Energy-Reduced Fabrication of Light-Frame Ceramic Honeycombs by Replication of Additive Manufactured Templates

Abstract

1. Introduction

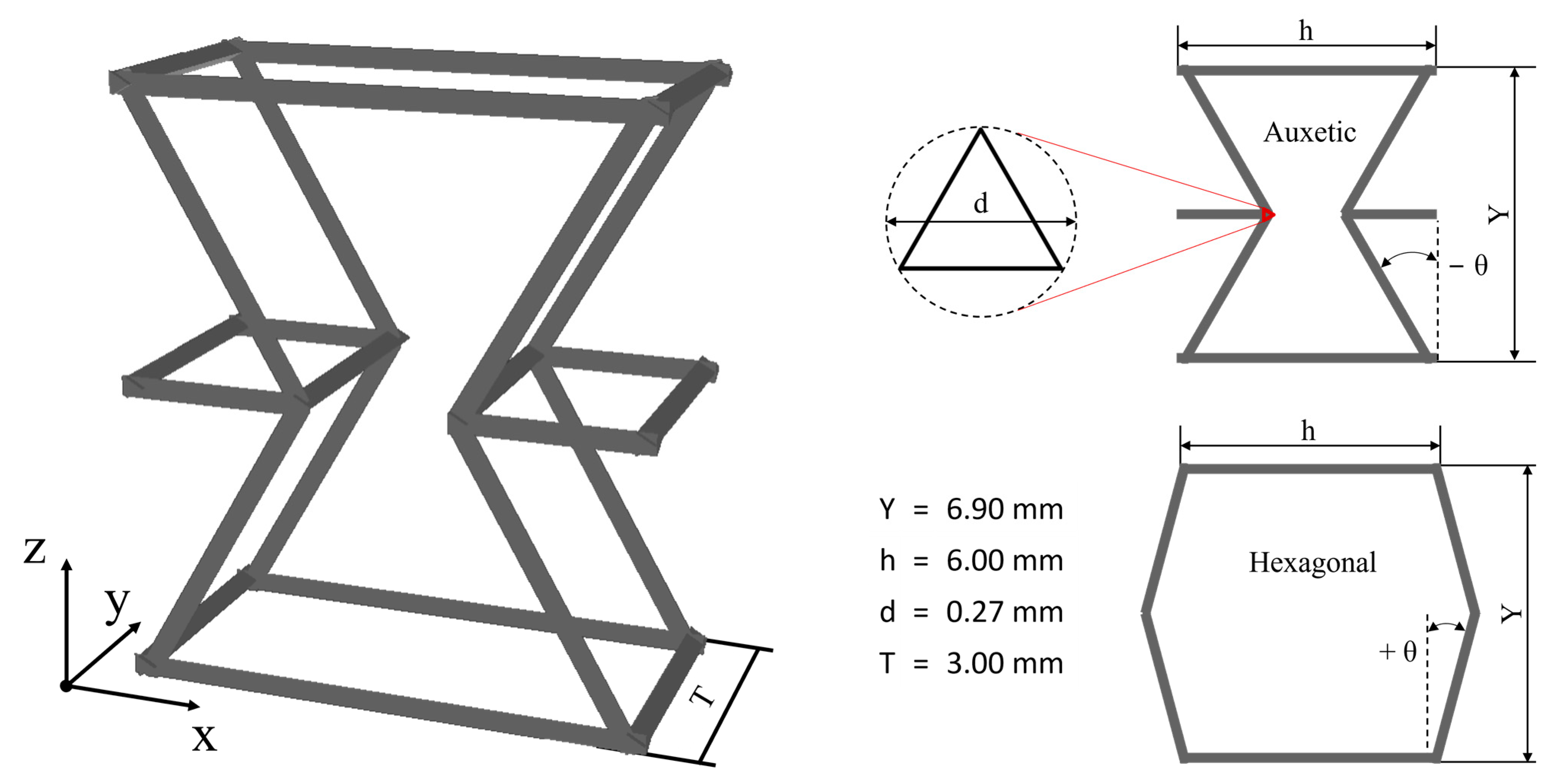

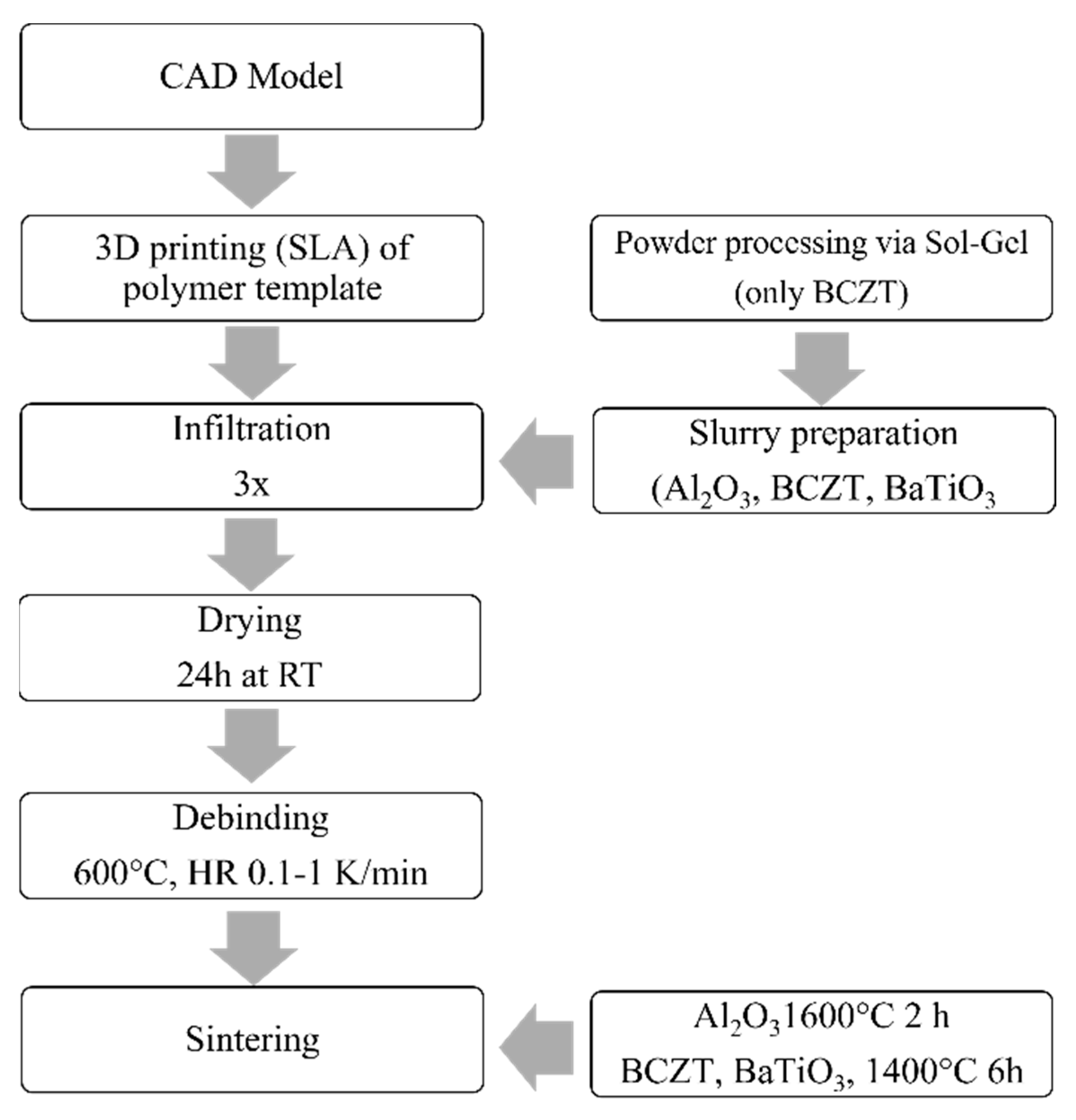

2. Materials and Methods

2.1. Sol–Gel Synthesis

2.2. Sample Preparation

2.3. Characterization

3. Results and Discussion

3.1. BCZT Sol–Gel Route

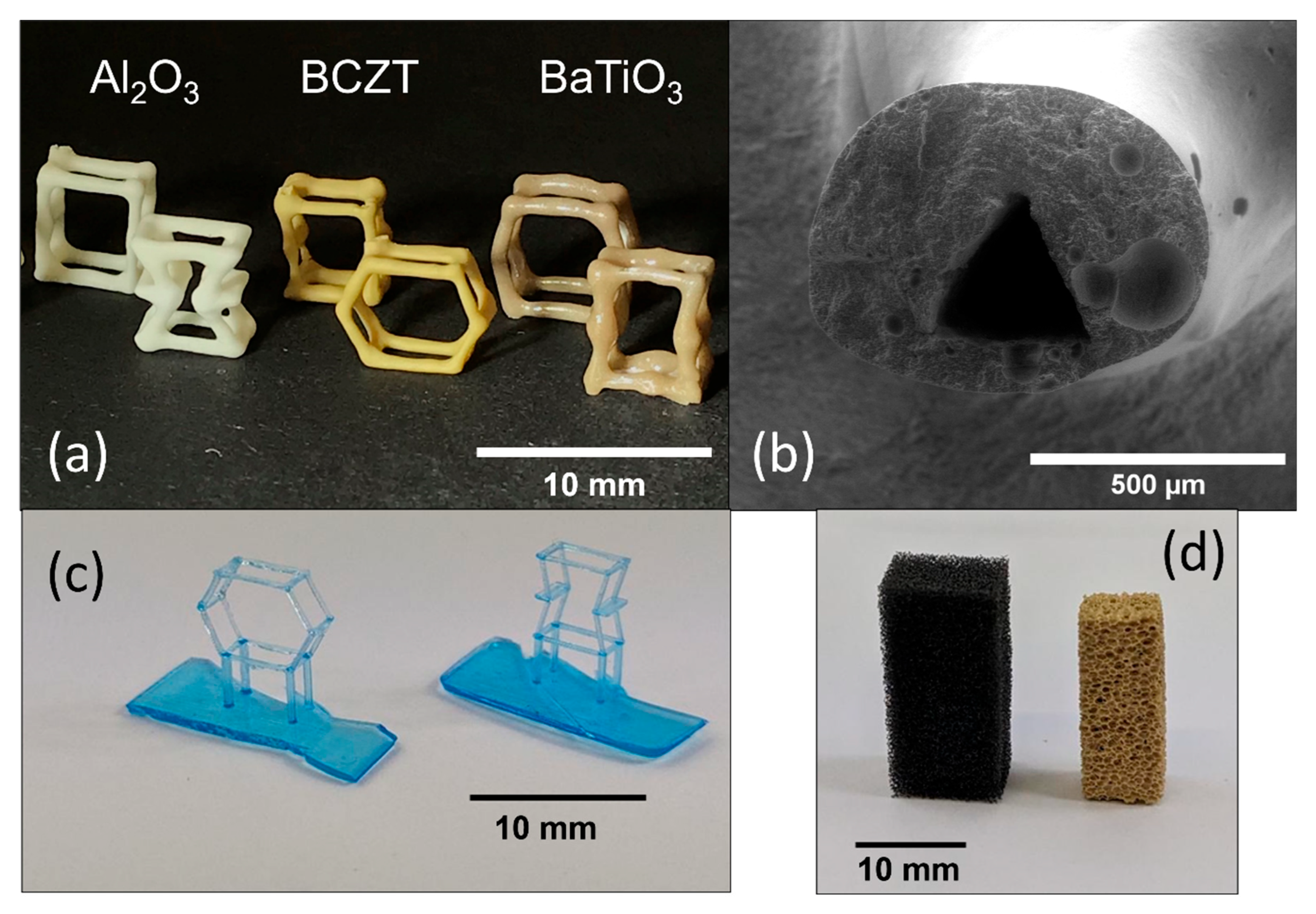

3.2. Macro- and Microstructure of Light-Frame Ceramic Honeycombs

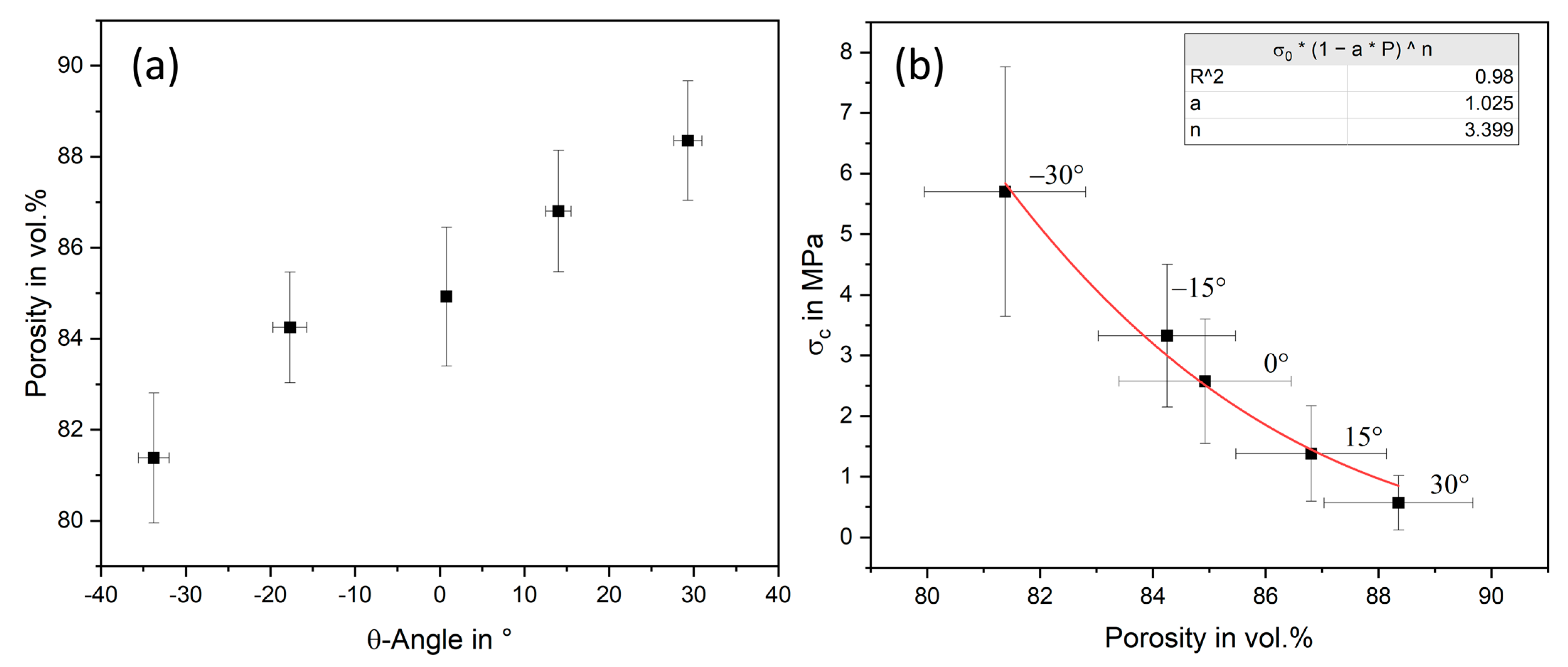

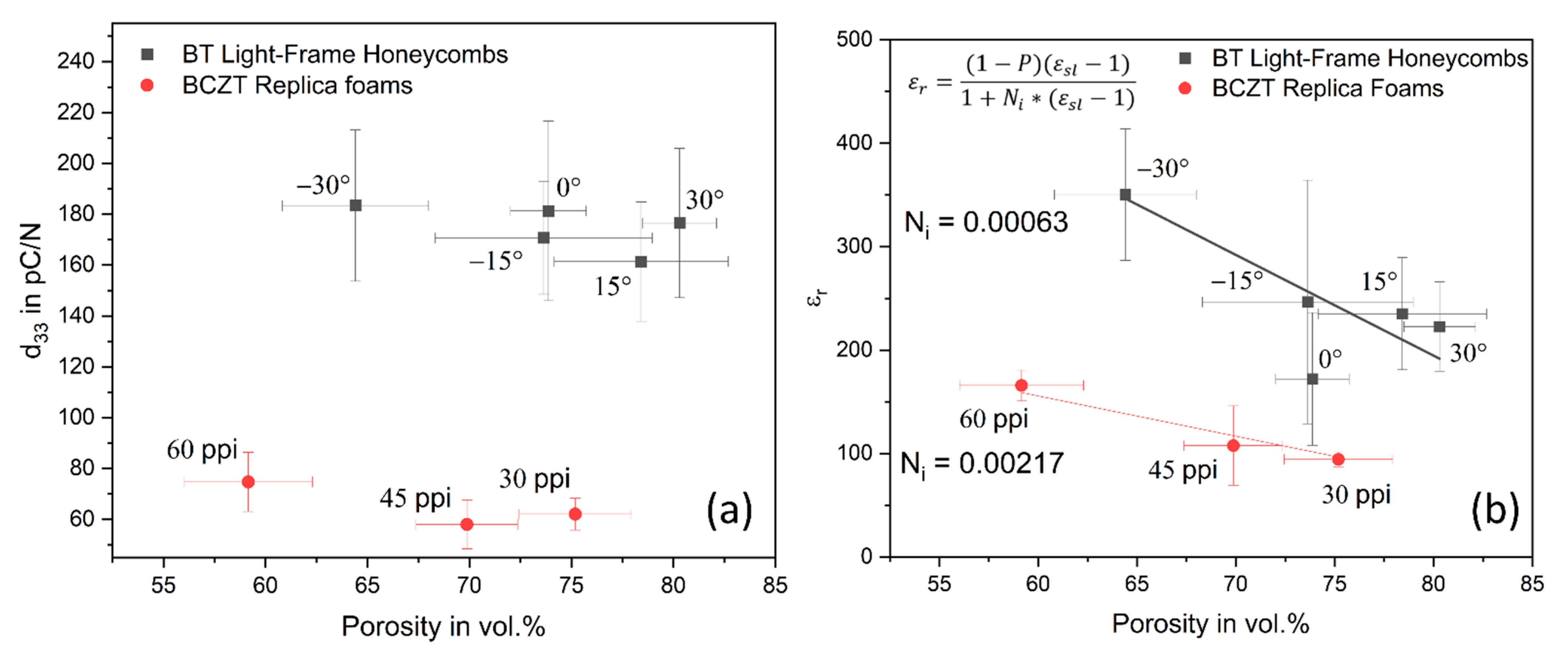

3.3. Mechanical and Piezoelectric Properties of Light-Frame Ceramic