Experimental and Statistical Study of the Fracture Mechanism of Sn96.5Ag3Cu0.5 Solder Joints via Ball Shear Test

Abstract

:1. Introduction

2. Materials and Methods

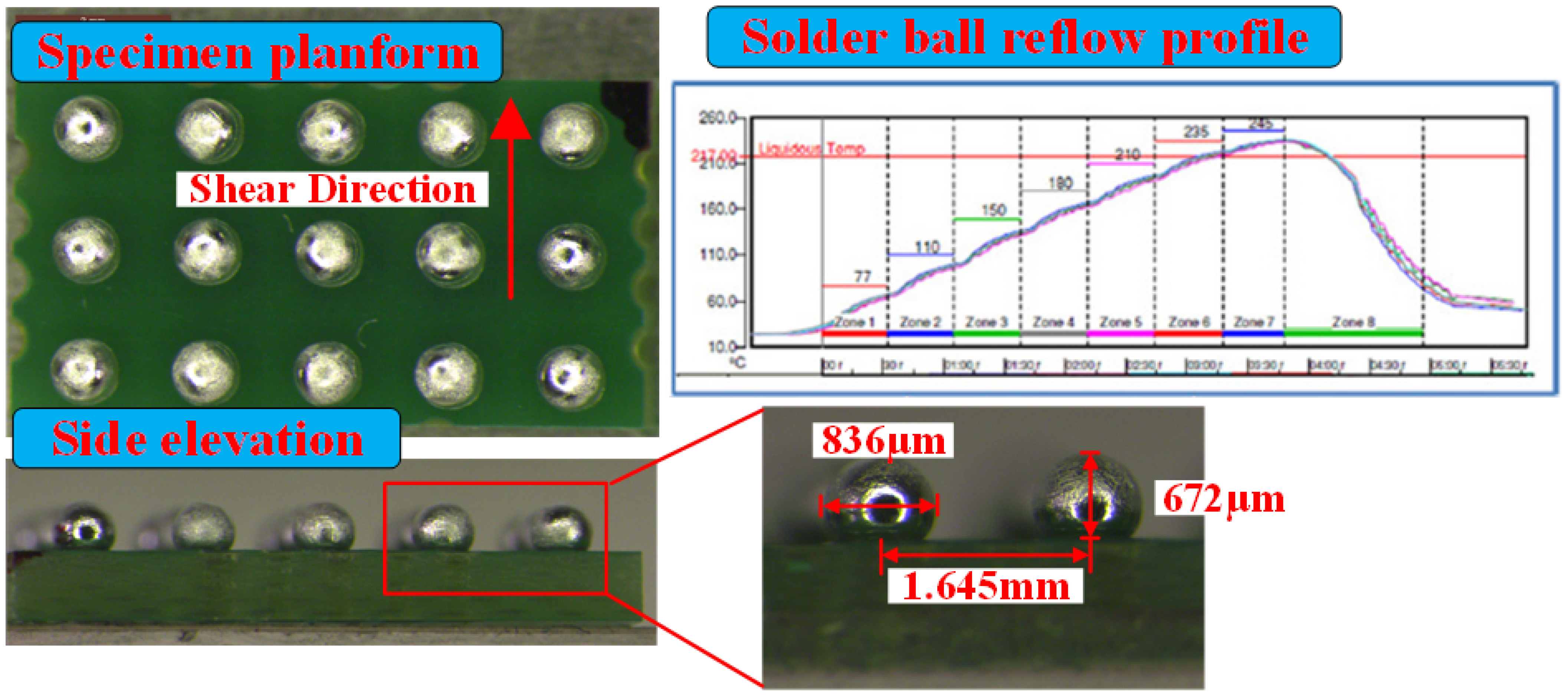

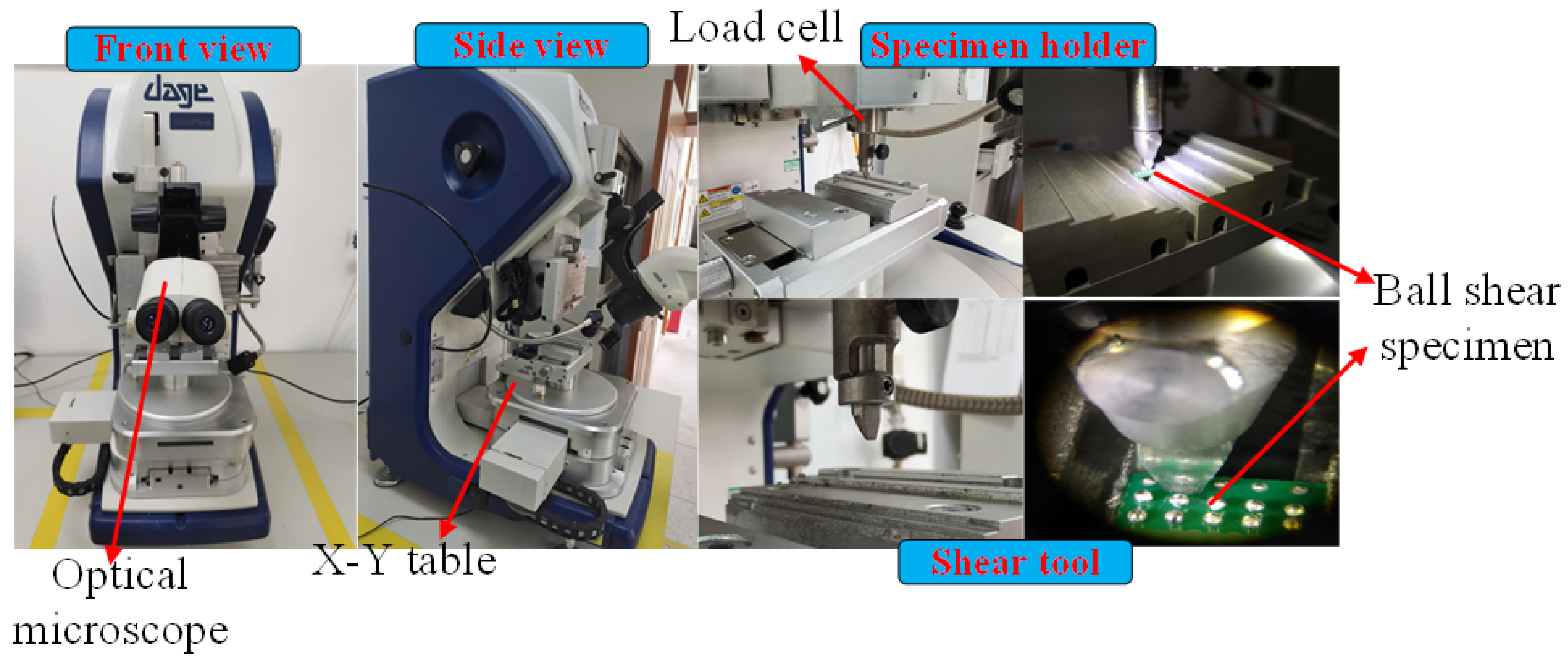

2.1. Ball Shear Specimens and Test Setup

2.2. Test Procedure

3. Results and Discussion

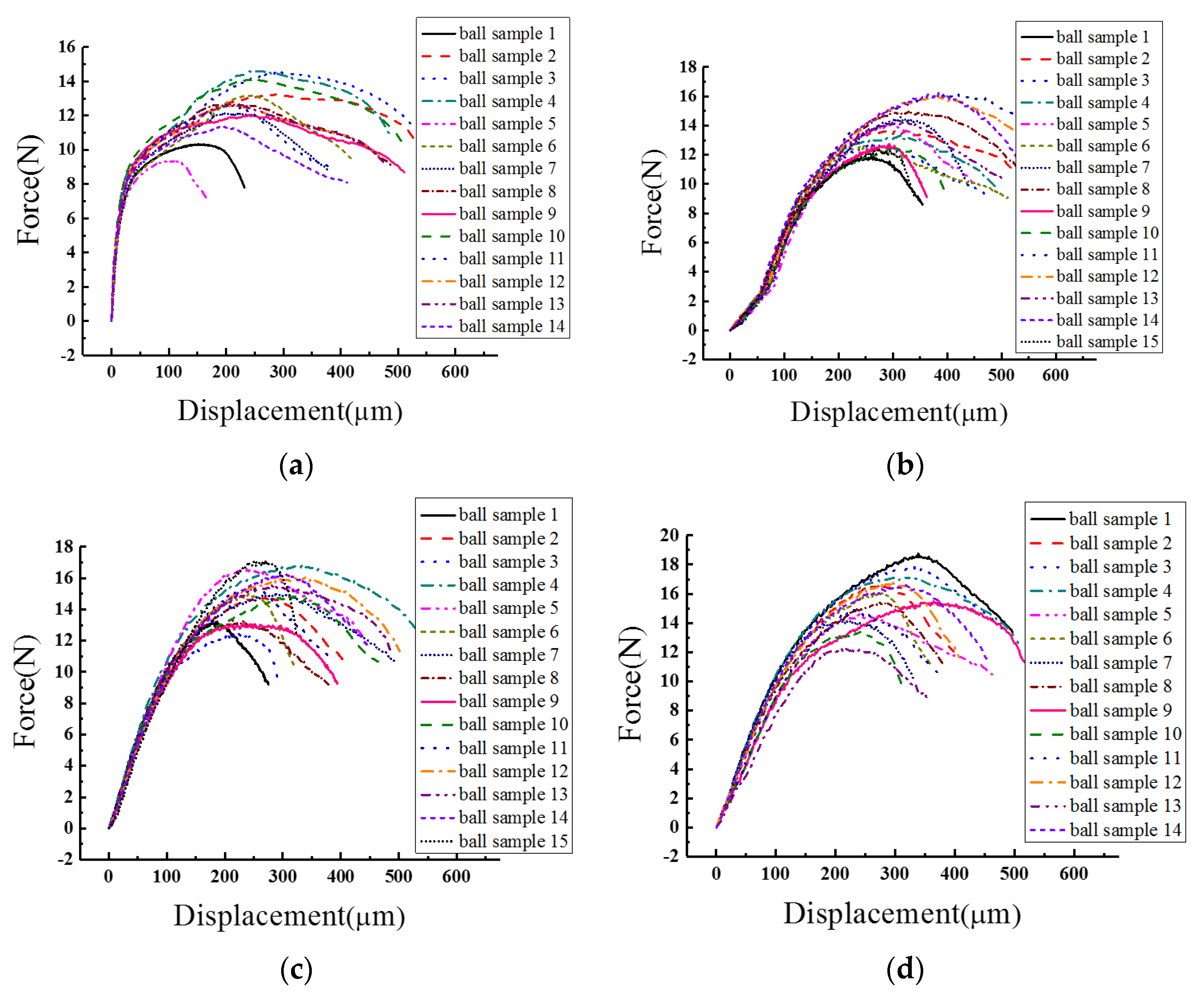

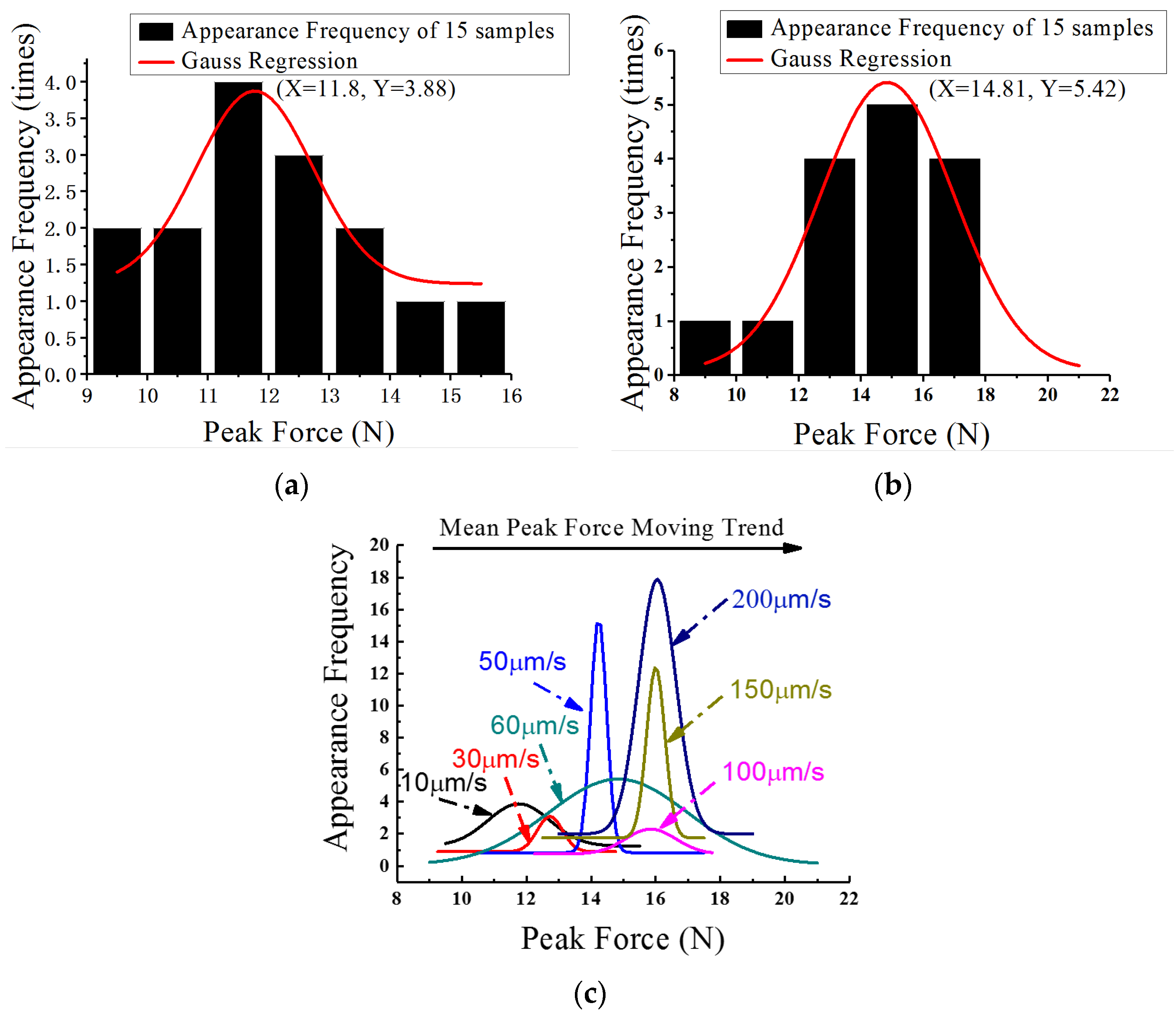

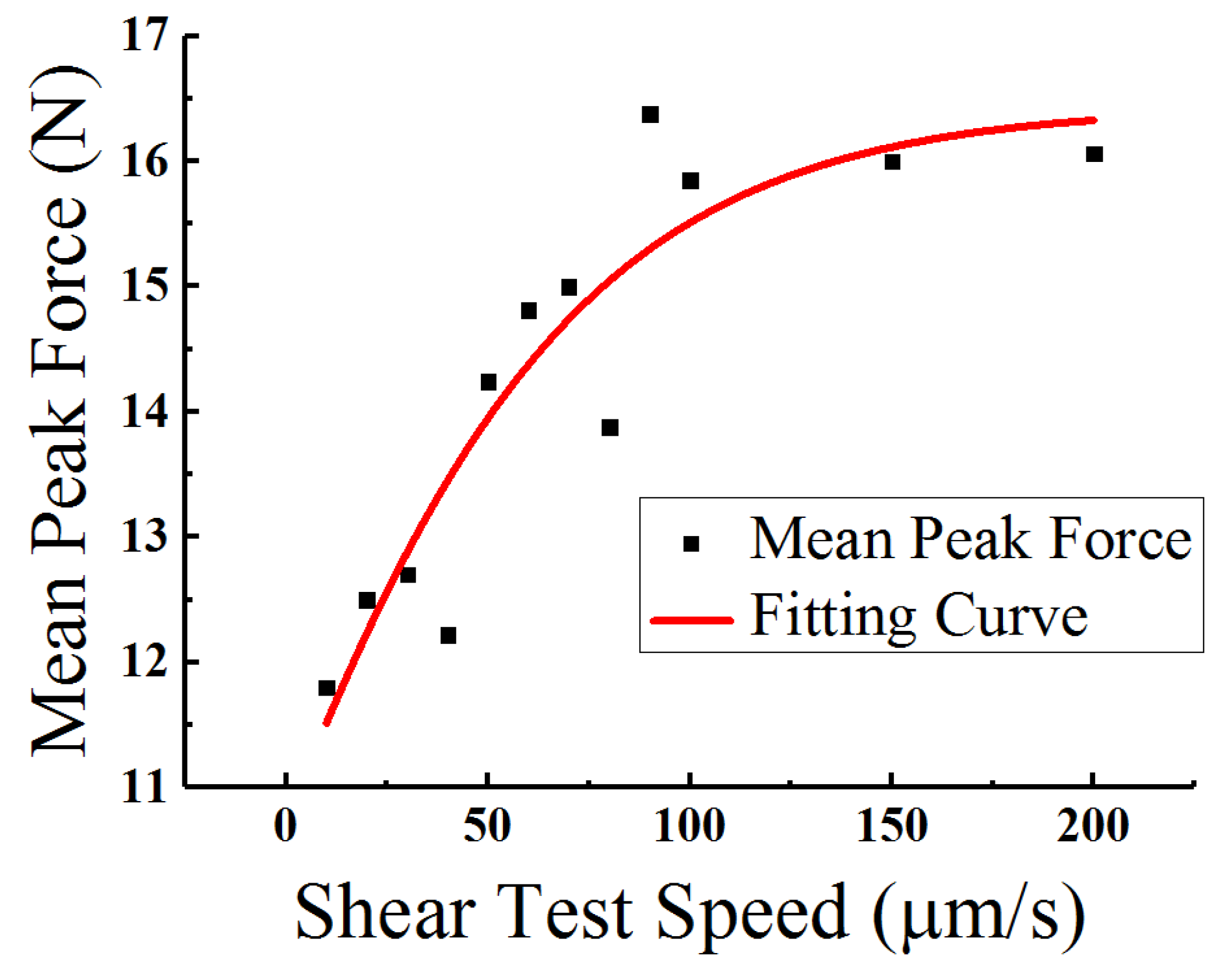

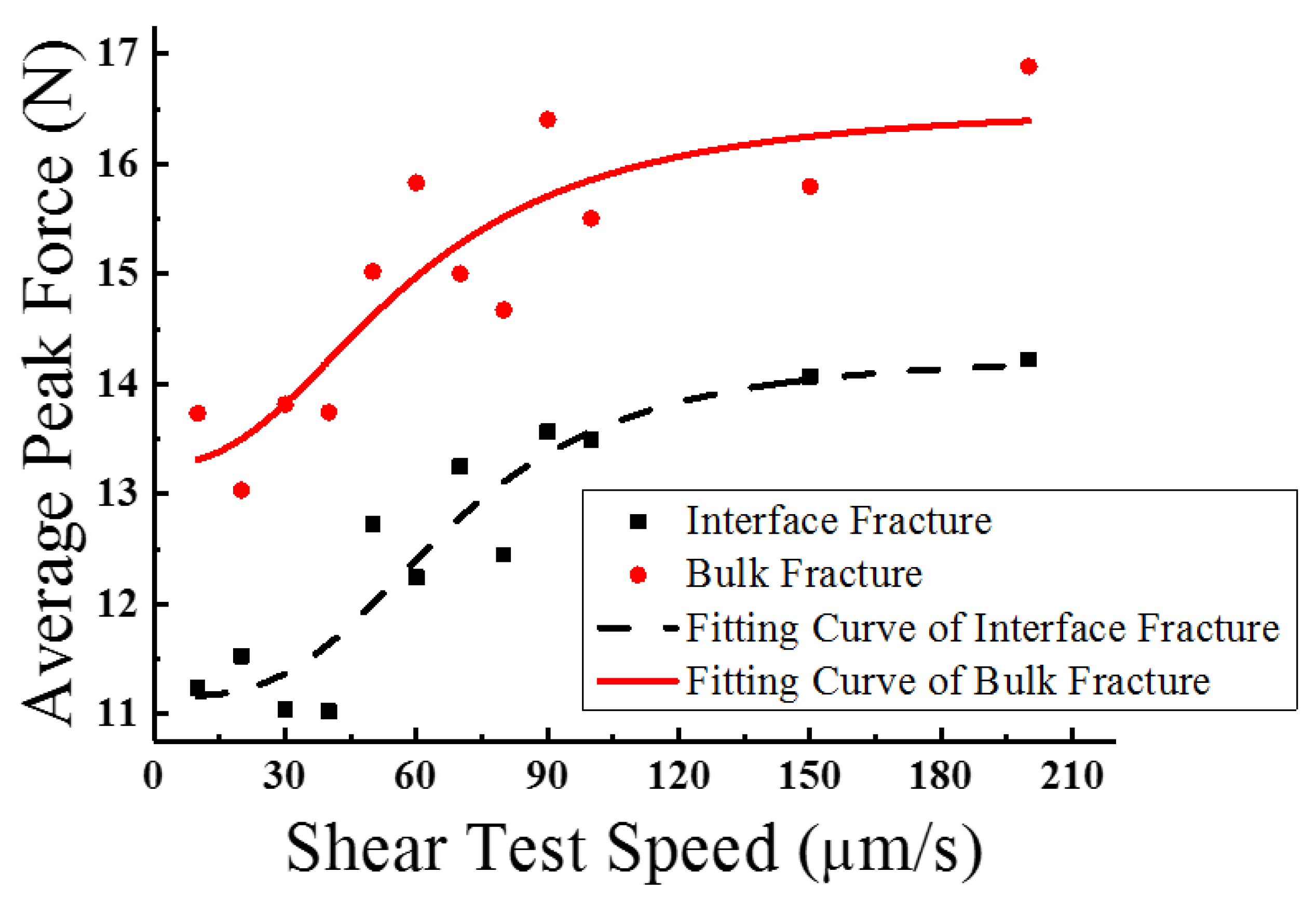

