An Insight into Reverse Logistics with a Focus on Collection Systems

Abstract

1. Introduction

2. Methodology

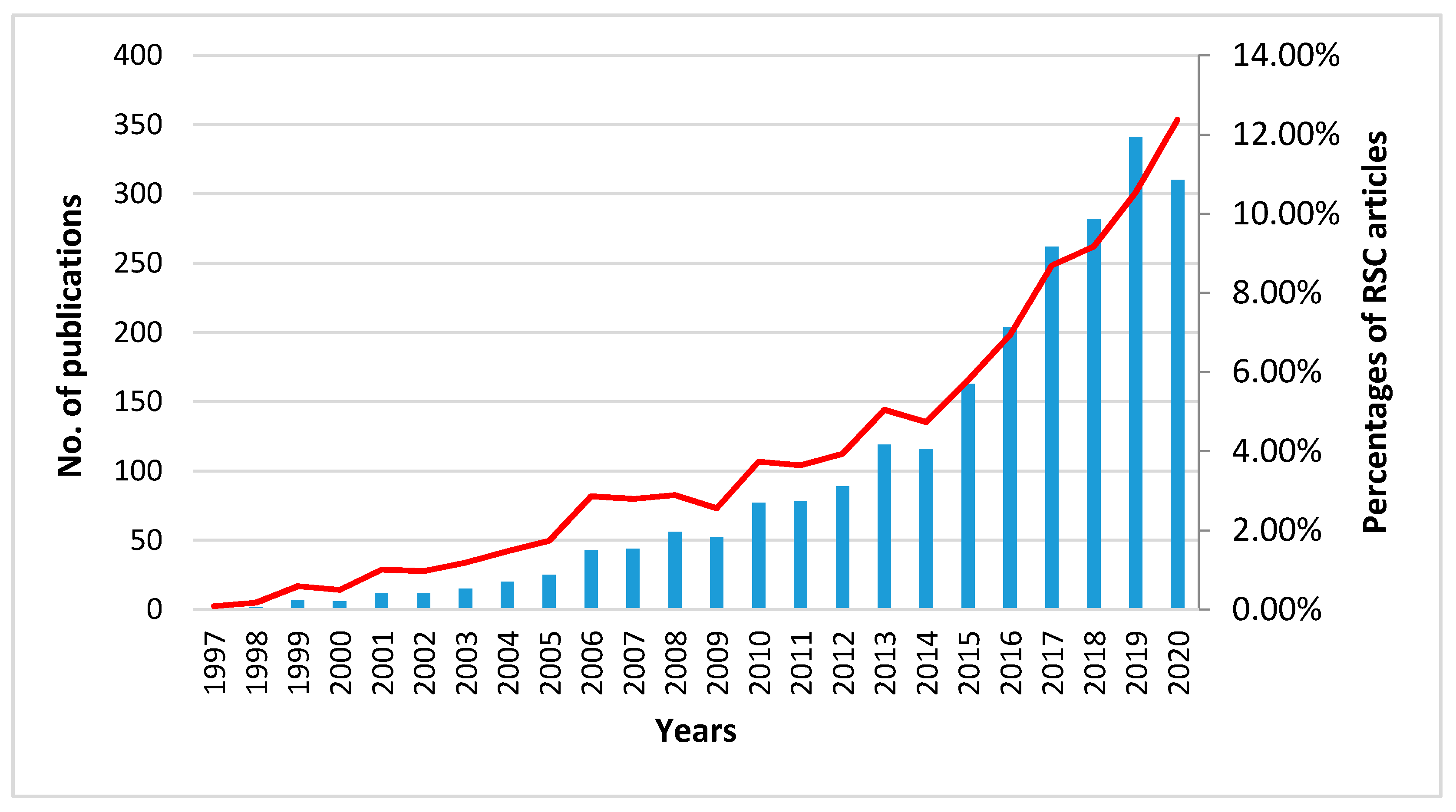

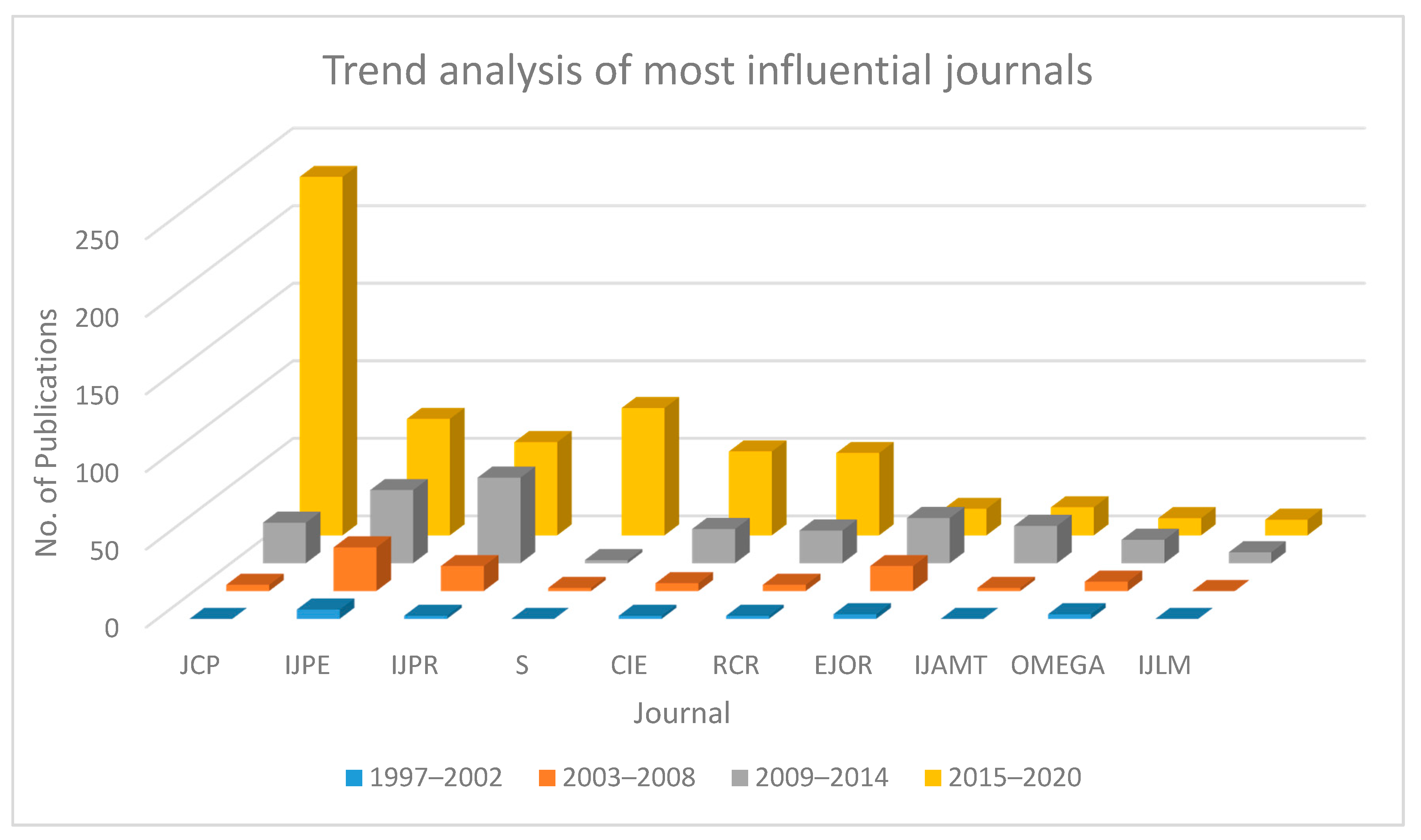

Bibliometric Analysis

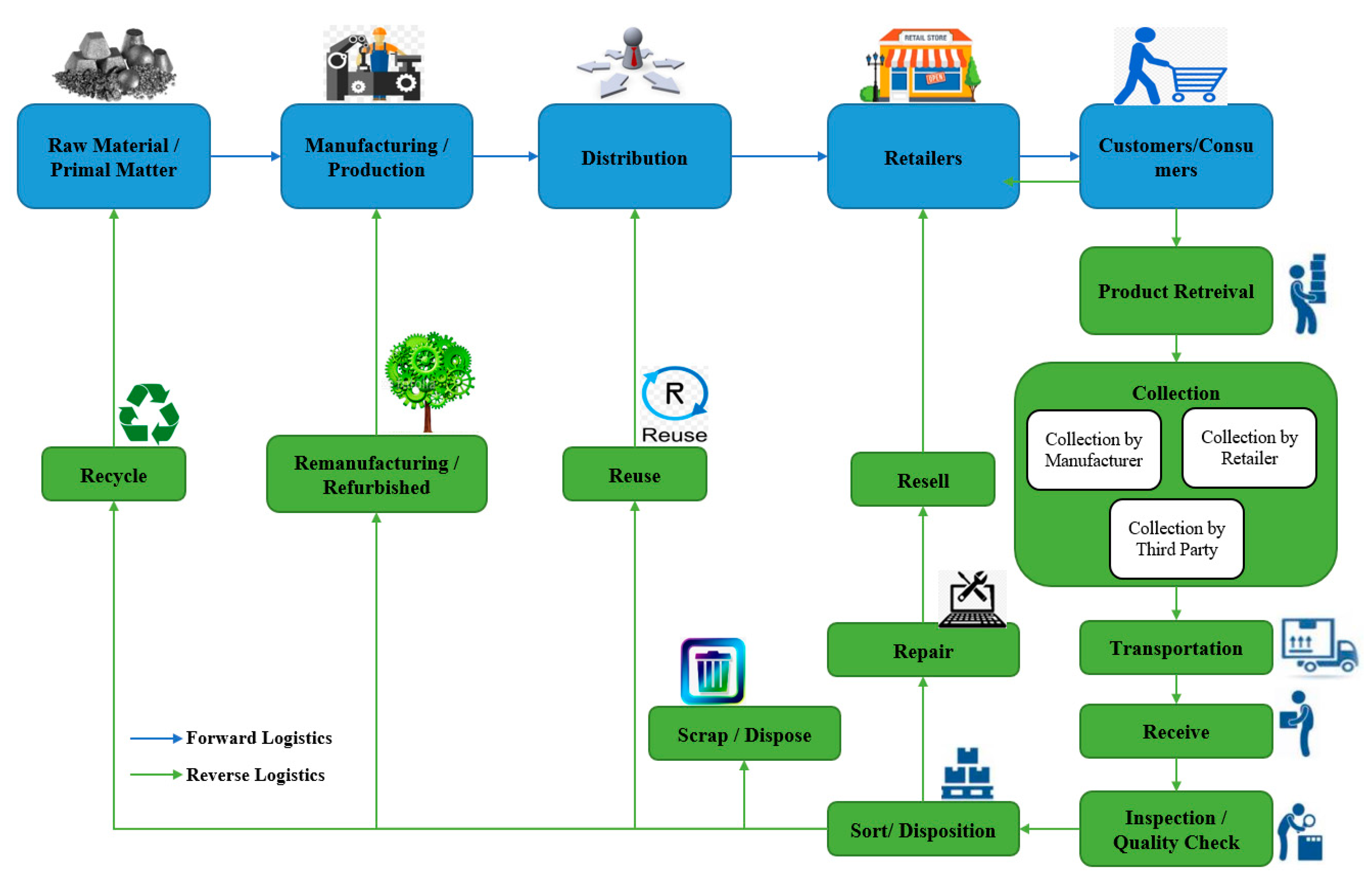

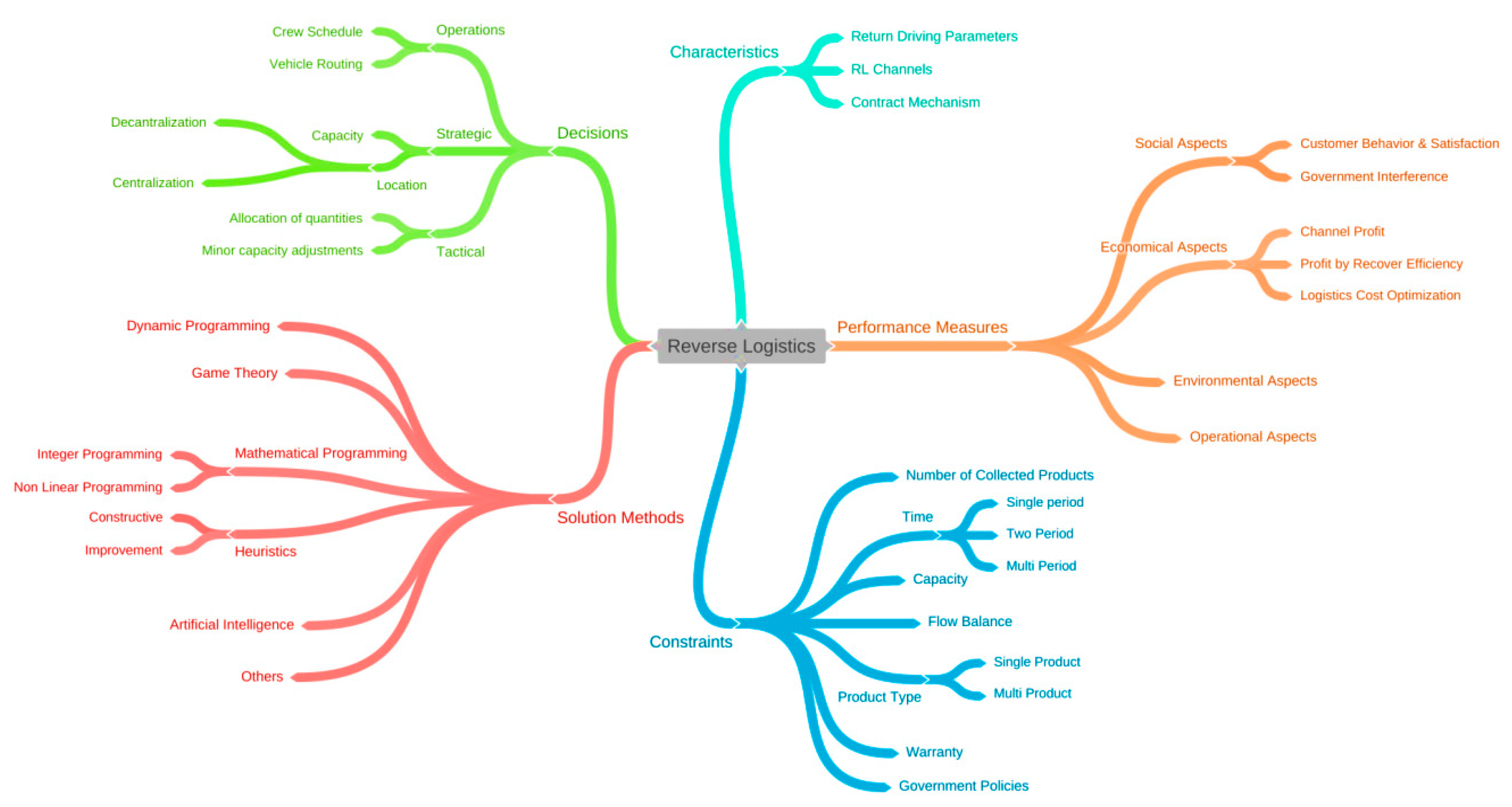

3. Reverse Logistic Characteristics and Decision Delineation

3.1. Reverse Logistic Characteristics

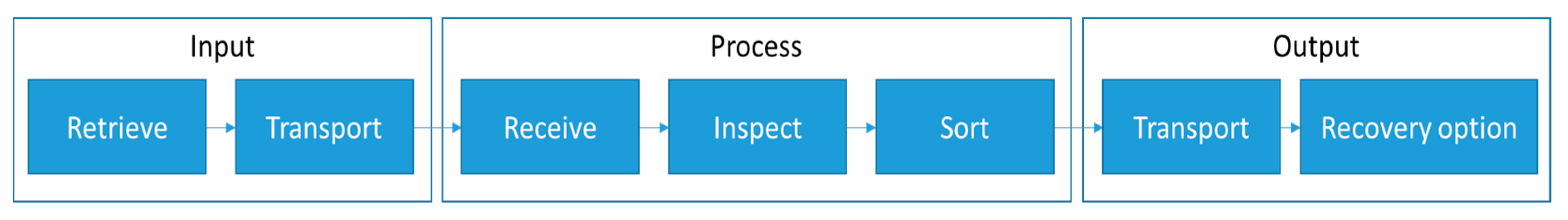

3.1.1. Reverse Logistic Channel(s)

3.1.2. Contract Mechanism

3.1.3. Return Driving Parameters

3.2. Decision Delineation

3.2.1. Center Location/Allocation and Its Capacity

3.2.2. Quality and Quantity of the Returned Product

3.2.3. Centralization vs. Decentralization

3.2.4. Inventory System

3.2.5. Others

4. Constraints and Performance Measurements

4.1. Constraints

4.2. Performance Measures

4.2.1. Economical Aspects

Logistics Cost Optimization

Profit by Recovery Efficiency

Channel Profit

4.2.2. Environmental Aspects

4.2.3. Social Aspects

Customer Behavior and Satisfaction

Government Interference

4.2.4. Operational Aspects

5. Solution Method and Uncertainty Incorporation

6. Application Area and Applicability of the Research

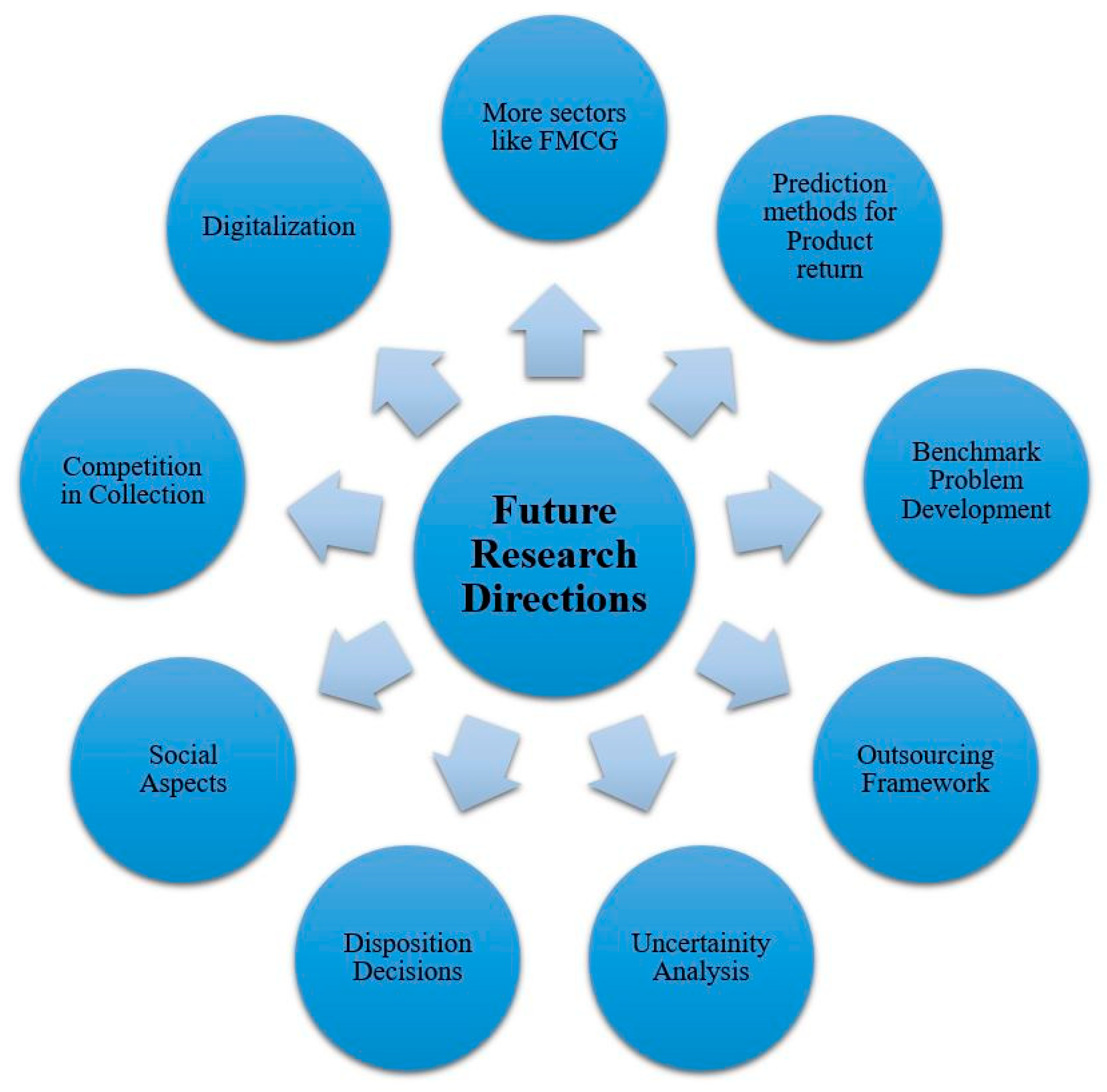

7. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bazan, E.; Jaber, M.Y.; Zanoni, S. A review of mathematical inventory models for reverse logistics and the future of its modeling: An environmental perspective. Appl. Math. Model. 2016, 40, 4151–4178. [Google Scholar] [CrossRef]

- Jaehn, F.; Juopperi, R. A Description of Supply Chain Planning Problems in the Paper Industry with Literature Review. Asia-Pac. J. Oper. Res. 2019, 36. [Google Scholar] [CrossRef]

- Thaba, S.C. Drivers for Reverse Logistics in South Africa: A Taxonomic Literature Review. World Congr. Eng. Comput. Sci. Wcecs 2017, 2, 991–994. [Google Scholar]

- Tombido, L.L.; Louw, L.; van Eeden, J. A systematic review of 3PLS’ entry into reverse logistics. S. Afr. J. Ind. Eng. 2018, 29, 235–260. [Google Scholar] [CrossRef]

- Guo, S.; Shen, B.; Choi, T.M.; Jung, S.J. A review on supply chain contracts in reverse logistics: Supply chain structures and channel leaderships. J. Clean. Prod. 2017, 144, 387–402. [Google Scholar] [CrossRef]

