Antibacterial Effect of Aluminum Surfaces Untreated and Treated with a Special Anodizing Based on Titanium Oxide Approved for Food Contact

Abstract

:Simple Summary

Abstract

1. Introduction

2. Materials and Methods

2.1. Microbiological Analysis

2.2. Inoculum Preparation

2.3. Sanitizing Procedures and Surface Swabbing

2.4. Atomic Force Microscopy Analysis

2.5. Environmental Scanning Microscopy Analysis

2.6. Statistical Analysis

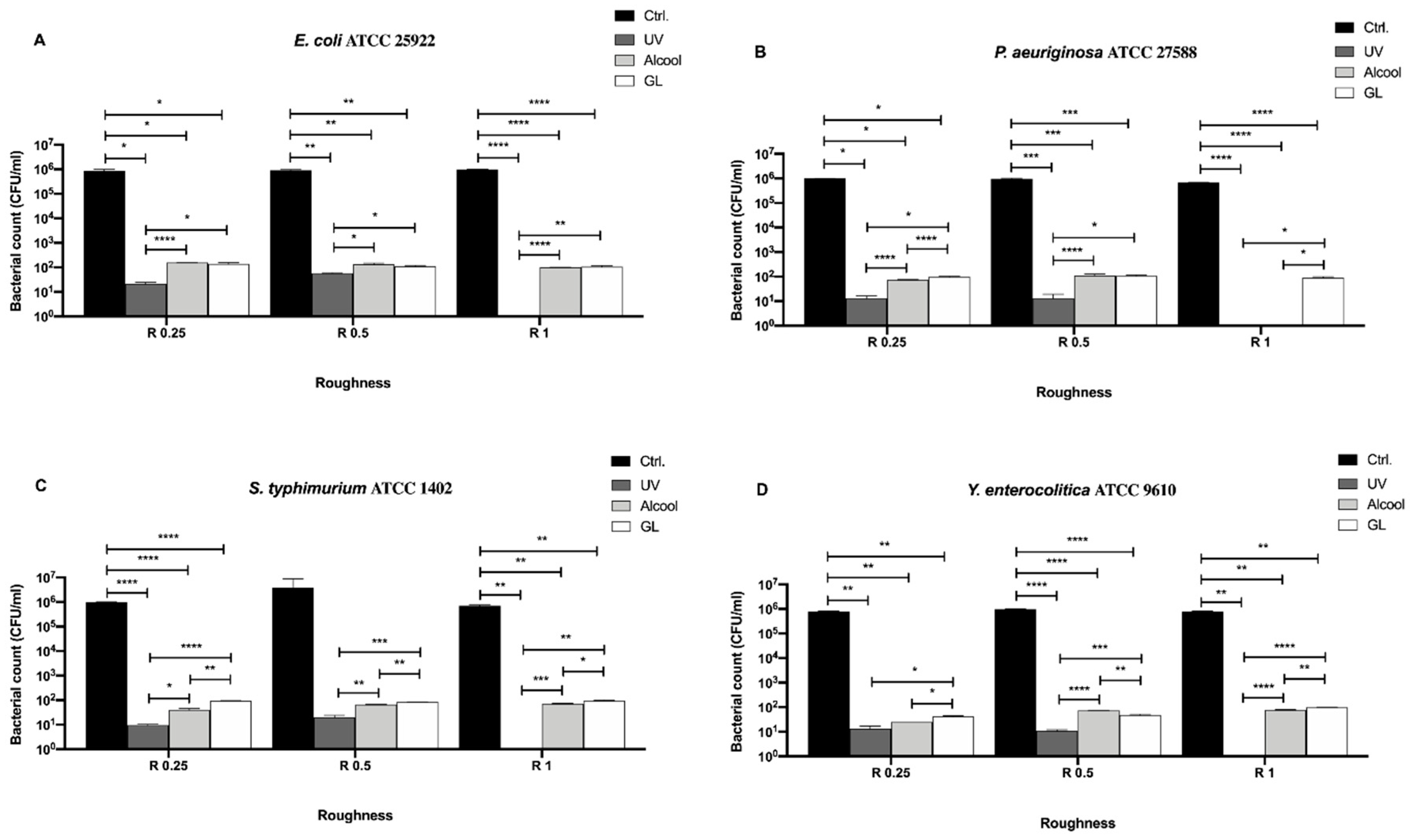

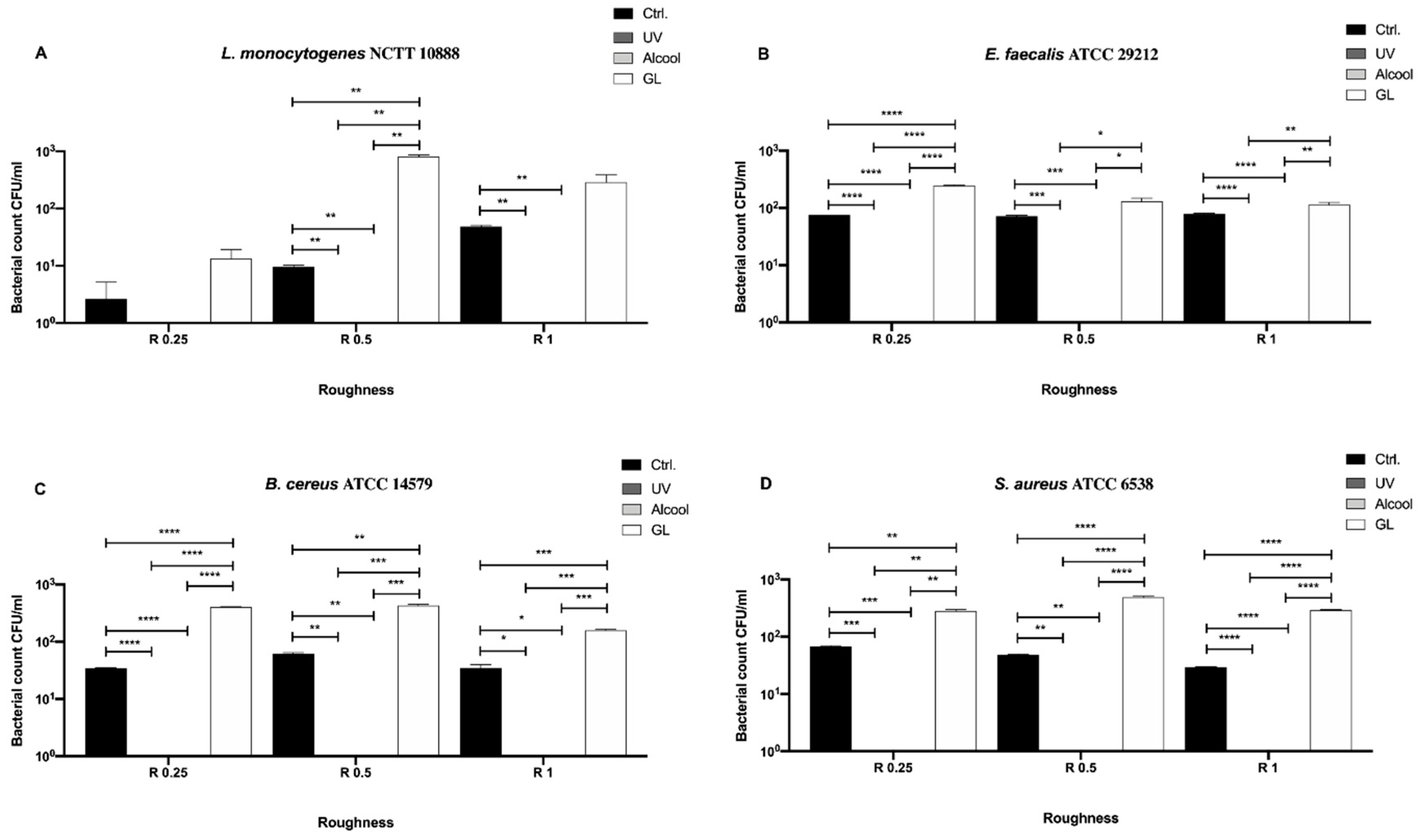

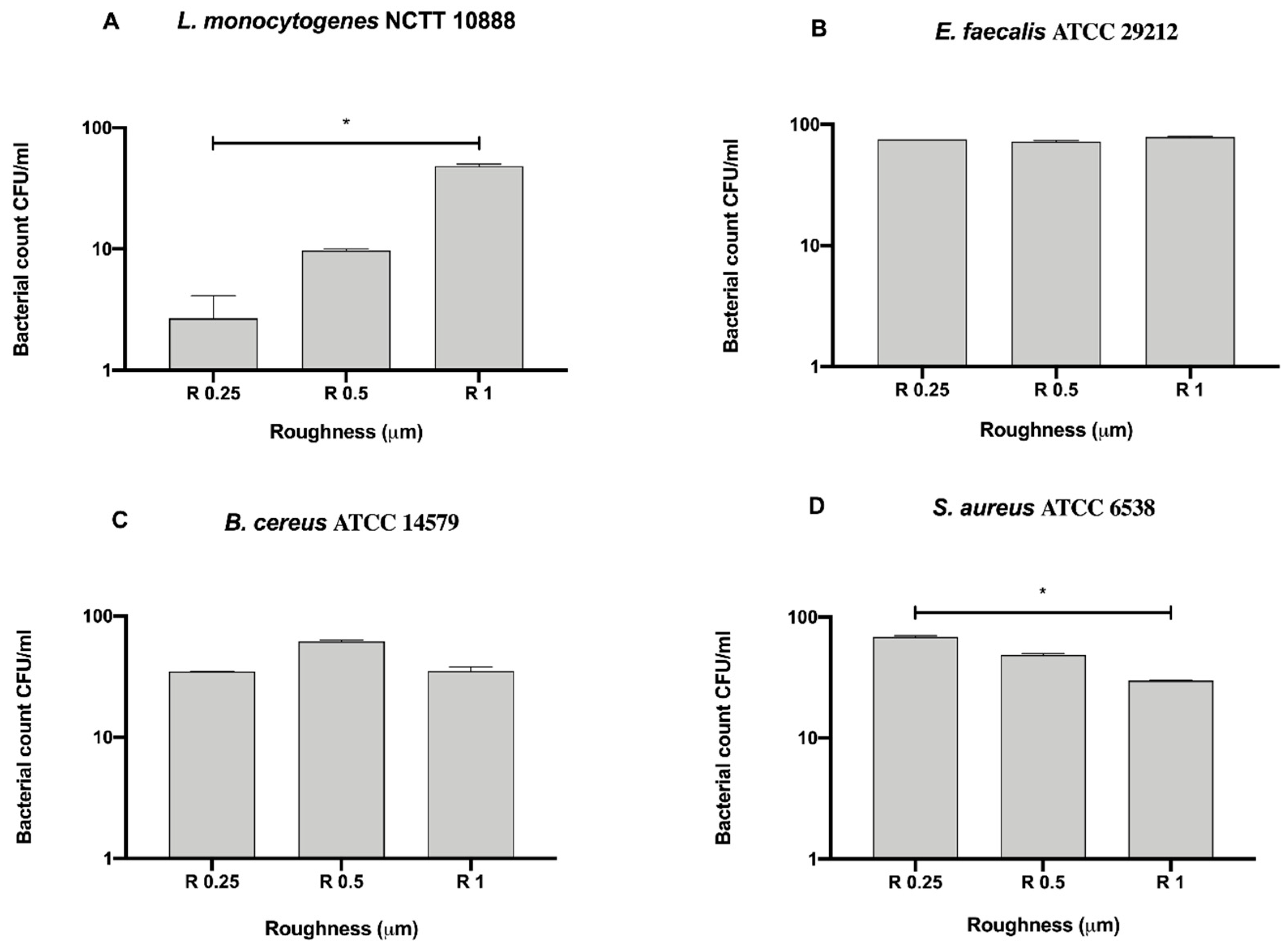

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Meshref, A.M.S.; Moselhy, W.A.; Hassan, N.E.-H.Y. Aluminium Content in Milk and Milk Products and its Leachabilityfrom Dairy Utensils. Int. J. Dairy Sci. 2015, 10, 236–242. [Google Scholar] [CrossRef] [Green Version]

