Recent Progress in Hybrid Biocomposites: Mechanical Properties, Water Absorption, and Flame Retardancy

Abstract

:1. Introduction

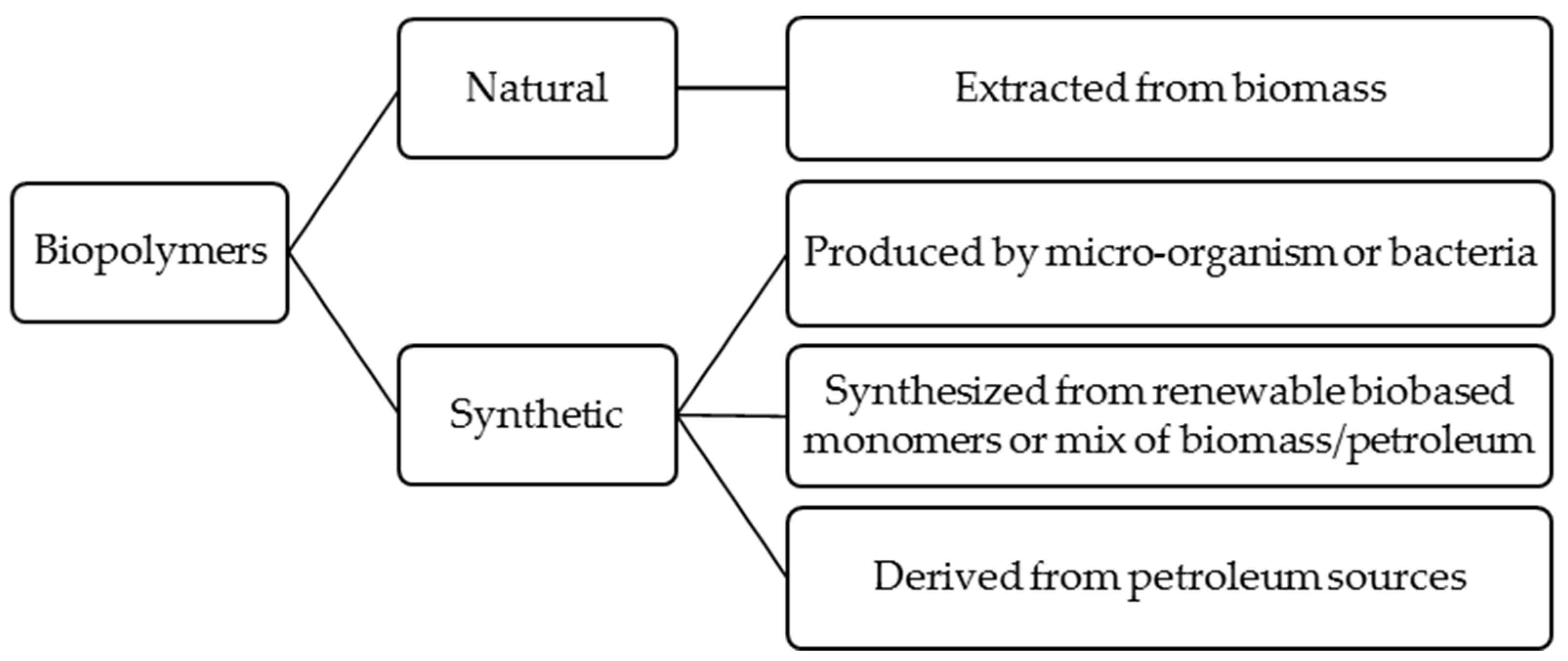

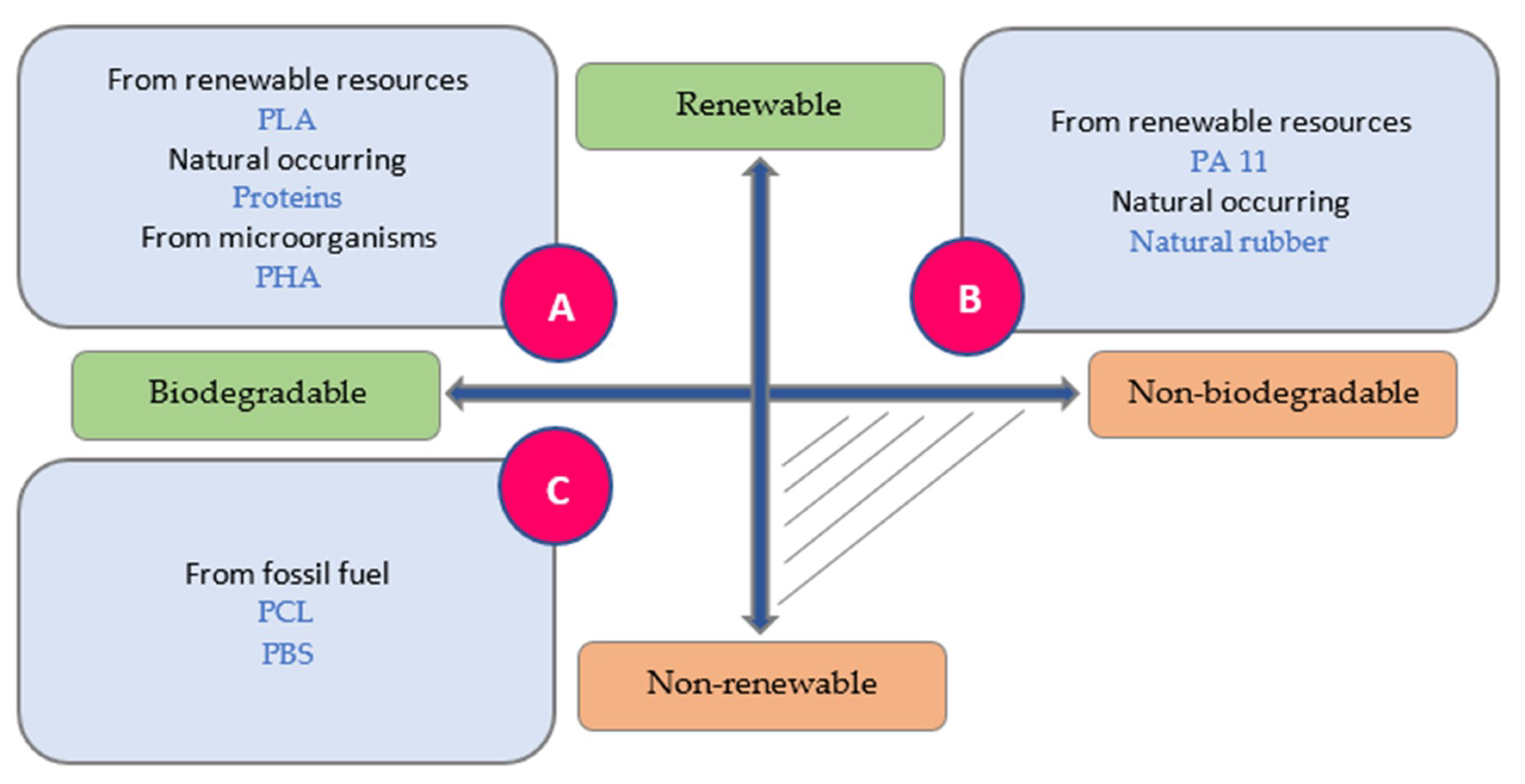

- Natural biopolymers extracted from biomass (e.g., polysaccharides, proteins)

- Synthetic biopolymers produced by a micro-organism or bacteria (e.g., bacterial cellulose, polyhydroxyvalerate, polyhydroxybutyrate)

- Synthetic biopolymers synthesized from renewable bio-based monomers or mixed sources of biomass and petroleum (e.g., polylactic acid, aliphatic polyester, aliphatic-aromatic copolyesters)

- Biodegradable polymers that are derived from nonrenewable resources (petroleum sources) (e.g., polycaprolactone)

