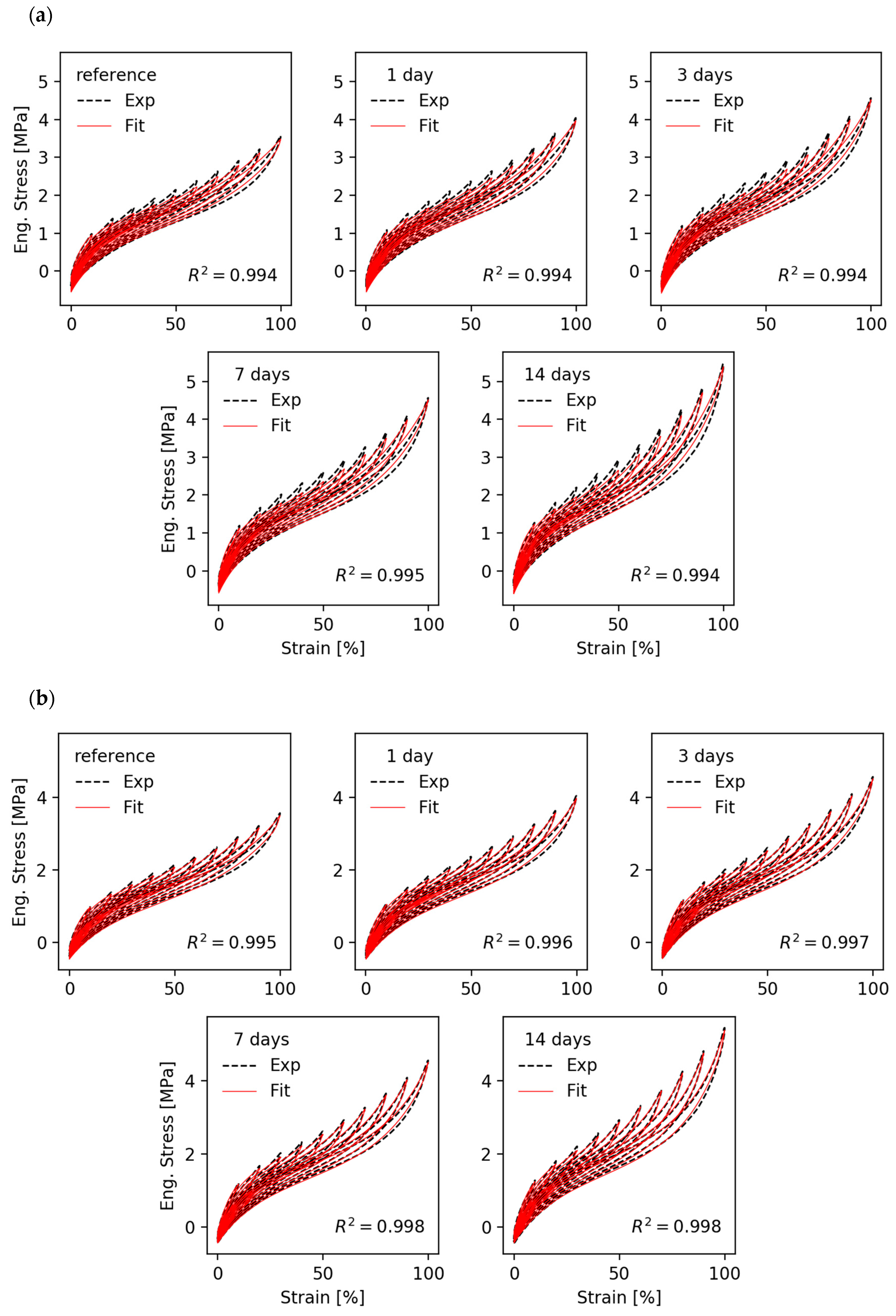

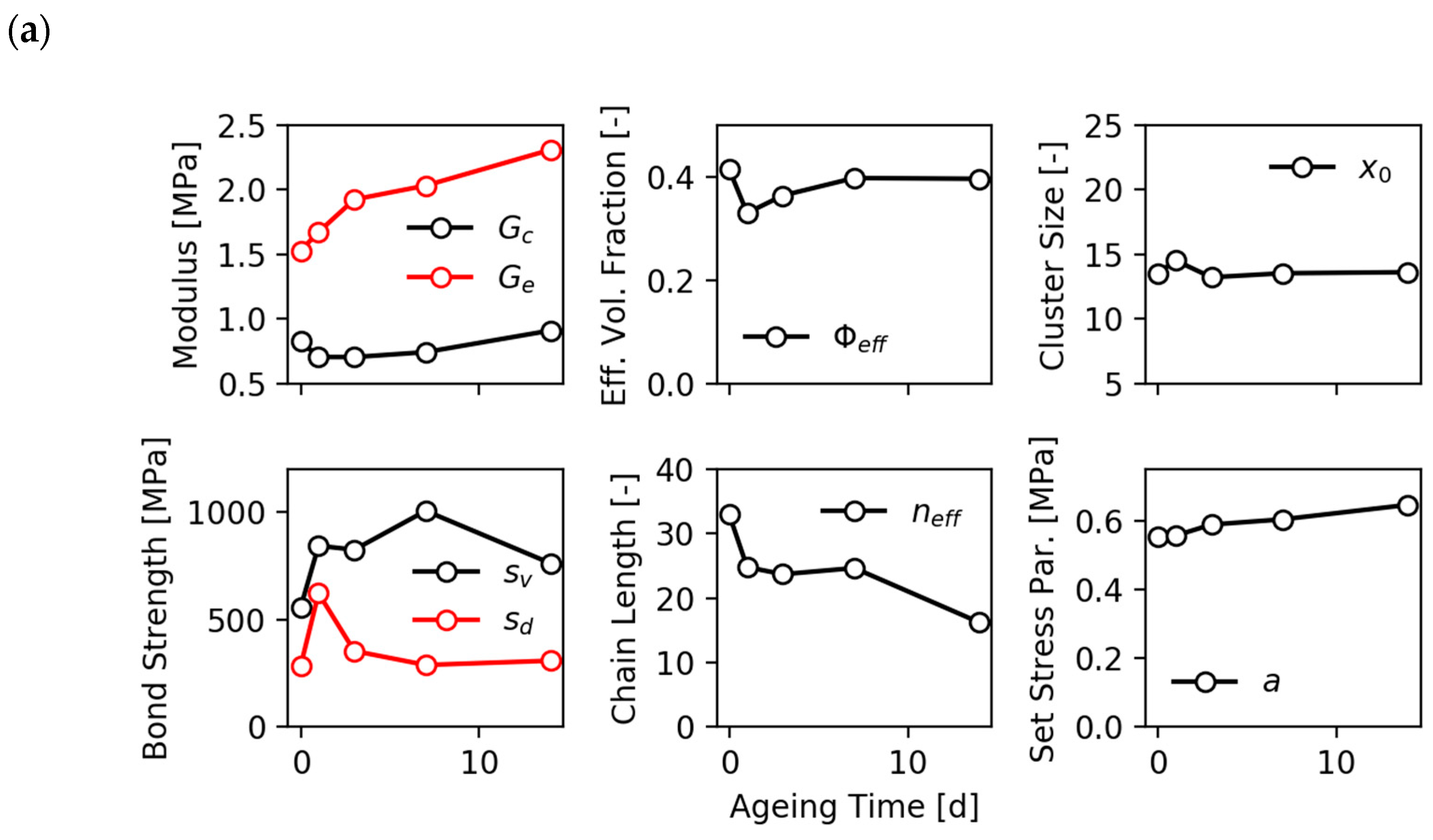

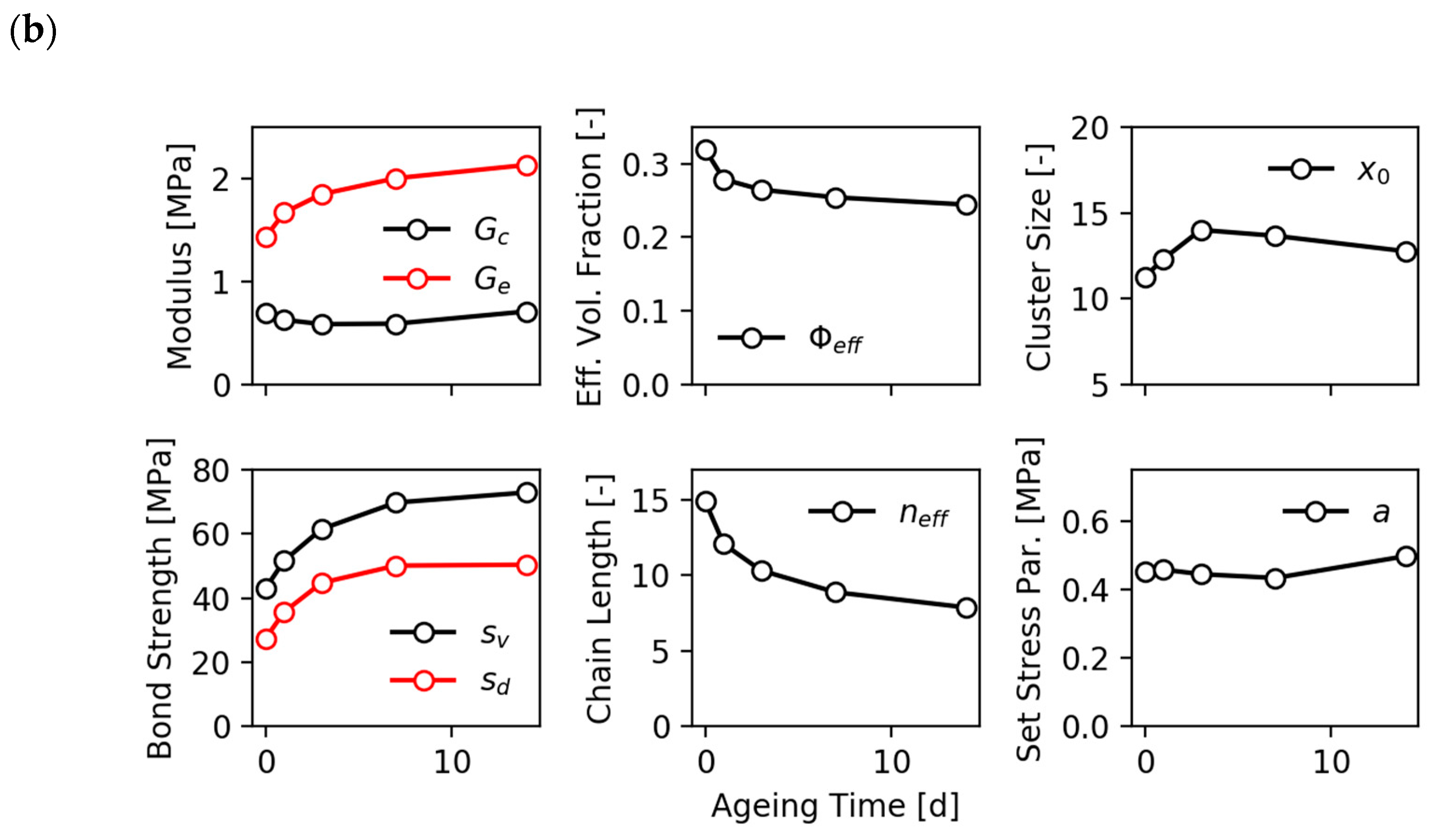

2.1. Basic Assumptions of the Dynamic Flocculation Model

The (microscopic) free energy density of the dynamic flocculation model (DFM) consists of two contributions, which are weighted by the effective filler volume fraction

:

The first addend is the equilibrium energy density stored in the extensively strained rubber matrix, which includes hydrodynamic amplification by a fraction of rigid filler clusters. The second addend considers the energy stored in the strained soft filler clusters and is responsible for the filler-induced hysteresis. The symbol

is defined in this work as the macroscopic strain in direction

. The rubber elastic part is modeled by the free energy density of the extended non-affine tube model [

12,

28]:

with

being the number of statistical chain segments between neighboring entanglements and

is the trapping factor

