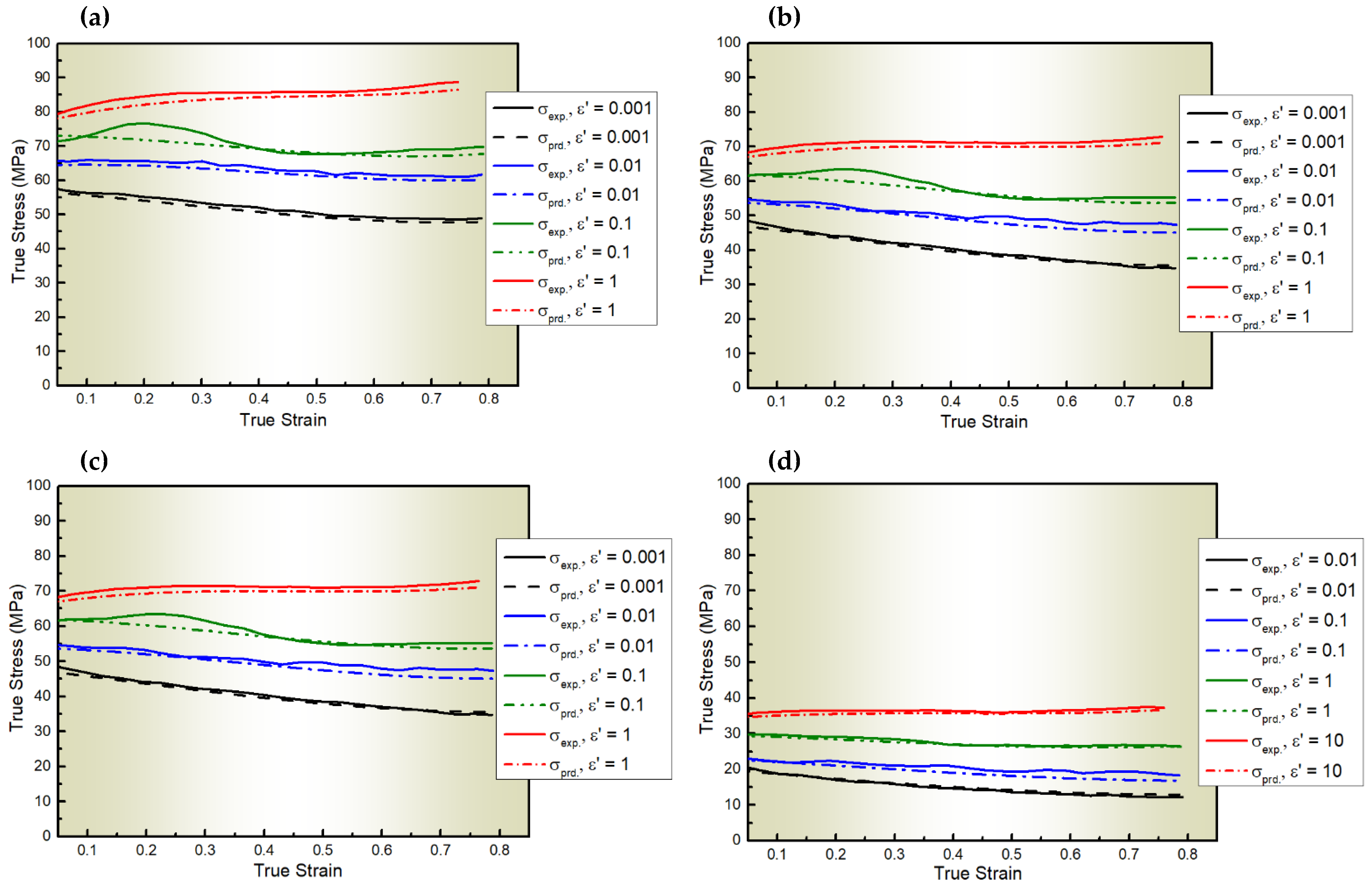

- Several Constitutive models (CP, MZA, S1-MJC, S2-MJC) are proposed to predict the hot flow behavior of Al-Mg-Si alloy.

- Advanced mathematical techniques are used to determine their material parameters.

- The CP model achieves superior predictions by connecting Al-Mg-Si microstructure and mechanical behavior.

- The S2-MJC model accurately predicts Al-Mg-Si flow behavior by linking softening and dynamic recovery.

