3.1. Size of Ground Reflective Material

The albedo is the most influenced parameter by rear-side irradiance. The ground albedo under the PV module is influenced not only by the type, but also by the size and age of the material as well as the presence of dirt on the reflective material underneath the module [

21,

22].

The irradiance incident on a module’s rear surface in a shaded area is less influenced by the reflective material than that for a rear surface in a non-shaded area.

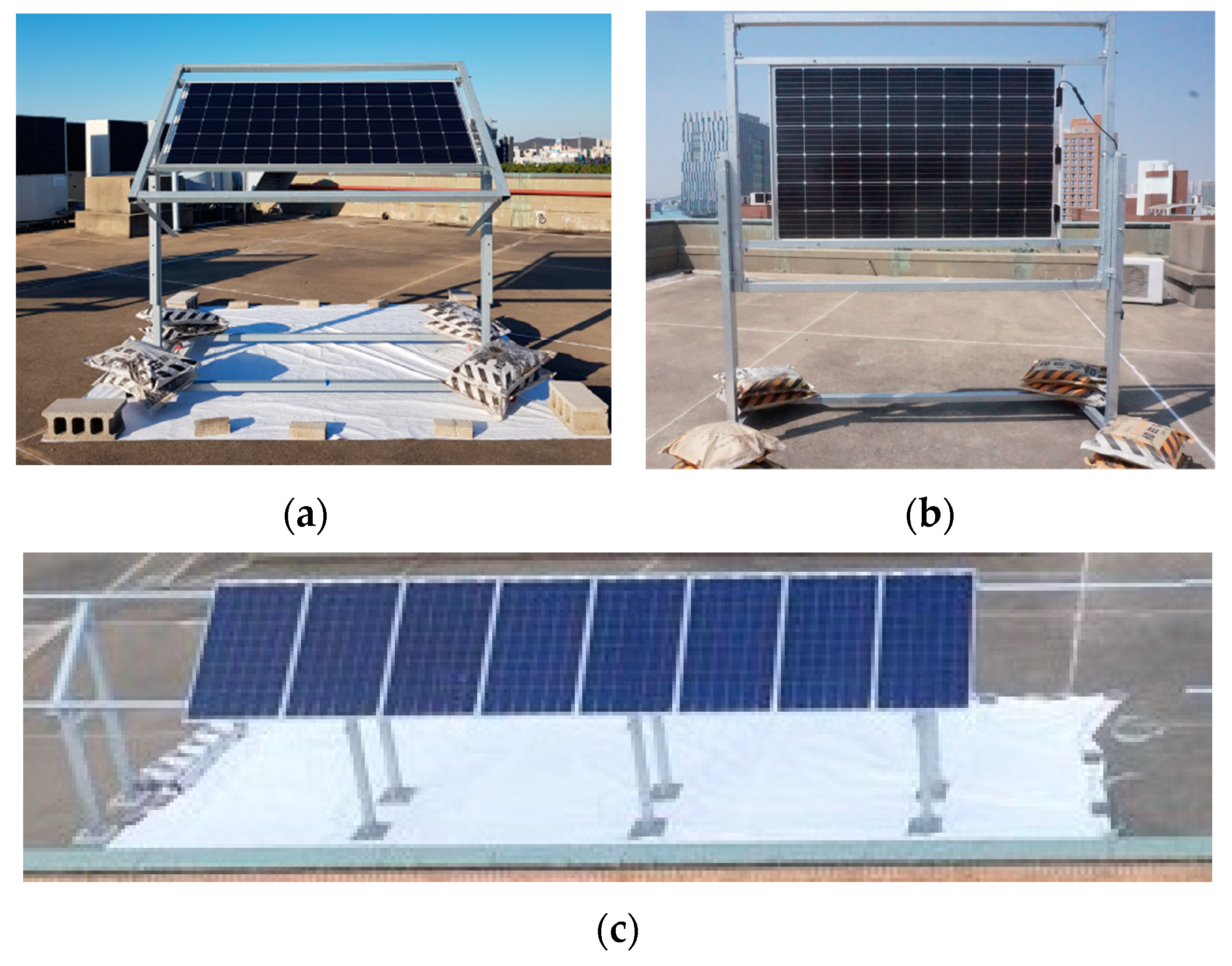

Figure 2 shows the size of the material for the two cases evaluated in this experiment. Testbed 1 is installed with a 37° tilt angle and a 0° (south) azimuth angle.

Figure 2 also shows the plan view of each case at Testbed 1 where the blue square represents the module and the gray square with gray diagonal lines represents the reflective material.

