The Effects of Lime and Cement Addition on the Compaction and Shear Strength Parameters of Silty Soils

Abstract

:1. Introduction

2. Materials and Methods

3. Characteristics and Application of Binders

3.1. Lime

3.2. Cement CEM I 32.5R

4. Study Results

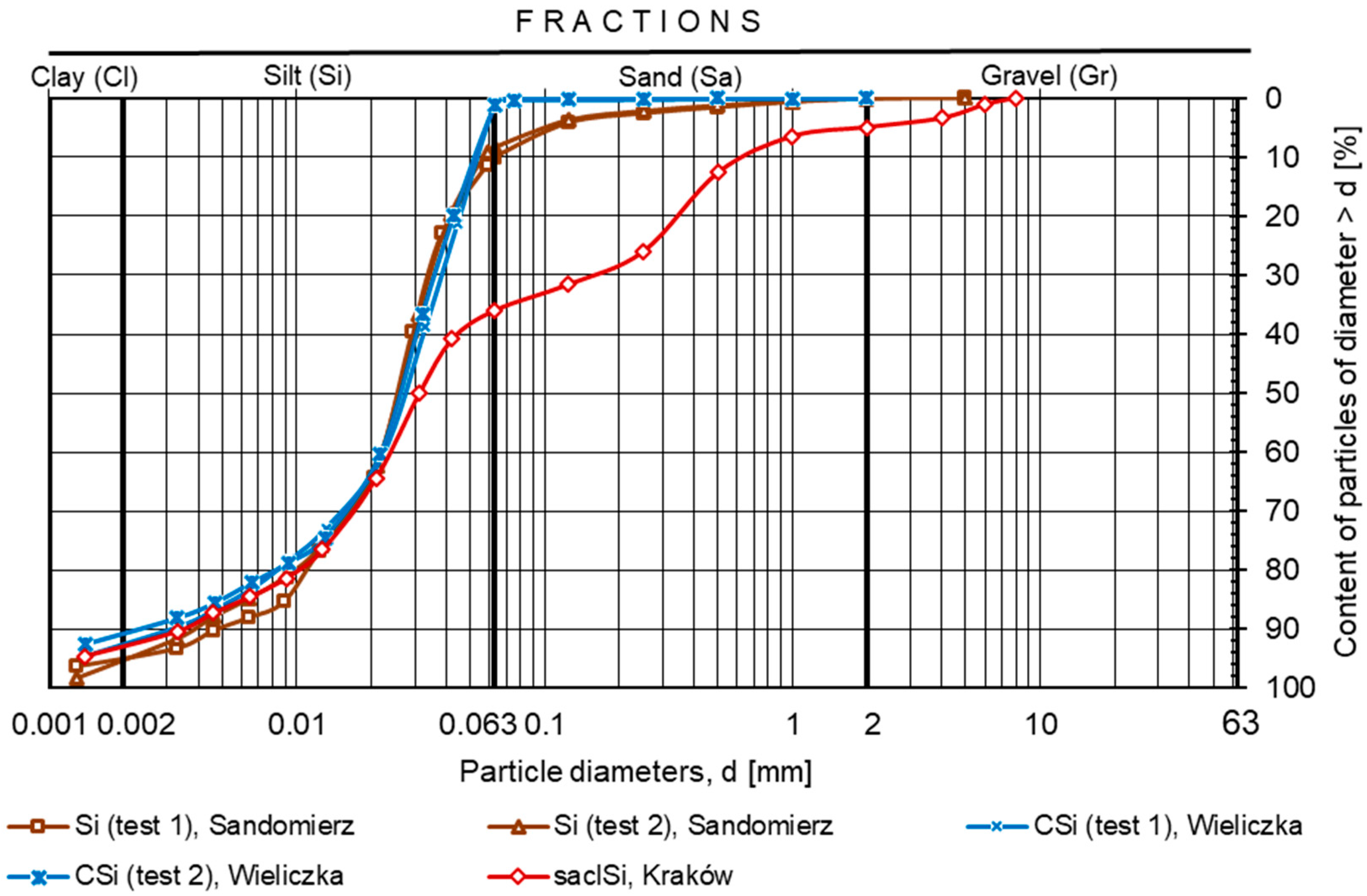

