Room- and high temperature Wear Resistance of MCrAlY Coatings Deposited by Detonation Gun (D-gun) and Supersonic Plasma Spraying (SSPS) Techniques

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

- CoNiCrAlY metallic powders were successfully deposited on the Inconel 718 superalloy substrates using D-gun and SSPS coating techniques.

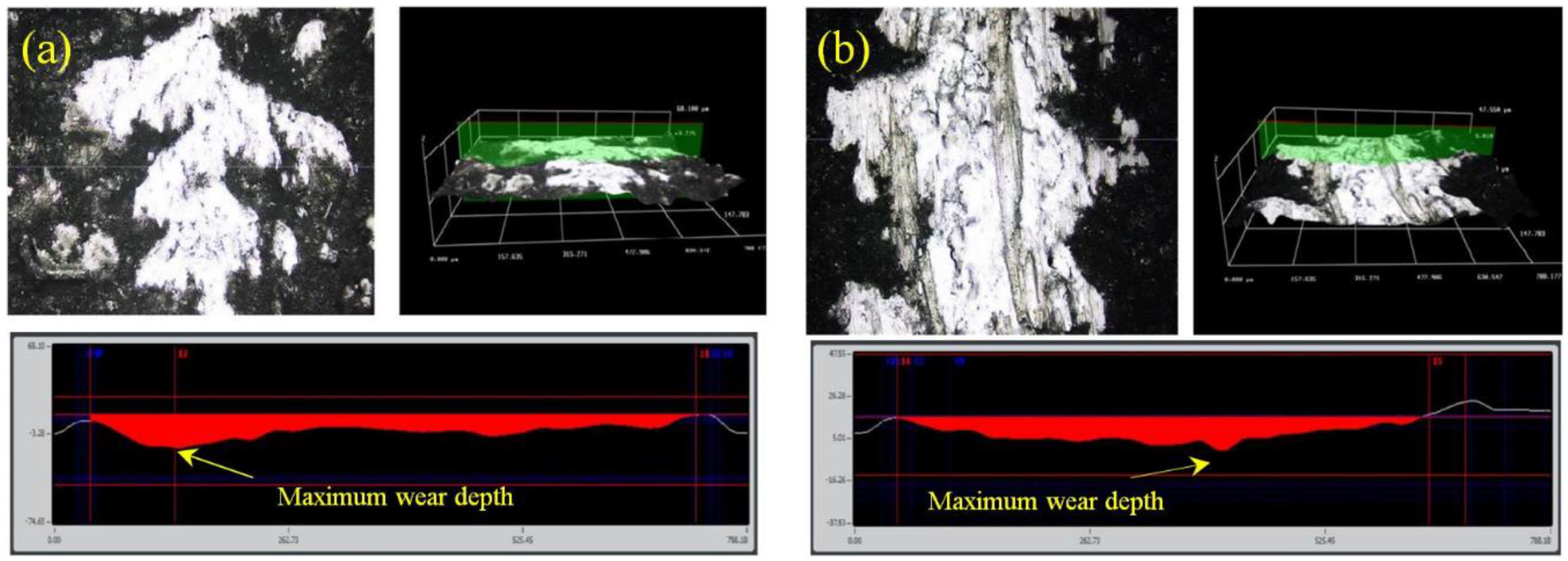

- The high temperature wear behavior of the coatings has changed depending on the processes used in the coating production and the microstructural properties of the coatings after production.

- Depending on the increasing loading rates and temperature, wear losses were likewise increased. However, this increase was not linear.