- Pokharel, S.; Mutha, A. Perspectives in reverse logistics: A review. Resour. Conserv. Recycl. 2009, 53, 175–182. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H.; Kannan, D. Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. Eur. J. Oper. Res. 2015, 240, 603–626. [Google Scholar] [CrossRef]

- Shekarian, E. A review of factors affecting closed-loop supply chain models. J. Clean. Prod. 2020, 253. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Rajak, S.; Panigrahi, S.S.; Agarwal, V.; Manani, D. Reverse supply chain management in manufacturing industry: A systematic review. Int. J. Product. Perform. Manag. 2020. [Google Scholar] [CrossRef]

- Islam, M.T.; Huda, N. Reverse logistics and closed-loop supply chain of Waste Electrical and Electronic Equipment (WEEE)/E-waste: A comprehensive literature review. Resour. Conserv. Recycl. 2018, 137, 48–75. [Google Scholar] [CrossRef]

- Moniveena, M.G.; Kumar, T.M.P.; Venkatesh, M.P. Regulation of Reverse Logistics of Pharmaceutical Products in United States: A Review. Res. J. Pharm. Biol. Chem. Sci. 2017, 8, 315–320. [Google Scholar]

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A Journal of Cleaner Production focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- de Campos, E.A.R.; de Paula, I.C.; Pagani, R.N.; Guarnieri, P. Reverse logistics for the end-of-life and end-of-use products in the pharmaceutical industry: A systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 375–392. [Google Scholar] [CrossRef]

- Vahabzadeh, A.H.; Yusuff, R.B.M. A Content Analysis in Reverse Logistics: A review. J. Stat. Manag. Syst. 2015, 18, 329–379. [Google Scholar] [CrossRef]

- Taghipour, A.; Abed, M.; Zoghlami, N. Design for remanufacturing respecting reverse logistics processes: A review. In Proceedings of the 2015 4th Ieee International Conference on Advanced Logistics and Transport (Icalt), Valenciennes, France, 20–22 May 2015; pp. 121–126. [Google Scholar]

- Rezaei, J. A systematic review of multi-criteria decision-making applications in reverse logistics. 18th Euro Working Group Transp. Ewgt 2015 2015, 10, 766–776. [Google Scholar] [CrossRef]

- Bhakthavatchalam, S.; Diallo, C.; Venkatadri, U.; Khatab, A. Quality, Reliability, Maintenance Issues in Closed-Loop Supply Chains: A Review. Ifac Pap. 2015, 48, 466–471. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Gan, J.W.; He, Z.G. Literature Review and Prospect on the End-of-Life Vehicles Reverse Logistics. Sel. Proc. Eighth Int. Conf. Waste Manag. Technol. 2014, 878, 66–74. [Google Scholar] [CrossRef]