4.1. Grain Size Composition and Specific Density

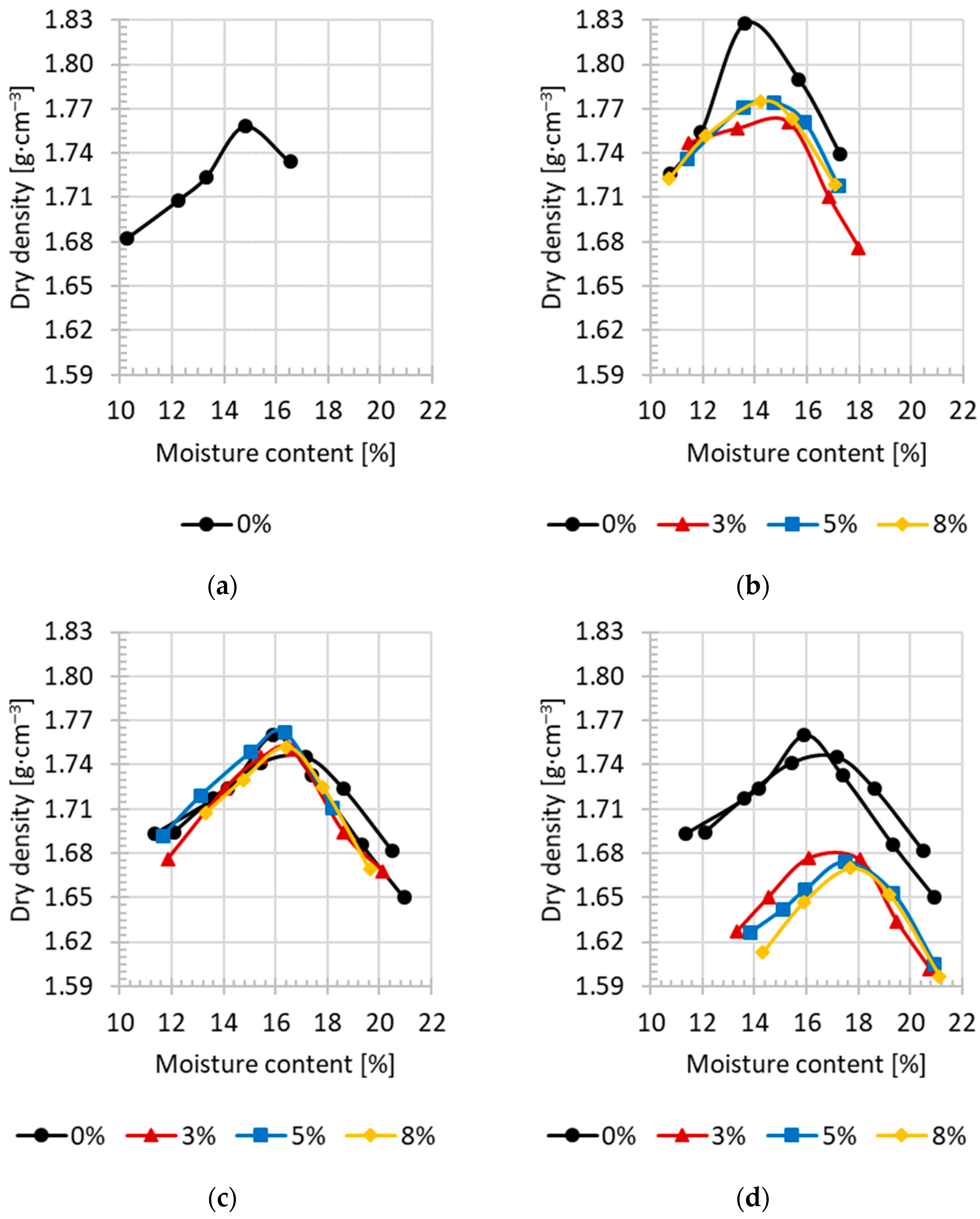

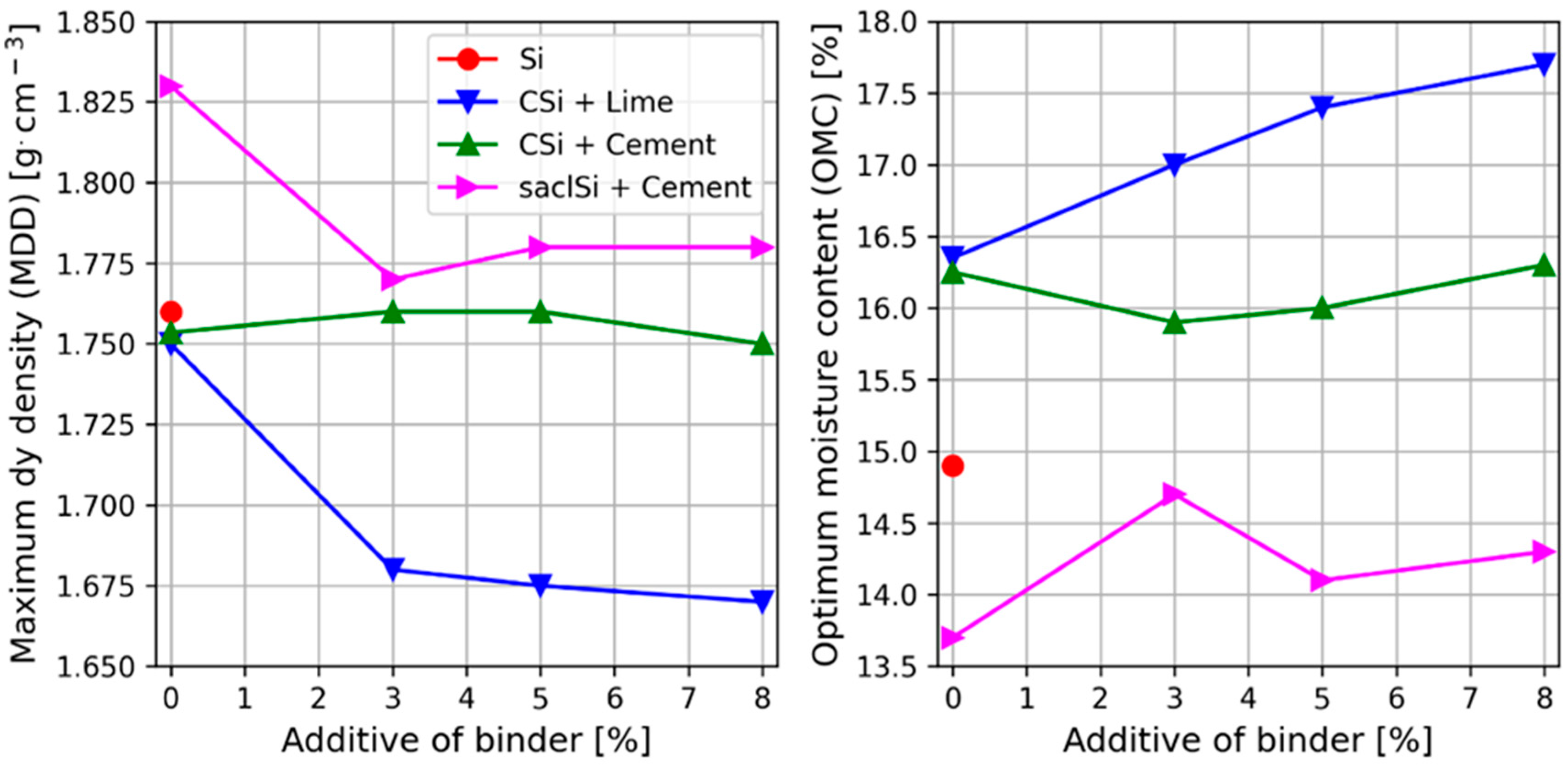

4.2. Compaction Parameters

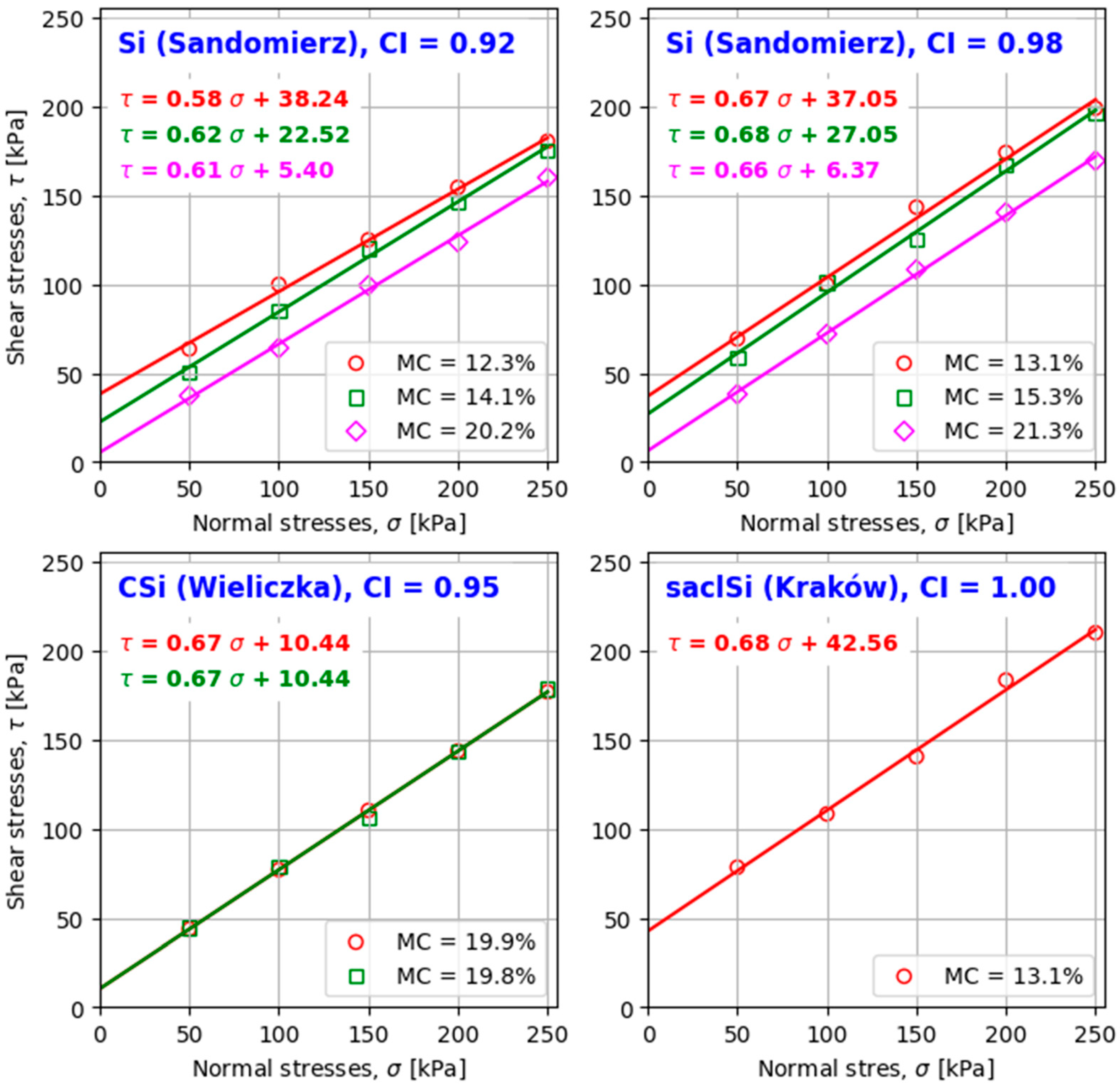

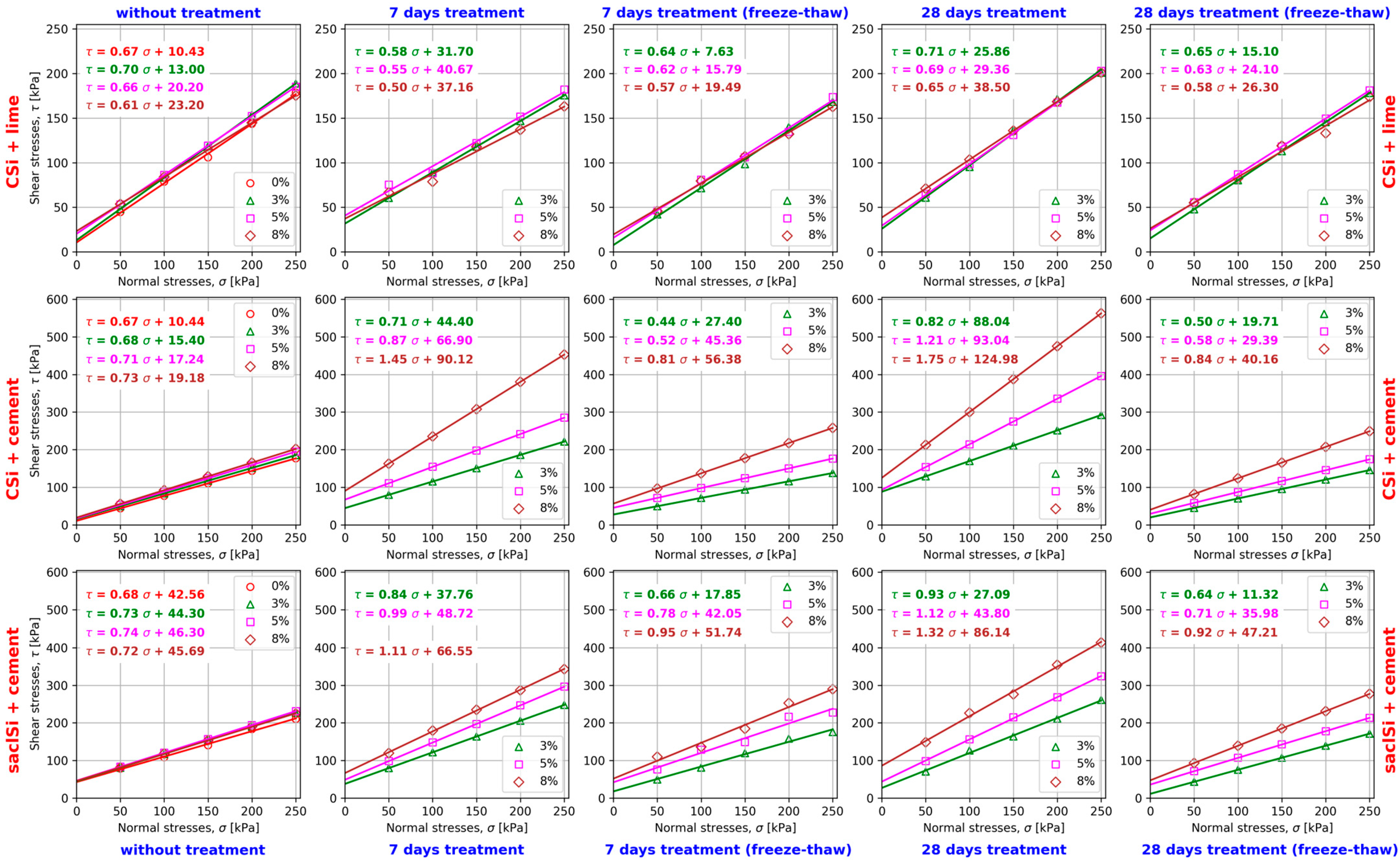

4.3. Shear Strength

4.4. Shear Strength Parameters