Honeycombs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bowen, C.; Perry, A.; Lewis, A.; Kara, H. Processing and properties of porous piezoelectric materials with high hydrostatic figures of merit. J. Eur. Ceram. Soc. 2004, 24, 541–545. [Google Scholar] [CrossRef]

- Maeda, K.; Fujii, I.; Nakashima, K.; Fujimoto, G.; Suma, K.; Sukigara, T.; Wada, S. Preparation of barium titanate porous ceramics and their sensor properties. J. Ceram. Soc. Jpn. 2013, 121, 698–701. [Google Scholar] [CrossRef]

- Yang, A.-K.; Wang, C.-A.; Guo, R.; Huang, Y. Effects of porosity on dielectric and piezoelectric properties of porous lead zirconate titanate ceramics. Appl. Phys. Lett. 2011, 98, 152904. [Google Scholar] [CrossRef]

- Boumchedda, K.; Hamadi, M.; Fantozzi, G. Properties of a hydrophone produced with porous PZT ceramic. J. Eur. Ceram. Soc. 2007, 27, 4169–4171. [Google Scholar] [CrossRef]

- Khansur, N.H.; Biggemann, J.; Stumpf, M.; Riess, K.; Fey, T.; Webber, K.G. Temperature- and Stress-Dependent Electromechanical Response of Porous Pb(Zr, Ti)O3. Adv. Eng. Mater. 2020, 22, 2000389. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids; Cambridge University Press: Cambridge, UK, 1997; ISBN 9780521499118. [Google Scholar]

- Eichhorn, F.; Biggemann, J.; Kellermann, S.; Kawai, A.; Kato, K.; Kakimoto, K.; Fey, T. Influence of Cell Size on Mechanical and Piezoelectric Properties of PZT and LNKN Ceramic Foams. Adv. Eng. Mater. 2017, 19, 1700420. [Google Scholar] [CrossRef]

