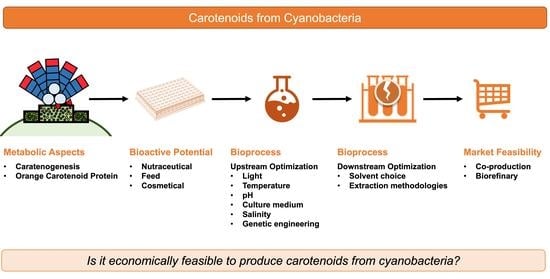

Carotenoids from Cyanobacteria: Biotechnological Potential and Optimization Strategies

Abstract

:1. Introduction

2. Chemistry

3. Orange Carotenoid Protein (OCP)

4. Applications of Carotenoids from Cyanobacteria

| Application | Product | Main Identified Carotenoids | Source | Assay | Reference |

|---|---|---|---|---|---|

| Anti-inflammatory | Acetonic extract | β-carotene and echinenone | Nodosilinea (Leptolyngbya) antarctica | LPS-induced macrophages (RAW 264.7) | [21] |

| Antioxidant | Acetone extract after water extraction | Zeaxanthin and β-carotene | Cyanobium sp. | ABTS•+ and •NO | [22] |

| Acetonic extract | β-carotene and echinenone | Arthrospira platensis | DPPH• and ABTS•+ | [23] | |

| Ethyl acetate extract | β-carotene | Trichodesmium sp. | FRAP | [24] | |

| Methanolic extract | Myxoxanthophyll, zeaxanthin, canthaxanthin and α- and β-carotenes | Lyngbya sp. | DPPH• | [25] | |

| Ethyl acetate/Methanol extract | Zeaxanthin, myxoxanthophyll, β-carotene, echinenone and β-cryptoxanthin | Arthrospira platensis mixed with Dunaliella salina | DMBA-induced tumour in hamster | [26] | |

| Antiurolithiasis | Methanol extract | Myxoxanthophyll, zeaxanthin, canthaxanthin and 〈- and β-carotenes | Pseudanabaena sp., Spirulina sp. and Lyngbya sp. | Calcium oxalate crystallization | [25] |

| Colour Enhancer (Feed) | Raw biomass | Zeaxanthin, β-carotene and myxoxanthophyll | Arthrospira platensis | In vivo fish and poultry assays | [27,28,29,30] |

| Hyaluronidase inhibitor | Ethanol 70% extract | Zeaxanthin, lutein, canthaxanthin and echinenone | Cyanobium sp. and Tychonema sp. | Hyaluronidase in vitro assay | [31] |

5. Bioprocess Optimization

5.1. Production of Carotenoids

5.1.1. Light

| Cyanobacterium | Tested Conditions a | Processing Parameters b | Optimal Condition | Carotenoids Content | Reference |

|---|---|---|---|---|---|

| Light Quality | |||||

| Arthrospira platensis | W, B, R | LS: FL; I: 133; LC: 24:0 h; T: 36 °C; pH: ns; M: Zarrouk | R | 23.2 mg.gDW−1 | [39] |

| Arthrospira platensis | R + B (0–100% mixtures) | LS: LED; I: 100; LC: 24:0 h; T: 32 °C; pH: 8.0; M: Zarrouk | R + B (70:30, %) | 6.91 μg.mL−1 | [44] |

| Cyanobium sp. | R; G; B; UV supplements | LS: SOX + LED; I: 200; LC: 12:12 h; T: 25 °C; pH: 7.5; M: BG11 saline | R supplement | 6.5 mg.gDW−1 | [37] |

| Cyanobium sp. | W + R in different times | LS: LED; I: 200; LC: 16:8 h; T: 20 °C; pH: 9; M: BG11 saline | 10 days of W and 4 days of R | 32 mg.gDW−1 | [38] |

| Leptolyngbya cf. fragilis | (+/−) UV-B | LS: FL + UV lamp; I: 18 W.m−2; LC: 12:12 h; T: 25 °C; pH: ns; M: BG11 | +UV | 0.29 mg.gDW−1 | [45] |

| Lyngbya aestuarii | (+/−) UV-B | LS: FL + UV lamp; I: 7.5 W.m−2 FL or 5 W.m−2 UV; LC: 24:0 h; T: 25 °C; pH: ns; M: ASN-III | +UV | ns | [46] |

| Nostoc commune | (+/−) UV-B | LS: FL + UV lamp; I: 1 W.m−2; LC: ns; T: 30 °C; pH: ns; M: BG110 | +UV-B | ns | [48] |

| Pseudanabaena sp. | W, B, R, G, Y | LS: FL + colour filters; I: 75–220 lux; LC: 12:12 h; T: 25 °C; pH: ns; M: ASN-III | G | 0.16 mg.L−1 | [40] |

| Synechocystis sp. | (+/−) UV-B | LS: FL + UV lamp; I: 60; LC: ns; T: 30 °C; pH: ns; M: BG11 | +UV | ns | [49] |

| Light Intensity | |||||

| Cyanobium sp. | 50, 100, 200, 300 | LS: FL or SOX; LC: 12:12 h; T: 25 °C; pH: 7.5; M: BG11 saline | 200 | 0.12 mg.L−1.d−1 | [53] |