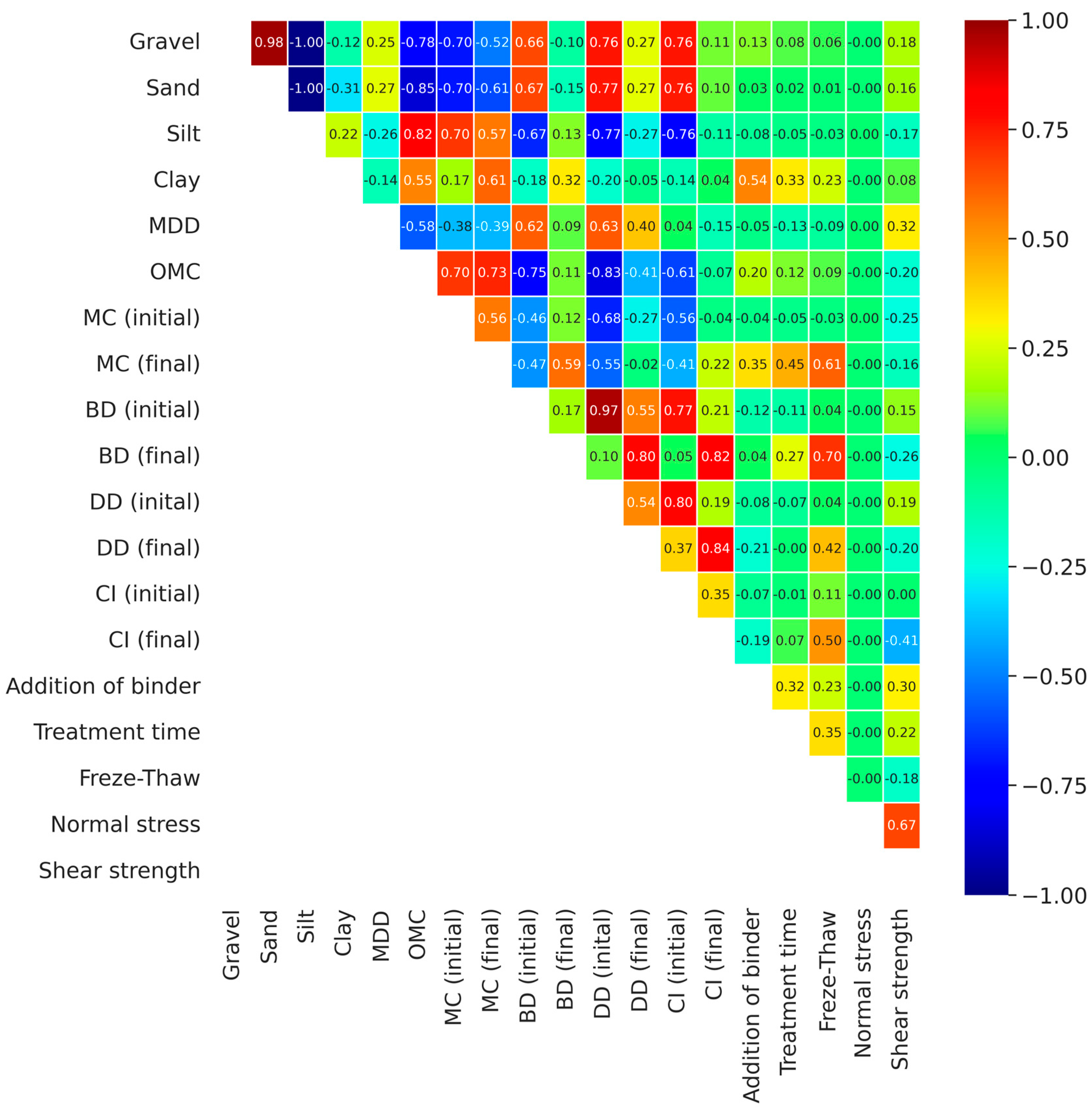

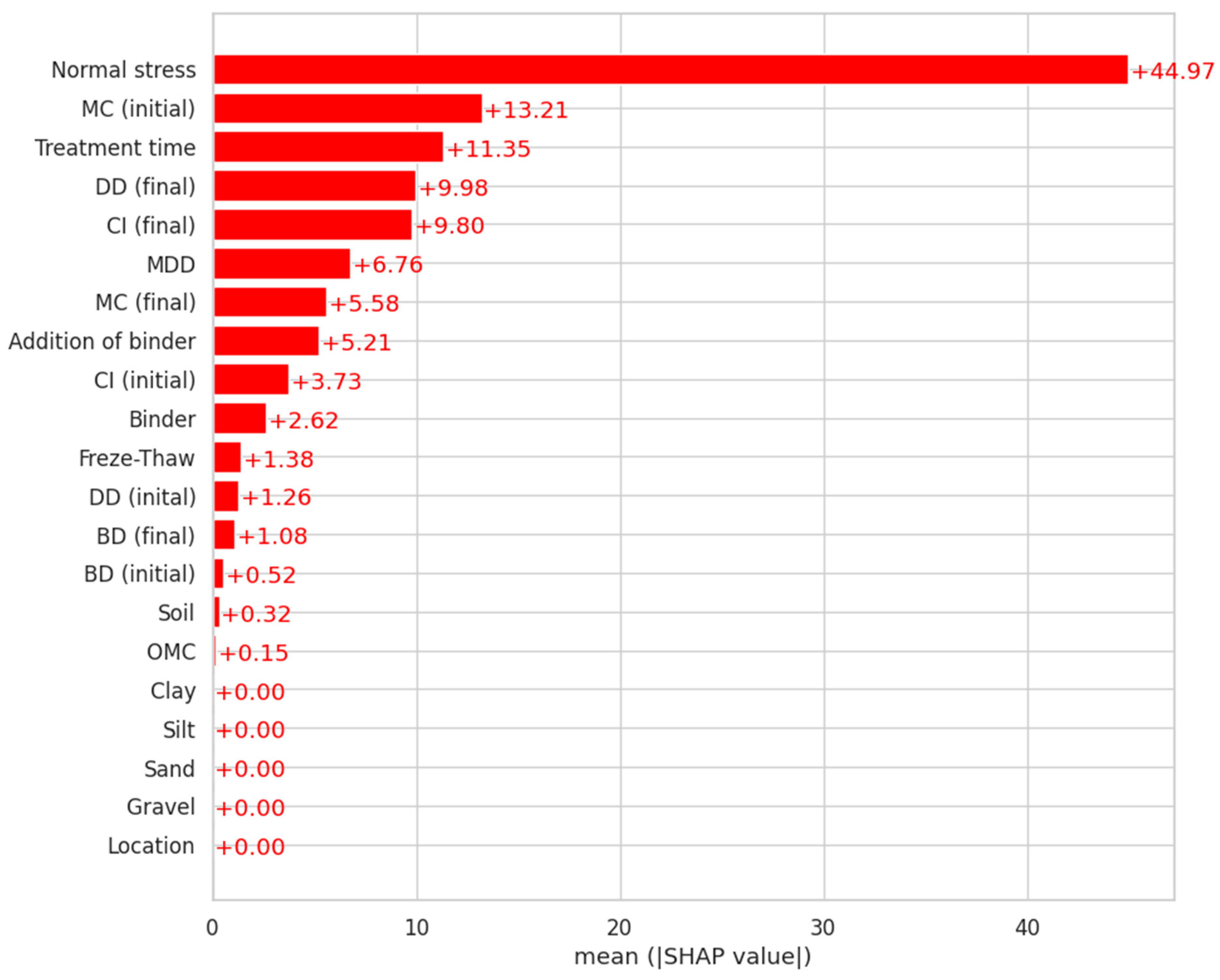

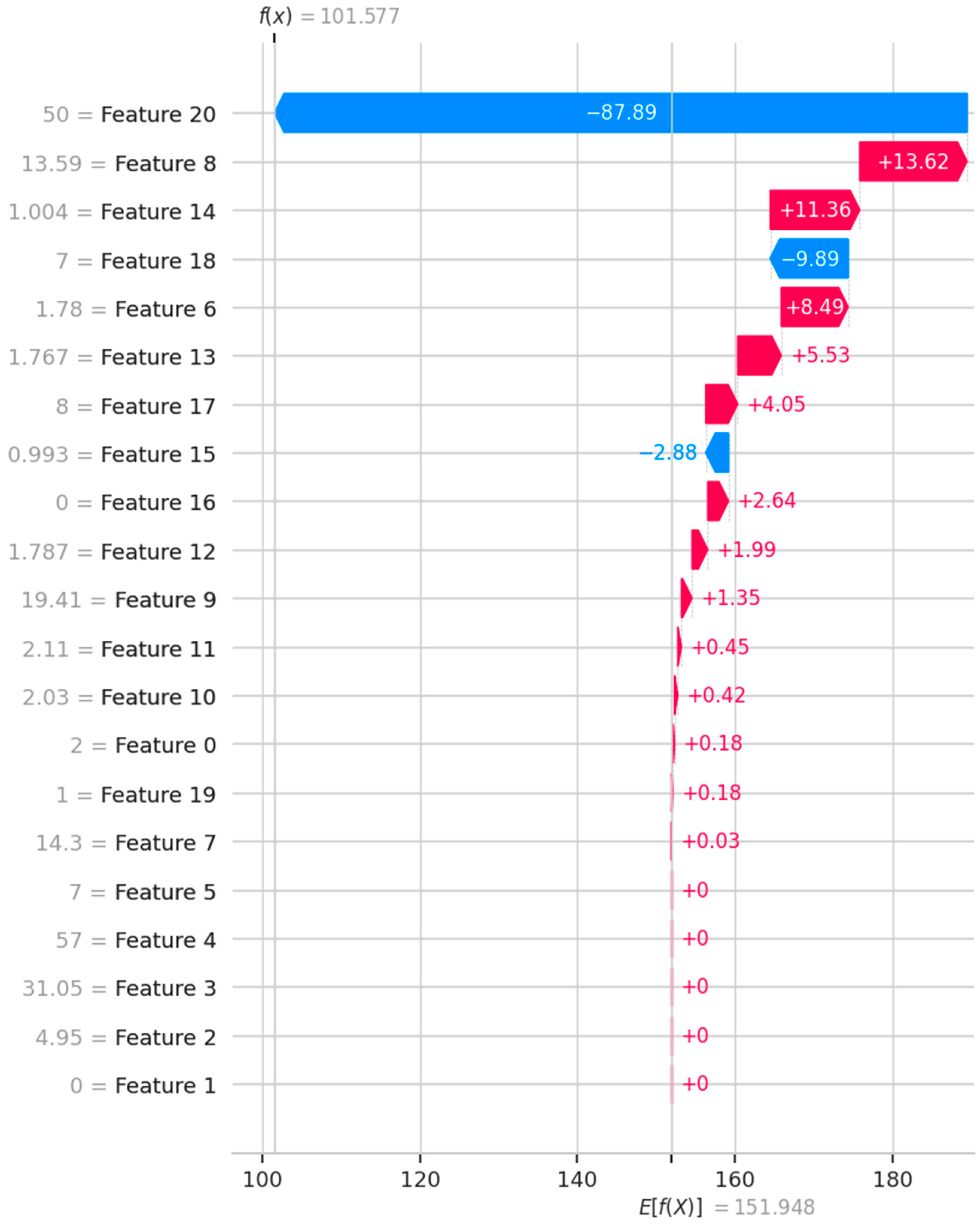

4.5. Numerical Modeling Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gruchot, A. Utylizacja odpadów powęglowych i poenergetycznych do celów inżynierskich jako czynnik kształtowania i ochrony środowiska. In Utilisation of Coal Mining Wastes and Fuel Ashes for Engineering as a Factor of Environmental Development and Protection; Uniwersytet Rolniczy im. H. Kołłątaja: Kraków, Poland, 2016; Volume 533, p. 238. (In Polish) [Google Scholar]

