Kinetic Analysis for High-Temperature Coarsening of γ″ Phase in Ni-Based Superalloy GH4169

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

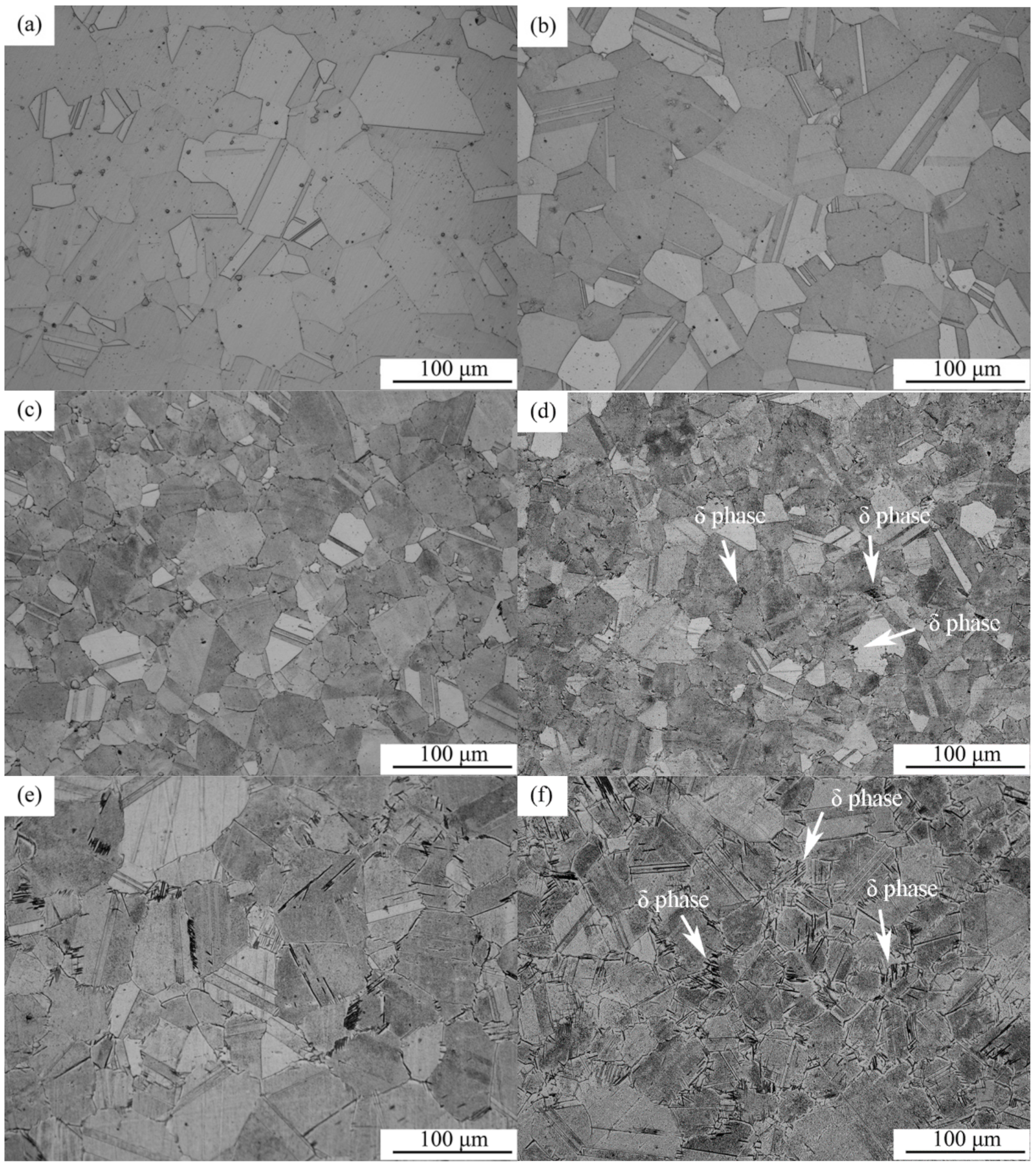

3.1. Precipitation of δ Phase

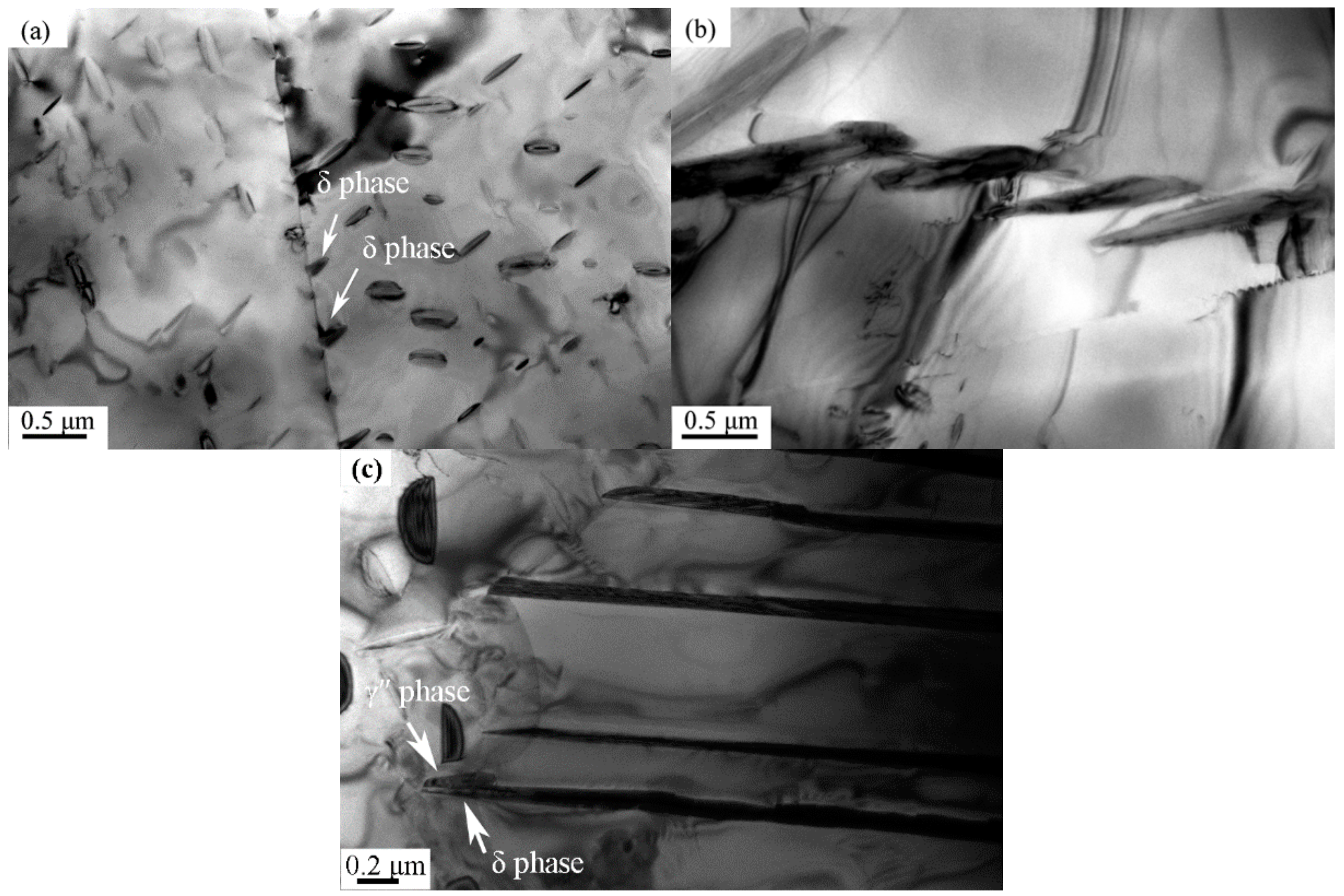

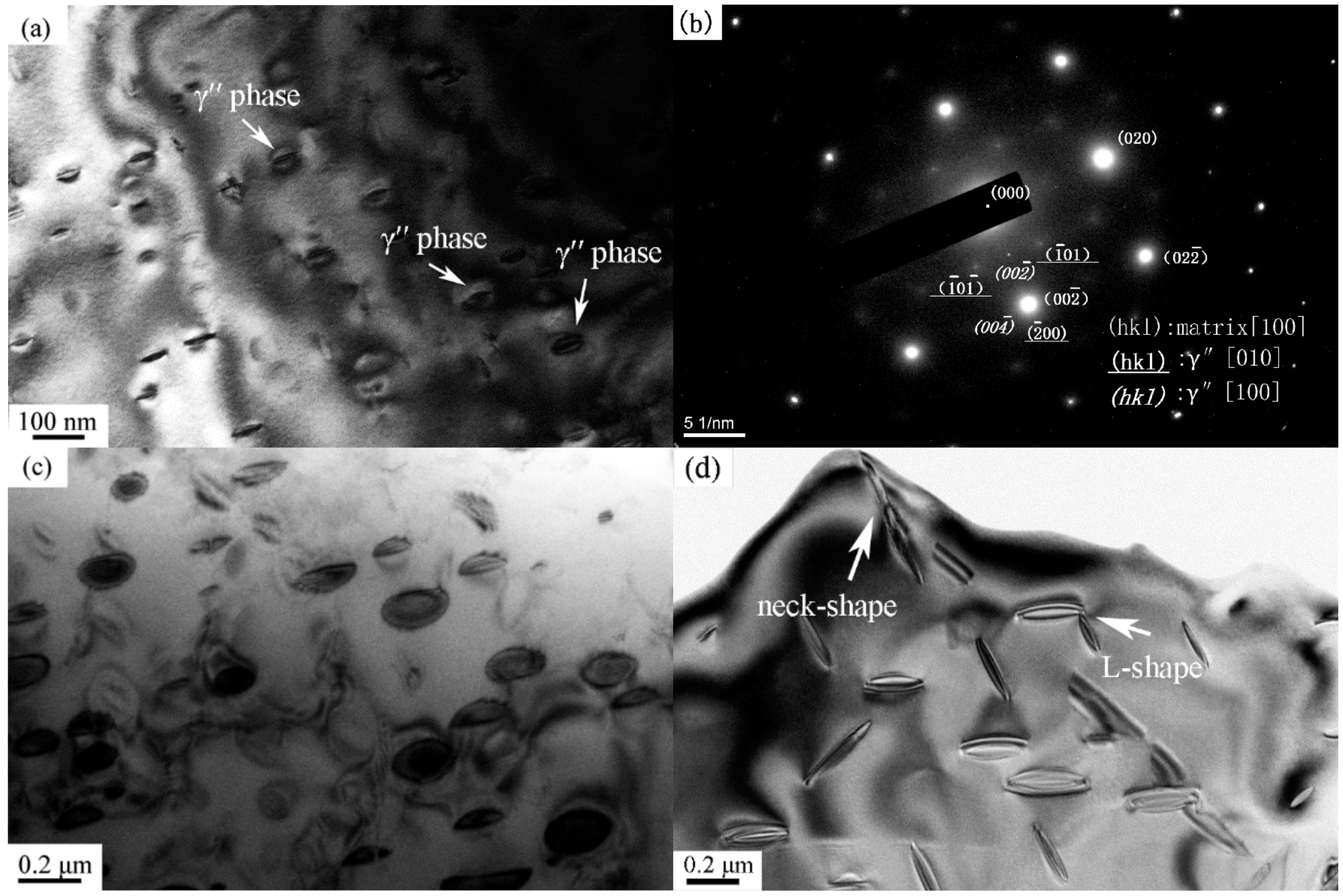