- Duckworth, W. Discussion of Ryshkewitch Paper by Winston Duckworth. J. Am. Ceram. Soc. 1953, 36, 68. [Google Scholar] [CrossRef]

- Khan, K.A.; Khan, M.A. 3-3 piezoelectric metamaterial with negative and zero Poisson’s ratio for hydrophones applications. Mater. Res. Bull. 2019, 112, 194–204. [Google Scholar] [CrossRef]

- Tang, H.; Jiang, X.; Ling, L.; Li, L.; Hu, Y. Highly tailorable electromechanical properties of auxetic piezoelectric ceramics with ultra-low porosity. J. Am. Ceram. Soc. 2020, 103, 6330–6347. [Google Scholar] [CrossRef]

- Abd El-Sayed, F.K.; Jones, R.; Burgess, I.W. A theoretical approach to the deformation of honeycomb based composite materials. Composites 1979, 10, 209–214. [Google Scholar] [CrossRef]

- Fey, T.; Eichhorn, F.; Han, G.; Ebert, K.; Wegener, M.; Roosen, A.; Kakimoto, K.; Greil, P. Mechanical and electrical strain response of a piezoelectric auxetic PZT lattice structure. Smart Mater. Struct. 2016, 25, 15017. [Google Scholar] [CrossRef]

- Hoffman, G.A. Poisson’s Ratio for Honeycomb Sandwich Cores. J. Aerosp. Sci. 1958, 25, 534–535. [Google Scholar] [CrossRef]

- Balawi, S.; Abot, J.L. The effect of honeycomb relative density on its effective in-plane elastic moduli: An experimental study. Compos. Struct. 2008, 84, 293–299. [Google Scholar] [CrossRef]