- Gabryś, K.; Soból, E.; Sas, W. Physical, deformation, and stiffness properties of recycled concrete aggregate. Sustainability 2021, 13, 4245. [Google Scholar] [CrossRef]

- Almuaythir, S.; Zaini, M.S.I.; Hasan, M.; Hoque, I. Sustainable soil stabilization using industrial waste ash: Enhancing expansive clay properties. Heliyon 2024, 10, e39124. [Google Scholar] [CrossRef]

- Del Angel, G.G.; Aghajanian, A.; Tamayo, P.; Rico, J.; Thomas, C. Siderurgical aggregate cement-treated bases and concrete using foundry sand. Appl. Sci. 2021, 11, 435. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Olgun, C.G.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Saldanha, R.B.; Nunez, V.F.; Lotero, A.; Consoli, N.C. Life cycle assessment of green binder for organic soil stabilization. Transp. Geotech. 2024, 49, 101398. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Gruchot, A.; Michniak, D. Wytrzymałość na ściskanie popiołów lotnych z dodatkiem zbrojenia rozproszonego. (in Polish: Compression strength of fly ash with the addition of fiber reinforcement). Acta Sci. Pol. Form. Circumiectus 2015, 14, 43–54. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Concha-Riedel, J.; Antico, F.C.; Valdés, C.; Cáceres, G. Influence of natural fiber dosage and length on adobe mixes damage-mechanical behavior. Constr. Build. Mater. 2018, 174, 645–655. [Google Scholar] [CrossRef]

- Falah, M.W.; Muteb, H. Applying different soil stabilization mechanisms: A review. Arch. Civ. Eng. 2023, LXIX, 339–358. [Google Scholar] [CrossRef]

- Croft, J.B. The influence of soil mineralogical composition on cement stabilization. Geotechnique 1967, 17, 119–135. [Google Scholar] [CrossRef]

- Rahman, A.A. Comparative study of the potentials of rice husk ash on cohesive and cohesionless soils. Build. Environ. 1987, 22, 331–337. [Google Scholar] [CrossRef]

- Bryan, A.J. Soil/cement as a walling material I. Stress/strain properties. Build. Environ. 1988, 23, 321–330. [Google Scholar] [CrossRef]

- Bell, F.G. Lime stabilization of clay minerals and soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Miller, G.; Azad, S. Influence of soil type on stabilization with cement kiln dust. Constr. Build. Mater. 2000, 14, 89–97. [Google Scholar] [CrossRef]

- Rao, S.M.; Reddy, B.V.V.; Muttharam, M. The impact of cyclic wetting and drying on the swelling behaviour of stabilized expansive soils. Eng. Geol. 2001, 60, 223–233. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Taha, R.; Nelson, J.D.; Beit Al-Shab, T.; Al-Siyabi, H. A comparative evaluation of various additives used in the stabilization of expansive soils. ASTM Geotech. Test. J. 2002, 25, 199–209. [Google Scholar] [CrossRef]

- Kalkan, E. Utilization of red mud as a stabilization material for the preparation of clay liners. Eng. Geol. 2006, 87, 220–229. [Google Scholar] [CrossRef]

- Degirmenci, N.; Okucu, A.; Turabib, A. Application of phosphogypsum in soil stabilization. Build. Environ. 2007, 42, 3393–3398. [Google Scholar] [CrossRef]

- Guney, Y.; Sari, D.; Cetin, M.; Tuncan, M. Impact of cyclic wetting-drying on swelling behavior of lime-stabilized soil. Build. Environ. 2007, 42, 681–688. [Google Scholar] [CrossRef]

- Segetin, M.; Jayaraman, K.; Xu, X. Harakeke reinforcement of soil-cement building materials: Manufacturability and properties. Build. Environ. 2007, 42, 3066–3079. [Google Scholar] [CrossRef]

- Harichane, K.; Ghrici, M.; Kenai, S. Effect of curing time on shear strength of cohesive soils stabilized with combination of lime and natural pozzolana. Int. J. Civ. Eng. 2011, 9, 90–96. [Google Scholar]

- Sunitsakul, J.; Sawatparnich, A.; Sawangsuriya, A. Prediction of unconfined compressive strength of soil–cement at 7 days. Geotech. Geol. Eng. 2012, 30, 263–268. [Google Scholar] [CrossRef]

- Yilmaz, Y.; Ozaydin, V. Compaction and shear strength characteristics of colemanite ore waste modified active belite cement stabilized high plasticity soils. Eng. Geol. 2013, 155, 45–53. [Google Scholar] [CrossRef]

- Ashiq, H.M.; Sabab, S.R.; Joy, J.A.; Zahid, C.Z.B.; Kabir, M.U. Analysis of cement-stabilized soil on road embankment employing finite element analysis—A case study. Eng. Res. Express 2024, 6, 045101. [Google Scholar] [CrossRef]

- Bellil, S.; Abbeche, K.; Bahloul, O. Treatment of a collapsible soil using a bentonite-cement mixture. Stud. Geotech. Mech. 2018, 40, 233–243. [Google Scholar] [CrossRef]

- Mallela, J.; Quintus, H.V.; Smith, K. Consideration of Lime-Stabilized Layers in Mechanistic–Empirical Pavement Design; The National Lime Association: Arlington, TX, USA, 2004. [Google Scholar]

- Kumar, S.; Mahato, R.K.; Kumar, N.; Ranjan, N.; Mondal, D.; Chowdhury, S.S. Effect of lime (content & duration) on strength of cohesive soil. Int. Res. J. Eng. Technol. 2019, 6, 198–205. [Google Scholar]

- Utkarsh; Jain, P.K. Enhancing the properties of swelling soils with lime, fly ash, and expanded polystyrene—A review. Heliyon 2024, 10, e32908. [Google Scholar] [CrossRef]

- Basma, A.A.; Tuncer, E.R. Effect of Lime on Volume Change and Compressibility of Expansive Clays; TRR No. 1296; Transportation Research Record: Washington, DC, USA, 1991; pp. 54–61. [Google Scholar]

- Pereira, R.S.; Emmert, F.; Miguel, E.P.; Gatto, A. Soil stabilization with lime for the construction of forest roads. Floresta Ambiente 2018, 25, e20150077. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Nahazanan, H.; Nasir, N.A.M.; Huseien, G.F.; Saad, A.H. Calcium-based binders in concrete or soil stabilization: Challenges, problems, and calcined clay as partial replacement to produce low-carbon cement. Materials 2023, 16, 2020. [Google Scholar] [CrossRef]

- Roshan, M.J.; Rashid, A.S.B.A. Geotechnical characteristics of cement stabilized soils from various aspects: A comprehensive review. Arab. J. Geosci. 2024, 17, 1. [Google Scholar] [CrossRef]

- Balmer, G.G. Shear Strength and Elastic Properties of Soil-Cement Mixture Under Triaxial Loading; Portland Cement Association Research and Development Laboratories: Skokie, IL, USA, 1958. [Google Scholar]

- Baghdadi, Z.A.; Rahman, M.A. The potential of cement kiln dust for the stabilization of dune sand in highway construction. Build. Environ. 1990, 25, 285–289. [Google Scholar] [CrossRef]