) characterizing the fraction of elastically active entanglements. We define

to be the microscopic strain ratio (or stretch) on the nanoscale in direction

. Thus, for unfilled rubbers the usual relation

holds. The first addend in Equation (2) considers the constraints due to interchain junctions, with an elastic modulus

proportional to the density of network junctions. The second addend considers topological constraints in densely packed polymer networks, whereby

is proportional to the entanglement density of the rubber. The parenthetical expression in the first addend considers the finite chain extensibility of polymer networks by referring to an approach of Edwards and Vilgis [

29]. For the limiting case

a singularity is obtained for the free energy density

, indicating the maximum extensibility of the network. This is reached when the chains between successive trapped entanglements are fully stretched out. In the limit

the original Gaussian formulation of the non-affine tube model, derived by Heinrich et al. [

30] for infinite long chains, is recovered.

The presence of tightly bonded (virgin bonds) rigid filler clusters gives rise to hydrodynamic reinforcement of the rubber matrix. This is specified by the strain amplification factor

as proposed by Mullins and Tobin [

6], which relates the external, macroscopic strain

of the sample to the internal, microscopic strain ratio

of the rubber matrix,

. For strain amplified rubbers this strain has to be used in the free energy density Equation (2). The microscopic stress of the rubber matrix is then obtained by differentiation with respect to the internal strain

:

This is the microscopic stress between the filler clusters that can be identified with the macroscopically measured engineering stress (1. PK stress) in equilibrium. For uniaxial deformations (

and

) we obtain for the engineering stress in stretching direction:

In the case of a preconditioned sample and for strains smaller than the previous straining