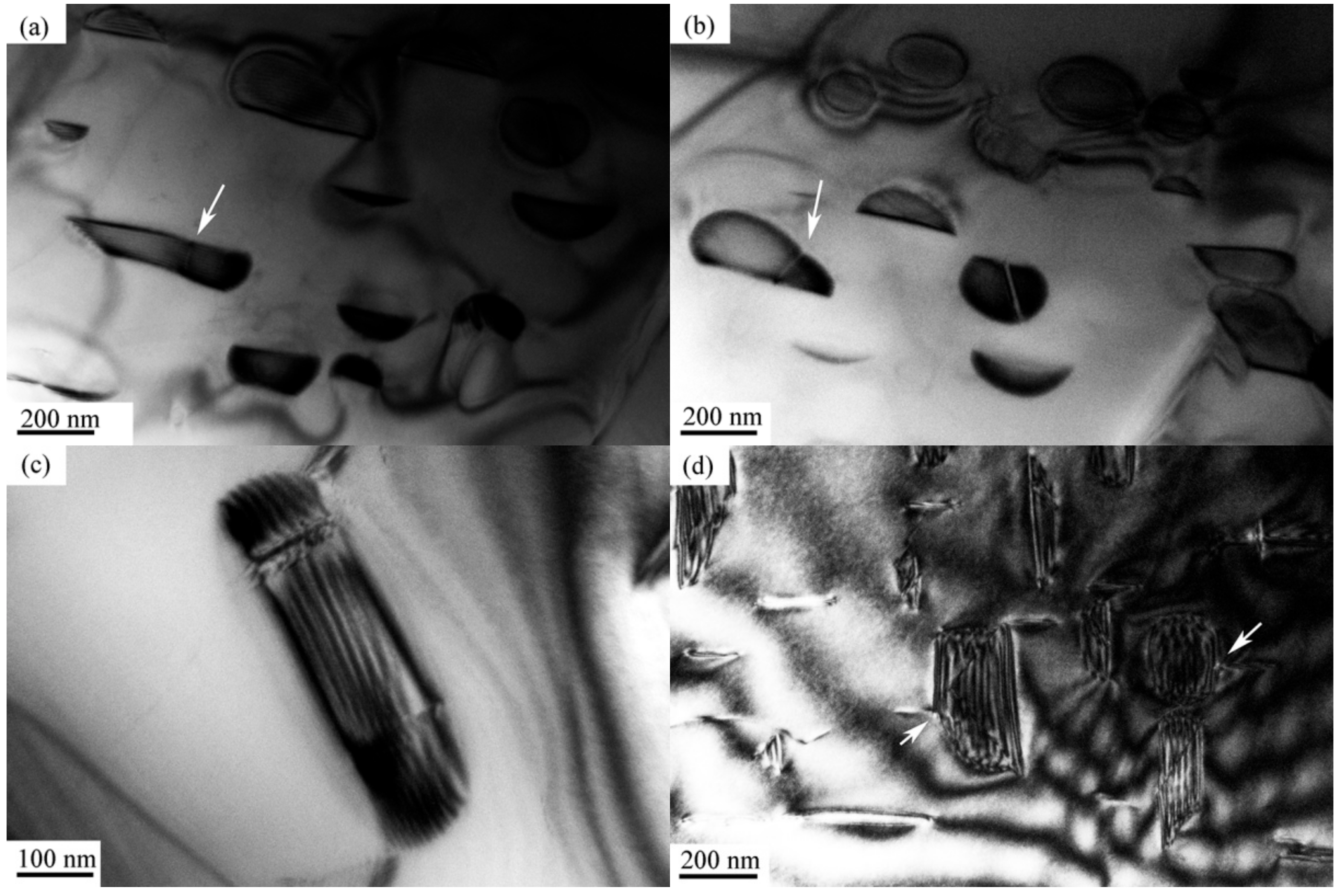

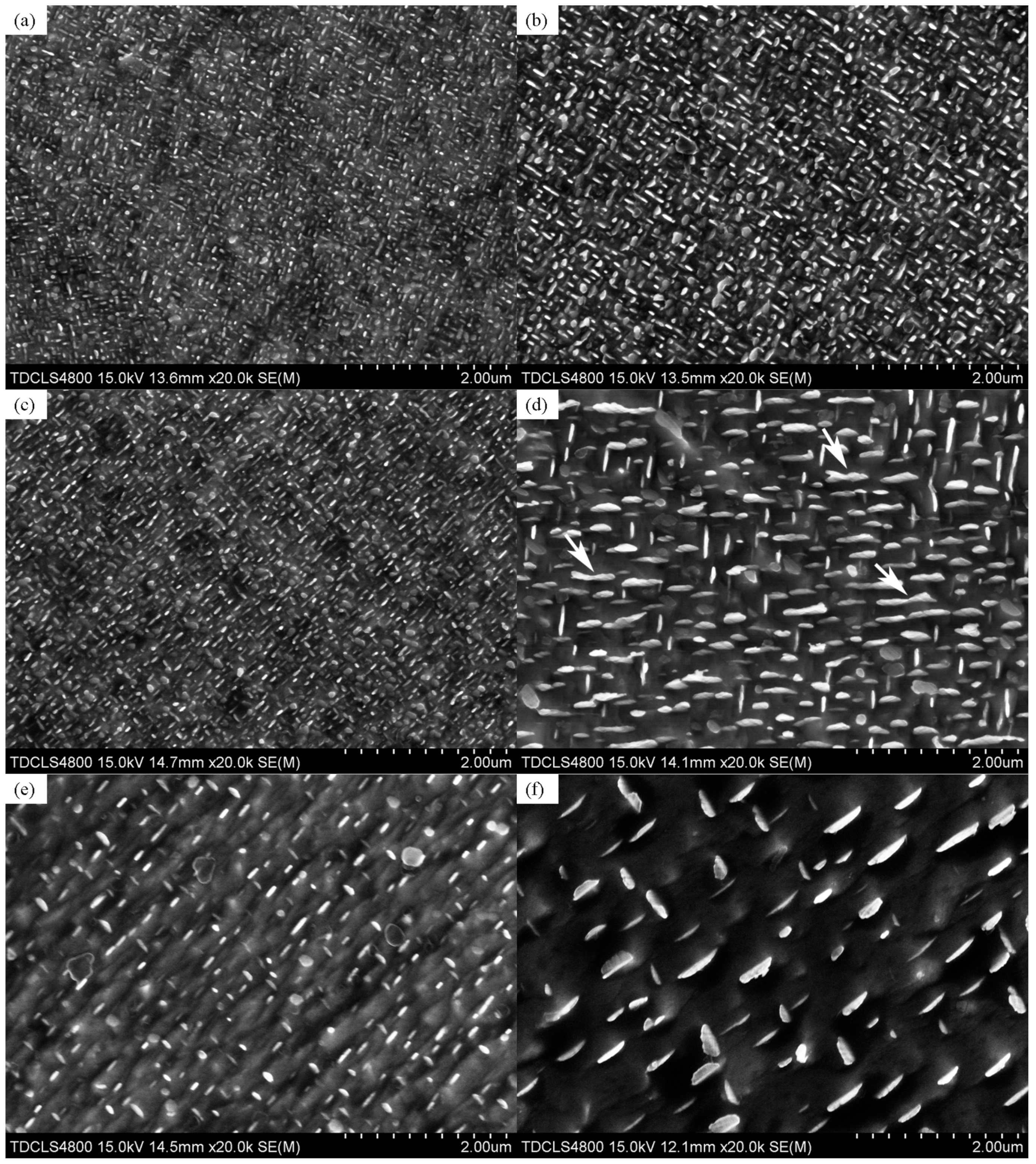

3.2. Morphological Changes of γ″ Phase

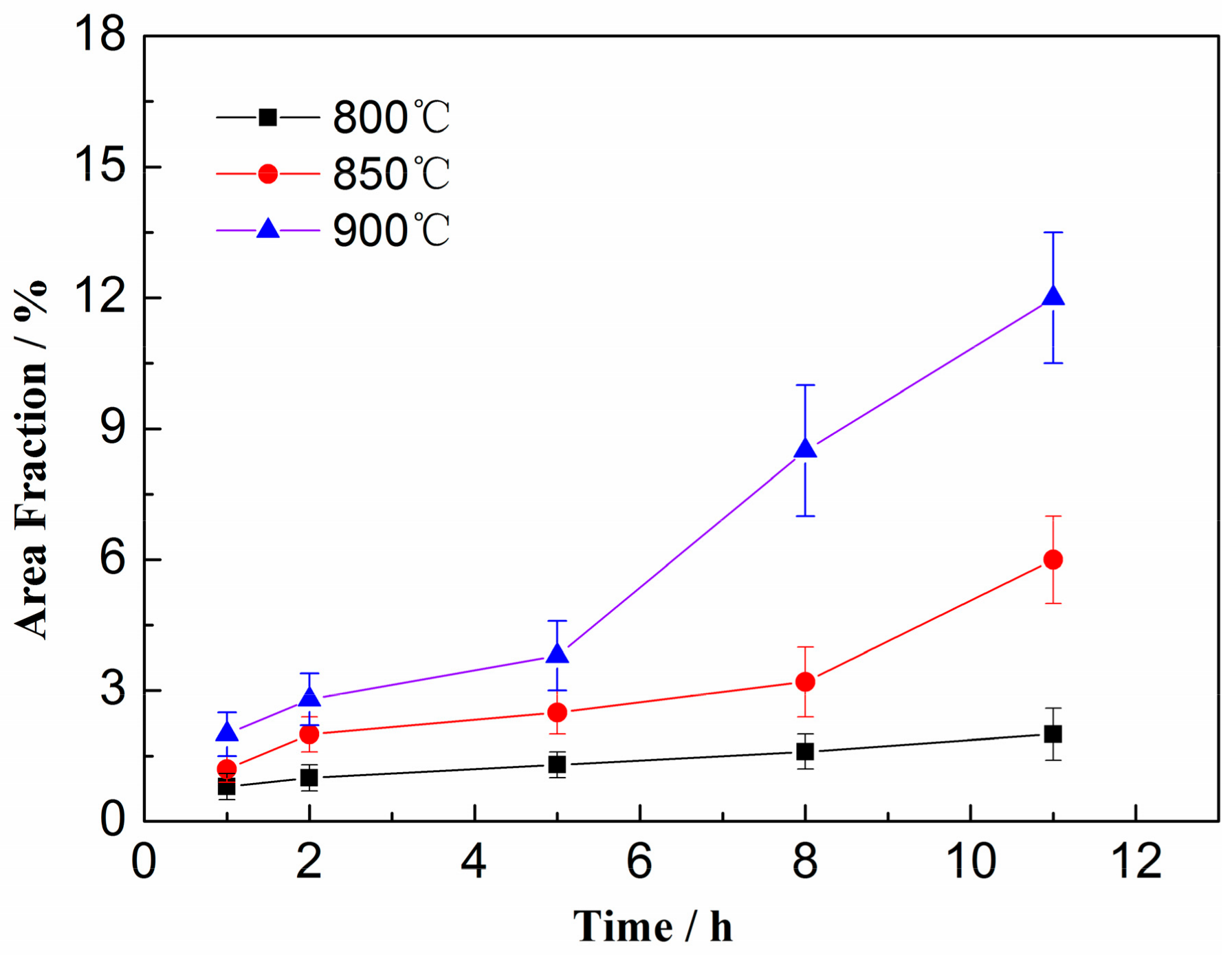