- Lo, S.R.; Wardani, S.P.R. Strength and dilatancy of a silt stabilized by a cement and fly ash mixture. Can. Geotech. J. 2002, 39, 77–89. [Google Scholar] [CrossRef]

- Lorenzo, G.A.; Bergado, D.T. Fundamental parameters of cement-admixed clay—New approach. J. Geotech. Geoenviron. Eng. 2004, 130, 1042–1050. [Google Scholar] [CrossRef]

- Sariosseiri, F.; Muhunthan, B. Effect of cement treatment on geotechnical properties of some Washington State soils. Eng. Geol. 2009, 104, 119–125. [Google Scholar] [CrossRef]

- Mitchell, J.K.; Soga, K. Fundamentals of Soil Behavior; John Wiley & Sons, Inc.: New York, NY, USA, 2005. [Google Scholar]

- Nelson, J.D.; Miller, J.D. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering; Wiley: New York, NY, USA, 1992. [Google Scholar] [CrossRef]

- Bergado, D.T.; Anderson, L.R.; Miura, N.; Balasubramaniam, A.S. Soft Ground Improvement—In Lowland and Other Environments; American Society of Civil Engineers: New York, NY, USA, 1996; p. 435. [Google Scholar]

- Narloch, P.; Woyciechowski, P.; Kotowski, J.; Gawriuczenkow, I.; Wójcik, E. The effect of soil mineral composition on the compressive strength of cement stabilized rammed earth. Materials 2020, 13, 324. [Google Scholar] [CrossRef]

- Bergado, D.T.; Anderson, L.R.; Miura, N.; Balasubramaniam, A.S. Lime/deep cement mixing method. In Improvement Techniques of Soft Ground in Subsiding and Lowland Environments; A. A. Balkelma: Rotterdam, The Netherlands, 1994; pp. 99–130. [Google Scholar]

- PN-EN ISO 14688-2:2018-05; Rozpoznanie i Badania Geotechniczne. Oznaczanie i Klasyfikowanie Gruntów. Część 2: Zasady Klasyfikowania. Polski Komitet Normalizacyjny: Warszawa, Poland, 2018.

- PN-EN ISO 17892-3:2016-03; Rozpoznanie i Badania Geotechniczne. Badania Laboratoryjne Gruntów. Część 3: Badanie Gęstości Właściwej. Polski Komitet Normalizacyjny: Warszawa, Poland, 2016.

- PN-B-04481:1988; Grunty Budowlane. Badania Próbek Gruntu. Polski Komitet Normalizacyjny: Warszawa, Poland, 1988.

- PN-EN 13286-2:2010; Mieszanki Niezwiązane i Związane Hydraulicznie. Część 2: Metody Badań Laboratoryjnych Gęstości na Sucho i Zawartości Wody. Zagęszczanie Metodą Proktora. Polski Komitet Normalizacyjny: Warszawa, Poland, 2010.

- PN-EN ISO 17892-10:2019-01; Rozpoznanie i Badania Geotechniczne. Badania Laboratoryjne Gruntów. Część 10: Badania w Aparacie Bezpośredniego Ścinania. Polski Komitet Normalizacyjny: Warszawa, Poland, 2019.

- PN-S-96011:1998; Drogi Samochodowe. Stabilizacja Gruntów Wapnem do Celów Drogowych. Polski Komitet Normalizacyjny: Warszawa, Poland, 1998.

- PN-S-96012:1997; Drogi Samochodowe. Podbudowa i Ulepszone Podłoże z Gruntu Stabilizowanego Cementem. Polski Komitet Normalizacyjny: Warszawa, Poland, 1997.

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016. [Google Scholar]

- Mohammadi, M.; Fatemi Aghda, S.M.; Talkhablou, M.; Cheshomi, A. Prediction of the shear strength parameters from easily-available soil properties by means of multivariate regression and artificial neural network methods. Geomech. Geoeng. 2022, 17, 442–454. [Google Scholar] [CrossRef]

- Momeni, E.; He, B.; Abdi, Y.; Armaghani, D.J. Novel hybrid XGBoost model to forecast soil shear strength based on some soil index tests. Comput. Model. Eng. Sci. 2023, 136, 2527–2550. [Google Scholar] [CrossRef]

- SHAP Documentation. Available online: https://Shap.readthedocs.io/en/stable/index.html (accessed on 5 October 2024).

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- PN-EN 459-1:2012; Wapno Budowlane. Część 1: Definicje, Wymagania i Kryteria Zgodności. Polski Komitet Normalizacyjny: Warszawa, Poland, 2012.

- Osiecka, E. Rodzaje i właściwości wapna budowlanego. Mater. Bud. 2001, 8, 146–147. [Google Scholar]

- Szajna, W. Stabilizacja chemiczna gruntów problematycznych. Prz. Bud. 2021, 11–12, 38–43. [Google Scholar]

- Kraszewski, C.; Dreger, M.; Mitrut, M.; Przygoda, M. Stabilizacja gruntów wapnem palonym w inżynierii komunikacyjnej—Teoria i praktyka. Inż. Morska Geotech. 2020, 2, 82–86. [Google Scholar]

- PN-EN 197-1:2012; Cement. Część 1: Skład, Wymagania i Kryteria Zgodności Dotyczące Cementów Powszechnego Użytku. Polski Komitet Normalizacyjny: Warszawa, Poland, 2012.

- Topolnicki, M. Zasady stosowania i projektowania wzmocnienia gruntu metodą wgłębnego mieszania na mokro (DSM). Inż. I Bud. 2018, 1, 3–16. [Google Scholar]

- Shi, Y.; Li, S.; Zhang, T.; Liu, J.; Zhang, J. Compaction and shear performance of lime-modified high moisture content silty clay. Case Stud. Constr. Mater. 2024, 21, e03529. [Google Scholar] [CrossRef]

- Zydroń, T.; Dąbrowska, J. The influence of moisture content on shear strength of cohesive soils from the landslide area around Gorlice. AGH J. Min. Geoeng. 2012, 36, 309–317. [Google Scholar]

- Zhang, Y.; Lu, J.; Han, W.; Xiong, Y.; Qian, J. Effects of moisture and stone content on the shear strength characteristics of soil-rock mixture. Materials 2023, 16, 567. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Qin, X.; Tan, J.; Yang, L.; Ou, L.; Duan, X.; Deng, Y. Effect of the moisture content and dry density on the shear strength parameters of collapsing wall in hilly granite areas of South China. Int. Soil Water Conserv. Res. 2024, 12, 697–713. [Google Scholar] [CrossRef]

- Gruchot, A.; Zawisza, E. Wpływ stabilizacji cementem lub Silmentem na wytrzymałość i mrozoodporność gruntu pylastego. Gór. Geoinż. 2008, 32, 371–379. [Google Scholar]

- Kang, Q.; Xia, Y.; Li, X.; Zhang, W.; Feng, C. Study on the effect of moisture content and dry density on shear strength of silty clay based on direct shear test. Adv. Civ. Eng. 2022, 1, 2213363. [Google Scholar] [CrossRef]

- Weia, Y.; Wub, X.; Xiaa, J.; Millerc, G.A.; Caia, C.; Guoa, Z.; Hassanikhah, A. The effect of water content on the shear strength characteristics of granitic soils in South China. Soil Tillage Res. 2019, 187, 50–59. [Google Scholar] [CrossRef]

- Bláhová, K.; Ševelová, L.; Pilařová, P. Influence of water content on the shear strength parameters of clayey soil in relation to stability analysis of a hillside in Brno region. Acta Univ. Agric. Silvic. Mendel. Brun. 2013, LXI, 1583–1588. [Google Scholar] [CrossRef]