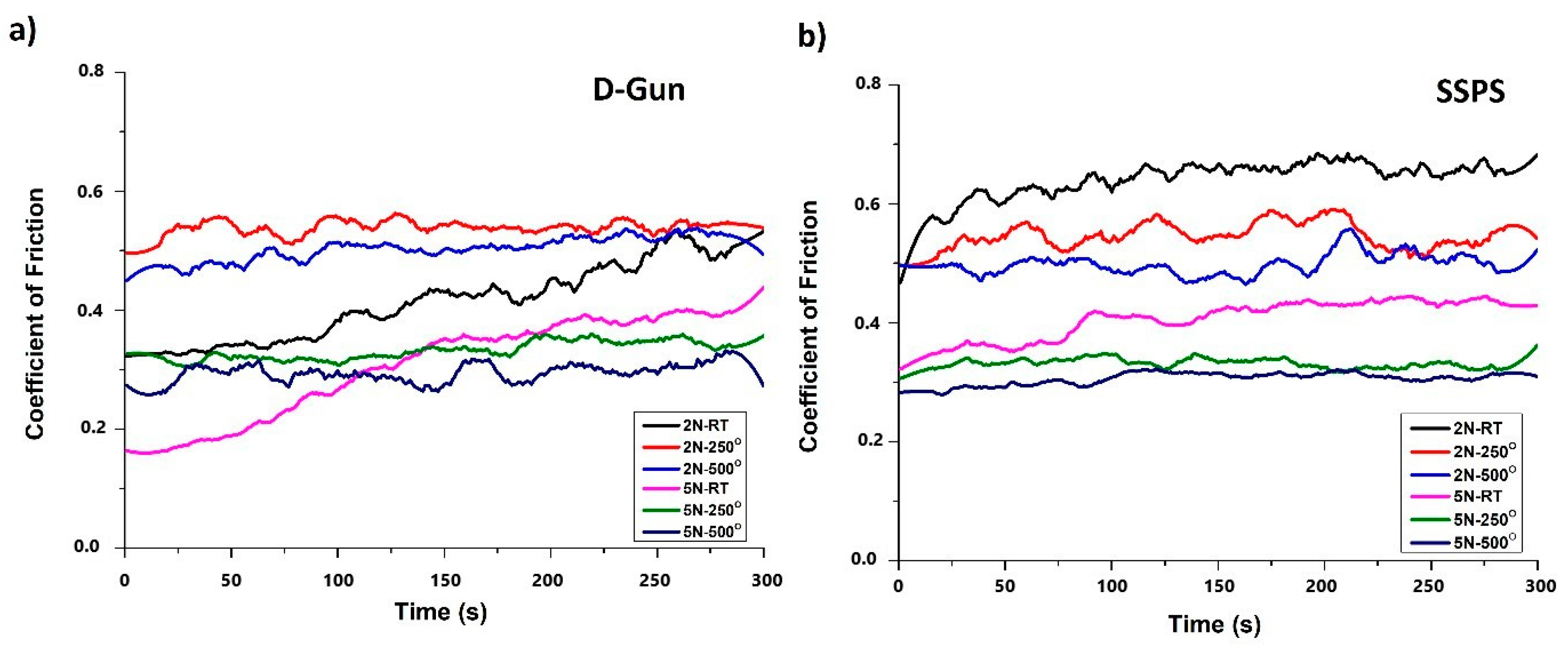

- For D-gun and SSPS coatings, increasing load resulted in lower coefficient of friction values. Increasing temperature resulted in lower COF values for SSPS coatings; however, those produced with D-gun did not follow the same trend.