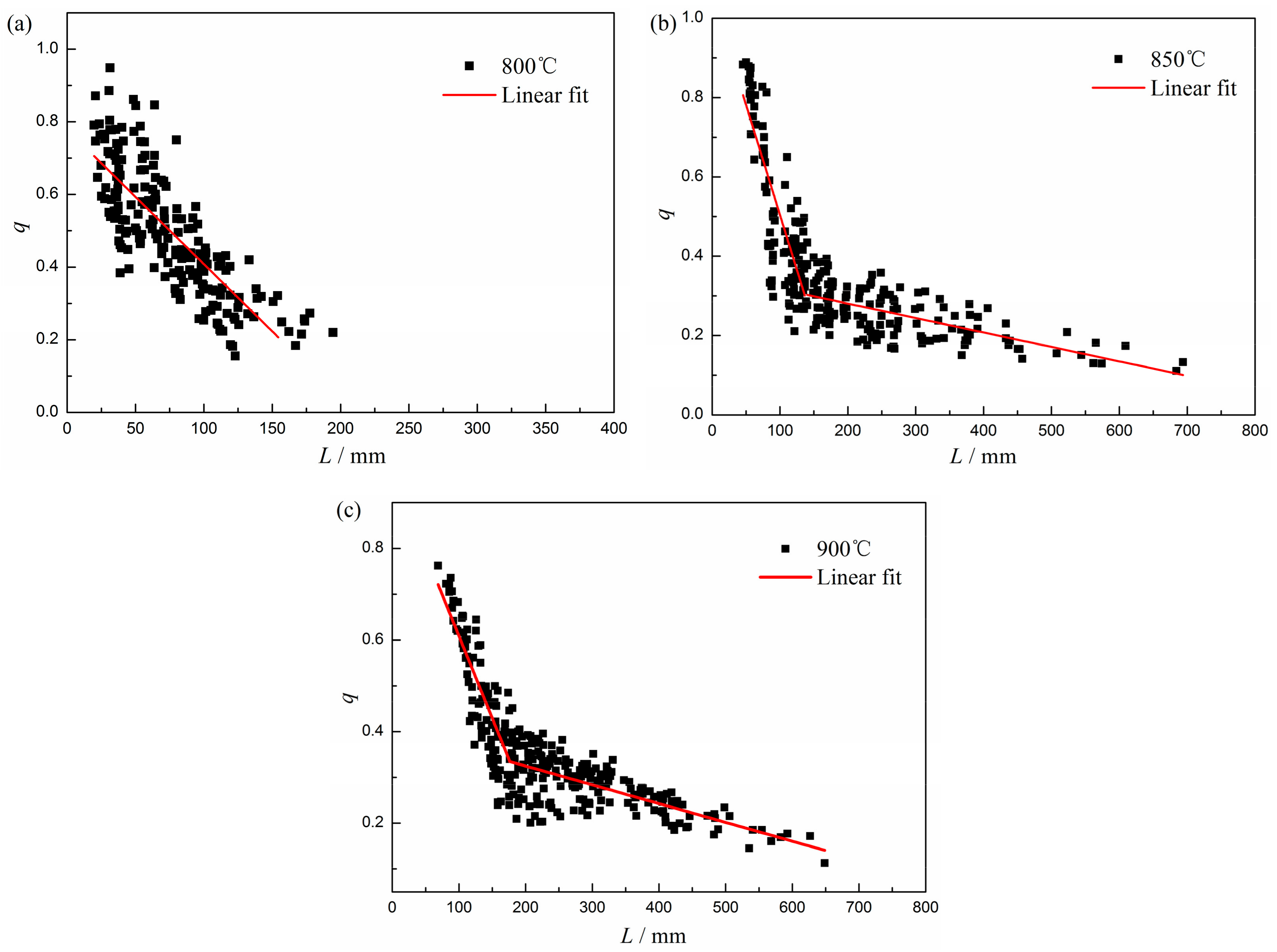

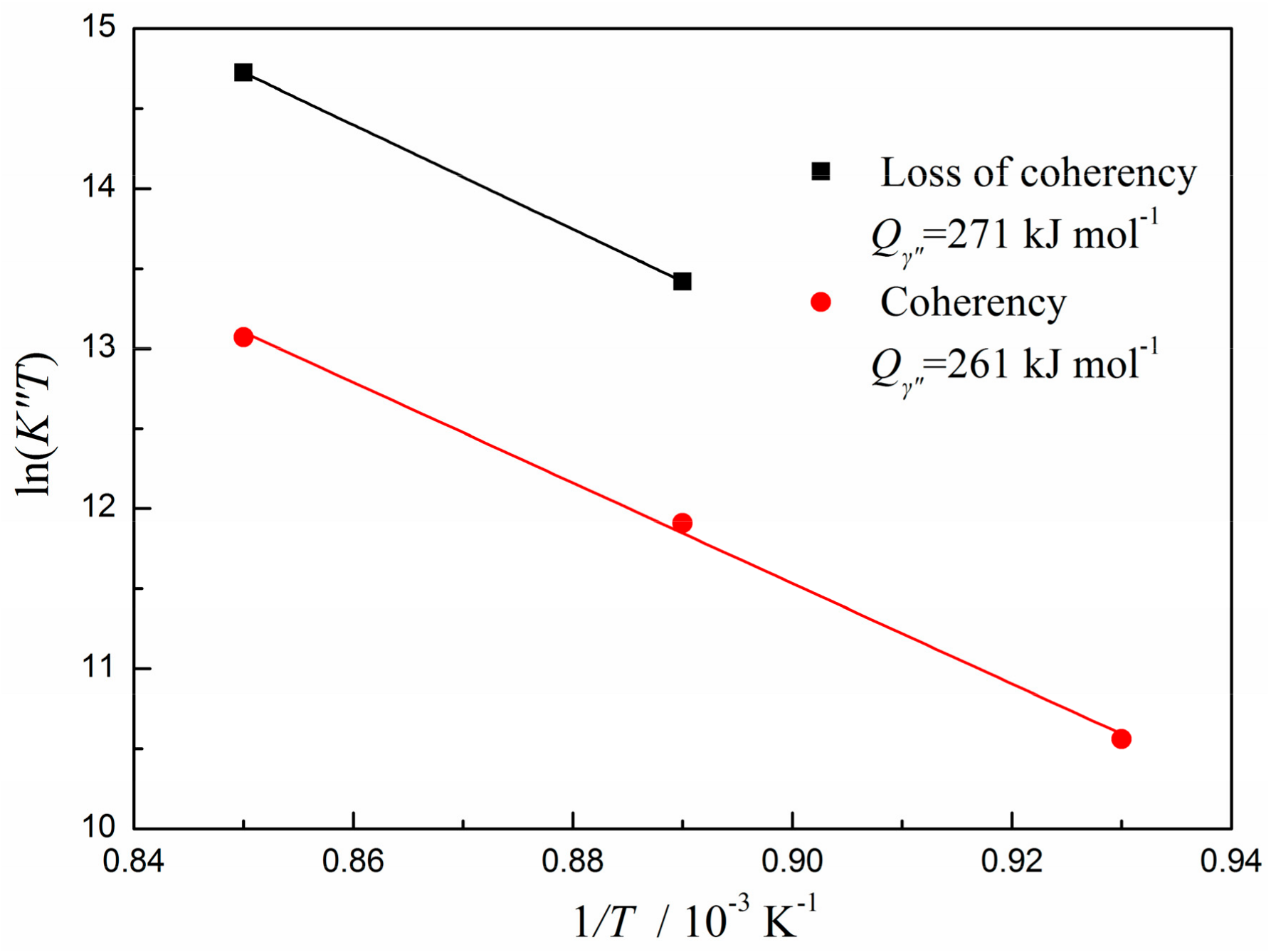

3.3. Coarsening Kinetics of γ″ Precipitates

4. Conclusions

- (1)

- The grain/twin boundary precipitation and intra-granular precipitation of δ phase both occur during the aging processes at 850 °C and 900 °C. There is a time lag between the grain/twin boundary precipitation and the intra-granular precipitation of δ phase, and the pre-precipitating γ″ phase can suppress the intra-granular precipitation of δ phase.