In Case 1, the size of the reflective material was set to match the boundary of the non-shaded area at noon during the winter solstice when the shadow produced by the module was at its largest. In Case 2, the size of the material was chosen to be twice as large as Case 1 to contain the shaded area. The albedo of the reflective material in each case was 55%.

Figure 3 shows the specific yield comparison for both Cases 1 and 2 based on the size of the reflective material. As depicted by the graph, we measured the output power of the bifacial PV module from 10:00 a.m. to 16:00 p.m. every 30 min. We also observed a deviation of the output power for the bifacial PV module. The performance of the bifacial module was higher in Case 2 than that in Case 1, even though Case 2 included the shaded area. The average deviation of the specific yield was 1.6%.

From these experiments, we confirmed that an increase in the size of the reflective material area increased the performance of the bifacial PV module. The rear-surface irradiance of the bifacial module was influenced not only by being at the underside of the PV module, but also by the surrounding area. This testbed was composed of only one module. Therefore, we found that the irradiance at the rear side was more affected by the surrounding area.

3.2. Vertical Installation of PV Module

The installation azimuth of the bifacial PV module was considered not only for the south-facing orientation, but also east-west orientation for the vertical installation setup.

We analyzed the output performance based on the bifaciality factor of the bifacial PV module. As indicated by the bifaciality factor, the efficiency of the bifacial PV modules on each side was different. However, the azimuth to be used for the front side must still needed be determined. Therefore, we divided the case into two conditions, as follows:

east (front)-west

west (front)-east

The albedo was 23% for each case and the bifaciality factor of the bifacial PV module was 82%.