- Andrade, R.P.; Lucato, W.C.; Vanalle, R.M.; Vieira, M. Review of the Relationship between Reverse Logistics and Competitiveness. Mater. Ind. Manuf. Eng. Res. Adv. 1.1 2014, 845, 614–617. [Google Scholar] [CrossRef]

- Steeneck, D.W.; Sarin, S.C. Pricing and production planning for reverse supply chain: A review. Int. J. Prod. Res. 2013, 51, 6972–6989. [Google Scholar] [CrossRef]

- Souza, G.C. Closed-Loop Supply Chains: A Critical Review, and Future Research*. Decis. Sci. 2013, 44, 7–38. [Google Scholar] [CrossRef]

- Chan, H.K.; Yin, S.Z.; Chan, F.T.S. Implementing just-in-time philosophy to reverse logistics systems: A review. Int. J. Prod. Res. 2010, 48, 6293–6313. [Google Scholar] [CrossRef]

- Chanintrakul, P.; Mondragon, A.E.C.; Lalwani, C.; Wong, C.Y. Reverse Logistics Network Design: A State-of-the-art Literature Review. Int. J. Bus. Perfor. Supply Chain Model 2008, 1, 61–81. [Google Scholar] [CrossRef]

- Ullah, M.; Sarkar, B. Recovery-channel selection in a hybrid manufacturing-remanufacturing production model with RFID and product quality. Int. J. Product. Econ. 2020, 219, 360–374. [Google Scholar] [CrossRef]

- Singhal, D.; Tripathy, S.; Jena, S.K. Remanufacturing for the circular economy: Study and evaluation of critical factors. Resour. Conserv. Recycl. 2020, 156. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Podsakoff, N.P.; Bachrach, D.G. Scholarly influence in the field of management: A bibliometric analysis of the determinants of university and author impact in the management literature in the past quarter century. J. Manag. 2008, 34, 641–720. [Google Scholar] [CrossRef]

- Baltagi, B.H. Worldwide econometrics rankings: 1989–2005. Econom. Theory 2007, 23, 952–1012. [Google Scholar] [CrossRef]

- Wagstaff, A.; Culyer, A.J. Four decades of health economics through a bibliometric lens. J. Health Econ. 2012, 31, 406–439. [Google Scholar] [CrossRef]

- Seggie, S.H.; Griffith, D.A. What does it take to get promoted in marketing academia? Understanding exceptional publication productivity in the leading marketing journals. J. Mark. 2009, 73, 122–132. [Google Scholar] [CrossRef]