Abstract

1. Introduction

2. Experimental Section

3. Physically Based Models

3.1. CP Modeling

3.2. Modified ZA (MZA) Constitutive Model

4. Phenomenological Models

4.1. Shokry’s MJC-1 (S1-MJC)

4.2. Shokry’s MJC-2 (S2-MJC)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Abbreviations |

| Temperature | |

| Strain rate | |

| Deformation gradient | |

| Elastic component of deformation gradient | |

| Plastic component of deformation gradient | |

| Velocity gradient tensor | |

| Elastic component of velocity gradient tensor | |

| Plastic component of velocity gradient tensor | |

| locally stress-free intermediate configuration | |

| shearing rate on the α-slip system | |

| potential slip system’s number | |

| Schmid tensor , and are orthogonal to each other | |

| Slip plane direction | |

| Slip plane normal | |

| Slipping direction | |

| Equivalent slip plane normal | |

| The second Paola-Kirchhoff stress tensor | |

| Cauchy stress tensor | |

| The elastic Green-Lagrange strain tensor | |

| The elastic right Cauchy-Green deformation tensor | |

| Identity tensor | |

| The absolute temperature (K) | |

| The resolved shear stress tensor | |

| The magnitude of the Burgers vector | |

| The mobile dislocations density on the slip system. | |

| The average velocity of mobile dislocations on the slip system. | |

| The average dislocation velocity | |

| The average distance between each obstacle on the slip plane. | |

| The waiting time for a dislocation to surpass the local obstacles. | |

| The Debye frequency | |

| The Boltzmann constant | |

| The difference in the activation-free enthalpy when the dislocation segment moves from the stable configuration to the unstable configuration | |

| The reference slip rate | |

| The fraction of the shearing rate by the total dislocation | |

| The mean free path | |

| The critical annihilation distance for canceling out the two dislocations with opposite polarities | |

| The total dislocation density | |

| Edge dislocation component | |

| Screw dislocation component | |

| The dislocation density evaluation, where: | |

| The reference critical annihilation distance | |

| Constant = 0.001 | |

| Constant = 8.617E-5 | |

| The total athermal slip resistance parameters | |

| b | The Burgers vector’s magnitude |

| The shear modulus, | |

| λ | For identifying the deviations from the regular spatial arrangements of dislocation density |

| The matrix of dislocation interaction | |

| The Kronecker delta | |

| , | The interaction coefficients |

| correlation coefficient | |

| average absolute relative error | |

| root mean square error | |

| The total number of points included in the analysis | |

| The experimental stress values | |

| The predicted stress values | |

| The mean values of experimental stress | |

| The mean values of predicted stress | |

| The athermal activation flow stress | |

| The thermal activation flow stress. | |

| Body-centered cubic | |

| face-centered cubic | |

| , , , , | material constants |

| The testing temperature | |

| Von-Mises flow stress | |

| equivalent plastic strain | |

| reference strain rates | |

| the ratio between the testing and () | |

| Reference temperatures | |

| The difference between testing and ( | |

| , | material constants |

| The melting temperature of AA6082 Al-Mg-Si | |

| constants correlate with the | |

| representing the strain-hardening component | |

| constants associate with the | |

| constants related to the softening parameter |

References

- Abd El-Aty, A.; Xu, Y.; Guo, X.; Zhang, S.; Ma, Y.; Chen, D. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Sun, Y. The use of aluminum alloys in structures: Review and outlook. Structures 2023, 57, 105290. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2022, 12, 9. [Google Scholar] [CrossRef]

- Emadi, P.; Andilab, B.; Ravindran, C. Engineering Lightweight Aluminum and Magnesium Alloys for a Sustainable Future. J. Indian Inst. Sci. 2022, 102, 405–420. [Google Scholar] [CrossRef]

- Hou, Y.; Myung, D.; Park, J.K.; Min, J.; Lee, H.-R.; El-Aty, A.A.; Lee, M.-G. A Review of Characterization and Modelling Approaches for Sheet Metal Forming of Lightweight Metallic Materials. Materials 2023, 16, 836. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Khorshidi, M.; Mohammadzadeh, R.; Khajeh, R.; Mofarrehi, M.; Javidani, M.; Chen, X.G. Multipass friction stir processing of laser-powder bed fusion AlSi10Mg: Microstructure and mechanical properties. Materials 2023, 16, 1559. [Google Scholar] [CrossRef]