, the materials microscopic structure is already adjusted to the maximum load and the strain amplification factor

is independent of strain. In that case it is determined by

(

. We relate this to the irreversible fracture of filler clusters (see below). A relation for the strain amplification factor of overlapping fractal clusters of size

was derived by Huber and Vilgis [

31]. By using path integral methods they found

where

is the filler volume fraction and

is a constant of order one. With this,

can be evaluated by averaging over the size distribution of hard clusters in all space directions. In the case of preconditioned samples this yields:

Here,

is the particle size,

is the cluster size in spatial direction

and

is the minimum cluster size which will be calculated later on. The fractal exponents are determined as

for the mass fractal dimension and

for the anomalous diffusion exponent of CCA-clusters [

2]. Note that the effective filler volume fraction

is used in Equations (1) and (5), which considers the effective volume of the rigid phase of structured filler particles, e.g., carbon black or silica, according to the “occluded rubber concept” of Medalia [

32]. Occluded rubber is defined as the rubber part of the rubber matrix that penetrates into the voids of the particles, which partially shields it from deformation. The second addend of Equation (5) takes into account that also fully broken clusters contribute to the strain amplification factor by the remaining particles.

is the normalized cluster size distribution:

This is a peaked cluster size distribution with

being the ensemble average in spatial direction

. It is motivated by analytical results referring to Smoluchowski’s equation for the kinetics of cluster–cluster aggregation of colloids [

33,

34,

35] (comp. also [

7]). In the undeformed state it is assumed to be isotropic, i.e.,

.