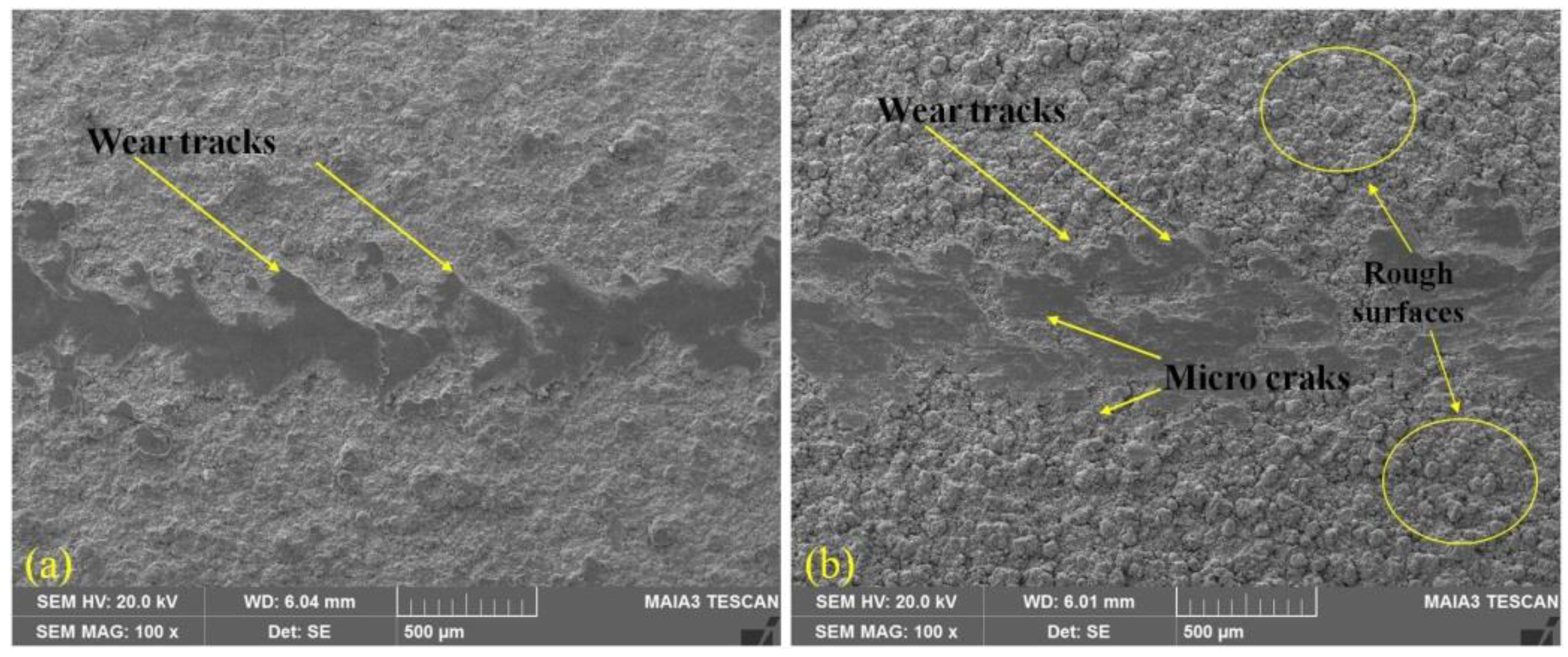

- It has been understood that at 250 °C and rt surface fatigue wear by using D-gun technique is comparatively more severe than SSPS technique.