- Genest, C.; Guay, M. Worldwide research output in probability and statistics: An update. Can. J. Stat. 2002, 30, 329–342. [Google Scholar] [CrossRef]

- Hoepner, A.G.; Kant, B.; Scholtens, B.; Yu, P.-S. Environmental and ecological economics in the 21st century: An age adjusted citation analysis of the influential articles, journals, authors and institutions. Ecol. Econ. 2012, 77, 193–206. [Google Scholar] [CrossRef]

- Deng, G.-F.; Lin, W.-T. Citation analysis and bibliometric approach for ant colony optimization from 1996 to 2010. Expert Syst. Appl. 2012, 39, 6229–6237. [Google Scholar] [CrossRef]

- Leone, R.P.; Robinson, L.M.; Bragge, J.; Somervuori, O. A citation and profiling analysis of pricing research from 1980 to 2010. J. Bus. Res. 2012, 65, 1010–1024. [Google Scholar] [CrossRef]

- Landström, H.; Harirchi, G.; Åström, F. Entrepreneurship: Exploring the knowledge base. Res. Pol. 2012, 41, 1154–1181. [Google Scholar] [CrossRef]

- Holsapple, C.W.; Lee-Post, A. Behavior-based analysis of knowledge dissemination channels in operations management. Omega 2010, 38, 167–178. [Google Scholar] [CrossRef]

- Hsieh, P.-N.; Chang, P.-L. An assessment of world-wide research productivity in production and operations management. Int. J. Product. Econ. 2009, 120, 540–551. [Google Scholar] [CrossRef]

- Pilkington, A.; Meredith, J. The evolution of the intellectual structure of operations management—1980–2006: A citation/co-citation analysis. J. Oper. Manag. 2009, 27, 185–202. [Google Scholar] [CrossRef]

- Liu, J.S.; Lu, L.Y.; Lu, W.-M.; Lin, B.J. Data envelopment analysis 1978–2010: A citation-based literature survey. Omega 2013, 41, 3–15. [Google Scholar] [CrossRef]

- Yin, M.-S. Fifteen years of grey system theory research: A historical review and bibliometric analysis. Expert Syst. Appl. 2013, 40, 2767–2775. [Google Scholar] [CrossRef]

- Fagerberg, J.; Fosaas, M.; Sapprasert, K. Innovation: Exploring the knowledge base. Res. Pol. 2012, 41, 1132–1153. [Google Scholar] [CrossRef]

- Merigó, J.M.; Gil-Lafuente, A.M.; Yager, R.R. An overview of fuzzy research with bibliometric indicators. Appl. Soft Comput. 2015, 27, 420–433. [Google Scholar] [CrossRef]

- Martínez, M.; Herrera, M.; López-Gijón, J.; Herrera-Viedma, E. H-Classics: Characterizing the concept of citation classics through H-index. Scientometrics 2014, 98, 1971–1983. [Google Scholar] [CrossRef]

- Hirsch, J.E. An index to quantify an individual’s scientific research output. Proc. Natl. Acad. Sci. USA 2005, 102, 16569–16572. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Fleischmann, M.; BloemhofRuwaard, J.M.; Dekker, R.; vanderLaan, E.; vanNunen, J.; VanWassenhove, L.N. Quantitative models for reverse logistics: A review. Eur. J. Oper. Res. 1997, 103, 1–17. [Google Scholar] [CrossRef]

- Savaskan, R.C.; Bhattacharya, S.; Van Wassenhove, L.N. Closed-loop supply chain models with product remanufacturing. Manag. Sci. 2004, 50, 239–252. [Google Scholar] [CrossRef]

- Melo, M.T.; Nickel, S.; Saldanha-da-Gama, F. Facility location and supply chain management—A review. Eur. J. Oper. Res. 2009, 196, 401–412. [Google Scholar] [CrossRef]

- Linton, J.D.; Klassen, R.; Jayaraman, V. Sustainable supply chains: An introduction. J. Oper. Manag. 2007, 25, 1075–1082. [Google Scholar] [CrossRef]

- Sarkis, J.; Gonzalez-Torre, P.; Adenso-Diaz, B. Stakeholder pressure and the adoption of environmental practices: The mediating effect of training. J. Oper. Manag. 2010, 28, 163–176. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Product. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- He, Q.; Wang, N.; Yang, Z.; He, Z.; Jiang, B. Competitive collection under channel inconvenience in closed-loop supply chain. Eur. J. Oper. Res. 2019, 275, 155–166. [Google Scholar] [CrossRef]

- Wang, J.B.; Zhang, T.; Fan, X.J. Reverse channel design with a dominant retailer and upstream competition in emerging markets: Retailer- or manufacturer-collection? Transp. Res. Part E-Logist. Transp. Rev. 2020, 137. [Google Scholar] [CrossRef]

- Li, C.F.; Feng, L.P.; Luo, S.Y. Strategic introduction of an online recycling channel in the reverse supply chain with a random demand. J. Clean. Prod. 2019, 236. [Google Scholar] [CrossRef]

- Rahmani, S.; Haeri, A.; Hosseini-Motlagh, S.M. Proposing channel coordination and horizontal cooperation in two competitive three-echelon reverse supply chains. Int. Trans. Oper. Res. 2020, 27, 1447–1477. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Mamaghan, M.K.; Torabi, S.A. A possibilistic closed-loop supply chain: Pricing, advertising and remanufacturing optimization. Neural Comput. Appl. 2020, 32, 1195–1215. [Google Scholar] [CrossRef]

- Zerang, E.S.; Taleizadeh, A.A.; Razmi, J. Analytical comparisons in a three-echelon closed-loop supply chain with price and marketing effort-dependent demand: Game theory approaches. Environ. Dev. Sustain. 2018, 20, 451–478. [Google Scholar] [CrossRef]

- Wei, J.; Wang, Y.; Zhao, J.; Gonzalez, E.D.R.S. Analyzing the performance of a two-period remanufacturing supply chain with dual collecting channels. Comput. Ind. Eng. 2019, 135, 1188–1202. [Google Scholar] [CrossRef]

- Kushwaha, S.; Ghosh, A.; Rao, A.K. Collection activity channels selection in a reverse supply chain under a carbon cap-and-trade regulation. J. Clean. Prod. 2020, 260. [Google Scholar] [CrossRef]

- Wu, D.; Chen, J.H.; Li, P.; Zhang, R.J. Contract coordination of dual channel reverse supply chain considering service level. J. Clean. Prod. 2020, 260. [Google Scholar] [CrossRef]

- Cao, J.; Zhang, X.M.; Hu, L.L.; Xu, J.Y.; Zhao, Y.W.; Zhou, G.G.; Schnoor, J.L. EPR regulation and reverse supply chain strategy on remanufacturing. Comput. Ind. Eng. 2018, 125, 279–297. [Google Scholar] [CrossRef]

- Nnorom, I.C.; Osibanjo, O. Overview of electronic waste (e-waste) management practices and legislations, and their poor applications in the developing countries. Resour. Conserv. Recycl. 2008, 52, 843–858. [Google Scholar] [CrossRef]

- Thurer, M.; Pan, Y.H.; Qu, T.; Luo, H.; Li, C.D.; Huang, G.Q. Internet of Things (IoT) driven kanban system for reverse logistics: Solid waste collection. J. Intell. Manuf. 2019, 30, 2621–2630. [Google Scholar] [CrossRef]

- Misni, F.; Lee, L.S. A Review on Strategic, Tactical and Operational Decision Planning in Reverse Logistics of Green Supply Chain Network Design. J. Comput. Commun. 2017, 05, 83–104. [Google Scholar] [CrossRef]

- Mishra, S.; Singh, S.P. Designing dynamic reverse logistics network for post-sale service. Ann. Oper. Res. 2020, 30. [Google Scholar] [CrossRef]

- Reddy, K.N.; Kumar, A.; Sarkis, J.; Tiwari, M.K. Effect of carbon tax on reverse logistics network design. Comput. Ind. Eng. 2020, 139. [Google Scholar] [CrossRef]

- Park, K.; Kim, J.; Ko, Y.D.; Song, B.D. Redesign of reverse logistics network with managerial decisions on the minimum quality level and remanufacturing policy. J. Oper. Res. Soc. 2020. [Google Scholar] [CrossRef]

- Reddy, K.N.; Kumar, A.; Ballantyne, E.E.F. A three-phase heuristic approach for reverse logistics network design incorporating carbon footprint. Int. J. Prod. Res. 2019, 57, 6090–6114. [Google Scholar] [CrossRef]

- Das, K. Planning Environmental and Economic Sustainability in Closed-Loop Supply Chains. Oper. Supply Chain Manag. Int. J. 2020, 13, 64–81. [Google Scholar] [CrossRef]

- Zhou, Y.C.; Sun, X.C. Robust optimal inventory and acquisition effort decisions in a hybrid manufacturing/remanufacturing system. J. Ind. Prod. Eng. 2019, 36, 335–350. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, Z.G.; Zhang, H.; Wang, Y.; Yang, Y.H.; Li, Y. An integrated MCDM approach considering demands-matching for reverse logistics. J. Clean. Prod. 2019, 208, 199–210. [Google Scholar] [CrossRef]