3.1. Ball Shear Tests at Different Speeds

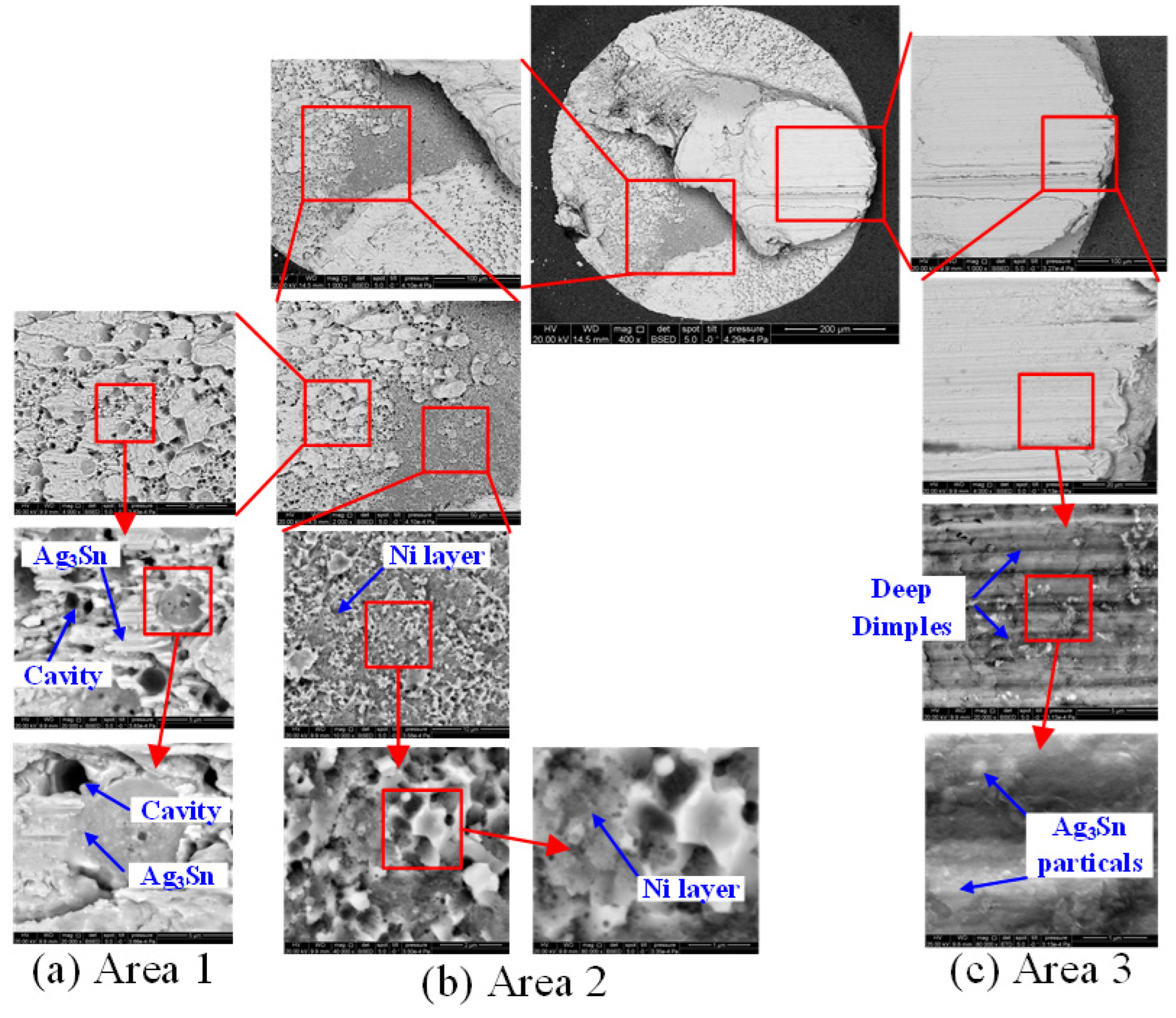

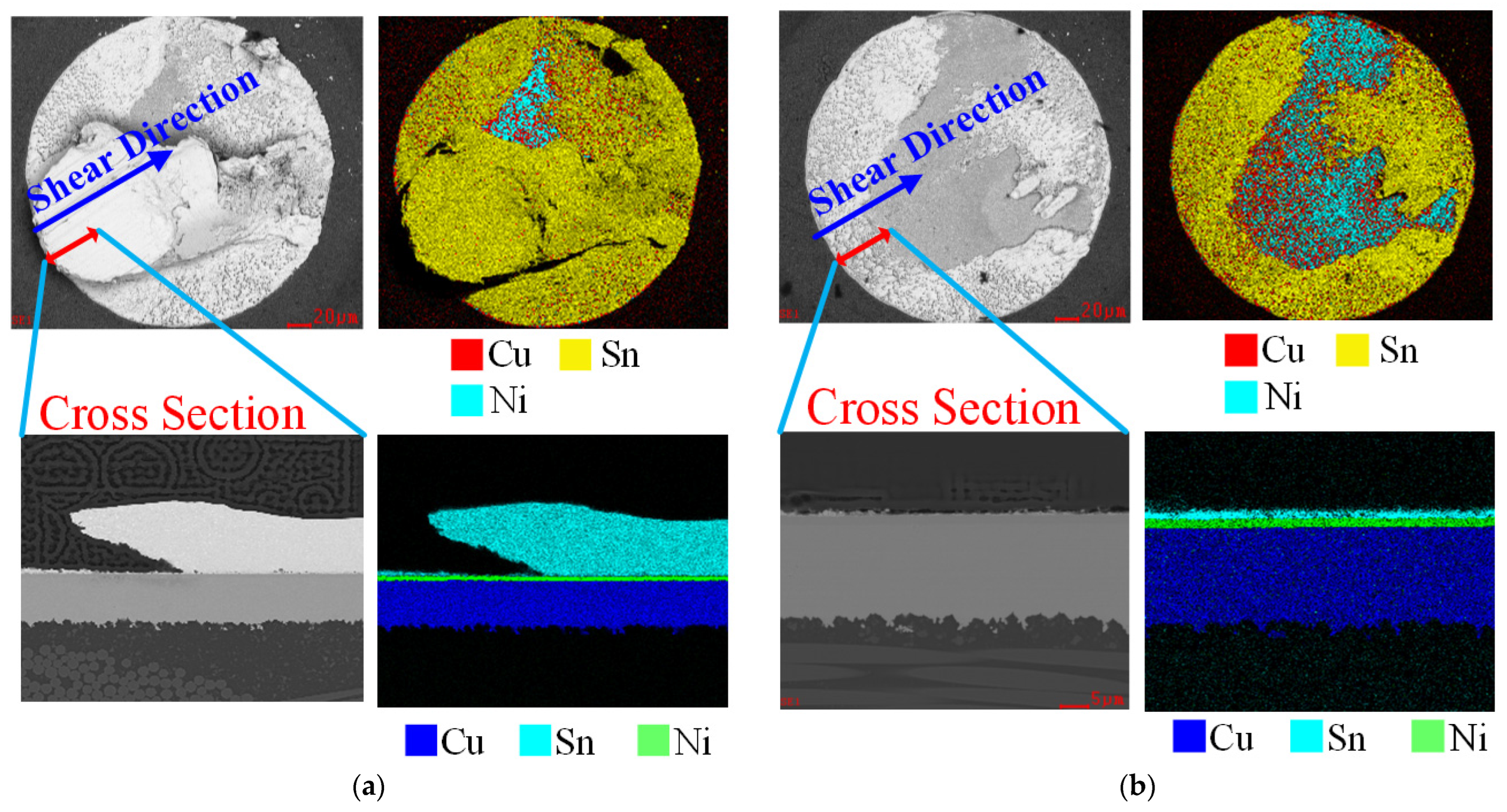

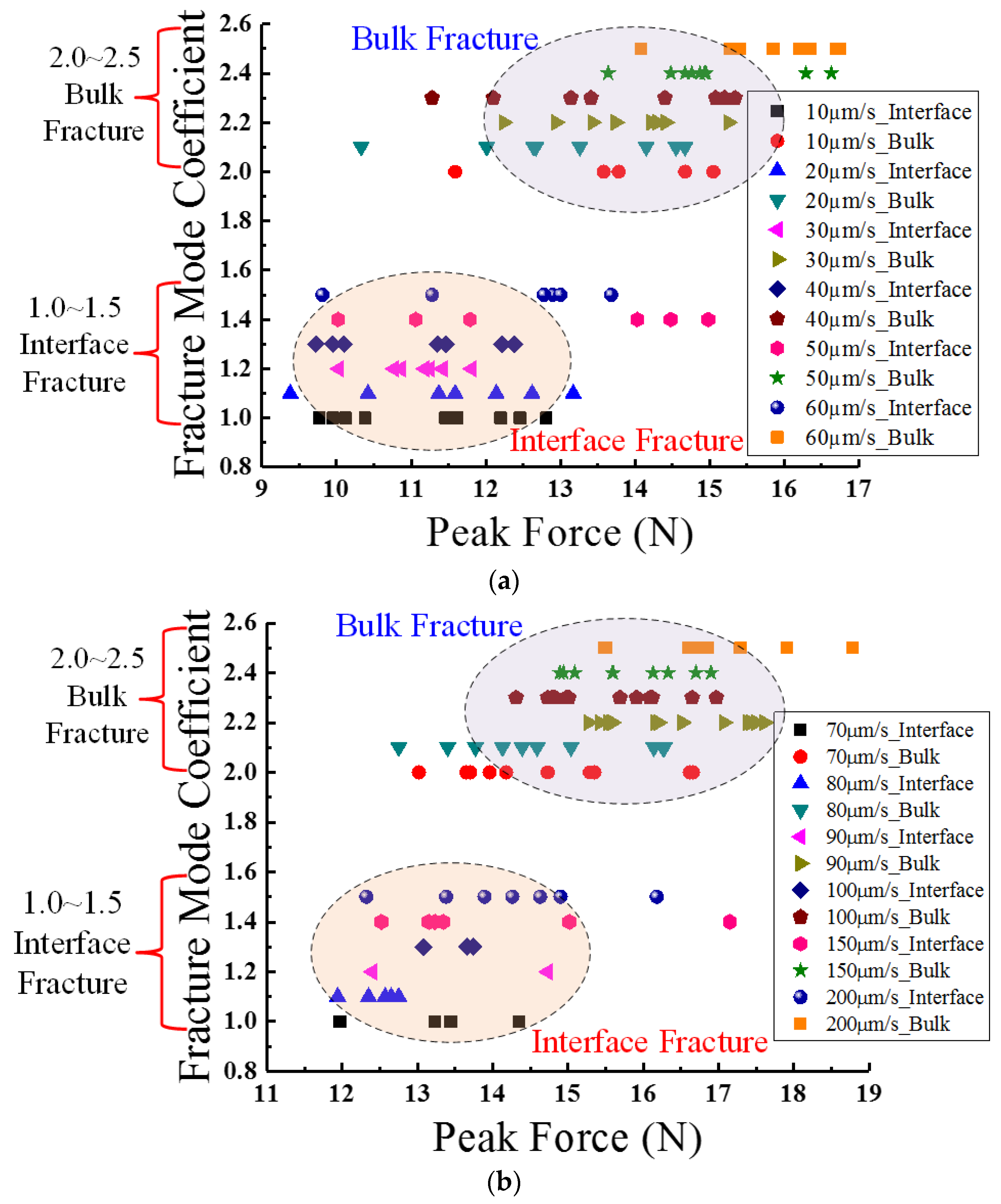

3.2. Ball Fracture Mechanism Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fang, Y.; Fu, Y.G.; Wang, L.; Wang, P.C.; Zhou, J. Progress and Review on Lead-Free Solder Joint Reliability in Micro-Electronic Packaging. Electron. Process Technol. 2010, 2, 72–76. [Google Scholar]