- (2)

- The morphology of γ″ phase changes from a lip-shape to a disc-shape and finally becomes an irregular rectangle-shape.

- (3)

- The coarsening process of γ″ phase in GH4169 is controlled by the volume diffusion of Nb atoms in the matrix and follows the LSW theory. The activation energies before and after γ″ phase losing the coherent relationship with matrix are determined as 261 kJ mol−1 and 271 kJ mol−1, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, H.; Li, C.; Guo, Q.; Ma, Z.; Huang, Y.; Li, H.; Liu, Y. Hot tensile behavior of cold-rolled Inconel 718 alloy at 650 °C: The role of δ phase. Mater. Sci. Eng. A 2018, 722, 136–146. [Google Scholar] [CrossRef]

- Lu, X.; Du, J.; Deng, Q. High temperature structure stability of GH4169 superalloy. Mater. Sci. Eng. A 2013, 559, 623–628. [Google Scholar] [CrossRef]

- Mignanelli, P.M.; Jones, N.G.; Perkins, K.; Hardy, M.; Stone, H.J. Microstructural evolution of a delta containing nickel-base superalloy during heat treatment and isothermal forging. Mater. Sci. Eng. A 2015, 621, 265–271. [Google Scholar] [CrossRef]

- Paulonis, D.; Oblak, J.; Duvall, D. Precipitation in nickel-base alloy 718. Trans. ASM 1969, 62, 611–622. [Google Scholar] [CrossRef]

- Oblak, J.; Paulonis, D.; Duvall, D. Coherency strengthening in Ni base alloys hardened by DO22 γ′ precipitates. Metall. Trans. 1974, 5, 143–153. [Google Scholar] [CrossRef]

- Chaturvedi, M.; Han, Y. Strengthening mechanisms in Inconel 718 superalloy. Met. Sci. 1983, 17, 145–149. [Google Scholar] [CrossRef]

- Chang, S.H.; Lee, S.C.; Huang, K.T. Influences of γ″ and δ Precipitations on the Microstructural Properties of 718 Alloy through HIP, Solid-Solution, and Different Aging Heat Treatments. Mater. Trans. 2010, 51, 1683–1688. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, Q.; Li, C.; Mei, Y.; Zhou, X.; Huang, Y.; Li, H. Recent progress on evolution of precipitates in Inconel 718 superalloy. Acta Metall. 2016, 52, 1259–1266. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Guo, Q.; Zhou, X.; Ma, Z.; Huang, Y.; Li, H. Microstructure evolution of Inconel 718 superalloy during hot working and its recent development tendency. Acta Metall. 2018, 54, 1653–1664. [Google Scholar] [CrossRef]

- Mei, Y.; Liu, Y.; Liu, C.; Li, C.; Yu, L.; Guo, Q.; Li, H. Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel 718. Mater. Des. 2016, 89, 964–977. [Google Scholar] [CrossRef]

- Huang, Y.; Langdon, T.G. The evolution of delta-phase in a superplastic Inconel 718 alloy. J. Mater. Sci. 2007, 42, 421–427. [Google Scholar] [CrossRef]

- Zhang, H.; Li, C.; Liu, Y.; Guo, Q.; Li, H. Precipitation behavior during high-temperature isothermal compressive deformation of Inconel 718 alloy. Mater. Sci. Eng. A 2016, 677, 515–521. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Li, C.; Liu, Y.; Guo, Q.; Huang, Y.; Li, H.; Yu, J. Effect of hot deformation on γ″and δ phase precipitation of Inconel 718 alloy during deformation&isothermal treatment. J. Alloys Compd. 2017, 716, 65–72. [Google Scholar] [CrossRef]

- Han, Y.; Deb, P.; Chaturvedi, M. Coarsening behaviour of γ″-and γ′-particles in Inconel alloy 718. Met. Sci. 1982, 16, 555–562. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. The kinetics of precipitation from supersaturated solid solutions. J. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wanger, C. Theorie der Alterung von Niederschlagen durch Umlosen. Z. Elektrochem. 1961, 65, 581–591. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Liu, Y.; Song, X.; Lü, X.; Zhang, B. Coarsening behavior of γ′and γ″phases in GH4169 superalloy by electric field treatment. Int. J. Miner. Metall. Mater. 2013, 20, 861–866. [Google Scholar] [CrossRef]

- Devaux, A.; Nazé, L.; Molins, R.; Pineau, A.; Organista, A.; Guédou, J.; Uginet, J.; Héritier, P. Gamma double prime precipitation kinetic in Alloy 718. Mater. Sci. Eng. A 2008, 486, 117–122. [Google Scholar] [CrossRef]