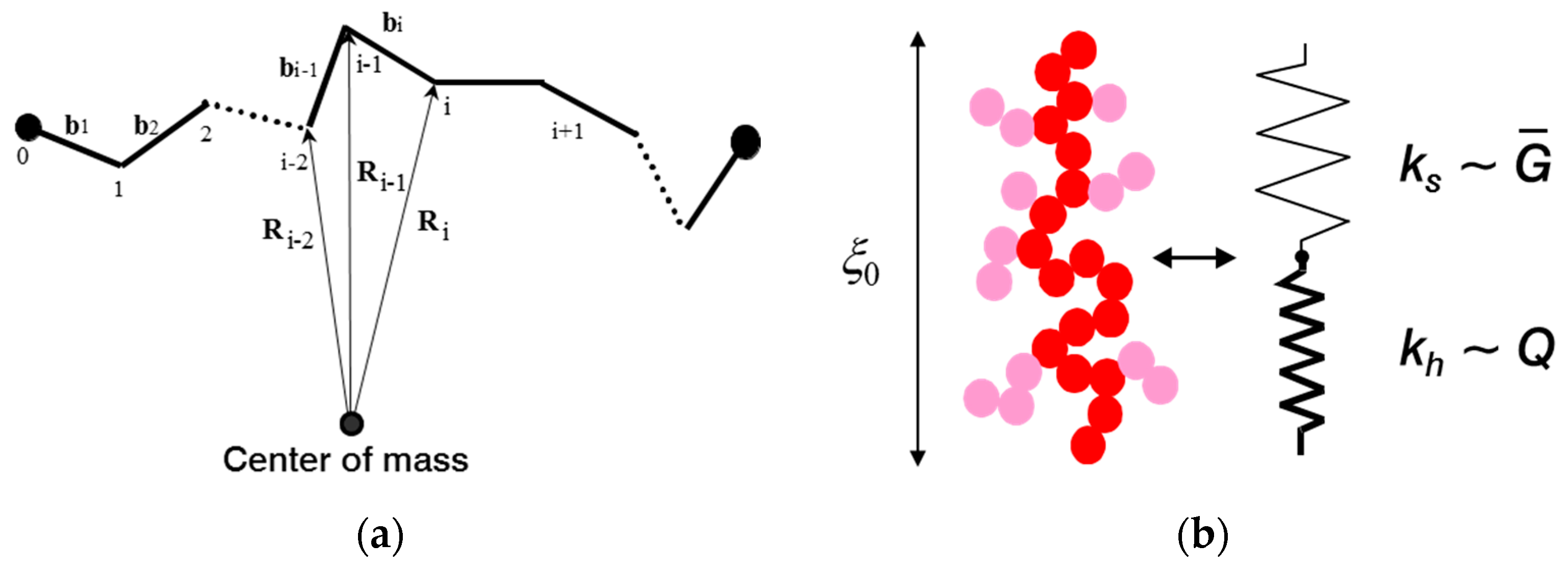

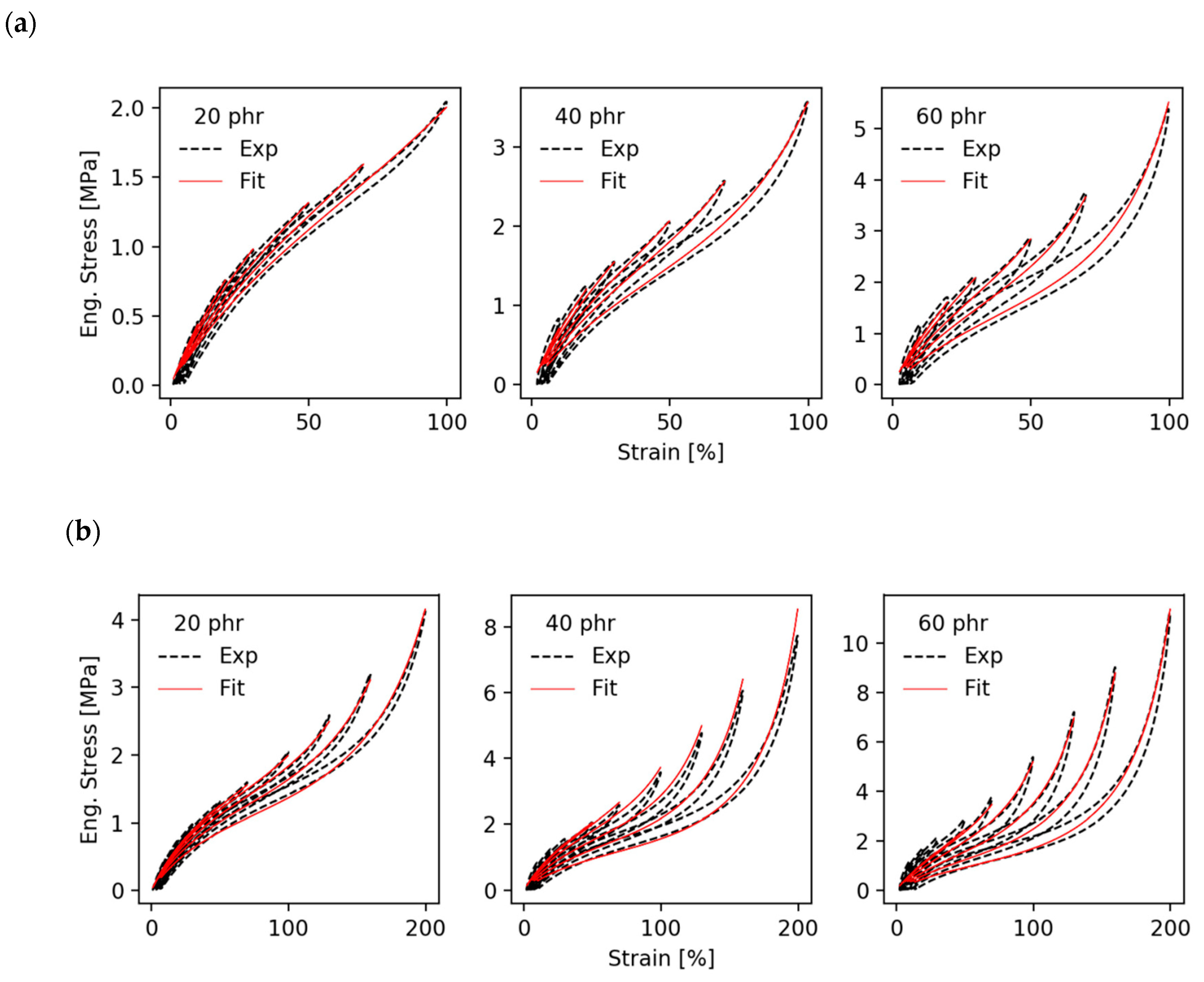

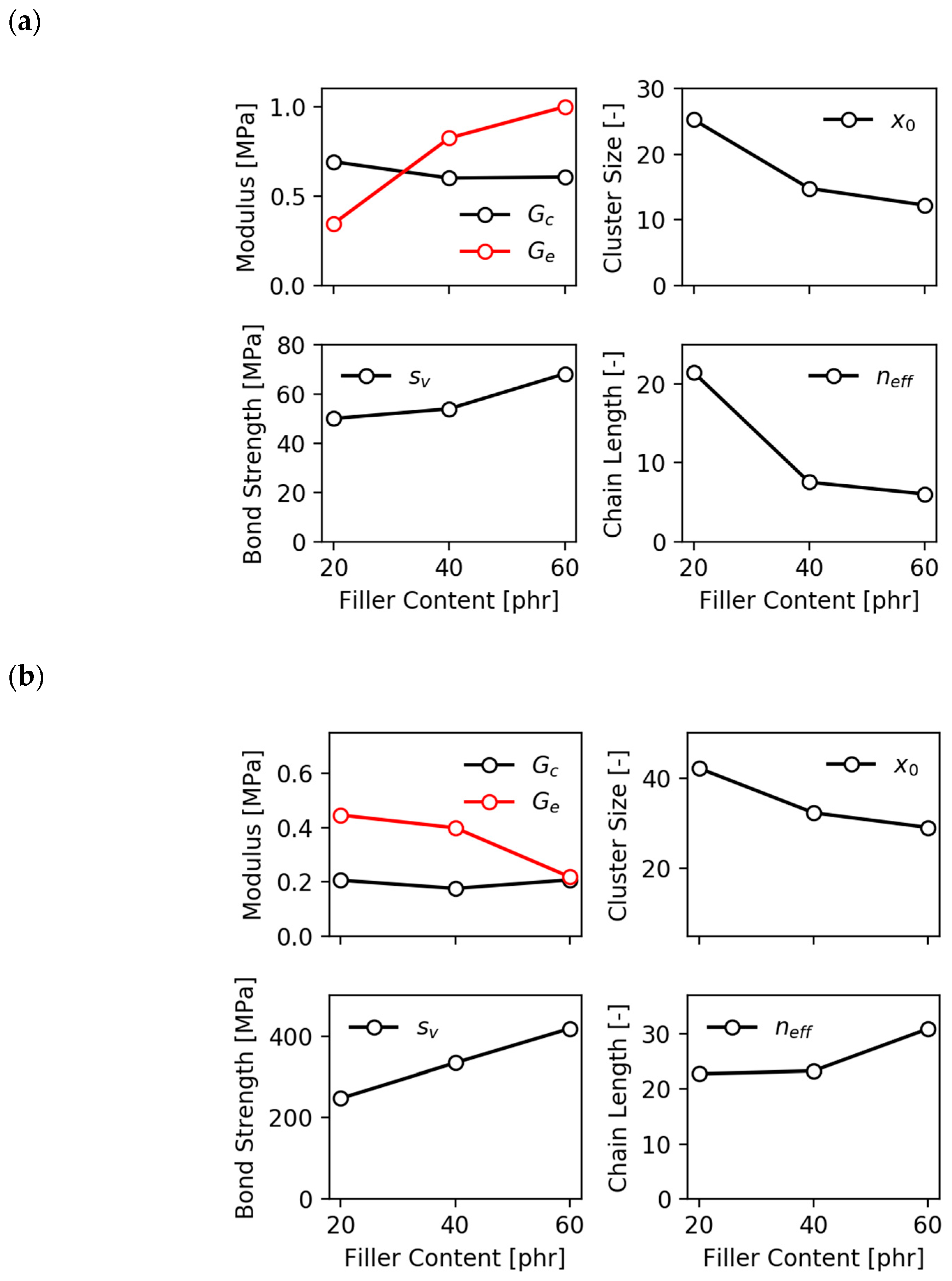

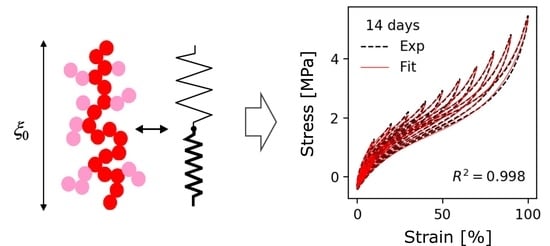

The model of stress softening and hysteresis assumes that the breakdown of filler clusters during the first deformation of the virgin samples is reversible, though the initial virgin state of filler–filler bonds is not recovered. This implies that, on the one side, the fraction of hard (virgin) filler clusters decreases with increasing pre-strain, leading to pronounced stress softening after the first deformation cycle. On the other side, the fraction of soft (reaggregated) filler clusters increases with rising pre-strain, which affects the filler-induced hysteresis. A schematic view of the decomposition of filler clusters in hard and soft units for preconditioned samples is shown in

Figure 1.

The second addend of Equation (1) describes the filler-induced hysteresis. It considers the energy stored in the substantially strained soft filler clusters, which break under stress and reaggregate on retraction

is the elastic modulus and is the strain of the fragile filler clusters in spatial direction . These quantities and their dependence on cluster size and external strain will be specified in the next sections. In addition. The integral boundaries of Equations (5) and (7) have to be described more closely, which requires the consideration of elasticity and fracture of filler clusters in stretched elastomers.