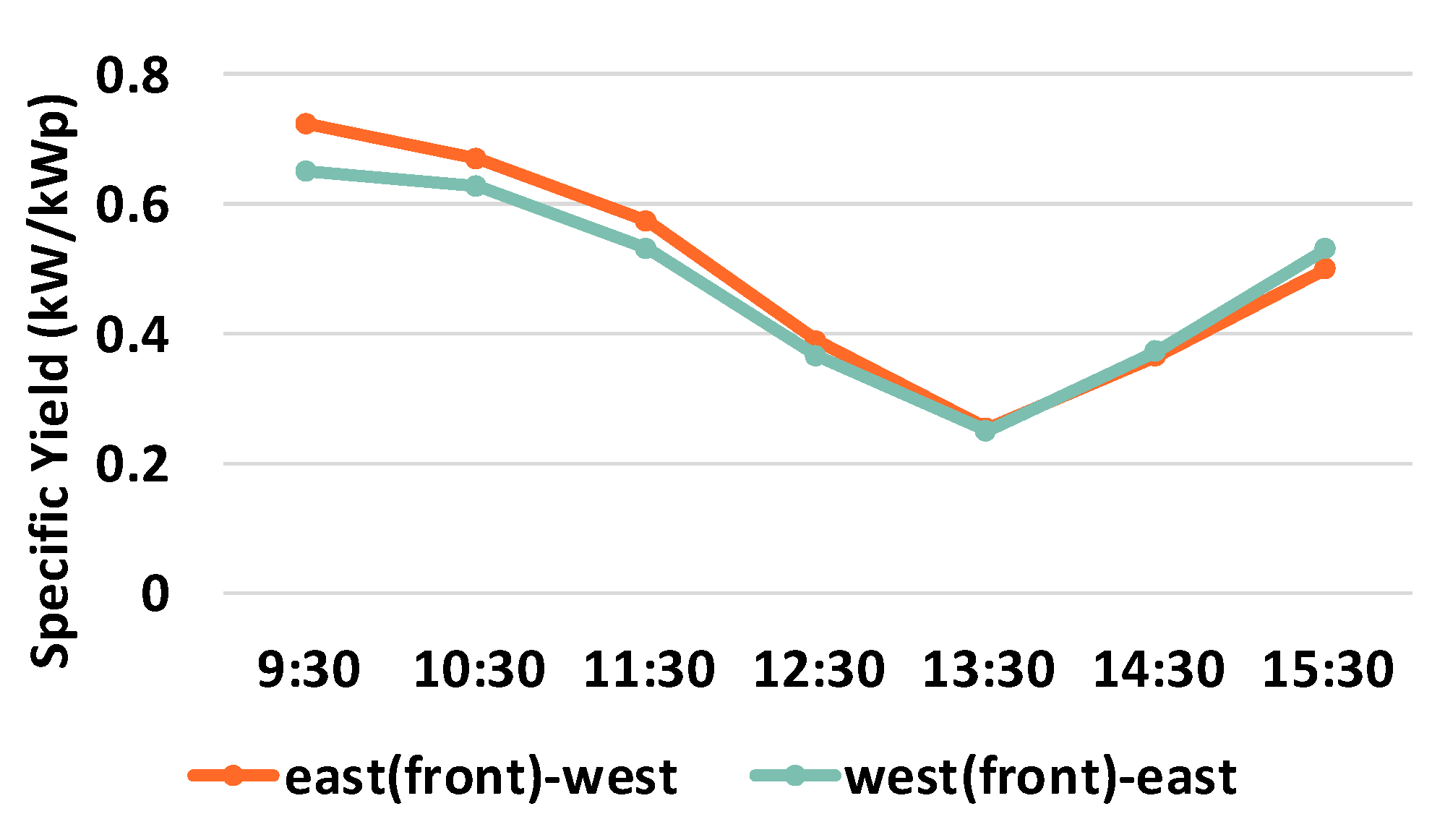

Figure 4 shows the specific yield based on the bifacial PV module’s azimuth angle relative to the front panel. The efficiency of the bifacial PV module was different for each surface, and the graph indicates this difference for each installation setup. The output performance of the module with the east (front)-west orientation demonstrated a high specific yield in the morning, whereas the output performance of the module with the west (front)-east orientation demonstrated a high specific yield in the afternoon.

Figure 5 shows the I–V curve for each orientation of the vertically installed bifacial PV module. The curves for the two conditions indicate a step I–V curve before and after 13:30 p.m. More specifically, the I–V curve for the module with the east (front)-west orientation shows a step curve at 14:30 p.m., whereas the I–V curve for the module with the west (front)-east orientation shows a step curve at 12:30 p.m.

A shadow was produced by the module structure, which led to power losses [

23].

Figure 6 shows the rear surface shading of the bifacial PV module corresponding to the I–V curves in

Figure 5. Here, we can observe the shadows produced on the rear side of the module. The I–V curve in

Figure 5a indicates a step curve due to a shadow created by the junction box and the module frame, as depicted in

Figure 6a. Similarly, the I–V curve in

Figure 5b shows a step curve due to the shadow produced by the module frame, as depicted in

Figure 6b. From

Figure 5 and

Figure 6, it is evident that shadows are produced on the rear surface of the bifacial PV module by the junction box and the module frame. This is because the junction box and module frame are not fully hidden in the rear surface of the module, resulting in the shadows observed on the rear surface due to the positioning of the module and the angle of the sun.

Table 6 shows the measured I–V curve data at 14:30 p.m. and 12:30 p.m. When we measured a PV module I–V curve in normal conditions, the maximum current was similar to the short-circuit current. Therefore, we compared the maximum current with the short-circuit current of the bifacial PV module at each orientation.

As presented in

Table 6, the maximum current was 14.0% lower than the short-circuit current for the module with the east (front)-west orientation at 14:30 p.m. However, the maximum current for the module with the west (front)-east orientation was 5.3% lower than the short-circuit current.

The maximum current was 4.8% lower than the short-circuit current for the module with the east (front)-west orientation at 12:30 p.m., whereas the maximum current for the module with the west (front)-east orientation was 14.5% lower than the short-circuit current.

To summarize, when a shadow was produced on the rear surface of the bifacial PV module, the maximum current was on average 14.3% lower than the short-circuit current. However, when a shadow was not produced on the rear surface of the bifacial PV module, the maximum current was on average 5.1% lower than the short-circuit current.

3.3. Mismatch in Module Temperature

Irradiance mismatch in a module can occur depending on the module installation, as well as its positioning within a row. The surface temperature of a module changes with irradiance [

24]. Therefore, we measured the surface temperature of the modules in the row to determine the module temperature mismatch.

Figure 7 shows the modules for which the temperature was measured. Because the mismatch of module temperature can differ depending on the location, we divided the measurements into the following two conditions.

We selected the module that was less affected by the module structure and considered the performance deviation according to the location in the row. Each experiment was performed based on the time when the sun’s azimuth angle coincided with the module installation’s azimuth angle (south-west 37°; summer 11:00 a.m.–15:00 p.m. and winter: 13:00 p.m.–17:00 p.m.).

Figure 8 shows the module surface temperatures for the summer and winter seasons.

is the azimuth of the sun’s position and

is the azimuth of the module’s position. The average deviation of the module surface temperature for Case 1 (neighboring modules) was 0.4 °C in the summer and 0.53 °C in the winter. The average deviation of the module surface temperatures for Case 2 (Distant modules) was 0.86 °C in the summer and 2.19 °C in the winter. Both cases reported a higher temperature deviation in the winter.