- Tian, G.D.; Liu, X.; Zhang, M.H.; Yang, Y.S.; Zhang, H.H.; Lin, Y.; Ma, F.W.; Wang, X.Y.; Qu, T.; Li, Z.W. Selection of take-back pattern of vehicle reverse logistics in China via Grey-DEMATEL and Fuzzy-VIKOR combined method. J. Clean. Prod. 2019, 220, 1088–1100. [Google Scholar] [CrossRef]

- Ruiz-Torres, A.J.; Mahmoodi, F.; Ohmori, S. Joint determination of supplier capacity and returner incentives in a closed-loop supply chain. J. Clean. Prod. 2019, 215, 1351–1361. [Google Scholar] [CrossRef]

- Xiao, Z.D.; Sun, J.N.; Shu, W.J.; Wang, T.W. Location-allocation problem of reverse logistics for end-of-life vehicles based on the measurement of carbon emissions. Comput. Ind. Eng. 2019, 127, 169–181. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, S.; Niu, B. Coordination mechanism of dual-channel closed-loop supply chains considering product quality and return. J. Clean. Prod. 2020, 248, 119273. [Google Scholar] [CrossRef]

- Dou, G.W.; Cao, K.Y. A joint analysis of environmental and economic performances of closed-loop supply chains under carbon tax regulation. Comput. Ind. Eng. 2020, 146. [Google Scholar] [CrossRef]

- Vieira, B.d.O.; Guarnieri, P.; Camara e Silva, L.; Alfinito, S. Prioritizing Barriers to Be Solved to the Implementation of Reverse Logistics of E-Waste in Brazil under a Multicriteria Decision Aid Approach. Sustainability 2020, 12, 4337. [Google Scholar] [CrossRef]

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Product. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- Waqas, M.; Dong, Q.-l.; Ahmad, N.; Zhu, Y.; Nadeem, M. Critical Barriers to Implementation of Reverse Logistics in the Manufacturing Industry: A Case Study of a Developing Country. Sustainability 2018, 10, 4202. [Google Scholar] [CrossRef]

- Vahdani, B.; Razmi, J.; Tavakkoli-Moghaddam, R. Fuzzy Possibilistic Modeling for Closed Loop Recycling Collection Networks. Environ. Model. Assess. 2012, 17, 623–637. [Google Scholar] [CrossRef]

- Voigt, D.; Casarotto, N.; Macedo, M.A.; Braga, T.G.; da Rocha, R.U.G. Performance Evaluation of Reverse Logistics: Opportunities for Future Research. Sustainability 2019, 11, 291. [Google Scholar] [CrossRef]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. Triple bottom line performance evaluation of reverse logistics. Compet. Rev. 2016, 26, 289–310. [Google Scholar] [CrossRef]

- Wan, N.N.; Hong, D.J. The impacts of subsidy policies and transfer pricing policies on the closed-loop supply chain with dual collection channels. J. Clean. Prod. 2019, 224, 881–891. [Google Scholar] [CrossRef]

- Sviatskii, V.; Bialy, W.; Sentyakov, K.; Repko, A. Estimation of quality indicators of ecological thermoplastic fiber materials. Acta Montan. Slovaca 2020, 25, 14–23. [Google Scholar] [CrossRef]

- Wang, Z.; Huo, J.Z.; Duan, Y.R. Impact of government subsidies on pricing strategies in reverse supply chains of waste electrical and electronic equipment. Waste Manag. 2019, 95, 440–449. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.d.; Ruiz, M.S.; Correia, A.J.C.; Mendes, H.M.R. Environmental advantages of the reverse logistics: A case study in the batteries collection in Brazil. Production 2018, 28. [Google Scholar] [CrossRef]

- Uriarte-Miranda, M.-L.; Caballero-Morales, S.-O.; Martinez-Flores, J.-L.; Cano-Olivos, P.; Akulova, A.-A. Reverse Logistic Strategy for the Management of Tire Waste in Mexico and Russia: Review and Conceptual Model. Sustainability 2018, 10, 3398. [Google Scholar] [CrossRef]

- Marsillac, E. Environmental impacts on reverse logistics and green supply chains: Similarities and integration. Int. J. Logist. Syst. Manag. 2008, 4. [Google Scholar] [CrossRef]

- Li, R.C.; Tee, T.J.C. A Reverse Logistics Model For Recovery Options Of E-waste Considering the Integration of the Formal and Informal Waste Sectors. Procedia Soc. Behav. Sci. 2012, 40, 788–816. [Google Scholar] [CrossRef]

- Lau, H.K.; Wang, Y. Reverse logistics in the electronic industry of China: A case study. Supply Chain Manag. Int. J. 2009, 14, 447–465. [Google Scholar] [CrossRef]

- Liu, H.; Lei, M.; Deng, H.; Keong Leong, G.; Huang, T. A dual channel, quality-based price competition model for the WEEE recycling market with government subsidy. Omega 2016, 59, 290–302. [Google Scholar] [CrossRef]

- Foelster, A.-S.; Andrew, S.; Kroeger, L.; Bohr, P.; Dettmer, T.; Boehme, S.; Herrmann, C. Electronics recycling as an energy efficiency measure—A Life Cycle Assessment (LCA) study on refrigerator recycling in Brazil. J. Clean. Prod. 2016, 129, 30–42. [Google Scholar] [CrossRef]

- Guarnieri, P.; e Silva, L.C.; Levino, N.A. Analysis of electronic waste reverse logistics decisions using Strategic Options Development Analysis methodology: A Brazilian case. J. Clean. Prod. 2016, 133, 1105–1117. [Google Scholar] [CrossRef]

- Caiado, N.; Guarnieri, P.; Xavier, L.H.; de Lorena Diniz Chaves, G. A characterization of the Brazilian market of reverse logistic credits (RLC) and an analogy with the existing carbon credit market. Resour. Conserv. Recycl. 2017, 118, 47–59. [Google Scholar] [CrossRef]

- Vaz, R.; Grabot, B.; Maldonado, M.U.; Selig, P.M. Some reasons to implement reverse logistics in companies. Int. J. Environ. Technol. Manag. (IJETM) 2013, 16, 467–479. [Google Scholar] [CrossRef]

- Alnoor, A.; Eneizan, B.; Makhamreh, H.Z.; Rahoma, I.A. The Effect of Reverse Logistics on Sustainable Manufacturing. Int. J. Acad. Res. Account. Financ. Manag. Sci. 2019, 9, 71–79. [Google Scholar] [CrossRef]

- Arrieta, V. Reverse Logistics as Alleviation of Ecological Issues; Helsinki Metropolia University of Applied Sciences: Helsinki, Finland, 2015. [Google Scholar]

- Banihashemi Taknaz, A.; Fei, J.; Chen Peggy, S.-L. Exploring the relationship between reverse logistics and sustainability performance: A literature review. Mod. Supply Chain Res. Appl. 2019, 1, 2–27. [Google Scholar] [CrossRef]

- Poppelaars, F.; Bakker, C.; van Engelen, J. Design for Divestment in a Circular Economy: Stimulating Voluntary Return of Smartphones through Design. Sustainability 2020, 12, 1488. [Google Scholar] [CrossRef]

- Pisitsankkhakarn, R.; Vassanadumrongdee, S. Enhancing purchase intention in circular economy: An empirical evidence of remanufactured automotive product in Thailand. Resour. Conserv. Recycl. 2020, 156. [Google Scholar] [CrossRef]

- Mohamed, A.G.; Fathi, A.A.; Marouf, M.A.; Hassan, M.S.; ElBarky, S.S. Impact of Reverse Logistics Applications on Customer Satisfaction. In Proceedings of the International Conference on Operations Excellence and Service Engineering, Orlando, FL, USA, 10–11 Septemeber; pp. 393–405.

- Jalil, E.E.A. Customer satisfaction and reverse logistics in ecommerce: The case of klang valley. In Proceedings of the 9th International Conference on Operations and Supply Chain Management, Ho Chi Minh City, Vietnam, 15–18 December 2019; pp. 1–9. [Google Scholar]

- Milanez, B.; Bührs, T. Extended producer responsibility in Brazil: The case of tyre waste. J. Clean. Prod. 2009, 17, 608–615. [Google Scholar] [CrossRef]

- Mitra, S.; Webster, S. Competition in remanufacturing and the effects of government subsidies. Int. J. Product. Econ. 2008, 111, 287–298. [Google Scholar] [CrossRef]

- Liu, H.; Yue, X.; Ding, H.; Leong, G. Optimal Remanufacturing Certification Contracts in the Electrical and Electronic Industry. Sustainability 2017, 9, 516. [Google Scholar] [CrossRef]

- Jena, S.K.; Ghadge, A.; Sarmah, S.P. Managing channel profit and total surplus in a closed-loop supply chain network. J. Oper. Res. Soc. 2017, 69, 1345–1356. [Google Scholar] [CrossRef]

- Jena, S.K.; Sarmah, S.P.; Padhi, S.S. Impact of government incentive on price competition of closed-loop supply chain systems. INFOR Inf. Syst. Oper. Res. 2017, 56, 192–224. [Google Scholar] [CrossRef]

- Sharma, V.; Garg, S.K.; Sharma, P.B. Identification of major drivers and roadblocks for remanufacturing in India. J. Clean. Prod. 2016, 112, 1882–1892. [Google Scholar] [CrossRef]