- Bui, Q.V.; Jung, S.B. Evaluation of Mechanical Properties of Low-Ag Ball Grid Array Solder Joints Using a High-Speed Ball Shear Test. J. Alloys Compd. 2014, 589, 590–595. [Google Scholar] [CrossRef]

- Su, S.; Hamasha, S.; Hamasha, K. Effect of Surface Finish on the Shear Properties of SnAgCu-Based Solder Alloys. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1473–1485. [Google Scholar] [CrossRef]

- Liu, W.; An, R.; Wang, C.; Tian, Y. Effect of Au-Sn IMCS’ Formation and Morphologies on Shear Properties of Laser Reflowed Micro-Solder Joints. Solder. Surf. Mt. Technol. 2015, 27, 45–51. [Google Scholar] [CrossRef]

- Kim, J.W.; Jung, S.B. Failure Mechanism of Pb-Bearing and Pb-Free Solder Joints under High-Speed Shear Loading. Met. Mater. Int. 2010, 16, 7–12. [Google Scholar] [CrossRef]

- Wen, S.; Keer, L.M. A Theory of Fatigue: A Physical Approach with Application to Lead-Rich Solder. J. Appl. Mech. 2002, 69, 1–10. [Google Scholar] [CrossRef]

- Farooq, M.G.; Lyer, S.S. 3D Integration Review. Sci. China Inf. Sci. 2011, 54, 1012–1025. [Google Scholar] [CrossRef] [Green Version]