- Beaubois, V.; Huez, J.; Coste, S.; Brucelle, O.; Lacaze, J. Short term precipitation kinetics of delta phase in strain free Inconel* 718 alloy. Mater. Sci. Technol. 2004, 20, 1019–1026. [Google Scholar] [CrossRef]

- Kirman, I.; Warrington, D. The precipitation of Ni3Nb phases in a Ni-Fe-Cr-Nb alloy. Metall. Trans. 1970, 1, 2667–2675. [Google Scholar] [CrossRef]

- Sundararaman, M.; Mukhopadhyay, P.; Banerjee, S. Some aspects of the precipitation of metastable intermetallic phases in Inconel 718. Metall. Trans. A 1992, 23, 2015–2028. [Google Scholar] [CrossRef]

- Azadian, S.; Wei, L.; Warren, R. Delta phase precipitation in Inconel 718. Mater. Charact. 2004, 53, 7–16. [Google Scholar] [CrossRef]

- Deng, G.; Tu, S.; Zhang, X.; Wang, J.; Zhang, C.; Qian, X.; Wang, Y. Small fatigue crack initiation and growth mechanisms of nickel-based superalloy GH4169 at 650 °C in air. Eng. Fract. Mech. 2016, 153, 35–49. [Google Scholar] [CrossRef]

- Yeh, A.; Lu, K.; Kuo, C.; Bor, H.; Wei, C. Effect of serrated grain boundaries on the creep property of Inconel 718 superalloy. Mater. Sci. Eng. A 2011, 530, 525–529. [Google Scholar] [CrossRef]

- Davies, C.; Nash, P.; Stevens, R.N. The effect of volume fraction of precipitate on Ostwald ripening. Acta Metall. 1980, 28, 179–189. [Google Scholar] [CrossRef]

- Zhang, J.; Guo, Q.; Liu, Y.; Li, C.; Yu, L.; Li, H. Effect of cold rolling and first precipitates on the coarsening behavior of γ″-phases in Inconel 718 alloy. Int. J. Miner. Metall. Mater. 2016, 23, 1087–1096. [Google Scholar] [CrossRef]

- Moore, I.; Burke, M.; Nuhfer, N.; Palmiere, E. Evaluation of classical precipitation descriptions for γ″ (Ni3Nb-D022) in Ni-base superalloys. J. Mater. Sci. 2017, 52, 8665–8680. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Zhou, X.; Liu, C.; Yu, J.; Huang, Y.; Li, H.; Li, W. Precipitation and hot deformation behavior of austenitic heat-resistant steels: A review. J. Mater. Sci. Technol. 2017, 33, 1448–1456. [Google Scholar] [CrossRef]

- Boyd, J.; Nicholson, R. The coarsening behaviour of θ″ and θ′ precipitates in two Al-Cu alloys. Acta Metall. 1971, 19, 1379–1391. [Google Scholar] [CrossRef]

- Wu, J.; Li, C.; Liu, Y.; Wu, Y.; Guo, Q.; Li, H.; Wang, H. Effect of annealing treatment on microstructure evolution and creep behavior of a multiphase Ni3Al-based superalloy. Mater. Sci. Eng. A 2019, 743, 623–635. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, Y.; Li, C.; Xia, X.; Wu, J.; Li, H. Coarsening behavior of γ′ precipitates in the γ′ + γ area of a Ni3Al-based alloy. J. Alloys Compd. 2019, 771, 526–533. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Nb | C | Mn | Si | Mo | Cu |

| Content | 52.70 | 19.63 | 5.26 | <0.08 | <0.35 | 0.13 | 3.17 | <0.30 |

| Element | Co | Al | Ti | B | S | P | Fe | |

| Content | <1.00 | 0.63 | 1.01 | <0.01 | <0.01 | <0.01 | 15.79. |

| Temperature (°C) | 800 | 850 | 900 |

|---|---|---|---|

| K″/(10 nm3 s−1) | K″ = 3.60 | K″ = 13.26 for L < 122 K″ = 60.00 for L > 122 | K″ = 40.52 for L < 181 K″ = 211.46 for L > 181 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yu, L.; Wang, H. Kinetic Analysis for High-Temperature Coarsening of γ″ Phase in Ni-Based Superalloy GH4169. Materials 2019, 12, 2096. https://doi.org/10.3390/ma12132096

Zhang C, Yu L, Wang H. Kinetic Analysis for High-Temperature Coarsening of γ″ Phase in Ni-Based Superalloy GH4169. Materials. 2019; 12(13):2096. https://doi.org/10.3390/ma12132096

Chicago/Turabian StyleZhang, Cheng, Liming Yu, and Hui Wang. 2019. "Kinetic Analysis for High-Temperature Coarsening of γ″ Phase in Ni-Based Superalloy GH4169" Materials 12, no. 13: 2096. https://doi.org/10.3390/ma12132096

APA StyleZhang, C., Yu, L., & Wang, H. (2019). Kinetic Analysis for High-Temperature Coarsening of γ″ Phase in Ni-Based Superalloy GH4169. Materials, 12(13), 2096. https://doi.org/10.3390/ma12132096