| Synechococcus sp. | 40, 1300 | LS: FL; LC: 24:0 h; T: 25 °C; pH: ns; M: BG11 | 1300 | 7.59 nmol.A750−1.mL−1 | [51] |

| Microcystis aeruginosa | 20, 40, 70 | LS: FL; LC: 12:12 h; T: 25 °C; pH: ns; M: ASM | 40 | β-carotene: 579.7 μg.gDW-1 | [55] |

| Zeaxanthin: 431.2 μg.gDW-1 | |||||

| Echinenone: 143.3 μg.gDW-1 | |||||

| Anabaena cylindrica | 15, 120 | LS: FL; LC: 24:0 h; T: 20 °C; pH: ns; M: Juttner | 120 | ns | [52] |

| Anabaenopsis elenkinii | 15, 120 | LS: FL; LC: 24:0 h; T: 20 °C; pH: ns; M: Juttner | 120 | ns | [52] |

| Anabaena torulosa | 15, 120 | LS: FL; LC: 24:0 h; T: 20 °C; pH: ns; M: Juttner | 120 | ns | [52] |

| Nostoc sp. | 15, 120 | LS: FL; LC: 24:0 h; T: 20 °C; pH: ns; M: Juttner | 120 | ns | [52] |

| Microcystis aeruginosa | 15, 176 | LS: FL; LC: 16:8 h; T: 20 °C; pH: ns; M: BG11 | 176 | ca. 0.035 pg.cell−1 | [50] |

| Cyanobacterium aponinum | 15, 40, 70, 100, 150, 300, 500, 650 | LS: FL; LC: 24:0 h; T: 35 °C; pH: 8.0; M: BG11 | β-carotene: 100 | β-carotene:4.03 mg.gDW−1 | [54] |

| Zeaxanthin: 650 | Zeaxanthin: 3.17 mg.gDW−1 | ||||

5.1.2. Temperature and pH

| Cyanobacterium | Tested Conditions | Processing Parameters a | Optimal Condition | Carotenoids Content | Reference |

|---|---|---|---|---|---|

| pH | |||||

| Arthrospira platensis | 7.5–11.0 | LS: FL; I: 60; LC: ns; T: 31 °C; M: Zarrouk | 8.0-9.0 | 2.4 mg.gDW−1 | [60] |

| Cyanobium sp. | 6.0–9.0 | LS: FL; I: 200; LC: 16:8 h; T: 20 °C; M: BG11 saline | 9.0 | 2.04 mg.L−1.d−1 | [61] |

| Temperature | |||||

| Anabaena sp. | 15, 23, 30, 37 °C | LS: FL; I: 60; LC: 24:0 h; pH: 7.5; M: BG110 | 23 °C | 0.39 mg.gDW−1 | [59] |

| Cyanobium sp. | 20–30 °C | LS: FL; I: 200; LC: 16:8; pH: 9.0; M: BG11 saline | 20 °C | 2.04 mg.L−1.d−1 | [61] |

5.1.3. Culture Medium Composition

| Cyanobacterium | Tested Culture Media | Processing Parameters a | Optimal Condition | Carotenoids Content | Reference |

|---|---|---|---|---|---|

| Culture Media Comparison | |||||

| Arthrospira platensis | Zarrouk and RM6 | LS: ns; I: 2000–3000 lux; LC: 12:12 h; T: 20 °C; pH: 8.2; | Zarrouk | 2.26 mg.gDW−1 | [65] |

| Synechocystis sp. | CHU10, GB11 and Zarrouk | LS: ns; I: 60; LC: ns; T: 25 °C; pH: ns; | Zarrouk | 7.99 mg.gDW−1 | [67] |

| Geitlerinema amphibium | WC and BBM | LS: ns; I: 80; LC: 24:0h; T: 29 °C; pH: ns; | BBM | Astaxanthin: 2.74 mg.gDW−1 Lutein: 5.49 mg.gDW−1 | [66] |

| Nutrient’s concentration | |||||

| Arthrospira platensis | 0–2.5 g.L−1 of N:P:K (1:1:1) | LS: ns; I: 1500 lux; LC: 14:10 h; T: 35 °C; pH: 10; M: Lonar lake water | 2 g.L−1 | 0.0998 μg.mL−1 | [62] |

| Arthrospira platensis | 0.1–5 g.L−1 of NaNO3 | LS: FL; I: 475 lux; LC: 24:0 h; T: 25 °C; pH: 9.5; M: Zarrouk | 0.1 g.L−1 | 45.54 mg.gDW−1 | [63] |

| Cyanobium sp. | (+/−) NaNO3; K2HPO4 | LS: SOX; I: 200; LC: 12:12 h; T: 25 °C; pH: 7.5; M: BG11 saline | +NaNO3; K2HPO4 | 0.12 mg.L−1.d−1 | [53] |

| Nitrogen source | |||||

| Prochlorococcus sp. | NaNO3, NaNO2, NH4Cl, CH4N2O | LS: FL; I: 27; LC: 24:0 h; T: 25 °C; pH: ns; M: BBM | CH4N2O | 3.34 mg.gDW−1 | [64] |