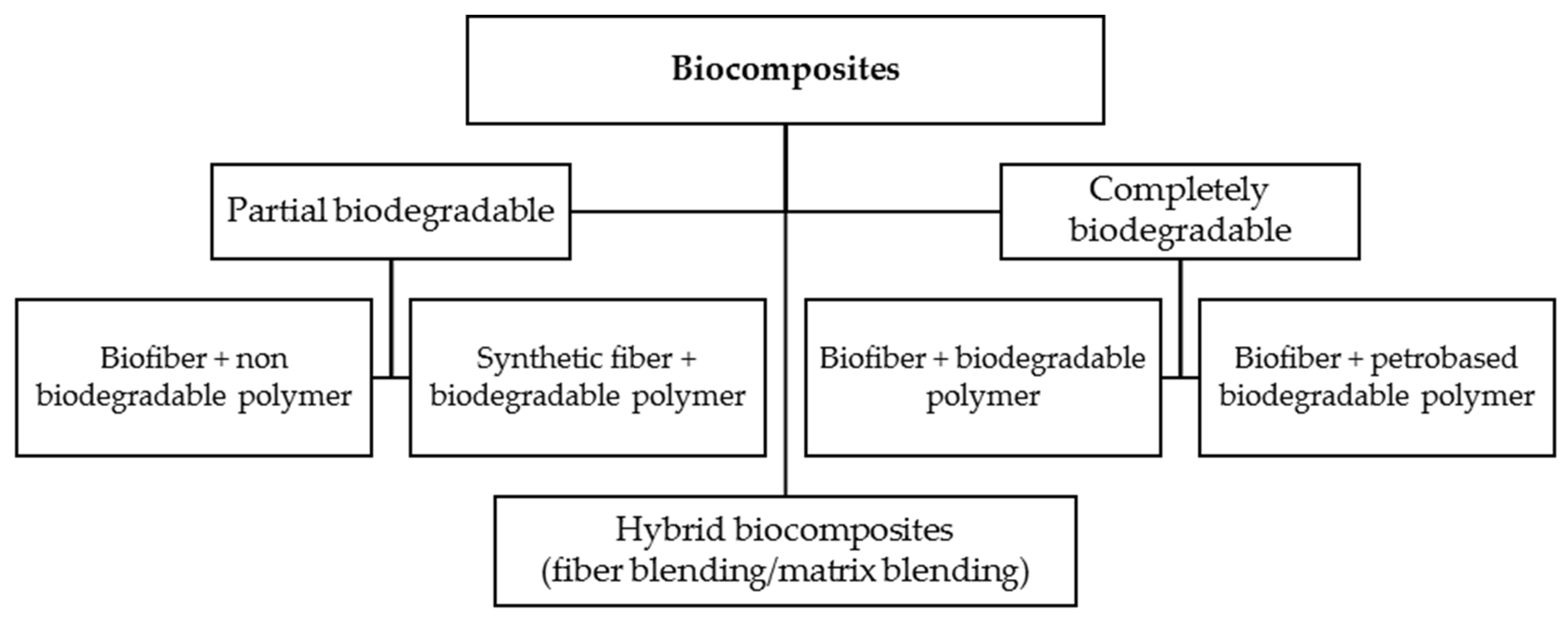

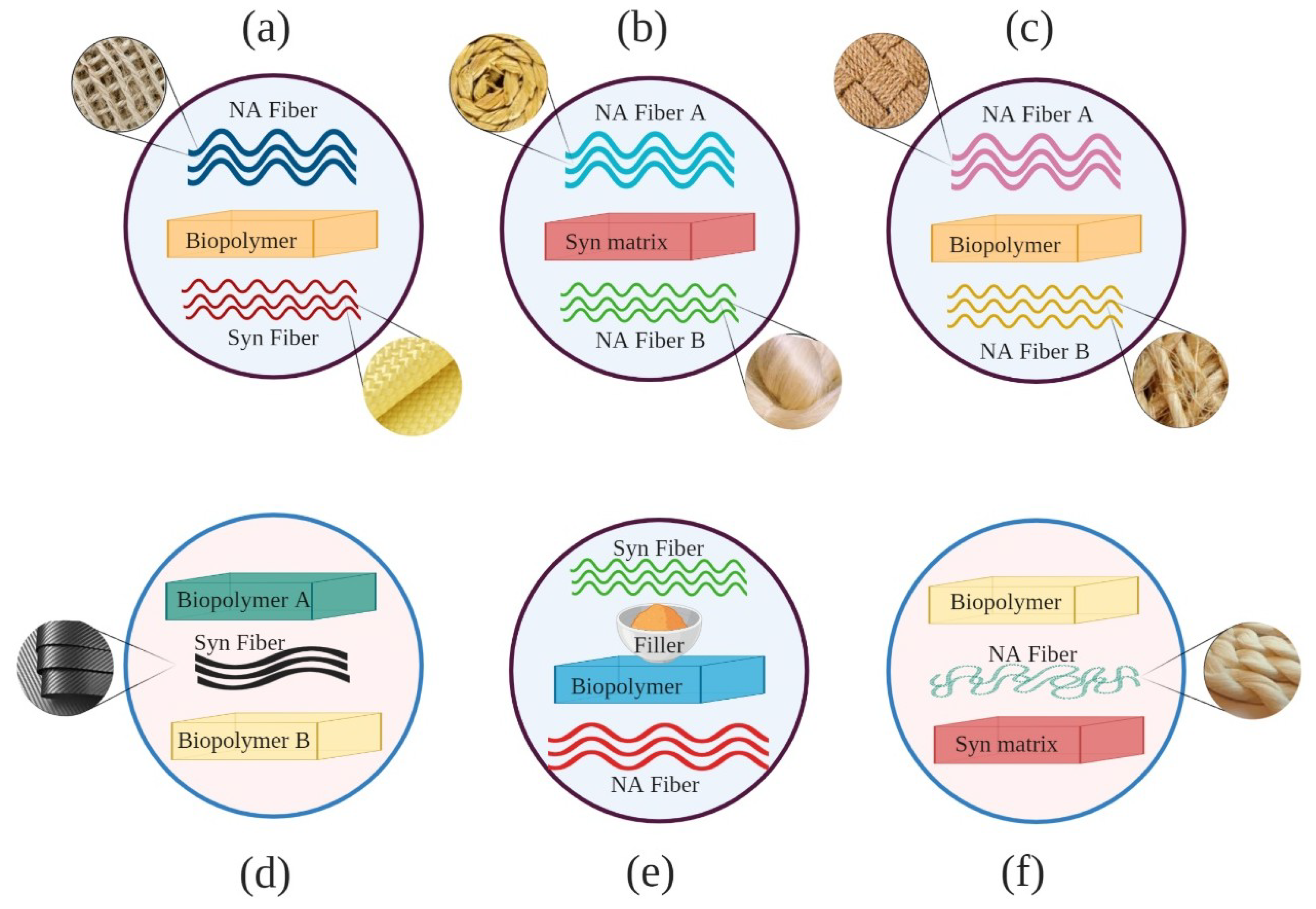

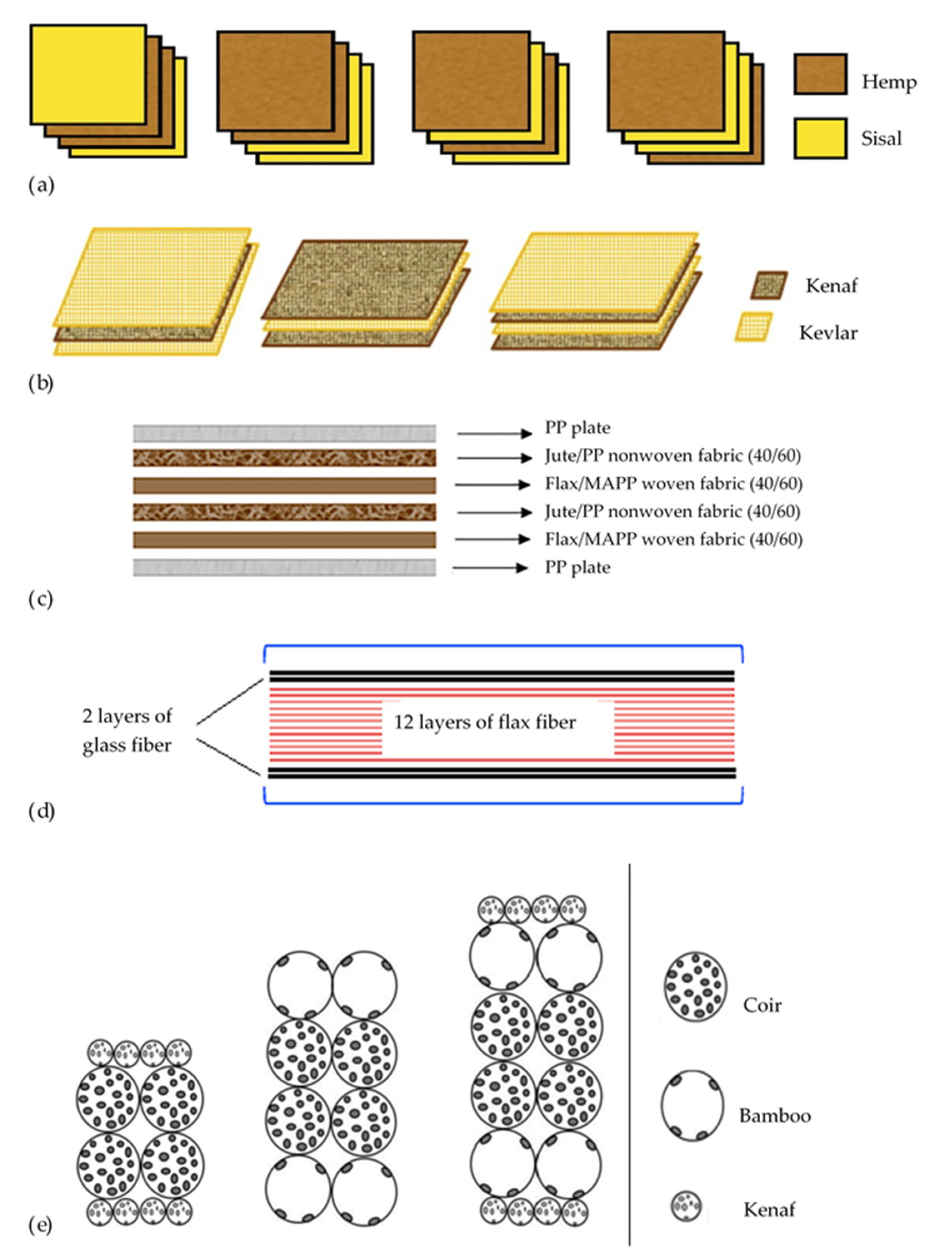

2. Hybridization

- Materials selection (matrix and fiber), which depend mostly on the proposed application;

- Preparation technique, which depends on the fiber, matrix, and working conditions (viz. outdoors or indoors);

- Interaction between the fibers and matrix, which can be controlled by fiber treatment or the use of coupling agents.

3. Materials Selection

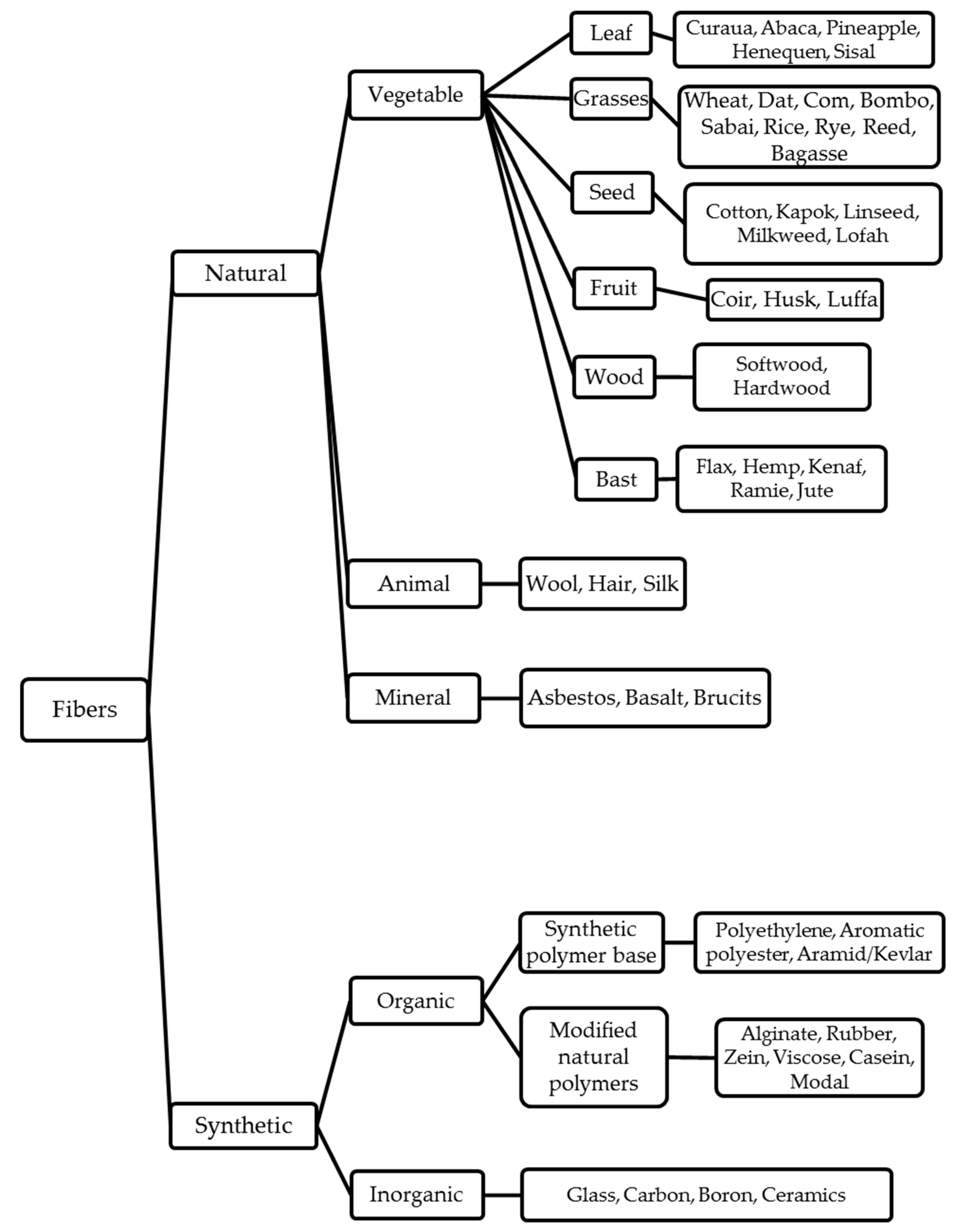

3.1. Fiber Selection

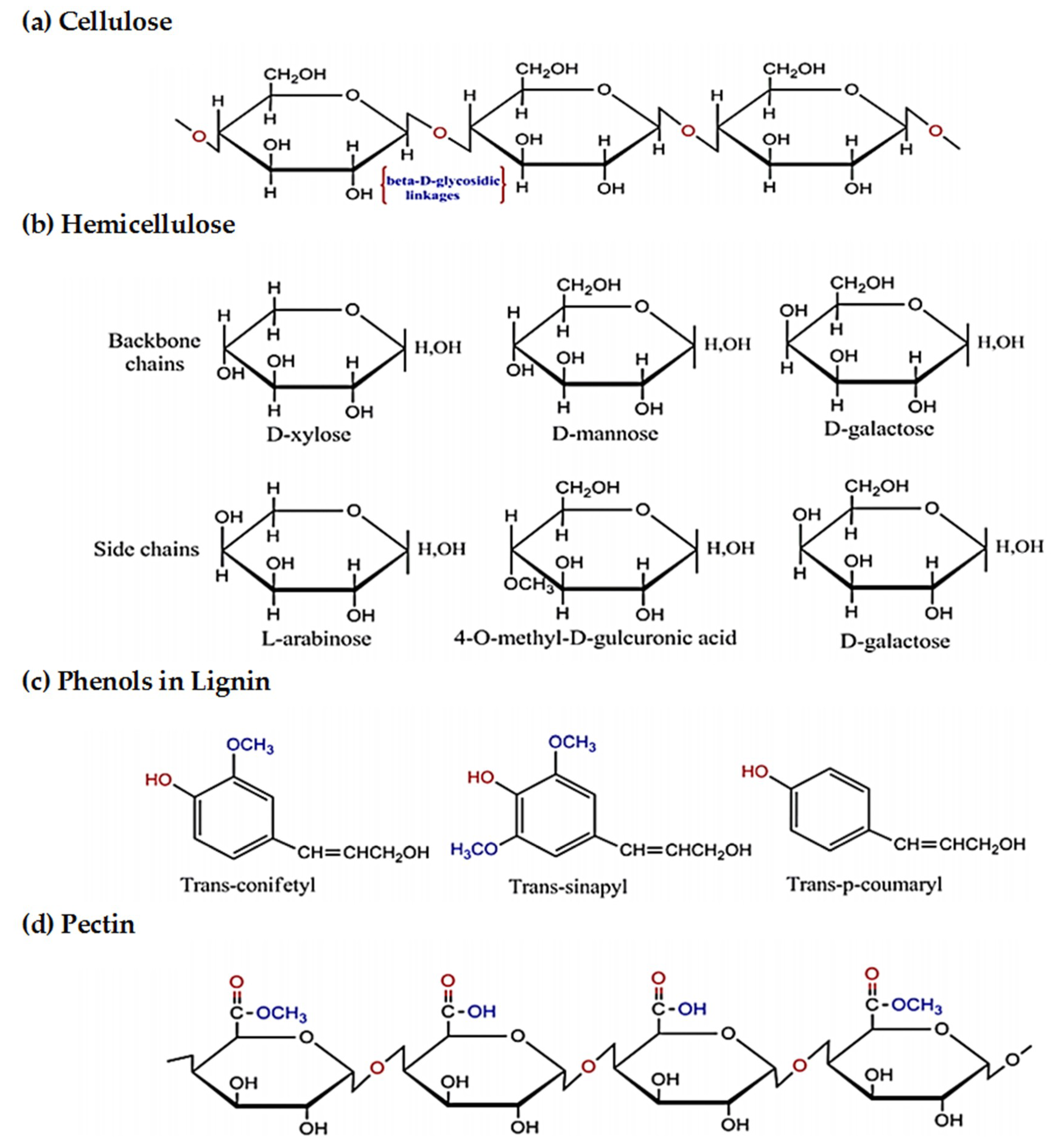

3.1.1. Natural Fibers

3.1.2. Engineered Fibers

3.2. Matrix Selection

3.2.1. Bio-Based Thermoplastics

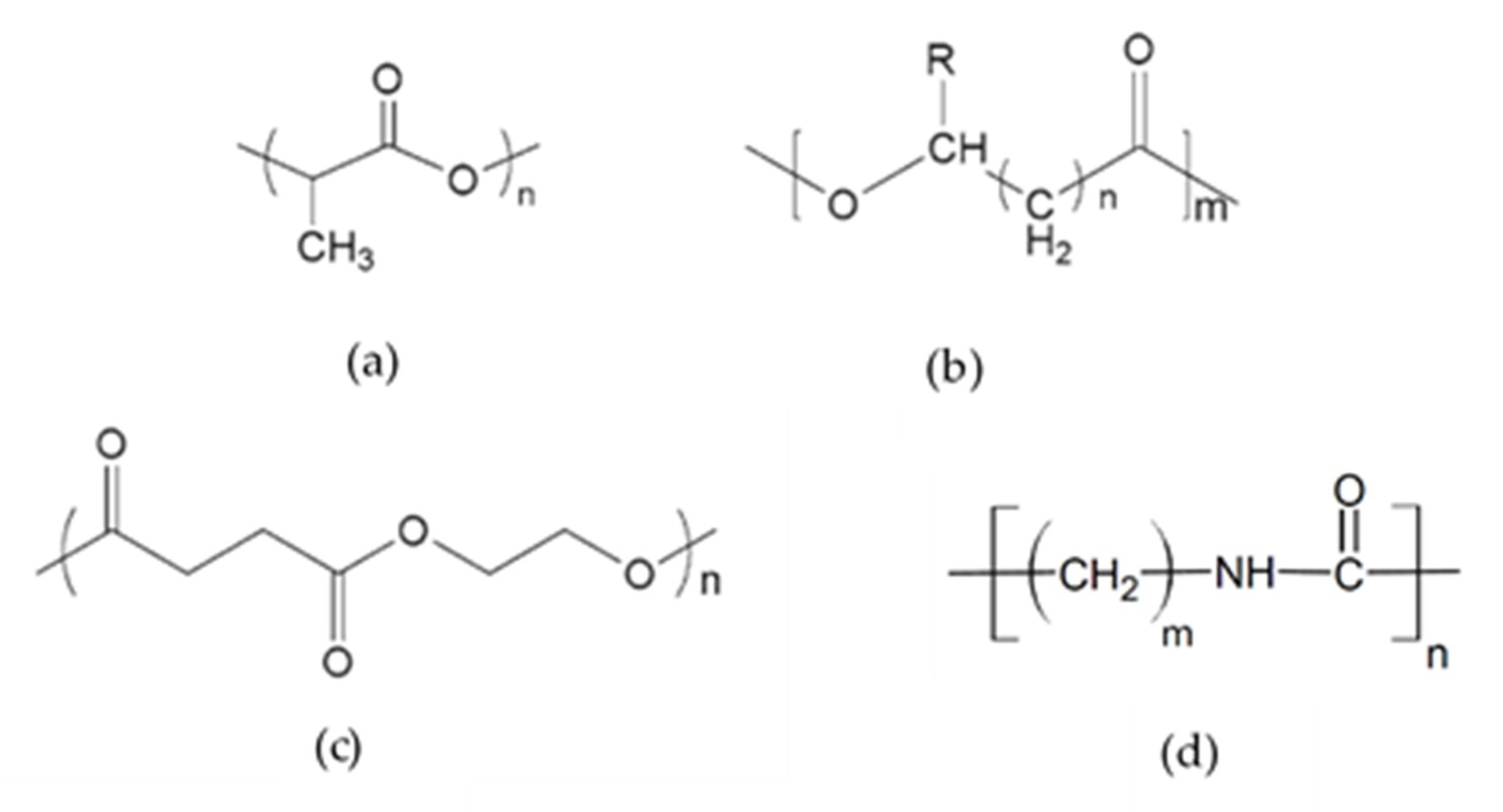

- Polylactic acid

- Polyhydroxyalkanoates

- Polybutylene succinate

- Polyamide

3.2.2. Bio-Based Thermosets

- Epoxy resins

- Phenolic resins

- Polyester resins

4. Mechanical Properties of Hybrid Biocomposites

4.1. Strength (Tensile, Flexural, Impact)

4.2. Water Absorption

4.3. Flame Retardancy

- Impregnation of fibers with a solution of the fire retardant

- Addition of microparticles or nanoparticles in matrix or reinforcement phase

- Direct incorporation of fire retardants

- Use of bio-based polymers that can potentially possess inherent fire retardancy