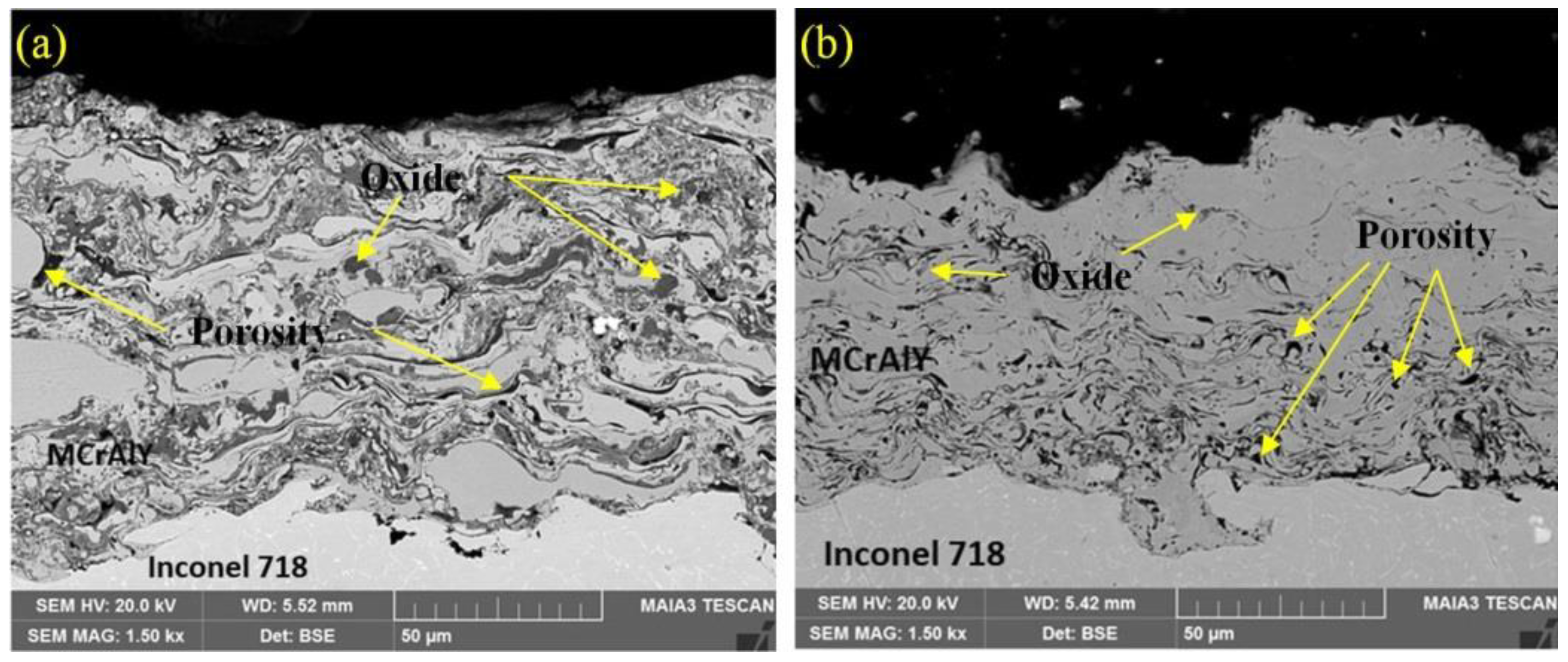

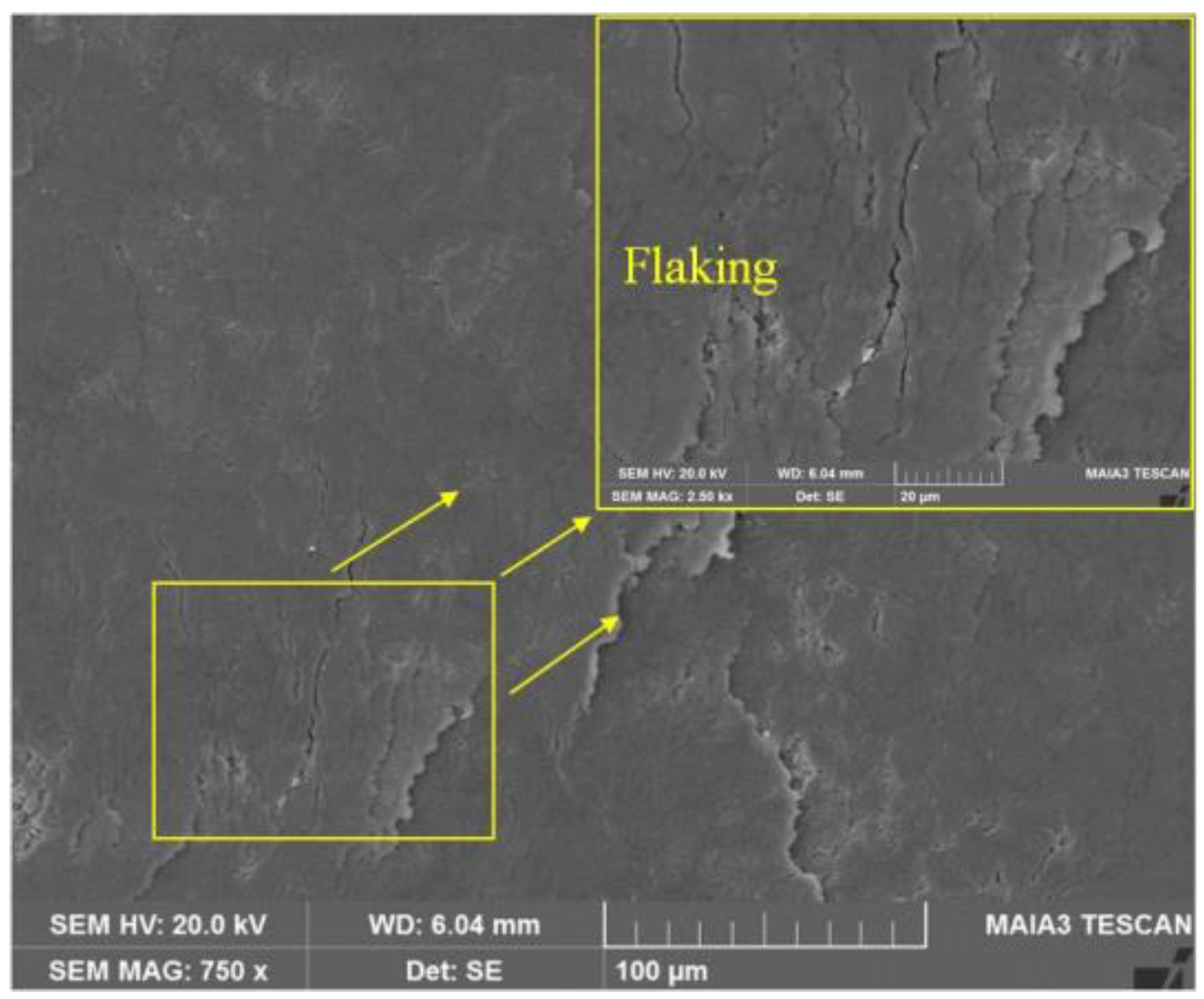

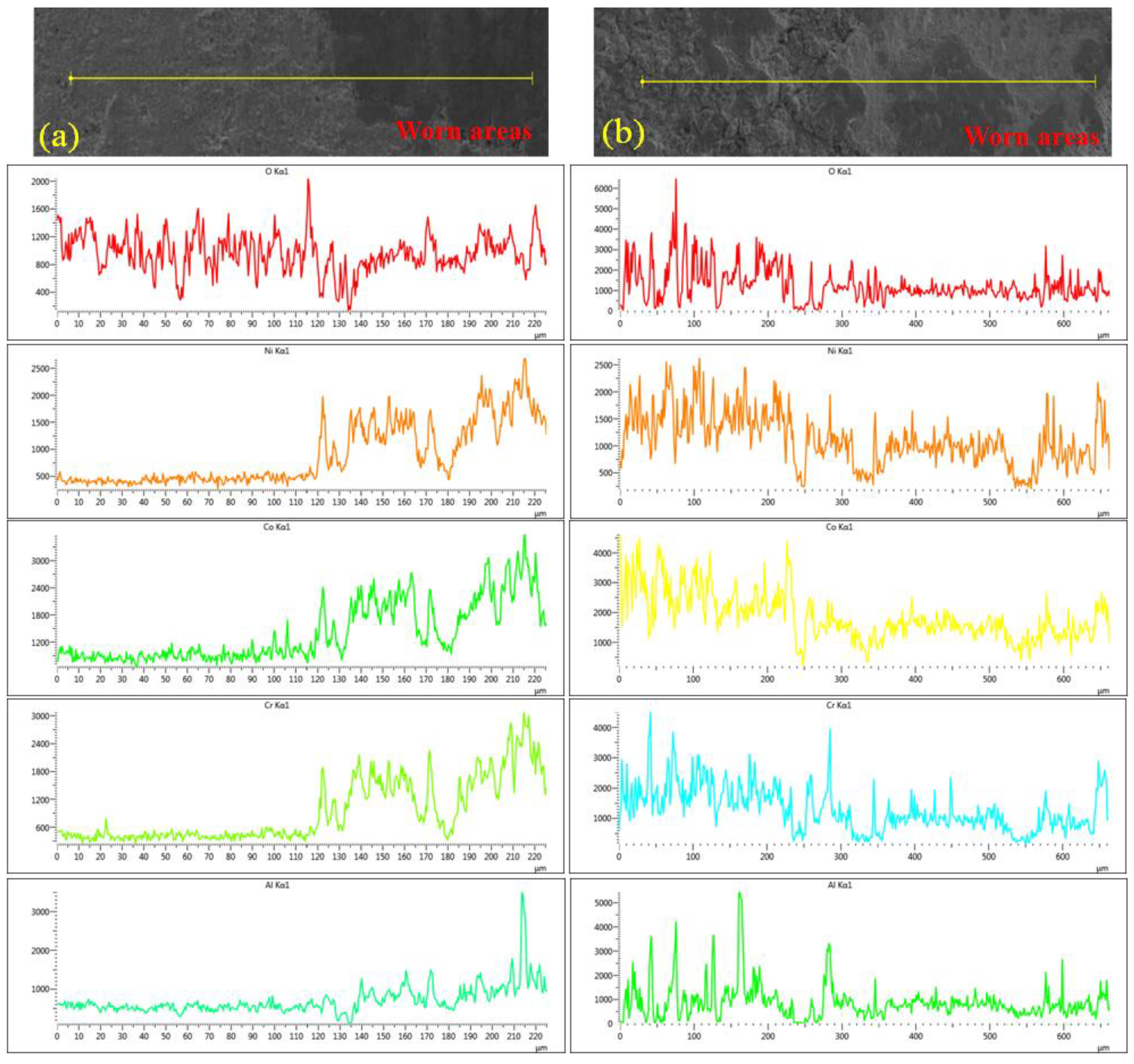

- It has been observed that tribological layers and superficial changes occur in the microstructures of the coatings due to temperature and time by both thermal spray coating techniques.

- When high temperature wear behaviors of CoNiCrAlY coatings are examined, it is seen that D-gun coatings show superior properties compared to SSPS coatings.