5.1.4. Salinity

| Cyanobacterium | Tested [NaCl] | Processing Parameters a | Optimal Condition | Carotenoids Content | Reference |

|---|---|---|---|---|---|

| Cyanobium sp. | 10–30 g.L−1 | LS: FL; I: 200; LC: 16:8; T: 20 °C; pH: 9.0; M: BG11 saline | 10 g.L−1 | 2.04 mg.L−1.d−1 | [61] |

| Euhalothece sp. | 0 and 30 g.L−1 | LS: ns; I: 75; LC: 14:10; T: 27 °C; pH: 7.5; M: BG11 | 0 g.L−1 | 0.61 μg.A750−1 | [68] |

5.1.5. Genetic Engineering

5.2. Downstream Process

| Cyanobacterium | Tested Solvents | Optimal Solvent | Carotenoid Content (mg.gDW−1) | Main Identified Carotenoids | Reference |

|---|---|---|---|---|---|

| Gloeothece sp. | Ethanol, acetone, ethyl lactate, and hexane/isopropanol (60:40, in percentages). | Acetone | 1.8 | Lutein, β-carotene, neoxanthin, violaxanthin, and α-carotene | [75] |

| Arthrospira platensis | Ethanol, acetone, methanol, diethyl ether, and DMSO after enzymatic pre-treatment | Ethanol | 5.3 | n.s. | [76] |

| Cyanobium sp. | Acetone, ethyl acetate, and ethanol | Acetone | 4.4 | β-carotene, echinenone, zeaxanthin, and lutein | [22] |

| Chroococcidiopsis sp. | Acetone, ethanol, and methanol | Methanol | 1.7 | Echinenone, β-carotene, α-carotene, lycopene, and zeaxanthin | [78] |

| Cyanobacterium | Extraction Method | Carotenoid Content (mg.gDW−1) | Main Identified Carotenoids | Reference |

|---|---|---|---|---|

| Phormidium spp. | Pressurized liquid extraction | n.s. | β-carotene, followed by lutein, violaxanthin, and neoxanthin | [81] |

| Gloeothece sp. | Continuous pressurized solvent extraction | Lutein: 2.9 β-carotene: 1.5 | Lutein, β-carotene, neoxanthin, violaxanthin and α-carotene | [82] |

| Arthrospira platensis | Ultrasound-assisted extraction | ca. 1.0 | β-carotene | [83] |

| Synechococcus sp. | Supercritical fluid extraction | ca. 2.0 | β-carotene, zeaxanthin, myxoxanthophyll and β-cryptoxanthin | [84] |

| Synechococcus sp. | Supercritical fluid extraction | 1.5 | n.s. | [85] |

6. Economical Perspective

7. Final Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Masojídek, J.; Torzillo, G.; Koblížek, M.; Masojídek, J.; Torzillo, G.; Koblížek, M. Photosynthesis in Microalgae. In Handbook of Microalgal Culture; Richmond, A., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013; pp. 21–36. [Google Scholar] [CrossRef]

- Holt, T.K.; Krogmann, D.W. A carotenoid-protein from cyanobacteria. BBA Bioenerg. 1981, 637, 408–414. [Google Scholar] [CrossRef]

- Mullineaux, C.W. The thylakoid membranes of cyanobacteria: Structure, dynamics and function. Aust. J. Plant Physiol. 1999, 26, 671–677. [Google Scholar] [CrossRef]

- Guedes, A.C.; Amaro, H.M.; Malcata, F.X. Microalgae as sources of carotenoids. Mar. Drugs 2011, 9, 625–644. [Google Scholar] [CrossRef] [PubMed]

- Hirschberg, J.; Chamovitz, D. Carotenoids in Cyanobacteria. In The Molecular Biology of Cyanobacteria; Kluwer Academic Publishers: Drive Norwell, MA, USA, 1994; pp. 559–579. [Google Scholar] [CrossRef]

- Pagels, F.; Salvaterra, D.; Amaro, H.M.; Guedes, A.C. Pigments from microalgae. In Handbook of Microalgae-Based Processes and Products; Jacob-Lopes, E., Maroneze, M.M., Queiroz, M.I., Zepka, L.Q., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 465–492. [Google Scholar] [CrossRef]

- Gong, M.; Bassi, A. Carotenoids from microalgae: A review of recent developments. Biotechnol. Adv. 2016, 34, 1396–1412. [Google Scholar] [CrossRef] [PubMed]

- Markets and Markets. Carotenoids Market by Type (Astaxanthin, Beta-Carotene, Lutein, Lycopene, Canthaxanthin, and Zeaxanthin), Application (Feed, Food & Beverages, Dietary Supplements, Cosmetics, and Pharmaceuticals), Source, Formulation, and Region—Global Forecast to 2026. 2020. Available online: https://www.marketsandmarkets.com/Market-Reports/carotenoid-market-158421566.html (accessed on 14 May 2021).