- Stahl, T.; Falk, S.; Rohrbeck, A.; Georgii, S.; Herzog, C.; Wiegand, A.; Hotz, S.; Boschek, B.; Zorn, H.; Brunn, H. Migration of aluminum from food contact materials to food-a health risk for consumers? Part I of III: Exposure to aluminum, release of aluminum, tolerable weekly intake (TWI), toxicological effects of aluminum, study design, and methods. Environ. Sci. Eur. 2017, 29, 19. [Google Scholar] [CrossRef] [PubMed]

- Bower, C.K.; McGuire, J.; Daeschel, M.A. The adhesion and detachment of bacteria and spores on food-contact surfaces. Trends Food Sci. Technol. 1996, 7, 152–157. [Google Scholar] [CrossRef]

- Saini, J.K.; Marsden, J.L.; Fung, D.Y.C.; Crozier-Dodson, B.A. Evaluation of Potential for Translocation of Listeria monocytogenes from Floor Drains to Food Contact Surfaces in the Surrounding Environment Using Listeria innocua as a Surrogate. Adv. Microbiol. 2012, 2, 565–570. [Google Scholar] [CrossRef] [Green Version]

- Møretrø, T.; Langsrud, S. Residential Bacteria on Surfaces in the Food Industry and Their Implications for Food Safety and Quality. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1022–1041. [Google Scholar] [CrossRef] [Green Version]

- Fink, R.; Okanovic, D.; Drazic, G.; Abram, A.; Oder, M.; Jevsnik, M.; Bohinc, K. Bacterial adhesion capacity on food service contact surfaces. Int. J. Environ. Health Res. 2017, 27, 169–178. [Google Scholar] [CrossRef]

- Mafu, A.A.; Plumety, C.; Deschenes, L.; Goulet, J. Adhesion of Pathogenic Bacteria to Food Contact Surfaces: Influence of pH of Culture. Int. J. Microbiol. 2011, 2011, 972494. [Google Scholar] [CrossRef] [Green Version]

- Galie, S.; Garcia-Gutierrez, C.; Miguelez, E.M.; Villar, C.J.; Lombo, F. Biofilms in the Food Industry: Health Aspects and Control Methods. Front. Microbiol. 2018, 9, 898. [Google Scholar] [CrossRef]

- Holah, J.T.; Kearney, L.R. Introduction to Biofilms in the Food Industry. In Biofilms—Science and Technology; Melo, L.F., Bott, T.R., Fletcher, M., Capdeville, B., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 35–41. [Google Scholar] [CrossRef]

- Holah, J.T.; Holder, J.S.; Taylor, J.H.; Campden Food and Drink Research Association. The Spread of Listeria by Cleaning Systems. Part. II; Campden Food and Drink Research Association: Chipping Campden, UK, 1993. [Google Scholar]

- Lappin-Scott, H.M.; Costerton, J.W. Bacterial biofilms and surface fouling. Biofouling 1989, 1, 323–342. [Google Scholar] [CrossRef]

- Ludensky, M. Control and monitoring of biofilms in industrial applications. Int. Biodeterior. Biodegrad. 2003, 51, 255–263. [Google Scholar] [CrossRef]

- Razatos, A.; Ong, Y.L.; Sharma, M.M.; Georgiou, G. Molecular determinants of bacterial adhesion monitored by atomic force microscopy. Proc. Natl. Acad. Sci. USA 1998, 95, 11059–11064. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ronner, A.B.; Wong, A.C.L. Biofilm Development and Sanitizer Inactivation of Listeria monocytogenes and Salmonella typhimurium on Stainless Steel and Buna-n Rubber. J. Food Prot. 1993, 56, 750–758. [Google Scholar] [CrossRef] [PubMed]

- Samelis, J.; Metaxopoulos, J. Incidence and principal sources of Listeria spp. and Listeria monocytogenes contamination in processed meats and a meat processing plant. Food Microbiol. 1999, 16, 465–477. [Google Scholar] [CrossRef]

- Sand, W. Microbial mechanisms of deterioration of inorganic substrates—A general mechanistic overview. Int. Biodeterior. Biodegrad. 1997, 40, 183–190. [Google Scholar] [CrossRef]