- Incorporation of the fire retardant into the adhesive system

- Mixing of fibers and fire retardant before adding an adhesive

- Chemical modification of matrix

- Surface treatment of fibers

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Joseph, S.; Jacob, M.; Thomas, S. Natural fiber-rubber composites and their applications. In Natural Fibers, Biopolymers, Biocomposites; Taylor Francis Group, LLC: Bacon Raton, FL, USA, 2005. [Google Scholar]

- Mohanty, A.K.; Lawrence, M.M.; Drzal, T. Natural Fibers, Biopolymers, and Biocomposites: An Introduction; CRC Press: Bacon Raton, FL, USA, 2005. [Google Scholar]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment; Publications Office of the European Union: Brussels, Belgium, 2018. [Google Scholar]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Drzal Lawrence, T.; Mohanty, A.; Misra, M. Bio-composite materials as alternatives to petroleum-based composites for automotive applications. Magnesium 2001, 40, 1–3. [Google Scholar]

- Prameela, K.; Mohan, C.M.; Ramakrishna, C. Biopolymers for Food Design: Consumer-Friendly Natural Ingredients. In Biopolymers for Food Design; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1–32. [Google Scholar]

- Ozilgen, S.; Bucak, S. Functional Biopolymers in Food Manufacturing. In Biopolymers for Food Design; Elsevier: Amsterdam, The Netherlands, 2018; pp. 157–189. [Google Scholar]

- Sumrith, N.; Rangappa, S.M.; Dangtungee, R.; Siengchin, S.; Jawaid, M.; Pruncu, C.I. Biopolymers-Based Nanocomposites: Properties and Applications. In Bio-Based Polymers and Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 255–272. [Google Scholar]

- Sadasivuni, K.K.; Saha, P.; Adhikari, J.; Deshmukh, K.; Ahamed, M.B.; Cabibihan, J.J. Recent advances in mechanical properties of biopolymer composites: A review. Polym. Compos. 2019, 7, 9–17. [Google Scholar] [CrossRef]

- Muratore, G.; Nobile, D.; Buonocore, G.; Lanza, C.; Asmundo, N. The influence of using biodegradable packaging films on the quality decay kinetic of plum tomato (PomodorinoDatterino®). Food Eng. 2005, 67, 393–399. [Google Scholar] [CrossRef]

- Rhim, J.-W.; Park, H.-M.; Ha, C.-S. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Rangari, V.K.; Biswas, M.C.; Tiimob, B.J. Biodegradable Polymer Blends for Food Packaging Applications. In Food Packaging Innovations and Shelf-Life; CRC Press: Boca Raton, FL, USA, 2019; p. 151. [Google Scholar]

- Motaung, T.E.; Linganiso, L.Z. Critical review on agrowaste cellulose applications for biopolymers. Int. J. Plast. Technol. 2018, 22, 185–216. [Google Scholar] [CrossRef]

- Deshmukh, K.; Ahamed, M.B.; Sadasivuni, K.K.; Ponnamma, D.; AlMaadeed, M.A.A.; Deshmukh, R.R.; Pasha, S.K.; Polu, A.R.; Chidambaram, K. Fumed SiO2 nanoparticle reinforced biopolymer blend nanocomposites with high dielectric constant and low dielectric loss for flexible organic electronics. Appl. Polym. Sci. 2017, 134. [Google Scholar] [CrossRef]

- Ashik, K.; Sharma, R.S.; Guptha, V.J. Investigation of moisture absorption and mechanical properties of natural/glass fiber reinforced polymer hybrid composites. Mater. Today Proc. 2018, 5, 3000–3007. [Google Scholar] [CrossRef]

- Galvez, P.; Abenojar, J.; Martinez, M.A. Effect of moisture and temperature on the thermal and mechanical properties of a ductile epoxy adhesive for use in steel structures reinforced with CFRP. Compos. Part B Eng. 2019, 176, 107194. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Zdero, R.; Bougherara, H. Mechanical, morphological, and water absorption properties of a new hybrid composite material made from 4 harness satin woven carbon fibres and flax fibres in an epoxy matrix. Compos. Part A Appl. Sci. Manuf. 2018, 115, 46–56. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers-a short review. Compos. Part B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Verma, D.; Fortunati, E.; Jain, S.; Zhang, X. Biomass, Biopolymer-Based Materials, and Bioenergy: Construction, Biomedical, and Other Industrial Applications; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Bindu, J.; Kumar, K.S.; Panda, S.K.; Katiyar, V. Biopolymer Dispersed Poly Lactic Acid Composites and Blends for Food Packaging Applications. In Advances in Sustainable Polymers; Springer: Berlin/Heidelberg, Germany, 2019; pp. 209–235. [Google Scholar]

- Daramola, O.O.; Olajide, J.L.; Agwuncha, S.C.; Mochane, M.J.; Sadiku, E.R. Nanostructured Green Biopolymer Composites for Orthopedic Application. In Green Biopolymers and Their Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 159–190. [Google Scholar]

- Sangeetha, K.; Vinodhini, P.A.; Sudha, P. Clay Based Biopolymer Nanocomposites and Their Applications in Environmental and Biomedical Fields. In Sustainable Polymer Composites and Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1159–1183. [Google Scholar]

- Ibrahim, I.D.; Sadiku, E.R.; Jamiru, T.; Hamam, Y.; Alayli, Y.; Eze, A.A.; Kupolati, W.K. Biopolymer Composites and Bionanocomposites for Energy Applications. In Green Biopolymers and Their Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 313–341. [Google Scholar]

- Allende, M.I.; Davis, B.A.; Miller, J.E.; Christiansen, E.L.; Lepech, M.D.; Loftus, D.J. Hypervelocity Impact Performance of Biopolymer-Bound Soil Composites for Space Construction. Aerosp. Eng. 2020, 33, 04020001. [Google Scholar] [CrossRef]

- Angellier, H.; Molina-Boisseau, S.; Dole, P.; Dufresne, A. Thermoplastic starch—Waxy maize starch nanocrystals nanocomposites. Biomacromolecules 2006, 7, 531–539. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos Rosa, D.; Lenz, D.M. Biocomposites: Influence of matrix nature and additives on the properties and biodegradation behaviour. Biodegrad. Eng. Technol. Intech Rij. Croat. 2013, 433–475. [Google Scholar] [CrossRef] [Green Version]

- Mochane, M.; Mokhena, T.C.; Mokhothu, T.; Mtibe, A.; Sadiku, E.; Ray, S.S.; Ibrahim, I.; Daramola, O. Recent progress on natural fiber hybrid composites for advanced applications: A review. Gen. Sci. Eng. Technol. 2019. [Google Scholar] [CrossRef]

- Islam, M.S.; Ramli, I.B.; Hasan, M.; Islam, M.M.; Islam, K.N.; Hasan, M.; Harmaen, A.S. Effect of kenaf and EFB fiber hybridization on physical and thermo-mechanical properties of PLA biocomposites. Fibers Polym. 2017, 18, 116–121. [Google Scholar] [CrossRef]

- Potluri, R. Natural Fiber-Based Hybrid Bio-composites: Processing, Characterization, and Applications. In Green Composites; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–46. [Google Scholar]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S. Thermal properties of coir and pineapple leaf fibre reinforced polylactic acid hybrid composites. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Advances in Manufacturing and Materials Engineering (ICAMME 2017), Kuala Lumpur, Malaysia, 8–9 August 2017; IOP Publishing: Bristol, UK, 2018; p. 012019. [Google Scholar]

- Asim, M.; Jawaid, M.; Paridah, M.T.; Saba, N.; Nasir, M.; Shahroze, R.M. Dynamic and thermo-mechanical properties of hybridized kenaf/PALF reinforced phenolic composites. Polym. Compos. 2019, 40, 3814–3822. [Google Scholar] [CrossRef]

- Sreekala, M.; George, J.; Kumaran, M.; Thomas, S. The mechanical performance of hybrid phenol-formaldehyde-based composites reinforced with glass and oil palm fibres. Compos. Sci. Technol. 2002, 62, 339–353. [Google Scholar] [CrossRef]

- Zweben, C. Tensile strength of hybrid composites. Mater. Sci. 1977, 12, 1325–1337. [Google Scholar] [CrossRef]

- Hariharan, A.B.A.; Khalil, H.A. Lignocellulose-based hybrid bilayer laminate composite: Part I-Studies on tensile and impact behavior of oil palm fiber-glass fiber-reinforced epoxy resin. Compos. Mater. 2005, 39, 663–684. [Google Scholar] [CrossRef]

- Marom, G.; Fischer, S.; Tuler, F.; Wagner, H. Hybrid effects in composites: Conditions for positive or negative effects versus rule-of-mixtures behaviour. Mater. Sci. 1978, 13, 1419–1426. [Google Scholar] [CrossRef]

- Dong, C. Review of natural fibre-reinforced hybrid composites. Reinf. Plast. Compos. 2018, 37, 331–348. [Google Scholar]

- Bassyouni, M.; Javaid, U.; ul Hasan, S.W. Bio-based hybrid polymer composites: A sustainable high performance material. In Hybrid Polymer Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 23–70. [Google Scholar]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar]

- Bledzki, A.; Gassan, J. Progress in Polym. Science 1999, 24, 221. [Google Scholar]

- Dhyani, V.; Bhaskar, T. Pyrolysis of Biomass. In Biofuels: Alternative Feedstocks and Conversion Processes for the Production of Liquid and Gaseous Biofuels; Elsevier: Amsterdam, The Netherlands, 2019; pp. 217–244. [Google Scholar]

- Nevell, T.P.; Zeronian, S.H. (Eds.) Cellulose Chemistry and Its Applications; Ellis Horwood Ltd: Hemel Hempstead, UK, 1985. [Google Scholar]

- Kim, C.-H.; Cho, K.; Park, J.-K. Grafting of glycidyl methacrylate onto polycaprolactone: Preparation and characterization. Polymer 2001, 42, 5135–5142. [Google Scholar] [CrossRef]

- Azwa, Z.; Yousif, B.; Manalo, A.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef] [Green Version]

- Mokhothu, T.H.; John, M.J. Review on hygroscopic aging of cellulose fibres and their biocomposites. Carbohydr. Polym. 2015, 131, 337–354. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Singh, S.; Mohanty, A. Wood fiber reinforced bacterial bioplastic composites: Fabrication and performance evaluation. Compos. Sci. Technol. 2007, 67, 1753–1763. [Google Scholar] [CrossRef]

- Cousins, W. Young’s modulus of hemicellulose as related to moisture content. Wood Sci. Technol. 1978, 12, 161–167. [Google Scholar] [CrossRef]

- Jarvis, M.C. Structure and properties of pectin gels in plant cell walls. Plant. Cell Environ. 1984, 7, 153–164. [Google Scholar]

- Satyanarayana, K.G.; Arizaga, G.G.; Wypych, F. Biodegradable composites based on lignocellulosic fibers—An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A review of natural fibers used in biocomposites: Plant, animal and regenerated cellulose fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Marques, A.R.; de Oliveira Patrício, P.S.; dos Santos, F.S.; Monteiro, M.L.; de Carvalho Urashima, D.; de Souza Rodrigues, C. Effects of the climatic conditions of the southeastern Brazil on degradation the fibers of coir-geotextile: Evaluation of mechanical and structural properties. Geotext. Geomembr. 2014, 42, 76–82. [Google Scholar] [CrossRef]

- Bledzki, A.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Huo, S.; Ulven, C.A. Natural fiber reinforced composites. Polym. Rev. 2012, 52, 259–320. [Google Scholar] [CrossRef]

- Mwaikambo, L.a.; Ansell, M. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials. I. Hemp fibres. Mater. Sci. 2006, 41, 2483–2496. [Google Scholar] [CrossRef]

- Dicker, M.P.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Mwaikambo, L. Review of the history, properties and application of plant fibres. Afr. J. Sci. Technol. 2006, 7, 121. [Google Scholar]

- Mohanty, A.; Misra, M.A.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R.; Rajini, N. Characterization of natural fiber and composites–A review. J. Reinf. Plast. Compos. 2013, 32, 1457–1476. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.A. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Komuraiah, A.; Kumar, N.S.; Prasad, B.D. Chemical composition of natural fibers and its influence on their mechanical properties. Mech. Compos. Mater. 2014, 50, 359–376. [Google Scholar] [CrossRef]

- Murkherjee, P.; Satyanarayana, K. Structure and properties of some vegetable fibers-Part 1: Sisal fiber. Mater. Sci. 1984, 19, 3925–3934. [Google Scholar] [CrossRef]

- Murherjee, P.; Satyanarayana, K. Structure and properties of some vegetable fibers-Part 2 Pineapple fiber (Ananas comosus). Mater. Sci. 1986, 21, 51–56. [Google Scholar] [CrossRef]