- Mukherjee, S.; Zhou, B.; Dasgupta, A.; Bieler, T.R. Multiscale Modeling of the Anisotropic Transient Creep Response of Heterogeneous Single Crystal SnAgCu Solder. Int. J. Plast. 2016, 78, 1–25. [Google Scholar] [CrossRef]

- Xie, M.W.; Chen, G.; Yang, J.; Xu, W.L. Temperature- and Rate-Dependent Deformation Behaviors of SAC305 Solder Using Crystal Plasticity Model. Mech. Mater. 2021, 157, 103834. [Google Scholar] [CrossRef]

- Bang, W.H.; Kim, C.-U.; Kang, S.H.; Oh, K.H. Fracture Mechanics of Solder Bumps during Ball Shear Testing: Effect of Bump Size. J. Electron. Mater. 2009, 38, 1896–1905. [Google Scholar] [CrossRef]

- Bernhardt-Barry, M.L.; Biscontin, G.; O’sullivan, C. Analysis of the Stress Distribution in a Laminar Direct Simple Shear Device and Implications for Test Data Interpretation. Granul. Matter 2021, 23, 55. [Google Scholar] [CrossRef]

- Lee, H.; Kim, C.; Heo, C.; Kim, C.; Lee, J.-H.; Kim, Y. Effect of Solder Resist Dissolution on the Joint Reliability of ENIG Surface and Sn-Ag-Cu Solder. Microelectron. Reliab. 2018, 87, 75–80. [Google Scholar] [CrossRef]

- Bui, Q.V.; Jung, S.B. Characterization of Low Speed Shear Test Reliability of Sn-1.0Ag-XCe/ENEPIG Solder Joint. J. Alloys Compd. 2013, 560, 54–61. [Google Scholar] [CrossRef]

- Lee, C.J.; Min, K.D.; Jeong, H.; Hwang, B.-U.; Jung, S.-B. The Fabrication of Ni-MWCNT Composite Solder and Its Reliability under High Relative Humidity and Temperature. J. Electron. Mater. 2020, 49, 6746–6753. [Google Scholar] [CrossRef]