- Zheng, K.; Cheng, J.; Xia, J.F.; Liu, G.Y.; Xu, L. Effects of soil bulk density and moisture content on the physico-mechanical properties of paddy soil in plough layer. Water 2021, 13, 2290. [Google Scholar] [CrossRef]

- Furlan, A.P.; Razakamanantsoa, A.; Ranaivomanana, H.; Levacher, D.; Katsumi, T. Shear strength performance of marine sediments stabilized using cement, lime and fly ash. Constr. Build. Mater. 2018, 184, 454–463. [Google Scholar] [CrossRef]

- Boutouba, K.; Benessalah, I.; Arab, A.; Henni, A.D. Shear strength enhancement of cemented reinforced sand: Role of cement content on the macro-mechanical behavior. Stud. Geotech. Mech. 2019, 41, 200–211. [Google Scholar] [CrossRef]

- Zeinali, A.; Edeskär, T.; Laue, J. Mechanism of thawing. Cogent Eng. 2020, 7, 1716438. [Google Scholar] [CrossRef]

- Liu, Y.; Fabbri, A.; Wong, H.K.K.; Traore, L.B.; Li, X.; Pardoen, B. Experimental study on the freezing-thawing behavior of compacted earth. Constr. Build. Mater. 2023, 404, 133130. [Google Scholar] [CrossRef]

- Errousso, H.; Abdellaoui Alaoui, E.A.; Benhadou, S.; Medromi, H. Exploring how independent variables influence parking occupancy prediction: Toward a model results explanation with SHAP values. Prog. Artif. Intell. 2022, 11, 367–396. [Google Scholar] [CrossRef]

- Dzięcioł, J.; Sas, W. Estimation of the coefficient of permeability as an example of the application of the Random Forest algorithm in Civil Engineering. Arch. Civ. Eng. 2024, LXX, 119–134. [Google Scholar] [CrossRef]

- Ahmad, M.; Wróblewski, P.; Kamiński, P.; Amjad, U. Prediction of pile bearing capacity using XGBoost algorithm: Modeling and performance evaluation. Appl. Sci. 2022, 12, 2126. [Google Scholar] [CrossRef]

- Kaushik, J.; Dodagoudar, G.R. Explainable machine learning model for liquefaction potential assessment of soils using XGBoost-SHAP. Soil Dyn. Earthq. Eng. 2023, 165, 107662. [Google Scholar] [CrossRef]

- Letif, M.; Bahar, R.; Mezouar, N. The use of machine learning models and SHAP interaction values to predict the soil swelling index. Period. Polytech. Civ. Eng. 2025, 69, 239–250. [Google Scholar] [CrossRef]

| Treatment Time [Days] | Addition of Lime or Cement [%] | Type of Sample Treatment | Number of Samples for Each Binder Addition | Sample Treatment Description |

|---|---|---|---|---|

| 0 | 0 | Without treatment | 4 | Shear strength determination immediately after forming the samples. |

| 3 | ||||

| 5 | ||||

| 8 | ||||

| 7 | 3 | Air–water treatment | 4 | 3 days at room temperature protected from drying out, 1 day immersed in water to a height of 1 cm, 3 days completely immersed in water. |

| 5 | ||||

| 8 | ||||

| 28 | 3 | 4 | 13 days at room temperature protected from drying out, 1 day immersed in water to a height of 1 cm, 14 days completely immersed in water. | |

| 5 | ||||

| 8 | ||||

| 7 | 3 | Air–water treatment with freeze–thaw cycles | 4 | 3 days at room temperature protected from drying out, 1 day completely immersed in water, 3 days with freeze–thaw cycles. |

| 5 | ||||

| 8 | ||||

| 28 | 3 | 4 | 13 days at room temperature protected from drying out, 1 day completely immersed in water, 14 days with freeze–thaw cycles. | |

| 5 | ||||

| 8 |

| Parameter | Unit | Location of Soil Collection | ||||

|---|---|---|---|---|---|---|

| Sandomierz | Wieliczka | Kraków | ||||

| Value | ||||||

| Fraction content | Gravel, Gr: 63 ÷ 2 mm | % | 0 | 0 | 4.95 | |

| Sand, Sa: 2 ÷ 0.063 mm | 8.39–10.5 | 1.26–1.30 | 31.05 | |||

| Silt, Si: 0.063 ÷ 0.002 mm | 85.1–87.11 | 89.70–92.24 | 57.00 | |||

| Clay, Cl: <0.002 mm | 4.85–4.50 | 6.50–9.00 | 7.00 | |||

| Name of soil according to [44] | Silt (Si) | Coarse silt (CSi) | Clayey silt with sand (saclSi) | |||

| Equivalent diameter | d60 | mm | 0.30 | 0.032 | 0.045 | |

| d30 | 0.0175 | 0.0017 | 0.0175 | |||

| d10 | 0.0042 | 0.0026 | 0.0035 | |||

| Uniformity coefficient, | - | 7.0 | 15.0 | 14.3 | ||

| Coefficient of curvature, | - | 2.43 | 4.82 | 1.85 | ||

| Density of solid particles, ρs | g∙cm−3 | 2.67 | 2.67 | 2.69 | ||

| Name of Soil | Location of Soil Collection | Binder | Maximum Dry Density (MDD) [g∙cm−3] | Optimum Moisture Content (OMC) [%] | |

|---|---|---|---|---|---|

| Type | Additive [%] | ||||

| Silt (Si) | Sandomierz | Without | 0 | 1.76 | 14.9 |

| Coarse silt (CSi) | Wieliczka | Without | 0 | 1.75 and 1.76 mean 1.75 | 15.9 and 16.6 mean 16.3 |