- Varma, D.; Varma, M.; Varma, I. Coir fibers: Part I: Effect of physical and chemical treatments on properties. Text. Res. J. 1984, 54, 827–832. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.-W.; Ye, L. Sisal fibre and its composites: A review of recent developments. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar] [CrossRef]

- Duhovic, M.; Peterson, S.; Jayaraman, K. Natural-fibre–biodegradable polymer composites for packaging. In Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; pp. 301–329. [Google Scholar]

- Sanjay, M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar]

- Sanjay, M.; Arpitha, G.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B. Applications of natural fibers and its composites: An overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef] [Green Version]

- Wenger, J.; Stern, T.; Schoggl, J.; Ree, R.; Corato, U.; Bari, I.; Bell, G.; Stichnothe, H. Natural Fibers and Fiber-Based Materials in Biorefineries: Status Report 2018; IEA Bioenergy: Paris, France, 2018; ISBN 978-1-910154-53-3. [Google Scholar]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Rahman, R.; Putra, S.Z.F.S. Tensile properties of natural and synthetic fiber-reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 81–102. [Google Scholar]

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Murawski, A.; Diaz, R.; Inglesby, S.; Delabar, K.; Quirino, R.L. Synthesis of Bio-based Polymer Composites: Fabrication, Fillers, Properties, and Challenges. In Polymer Nanocomposites in Biomedical Engineering; Springer: Berlin/Heidelberg, Germany, 2019; pp. 29–55. [Google Scholar]

- Zaid, A.; Jimeniez, E. Date palm cultivation. In FAO Plant Production and Protection Paper; Food and Agriculture Organization (FAO): Rome, Italy, 1999; p. 287. [Google Scholar]

- Ma, S.; Li, T.; Liu, X.; Zhu, J. Research progress on bio-based thermosetting resins. Polym. Int. 2016, 65, 164–173. [Google Scholar] [CrossRef]

- Rodriguez-Castellanos, W.; Rodrigue, D. Production and Characterization of Hybrid Polymer Composites Based on Natural Fibers. In Composites from Renewable and Sustainable Materials; InTech: London, UK, 2016; pp. 273–302. [Google Scholar]

- Niaounakis, M. Biopolymers: Applications and Trends; William Andrew: Norwich, NY, USA, 2015. [Google Scholar]

- Zhu, J. Development of Novel Flax Bio-Matrix Composites for Non-Structural and Structural Vehicle Applications. Ph.D. Thesis, Cranfield University, Bedford, UK, 2015. [Google Scholar]

- Bravo, A.; Toubal, L.; Koffi, D.; Erchiqui, F. Development of novel green and biocomposite materials: Tensile and flexural properties and damage analysis using acoustic emission. Mater. Des. 1980–2015 2015, 66, 16–28. [Google Scholar] [CrossRef] [Green Version]

- Stevens, C.V. Bio-Based Plastics: Materials and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Ganster, J.; Fink, H.-P. Man-Made Cellulose Short Fiber Reinforced Oil and Bio-Based Thermoplastics. In Cellulose Fibers: Bio-and Nano-Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2011; pp. 479–506. [Google Scholar]

- Zhang, Y.; Yuan, Z.; Xu, C.C. Bio-based resins for fiber-reinforced polymer composites. In Natural Fiber-Reinforced Biodegradable and Bioresorbable Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 137–162. [Google Scholar]

- Graupner, N.; Herrmann, A.S.; Müssig, J. Natural and man-made cellulose fibre-reinforced poly (lactic acid)(PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 2009, 40, 810–821. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications-A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Kamthai, S.; Magaraphan, R. Thermal and mechanical properties of polylactic acid (PLA) and bagasse carboxymethyl cellulose (CMCB) composite by adding isosorbide diesters. AIP Conf. Proc. 2015, 1664, 060006. [Google Scholar] [CrossRef]

- Williams, J.K.; Yoo, J.J.; Atala, A. Regenerative medicine approaches for tissue engineered heart valves. In Principles of Regenerative Medicine; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1041–1058. [Google Scholar]

- Díez-Pascual, A.M. Biodegradable food packaging nanocomposites based on ZnO-reinforced polyhydroxyalkanoates. In Food Packaging; Elsevier: Amsterdam, The Netherlands, 2017; pp. 185–221. [Google Scholar]

- Russell, R.A.; Garvey, C.J.; Darwish, T.A.; Foster, L.J.R.; Holden, P.J. Biopolymer deuteration for neutron scattering and other isotope-sensitive techniques. In Methods in Enzymology; Elsevier: Amsterdam, The Netherlands, 2015; Volume 565, pp. 97–121. [Google Scholar]

- Zhang, Z.; Ortiz, O.; Goyal, R.; Kohn, J. Biodegradable polymers. In Handbook of Polymer Applications in Medicine and Medical Devices; Elsevier: Amsterdam, The Netherlands, 2014; pp. 303–335. [Google Scholar]

- Madison, L.L.; Huisman, G.W. Metabolic engineering of poly (3-hydroxyalkanoates): From DNA to plastic. Microbiol. Mol. Biol. Rev. 1999, 63, 21–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Griffin, G.J. Chemistry and Technology of Biodegradable Polymers; Blackie Academic and Professional: London, UK, 1994. [Google Scholar]

- Reddy, C.; Ghai, R.; Kalia, V.C. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146. [Google Scholar] [CrossRef]

- Roy, I.; Visakh, P. Polyhydroxyalkanoate (PHA) Based Blends, Composites and Nanocomposites; Royal Society of Chemistry: Cambridge, UK, 2014; Volume 30. [Google Scholar]

- Ten, E.; Jiang, L.; Zhang, J.; Wolcott, M.P. Mechanical performance of polyhydroxyalkanoate (PHA)-based biocomposites. In Biocomposites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 39–52. [Google Scholar]

- Niaounakis, M. Biopolymers: Processing and Products; William Andrew: Norwich, NY, USA, 2014. [Google Scholar]

- Jamaluddin, N.; Razaina, M.; Ishak, Z.M. Mechanical and morphology behaviours of polybutylene (succinate)/thermoplastic polyurethaneblend. Procedia Chem. 2016, 19, 426–432. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.X.; Kim, E.S.; Yoon, J.S. Poly (butylene succinate)/twice functionalized organoclay nanocomposites: Preparation, characterization, and properties. Appl. Polym. Sci. 2005, 98, 1727–1732. [Google Scholar] [CrossRef]

- Someya, Y.; Nakazato, T.; Teramoto, N.; Shibata, M. Thermal and mechanical properties of poly (butylene succinate) nanocomposites with various organo-modified montmorillonites. Appl. Polym. Sci. 2004, 91, 1463–1475. [Google Scholar] [CrossRef]

- Han, H.; Wang, X.; Wu, D. Mechanical properties, morphology and crystallization kinetic studies of bio-based thermoplastic composites of poly (butylene succinate) with recycled carbon fiber. Chem. Technol. Biotechnol. 2013, 88, 1200–1211. [Google Scholar] [CrossRef]

- Song, L.; Qiu, Z. Influence of low multi-walled carbon nanotubes loadings on the crystallization behavior of biodegradable poly (butylene succinate) nanocomposites. Polym. Adv. Technol. 2011, 22, 1642–1649. [Google Scholar] [CrossRef]

- Yuan, L.; Wu, D.; Zhang, M.; Zhou, W.; Lin, D. Rheological percolation behavior and isothermal crystallization of poly (butyene succinte)/carbon nanotube composites. Ind. Eng. Chem. Res. 2011, 50, 14186–14192. [Google Scholar] [CrossRef]

- Ge, F.; Wang, X.; Ran, X. Properties of biodegradable poly (butylene succinate)(PBS) composites with carbon black. Polym. Sci. Ser. A 2017, 59, 416–424. [Google Scholar] [CrossRef]

- McKeen, L.W. The Effect of UV Light and Weather on Plastics and Elastomers; William Andrew: Norwich, NY, USA, 2019. [Google Scholar]

- Kausar, A. Physical properties of hybrid polymer/clay composites. In Hybrid Polymer Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 115–132. [Google Scholar]

- Di Lorenzo, M.L.; Longo, A.; Androsch, R. Polyamide 11/Poly (butylene succinate) Bio-Based Polymer Blends. Materials 2019, 12, 2833. [Google Scholar] [CrossRef] [Green Version]

- Patel, R.; Ruehle, D.A.; Dorgan, J.R.; Halley, P.; Martin, D. Biorenewable blends of polyamide-11 and polylactide. Polym. Eng. Sci. 2014, 54, 1523–1532. [Google Scholar] [CrossRef]

- Liu, T.; Lim, K.P.; Tjiu, W.C.; Pramoda, K.; Chen, Z.-K. Preparation and characterization of nylon 11/organoclay nanocomposites. Polymer 2003, 44, 3529–3535. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Focke, W.; Androsch, R. Thermal properties of biobased polyamide 11. Therm. Prop. Bio-Based Polym. 2019, 143–187. [Google Scholar] [CrossRef]

- Stoclet, G.; Seguela, R.; Lefebvre, J.-M. Morphology, thermal behavior and mechanical properties of binary blends of compatible biosourced polymers: Polylactide/polyamide11. Polymer 2011, 52, 1417–1425. [Google Scholar] [CrossRef]

- Heshmati, V.; Zolali, A.M.; Favis, B.D. Morphology development in poly (lactic acid)/polyamide11 biobased blends: Chain mobility and interfacial interactions. Polymer 2017, 120, 197–208. [Google Scholar] [CrossRef]

- Ke, Y.; Zhang, X.; Ramakrishna, S.; He, L.; Wu, G. Reactive blends based on polyhydroxyalkanoates: Preparation and biomedical application. Mater. Sci. Eng. C 2017, 70, 1107–1119. [Google Scholar] [CrossRef]

- Tercjak, A.; Haponiuk, J.; Masiulanis, B. Study of thermal property changes of biopol/polyamide 11 blends during biodegradation in compost. J. Therm. Anal. Calorim. 2003, 74, 605–608. [Google Scholar] [CrossRef]

- Moriyama, T.; Sumiya, N.; Saito, T. Impact strength improvement of polyamide 11 without flexural modulus reduction by dispersing poly (butylene succinate) particles. Polym. J. 2016, 48, 221–224. [Google Scholar] [CrossRef]

- Jariyavidyanont, K.; Focke, W.; Androsch, R. Crystallization kinetics of polyamide 11 in the presence of sepiolite and montmorillonite nanofillers. Colloid Polym. Sci. 2016, 294, 1143–1151. [Google Scholar] [CrossRef] [Green Version]

- Halim, K.A.A.; Farrell, J.B.; Kennedy, J.E. Preparation and characterisation of polyamide 11/montmorillonite (MMT) nanocomposites for use in angioplasty balloon applications. Mater. Chem. Phys. 2013, 143, 336–348. [Google Scholar] [CrossRef]

- Sahnoune, M.; Taguet, A.; Otazaghine, B.; Kaci, M.; Lopez-Cuesta, J.-M. Effects of functionalized halloysite on morphology and properties of polyamide-11/SEBS-g-MA blends. Eur. Polym. J. 2017, 90, 418–430. [Google Scholar] [CrossRef]

- Mahapatro, A.; Singh, D.K. Biodegradable nanoparticles are excellent vehicle for site directed in-vivo delivery of drugs and vaccines. J. Nanobiotechnol. 2011, 9, 55. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kabilan, S.; Ayyasamy, M.; Jayavel, S.; Paramasamy, G. Pseudomonas sp. as a source of medium chain length polyhydroxyalkanoates for controlled drug delivery: Perspective. Int. J. Microbiol. 2012, 2012. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Manepalli, P.H.; Zhu, L.; Narayan-Sarathy, S.; Alavi, S. Morphological, barrier and mechanical properties of films from poly (butylene succinate) reinforced with nanocrystalline cellulose and chitin whiskers using melt extrusion. J. Polym. Res. 2019, 26, 188. [Google Scholar] [CrossRef]

- Jiang, Y.; Loos, K. Enzymatic synthesis of biobased polyesters and polyamides. Polymers 2016, 8, 243. [Google Scholar] [CrossRef] [Green Version]

- Laine, L.; Rozite, L. Eco-Efficient Composite Materials; European Union European Regional Development Fund. October 2010. Available online: https://people.arcada.fi/~rene/biocomposites/lectures/STATE%20OF%20THE%20ART_material_examples.pdf (accessed on 12 November 2020).

- Pilla, S. Handbook of Bioplastics and Biocomposites Engineering Applications; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 81. [Google Scholar]

- Lutton, R.; Taylor, S.; Sonebi, M.; Murphy, A. Commercial potential of bioresins and their success in thermosetting composites: An overview. In Proceedings of the ICBBM ECOGRAFI, Clermont-Ferrand, France, 21–23 June 2017. [Google Scholar]

- Jin, F.-L.; Li, X.; Park, S.-J. Synthesis and application of epoxy resins: A review. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Kausar, A. Role of thermosetting polymer in structural composite. Am. J. Polym. Sci. Eng. 2017, 5, 1–12. [Google Scholar]

- Hamerton, I.; Mooring, L. The use of thermosets in aerospace applications. In Thermosets; Elsevier: Amsterdam, The Netherlands, 2012; pp. 189–227. [Google Scholar]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process. Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Ma, S.; Liu, X.; Jiang, Y.; Tang, Z.; Zhang, C.; Zhu, J. Bio-based epoxy resin from itaconic acid and its thermosets cured with anhydride and comonomers. Green Chem. 2013, 15, 245–254. [Google Scholar] [CrossRef]

- Zabihi, O.; Ahmadi, M.; Khayyam, H.; Naebe, M. Fish DNA-modified clays: Towards highly flame retardant polymer nanocomposite with improved interfacial and mechanical performance. Sci. Rep. 2016, 6, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Ramon, E.; Sguazzo, C.; Moreira, P.M. A review of recent research on bio-based epoxy systems for engineering applications and potentialities in the aviation sector. Aerospace 2018, 5, 110. [Google Scholar] [CrossRef] [Green Version]

- Raquez, J.-M.; Deléglise, M.; Lacrampe, M.-F.; Krawczak, P. Thermosetting (bio) materials derived from renewable resources: A critical review. Prog. Polym. Sci. 2010, 35, 487–509. [Google Scholar] [CrossRef]

- Cardona, F.; Aravinthan, T.; Fedrigo, J.; Moscou, C. Synthesis of phenolic bio-resins for advanced composites in civil engineering structures. In Proceedings of the Southern Region Engineering Conference (SREC 2010), Toowoomba, Australia, 11–12 November 2010; pp. 58–64. [Google Scholar]

- Ono, H.; Sudo, K.; Karasawa, H. Phenolated wood-a source of wood adhesives. In Proceedings of the International Symposium on Chemical Modification of Wood, Kyoto, Japan, 17–18 May 1991; pp. 35–37. [Google Scholar]

- Maldas, D.; Shiraishi, N. Liquefaction of biomass in the presence of phenol and H2O using alkalies and salts as the catalyst. Biomass Bioenergy 1997, 12, 273–279. [Google Scholar] [CrossRef]

- US National Renewable Energy Laboratory (NREL). Available online: http://www.nrel.gov/docs/legosti/old/5819.pdf (accessed on 23 September 2020).