- Xia, L.; Zhang, S.-H.; Xu, Y.; Chen, S.; El-Aty, A.A.; Pokrovsky, A.I.; Bakinovskaya, A.A. Study of the ductility enhancement of 5A90 Al–Mg–Li alloy sheets with stress relaxation. Philos. Mag. 2021, 101, 2449–2472. [Google Scholar] [CrossRef]

- Cao, L.; Liao, B.; Wu, X.; Li, C.; Huang, G.; Cheng, N. Hot Deformation Behavior and Microstructure Characterization of an Al-Cu-Li-Mg-Ag Alloy. Crystals 2020, 10, 416. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex-shaped aluminium panel components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Hu, M.; Sun, Y.; He, J.; Li, C.; Li, H.; Yu, L.; Liu, Y. Hot deformation behaviour and microstructure evolution of Al-3%Mg2Si alloy. Mater. Charact. 2022, 183, 111623. [Google Scholar] [CrossRef]

- Liang, H.; Nan, Y.; Ning, Y.; Li, H.; Zhang, L.; Shi, Z.; Guo, H. Correlation between strain-rate sensitivity and dynamic softening behavior during hot processing. J. Alloys Compd. 2013, 632, 478–485. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.T.; Xia, Y.C.; Jiang, Y.Q. Hot deformation and processing map of a typical Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2013, 550, 438–445. [Google Scholar] [CrossRef]

- Liang, Z.; Zhang, Q.; Niu, L.; Luo, W. Hot deformation behavior and processing maps of as-cast hypoeutectic Al-Si-Mg alloy. J. Mater. Eng. Perform. 2019, 28, 4871–4881. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, L.; Xiao, Z.; Wang, S. Hot deformation behavior of 6063 aluminum alloy studied using processing maps and microstructural analysis. Phys. Met. Metallogr. 2019, 120, 1115–1125. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Zhang, S.-H.; Ha, S.; Ma, Y.; Chen, D. Impact of high strain rate deformation on the mechanical behavior, fracture mechanisms, and anisotropic response of 2060 Al-Cu-Li alloy. J. Adv. Res. 2019, 18, 19–37. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Tang, H.; Liu, T.; Li, Z.; Jiang, H.; Wang, K.; Ebrahimi, M.; Ding, W. Hot deformation constitutive model and processing maps of homogenized Al–5Mg–3Zn–1Cu alloy. J. Mater. Res. Technol. 2021, 14, 324–339. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Ebrahimi, M.; Li, D.; Tang, H.; Zhang, N.; Cai, H. Hot Deformation Behavior and Processing Maps of an As-Cast Al-5Mg-3Zn-1Cu (wt%) Alloy. Materials 2023, 16, 4093. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Gao, K.Y.; Wu, X.L.; Wang, W.; Nie, Z.R. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy. J. Alloys Compd. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Wei, T.; Wang, Y.; Tang, Z.; Xiao, S. The constitutive modeling and processing map of homogenized Al-Mg-Si-Cu-Zn alloy. Mater. Today Commun. 2021, 27, 102471. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mohammadzadeh, R.; Jafarian, H.R.; Pruncu, C.I.; Simar, A. Role of geometrically necessary dislocations on mechanical properties of friction stir welded single-phase copper with medium stacking fault energy. J. Mater. Res. Technol. 2022, 16, 194–200. [Google Scholar] [CrossRef]

- Liu, S.; Pan, Q.; Li, H.; Huang, Z.; Li, K.; He, X.; Li, X. Characterization of hot deformation behavior and constitutive modeling of Al–Mg–Si–Mn–Cr alloy. J. Mater. Sci. 2019, 54, 4366–4383. [Google Scholar] [CrossRef]

- Abedrabbo, N.; Pourboghrat, F.; Carsley, J. Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int. J. Plast. 2007, 23, 841–875. [Google Scholar] [CrossRef]

- Clayton, D. Dynamic plasticity and fracture in high density polycrystals: Constitutive modeling and numerical simulation. J. Mech. Phys. Solids 2005, 53, 261–301. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Ou, L.; Zheng, Z.; Nie, Y.; Jian, H. Hot deformation behavior of 2060 alloy. J. Alloys Compd. 2015, 648, 681–689. [Google Scholar] [CrossRef]