- Due to the increased surface hardness and microstructural dense structure with high temperature effect, the wear resistance of the coatings increases.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fauchais, P.; Vardelle, A. Thermal sprayed coatings used against corrosion and corrosive wear. In Advanced Plasma Spray Applications; SalimiJazi, H., Ed.; InTech.: Rijeka, Croatia, 2012; Volume 10, p. 34448. [Google Scholar]

- Oksa, M.; Turunen, E.; Suhonen, T.; Varis, T.; Hannula, S.P. Optimization and characterization of high velocity oxy-fuel sprayed coatings: Techniques, materials, and applications. Coatings 2011, 1, 17–52. [Google Scholar] [CrossRef]

- Karaoglanli, A.C. Effects of plastic deformation on isothermal oxidation behavior of CoNiCrAlY coatings. Sci. Adv. Mater. 2015, 7, 173–177. [Google Scholar] [CrossRef]

- Matthews, S.; James, B. Review of thermal spray coating applications in the steel industry: Part 1-hardware in steel making to the continuous annealing process. J. Therm. Spray Technol. 2010, 19, 1267–1276. [Google Scholar] [CrossRef]

- Hardwicke, C.U.; Lau, Y.C. Advances in thermal spray coatings for gas turbines and energy generation: A review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef]

- Khan, M.A.; Sundarrajan, S.; Duraiselvam, M.; Natarajan, S.; Kumar, A.S. Sliding wear behaviour of plasma sprayed coatings on nickel based superalloy. Surf. Eng. 2017, 33, 35–41. [Google Scholar] [CrossRef]

- Huang, C.B.; Du, L.Z.; Zhang, W.G. Microstructure, mechanical and tribological characteristics of plasma, detonation gun and HVOF sprayed NiCr/Cr3C2–BaF2.CaF2 coatings. Surf. Eng. 2011, 27, 762–769. [Google Scholar] [CrossRef]

- Mehta, J.; Mittal, V.K.; Gupta, P. Role of thermal spray coatings on wear, erosion and corrosion behavior: A review. J. Appl. Sci. Eng. 2017, 20, 445–452. [Google Scholar]

- Karaoglanli, A.C.; Grund, T.; Turk, A.; Lampke, T. A comparative study of oxidation kinetics and thermal cyclic performance of thermal barrier coatings (TBCs). Surf. Coat. Technol. 2019, 371, 47–67. [Google Scholar] [CrossRef]

- Fauchais, P.L.; Heberlein, J.V.; Boulos, M.I. Thermal Spray Fundamentals: From Powder to Part; Science and Business Media Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Winnicki, M.; Baszczuk, A.; Rutkowska-Gorczyca, M.; Małachowska, A.; Ambroziak, A. Corrosion resistance of tin coatings deposited by cold spraying. Surf. Eng. 2016, 32, 691–700. [Google Scholar] [CrossRef]

- Bai, Y.; Ding, C.; Li, H.; Han, Z.; Ding, B.; Wang, T.; Yu, L. Isothermal oxidation behavior of supersonic atmospheric plasma-sprayed thermal barrier coating system. J. Therm. Spray Technol. 2013, 22, 1201–1209. [Google Scholar] [CrossRef]

- Pereira, J.; Zambrano, J.; Licausi, M.; Tobar, M.; Amigó, V. Tribology and high temperature friction wear behavior of MCrAlY laser cladding coatings on stainless steel. Wear 2015, 330, 280–287. [Google Scholar] [CrossRef]

- Kamal, S.; Jayaganthan, R.; Prakash, S. Hot corrosion behaviour of D-gun sprayed NiCoCrAlYTa coated superalloys at 900 °C in molten salt environment. Surf. Eng. 2010, 26, 453–462. [Google Scholar] [CrossRef]

- Karaoglanli, A.C. Microstructure characteristics of detonation gun sprayed CoNiCrAlY coatings. J. Aeronaut. Space Technol. 2016, 9, 47–53. [Google Scholar]

- Ozgurluk, Y.; Doleker, K.M.; Ozkan, D.; Ahlatci, H.; Karaoglanli, A.C. Cyclic hot corrosion failure behaviors of EB-PVD TBC systems in the presence of sulfate and vanadate molten salts. Coatings 2019, 9, 166. [Google Scholar] [CrossRef]