- Gani, A.; Naruse, I. Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew. Energy 2007, 32, 649–661. [Google Scholar] [CrossRef]

- Bridgwater, A.; Peacocke, G. Fast pyrolysis processes for biomass. Renew. Sustain. Energy Rev. 2000, 4, 1–73. [Google Scholar] [CrossRef]

- Maxineasa, S.G.; Taranu, N. Life cycle analysis of strengthening concrete beams with FRP. In Eco-Efficient Repair and Rehabilitation of Concrete Infrastructures; Elsevier: Amsterdam, The Netherlands, 2018; pp. 673–721. [Google Scholar]

- Loos, M. Carbon Nanotube Reinforced Composites: CNT Polymer Science and Technology; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Jawaid, M.; Thariq, M.; Saba, N. Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Sheel, A.; Pant, D. Chemical Depolymerization of PET Bottles via Glycolysis. In Recycling of Polyethylene Terephthalate Bottles; Elsevier: Amsterdam, The Netherlands, 2019; pp. 61–84. [Google Scholar]

- Transparency Market Research. Itaconic Acid Market for Synthetic Latex, Unsaturated Polyester Resins, Detergents, Superabsorbent Polymers (SAP), and Other Applications—Global Industry Analysis, Size, Share, Growth, Trends and Forecast 2015−2023, TMRGL5492; Transparency Market Research: Albany, NY, USA, 27 July 2015. [Google Scholar]

- Mighani, H. Synthesis of thermally stable polyesters. In Polyester; InTech: Rijeka, Croatia, 2012; pp. 3–17. [Google Scholar]

- Fink, J.K. Reactive Polymers: Fundamentals and Applications: A Concise Guide to Industrial Polymers; William Andrew: Norwich, NY, USA, 2017. [Google Scholar]

- Meier, M.A.; Metzger, J.O.; Schubert, U.S. Plant oil renewable resources as green alternatives in polymer science. Chem. Soc. Rev. 2007, 36, 1788–1802. [Google Scholar] [CrossRef]

- Biermann, U.; Bornscheuer, U.; Meier, M.A.; Metzger, J.O.; Schäfer, H.J. Oils and fats as renewable raw materials in chemistry. Angew. Chem. Int. Ed. 2011, 50, 3854–3871. [Google Scholar] [CrossRef]

- Mehta, G.; Mohanty, A.; Misra, M.; Drzal, L. Biobased resin as a toughening agent for biocomposites. Green Chem. 2004, 6, 254–258. [Google Scholar] [CrossRef]

- Das, K.; Ray, D.; Banerjee, C.; Bandyopadhyay, N.; Mohanty, A.K.; Misra, M. Novel materials from unsaturated polyester resin/styrene/tung oil blends with high impact strengths and enhanced mechanical properties. Appl. Polym. Sci. 2011, 119, 2174–2182. [Google Scholar] [CrossRef]

- Kureemun, U.; Ravandi, M.; Tran, L.; Teo, W.; Tay, T.; Lee, H. Effects of hybridization and hybrid fibre dispersion on the mechanical properties of woven flax-carbon epoxy at low carbon fibre volume fractions. Compos. Part B Eng. 2018, 134, 28–38. [Google Scholar] [CrossRef]

- Nguyen, H.; Zatar, W.; Mutsuyoshi, H. Mechanical properties of hybrid polymer composite. In Hybrid Polymer Composite Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 83–113. [Google Scholar]

- Ismail, K.I.; Sultan, M.T.H.H.; Shah, A.U.; Mazlan, N.; Ariffin, A.H. Tensile Properties of Hybrid Biocomposite Reinforced Epoxy Modified with Carbon Nanotube (CNT). BioResources 2018, 13, 1787–1800. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Ramakrishnan, S.; Navaneethakrishnan, P. Effect of Glass and Banana Fiber Mat Orientation and Number of Layers on Mechanical Properties of Hybrid Composites. In Biofibers and Biopolymers for Biocomposites; Springer: Berlin/Heidelberg, Germany, 2020; pp. 295–312. [Google Scholar]

- Prasanna, G.; Venkatesha. Surface modification, characterization and optimization of hybrid bio composites. In Fatigue, Durability, and Fracture Mechanics; Springer: Singapore, 2020; p. 632. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Malkapuram, R.; Kumar, V.; Negi, Y.S. Recent development in natural fiber reinforced polypropylene composites. J. Reinf. Plast. Compos. 2009, 28, 1169–1189. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Lee, B.-H.; Kim, H.-J.; Yu, W.-R. Fabrication of long and discontinuous natural fiber reinforced polypropylene biocomposites and their mechanical properties. Fibers Polym. 2009, 10, 83–90. [Google Scholar] [CrossRef]

- López Manchado, M.; Arroyo, M.; Biagiotti, J.; Kenny, J. Enhancement of mechanical properties and interfacial adhesion of PP/EPDM/flax fiber composites using maleic anhydride as a compatibilizer. J. Appl. Polym. Sci. 2003, 90, 2170–2178. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical properties of poly (butylene succinate)(PBS) biocomposites reinforced with surface modified jute fibre. Compos. Part A Appl. Sci. Manuf. 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Phillips, L. The hybrid effect-does it exist? Composites 1976, 7, 7–8. [Google Scholar] [CrossRef]

- Hayashi, T. On the improvement of mechanical properties of composites by hybrid composition. In Proceedings of the 8th Reinforced Plastics Conference, London, UK, 10–12 October 1972; pp. 149–152. [Google Scholar]

- Bunsell, A.; Harris, B. Hybrid carbon and glass fibre composites. Composites 1974, 5, 157–164. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Enfedaque, A.; Molina-Aldareguía, J.; Gálvez, F.; González, C.; Llorca, J. Effect of glass fiber hybridization on the behavior under impact of woven carbon fiber/epoxy laminates. J. Compos. Mater. 2010, 44, 3051–3068. [Google Scholar] [CrossRef] [Green Version]

- Sevkat, E.; Liaw, B.; Delale, F.; Raju, B.B. Drop-weight impact of plain-woven hybrid glass–graphite/toughened epoxy composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1090–1110. [Google Scholar] [CrossRef]

- Onal, L.; Adanur, S. Effect of stacking sequence on the mechanical properties of glass–carbon hybrid composites before and after impact. J. Ind. Text. 2002, 31, 255–271. [Google Scholar] [CrossRef]

- Naik, N.; Ramasimha, R.; Arya, H.; Prabhu, S.; ShamaRao, N. Impact response and damage tolerance characteristics of glass–carbon/epoxy hybrid composite plates. Compos. Part B Eng. 2001, 32, 565–574. [Google Scholar] [CrossRef]

- Sevkat, E.; Liaw, B.; Delale, F.; Raju, B.B. Effect of repeated impacts on the response of plain-woven hybrid composites. Compos. Part B Eng. 2010, 41, 403–413. [Google Scholar] [CrossRef]

- P., D.C. Interlayer Hybridisation of Steel Fibre and Self-Reinforced Composites; KU Leuven: Leuven, Belgium, 2012. [Google Scholar]

- Park, R.; Jang, J. Effect of laminate geometry on impact performance of aramid fiber/polyethylene fiber hybrid composites. Appl. Polym. Sci. 2000, 75, 952–959. [Google Scholar] [CrossRef]

- Peijs, A.; Venderbosch, R. Hybrid composites based on polyethylene and carbon fibres Part IV Influence of hybrid design on impact strength. Mater. Sci. Lett. 1991, 10, 1122–1124. [Google Scholar] [CrossRef] [Green Version]

- Saito, H.; Morita, M.; Kawabe, K.; Kanesaki, M.; Takeuchi, H.; Tanaka, M.; Kimpara, I. Effect of ply-thickness on impact damage morphology in CFRP laminates. J. Reinf. Plast. Compos. 2011, 30, 1097–1106. [Google Scholar] [CrossRef]

- Galvez, P.; Quesada, A.; Martinez, M.A.; Abenojar, J.; Boada, M.J.L.; Diaz, V. Study of the behaviour of adhesive joints of steel with CFRP for its application in bus structures. Compos. Part B Eng. 2017, 129, 41–46. [Google Scholar] [CrossRef]

- Thiagamani, S.M.K.; Krishnasamy, S.; Muthukumar, C.; Tengsuthiwat, J.; Nagarajan, R.; Siengchin, S.; Ismail, S.O. Investigation into mechanical, absorption and swelling behaviour of hemp/sisal fibre reinforced bioepoxy hybrid composites: Effects of stacking sequences. Int. J. Biol. Macromol. 2019, 140, 637–646. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.; Jawaid, M.; Leman, Z.; Zainudin, E. Effect of layering sequence and chemical treatment on the mechanical properties of woven kenaf–aramid hybrid laminated composites. Mater. Des. 2015, 67, 173–179. [Google Scholar] [CrossRef]

- Guna, V.; Ilangovan, M.; Ananthaprasad, M.; Reddy, N. Hybrid biocomposites. Polym. Compos. 2018, 39, E30–E54. [Google Scholar] [CrossRef]

- Manteghi, S.; Mahboob, Z.; Fawaz, Z.; Bougherara, H. Investigation of the mechanical properties and failure modes of hybrid natural fiber composites for potential bone fracture fixation plates. J. Mech. Behav. Biomed. Mater. 2017, 65, 306–316. [Google Scholar] [CrossRef] [PubMed]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crop. Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Subagia, I.A.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Sivasaravanan, S.; Bupesh Raja, V.K. Impact characterization of epoxy LY556/E-glass fibre/nano clay hybrid nano composite materials. Procedia Eng. 2014, 97, 968–974. [Google Scholar] [CrossRef] [Green Version]

- Özturk, S. Effect of fiber loading on the mechanical properties of kenaf and fiberfrax fiber-reinforced phenol-formaldehyde composites. J. Compos. Mater. 2010, 44, 2265–2288. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Santulli, C. Impact properties of glass/plant fibre hybrid laminates. J. Mater. Sci. 2007, 42, 3699–3707. [Google Scholar] [CrossRef]

- Shahzad, A. Impact and fatigue properties of hemp–glass fiber hybrid biocomposites. J. Reinf. Plast. Compos. 2011, 30, 1389–1398. [Google Scholar] [CrossRef]

- Mishra, S.M.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Yang, Y.Z.; Zhao, D.; Xu, J.; Dong, Y.; Ma, Y.; Qin, X.; Fujiwara, K.; Suzuki, E.; Furukawa, T.; Takai, Y. Mechanical and optical properties of silk fabric/glass fiber mat composites: An artistic application of composites. Text. Res. J. 2018, 88, 932–945. [Google Scholar] [CrossRef]

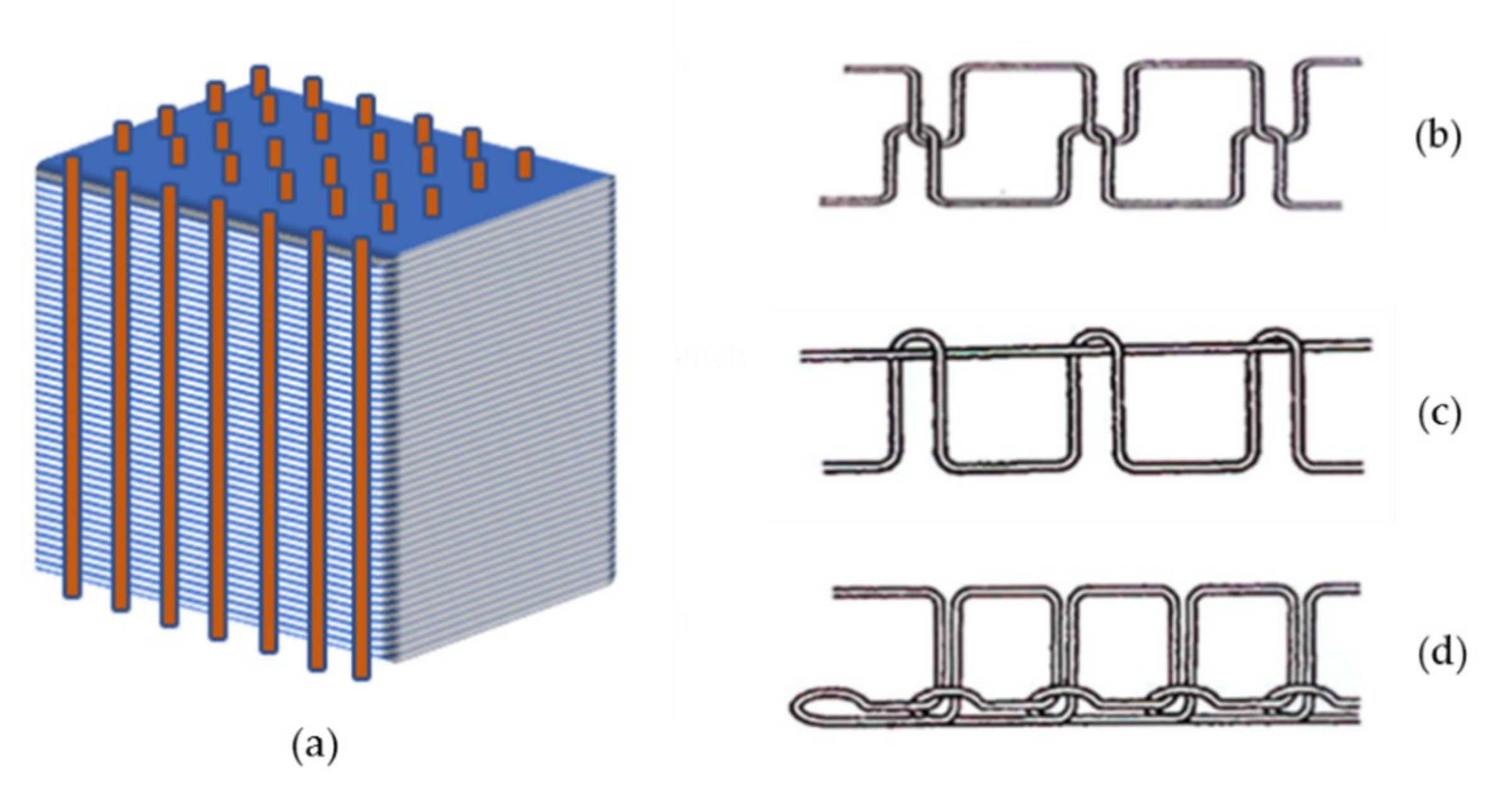

- Ravandi, M.T.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. The effects of through-the-thickness stitching on the Mode I interlaminar fracture toughness of flax/epoxy composite laminates. Mater. Des. 2016, 109, 659–669. [Google Scholar] [CrossRef]