- Masudin, I.; Jannah, F.R.; Utama, D.M.; Restuputri, D.P. Capacitated Remanufacturing Inventory Model Considering Backorder: A Case Study of Indonesian Reverse Logistics. IEEE Access 2019, 7, 143046–143057. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.S.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics-a review. Environ. Res. Lett. 2019, 14. [Google Scholar] [CrossRef]

- Cilacı Tombuş, A.; Aras, N.; Verter, V. Designing distribution systems with reverse flows. J. Remanufacturing 2017, 7, 113–137. [Google Scholar] [CrossRef][Green Version]

- Tahirov, N.; Hasanov, P.; Jaber, M.Y. Optimization of closed-loop supply chain of multi-items with returned subassemblies. Int. J. Product. Econ. 2016, 174, 1–10. [Google Scholar] [CrossRef]

- John, S.T.; Sridharan, R.; Kumar, P.N.R. Reverse logistics network design: A case of mobile phones and digital cameras. Int. J. Adv. Manuf. Technol. 2018, 94, 615–631. [Google Scholar] [CrossRef]

- John, S.T.; Sridharan, R.; Kumar, P.N.R.; Krishnamoorthy, M. Multi-period reverse logistics network design for used refrigerators. Appl. Math. Model. 2018, 54, 311–331. [Google Scholar] [CrossRef]

- Cavallin, A.; Rossit, D.G.; Symonds, V.H.; Rossit, D.A.; Frutos, M. Application of a methodology to design a municipal waste pre-collection network in real scenarios. Waste Manag. Res. 2020, 38, 117–128. [Google Scholar] [CrossRef] [PubMed]

- Rossit, D.G.; Toutouh, J.; Nesmachnow, S. Exact and heuristic approaches for multi-objective garbage accumulation points location in real scenarios. Waste Manag. 2020, 105, 467–481. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.R.; Chen, X.H. A novel approach integrating FANP and MOMILP for the collection centre location problem in closed-loop supply chain. Int. J. Sustain. Eng. 2020, 13, 171–183. [Google Scholar] [CrossRef]

- Zhen, L.; Lv, W.Y.; Wang, K.; Ma, C.L.; Xu, Z.H. Consistent vehicle routing problem with simultaneous distribution and collection. J. Oper. Res. Soc. 2020, 71, 813–830. [Google Scholar] [CrossRef]

- Santander, P.; Sanchez, F.A.C.; Boudaoud, H.; Camargo, M. Closed loop supply chain network for local and distributed plastic recycling for 3D printing: A MILP-based optimization approach. Resour. Conserv. Recycl. 2020, 154. [Google Scholar] [CrossRef]

- Coelho, E.K.F.; Mateus, G.R. A capacitated plant location model for Reverse Logistics Activities. J. Clean. Prod. 2017, 167, 1165–1176. [Google Scholar] [CrossRef]

- Zouadi, T.; Yalaoui, A.; Reghioui, M. Hybrid manufacturing/remanufacturing lot-sizing and supplier selection with returns, under carbon emission constraint. Int. J. Prod. Res. 2018, 56, 1233–1248. [Google Scholar] [CrossRef]

- Paydar, M.M.; Olfati, M. Designing and solving a reverse logistics network for polyethylene terephthalate bottles. J. Clean. Prod. 2018, 195, 605–617. [Google Scholar] [CrossRef]

- Subulan, K.; Tasan, A.S.; Baykasoglu, A. Designing an environmentally conscious tire closed-loop supply chain network with multiple recovery options using interactive fuzzy goal programming. Appl. Math. Model. 2015, 39, 2661–2702. [Google Scholar] [CrossRef]

- Alshamsi, A.; Diabat, A. A reverse logistics network design. J. Manuf. Syst. 2015, 37, 589–598. [Google Scholar] [CrossRef]

- Elahi, B.; Franchetti, M. A New Optimization Model for Closed-Loop Supply Chain Networks. In Proceedings of the 2014 IEEE International Technology Management Conference, Chicago, IL, USA, 12–15 June 2014; IEEE: New York, NY, USA, 2014. [Google Scholar]

- Amin, S.H.; Zhang, G.Q. A proposed mathematical model for closed-loop network configuration based on product life cycle. Int. J. Adv. Manuf. Technol. 2012, 58, 791–801. [Google Scholar] [CrossRef]

- Alumur, S.A.; Nickel, S.; Saldanha-Da-Gama, F.; Verter, V. Multi-period reverse logistics network design. Eur. J. Oper. Res. 2012, 220, 67–78. [Google Scholar] [CrossRef]

- Temucin, T.; Tuzkaya, G. A multi-objective reverse logistics network design model for after-sale services and a tabu search based methodology. J. Intell. Fuzzy Syst. 2020, 38, 4139–4157. [Google Scholar] [CrossRef]

- Shi, J.M.; Chen, W.Y.; Zhou, Z.B.; Zhang, G.Q. A bi-objective multi-period facility location problem for household e-waste collection. Int. J. Prod. Res. 2020, 58, 526–545. [Google Scholar] [CrossRef]

- Sas, I.; Joines, J.A.; Thoney, K.A.; King, R.E. Logistics of carpet recycling in the US: Designing the collection network. J. Text. Inst. 2019, 110, 328–337. [Google Scholar] [CrossRef]

- Shokouhyar, S.; Aalirezaei, A. Designing a sustainable recovery network for waste from electrical and electronic equipment using a genetic algorithm. Int. J. Environ. Sustain. Dev. 2017, 16, 60–79. [Google Scholar] [CrossRef]

- Huang, M.; Yi, P.X.; Guo, L.J.; Shi, T.L. A Modal Interval Based Genetic Algorithm for Closed-loop Supply Chain Network Design under Uncertainty. IFAC Pap. 2016, 49, 616–621. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Lee, C.K.M. Optimization of Facility Location Problem in Reverse Logistics Network using Artificial Bee Colony Algorithm. In Proceedings of the 2013 IEEE International Conference on Industrial Engineering and Engineering Management, Bangkok, Thailand, 10–13 December 2013; IEEE: New York, NY, USA, 2013; pp. 1348–1352. [Google Scholar]

- Hong, Z.F.; Zhang, H.Y. Innovative crossed advertisement for remanufacturing with interactive production constraints. J. Clean. Prod. 2019, 216, 197–216. [Google Scholar] [CrossRef]

- Guo, L.L.; Qu, Y.; Tseng, M.L.; Wu, C.Y.; Wang, X.Y. Two-echelon reverse supply chain in collecting waste electrical and electronic equipment: A game theory model. Comput. Ind. Eng. 2018, 126, 187–195. [Google Scholar] [CrossRef]

- Chu, X.; Zhong, Q.Y.; Li, X. Reverse channel selection decisions with a joint third-party recycler. Int. J. Prod. Res. 2018, 56, 5969–5981. [Google Scholar] [CrossRef]

- Zheng, B.R.; Yang, C.; Yang, J.; Zhang, M. Pricing, collecting and contract design in a reverse supply chain with incomplete information. Comput. Ind. Eng. 2017, 111, 109–122. [Google Scholar] [CrossRef]

- Li, J.; Wang, Z.; Jiang, B.; Kim, T. Coordination strategies in a three-echelon reverse supply chain for economic and social benefit. Appl. Math. Model. 2017, 49, 599–611. [Google Scholar] [CrossRef]

- Weng, T.C.; Chen, C.K. Competitive analysis of collection behavior between retailer and third-party in the reverse channel. Rairo-Oper. Res. 2016, 50, 175–188. [Google Scholar] [CrossRef]

- Ocampo, L.A.; Himang, C.M.; Kumar, A.; Brezocnik, M. A novel multiple criteria decision-making approach based on fuzzy DEMATEL, fuzzy ANP and fuzzy AHP for mapping collection and distribution centers in reverse logistics. Adv. Prod. Eng. Manag. 2019, 14, 297–322. [Google Scholar] [CrossRef]

- Soleimani, H.; Chaharlang, Y.; Ghaderi, H. Collection and distribution of returned-remanufactured products in a vehicle routing problem with pickup and delivery considering sustainable and green criteria. J. Clean. Prod. 2018, 172, 960–970. [Google Scholar] [CrossRef]

- Singh, R.K.; Agrawal, S. Analyzing disposition strategies in reverse supply chains: Fuzzy TOPSIS approach. Manag. Environ. Qual. 2018, 29, 427–443. [Google Scholar] [CrossRef]

- Jain, S.; Tiwari, S.; Cardenas-Barron, L.E.; Shaikh, A.A.; Singh, S.R. A fuzzy imperfect production and repair inventory model with time dependent demand, production and repair rates under inflationary conditions. Rairo-Oper. Res. 2018, 52, 217–239. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Masehian, E.; Soltani, R.; Khosrojerdi, A. A reverse logistics network for recovery systems and a robust metaheuristic solution approach. Int. J. Adv. Manuf. Technol. 2014, 74, 1393–1406. [Google Scholar] [CrossRef]

- Alshamsi, A.; Diabat, A. A Genetic Algorithm for Reverse Logistics network design: A case study from the GCC. J. Clean. Prod. 2017, 151, 652–669. [Google Scholar] [CrossRef]