- Guerra, N.P.; Araujo, A.B.; Barrera, A.M.; Agrasar, A.T.; Macias, C.L.; Carballo, J.; Pastrana, L. Antimicrobial activity of nisin adsorbed to surfaces commonly used in the food industry. J. Food Prot. 2005, 68, 1012–1019. [Google Scholar] [CrossRef]

- Brooks, J.D.; Flint, S.H. Biofilms in the food industry: Problems and potential solutions. Int. J. Food Sci. Technol. 2008, 43, 2163–2176. [Google Scholar] [CrossRef]

- Romanova, N.; Favrin, S.; Griffiths, M.W. Sensitivity of Listeria monocytogenes to sanitizers used in the meat processing industry. Appl. Environ. Microbiol. 2002, 68, 6405–6409. [Google Scholar] [CrossRef] [Green Version]

- Sinde, E.; Carballo, J. Attachment of Salmonella spp. and Listeria monocytogenes to stainless steel, rubber and polytetrafluorethylene: The influence of free energy and the effect of commercial sanitizers. Food Microbiol. 2000, 17, 439–447. [Google Scholar] [CrossRef]

- Taormina, P.J.; Beuchat, L.R. Survival of Listeria monocytogenes in commercial food-processing equipment cleaning solutions and subsequent sensitivity to sanitizers and heat. J. Appl. Microbiol. 2002, 92, 71–80. [Google Scholar] [CrossRef]

- Bott, T.R. Introduction to the Problem of Biofouling in Industrial Equipment. In Biofilms—Science and Technology; Melo, L.F., Bott, T.R., Fletcher, M., Capdeville, B., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 3–11. [Google Scholar] [CrossRef]

- Labbé, R.G.; García, S. Guide to Foodborne Pathogens; Wiley-Blackwell: Hoboken, NJ, USA, 2001. [Google Scholar]

- Cabeca, T.K.; Pizzolitto, A.C.; Pizzolitto, E.L. Activity of disinfectants against foodborne pathogens in suspension and adhered to stainless steel surfaces. Braz. J. Microbiol. 2012, 43, 1112–1119. [Google Scholar] [CrossRef] [Green Version]

- Devine, C.; Dikeman, M. Encyclopedia of Meat Sciences; Elsevier Science: San Diego, CA, USA, 2014. [Google Scholar]

- Husmark, U.; Ronner, U. Forces involved in adhesion of Bacillus cereus spores to solid surfaces under different environmental conditions. J. Appl. Bacteriol. 1990, 69, 557–562. [Google Scholar] [CrossRef]

- Brooker, B.E. Surface coat transformation and capsule formation by Leuconostoc mesenteroides NCDO 523 in the presence of sucrose. Arch. Microbiol. 1976, 111, 99–104. [Google Scholar] [CrossRef]

- Korber, D.R.; Lawrence, J.R.; Sutton, B.; Caldwell, D.E. Effect of laminar flow velocity on the kinetics of surface recolonization by Mot(+) and Mot(−) Pseudomonas fluorescens. Microb. Ecol. 1989, 18, 1–19. [Google Scholar] [CrossRef]

- McClaine, J.W.; Ford, R.M. Characterizing the adhesion of motile and nonmotile Escherichia coli to a glass surface using a parallel-plate flow chamber. Biotechnol. Bioeng. 2002, 78, 179–189. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Feng, G.; Moraru, C.I. Micro- and Nanotopography Sensitive Bacterial Attachment Mechanisms: A Review. Front. Microbiol. 2019, 10, 191. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hsu, L.C.; Fang, J.; Borca-Tasciuc, D.A.; Worobo, R.W.; Moraru, C.I. Effect of micro- and nanoscale topography on the adhesion of bacterial cells to solid surfaces. Appl. Environ. Microbiol. 2013, 79, 2703–2712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Feng, G.; Cheng, Y.; Wang, S.Y.; Borca-Tasciuc, D.A.; Worobo, R.W.; Moraru, C.I. Bacterial attachment and biofilm formation on surfaces are reduced by small-diameter nanoscale pores: How small is small enough? NPJ Biofilms Microbiomes 2015, 1, 15022. [Google Scholar] [CrossRef]