- Yaich, M.; Gavrus, A. New phenomenological material constitutive models for the description of the Ti6Al4V titanium alloy behavior under static and dynamic loadings. Proc. Manuf. 2020, 47, 1496–1503. [Google Scholar] [CrossRef]

- Ma, L.; Wan, M.; Li, W.; Shao, J.; Bai, X.; Zhang, J. Superplastic deformation mechanical behavior and constitutive modelling of a near-a titanium alloy TNW700 sheet. Mater. Sci. Eng. A 2021, 817, 141419. [Google Scholar] [CrossRef]

- Shrot, A.; Beaker, M. Determination of Johnson-Cook parameters from machining simulations. Comput. Mater. Sci. 2012, 52, 298–304. [Google Scholar] [CrossRef]

- Qiao, L.; Zhu, J. Constitutive modeling of hot deformation behavior of AlCrFeNi multi-component alloy. Vacuum 2022, 201, 111059. [Google Scholar] [CrossRef]

- Wang, H.; Qin, G.; Li, C. A modified Arrhenius constitutive model of 2219-O aluminum alloy based on hot compression with simulation verification. J. Mater. Res. Technol. 2022, 19, 3302–3320. [Google Scholar] [CrossRef]

- Jia, W.; Xu, S.; Le, Q.; Fu, L.; Ma, L.; Tang, Y. Modified Fields- Backofen model for constitutive behavior of as-cast AZ31B magnesium alloy during hot deformation. Mater. Des. 2016, 106, 120–132. [Google Scholar] [CrossRef]

- Shen, J.; Hu, L.; Sun, Y.; Wan, Z.; Feng, X.; Ning, Y. A comparative study on artificial neural network, phenomenological-based constitutive and modified fields-backofen models to predict flow stress in Ti-4Al-3V-2Mo-2Fe alloy. J. Mater. Eng. Perform. 2019, 28, 4302.e15. [Google Scholar] [CrossRef]

- Seshacharyulu, K.; Mahalle, G.; Kotkunde, N.; Singh, S.K.; Balu Naik, B. High temperatures deformation and formability behavior of DP590 steel: Mechanical characterization and modeling. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–23. [Google Scholar] [CrossRef]

- Mahalle, G.; Salunke, O.; Kotkunde, N.; Kumar Gupta, A.; Singh, S.K. Study of Khan-Huang-liang (KHL) anisotropic deformation model for deep drawing behaviour of inconel 718 alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 967, 12054. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data formetals subjected to large strains, high strain rates and hightemperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of Steel Flow Stresses at High Temperatures and Strain Rates. Metall. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Zheng, X.; Luo, A.A.; Dong, J.; Sachdev, A.K.; Ding, W. Plastic flow behavior of a high-strength magnesium alloy NZ30K. Mater. Sci. Eng. A 2012, 532, 616–622. [Google Scholar] [CrossRef]

- Meng, Q.; Bai, C.; Xu, D. Flow behavior and processing map for hot deformation of ATI425 titanium alloy. J. Mater. Sci. Technol. 2018, 34, 679–688. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.; Liu, G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6989. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Shi, H.M.; McLaren, A.J.; Sellars, C.M.; Shahani, R.; Bolingbroke, R. Constitutive equations for high temperature flow stress of aluminium alloys. Mater. Sci. Technol. 1997, 13, 210–216. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K.; Venugopal, S.; Sivaprasad, P.V. Analysis and mathematical modelling of elevated temperature flow behaviour of austenitic stainless steels. Mater. Sci. Eng. A 2011, 528, 1937–1943. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Borah, U.; Bhaduri, A.K.; Sivaprasad, P.V. A thermo-viscoplastic constitutive model to predict elevated-temperature flow behaviour in a titanium-modified austenitic stainless steel. Mater. Sci. Eng. A 2009, 526, 1–6. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. Constitutive analysis to predict high-temperature flow stress in modified 9Cre1Mo (P91) steel. Mater. Des. 2010, 31, 981–984. [Google Scholar] [CrossRef]

- Kumar, S.; Karmakar, A.; Nath, S.K. Construction of hot deformation processing maps for 9Cr-1Mo steel through conventional and ANN approach. Mater. Today Commun. 2021, 26, 101903. [Google Scholar] [CrossRef]