- Liang, C.; Zhao, F.; Wei, W.; Wen, Z.; Qin, S. Carotenoid biosynthesis in cyanobacteria: Structural and evolutionary scenarios based on comparative genomics. Int. J. Biol. Sci. 2006, 2, 197–207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sugiyama, K.; Takaichi, S. Carotenogenesis in cyanobacteria: CruA/CruP-type and CrtL-type lycopene cyclases. J. Gen. Appl. Microbiol. 2020, 66, 53–58. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, H.E.; van de Meene, A.M.L.; Roberson, R.W.; Vermaas, W.F.J. Myxoxanthophyll is required for normal cell wall structure and thylakoid organization in the cyanobacterium Synechocystis sp. strain PCC 6803. J. Bacteriol. 2005, 187, 6883–6892. [Google Scholar] [CrossRef] [Green Version]

- Duan, H.K.; Zhu, Y.; Qi, D.D.; Li, W.L.; Hua, X.J.; Liu, Y.X.; Deng, X. Comparative study on the expression of genes involved in carotenoid and ABA biosynthetic pathway in response to salt stress in tomato. J. Integr. Agric. 2012, 11, 1093–1102. [Google Scholar] [CrossRef]

- Diao, J.; Song, X.; Zhang, L.; Cui, J.; Chen, L.; Zhang, W. Tailoring cyanobacteria as a new platform for highly efficient synthesis of astaxanthin. Metab. Eng. 2020, 61, 275–287. [Google Scholar] [CrossRef] [PubMed]

- Takaichi, S.; Mochimaru, M. Carotenoids and carotenogenesis in cyanobacteria: Unique ketocarotenoids and carotenoid glycosides. Cell. Mol. Life Sci. 2007, 64, 2607. [Google Scholar] [CrossRef]

- Pagels, F.; Guedes, A.C.; Amaro, H.M.; Kijjoa, A.; Vasconcelos, V. Phycobiliproteins from cyanobacteria: Chemistry and biotechnological applications. Biotechnol. Adv. 2019, 37, 422–443. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Niedzwiedzki, D.M.; Prado, M.; Jiang, J.; Gross, M.L.; Blankenship, R.E. Molecular mechanism of photoactivation and structural location of the cyanobacterial orange carotenoid protein. Biochemistry 2014, 53, 13–19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kirilovsky, D.; Kerfeld, C.A. Cyanobacterial photoprotection by the orange carotenoid protein. Nat. Plants 2016, 2, 16180. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.P.; Krogmann, D.W. The orange carotenoid protein of Synechocystis PCC 6803. Biochim. Biophys. Acta Bioenerg. 1997, 1322, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Kerfeld, C.A.; Kirilovsky, D. Photoprotection in cyanobacteria: The orange carotenoid protein and energy dissipation. In Bioenergetic Processes of Cyanobacteria: From Evolutionary Singularity to Ecological Diversity; Peschek, G.A., Obinger, C., Renger, G., Eds.; Springer: Dordrecht, The Netherlands, 2011; pp. 395–421. [Google Scholar] [CrossRef]

- Morone, J.; Alfeus, A.; Vasconcelos, V.; Martins, R. Revealing the potential of cyanobacteria in cosmetics and cosmeceuticals—A new bioactive approach. Algal Res. 2019, 41, 101541. [Google Scholar] [CrossRef]

- Lopes, G.; Clarinha, D.; Vasconcelos, V. Carotenoids from cyanobacteria: A biotechnological approach for the topical treatment of psoriasis. Microorganisms 2020, 8, 302. [Google Scholar] [CrossRef] [Green Version]

- Pagels, F.; Salvaterra, D.; Amaro, H.M.; Lopes, G.; Sousa-Pinto, I.; Vasconcelos, V.; Guedes, A.C. Bioactive potential of Cyanobium sp. pigment-rich extracts. J. Appl. Phycol. 2020, 32, 3031–3040. [Google Scholar] [CrossRef]

- Patias, L.D.; Fernandes, A.S.; Petry, F.C.; Mercadante, A.Z.; Jacob-Lopes, E.; Zepka, L.Q. Carotenoid profile of three microalgae/cyanobacteria species with peroxyl radical scavenger capacity. Food Res. Int. 2017, 100, 260–266. [Google Scholar] [CrossRef] [PubMed]

- Kelman, D.; Ben-Amotz, A.; Berman-Frank, I. Carotenoids provide the major antioxidant defence in the globally significant N2-fixing marine cyanobacterium Trichodesmium. Environ. Microbiol. 2009, 11, 1897–1908. [Google Scholar] [CrossRef]

- Paliwal, C.; Ghosh, T.; Bhayani, K.; Maurya, R.; Mishra, S. Antioxidant, anti-nephrolithe activities and in vitro digestibility studies of three different cyanobacterial pigment extracts. Mar. Drugs 2015, 13, 5384–5401. [Google Scholar] [CrossRef] [PubMed]

- Schwartz, J.L.; Shklar, G. A cyanobacteria extract and β-carotene stimulate an antitumor host response against an oral cancer cell line. Phyther. Res. 1989, 3, 243–248. [Google Scholar] [CrossRef]

- Belay, A.; Kato, T.; Ota, Y. Spirulina (Arthrospira): Potential application as an animal feed supplement. J. Appl. Phycol. 1996, 8, 303–311. [Google Scholar] [CrossRef]