- Marselli, S.; Pavia, V.; Galassi, C.; Roncari, E.; Craciun, F.; Guidarelli, G. Porous piezoelectric ceramic hydrophone. J. Acoust. Soc. Am. 1999, 106, 733–738. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Q.; Zhu, J.; Huang, C.; Darvell, B.W.; Chen, Z. Effects of pore shape and porosity on the properties of porous LNKN ceramics as bone substitute. Mater. Chem. Phys. 2008, 109, 488–491. [Google Scholar] [CrossRef]

- Mancuso, E.; Shah, L.; Jindal, S.; Serenelli, C.; Tsikriteas, Z.M.; Khanbareh, H.; Tirella, A. Additively manufactured BaTiO3 composite scaffolds: A novel strategy for load bearing bone tissue engineering applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2021, 126, 112192. [Google Scholar] [CrossRef]

- Li, J.-F.; Takagi, K.; Ono, M.; Pan, W.; Watanabe, R.; Almajid, A.; Taya, M. Fabrication and Evaluation of Porous Piezoelectric Ceramics and Porosity-Graded Piezoelectric Actuators. J. Am. Ceram. Soc. 2003, 86, 1094–1098. [Google Scholar] [CrossRef]

- Zeng, T.; Dong, X.; Chen, S.; Yang, H. Processing and piezoelectric properties of porous PZT ceramics. Ceram. Int. 2007, 33, 395–399. [Google Scholar] [CrossRef]

- Curecheriu, L.; Lukacs, V.A.; Padurariu, L.; Stoian, G.; Ciomaga, C.E. Effect of Porosity on Functional Properties of Lead-Free Piezoelectric BaZr0.15Ti0.85O3 Porous Ceramics. Materials 2020, 13, 3324. [Google Scholar] [CrossRef]

- Lee, S.-H.; Jun, S.-H.; Kim, H.-E.; Koh, Y.-H. Fabrication of Porous PZT?PZN Piezoelectric Ceramics with High Hydrostatic Figure of Merits Using Camphene-Based Freeze Casting. J. Am. Ceram. Soc. 2007, 90, 2807–2813. [Google Scholar] [CrossRef]

- Lee, S.-H.; Jun, S.-H.; Kim, H.-E.; Koh, Y.-H. Piezoelectric Properties of PZT-Based Ceramic with Highly Aligned Pores. J. Am. Ceram. Soc. 2008, 91, 1912–1915. [Google Scholar] [CrossRef]

- Roscow, J.I.; Zhang, Y.; Kraśny, M.J.; Lewis, R.W.C.; Taylor, J.; Bowen, C.R. Freeze cast porous barium titanate for enhanced piezoelectric energy harvesting. J. Phys. D Appl. Phys. 2018, 51, 225301. [Google Scholar] [CrossRef]

- Zhang, Y.; Roscow, J.; Xie, M.; Bowen, C. High piezoelectric sensitivity and hydrostatic figures of merit in unidirectional porous ferroelectric ceramics fabricated by freeze casting. J. Eur. Ceram. Soc. 2018, 38, 4203–4211. [Google Scholar] [CrossRef]

- Köllner, D.; Biggemann, J.; Simon, S.; Hoffmann, P.; Kakimoto, K.; Fey, T. Additive manufactured replica foams. Open Ceram. 2022, 10, 100258. [Google Scholar] [CrossRef]

- Köllner, D.; Simon, S.; Niedermeyer, S.; Spath, I.; Wolf, E.; Kakimoto, K.; Fey, T. Relation between Structure, Mechanical and Piezoelectric Properties in Cellular Ceramic Auxetic and Honeycomb Structures. Adv. Eng. Mater. 2023, 25, 2201387. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X. Large piezoelectric effect in Pb-free ceramics. Phys. Rev. Lett. 2009, 103, 257602. [Google Scholar] [CrossRef]

- Gadelmawla, A.; Dobesh, D.; Eckstein, U.; Grübl, O.; Ehmke, M.; Cicconi, M.R.; Khansur, N.H.; de Ligny, D.; Webber, K.G. Influence of stress on the electromechanical properties and the phase transitions of lead-free (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3. J. Mater. Sci. 2022, 57, 16581–16599. [Google Scholar] [CrossRef]

- Castkova, K.; Maca, K.; Cihlar, J.; Hughes, H.; Matousek, A.; Tofel, P.; Bai, Y.; Button, T.W. Chemical Synthesis, Sintering and Piezoelectric Properties of Ba0.85Ca0.15Zr0.1Ti0.9O3 Lead-Free Ceramics. J. Am. Ceram. Soc. 2015, 98, 2373–2380. [Google Scholar] [CrossRef]