- Feng, G.; Cheng, Y.; Wang, S.Y.; Hsu, L.C.; Feliz, Y.; Borca-Tasciuc, D.A.; Worobo, R.W.; Moraru, C.I. Alumina surfaces with nanoscale topography reduce attachment and biofilm formation by Escherichia coli and Listeria spp. Biofouling 2014, 30, 1253–1268. [Google Scholar] [CrossRef]

- Alessandrini, A.; Facci, P. AFM: A versatile tool in biophysics. Meas. Sci. Technol. 2005, 16, R65–R92. [Google Scholar] [CrossRef]

- Mescola, A.; Ragazzini, G.; Alessandrini, A. Daptomycin Strongly Affects the Phase Behavior of Model Lipid Bilayers. J. Phys. Chem. B 2020, 124, 8562–8571. [Google Scholar] [CrossRef]

- Seeger, H.M.; Di Cerbo, A.; Alessandrini, A.; Facci, P. Supported lipid bilayers on mica and silicon oxide: Comparison of the main phase transition behavior. J. Phys. Chem. B 2010, 114, 8926–8933. [Google Scholar] [CrossRef] [PubMed]

- Alessandrini, A.; Seeger, H.M.; Di Cerbo, A.; Caramaschi, T.; Facci, P. What do we really measure in AFM punch-through experiments on supported lipid bilayers? Soft Matter 2011, 7, 7054–7064. [Google Scholar] [CrossRef]

- Mescola, A.; Canale, C.; Fragouli, D.; Athanassiou, A. Controlled formation of gold nanostructures on biopolymer films upon electromagnetic radiation. Nanotechnology 2017, 28, 415601. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stokes, D.J. 1—Environmental scanning electron microscopy (ESEM): Principles and applications to food microstructures. In Food Microstructures; Morris, V.J., Groves, K., Eds.; Woodhead Publishing: Cambridge, UK, 2013; pp. 3–26. [Google Scholar] [CrossRef]

- The European Parliament and the Council of the European Union. REGULATION (EC) No 1935/2004 on materials and articles intended to come into contact with food and repealing Directives 80/590/EEC and 89/109/EEC. Off. J. Eur. Union 2004. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32004R1935&from=IT (accessed on 29 October 2020).

- The Commission of the European COMMUNITIES. Commission Regulation (EC) No 2023/2006 on Good Manufacturing Practice for Materials and Articles Intended to Come into Contact with Food. Off. J. Eur. Union 2006. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32006R2023&from=IT (accessed on 29 October 2020).

- The European Parliament and the Council of the European Union. Regulation (EC) No 764/2008 Laying Down Procedures Relating to the Application of Certain National Technical Rules to Products Lawfully Marketed in another Member State and Repealing Decision No 3052/95/EC. Off. J. Eur. Union. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32008R0764&from=EN (accessed on 29 October 2020).

- Moerman, F.; Partington, E. Materials of construction for food processing equipment and services: Requirements, strengths and weaknesses. J. Hyg. Eng. Des. 2014, 6, 10–37. [Google Scholar]

- GruppoGaser. Available online: https://www.gruppogaser.com/en/treatments/anodizing/duralti/ (accessed on 29 October 2020).

- Omer, M.K.; Alvarez-Ordonez, A.; Prieto, M.; Skjerve, E.; Asehun, T.; Alvseike, O.A. A Systematic Review of Bacterial Foodborne Outbreaks Related to Red Meat and Meat Products. Foodborne Pathog. Dis. 2018, 15, 598–611. [Google Scholar] [CrossRef] [Green Version]

- Chlebicz, A.; Slizewska, K. Campylobacteriosis, Salmonellosis, Yersiniosis, and Listeriosis as Zoonotic Foodborne Diseases: A Review. Int. J. Environ. Res. Public Health 2018, 15, 863. [Google Scholar] [CrossRef] [Green Version]

- Gaser, G. 2019. Available online: https://www.gruppogaser.com/wp-content/uploads/2019/07/DURALTI_ENG.pdf (accessed on 29 October 2020).