2.2. Elasticity and Fracture of Filler Clusters in Stretched Elastomers

For consideration of filler network breakdown in stretched rubbers, the elasticity and failure properties of tender filler clusters have to be evaluated in dependence of cluster size. This will be obtained by referring to the two-dimensional Kantor–Webman model of flexible chains of arbitrary connected filler particles [

11] as represented in

Figure 2a. We apply here a simplified generalization of this model to three dimensions, where on-plane bending, and off-plain twisting deformations of bonds are considered by a single bending–twisting term [

20]. By identifying the three-dimensional flexible chain with the backbone of a CCA-cluster, the model can be applied for modeling the small-strain modulus of fractal filler networks, consisting of a space-filling configuration of CCA-clusters [

7,

8,

9,

10]. Here, we use it for a micromechanical description of CCA-clusters that are deformed in the stress field of a strained rubber matrix. Note that this is possible because the CCA-cluster backbone is not branched on large length scales, which is a typical result of cluster–cluster aggregation.

In our model two kinds of deformations of filler–filler bonds are considered, bending–twisting- and tension deformations. This corresponds to a mechanical equivalence between a filler cluster and a series of two molecular springs depicted schematically in

Figure 2b. We will see that the bending–twisting deformation governs the elasticity while the tension deformation is sensitive for fracture. The total force constant of a cluster of size

0 with

NB particles in the backbone reads:

with the tension part given by:

The bending–twisting part reads:

Here, is the bond length (particle size), is the force and is the average projection of bond vectors on the direction of the force (). is the average squared radius of gyration in direction perpendicular to the force and includes a unit vector pointing perpendicular to the connecting vector . It scales with the squared cluster size, , with a scaling factor . and are elastic constants due to bending–twisting—and tension deformations, respectively. For the particle number the scaling relation was used with being the backbone fractal dimension of CCA-clusters.

By comparing the exponents of Equations (9) and (10) one finds that the force constant

decreases much more rapidly with cluster size

than the force constants

. Accordingly, Equation (8) implies

for sufficient large clusters, i.e., the stiffness of the cluster is determined by the bending–twisting deformations of bonds. This determines the following scaling law for the elastic modulus entering Equation (7):

This approximation without the tension term can be applied for sufficient large clusters with . For the evaluation of the scaling factor in Equation (11) we have to consider the ensemble average of clusters. However, this will not be considered here, because we are mainly interested in the scaling exponents.

The stretching of the clusters can be evaluated in the same approximation [

7]:

Here, we have introduced the stretching and force constant related to stretching of the single bonds. In addition. we used the equilibrium conditions for the force and . In the next section we will use Equation (12) for describing the fracture of filler clusters by relating it to the fracture of bonds under tension.

Examples:

The cluster mechanics described by Equations (8)–(10) shall be illustrated by two simple examples which are depicted in

Figure 3. In

Figure 3a a linear chain is considered with the force

pointing perpendicular or alternatively in direction of the chain. In the first case we have

and

points into the direction of the chain. This implies for the force constant and the deformation:

With being the ratio between the squared radius of gyration and the squared length of a linear chain. Accordingly, the force constants drops with the 3rd power of the length.

In the second case, where

points parallel to the chain, we have

and

points perpendicular to the chain. This implies

yielding:

As expected, the deformation increases linear with the number of bonds.

In

Figure 3b we consider the case where a random walk structure of the chain is realized, corresponding to three 1-dimensional random walks with

particles. The average projection

is then given by

= 1/3. The ratio between the ensemble average of the squared radius of gyration

and the squared end-to-end distance

is evaluated as

(see e.g., Chapter 2 in [

36]). This implies for the force constant:

For the deformation under tension of the 1-dimensional random walk shown in

Figure 3b one obtains:

For the more general case that the force points in arbitrary direction also the bending–twisting deformations of bonds must be taken into account by referring to the full force constant of Equation (15).

2.3. Evaluation of Boundary Cluster Size and Cluster Stress

In view of introducing a fracture criterion for strained clusters, we assume that the tension of bonds is a much more critical deformation compared to bending and twisting, since it separates the filler particles from each other. Equation (12) relates the total stretching of a cluster to the stretching of the bonds and can therefore be used for evaluation of the failure strain of the cluster by defining a fracture criterion for the bonds. We will introduce here two different fracture criteria, which will be denoted “monodisperse” and “hierarchical”.

In the first approach all bonds are considered to be equal (monodisperse) having the same strength. Then, the failure strain

of the bonds is given by the critical stretch of the bonds

in relation to the bond length:

. This implies for the failure strain of the cluster:

In contrast, the hierarchical model takes into account that a hierarchy of bond strengths develops during cluster–cluster aggregation, because the mobility of the clusters decreases with cluster size. Accordingly, the first bond formed between two particles is the strongest while successive bonds formed between the growing sub-clusters become weaker and weaker. The last bond formed in the cluster is the weakest and will break first under tension. This effect is taken into account by the hierarchical fracture criterion, where the failure strain

of the bonds is defined in relation to the cluster size, which is the only relevant length scale in our model:

. This implies that the failure strain of the cluster increases more rapidly with cluster size compared to the monodisperse case:

For the evaluation of the boundary cluster size between broken and unbroken clusters in stretched rubbers, we assume that a stress equilibrium is realized between the strain amplified rubber matrix and the clusters

. With the scaling relation Equation (11) for the elastic modulus of the clusters this delivers for the cluster strain:

Here we have replaced the rubber stress by a relative stress with respect to the minimum strain:

This ensures that the stretching of clusters in spatial direction starts at the minimum strain for each cycle. Here, we assume that clusters reaggregate into a stress-free state at minimum strain.