- Liao, W.L.; Nur-E-Borhan, S.A.; Okada, S.; Matsui, T.; Yamaguchi, K. pigmentation of cultured black tiger prawn by feeding with a Spirulina-supplemented diet. Nippon. Suisan Gakkaishi 1993, 59, 165–169. [Google Scholar] [CrossRef] [Green Version]

- Mori, T.; Yamaguchi, K.; Konosu, S.; Muranaka, T.; Miki, W.; Watanabe, T. pigmentation of cultured sweet smelt fed diets supplemented with a blue-green alga Spirulina maxima. Nippon. Suisan Gakkaishi 1987, 53, 433–438. [Google Scholar] [CrossRef] [Green Version]

- Okada, S.; Liao, W.L.; Mori, T.; Yamaguchi, K.; Watanabe, T. pigmentation of cultured striped jack reared on diets supplemented with the blue-green alga Spirulina maxima. Nippon Suisan Gakkaishi 1991, 57, 1403–1406. [Google Scholar] [CrossRef] [Green Version]

- Morone, J.; Lopes, G.; Preto, M.; Vasconcelos, V.; Martins, R. Exploitation of filamentous and picoplanktonic cyanobacteria for cosmetic applications: Potential to improve skin structure and preserve dermal matrix components. Mar. Drugs 2020, 18, 486. [Google Scholar] [CrossRef] [PubMed]

- Park, W.S.; Kim, H.J.; Li, M.; Lim, D.H.; Kim, J.; Kwak, S.S.; Kang, C.M.; Ferruzzi, M.G.; Ahn, M.J. Two classes of pigments, carotenoids and c-phycocyanin, in Spirulina powder and their antioxidant activities. Molecules 2018, 23, 2065. [Google Scholar] [CrossRef] [Green Version]

- Guedes, A.C.; Katkam, N.G.; Varela, J.; Malcata, F.X. Photobioreactors for cyanobacterial culturing. In Cyanobacteria: An Economic Perspective; Sharma, N.K., Rai, A.K., Stal, L.J., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 270–292. [Google Scholar] [CrossRef]

- Saini, D.K.; Pabbi, S.; Shukla, P. Cyanobacterial pigments: Perspectives and biotechnological approaches. Food Chem. Toxicol. 2018, 120, 616–624. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, B.L. Seeing new light: Recent insights into the occurrence and regulation of chromatic acclimation in cyanobacteria. Curr. Opin. Plant Biol. 2017, 37, 18–23. [Google Scholar] [CrossRef] [Green Version]

- Figueroa, F.L. Red, green and blue light photoreceptors controlling chlorophyll a, biliprotein and total protein synthesis in the red alga Chondrus crispus. Br. Phycol. J. 1991, 26, 383–393. [Google Scholar] [CrossRef]

- Pagels, F.; Bonomi-Barufi, J.; Vega, J.; Abdala-Díaz, R.; Vasconcelos, V.; Guedes, A.C.; Figueroa, F.L. Light quality triggers biochemical modulation of Cyanobium sp.—Photobiology as tool for biotechnological optimization. J. Appl. Phycol. 2020, 32, 2851–2861. [Google Scholar] [CrossRef]

- Pagels, F.; Lopes, G.; Vasconcelos, V.; Guedes, A.C. White and red LEDs as two-phase batch for cyanobacterial pigments production. Bioresour. Technol. 2020, 307, 123105. [Google Scholar] [CrossRef] [PubMed]

- Olaizola, M.; Duerr, E.O. Effects of light intensity and quality on the growth rate and photosynthetic pigment content of Spirulina platensis. J. Appl. Phycol. 1990, 2, 97–104. [Google Scholar] [CrossRef]

- Mishra, S.K.; Shrivastav, A.; Maurya, R.R.; Patidar, S.K.; Haldar, S.; Mishra, S. Effect of light quality on the C-phycoerythrin production in marine cyanobacteria Pseudanabaena sp. isolated from Gujarat coast. India. Protein Expr. Purif. 2012, 81, 5–10. [Google Scholar] [CrossRef] [PubMed]

- Gutu, A.; Kehoe, D.M. Emerging perspectives on the mechanisms, regulation, and distribution of light color acclimation in cyanobacteria. Mol. Plant 2012, 5, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Amaro, H.M.; Pagels, F.; Azevedo, I.C.; Azevedo, J.; Sousa Pinto, I.; Malcata, F.X.; Guedes, A.C. Light-emitting diodes—A plus on microalgae biomass and high-value metabolite production. J. Appl. Phycol. 2020, 32, 3605–3618. [Google Scholar] [CrossRef]

- Schulze, P.S.C.; Barreira, L.A.; Pereira, H.G.C.; Perales, J.A.; Varela, J.C.S. Light emitting diodes (LEDs) applied to microalgal production. Trends Biotechnol. 2014, 32, 422–430. [Google Scholar] [CrossRef]

- Lima, G.M.; Teixeira, P.C.N.; Teixeira, C.M.L.L.; Filócomo, D.; Lage, C.L.S. Influence of spectral light quality on the pigment concentrations and biomass productivity of Arthrospira platensis. Algal Res. 2018, 31, 157–166. [Google Scholar] [CrossRef]