- Lai, C.S.; Li, S.; Liu, C.B.; Miyauchi, Y.; Suzawa, M.; Ho, C.T.; Pan, M.H. Effective suppression of azoxymethane-induced aberrant crypt foci formation in mice with citrus peel flavonoids. Mol. Nutr. Food Res. 2013, 57, 551–555. [Google Scholar] [CrossRef]

- Reda, F.M. Antibacterial and anti-adhesive efficiency of Pediococcus acidilactici against foodborne biofilm producer Bacillus cereus attached on different food processing surfaces. Food Sci. Biotechnol. 2019, 28, 841–850. [Google Scholar] [CrossRef]

- Rentschler, H.C.; Nagy, R.; Mouromseff, G. Bactericidal Effect of Ultraviolet Radiation. J. Bacteriol. 1941, 41, 745–774. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vermeulen, N.; Keeler, W.J.; Nandakumar, K.; Leung, K.T. The bactericidal effect of ultraviolet and visible light on Escherichia coli. Biotechnol. Bioeng. 2008, 99, 550–556. [Google Scholar] [CrossRef] [PubMed]

- Guffey, S.; Wilborn, J. In Vitro Bactericidal Effects of 405-nm and 470-nm Blue Light. Photomed. Laser Surg. 2006, 24, 684–688. [Google Scholar] [CrossRef]

- Price, P.B. Ethyl alcohol as a germicide. Arch. Surg. 1939, 38, 528–542. [Google Scholar] [CrossRef]

- Harrington, C.; Walker, H. The Germicidal Action of Alcohol. Boston Med. Surg. J. 1903, 148, 548–552. [Google Scholar] [CrossRef]

- Koshiro, A.; Oie, S. Bactericidal activity of ethanol against glucose nonfermentative Gram-negative bacilli. Microbios 1984, 40, 33–40. [Google Scholar]

- Bagherifard, S.; Hickey, D.J.; de Luca, A.C.; Malheiro, V.N.; Markaki, A.E.; Guagliano, M.; Webster, T.J. The influence of nanostructured features on bacterial adhesion and bone cell functions on severely shot peened 316L stainless steel. Biomaterials 2015, 73, 185–197. [Google Scholar] [CrossRef]

- Ludecke, C.; Roth, M.; Yu, W.; Horn, U.; Bossert, J.; Jandt, K.D. Nanorough titanium surfaces reduce adhesion of Escherichia coli and Staphylococcus aureus via nano adhesion points. Colloids Surf. B Biointerfaces 2016, 145, 617–625. [Google Scholar] [CrossRef]

- Rizzello, L.; Sorce, B.; Sabella, S.; Vecchio, G.; Galeone, A.; Brunetti, V.; Cingolani, R.; Pompa, P.P. Impact of nanoscale topography on genomics and proteomics of adherent bacteria. ACS Nano 2011, 5, 1865–1876. [Google Scholar] [CrossRef]

- Boukerchea, I.; Djerada, S.; Benmansoura, L.; Tifoutia, L.; Salehb, K. Degradability of aluminum in acidic and alkaline solutions. Corros. Sci. 2014, 78, 343–352. [Google Scholar] [CrossRef]

- Kumar, V.; Sharma, N.; Maitra, S.S. In vitro and in vivo toxicity assessment of nanoparticles. Int. Nano Lett. 2017, 7, 243–256. [Google Scholar] [CrossRef] [Green Version]

- Iannitti, T.; Di Cerbo, A.; Loschi, A.R.; Rea, S.; Suzawa, M.; Morales-Medina, J.C. Repeated administration of a flavonoid-based formulated extract from citrus peels significantly reduces peripheral inflammation-induced pain in the rat. Food Sci. Nutr. 2020, 8, 3173–3180. [Google Scholar] [CrossRef]

- Celiz, G.; Daz, M.; Audisio, M.C. Antibacterial activity of naringin derivatives against pathogenic strains. J. Appl. Microbiol. 2011, 111, 731–738. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Köksal Karayıldırım, Ç. Characterization and in vitro Evolution of Antibacterial Efficacy of Novel Hesperidin Microemulsion. Celal Bayar Univ. J. Sci. 2017, 13, 943–947. [Google Scholar] [CrossRef]

- Yao, X.; Zhu, X.; Pan, S.; Fang, Y.; Jiang, F.; Phillips, G.O.; Xu, X. Antimicrobial activity of nobiletin and tangeretin against Pseudomonas. Food Chem. 2012, 132, 1883–1890. [Google Scholar] [CrossRef]