- Benaissa, M.; Slama, I.; Dhiaf, M.M. Reverse Logistics Network Problem using simulated annealing with and without Priority-algorithm. Arch. Transp. 2018, 47, 7–17. [Google Scholar] [CrossRef]

- Trochu, J.; Chaabane, A.; Ouhimmou, M. Reverse logistics network redesign under uncertainty for wood waste in the CRD industry. Resour. Conserv. Recycl. 2018, 128, 32–47. [Google Scholar] [CrossRef]

- Paduloh, P.; Djatna, T.; Sukardi, S.; Muslich, M. Uncertainty Models in Reverse Supply Chain: A Review. Int. J. Supply Chain Manag 2020, 9, 139–149. [Google Scholar] [CrossRef]

- Gu, F.; Zhang, W.J.; Guo, J.F.; Hall, P. Exploring “Internet plus Recycling”: Mass balance and life cycle assessment of a waste management system associated with a mobile application. Sci. Total Environ. 2019, 649, 172–185. [Google Scholar] [CrossRef]

- Grandjean, T.R.B.; Groenewald, J.; Marco, J. The experimental evaluation of lithium ion batteries after flash cryogenic freezing. J. Energy Storage 2019, 21, 202–215. [Google Scholar] [CrossRef]

- Alkahtani, M.; Ziout, A. Design of a sustainable reverse supply chain in a remanufacturing environment: A case study of proton-exchange membrane fuel cell battery in Riyadh. Adv. Mech. Eng. 2019, 11. [Google Scholar] [CrossRef]

- Grandjean, T.R.B.; Groenewald, J.; McGordon, A.; Marco, J. Cycle life of lithium ion batteries after flash cryogenic freezing. J. Energy Storage 2019, 24. [Google Scholar] [CrossRef]

- Jayant, A.; Gupta, P.; Garg, S.K. Simulation Modelling and Analysis of Network Design for Closed-Loop Supply Chain: A Case Study of Battery Industry. Procedia Eng. 2014, 97, 2213–2221. [Google Scholar] [CrossRef]

- Angouria-Tsorochidou, E.; Cimpan, C.; Parajuly, K. Optimized collection of EoL electronic products for Circular economy: A techno-economic assessment. Proc. CIRP 2018, 69, 986–991. [Google Scholar] [CrossRef]

- Zhao, S.L.; Zhu, Q.H. A risk-averse marketing strategy and its effect on coordination activities in a remanufacturing supply chain under market fluctuation. J. Clean. Prod. 2018, 171, 1290–1299. [Google Scholar] [CrossRef]

- Liu, C.H.; Cai, W.; Dinolov, O.; Zhang, C.X.; Rao, W.Z.; Jia, S.; Li, L.; Chan, F.T.S. Emergy based sustainability evaluation of remanufacturing machining systems. Energy 2018, 150, 670–680. [Google Scholar] [CrossRef]

- Zhao, S.L.; Zhu, Q.H. Remanufacturing supply chain coordination under the stochastic remanufacturability rate and the random demand. Ann. Oper. Res. 2017, 257, 661–695. [Google Scholar] [CrossRef]

- Kumar, A.; Chinnam, R.B.; Murat, A. Hazard rate models for core return modeling in auto parts remanufacturing. Int. J. Product. Econ. 2017, 183, 354–361. [Google Scholar] [CrossRef]

- Starostka-Patyk, M. Defective products management with reverse logistics processes in the furniture production companies. Pol. J. Manag. Stud. 2019, 20, 502–515. [Google Scholar] [CrossRef]

- González-Sánchez, R.; Settembre-Blundo, D.; Ferrari, A.M.; García-Muiña, F.E. Main Dimensions in the Building of the Circular Supply Chain: A Literature Review. Sustainability 2020, 12, 2459. [Google Scholar] [CrossRef]

- Julianelli, V.; Caiado, R.G.G.; Scavarda, L.F.; Cruz, S.P.d.M.F. Interplay between reverse logistics and circular economy: Critical success factors-based taxonomy and framework. Resour. Conserv. Recycl. 2020, 158, 104784. [Google Scholar] [CrossRef]

- De Oliveira, C.T.; Luna, M.M.M.; Campos, L.M.S. Understanding the Brazilian expanded polystyrene supply chain and its reverse logistics towards circular economy. J. Clean. Prod. 2019, 235, 562–573. [Google Scholar] [CrossRef]

- Turrisi, M.; Bruccoleri, M.; Cannella, S. Impact of reverse logistics on supply chain performance. Int. J. Phys. Distrib. Logist. Manag. 2013, 43, 564–585. [Google Scholar] [CrossRef]

- Schoenherr, T. The role of environmental management in sustainable business development: A multi-country investigation. Int. J. Product. Econ. 2012, 140, 116–128. [Google Scholar] [CrossRef]

- Younis, H.; Sundarakani, B.; Vel, P. The impact of implementing green supply chain management practices on corporate performance. Compet. Rev. 2016, 26, 216–245. [Google Scholar] [CrossRef]

- Geng, R.; Mansouri, S.A.; Aktas, E. The relationship between green supply chain management and performance: A meta-analysis of empirical evidences in Asian emerging economies. Int. J. Product. Econ. 2017, 183, 245–258. [Google Scholar] [CrossRef]

- Ying, D.; Kaku, I.; Jiafu, T. Inventory management in reverse logistics: A survey. In Proceedings of the ICSSSM ’05. 2005 International Conference on Services Systems and Services Management, Chongquing, China, 13–15 June 2005; Volume 351, pp. 352–356. [Google Scholar]

- Casper, R.; Sundin, E. Reverse Logistic Transportation and Packaging Concepts in Automotive Remanufacturing. Procedia Manuf. 2018, 25, 154–160. [Google Scholar] [CrossRef]

- Nikolaidis, Y. Quality Management in Reverse Logistics; Springer: London, UK, 2013; p. 160. [Google Scholar] [CrossRef]

- Wen, L.; Yunxian, H.; Anan, M.; Yuguo, H. Reverse logistics: The game between government and distribution centers on recycling products packaging. In Proceedings of the 2010 7th International Conference on Service Systems and Service Management, Tokyo, Japan, 28–30 June 2010; pp. 1–4. [Google Scholar]

- Filip, F.G.; Duta, L. Decision Support Systems in Reverse Supply Chain Management. Procedia Econ. Financ. 2015, 22, 154–159. [Google Scholar] [CrossRef]

- Tavakkoli Moghaddam, S.; Javadi, M.; Hadji Molana, S.M. A reverse logistics chain mathematical model for a sustainable production system of perishable goods based on demand optimization. J. Ind. Eng. Int. 2019, 15, 709–721. [Google Scholar] [CrossRef]

- Dekker, R.; Fleischmann, M.; Inderfurth, K.; Van Wassenhove, L.N. Quantitative Models for Reverse Logistics Decision Making. In Reverse Logistics: Quantitative Models for Closed-Loop Supply Chains; Dekker, R., Fleischmann, M., Inderfurth, K., Van Wassenhove, L.N., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; pp. 29–41. [Google Scholar]

| Reference | Year of Publication | Scope | Finding | Year Under Consideration | No. of Articles Reviewed |

|---|---|---|---|---|---|

| E. Shekarian [8] | 2020 | CLSC/RL | CLSC categories based on game theory articles | 2004–2018 | 215 |

| K. Mathiyazhagan et al. [9] | 2020 | CLSC/RL | Classification in forward and backward supply chain | 2002–2017 | 204 |

| F. Jaehn and R. Juopperi [2] | 2019 | RL | Identifying RL planning in paper industry | 2009 | |

| L. L. Tombido et al. [4] | 2018 | CLSC/RL | Performance measures and technological use | 2000–2018 | 134 |

| M. T. Islam and N. Huda [10] | 2018 | CLSC/RL | Classification of four research types in E-waste product (designing and planning of reverse distribution, decision making and performance evaluation, conceptual framework, and qualitative studies) | 1999–2017 | 157 |

| S. C. Thaba [3] | 2017 | RL | Identifying drivers | ||

| M. G. Moniveena et al. [11] | 2017 | RL | Identify the regulation of reverse logistic for pharmaceutical industry | ||

| S. Guo et al. [5] | 2017 | RL | Classification of supply chain structure (contract, link, and leadership) | 2006–2016 | 62 |

| K. Govindan and H. Soleimani [12] | 2017 | CLSC/RL | Trend in CLSC/RL in Journal of Cleaner Production | ~2014 | 83 |

| E. A. R. de Campos et al. [13] | 2017 | RL | Classification of four research types in pharmaceutical industry (environmental risk, evolution and regulatory, and stakeholder’s educational perspective) | 1996–2015 | 39 |

| E. Bazan et al. [1] | 2016 | RL | Identifying mathematical modeling of RL inventory systems | 1967–2014 | 183 |

| A. H. Vahabzadeh and R. B. M. Yusuff [14] | 2015 | RL | Identifying RL characteristic, modeling, and stakeholder RL | 1998–2012 | |

| A. Taghipour et al. [15] | 2015 | RL, RM | Identifying the aspect of design for remanufacture | ||

| J. Rezaei [16] | 2015 | RL | Categorizing the multicriteria decision making in RL | ||