| Lime | 3 | 1.68 | 17.0 | ||

| 5 | 1.68 | 17.4 | |||

| 8 | 1.67 | 17.7 | |||

| Cement | 3 | 1.75 | 16.2 | ||

| 5 | 1.76 | 16.0 | |||

| 8 | 1.75 | 16.3 | |||

| Clayey silt with sand (saclSi) | Kraków | Without | 0 | 1.83 | 13.7 |

| Cement | 3 | 1.77 | 14.7 | ||

| 5 | 1.78 | 14.1 | |||

| 8 | 1.78 | 14.3 | |||

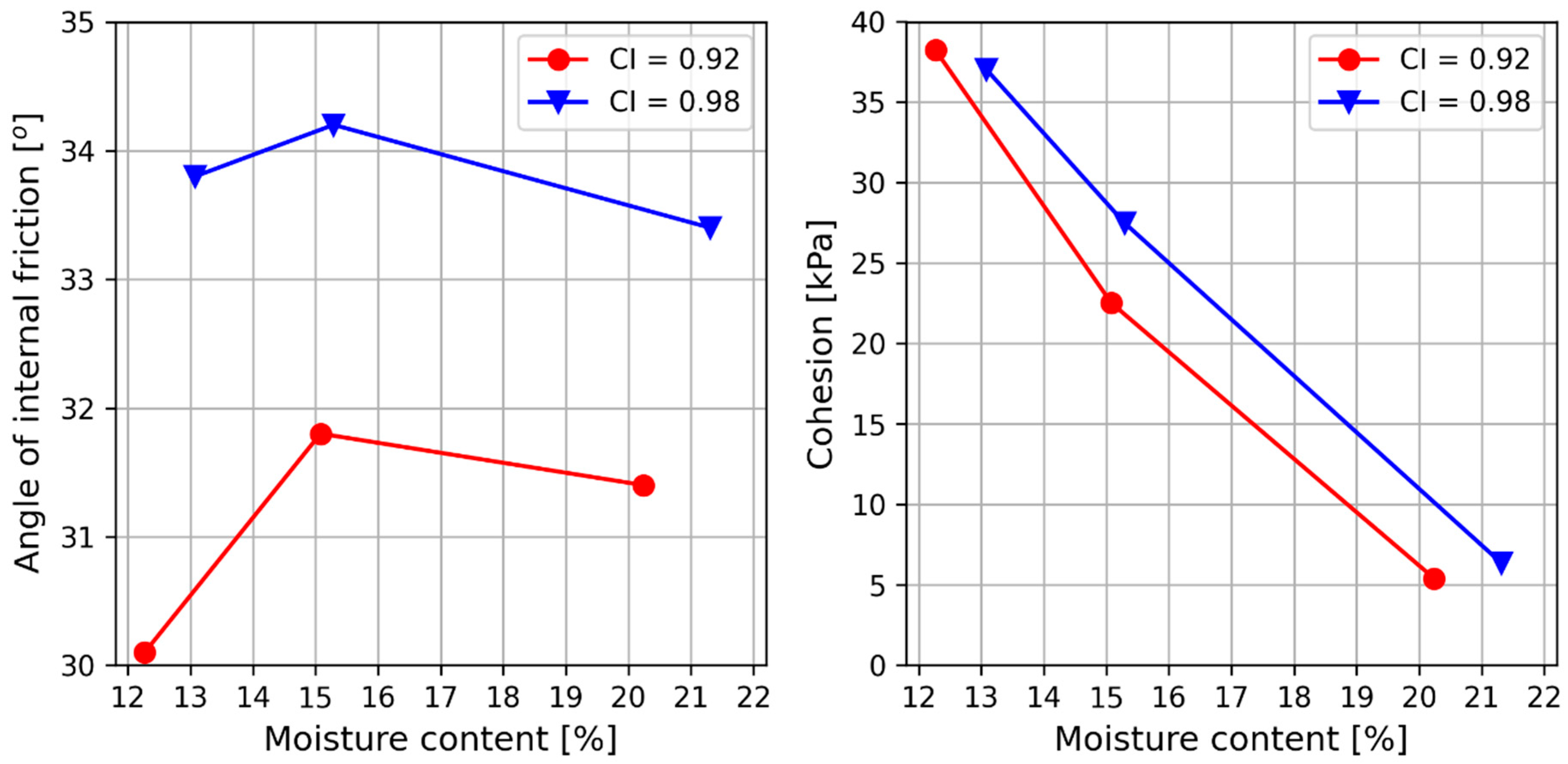

| Parameter | Unit | Value | |||||

| Compaction index (CI) | - | 0.92 | 0.98 | ||||

| Moisture content—description | - | ||||||

| Moisture content after test | % | 12.3 | 15.1 | 20.2 | 13.1 | 15.3 | 21.3 |

| Angle of internal friction | ° | 30.1 | 31.8 | 31.4 | 33.8 | 34.2 | 33.4 |

| Cohesion | kPa | 38.2 | 27.5 | 6.4 | 37.1 | 22.5 | 5.4 |

| Binder Additive | Treatment Time | Moisture Content After Test | Angle of Internal Friction | S Cohesion | Moisture Content After Test | Angle of Internal Friction | Cohesion | Moisture Content After Test | Angle of Internal Friction | Cohesion | Moisture Content After Test | Angle of Internal Friction | Cohesion |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % | days | % | ° | kPa | % | ° | kPa | % | ° | kPa | % | ° | kPa |

| Binder | Lime | Cement | |||||||||||

| Type of treatment | Immediately after forming the sample | Immediately after forming the sample | |||||||||||

| 0 | 0 | 16.8 | 33.6 | 10.4 | 16.9 | 33.6 | 10.4 | ||||||

| 3 | 17.3 | 35.1 | 13.0 | 16.5 | 34.2 | 15.4 | |||||||

| 5 | 17.6 | 33.4 | 20.2 | 16.2 | 35.4 | 17.2 | |||||||

| 8 | 18.2 | 31.3 | 23.2 | 16.1 | 36.2 | 19.2 | |||||||

| Type of treatment | Air–water treatment | Air–water treatment with 3 freeze–thaw cycles | Air–water treatment | Air–water treatment with 3 freeze–thaw cycles | |||||||||

| 3 | 7 | 16.7 | 29.9 | 31.7 | 16.9 | 32.7 | 7.6 | 16.1 | 35.3 | 44.4 | 16.1 | 23.8 | 27.4 |

| 5 | 17.7 | 29.0 | 40.7 | 17.2 | 31.6 | 15.8 | 15.9 | 41.1 | 66.9 | 15.3 | 27.6 | 45.4 | |

| 8 | 17.8 | 25.5 | 43.4 | 17.7 | 29.8 | 19.4 | 15.8 | 55.4 | 90.1 | 15.7 | 38.9 | 56.4 | |

| Type of treatment | Air–water treatment | Air–water treatment with 14 freeze–thaw cycles | Air–water treatment | Air–water treatment with 14 freeze–thaw cycles | |||||||||

| 3 | 28 | 16.5 | 36.7 | 22.6 | 16.9 | 33.1 | 15.1 | 15.8 | 39.2 | 88.0 | 16.9 | 26.7 | 19.7 |

| 5 | 16.8 | 34.6 | 29.4 | 17.3 | 24.1 | 24.1 | 15.7 | 50.5 | 93.0 | 16.6 | 30.1 | 29.4 | |

| 8 | 17.3 | 33.0 | 38.5 | 17.7 | 26.3 | 26.3 | 16.6 | 60.3 | 125.0 | 15.6 | 39.9 | 40.1 | |

| Binder Additive | Treatment Time | Moisture Content After Test | Angle of Internal Friction | Cohesion | Moisture Content After Test | Angle of Internal Friction | Cohesion |

|---|---|---|---|---|---|---|---|

| % | days | % | ° | kPa | % | ° | kPa |

| Binder | Cement | ||||||

| Type of treatment | Immediately after forming the sample | ||||||

| 0 | 0 | 13.7 | 34.1 | 42.6 | |||

| 3 | 14.3 | 36.1 | 44.3 | ||||

| 5 | 14.1 | 36.5 | 46.3 | ||||

| 8 | 13.9 | 35.7 | 45.7 | ||||

| Type of treatment | Air–water treatment | Air–water treatment with 3 freeze–thaw cycles | |||||

| 3 | 7 | 14.1 | 40.0 | 37.8 | 14.0 | 33.4 | 17.9 |

| 5 | 13.6 | 44.7 | 48.7 | 13.6 | 38.0 | 42.1 | |

| 8 | 13.6 | 48.0 | 66.6 | 13.6 | 43.6 | 51.6 | |

| Type of treatment | Air–water treatment | Air–water treatment with 14 freeze–thaw cycles | |||||

| 3 | 28 | 14.2 | 42.9 | 27.1 | 14.3 | 32.7 | 11.3 |

| 5 | 13.6 | 48.2 | 43.8 | 13.8 | 35.4 | 36.0 | |

| 8 | 13.7 | 52.9 | 86.1 | 14.1 | 42.7 | 47.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gruchot, A.; Kamińska, K.; Woś, A. The Effects of Lime and Cement Addition on the Compaction and Shear Strength Parameters of Silty Soils. Materials 2025, 18, 974. https://doi.org/10.3390/ma18050974

Gruchot A, Kamińska K, Woś A. The Effects of Lime and Cement Addition on the Compaction and Shear Strength Parameters of Silty Soils. Materials. 2025; 18(5):974. https://doi.org/10.3390/ma18050974

Chicago/Turabian StyleGruchot, Andrzej, Katarzyna Kamińska, and Agnieszka Woś. 2025. "The Effects of Lime and Cement Addition on the Compaction and Shear Strength Parameters of Silty Soils" Materials 18, no. 5: 974. https://doi.org/10.3390/ma18050974

APA StyleGruchot, A., Kamińska, K., & Woś, A. (2025). The Effects of Lime and Cement Addition on the Compaction and Shear Strength Parameters of Silty Soils. Materials, 18(5), 974. https://doi.org/10.3390/ma18050974