As shown in

Figure 8, the module temperature deviation of Case 1 was smaller than that of Case 2 for both the summer and winter seasons. This was a result of the modules being situated in a row of one line.

Figure 9 shows the shadow locus for each season. Before the sun’s azimuth angle coincided with the module installation’s azimuth angle, there was a shadow under module No. 8. After the alignment of the azimuth angles, the shadow was cast under module No. 2. The size of the shadow was different for each season and hour. This shadow reduced the irradiance on the rear surface of the module and a reduced irradiance resulted in a lower temperature for that module. Therefore, the module temperature mismatch was different depending on the location of the module. Furthermore, the deviation of the module temperatures was higher in the winter.

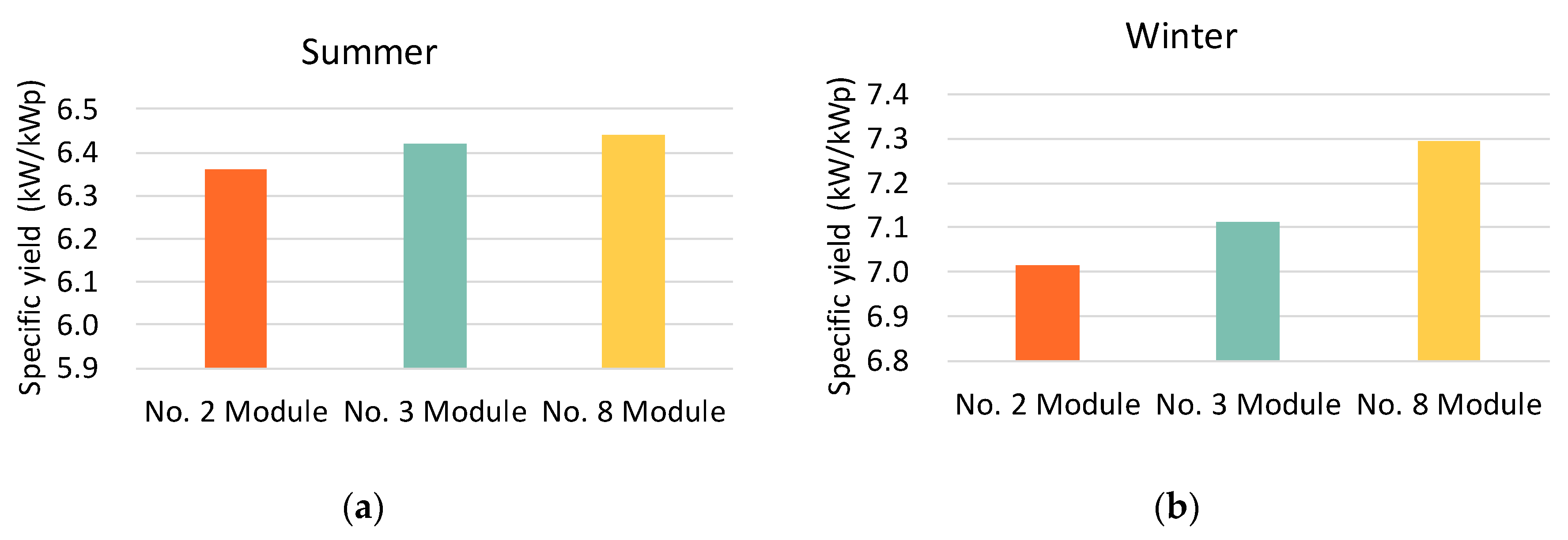

Figure 10 shows the daily specific yield comparison between the modules on two specific days, one in the summer and one in the winter. Module No. 8 achieved the highest energy yield among the three evaluated modules. The deviation of the daily energy yield for Case 1 (Neighboring modules) was 0.06 kW/kWp in the summer and 0.1 kW/kWp in the winter. The deviation of the daily energy yield for Case 2 (Distant modules) was 0.08 kW/kWp in the summer and 0.28 kW/kWp in the winter. A higher specific yield deviation was reported for both cases in the winter.

3.4. Effects of Particle Pollution

Nowadays, the concentration of particle pollution, also called particulate matter (PM), has been increasing in the Republic of Korea. PM is generally identified into two categories, PM 2.5 and PM 10, depending on the size of the particles. PM 2.5 and PM 10 are the particle pollution where the size of particles is smaller than 2.5 μm and 10 μm, respectively. PM reduces the direct irradiance and thus the global horizontal irradiance (GHI) received by a module surface [

24].