| K. Govindan et al. [7] | 2015 | CLSC/RL | The whole area in RL and CLSC | 2007–2013 | 382 |

| S. Bhakthavatchalam et al. [17] | 2015 | CLSC | Categorizing the problem (quality, reliability, maintenance and warranty), and mathematical tools and techniques | ||

| S. Agrawal et al. [18] | 2015 | RL | Classification of the references (forecasting, outsourcing, networks design from secondary market perspective, and disposition decisions) | 1986–2015 | 242 |

| J. W. Gan and Z. G. He [19] | 2014 | RL | Classification of four research types in vehicle industry (trend, performance measure of recycling, recycling mode, RL system and network) | ||

| R. P. Andrade et al. [20] | 2014 | RL | Identifying the influence of RL on the enterprise competitiveness | ||

| D. W. Steeneck and S. C. Sarin [21] | 2013 | RL | Identifying the correlation of the pricing of remanufactured products to the production cost | ||

| G. C. Souza [22] | 2013 | CLSC | Framework design tutorial | ||

| H. K. Chan et al. [23] | 2010 | RL | Identifying the correlation of Just In Time and RL | ~2009 | 125 |

| S. Pokharel and A. Mutha [6] | 2009 | CLSC/RL | Classification of RL processes (logistics, business, production, and operations management) | 1971–2008 | 164 |

| P. Chanintrakul et al. [24] | 2008 | RL | RL Network design | 2000–2008 |

| Number of Citations | Number of Papers | % Papers |

|---|---|---|

| ≥100 citations | 138 | 6.0% |

| ≥50 citations | 291 | 12.6% |

| ≥20 citations | 476 | 20.6% |

| <20 citations | 1402 | 60.8% |

| Total | 2307 | 100.0% |

| Rank | Journal | No. of Publications | Times Cited | Citations/Article |

|---|---|---|---|---|

| 1 | JCP | 259 | 7584 | 29.28 |

| 2 | IJPE | 153 | 8628 | 56.39 |

| 3 | IJPR | 131 | 3942 | 30.09 |

| 4 | Sustainability | 83 | 544 | 6.55 |

| 5 | CIE | 79 | 2865 | 36.27 |

| 6 | RCR | 79 | 3636 | 46.03 |

| 7 | EJOR | 65 | 7689 | 118.29 |

| 8 | IJAMT | 42 | 1312 | 31.24 |

| 9 | OMEGA | 36 | 3053 | 84.81 |

| 10 | IJLM | 34 | 543 | 15.97 |

| Rank | Journal | Article | TC | Author/s | Year | C/Y |

|---|---|---|---|---|---|---|

| 1 | IJMR | [45] | 1503 | Srivastava, Samir K. | 2007 | 115.62 |

| 2 | EJOR | [46] | 1028 | Fleischmann, M; et al. | 1997 | 44.70 |

| 3 | MS | [47] | 1007 | Savaskan, RC; et al. | 2004 | 62.94 |

| 4 | EJOR | [48] | 906 | Melo, M. T.; et al. | 2009 | 82.36 |

| 5 | JOM | [49] | 759 | Linton, D.; et al. | 2007 | 58.38 |

| 6 | EJOR | [7] | 700 | Govindan, K; et al. | 2015 | 140.00 |

| 7 | JOM | [50] | 548 | Sarkis, Joseph; et al. | 2010 | 54.80 |

| 8 | JEM | [51] | 534 | Ilgin, Ali; Gupta, M. | 2010 | 53.40 |

| 9 | EJOR | [52] | 516 | Brandenburg, et al. | 2014 | 86.00 |

| 10 | IJPE | [53] | 481 | Hassini, Elkafi; et al. | 2012 | 60.13 |

| Rank | Name | TP | TC | H | Citations per Paper |

|---|---|---|---|---|---|

| 1 | Govindan K. | 55 | 4794 | 33 | 87.16 |

| 2 | Tavakkoli-M | 21 | 637 | 11 | 30.33 |

| 3 | Gupta S.M. | 20 | 1018 | 13 | 50.90 |

| 4 | Jaber M.Y. | 18 | 771 | 16 | 42.83 |

| 5 | Kumar A. | 18 | 187 | 8 | 10.39 |

| 6 | Diabat A. | 17 | 853 | 14 | 50.18 |

| 7 | Kannan D. | 17 | 1719 | 14 | 101.12 |

| 8 | Mangla S.K. | 16 | 512 | 10 | 32.00 |

| 9 | Adenso-Diaz B. | 15 | 1056 | 12 | 70.40 |

| 10 | Shankar R. | 15 | 815 | 10 | 54.33 |

| Rank | Name | Country | H-Index | TP | TC | C/P |

|---|---|---|---|---|---|---|

| 1 | Indian Institute of Technology System | INDIA | 27 | 80 | 2664 | 33.30 |

| 2 | University of Southern Denmark | DENMARK | 38 | 70 | 5869 | 83.84 |

| 3 | University of Tehran | IRAN | 23 | 58 | 2653 | 45.74 |

| 4 | Islamic Azad University | IRAN | 20 | 53 | 1396 | 26.34 |

| 5 | Iran University Science Technology | IRAN | 13 | 43 | 627 | 14.58 |

| 6 | Erasmus University Rotterdam | NETHERLANDS | 27 | 36 | 4547 | 126.31 |

| 7 | Ryerson University | CANADA | 22 | 32 | 1730 | 54.06 |

| 8 | Aristotle University of Thessaloniki | GREECE | 21 | 29 | 1444 | 49.79 |

| 9 | Hong Kong Polytechnic University | CHINA | 16 | 28 | 1199 | 42.82 |

| 10 | State University System of Florida | USA | 13 | 24 | 843 | 35.13 |

| Decision Type | Reference |

|---|---|

| Center location/allocation | [67,68,69,70,71] |

| Quality of the returning product | [69,72,73] |

| Centralization vs. decentralization | [57,58] |

| Inventory system | [65,68,70,72,74] |

| Others | [25,68,69,70,74,75] |

| Constraints | References |

|---|---|

| Capacity/availability | [67,68,69,70,76] |

| Flow balance constraints | [61,67,68,69,70,76] |

| Time constraints | |

| Single period | [69] |

| Two period | [60,78] |

| Multiperiod | [67,70,72,76] |

| Product type constraints | |

| Single product | [68,69,70] |

| Multiproduct | [67] |

| Number of collected products constraints | [61,69] |

| Warranty constraints | [67] |

| Government policies | [79,80,81] |

| Performance Measurements | References |

|---|---|

| Economical | |

| Logistic cost | [25,67,69,76,111] |

| Recovery efficiency | [57,69,70,72] |

| Channel profit | [57,58,60,61,85] |

| Environmental | |

| Disposal policies | [69] |

| Emission reduction | [61,67,68,76,112] |

| Waste reduction | [87] |

| Social | |

| Customer behavior | [101,102] |

| Government interference | [59,78,85,87,105,106,107,108,109,110] |

| Operational | [25,69] |

| Solution Methods | References |

|---|---|

| Mathematical Programming | |

| Integer programming | [70,113,114,115,116,117,118,119,120,121,122,123,124,125,126,127,128,129] |

| Nonlinear programming | [67,69] |

| Heuristic | |

| Constructive | [113,118,120,130,131,132] |

| Improvement | [120,130,131,133,134,135] |

| Game theory | [54,55,56,57,59,60,62,85,87,136,137,138,139,140,141] |

| Artificial intelligence | [26,74,119,142,143,144,145] |

| Dynamic programming | [72] |

| Others | [73] |

| Application Area | References |

|---|---|

| Electronic | |

| - Mobile phone | [25,144,151] |

| - Battery | [67,152,153,154,155] |

| - Large appliances (washing machine) | [129] |

| - Camera | [68] |

| - General | [156] |

| Automotive | [74,76,125,157,158,159,160] |

| Furniture | [142,161] |

| Waste | [65,87,129,133,137] |

| Liquor manufacturing | [69] |

| Data set | [61,67,70] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkahtani, M.; Ziout, A.; Salah, B.; Alatefi, M.; Abd Elgawad, A.E.E.; Badwelan, A.; Syarif, U. An Insight into Reverse Logistics with a Focus on Collection Systems. Sustainability 2021, 13, 548. https://doi.org/10.3390/su13020548

Alkahtani M, Ziout A, Salah B, Alatefi M, Abd Elgawad AEE, Badwelan A, Syarif U. An Insight into Reverse Logistics with a Focus on Collection Systems. Sustainability. 2021; 13(2):548. https://doi.org/10.3390/su13020548

Chicago/Turabian StyleAlkahtani, Mohammed, Aiman Ziout, Bashir Salah, Moath Alatefi, Abd Elatty E. Abd Elgawad, Ahmed Badwelan, and Umar Syarif. 2021. "An Insight into Reverse Logistics with a Focus on Collection Systems" Sustainability 13, no. 2: 548. https://doi.org/10.3390/su13020548

APA StyleAlkahtani, M., Ziout, A., Salah, B., Alatefi, M., Abd Elgawad, A. E. E., Badwelan, A., & Syarif, U. (2021). An Insight into Reverse Logistics with a Focus on Collection Systems. Sustainability, 13(2), 548. https://doi.org/10.3390/su13020548