- Truchado, P.; Giménez-Bastida, J.-A.; Larrosa, M.; Castro-Ibáñez, I.; Espı́n, J.C.; Tomás-Barberán, F.A.; Garcı́a-Conesa, M.T.; Allende, A. Inhibition of Quorum Sensing (QS) in Yersinia enterocolitica by an Orange Extract Rich in Glycosylated Flavanones. J. Agric. Food Chem. 2012, 60, 8885–8894. [Google Scholar] [CrossRef] [PubMed]

- Di Cerbo, A.; Pezzuto, F.; Scarano, A. Cytotoxic and Bacteriostatic Activity of Nanostructured TiO2 Coatings. Pol. J. Microbiol. 2016, 65, 225–229. [Google Scholar] [CrossRef] [Green Version]

- Cho, M.; Choi, Y.; Park, H.; Kim, K.; Woo, G.-J.; Park, J. Titanium Dioxide/UV Photocatalytic Disinfection in Fresh Carrots. J. Food Prot. 2007, 70, 97–101. [Google Scholar] [CrossRef]

- Kunz, J.N.; Voronine, D.V.; Lu, W.; Liege, Z.; Lee, H.W.H.; Zhang, Z.; Scully, M.O. Aluminum plasmonic nanoshielding in ultraviolet inactivation of bacteria. Sci. Rep. 2017, 7, 9026. [Google Scholar] [CrossRef]

- Doskocz, N.; Affek, K.; Załęska-Radziwiłł, M. Effects of aluminium oxide nanoparticles on bacterial growth. In Proceedings of the E3S Web of Conferences, Warsaw, Poland, 24 May 2017. [Google Scholar]

- Ueda, T.; Sato, N.; Koizumi, R.; Ueda, K.; Ito, K.; Ogasawara, K.; Narushima, T. Formation of carbon-added anatase-rich TiO2 layers on titanium and their antibacterial properties in visible light. Dent. Mater. 2020. [Google Scholar] [CrossRef]

- Graziano, M.U.; Graziano, K.U.; Pinto, F.M.; Bruna, C.Q.; de Souza, R.Q.; Lascala, C.A. Effectiveness of disinfection with alcohol 70% (w/v) of contaminated surfaces not previously cleaned. Rev. Lat. Am. Enferm. 2013, 21, 618–623. [Google Scholar] [CrossRef] [PubMed] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Cerbo, A.; Mescola, A.; Iseppi, R.; Canton, R.; Rossi, G.; Stocchi, R.; Loschi, A.R.; Alessandrini, A.; Rea, S.; Sabia, C. Antibacterial Effect of Aluminum Surfaces Untreated and Treated with a Special Anodizing Based on Titanium Oxide Approved for Food Contact. Biology 2020, 9, 456. https://doi.org/10.3390/biology9120456

Di Cerbo A, Mescola A, Iseppi R, Canton R, Rossi G, Stocchi R, Loschi AR, Alessandrini A, Rea S, Sabia C. Antibacterial Effect of Aluminum Surfaces Untreated and Treated with a Special Anodizing Based on Titanium Oxide Approved for Food Contact. Biology. 2020; 9(12):456. https://doi.org/10.3390/biology9120456

Chicago/Turabian StyleDi Cerbo, Alessandro, Andrea Mescola, Ramona Iseppi, Roberto Canton, Giacomo Rossi, Roberta Stocchi, Anna Rita Loschi, Andrea Alessandrini, Stefano Rea, and Carla Sabia. 2020. "Antibacterial Effect of Aluminum Surfaces Untreated and Treated with a Special Anodizing Based on Titanium Oxide Approved for Food Contact" Biology 9, no. 12: 456. https://doi.org/10.3390/biology9120456

APA StyleDi Cerbo, A., Mescola, A., Iseppi, R., Canton, R., Rossi, G., Stocchi, R., Loschi, A. R., Alessandrini, A., Rea, S., & Sabia, C. (2020). Antibacterial Effect of Aluminum Surfaces Untreated and Treated with a Special Anodizing Based on Titanium Oxide Approved for Food Contact. Biology, 9(12), 456. https://doi.org/10.3390/biology9120456