We analyzed the performance based on the diffuse irradiance factor. The diffuse irradiance factor (DIF) is the ratio of diffuse horizontal irradiance and GHI [

25], and is affected by the amount of clouds and the position of the sun. To reduce the effects of other factors, we added the following criteria:

Elevation of sun > 10°

Exclude rainy days

A clearness index (kt) was also applied and is divided into three categories, namely: clear, partly cloudy, and overcast [

26].

In this study, we distinguished between two cases according to the kt value in order to analyze the performance of the bifacial PV system based on the PM concentration under different sky conditions.

Clear sky

Overcast

We analyzed the output performance of the module using monitoring data from 1 January 2019 to 28 February 2019, a period in which the PM concentration was high. The k

t is calculated as inversely proportional to

GHI and extraterrestrial irradiance (

I0), and it is affected by the solar altitude angle (

β). The k

t is defined as following formula [

26].

Figure 11 shows the DIF based on the concentration of PM. As the concentration of PM increases, the DIF tends to increase. This is because the particles halt direct irradiance, but they distribute the irradiance in the air. The concentration of PM was obtained from a website supported by the Ministry of Environmental Sciences. Additionally, data regarding the GHI, DHI, and power of the bifacial PV module were measured using a data logger located in our university.

Table 7 shows DIF based on the concentration of PM at specific points. In clear sky conditions, when the concentration of PM 2.5 changed from 0 µg/m

3 to 150 µg/m

3, we observed that the DIF changed from 19.77% to 57.27%. Similarly, when the concentration of PM 10 changed from 0 µg/m

3 to 100 µg/m

3, we observed a change in DIF from 18.27% to 34.27%. The reason for this is that the PM 2.5 and PM 10 particles distributed the irradiance. As the concentration of PM 10 and PM 2.5 increased, the pollution particles produced more distribute irradiance [

25].

In overcast conditions, when the concentration of PM 2.5 changed from 0 µg/m3 to 150 µg/m3, we observed that the DIF changed from 95.7% to 101.7%. In contrast, when the concentration of PM 10 changed from 0 µg/m3 to 100 µg/m3, we observed a change in the DIF from 98.68% to 96.68%. These results indicate that DIF increased when the concentration of PM increased.

When the sky conditions were clear, the difference in the DIF due to the increase in concentration levels of PM 2.5 and PM 10 was 37.28% and 16%, respectively. Otherwise, when the sky conditions were overcast, the deviation of the DIF due to the increase in PM concentration levels was less than 6%. Furthermore, the DIF in the overcast conditions was observed to be over 90%, regardless of the concentration level and size of PM. These results indicate that when the PM concentration levels increased, clear sky conditions had a larger effect on the change in the DIF than overcast conditions, in which the change in the DIF was much less. The size of the particles for PM 2.5 and PM 10 was smaller than the size of the water vapor molecules in the clouds. Therefore, the effect of the water vapors on the DIF was observed to be larger than that of the PM.

Figure 12 and

Table 8 show the bifacial gain based on the concentration of PM. As the concentration of PM increased, the bifacial gain tended to increase. This is because the performance of the bifacial gain depends on the concentration of PM. A higher DIF resulted in a higher value for the irradiance, which reached the rear surface of the module, even though the direct irradiance was reduced.

In clear sky conditions, when the concentration of PM 2.5 changed from 0 µg/m3 to 150 µg/m3, we observed that the bifacial gain changed from 32.01% to 38.1%. When the concentration of PM 10 changed from 0 µg/m3 to 100 µg/m3, we observed that the bifacial gain changed from 31.03% to 35.03%.

In overcast conditions, when the concentration of PM 2.5 changed from 0 µg/m3 to 150 µg/m3, we observed that the bifacial gain changed from 50.16% to 50.91%. When the concentration of PM 10 changed from 0 µg/m3 to 100 µg/m3, we observed that the bifacial gain changed from 51.2% to 50.3%.

The deviation of the bifacial gain due to the increase in PM concentration levels for PM 2.5 and PM 10 was 6.09% and 4%, respectively, in clear sky conditions. In overcast conditions, the deviation of the bifacial gain due to the increase in PM concentration levels for PM 2.5 and PM 10 was 0.75% and −0.9%, respectively. A high DIF was observed in overcast conditions, regardless of the size of the particulate matter, whether PM 2.5 or PM 10. Therefore, a bifacial gain was also present regardless of the PM size.