- Ravandi, M.T.; Teo, W.S.; Yong, M.S.; Tay, T.E. Prediction of Mode I interlaminar fracture toughness of stitched flax fiber composites. J. Mater. Sci. 2018, 53, 4173–4188. [Google Scholar] [CrossRef]

- Jain, L.K.; Mai, Y.W. Determination of mode II delamination toughness of stitched laminated composites. Compos. Sci. Technol. 1995, 55, 241–253. [Google Scholar] [CrossRef]

- Ghasemnejad, H.A.Y.; Tez, T.A.; Barrington, P.E. Impact damage response of natural stitched single lap-joint in composite structures. Mater. Des. 2013, 51, 552–560. [Google Scholar] [CrossRef]

- Arju, S.N.; Afsar, A.M.; Khan, M.; Das, D. Effects of jute fabric structures on the performance of jute-reinforced polypropylene composites. J. Reinf. Plast. Compos. 2015, 34, 1306–1314. [Google Scholar] [CrossRef]

- Kumar, R.K.; Bhowmik, S. Mechanical characterization and quantification of tensile, fracture and viscoelastic characteristics of wood filler reinforced epoxy composite. Wood Sci. Technol. 2018, 52, 677–699. [Google Scholar] [CrossRef]

- Bartolomé, J.F.; Gutiérrez-González, C.F.; Torrecillas, R. Mechanical properties of alumina–zirconia–Nb micro–nano-hybrid composites. Compos. Sci. Technol. 2008, 68, 1392–1398. [Google Scholar] [CrossRef] [Green Version]

- Prasob, P.S.M. Static and dynamic behavior of jute/epoxy composites with ZnO and TiO2 fillers at different temperature conditions. Polym. Test. 2018, 69, 52–62. [Google Scholar] [CrossRef]

- Demirci, M.T.; Necmettin, T.; Avcı, A.; Akdemir, A.; Demirci, I. Fracture toughness (Mode I) characterization of SiO2 nanoparticle filled basalt/epoxy filament wound composite ring with split-disk test method. Compos. Part B Eng. 2017, 119, 114–124. [Google Scholar] [CrossRef]

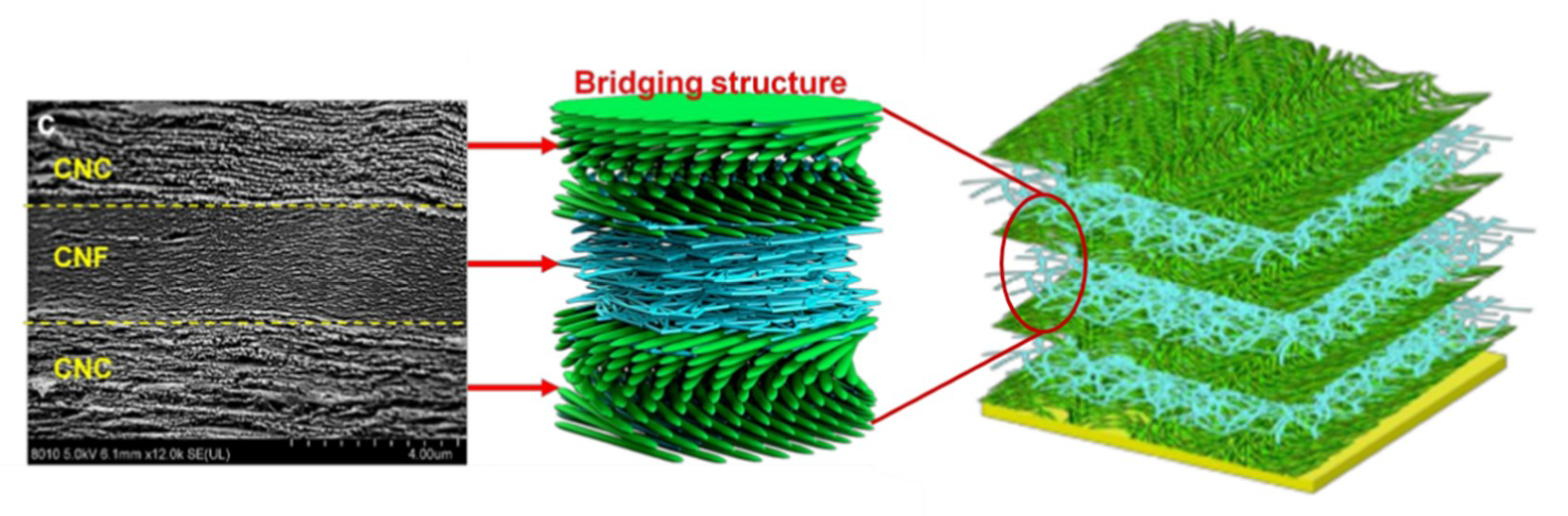

- Zhang, X.; Xiong, R.; Kang, S.; Yang, Y.; Tsukruk, V.V. Alternating Stacking of Nanocrystals and Nanofibers into Ultrastrong Chiral Biocomposite Laminates. ACS Nano 2020. [Google Scholar] [CrossRef] [PubMed]

- Göktaş, D.; Kennon, W.; Potluri, P. Improvement of Mode I interlaminar fracture toughness of stitched glass/epoxy composites. Appl. Compos. Mater. 2017, 24, 351–375. [Google Scholar] [CrossRef] [Green Version]

- Prasanna, G.V.; Kumar, J.N.; Kumar, K.A. Optimisation & Mechanical Testing Of Hybrid BioComposites. Mater. Today Proc. 2019, 18, 3849–3855. [Google Scholar]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S. Mechanical, dynamic, and thermomechanical properties of coir/pineapple leaf fiber reinforced polylactic acid hybrid biocomposites. Polym. Compos. 2019, 40, 2000–2011. [Google Scholar] [CrossRef]

- Ridzuan, M.; Majid, M.A.; Khasri, A.; Tajul, L.; Cheng, E. Flexural properties of hybrid synthetic/Napier fibres reinforced epoxy composites. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 6th International Conference on Applications and Design in Mechanical Engineering, Penang Island, Malaysia, 26–27 August 2019; IOP Publishing: Bristol, UK, 2019; p. 012034. [Google Scholar]

- Ismail, K.; Sultan, M.; Shah, A.; Jawaid, M.; Safri, S. Low velocity impact and compression after impact properties of hybrid bio-composites modified with multi-walled carbon nanotubes. Compos. Part B Eng. 2019, 163, 455–463. [Google Scholar] [CrossRef]

- Zin, M.H.; Abdan, K.; Mazlan, N.; Zainudin, E.S.; Liew, K.E.; Norizan, M.N. Automated spray up process for Pineapple Leaf Fibre hybrid biocomposites. Compos. Part B Eng. 2019, 177, 107306. [Google Scholar] [CrossRef]

- Del Campo, A.M.; Robledo-Ortiz, J.; Arellano, M.; Jasso-Gastinel, C.; Silva-Jara, J.; López-Naranjo, E.; Pérez-Fonseca, A. GLYCIDYL Methacrylate-Compatibilized Poly (Lactic Acid)/Nanoclay/Agave Fiber Hybrid Biocomposites: Effect on The Physical and Mechanical Properties. Rev. Mex. Ing. Quím. 2020, 19, 455–469. [Google Scholar] [CrossRef] [Green Version]

- Duan, J.; Wu, H.; Fu, W.; Hao, M. Mechanical properties of hybrid sisal/coir fibers reinforced polylactide biocomposites. Polym. Compos. 2018, 39, E188–E199. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K. Morphological and mechanical properties of treated kenaf fiber/MMT clay reinforced PLA hybrid biocomposites. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2019; p. 020035. [Google Scholar] [CrossRef]

- Ribeiro Filho, S.L.M.; Oliveira, P.R.; Vieira, L.M.G.; Panzera, T.H.; Freire, R.T.S.; Scarpa, F. Hybrid bio-composites reinforced with sisal-glass fibres and Portland cement particles: A statistical approach. Compos. Part B Eng. 2018, 149, 58–65. [Google Scholar] [CrossRef] [Green Version]

- Khoshnava, S.M.; Rostami, R.; Ismail, M.; Rahmat, A.R.; Ogunbode, B.E. Woven hybrid Biocomposite: Mechanical properties of woven kenaf bast fibre/oil palm empty fruit bunches hybrid reinforced poly hydroxybutyrate biocomposite as non-structural building materials. Constr. Build. Mater. 2017, 154, 155–166. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Biodegradability and mechanical properties of pineapple leaf/coir Fiber reinforced hybrid epoxy composites. Mater. Res. Express 2019, 6, 045301. [Google Scholar] [CrossRef]

- Rihayat, T.; Suryani, S.; Fauzi, T.; Agusnar, H.; Wirjosentono, B.; Alam, P.; Sami, M. Mechanical properties evaluation of single and hybrid composites polyester reinforced bamboo, PALF and coir fiber. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 012081. [Google Scholar] [CrossRef] [Green Version]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Rahmah, M. Development of sugar palm yarn/glass fibre reinforced unsaturated polyester hybrid composites. Mater. Res. Express 2018, 5, 045308. [Google Scholar] [CrossRef]

- Rahman, M.; Das, S.; Hasan, M. Mechanical properties of chemically treated banana and pineapple leaf fiber reinforced hybrid polypropylene composites. Adv. Mater. Process. Technol. 2018, 4, 527–537. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.; Ishak, M. Dynamic mechanical properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. Polym. Compos. 2019, 40, 1329–1334. [Google Scholar] [CrossRef]

- Venkatarajan, S.; Bhuvaneswari, B.; Athijayamani, A.; Sekar, S. Effect of addition of areca fine fibers on the mechanical properties of Calotropis Gigantea fiber/phenol formaldehyde biocomposites. Vacuum 2019, 166, 6–10. [Google Scholar] [CrossRef]

- Sitticharoen, W.; Aukaranarakul, S.; Kantalue, K. Study of Thermal and Mechanical Properties of LLDPE/Sugarcane bagasse/Eggshell Hybrid Biocomposites. Walailak J. Sci. Technol. 2019, 16, 739–751. [Google Scholar]

- Athijayamani, A.; Das, M.C.; Sekar, S.; Ramanathan, K. Mechanical properties of phenol formaldehyde hybrid composites reinforced with natural cellulose fibers. BioResources 2017, 12, 1960–1967. [Google Scholar] [CrossRef] [Green Version]

- Jumaidin, R.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Thermal, mechanical, and physical properties of seaweed/sugar palm fibre reinforced thermoplastic sugar palm starch/agar hybrid composites. Int. J. Biol. Macromol. 2017, 97, 606–615. [Google Scholar] [CrossRef]

- Soundhar, A.; Rajesh, M.; Jayakrishna, K.; Sultan, M.; Shah, A. Investigation on mechanical properties of polyurethane hybrid nanocomposite foams reinforced with roselle fibers and silica nanoparticles. Nanocomposites 2019, 5, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Petrucci, R.; Santulli, C.; Puglia, D.; Nisini, E.; Sarasini, F.; Tirillò, J.; Torre, L.; Minak, G.; Kenny, J. Impact and post-impact damage characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Compos. Part B Eng. 2015, 69, 507–515. [Google Scholar] [CrossRef]

- Bujjibabu, G.; Das, V.C.; Ramakrishna, M.; Nagarjuna, K. Mechanical and water absorption behavior of natural fibers reinforced polypropylene hybrid composites. Mater. Today Proc. 2018, 5, 12249–12256. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Sharavanan, R.; Chandrasekaran, M.; Elanchezhian, C.; Sathyanarayanan, R.; Raja, R.N.; Kokan, S.J. Experimental determination of mechanical properties of banana jute hybrid composite. Fibers Polym. 2015, 16, 164–172. [Google Scholar] [CrossRef]

- Sathish, P.; Kesavan, R.; Ramnath, B.V.; Vishal, C. Effect of fiber orientation and stacking sequence on mechanical and thermal characteristics of banana-kenaf hybrid epoxy composite. Silicon 2017, 9, 577–585. [Google Scholar] [CrossRef]

- Gupta, M.; Srivastava, R. Mechanical, thermal and water absorption properties of hybrid sisal/jute fiber reinforced polymer composite. Indian J. Eng. Mater. Sci. 2016, 23, 231–238. [Google Scholar]

- Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part B Eng. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Essabir, H.; Bensalah, M.; Rodrigue, D.; Bouhfid, R.; Qaiss, A. Structural, mechanical and thermal properties of bio-based hybrid composites from waste coir residues: Fibers and shell particles. Mech. Mater. 2016, 93, 134–144. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.; Jawaid, M.; Leman, Z.; Zainudin, E. Effect of fibre orientations on the mechanical properties of kenaf–aramid hybrid composites for spall-liner application. Def. Technol. 2016, 12, 52–58. [Google Scholar] [CrossRef] [Green Version]

- Muhammad, Y.H.; Ahmad, S.; Abu Bakar, M.A.; Mamun, A.A.; Heim, H.P. Mechanical properties of hybrid glass/kenaf fibre-reinforced epoxy composite with matrix modification using liquid epoxidised natural rubber. J. Reinf. Plast. Compos. 2015, 34, 896–906. [Google Scholar] [CrossRef]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.; Ishak, M.R.; Hanim, M.A.A. Effects of kenaf fiber orientation on mechanical properties and fatigue life of glass/kenaf hybrid composites. BioResources 2016, 11, 1448–1465. [Google Scholar] [CrossRef]

- Braga, R.; Magalhaes, P., Jr. Analysis of the mechanical and thermal properties of jute and glass fiber as reinforcement epoxy hybrid composites. Mater. Sci. Eng. C 2015, 56, 269–273. [Google Scholar] [CrossRef] [PubMed]

- Essabir, H.; Boujmal, R.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R. Mechanical and thermal properties of hybrid composites: Oil-palm fiber/clay reinforced high density polyethylene. Mech. Mater. 2016, 98, 36–43. [Google Scholar] [CrossRef]

- Safri, S.N.A.; Sultan, M.T.H.; Shah, A.U.M. Characterization of benzoyl treated sugar palm/glass fibre hybrid composites. J. Mater. Res. Technol. 2020, 9, 11563–11573. [Google Scholar] [CrossRef]