- Praveen, J.P.; Karthik, T.; James, A.R.; Chandrakala, E.; Asthana, S.; Das, D. Effect of poling process on piezoelectric properties of sol–gel derived BZT–BCT ceramics. J. Eur. Ceram. Soc. 2015, 35, 1785–1798. [Google Scholar] [CrossRef]

- Ji, X.; Wang, C.; Li, S.; Zhang, S.; Tu, R.; Shen, Q.; Shi, J.; Zhang, L. Structural and electrical properties of BCZT ceramics synthesized by sol–gel process. J. Mater. Sci. Mater. Electron. 2018, 29, 7592–7599. [Google Scholar] [CrossRef]

- Mezzourh, H.; Belkhadir, S.; Mezzane, D.; Amjoud, M.; Choukri, E.; Lahmar, A.; Gagou, Y.; Kutnjak, Z.; El Marssi, M. Enhancing the dielectric, electrocaloric and energy storage properties of lead-free Ba0.85Ca0.15Zr0.1Ti0.9O3 ceramics prepared via sol-gel process. Phys. B Condens. Matter 2021, 603, 412760. [Google Scholar] [CrossRef]

- Rödel, J.; Webber, K.G.; Dittmer, R.; Jo, W.; Kimura, M.; Damjanovic, D. Transferring lead-free piezoelectric ceramics into application. J. Eur. Ceram. Soc. 2015, 35, 1659–1681. [Google Scholar] [CrossRef]

- Ehmke, M.C.; Ehrlich, S.N.; Blendell, J.E.; Bowman, K.J. Phase coexistence and ferroelastic texture in high strain (1 − x)Ba(Zr0.2Ti0.8)O3–x(Ba0.7Ca0.3)TiO3 piezoceramics. J. Appl. Phys. 2012, 111, 124110. [Google Scholar] [CrossRef]

- Ando, D.; Kakimoto, K. Pyroelectric energy harvesting using low- TC (1 − x)(Ba0.7Ca0.3)TiO3–x Ba(Zr0.2Ti0.8)O3 bulk ceramics. J. Am. Ceram. Soc. 2018, 101, 5061–5070. [Google Scholar] [CrossRef]

- OpenSCAD. Available online: https://openscad.org/ (accessed on 24 January 2022).

- ImageJ. Available online: https://imagej.net/downloads (accessed on 8 September 2022).

- Patil, K.C.; Chandrashekhar, G.V.; George, M.V.; Rao, C.N.R. Infrared spectra and thermal decompositions of metal acetates and dicarboxylates. Can. J. Chem. 1968, 46, 257–265. [Google Scholar] [CrossRef]

- Shi, M.; Zhong, J.; Zuo, R.; Xu, Y.; Wang, L.; Su, H.; Gu, C. Effect of annealing processes on the structural and electrical properties of the lead-free thin films of (Ba0.9Ca0.1)(Ti0.9Zr0.1)O3. J. Alloys Compd. 2013, 562, 116–122. [Google Scholar] [CrossRef]

- Keeble, D.S.; Benabdallah, F.; Thomas, P.A.; Maglione, M.; Kreisel, J. Revised structural phase diagram of (Ba0.7Ca0.3TiO3)-(BaZr0.2Ti0.8O3). Appl. Phys. Lett. 2013, 102, 092903. [Google Scholar] [CrossRef]

- Coondoo, I.; Panwar, N.; Alikin, D.; Bdikin, I.; Islam, S.S.; Turygin, A.; Shur, V.Y.; Kholkin, A.L. A comparative study of structural and electrical properties in lead-free BCZT ceramics: Influence of the synthesis method. Acta Mater. 2018, 155, 331–342. [Google Scholar] [CrossRef]

- Simon, S.; Köllner, D.; Hoffmann, P.; Keck, E.; Spath, I.; Meyse, M.; Fey, T. Influence of ceramic Kelvin Cell’s strut shape on mechanical properties. Open Ceram. 2023, 13, 100334. [Google Scholar] [CrossRef]

- Phani, K.K.; Niyogi, S.K. Young’s modulus of porous brittle solids. J. Mater. Sci. 1987, 22, 257–263. [Google Scholar] [CrossRef]