- Kokabi, M.; Yousefzadi, M.; Soltani, M.; Arman, M. Effects of different UV radiation on photoprotective pigments and antioxidant activity of the hot-spring cyanobacterium Leptolyngbya cf. fragilis. Phycol. Res. 2019, 67, 215–220. [Google Scholar] [CrossRef]

- Rath, J.; Adhikary, S.P. Response of the estuarine cyanobacterium Lyngbya aestuarii to UV-B radiation. J. Appl. Phycol. 2007, 19, 529–536. [Google Scholar] [CrossRef]

- Llewellyn, C.A.; Airs, R.L.; Farnham, G.; Greig, C. Synthesis, regulation and degradation of carotenoids under low level UV-B radiation in the filamentous cyanobacterium Chlorogloeopsis fritschii PCC 6912. Front. Microbiol. 2020, 11, 163. [Google Scholar] [CrossRef] [Green Version]

- Ehling-Schulz, M.; Bilger, W.; Scherer, S. UV-B-induced synthesis of photoprotective pigments and extracellular polysaccharides in the terrestrial cyanobacterium Nostoc commune. J. Bacteriol. 1997, 179, 1940–1945. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, L.; McCluskey, M.P.; Ni, H.; LaRossa, R.A. Global gene expression profiles of the cyanobacterium Synechocystis sp. strain PCC 6803 in response to irradiation with UV-B and white light. J. Bacteriol. 2002, 184, 6845–6858. [Google Scholar] [CrossRef] [Green Version]

- Bañares-España, E.; Kromkamp, J.C.; López-Rodas, V.; Costas, E.; Flores-Moya, A. Photoacclimation of cultured strains of the cyanobacterium Microcystis aeruginosa to high-light and low-light conditions. FEMS Microbiol. Ecol. 2013, 83, 700–710. [Google Scholar] [CrossRef] [Green Version]

- Masamoto, K.; Furukawa, K.I. Accumulation of zeaxanthin in cells of the cyanobacterium, Synechococcus sp. strain PCC 7942 grown under high irradiance. J. Plant Physiol. 1997, 151, 257–261. [Google Scholar] [CrossRef]

- Schagerl, M.; Müller, B. Acclimation of chlorophyll a and carotenoid levels to different irradiances in four freshwater cyanobacteria. J. Plant Physiol. 2006, 162, 709–716. [Google Scholar] [CrossRef]

- Pagels, F.; Barufi, J.B.; Vega, J.; Abdala-Díaz, R.; Vasconcelos, V.; Guedes, A.C.; Figueroa, F.L. Light regulating metabolic responses of Cyanobium sp. (Cyanobacteria). Fundam. Appl. Limnol. 2020, 193, 285–297. [Google Scholar] [CrossRef]

- Gris, B.; Sforza, E.; Morosinotto, T.; Bertucco, A.; la Rocca, N. Influence of light and temperature on growth and high-value molecules productivity from Cyanobacterium aponinum. J. Appl. Phycol. 2017, 29, 1781–1790. [Google Scholar] [CrossRef]

- Walsh, K.; Jones, G.J.; Dunstan, R.H. Effect of irradiance on fatty acid, carotenoid, total protein composition and growth of Microcystis aeruginosa. Phytochemistry 1997, 44, 817–824. [Google Scholar] [CrossRef]

- Juneja, A.; Ceballos, R.M.; Murthy, G.S. Effects of environmental factors and nutrient availability on the biochemical composition of algae for biofuels production: A review. Energies 2013, 6, 4607–4638. [Google Scholar] [CrossRef] [Green Version]

- Dadheech, P.K.; Glöckner, G.; Casper, P.; Kotut, K.; Mazzoni, C.J.; Mbedi, S.; Krienitz, L. Cyanobacterial diversity in the hot spring, pelagic and benthic habitats of a tropical soda lake. FEMS Microbiol. Ecol. 2013, 85, 389–401. [Google Scholar] [CrossRef] [Green Version]

- Shukla, S.P.; Kashyap, A.K. An assessment of biopotential of three cyanobacterial isolates from Antarctic for carotenoid production. Indian J. Biochem. Biophys. 2003, 40, 362–366. [Google Scholar]

- Kłodawska, K.; Bujas, A.; Turos-Cabal, M.; Żbik, P.; Fu, P.; Malec, P. Effect of growth temperature on biosynthesis and accumulation of carotenoids in cyanobacterium Anabaena sp. PCC 7120 under diazotrophic conditions. Microbiol. Res. 2019, 226, 34–40. [Google Scholar] [CrossRef]

- Ismaiel, M.M.S.; El-Ayouty, Y.M.; Piercey-Normore, M. Role of pH on antioxidants production by Spirulina (Arthrospira) platensis. Braz. J. Microbiol. 2016, 47, 298–304. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pagels, F.; Salvaterra, D.; Amaro, H.M.; Lopes, G.; Sousa-Pinto, I.; Vasconcelos, V.; Guedes, A.C. Factorial optimization of upstream process for Cyanobium sp. pigments production. J. Appl. Phycol. 2020, 32, 3861–3872. [Google Scholar] [CrossRef]

- Thirumala, M. Optimization of growth of Spirulina platensis Ln1 for production of carotenoids. Int. J. Life Sci. Biotechnol. Pharma Res. 2012, 1, 152–157. [Google Scholar]