- Agarwal, J.; Mohanty, S.; Nayak, S.K. Influence of cellulose nanocrystal/sisal fiber on the mechanical, thermal, and morphological performance of polypropylene hybrid composites. Polym. Bull. 2020, 1–27. [Google Scholar] [CrossRef]

- Ahmad, M.A.A.; Majid, M.A.; Ridzuan, M.; Mazlee, M.; Gibson, A. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef] [Green Version]

- Suriani, M.; Ruzaidi, C.; Nair, D. Flammability and Mechanical Properties of Arenga Pinnata Fibre/PET Reinforced Epoxy for Fire Retardant Composites. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012002. [Google Scholar]

- George, K.; Mohanty, S.; Biswal, M.; Nayak, S.K. Thermal insulation behaviour of Ethylene propylene diene monomer rubber/kevlar fiber based hybrid composites containing Nanosilica for solid rocket motor insulation. J. Appl. Polym. Sci. 2020, 49934. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.; Siengchin, S.; Fouad, H. Alkali treated coir/pineapple leaf fibres reinforced PLA hybrid composites: Evaluation of mechanical, morphological, thermal and physical properties. Express Polym. Lett. 2020, 14. [Google Scholar] [CrossRef]

- Dhakal, H.; Zhang, Z.; Richardson, M. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. Effect of moisture absorption on the mechanical performance of natural fiber reinforced woven hybrid bio-composites. J. Nat. Fibers 2020, 17, 84–100. [Google Scholar] [CrossRef]

- Mohanty, A.; Misra, M.; Drzal, L.T. Surface modifications of natural fibers and performance of the resulting biocomposites: An overview. Compos. Interfaces 2001, 8, 313–343. [Google Scholar] [CrossRef]

- Thomason, J. The interface region in glass fibre-reinforced epoxy resin composites: 2. Water absorption, voids and the interface. Composites 1995, 7, 477–485. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibres from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Shen, C.-H.; Springer, G.S. Moisture absorption and desorption of composite materials. J. Compos. Mater. 1976, 10, 2–20. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A. Mechanical and water absorption properties of woven jute/banana hybrid composites. Fibers Polym. 2012, 13, 907–914. [Google Scholar] [CrossRef]

- Ray, P.; Chakravarty, A.; Bandyopadhaya, S. Fine structure and mechanical properties of jute differently dried after retting. Appl. Polym. Sci. 1976, 20, 1765–1767. [Google Scholar] [CrossRef]

- Semsarzadeh, M.A. Fiber matrix interactions in jute reinforced polyester resin. Polym. Compos. 1986, 7, 23–25. [Google Scholar] [CrossRef]

- Haig Zeronian, S.; Kawabata, H.; Alger, K.W. Factors affecting the tensile properties of nonmercerized and mercerized cotton fibers. Text. Res. J. 1990, 60, 179–183. [Google Scholar] [CrossRef]

- Belgacem, M.; Bataille, P.; Sapieha, S. Effect of corona modification on the mechanical properties of polypropylene/cellulose composites. J. Appl. Polym. Sci. 1994, 53, 379–385. [Google Scholar] [CrossRef]

- Wang, H.; Rembold, M.; Wang, J. Characterization of surface properties of plasma-polymerized fluorinated hydrocarbon layers: Surface stability as a requirement for permanent water repellency. J. Appl. Polym. Sci. 1993, 49, 701–710. [Google Scholar] [CrossRef]

- Enciso, B.; Abenojar, J.; Paz, E.; Martínez, M. Influence of low pressure plasma treatment on the durability of thermoplastic composites LDPE-flax/coconut under thermal and humidity conditions. Fibers Polym. 2018, 19, 1327–1334. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Liu, Y.; Yang, G.C.; Zeng, H.M. The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 2001, 61, 1437–1447. [Google Scholar] [CrossRef]

- Jacob, M.; Varughese, K.; Thomas, S. A study on the moisture sorption characteristics in woven sisal fabric reinforced natural rubber biocomposites. J. Appl. Polym. Sci. 2006, 102, 416–423. [Google Scholar] [CrossRef]

- Ventura, H.; Claramunt, J.; Rodríguez-Pérez, M.; Ardanuy, M. Effects of hydrothermal aging on the water uptake and tensile properties of PHB/flax fabric biocomposites. Polym. Degrad. Stab. 2017, 142, 129–138. [Google Scholar] [CrossRef]

- Mishra, S.; Misra, M.; Tripathy, S.; Nayak, S.; Mohanty, A. Potentiality of pineapple leaf fibre as reinforcement in PALF-polyester composite: Surface modification and mechanical performance. J. Reinf. Plast. Compos. 2001, 20, 321–334. [Google Scholar] [CrossRef]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-treatment of flax fibers for use in rotationally molded biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Halonen, H.; Larsson, P.T.; Iversen, T. Mercerized cellulose biocomposites: A study of influence of mercerization on cellulose supramolecular structure, water retention value and tensile properties. Cellulose 2013, 20, 57–65. [Google Scholar] [CrossRef]

- Hashim, M.Y.; Roslan, M.N.; Amin, A.M.; Zaidi, A.M.A.; Ariffin, S. Mercerization treatment parameter effect on natural fiber reinforced polymer matrix composite: A brief review. World Acad. Sci. Eng. Technol. 2012, 68, 1638–1644. [Google Scholar]

- Kushwaha, P.K.; Kumar, R. Studies on water absorption of bamboo-polyester composites: Effect of silane treatment of mercerized bamboo. Polym. Plast. Technol. Eng. 2009, 49, 45–52. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevicius, A.; Vilkauskas, A.; Janusas, G. Review of Hybrid Fiber Based Composites with Nano Particles—Material Properties and Applications. Polymers 2020, 12, 2088. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K. Influence of Montmorillonite Clay Content on Thermal, Mechanical, Water Absorption and Biodegradability Properties of Treated Kenaf Fiber/PLA-Hybrid Biocomposites. Silicon 2020, 1–10. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K. Effect of MMT Clay on Mechanical, Thermal and Barrier Properties of Treated Aloevera Fiber/PLA-Hybrid Biocomposites. Silicon 2019, 1–10. [Google Scholar] [CrossRef]

- Anbukarasi, K.; Hussain, S.I.; Roseline, A.A.; Kalaiselvam, S. Effect of SiO2 nanospheres on mechanical, thermal and water absorption behaviours of luffa-coir/epoxy hybrid composites. Mater. Res. Express 2019, 6, 125618. [Google Scholar] [CrossRef]

- Miao, Y.-G.; Liu, H.-Y.; Suo, T.; Mai, Y.-W.; Xie, F.-Q.; Li, Y.-L. Effects of strain rate on mechanical properties of nanosilica/epoxy. Compos. Part B Eng. 2016, 96, 119–124. [Google Scholar] [CrossRef]

- Ulus, H.; Kaybal, H.B.; Eskizeybek, V.; Avcı, A. Enhanced salty water durability of halloysite nanotube reinforced epoxy/basalt fiber hybrid composites. Fibers Polym. 2019, 20, 2184–2199. [Google Scholar] [CrossRef]

- Kiatkamjornwong, S. Superabsorbent polymers and superabsorbent polymer composites. ScienceAsia 2007, 33, 39–43. [Google Scholar] [CrossRef]

- Vasile, C.; Pamfil, D.; Stoleru, E.; Baican, M. New Developments in Medical Applications of Hybrid Hydrogels Containing Natural Polymers. Molecules 2020, 25, 1539. [Google Scholar] [CrossRef] [Green Version]

- Kumar, A.; Lee, Y.; Kim, D.; Rao, K.M.; Kim, J.; Park, S.; Haider, A.; Han, S.S. Effect of crosslinking functionality on microstructure, mechanical properties, and in vitro cytocompatibility of cellulose nanocrystals reinforced poly (vinyl alcohol)/sodium alginate hybrid scaffolds. Int. J. Biol. Macromol. 2017, 95, 962–973. [Google Scholar] [CrossRef]

- Rodríguez-Rodríguez, R.; García-Carvajal, Z.; Jiménez-Palomar, I.; Jiménez-Avalos, J.; Espinosa-Andrews, H. Development of gelatin/chitosan/PVA hydrogels: Thermal stability, water state, viscoelasticity, and cytotoxicity assays. J. Appl. Polym. Sci. 2019, 136, 47149. [Google Scholar] [CrossRef]

- Sadeghi, A.; Moztarzadeh, F.; Mohandesi, J.A. Investigating the effect of chitosan on hydrophilicity and bioactivity of conductive electrospun composite scaffold for neural tissue engineering. Int. J. Biol. Macromol. 2019, 121, 625–632. [Google Scholar] [CrossRef]

- Zhan, H.; Löwik, D.W. A hybrid peptide amphiphile fiber PEG hydrogel matrix for 3D cell culture. Adv. Funct. Mater. 2019, 29, 1808505. [Google Scholar] [CrossRef]

- Rose, J.C.; Gehlen, D.B.; Haraszti, T.; Köhler, J.; Licht, C.J.; De Laporte, L. Biofunctionalized aligned microgels provide 3D cell guidance to mimic complex tissue matrices. Biomaterials 2018, 163, 128–141. [Google Scholar] [CrossRef]

- De Laporte, L.; Rose, J.; Kivilip, L.; Gehlen, D.; Omidinia, A.; Licht, C.; Rohlfs, W. Magnetic microgel assemblies for injectable soft biocomposites. In Proceedings of the Metal, Mining and Magnetic Materials Conference, Paris, France, 1–2 November 2018. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant fibre based bio-composites: Sustainable and renewable green materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Akash, G.K.; Venkatesha Gupta, N.; Sreenivas Rao, K. A study on flammability and moisture absorption behavior of sisal/coir fiber reinforced hybrid composites. IOP Conf. Ser. Mater. Sci. Eng. 2017, 191, 012003. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Effect of Layering Pattern on Flammability and Water Absorption Behavior of Pineapple Leaf/Coir Fiber Reinforced Hybrid Composites. I-Manag. J. Mater. Sci. 2019, 7, 44. [Google Scholar]

- Prakash, V.A.; Viswanthan, R. Fabrication and characterization of echinoidea spike particles and kenaf natural fibre-reinforced Azadirachta-Indica blended epoxy multi-hybrid bio composite. Compos. Part A Appl. Sci. Manuf. 2019, 118, 317–326. [Google Scholar] [CrossRef]

- Kc, B.; Tjong, J.; Jaffer, S.; Sain, M. Thermal and dimensional stability of injection-molded sisal-glass fiber hybrid PP biocomposites. J. Polym. Environ. 2018, 26, 1279–1289. [Google Scholar] [CrossRef]

- Liew, F.K.; Hamdan, S.; Rahman, M.; Rusop, M. Thermomechanical properties of jute/bamboo cellulose composite and its hybrid composites: The effects of treatment and fiber loading. Adv. Mater. Sci. Eng. 2017, 2017. [Google Scholar] [CrossRef] [Green Version]

- Verma, A.; Joshi, K.; Gaur, A.; Singh, V. Starch-Jute fiber hybrid biocomposite modified with Epoxy resin layer: Fabrication and Experimental Characterization. Preprints 2018. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.; Saba, N.; Jawaid, M.; Alothman, O.Y.; Nasir, M.; Almutairi, Z. Thermal, physical properties and flammability of silane treated kenaf/pineapple leaf fibres phenolic hybrid composites. Compos. Struct. 2018, 202, 1330–1338. [Google Scholar] [CrossRef]

- Dinesh, T.; Kadirvel, A.; Vincent, A. Effect of silane modified E-glass fibre/iron (III) oxide reinforcements on UP blended epoxy resin hybrid composite. Silicon 2019, 11, 2487–2498. [Google Scholar] [CrossRef]

- Das, G.; Biswas, S. Physical, mechanical and water absorption behaviour of coir fiber reinforced epoxy composites filled with Al2O3 particulates. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; p. 012012. [Google Scholar]

- Swain, P.T.R.; Das, S.N.; Patnaik, P.K.; Purohit, A. The Influence of Moisture Absorption on the Mechanical and Thermal Properties of Chemically Treated DPL Reinforced Hybrid Composite. Mater. Sci. Forum 2020, 978, 316–322. [Google Scholar] [CrossRef]

- Almansour, F.; Dhakal, H.; Zhang, Z.Y. Effect of water absorption on Mode I interlaminar fracture toughness of flax/basalt reinforced vinyl ester hybrid composites. Compos. Struct. 2017, 168, 813–825. [Google Scholar] [CrossRef] [Green Version]

- Chai, M.; Bickerton, S.; Bhattacharyya, D.; Das, R. Influence of natural fibre reinforcements on the flammability of bio-derived composite materials. Compos. Part B Eng. 2012, 43, 2867–2874. [Google Scholar] [CrossRef]

- Das, O.; Kim, N.K.; Sarmah, A.K.; Bhattacharyya, D. Development of waste based biochar/wool hybrid biocomposites: Flammability characteristics and mechanical properties. J. Clean. Prod. 2017, 144, 79–89. [Google Scholar] [CrossRef]

- Dorez, G.; Taguet, A.; Ferry, L.; Cuesta, J.-M.L. Phosphorous compounds as flame retardants for polybutylene succinate/flax biocomposite: Additive versus reactive route. Polym. Degrad. Stab. 2014, 102, 152–159. [Google Scholar] [CrossRef]

- Szolnoki, B.; Bocz, K.; Soti, P.L.; Bodzay, B.; Zimonyi, E.; Toldy, A.; Morlin, B.; Bujnowicz, K.; Wladyka-Przybylak, M.; Marosi, G. Development of natural fibre reinforced flame retarded epoxy resin composites. Polym. Degrad. Stab. 2015, 119, 68–76. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Paridah, M.; Al-Othman, O. A review on flammability of epoxy polymer, cellulosic and non-cellulosic fiber reinforced epoxy composites. Polym. Adv. Technol. 2016, 27, 577–590. [Google Scholar] [CrossRef]

- Babu, K.; Rendén, G.; Afriyie Mensah, R.; Kim, N.K.; Jiang, L.; Xu, Q.; Restás, Á.; Esmaeely Neisiany, R.; Hedenqvist, M.S.; Försth, M. A review on the flammability properties of carbon-based polymeric composites: State-of-the-art and future trends. Polymers 2020, 12, 1518. [Google Scholar] [CrossRef]

- Feng, Y.; He, C.; Wen, Y.; Ye, Y.; Zhou, X.; Xie, X.; Mai, Y.-W. Superior flame retardancy and smoke suppression of epoxy-based composites with phosphorus/nitrogen co-doped graphene. J. Hazard. Mater. 2018, 346, 140–151. [Google Scholar] [CrossRef]