- Zierath, B.; Greil, P.; Stumpf, M.; Fey, T. Enforcing of Mechanical Properties of Alumina Foams. In Advances in Ceramic Armor, Bioceramics, and Porous Materials; LaSalvia, J.C., Narayan, R., Colombo, P., Fukushima, M., Gyekenyesi, A., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; pp. 149–162. ISBN 9781119321682. [Google Scholar]

- Köllner, D.; Tolve-Granier, B.; Simon, S.; Kakimoto, K.; Fey, T. Advanced Estimation of Compressive Strength and Fracture Behavior in Ceramic Honeycombs by Polarimetry Measurements of Similar Epoxy Resin Honeycombs. Materials 2022, 15, 2361. [Google Scholar] [CrossRef] [PubMed]

- Ashby, M.F.; Medalist, R.F.M. The mechanical properties of cellular solids. MTA 1983, 14, 1755–1769. [Google Scholar] [CrossRef]

- Brezny, R.; Green, D.J. Fracture Behavior of Open-Cell Ceramics. J. Am. Ceram. Soc. 1989, 72, 1145–1152. [Google Scholar] [CrossRef]

- Voorhees, E.J.; Green, D.J. Failure Behavior of Cellular-Core Ceramic Sandwich Composites. J. Am. Ceram. Soc. 1991, 74, 2747–2752. [Google Scholar] [CrossRef]

- Singh, K.B.; Tirumkudulu, M.S. Cracking in drying colloidal films. Phys. Rev. Lett. 2007, 98, 218302. [Google Scholar] [CrossRef]

- Takahashi, H.; Numamoto, Y.; Tani, J.; Matsuta, K.; Qiu, J.; Tsurekawa, S. Lead-Free Barium Titanate Ceramics with Large Piezoelectric Constant Fabricated by Microwave Sintering. Jpn. J. Appl. Phys. 2006, 45, L30. [Google Scholar] [CrossRef]

- Somiya, S. Handbook of Advanced Ceramics; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 9780123854698. [Google Scholar]

- Moreira, E.A.; Innocentini, M.; Coury, J.R. Permeability of ceramic foams to compressible and incompressible flow. J. Eur. Ceram. Soc. 2004, 24, 3209–3218. [Google Scholar] [CrossRef]

- Okazaki, K. Recent developments in piezoelectric ceramics in japan. Ferroelectrics 1981, 35, 173–178. [Google Scholar] [CrossRef]

- Gauckler, L.J. Funktionskeramik; ETH: Zürich, Switzerland, 2001. [Google Scholar]

| αSS | d33 | Ni | αSS(1)/αSS(2) | d33(2)/d33(1) | Ni(1)/Ni(2) | ||

|---|---|---|---|---|---|---|---|

| in m2/m3 | in pC/N | ||||||

| 45 ppi | 12.0 × 103 | 58.0 | 2.17 × 10−3 | 3.75 | 3.12 | 3.44 | |

| (1) | (BCZT) | ||||||

| (2) | Light-frame HC | 3.2 × 103 | 181.3 | 0.63 × 10−3 | |||

| (1) | (BT, θ = 0°) | 1.88 | 1.43 | 1.99 | |||

| (2) | Normal HC | 1.7 × 103 | 259.0 | 0.31 × 10−3 | |||

| (BCZT, θ = 0°) | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Köllner, D.; Niedermeyer, S.; Vermes, M.; Simon, S.; Kakimoto, K.-i.; Fey, T. Energy-Reduced Fabrication of Light-Frame Ceramic Honeycombs by Replication of Additive Manufactured Templates. Materials 2023, 16, 4924. https://doi.org/10.3390/ma16144924

Köllner D, Niedermeyer S, Vermes M, Simon S, Kakimoto K-i, Fey T. Energy-Reduced Fabrication of Light-Frame Ceramic Honeycombs by Replication of Additive Manufactured Templates. Materials. 2023; 16(14):4924. https://doi.org/10.3390/ma16144924

Chicago/Turabian StyleKöllner, David, Sebastian Niedermeyer, Miklos Vermes, Swantje Simon, Ken-ichi Kakimoto, and Tobias Fey. 2023. "Energy-Reduced Fabrication of Light-Frame Ceramic Honeycombs by Replication of Additive Manufactured Templates" Materials 16, no. 14: 4924. https://doi.org/10.3390/ma16144924

APA StyleKöllner, D., Niedermeyer, S., Vermes, M., Simon, S., Kakimoto, K.-i., & Fey, T. (2023). Energy-Reduced Fabrication of Light-Frame Ceramic Honeycombs by Replication of Additive Manufactured Templates. Materials, 16(14), 4924. https://doi.org/10.3390/ma16144924