- El Baky, H.H.A.; El Baroty, G.S.; Mostafa, E.M. Optimization growth of Spirulina (Arthrospira) platensis in photobioreactor under varied nitrogen concentration for maximized biomass, carotenoids and lipid contents. Recent Pat. Food. Nutr. Agric. 2018, 11, 40–48. [Google Scholar] [CrossRef]

- Erdoğan, A.; Demirel, Z.; Eroğlu, A.E.; Dalay, M.C. Carotenoid profile in Prochlorococcus sp. and enrichment of lutein using different nitrogen sources. J. Appl. Phycol. 2016, 28, 3251–3257. [Google Scholar] [CrossRef] [Green Version]

- Tarko, T.; Duda-Chodak, A.; Kobus, M. Influence of growth medium composition on synthesis of bioactive compounds and antioxidant properties of selected strains of Arthrospira cyanobacteria. Czech J. Food Sci. 2012, 30, 258–267. [Google Scholar] [CrossRef]

- D’Alessandro, E.B.; Soares, A.T.; de Oliveira D’Alessandro, N.C.; Antoniosi Filho, N.R. Potential use of a thermal water cyanobacterium as raw material to produce biodiesel and pigments. Bioprocess Biosyst. Eng. 2019, 42, 2015–2022. [Google Scholar] [CrossRef] [PubMed]

- Paliwal, C.; Pancha, I.; Ghosh, T.; Maurya, R.; Chokshi, K.; Vamsi Bharadwaj, S.V.; Ram, S.; Mishra, S. Selective carotenoid accumulation by varying nutrient media and salinity in Synechocystis sp. CCNM 2501. Bioresour. Technol. 2015, 197, 363–368. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.W.; Song, J.Y.; Cho, S.M.; Kwon, H.C.; Pan, C.H.; Park, Y. Il Genomic survey of salt acclimation-related genes in the halophilic cyanobacterium Euhalothece sp. Z-M001. Sci. Rep. 2020, 10, 676. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lagarde, D.; Beuf, L.; Vermaas, W. Increased production of zeaxanthin and other pigments by application of genetic engineering techniques to Synechocystis sp. strain PCC 6803. Appl. Environ. Microbiol. 2000, 66, 64–72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gao, X.; Xu, H.; Zhu, Z.; She, Y.; Ye, S. Improved production of echinenone and canthaxanthin in transgenic Nostoc sp. PCC 7120 overexpressing a heterologous crtO gene from Nostoc flagelliforme. Microbiol. Res. 2020, 236, 126455. [Google Scholar] [CrossRef]

- Lin, P.C.; Pakrasi, H.B. Engineering cyanobacteria for production of terpenoids. Planta 2019, 249, 145–154. [Google Scholar] [CrossRef]

- Panis, G.; Carreon, J.R. Commercial astaxanthin production derived by green alga Haematococcus pluvialis: A microalgae process model and a techno-economic assessment all through production line. Algal Res. 2016, 18, 175–190. [Google Scholar] [CrossRef] [Green Version]

- Aguilar-Machado, D.; Morales-Oyervides, L.; Contreras-Esquivel, J.C.; Aguilar, C.; Méndez-Zavala, A.; Raso, J.; Montañez, J. Effect of ohmic heating processing conditions on color stability of fungal pigments. Food Sci. Technol. Int. 2017, 23, 338–348. [Google Scholar] [CrossRef]

- Kang, C.D.; Sim, S.J. Direct extraction of astaxanthin from Haematococcus culture using vegetable oils. Biotechnol. Lett. 2008, 30, 441–444. [Google Scholar] [CrossRef]

- Amaro, H.M.; Fernandes, F.; Valentão, P.; Andrade, P.B.; Sousa-Pinto, I.; Malcata, F.X.; Guedes, A.C. Effect of solvent system on extractability of lipidic components of Scenedesmus obliquus (M2-1) and Gloeothece sp. on antioxidant scavenging capacity thereof. Mar. Drugs 2015, 13, 6453–6471. [Google Scholar] [CrossRef] [Green Version]

- Tavanandi, H.A.; Vanjari, P.; Raghavarao, K.S.M.S. Synergistic method for extraction of high purity allophycocyanin from dry biomass of Arthrospira platensis and utilization of spent biomass for recovery of carotenoids. Sep. Purif. Technol. 2019, 225, 97–111. [Google Scholar] [CrossRef]

- Dorina, S.; Judith, S.; Björn, W.; Julia, S.; Andrea, S.; Sarah, D.N.; Muffler, K.; Roland, U. A new strategy for a combined isolation of EPS and pigments from cyanobacteria. J. Appl. Phycol. 2020, 32, 1729–1740. [Google Scholar] [CrossRef]

- Assunção, J.; Amaro, H.M.; Lopes, G.; Tavares, T.; Malcata, F.X.; Guedes, A.C. Exploration of marine genus Chroococcidiopsis sp.: A valuable source for antioxidant industry? J. Appl. Phycol. 2021. [Google Scholar] [CrossRef]