- Kumar, A.; Patnaik, P.C.; Chen, K. Damage assessment and fracture resistance of functionally graded advanced thermal barrier coating systems: Experimental and analytical modeling approach. Coatings 2020, 10, 474. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Turk, A. Isothermal oxidation behavior and kinetics of thermal barrier coatings produced by cold gas dynamic spray technique. Surf. Coat. Technol. 2017, 318, 72–81. [Google Scholar] [CrossRef]

- Fossati, A.; Di-Ferdinando, M.; Lavacchi, A.; Bardi, U.; Giolli, C.; Scrivani, A. Improvement of the isothermal oxidation resistance of CoNiCrAlY coating sprayed by High Velocity Oxygen Fuel. Surf. Coat. Technol. 2010, 204, 3723–3728. [Google Scholar] [CrossRef]

- Mohammadi, M.; Kobayashi, A.; Javadpour, S.; Jahromi, S.A.J. Evaluation of hot corrosion behaviors of Al2O3-YSZ composite TBC on gradient MCrAlY coatings in the presence of Na2SO4-NaVO3 salt. Vacuum 2019, 167, 547–553. [Google Scholar] [CrossRef]

- Fossati, A.; Ferdinando, M.D.; Lavacchi, A.; Scrivani, A.; Giolli, C.; Bardi, U. Improvement of the oxidation resistance of CoNiCrAlY bond coats sprayed by high velocity oxygen-fuel onto nickel superalloy substrate. Coatings 2011, 1, 3–16. [Google Scholar] [CrossRef]

- Bai, Y.; Han, Z.H.; Li, H.Q.; Xu, C.; Xu, Y.L.; Ding, C.H.; Yang, J.F. Structure–property differences between supersonic and conventional atmospheric plasma sprayed zirconia thermal barrier coatings. Surf. Coat. Technol. 2011, 205, 3833–3839. [Google Scholar] [CrossRef]

- Doolabi, D.S.; Rahimipour, M.R.; Alizadeh, M.; Pouladi, S.; Hadavi, S.M.M.; Vaezi, M.R. Effect of high vacuum heat treatment on microstructure and cyclic oxidation resistance of HVOF-CoNiCrAlY coatings. Vacuum 2017, 135, 22–33. [Google Scholar] [CrossRef]

- Tian, H.L.; Guo, M.Q.; Wang, C.L.; Tang, Z.H.; Cui, Y.J. Tribological behaviour of a self-lubricated GO/WC–12Co thermal spray coating. Surf. Eng. 2018, 34, 762–770. [Google Scholar] [CrossRef]

- Singh, L.; Chawla, V.; Grewal, J. A review on detonation gun sprayed coatings. J. Miner. Mater. Charact. Eng. 2012, 11, 243. [Google Scholar] [CrossRef]

- Rani, A.; Bala, N.; Gupta, C. Accelerated hot corrosion studies of D-gun-sprayed Cr2O3–50% Al2O3 coating on boiler steel and Fe-based superalloy. Oxid. Met. 2017, 88, 621–648. [Google Scholar] [CrossRef]

- Mehta, J.; Grewal, J.S.; Sadasivuni, K.K.; Gupta, P. Analysis of wear behavior and surface properties of detonation gun-sprayed composite coating of Cr3C2–NiCr–CeO2 on boron steel. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 2433–2443. [Google Scholar] [CrossRef]

- Bains, P.S.; Grewal, J.S.; Sidhu, S.S.; Kaur, S. Wear between ring and traveler: A pin-on-disc mapping of various detonation gun sprayed coatings. Mater. Today Proc. 2017, 4, 369–378. [Google Scholar] [CrossRef]

- Hou, Q.Y.; Luo, L.M.; Huang, Z.Y.; Wang, P.; Ding, T.T.; Wu, Y.C. Comparison of W–TiC composite coatings fabricated by atmospheric plasma spraying and supersonic atmospheric plasma spraying. Fusion Eng. Des. 2016, 105, 77–85. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, L.; Wang, Y.; Chen, D.; Li, B.Q.; Han, Z.H. Fragmentation of in-flight particles and its influence on the microstructure and mechanical property of YSZ coating deposited by supersonic atmospheric plasma spraying. J. Alloy. Compd. 2015, 632, 794–799. [Google Scholar] [CrossRef]

- Wei, Q.; Yin, Z.; Li, H. Oxidation control in plasma spraying NiCrCoAlY coating. Appl. Surf. Sci. 2012, 258, 5094–5099. [Google Scholar] [CrossRef]