- Araby, S.; Su, X.; Meng, Q.; Kuan, H.-C.; Wang, C.-H.; Mouritz, A.; Maged, A.; Ma, J. Graphene platelets versus phosphorus compounds for elastomeric composites: Flame retardancy, mechanical performance and mechanisms. Nanotechnology 2019, 30, 385703. [Google Scholar] [CrossRef]

- Lee, S.; Min Kim, H.; Seong, D.G.; Lee, D. Synergistic improvement of flame retardant properties of expandable graphite and multi-walled carbon nanotube reinforced intumescent polyketone nanocomposites. Carbon 2019, 143, 650–659. [Google Scholar] [CrossRef]

- Mochane, M.J.; Motaung, T.E.; Motloung, S.V. Morphology, flammability, and properties of graphite reinforced polymer composites. Systematic review. Polym. Compos. 2018, 39, E1487–E1499. [Google Scholar] [CrossRef]

- Mngomezulu, M.E.; Luyt, A.S.; John, M.J. Morphology, thermal and dynamic mechanical properties of poly (lactic acid)/expandable graphite (PLA/EG) flame retardant composites. J. Thermoplast. Compos. Mater. 2019, 32, 89–107. [Google Scholar] [CrossRef]

- Kanbur, Y.; Tayfun, U. Development of multifunctional polyurethane elastomer composites containing fullerene: Mechanical, damping, thermal, and flammability behaviors. J. Elastomers Plast. 2019, 51, 262–279. [Google Scholar] [CrossRef]

- Chen, Q.; Sai, T.; Fang, Z.; Guo, Z. Thermal stability and oxygen resistance of polypropylene composites with fullerene/montmorillonite hybrid fillers. J. Therm. Anal. Calorim. 2020, 1–10. [Google Scholar] [CrossRef]

- Qiu, M.; Wang, D.; Zhang, L.; Li, M.; Liu, M.; Fu, S. Simultaneously electrochemical exfoliation and functionalization of graphene nanosheets: Multifunctional reinforcements in thermal, flame-retardant, and mechanical properties of polyacrylonitrile composite fibers. Polym. Compos. 2020, 41, 1561–1573. [Google Scholar] [CrossRef]

- Zhao, Z.; Cai, W.; Xu, Z.; Mu, X.; Ren, X.; Zou, B.; Gui, Z.; Hu, Y. Multi-role p-styrene sulfonate assisted electrochemical preparation of functionalized graphene nanosheets for improving fire safety and mechanical property of polystyrene composites. Compos. Part B Eng. 2020, 181, 107544. [Google Scholar] [CrossRef]

- Yang, W.; Tawiah, B.; Yu, C.; Qian, Y.-F.; Wang, L.-L.; Yuen, A.C.-Y.; Zhu, S.-E.; Hu, E.-Z.; Chen, T.B.-Y.; Yu, B. Manufacturing, mechanical and flame retardant properties of poly (lactic acid) biocomposites based on calcium magnesium phytate and carbon nanotubes. Compos. Part A Appl. Sci. Manuf. 2018, 110, 227–236. [Google Scholar] [CrossRef]

- Kanbur, Y.; Tayfun, U. Investigating mechanical, thermal, and flammability properties of thermoplastic polyurethane/carbon nanotube composites. J. Thermoplast. Compos. Mater. 2018, 31, 1661–1675. [Google Scholar] [CrossRef]

- Kabir, I.I.; Fu, Y.; de Souza, N.; Nazir, M.T.; Baena, J.C.; Yuen, A.C.Y.; Yeoh, G.H. Improved flame-retardant properties of polydimethylsiloxane/multi-walled carbon nanotube nanocomposites. J. Mater. Sci. 2020, 1–20. [Google Scholar] [CrossRef]

- Rahimi-Aghdam, T.; Shariatinia, Z.; Hakkarainen, M.; Haddadi-Asl, V. Polyacrylonitrile/N, P co-doped graphene quantum dots-layered double hydroxide nanocomposite: Flame retardant property, thermal stability and fire hazard. Eur. Polym. J. 2019, 120, 109256. [Google Scholar] [CrossRef]

- Kausar, A. Epoxy and quantum dots-based nanocomposites: Achievements and applications. Mater. Res. Innov. 2020, 24, 235–243. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, H.; Yang, K.; Yi, W. Effect of biochar on mechanical and flame retardant properties of wood–plastic composites. Results Phys. 2017, 7, 2391–2395. [Google Scholar] [CrossRef]

- Savi, P.; Josè, S.P.; Khan, A.; Giorcelli, M.; Tagliaferro, A. Biochar and Carbon Nanotubes as fillers in polymers: A comparison. In Proceedings of the 2017 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Pavia, Italy, 20–22 September 2017; pp. 1–3. [Google Scholar]

- Dasari, A.; Yu, Z.-Z.; Cai, G.-P.; Mai, Y.-W. Recent developments in the fire retardancy of polymeric materials. Prog. Polym. Sci. 2013, 38, 1357–1387. [Google Scholar] [CrossRef]

- Dasari, A.; Cai, G.-P.; Mai, Y.-W.; Yu, Z.-Z. Flame retardancy of polymer–clay nanocomposites. In Physical Properties and Applications of Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2010; pp. 347–403. [Google Scholar]

- Dewaghe, C.; Lew, C.; Claes, M.; Dubois, P. Fire-retardant applications of polymer–carbon nanotubes composites: Improved barrier effect and synergism. In Polymer–Carbon Nanotube Composites; Elsevier: Amsterdam, The Netherlands, 2011; pp. 718–745. [Google Scholar]

- Sajna, V.; Mohanty, S.; Nayak, S.K. A study on thermal degradation kinetics and flammability properties of poly (lactic acid)/banana fiber/nanoclay hybrid bionanocomposites. Polym. Compos. 2017, 38, 2067–2079. [Google Scholar] [CrossRef]

- Dashtizadeh, Z.; Abdan, K.; Jawaid, M.; Dashtizadeh, M. Thermal and Flammability Properties of Kenaf/Recycled Carbon Filled with Cardanol Hybrid Composites. Int. J. Polym. Sci. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- Shivamurthy, B.; Thimmappa, B.; Monteiro, J. Sliding wear, mechanical, flammability, and water intake properties of banana short fiber/Al (OH) 3/epoxy composites. J. Nat. Fibers 2020, 17, 337–345. [Google Scholar] [CrossRef]

- Zuhudi, N.Z.M.; Lin, R.J.; Jayaraman, K. Flammability, thermal and dynamic mechanical properties of bamboo–glass hybrid composites. J. Thermoplast. Compos. Mater. 2016, 29, 1210–1228. [Google Scholar] [CrossRef]

- Idumah, C.I.; Hassan, A.; Bourbigot, S. Influence of exfoliated graphene nanoplatelets on flame retardancy of kenaf flour polypropylene hybrid nanocomposites. J. Anal. Appl. Pyrolysis 2017, 123, 65–72. [Google Scholar] [CrossRef]

- Subasinghe, A.; Somashekar, A.A.; Bhattacharyya, D. Effects of wool fibre and other additives on the flammability and mechanical performance of polypropylene/kenaf composites. Compos. Part B Eng. 2018, 136, 168–176. [Google Scholar] [CrossRef]

- Chee, S.S.; Jawaid, M.; Alothman, O.Y.; Yahaya, R. Thermo-oxidative stability and flammability properties of bamboo/kenaf/nanoclay/epoxy hybrid nanocomposites. RSC Adv. 2020, 10, 21686–21697. [Google Scholar] [CrossRef]

- Ezeh, E.; Onukwuli, O.; Odera, R.; Ugonabo, V.; Okeke, O. Thermal Decomposition and Flame retardancy of Functional Polyester/Banana Peduncle fibre and Aluminum Hydroxide particle Hybrid Composites. Chem. Process. Eng. Res. 2020, 62. [Google Scholar] [CrossRef] [Green Version]

- Saba, N.; Jawaid, M.; Alrashed, M.M.; Alothman, O.Y. Oil palm waste based hybrid nanocomposites: Fire performance and structural analysis. J. Build. Eng. 2019, 25, 100829. [Google Scholar] [CrossRef]

| Fiber | Cellulose | Hemicellulose | Lignin | Pectin | Wax | Microfibrillar Angle | Ref. |

|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | (°) | ||

| Bast/Stem fiber | |||||||

| Flax | 64–81 | 14–20.6 | 2–5 | 0.9–2.3 | 1.7 | 5–10 | [53,55,56,57,58,59] |

| Hemp | 57–92 | 14–22.4 | 3.7–13 | 0.9 | 0.8 | 2–6.2 | [53,54,55,58,59,60,61] |

| Jute | 45–84 | 12–21 | 5–13 | 0.2 | 0.5 | 8 | [57,58,59,60] |

| Kenaf | 44–72 | 21–24 | 8–21 | 2–5 | - | 2–6.2 | [38,53,55,61] |

| Ramie | 68.6–76.2 | 5–16.7 | 0.6–1 | 1.9–2 | 0.3 | 7.5 | [53,56,57,58,59,60] |

| Banana | 60–65 | 6–19 | 5–10 | 3–5 | - | 11 | [53,58,62] |

| Nettle | 86 | 10 | 5.4 | 0.6 | 3.1–4 | - | [38,60,61,63] |

| Leaf fiber | |||||||

| Sisal | 43–78 | 10–24 | 4–13 | 0.8–2 | 2 | 10–22 | [53,55,57,58,60,62,64] |

| Curaua | 70.7–73.6 | 4–9.9 | 7.5–13.1 | - | - | - | [38,56,60,61] |

| Pineapple | 80–83 | 15–20 | 4.6–12 | 2–4 | 4–7 | 8–15 | [38,58,63,65] |

| Abaca | 56–64 | 21–25 | 7–13 | 0.8–1 | 3 | - | [56,58,60,62] |

| Henequen | 60–77.6 | 4–8 | 8–13.1 | - | 0.5 | - | [38,57,59,60] |

| Fruit/Seed fiber | |||||||

| Cotton | 82–96 | 2–6 | 0.5–1.6 | 0–7 | 0.6 | 20–30 | [38,55,58,60] |

| Coir | 36–46 | 0.15–0.3 | 41–45 | 3–4 | - | 30–49 | [53,55,56,58,66] |

| Oil palm | 65 | 0–29 | 19 | - | 4 | 46 | [38,56,60,62] |

| Wood | |||||||

| Hardwood | 43–47 | 25–35 | 16–24 | - | - | - | [38] |

| Softwood | 40–44 | 25–29 | 25–31 | - | - | - | [38,53] |

| Grass fiber | |||||||

| Bagasse | 32–55.2 | 16.8–21 | 19.9–25.3 | 10 | - | - | [56,60,63] |

| Bamboo | 26–43 | 15–30 | 21–31 | - | - | - | [53,56,58,60] |

| Rice | 28–57 | 33 | 8–19 | 8–38 | - | - | [56] |

| Wheat | 29–45 | 15–31 | 13–20 | - | - | - | [53,56,60] |

| Fiber | Density (g/cm3) | Tensile Strength (MPa) | E-Modulus (GPa) | Elongation at Break (%) | Ref. |

|---|---|---|---|---|---|

| Bast fiber | |||||

| Flax | 1.5 | 345–1100 | 27.6 | 0.2–3.2 | [50,56,57,60] |

| Hemp | 1.48 | 690 | 30–70 | 1.6–4 | [54,56,57,60] |

| Jute | 1.3–1.45 | 393–773 | 10.0–30.0 | 1.2–1.8 | [50,56,57,60] |

| Kenaf | - | 930 | 22.0–60.0 | 1.6 | [50,56,60] |

| Ramie | 1.5 | 400–938 | 44–128.0 | 1.2–3.8 | [50,57,59,61] |

| Leaf fiber | |||||

| Sisal | 1.5 | 468–640 | 9.4–22.0 | 3.0–7.0 | [56,57,59,67] |

| Curaua | 1.4 | 500–1150 | 9–11.8 | 3.7–7.5 | [50,56,60] |

| Pineapple | 1.5 | 413–1627 | 34.5–82.5 | 0.8–1.6 | [38,50,62,63] |

| Abaca | 1.5 | 400 | 12.0 | 3.0–10.0 | [50,56,60,61] |

| Fruit/Seed fiber | |||||

| Cotton | 1.5–1.6 | 287–800 | 5.5–12.6 | 7.0–8.0 | [50,59,60] |

| Coir | 1.2 | 131–175 | 4.0–6.0 | 15.0–40 | [50,56,59,60] |

| Oil palm | 0.7–1.55 | 248 | 3.2 | 25.0 | [50,56,60,61] |

| Grass fiber | |||||

| Bagasse | 1.25 | 290 | 11–17 | - | [50,56,60,62] |

| Bamboo | 0.6–1.1 | 140–441 | 11–17 | - | [50,55,56,60] |

| Synthetic fiber | |||||

| Aramid | 1.4 | 3000–3150 | 63.0–67.0 | 3.3–3.7 | [50,57,59] |

| Carbon | 1.7 | 4000 | 230–240 | 1.4–1.8 | [50,57,59] |

| E-glass | 2.5 | 2000–3500 | 70.0 | 2.5 | [55,57,59,62] |

| S-glass | 2.5 | 4570 | 86.0 | 2.8 | [50,57,59,62] |

| Advantages | Disadvantages |

|---|---|

| Biodegradability | High water absorption |

| Renewability | Limited processing temperature |

| Low density | Dimensional instability |

| High filling levels and non-abrasive to the molding machinery | Poor fire resistance |

| Easily colored | Lower strength and lower thermal resistance |

| Non-abrasive to processing equipment | Anisotropic behavior |

| Good thermal and acoustic insulating properties | Sensitive to UV, microbial and fungus attach |

| Friendly processing atmosphere, non-harmful gases generation, reduced thermal and respiratory irritations | The volatility of properties and price based on the location |

| Zero fingerprint CO2 | Incompatibility with most hydrophobic polymers |

| Low production energy | Poor fiber/matrix adhesion |

| Non-brittle fracture on impact | Lower strength, especially impact strength |

| Polymers | |

|---|---|

| Thermoplastics | Thermosets |

| Polylactic acid (PLA) | Epoxy |

| Poly butylene succinate (PBS) | Phenolic |

| Polyhydroxyalkanoate (PHA) | Polyester |

| Polyamide (PA) | Polyurethane (PU) |

| Polyethylene (PE) | Vinyl ester |

| Polycarbonate (PC) | Silicone |

| Polyvinyl chloride (PVC) | Melamine |

| Polystyrene (PS) | - |

| Polypropylene (PP) | - |

| Polyurethane (PU) | - |