- Springstein, B.L.; Nürnberg, D.J.; Weiss, G.L.; Pilhofer, M.; Stucken, K. Structural determinants and their role in Cyanobacterial morphogenesis. Life 2020, 10, 355. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.C.; Mandal, V.; Das, A.K. Classification of Extraction Methods. In Essentials of Botanical Extraction; Mandal, S.C., Mandal, V., Das, A.K., Eds.; Academic Press: Cambridge, MA, USA, 2015; pp. 83–136. [Google Scholar] [CrossRef]

- Rodríguez-Meizoso, I.; Jaime, L.; Santoyo, S.; Cifuentes, A.; García-Blairsy Reina, G.; Señoráns, F.J.; Ibáñez, E. Pressurized fluid extraction of bioactive compounds from Phormidium species. J. Agric. Food Chem. 2008, 56, 3517–3523. [Google Scholar] [CrossRef] [PubMed]

- Amaro, H.M.; Catarina Guedes, A.; Preto, M.A.C.; Sousa-Pinto, I.; Xavier Malcata, F. Gloeothece sp. as a nutraceutical source-an improved method of extraction of carotenoids and fatty acids. Mar. Drugs 2018, 16, 327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dey, S.; Rathod, V.K. Ultrasound assisted extraction of β-carotene from Spirulina platensis. Ultrason. Sonochem. 2013, 20, 271–276. [Google Scholar] [CrossRef] [PubMed]

- Montero, O.; Macìas-Sánchez, M.D.; Lama, C.M.; Lubián, L.M.; Mantell, C.; Rodríguez, M.; De La Ossa, E.M. Supercritical CO2 extraction of β-carotene from a marine strain of the cyanobacterium Synechococcus species. J. Agric. Food Chem. 2005, 53, 9701–9707. [Google Scholar] [CrossRef] [PubMed]

- Macías-Sánchez, M.D.; Mantell, C.; Rodríguez, M.; Martínez de la Ossa, E.; Lubián, L.M.; Montero, O. Supercritical fluid extraction of carotenoids and chlorophyll a from Synechococcus sp. J. Supercrit. Fluids 2007, 39, 323–329. [Google Scholar] [CrossRef]

- Sierra, L.S.; Dixon, C.K.; Wilken, L.R. Enzymatic cell disruption of the microalgae Chlamydomonas reinhardtii for lipid and protein extraction. Algal Res. 2017, 25, 149–159. [Google Scholar] [CrossRef]

- Lee, S.Y.; Cho, J.M.; Chang, Y.K.; Oh, Y.K. Cell disruption and lipid extraction for microalgal biorefineries: A review. Bioresour. Technol. 2017, 244, 1317–1328. [Google Scholar] [CrossRef]

- Juin, C.; Chérouvrier, J.-R.; Thiéry, V.; Gagez, A.-L.; Bérard, J.-B.; Joguet, N.; Kaas, R.; Cadoret, J.-P.; Picot, L. Microwave-assisted extraction of phycobiliproteins from Porphyridium purpureum. Appl. Biochem. Biotechnol. 2015, 175, 1–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Luengo, E.; Condón-Abanto, S.; Álvarez, I.; Raso, J. Effect of pulsed electric field treatments on permeabilization and extraction of pigments from Chlorella vulgaris. J. Membr. Biol. 2014, 247, 1269–1277. [Google Scholar] [CrossRef] [PubMed]

- Guedes, A.C.; Gião, M.S.; Matias, A.A.; Nunes, A.V.; Pintado, M.E.; Duarte, C.M.; Malcata, F.X. Supercritical fluid extraction of carotenoids and chlorophylls a, b and c, from a wild strain of Scenedesmus obliquus for use in food processing. J. Food Eng. 2013, 116, 478–482. [Google Scholar] [CrossRef] [Green Version]

- Khazi, M.I.; Demirel, Z.; Dalay, M.C. Evaluation of growth and phycobiliprotein composition of cyanobacteria isolates cultivated in different nitrogen sources. J. Appl. Phycol. 2018, 30, 1513–1523. [Google Scholar] [CrossRef]

- Mitra, M.; Mishra, S. Multiproduct biorefinery from Arthrospira spp. towards zero waste: Current status and future trends. Bioresour. Technol. 2019, 291, 121928. [Google Scholar] [CrossRef]

- Bastiaens, L.; van Roy, S.; Thomassen, G.; Elst, K. Biorefinery of algae: Technical and economic considerations. In Woodhead Publishing Series in Energy; Gonzalez-Fernandez, C., Muñoz, R., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 327–345. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pagels, F.; Vasconcelos, V.; Guedes, A.C. Carotenoids from Cyanobacteria: Biotechnological Potential and Optimization Strategies. Biomolecules 2021, 11, 735. https://doi.org/10.3390/biom11050735

Pagels F, Vasconcelos V, Guedes AC. Carotenoids from Cyanobacteria: Biotechnological Potential and Optimization Strategies. Biomolecules. 2021; 11(5):735. https://doi.org/10.3390/biom11050735

Chicago/Turabian StylePagels, Fernando, Vitor Vasconcelos, and Ana Catarina Guedes. 2021. "Carotenoids from Cyanobacteria: Biotechnological Potential and Optimization Strategies" Biomolecules 11, no. 5: 735. https://doi.org/10.3390/biom11050735