- Bai, Y.; Han, Z.H.; Liu, H.Q.; Xu, C.; Xu, Y.L.; Wang, Z.; Ding, C.H.; Yang, J.F. High performance nanostructured ZrO2 based thermal barrier coatings deposited by high efficiency supersonic plasma spraying. Appl. Surf. Sci. 2011, 257, 7210–7216. [Google Scholar] [CrossRef]

- Li, X.; Zhai, H.; Li, W.; Cui, S.; Ning, W.; Qiu, X. Dry sliding wear behaviors of Fe-based amorphous metallic coating synthesized by D-gun spray. J. Non-Cryst. Solids 2020, 537, 120018. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Z.; Mu, R.; He, L.; Huang, G.; Cao, X. Thermal barrier coatings with a double-layer bond coat on Ni3Al based single-crystal superalloy. J. Alloy. Compd. 2014, 591, 41–51. [Google Scholar] [CrossRef]

- Saladi, S.; Menghani, J.V.; Prakash, S. Characterization and evaluation of cyclic hot corrosion resistance of detonation-gun sprayed Ni-5Al coatings on Inconel-718. J. Therm. Spray Technol. 2015, 24, 778–788. [Google Scholar] [CrossRef]

- Lin, L.; Li, G.L.; Wang, H.D.; Kang, J.J.; Xu, Z.L.; Wang, H.J. Structure and wear behavior of NiCr–Cr3C2 coatings sprayed by supersonic plasma spraying and high velocity oxy-fuel technologies. Appl. Surf. Sci. 2015, 356, 383–390. [Google Scholar] [CrossRef]

- Geetha, M.; Sathish, S.; Chava, K.; Joshi, S.V. Detonation gun sprayed Al2O3–13TiO2 coatings for biomedical applications. Surf. Eng. 2014, 30, 229–236. [Google Scholar] [CrossRef]

| Combustion Gas | Air Flow Velocity | Number of Shots | Spray Time | Spray Distance |

|---|---|---|---|---|

| C3H8 (7.5 slpm) O2 (25 slpm) Air (5 slpm) | 6.7–15 slpm | 100 | 14 s | 110–150 mm |

| Airflow Velocity | Current | Voltage | Spray Distance |

|---|---|---|---|

| 715 slpm | 270 A | 380 V | 200 mm |

| Coating Method | Hardness (HV0.25) | Ra (µm) | Porosity (%) | Oxide (%) |

|---|---|---|---|---|

| D-gun | 550 ± 50 | 4.50 | 1.2 ± 1.0 | 29 ± 3.0 |

| SSPS | 380 ± 30 | 6.90 | 1.5 ± 1.0 | 9 ± 2.0 |

| Temperature (°C) | D-gun | SSPS | ||

|---|---|---|---|---|

| Load | ||||

| 5 N | 2 N | 5 N | 2 N | |

| rt | 0.47 | 0.45 | 0.44 | 0.77 |

| 250 °C | 0.39 | 0.56 | 0.38 | 0.57 |

| 500 °C | 0.25 | 0.52 | 0.29 | 0.48 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kilic, M.; Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Room- and high temperature Wear Resistance of MCrAlY Coatings Deposited by Detonation Gun (D-gun) and Supersonic Plasma Spraying (SSPS) Techniques. Coatings 2020, 10, 1107. https://doi.org/10.3390/coatings10111107

Kilic M, Ozkan D, Gok MS, Karaoglanli AC. Room- and high temperature Wear Resistance of MCrAlY Coatings Deposited by Detonation Gun (D-gun) and Supersonic Plasma Spraying (SSPS) Techniques. Coatings. 2020; 10(11):1107. https://doi.org/10.3390/coatings10111107

Chicago/Turabian StyleKilic, Mehmet, Dervis Ozkan, Mustafa Sabri Gok, and Abdullah Cahit Karaoglanli. 2020. "Room- and high temperature Wear Resistance of MCrAlY Coatings Deposited by Detonation Gun (D-gun) and Supersonic Plasma Spraying (SSPS) Techniques" Coatings 10, no. 11: 1107. https://doi.org/10.3390/coatings10111107

APA StyleKilic, M., Ozkan, D., Gok, M. S., & Karaoglanli, A. C. (2020). Room- and high temperature Wear Resistance of MCrAlY Coatings Deposited by Detonation Gun (D-gun) and Supersonic Plasma Spraying (SSPS) Techniques. Coatings, 10(11), 1107. https://doi.org/10.3390/coatings10111107