- Cheng, C.; Ji, Y.; Guo, X.; El-Aty, A.A. Coupling theoretical analysis and FE framework for revealing the size effect on the deformation characteristics of 304 stainless steel microtubes manufactured via free-bending forming technology. CIRP J. Manuf. Sci. Technol. 2024, 55, 1–15. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; El-Aty, A.A.; Tao, J.; Guo, X.; Ji, Y. Multiscale framework-based crystal plasticity modeling and texture evolution of the deformation behavior of AISI 304 stainless steel microtubes manufactured through 3D-FBF technology. Sustain. Mater. Technol. 2024, 42, e01125. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; EI-Aty, A.A.; Tao, J.; Guo, X.; Ji, Y. Integrating crystal plasticity and experimentation for investigating the size effect on the deformation characteristics of AISI304 microtubes manufactured by free bending technology. Manuf. Lett. 2024, 42, 21–25. [Google Scholar] [CrossRef]

- Shokry, A.; Ståhle, P. A methodology for using Kalman filter to determine material parameters from uncertain measurements. Mater. Discov. 2016, 2, 1–15. [Google Scholar] [CrossRef]

- Shokry, A.; Gowid, S.; Youssef, S.S. Modeling the flow behavior of Haynes 214 superalloy during hot deformation using mathematical and artificial intelligence-based models. Mater. Today Commun. 2022, 33, 104326. [Google Scholar] [CrossRef]

- Ghosh, A.; Ali, E.; Parson, N.; Chen, X.-G. Hot deformation behavior and processing maps for an Al-Mg-Si-Zr-Mn alloy. J. Alloys Metall. Syst. 2004, 6, 100077. [Google Scholar] [CrossRef]

- Li, T.; Lu, Y.; Li, Z.; Wang, T.; Li, T. Hot deformation behavior and microstructure evolution of non-equimolar Ti2ZrHfV0.5Ta0.2 refractory high-entropy alloy. Intermetallics 2022, 146, 107586. [Google Scholar] [CrossRef]

- Li, X.; Le, Q.; Li, D.; Wang, P.; Jin, P.; Cheng, C.; Cheng, X.; Ren, L. Hot tensile deformation behavior of extruded LAZ532 alloy with heterostructure. Mater. Sci. Eng. A 2021, 801, 140412. [Google Scholar] [CrossRef]

- Che, B.; Lu, L.; Kang, W.; Luo, J.; Ma, M.; Liu, L. Hot deformation behavior and processing map of a new type Mg-6Zn-1Gd-1Er alloy. J. Alloys Compd. 2021, 862, 158700. [Google Scholar] [CrossRef]

- Cheong, K.S.; Busso, E.P. Discrete dislocation density modelling of single phase F.C.C. polycrystal aggregates. Acta Mater. 2004, 52, 5665–5675. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of non-uniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Essman, U.; Mughrabi, H. Annihilation of dislocations during tensile and cyclic deformation and limits of dislocation densities. Philos. Mag. A 1979, 40, 731–756. [Google Scholar] [CrossRef]

- Nix, W.; Gibeling, J.; Hughes, D. Time-dependent deformation of metals. Metall. Trans. A 1985, 16, 2215–2226. [Google Scholar] [CrossRef]

- Chen, B.; Tian, X.; Li, X.; Lu, C. Hot deformation behavior and processing maps of 2099 Al-Li alloy. J. Mater. Eng. Perform. 2014, 23, 1929–1935. [Google Scholar] [CrossRef]

- Arsenlis, A.; Parks, D. Modeling the evolution of crystallographic dislocation density in crystal plasticity. J. Mech. Phys. Solids 2002, 50, 1979–2009. [Google Scholar] [CrossRef]

- Asaro, R.; Needleman, A. Texture development and strain hardening in rate dependent polycrystals. Acta Metall. 1985, 33, 923–953. [Google Scholar] [CrossRef]

- Deng, L.; Zhao, T.; Jin, J.; Wang, X. Flow behavior of 2024 aluminium alloy sheet during hot tensile and compressive processes. Procedia Eng. 2014, 81, 1049–1054. [Google Scholar] [CrossRef]

- Humphreys, F.; Hatherly, M. Hot Deformation and Dynamic Restoration. In Recrystallization and Related Annealing Phenomena, 2nd ed.; Humphreys, F., Hatherly, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 415–450. [Google Scholar] [CrossRef]