- Zou, Y.S.; Chung, M.H.; Tennant, T.; Gan, C.L.; Hsu, Y.T.; Takiar, H. Investigation of Shear Strength and Temperature Cycling Performance of Bi-Doped Sn-Ag-Cu Solder Joints. In Proceedings of the 2020 IEEE 22nd Electronics Packaging Technology Conference (EPTC), Singapore, 2–4 December 2020; pp. 286–290. [Google Scholar]

- Hu, X.; Xu, T.; Keer, L.M.; Li, Y.; Jiang, X. Shear Strength and Fracture Behavior of Reflowed Sn3.0Ag0.5Cu/Cu Solder Joints under Various Strain Rates. J. Alloys Compd. 2017, 690, 720–729. [Google Scholar] [CrossRef]

- Sujan, G.K.; Haseeb, A.S.M.A.; Amalina, M.A.; Nishikawa, H. Ball Shear Strength and Fracture Modes of Lead-Free Solder Joints Prepared Using Nickel Nanoparticle Doped Flux. Electron. Mater. Lett. 2015, 11, 452–456. [Google Scholar] [CrossRef]

- Yu, K.; Yang, C.; Wang, J.; Yu, J.; Yang, Y. Study on The Strength of Diameter-Reducing Solder Balls by Shear and Pull Tests. Solder. Surf. Mt. Technol. 2019, 31, 240–249. [Google Scholar] [CrossRef]

- Yahaya, M.Z.; Mohamad, A.A. Hardness Testing of Lead-Free Solders: A Review. Solder. Surf. Mt. Technol. 2017, 29, 203–224. [Google Scholar] [CrossRef]

- Ha, S.S.; Jang, J.-K.; Ha, S.-O.; Kim, J.-W.; Yoon, J.-W.; Kim, B.-W.; Park, S.-K.; Jung, S.-B. Mechanical Property Evaluation of Sn-3.0A-0.5Cu BGA Solder Joints Using High-Speed Ball Shear Test. J. Electron. Mater. 2009, 38, 2489–2495. [Google Scholar] [CrossRef]

- Kim, J.M.; Jeong, M.H.; Yoo, S.; Lee, C.W.; Park, Y.B. Effects of Surface Finishes and Loading Speeds on Shear Strength of Sn-3.0Ag-0.5Cu Solder Joints. Microelectron. Eng. 2012, 89, 55–57. [Google Scholar] [CrossRef]

- Ho, C.E.; Yang, S.P.; Lee, P.T.; Lee, C.Y.; Chen, C.C.; Kuo, T.T. IMC Microstructure Modification and Mechanical Reinforcement of Sn-Ag-Cu/Cu Microelectronic Joints through an Advanced Surface Finish Technique. J. Mater. Res. Technol. 2021, 11, 1895–1910. [Google Scholar] [CrossRef]

- Long, X.; He, X.; Yao, Y. An Improved Unified Creep-Plasticity Model for SnAgCu Solder under a Wide Range of Strain Rates. J. Mater. Sci. 2017, 52, 6120–6137. [Google Scholar] [CrossRef]

- Yao, Y.; Li, X.; He, X. Effect of Deep Cryogenic Treatment on Mechanical Properities and Microstructure of Sn3.0Ag0.5Cu Solder. J. Mater. Sci. Mater. Electron. 2018, 29, 4517–4525. [Google Scholar] [CrossRef]

- Pandey, C.; Mahapatra, M.M.; Kumar, P.; Kumar, P.; Saini, N.; Thakare, J.; Kumar, S. Study on Effect of Double Austenitization Treatment on Fracture Morphology Tensile Tested Nuclear Grade P92 Steel. Eng. Fail. Anal. 2019, 96, 158–167. [Google Scholar] [CrossRef]

- Pandey, C.; Saini, N.; Mahapatra, M.M.; Kumar, P. Hydrogen Induced Cold Cracking of Creep Resistant Ferritic P91 Steel for Different Diffusible Hydrogen Levels in Deposited Metal. Int. J. Hydrogen Energy 2016, 41, 17695–17712. [Google Scholar] [CrossRef]

| Coefficient | ||||||||

|---|---|---|---|---|---|---|---|---|

| Typical Value | 11.16 | 13.27 | 14.27 | 16.55 | 67.93 | 57.97 | 3.21 | 2.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, K.; Wang, Y.; He, Z. Experimental and Statistical Study of the Fracture Mechanism of Sn96.5Ag3Cu0.5 Solder Joints via Ball Shear Test. Materials 2022, 15, 2455. https://doi.org/10.3390/ma15072455

Liang K, Wang Y, He Z. Experimental and Statistical Study of the Fracture Mechanism of Sn96.5Ag3Cu0.5 Solder Joints via Ball Shear Test. Materials. 2022; 15(7):2455. https://doi.org/10.3390/ma15072455

Chicago/Turabian StyleLiang, Kun, Yuexing Wang, and Zhigang He. 2022. "Experimental and Statistical Study of the Fracture Mechanism of Sn96.5Ag3Cu0.5 Solder Joints via Ball Shear Test" Materials 15, no. 7: 2455. https://doi.org/10.3390/ma15072455

APA StyleLiang, K., Wang, Y., & He, Z. (2022). Experimental and Statistical Study of the Fracture Mechanism of Sn96.5Ag3Cu0.5 Solder Joints via Ball Shear Test. Materials, 15(7), 2455. https://doi.org/10.3390/ma15072455