- Alankar, A.; Mastorakos, I.; Field, D. A dislocation-density-based 3D crystal plasticity model for pure aluminum. Acta Mater. 2009, 57, 5936–5946. [Google Scholar] [CrossRef]

- Alzahrani, B.; Abd El-Aty, A.; Elatriby, S.A.; Sobh, A.S.; Bhlol, M.A.; Elfar, A.A.; Siddiqui, M.A.; Shokry, A. A Modified Johnson Cook Model-Based Kalman Filter Method to Determine the Hot Flow Behavior of Sustainable AA6082 Al Alloy. Materials 2024, 17, 5169. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson Cook, modified Zerillie Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cre1Mo steel. Comput. Mater. Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Shokry, A. A modified Johnson–Cook model for flow behavior of alloy 800H at intermediate strain rates and high temperatures. J. Mater. Eng. Perform. 2017, 26, 5723–5730. [Google Scholar] [CrossRef]

- Shokry, A.; Gowid, S.; Kharmanda, G. An improved generic Johnson-Cook model for the flow prediction of different categories of alloys at elevated temperatures and dynamic loading conditions. Mater. Today Commun. 2021, 27, 102296. [Google Scholar] [CrossRef]

| (%) | (MPa) | |

|---|---|---|

| 0.999 | 1.1% | 0.55 |

| 58 | −12.738 | 0.847 | −0.0049 | −0.0041 | 0.0923 | −0.00005 |

| (%) | (MPa) | |

|---|---|---|

| 0.951 | 11.67% | 7.23 |

| 58.071 | −11.065 | −22.881 | 27.824 | 0.0616 | 0.0641 | 1.4884 | −0.3467 |

| (%) | (MPa) | |

|---|---|---|

| 0.983 | 7.09% | 3.56 |

| 58.071 | −11.065 | −22.881 | 27.824 | 0.0550 | 0.0828 | −0.0888 | 0.1637 |

| −1.2841 | 1.2652 | −0.1126 | 1.0707 | −1.0288 | −0.6668 | 2.7593 | −2.4307 |

| m010 | m011 | m012 | m020 | m021 | m022 | m100 | m101 |

| −0.2755 | −5.5232 | 5.0762 | −0.1888 | −2.1973 | −1.5661 | −0.0198 | 10.3673 |

| −9.3805 | 2.597 | −56.627 | 53.125 | −2.2348 | 35.0907 | 32.2649 | −1.6642 |

| 16.4578 | 14.7332 | −3.5334 | 73.087 | 68.9637 | −2.7157 | 52.349 | −49.0335 |

| (%) | (MPa) | |

|---|---|---|

| 0.99 | 1.87% | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alzahrani, B.; Abd El-Aty, A.; Xu, Y.; Hou, Y.; Zhang, S.-H.; Ali, A.; Ahmed, M.M.Z.; Shokry, A. Constitutive Analysis of the Deformation Behavior of Al-Mg-Si Alloy Under Various Forming Conditions Using Several Modeling Approaches. Materials 2025, 18, 1121. https://doi.org/10.3390/ma18051121

Alzahrani B, Abd El-Aty A, Xu Y, Hou Y, Zhang S-H, Ali A, Ahmed MMZ, Shokry A. Constitutive Analysis of the Deformation Behavior of Al-Mg-Si Alloy Under Various Forming Conditions Using Several Modeling Approaches. Materials. 2025; 18(5):1121. https://doi.org/10.3390/ma18051121

Chicago/Turabian StyleAlzahrani, Bandar, Ali Abd El-Aty, Yong Xu, Yong Hou, Shi-Hong Zhang, Alamry Ali, Mohamed M. Z. Ahmed, and Abdallah Shokry. 2025. "Constitutive Analysis of the Deformation Behavior of Al-Mg-Si Alloy Under Various Forming Conditions Using Several Modeling Approaches" Materials 18, no. 5: 1121. https://doi.org/10.3390/ma18051121

APA StyleAlzahrani, B., Abd El-Aty, A., Xu, Y., Hou, Y., Zhang, S.-H., Ali, A., Ahmed, M. M. Z., & Shokry, A. (2025). Constitutive Analysis of the Deformation Behavior of Al-Mg-Si Alloy Under Various Forming Conditions Using Several Modeling Approaches. Materials, 18(5), 1121. https://doi.org/10.3390/ma18051121