A comparison of the exponents in Equations (18) and (17) makes clear that the strain of the clusters under external strain increases faster with cluster size than the failure strain, in both cases. This implies that large clusters break first followed by smaller ones, i.e., the boundary cluster size between broken and unbroken clusters

moves from larger to smaller values with increasing strain. It is obtained by equating the cluster strain to the failure strain. This yields for the two fracture criteria:

Here, is defines as the fracture stress under tension of bonds, i.e., the tensile strength of damaged filler–filler bonds. The boundary cluster size applies for the integral boundaries of Equation (7), describing the filler-induced hysteresis due to the successive breakdown of soft filler clusters with damaged filler–filler bonds.

Similar expressions are found for the upper boundary of Equation (5), but now the tensile strength

of virgin filler–filler bonds is entering:

The elastic constant and failure strains are denoted by and , respectively. Note that the tensile strength of virgin filler–filler bonds must be larger than the tensile strength of damaged bonds, i.e., . Equation (21a) or (21b) together with Equation (5) define the amplification of the rubber matrix, and thus stress—softening effects of the model. Solving this set of equations for σ requires iterative methods, e.g., Newton iteration.

By referring to the stress equilibrium between the strain amplified rubber matrix and the clusters,

, the cluster stress

responsible for filler-induced hysteresis is obtained by differentiation of Equation (7) with respect to cluster strain:

The exponent

takes the two fracture criteria into account, i.e.,

for the “monodisperse” model and

for the “hierarchical” model. In addition. we assume that the clusters, on average, deform like the sample:

The sum in Equation (22) runs over stretching directions, only, implying that the up- and down cycles are different. The cluster stress of the upcycle is positive while the downcycle gives a negative contribution, producing the filler-induced hysteresis.

For uniaxial deformations, realized on microscales

;

) and macroscales

;

, the cluster stress in stretching direction for the upcycle (

) is obtained as:

For the down cycle, the lateral directions contribute to the cluster stress (

/∂

t > 0;

/∂

t > 0):

With

. This gives a negative stress contribution, which must be subtracted from the rubber stress. It can also be expressed by the rubber stress

in stretching direction. By assuming that the same energy is needed for stretching in 1-direction and compressing in 2- and 3-direction to obtain a final deformed state, the following relation is derived:

Finally, for the evaluation of the (measured) total stress we have to consider an additional set stress

that appears as a remaining stress in the undeformed state after stretching and retraction. Note that this is also found for unfilled rubbers and depends on temperature and stretching rate. It probably results from long time relaxation effects of the polymer network. We introduce it in a purely empirical manner for the case of uniaxial deformations:

Then for uniaxial deformations the total stress reads:

The stress of the rubber matrix

is given by Equation (4) with

and strain amplification factor

specified by Equation (5). The cluster stress

depends on the direction of straining and is determined by Equations (24) and (25) for up and down, respectively. The theory presented here describes the complex quasi-static deformation behavior of filler reinforced elastomers for repeated stretching with increasing amplitude. A more general formulation of the DFM that applies for arbitrary deformation histories requires an additional term for the free energy density of soft filler clusters Equation (7), which considers the relaxation of cluster stress upon retraction [

15,

16]. For a test of the theory the present formulation for repeated stretching with increasing amplitude is sufficient because all open parameters are entering already and the extension to arbitrary deformation histories requires no additional fitting parameters.

2.4. Frame-Independent Formulation of Stress-Softening for Fast FEM Simulations

The implementation of the DFM into a FEM algorithm faces several problems. First, the DFM is a microscopic theory, where stresses are calculated by differentiation of the free energy density with respect to the internal strain variables

and

, respectively. This is in discrepancy to continuum mechanical considerations, where corresponding differentiations have to be performed with respect to external strain variables. Second, the DFM is formulated in the main axis system and requires stress contributions of different directions, especially for description of filler-induced hysteresis, which all sum up to produce close cycles. This can hardly be transferred to a pure tensorial formulation. Nevertheless, a FEM implementation of the DFM was obtained by referring to the concept of representative directions, which considers uniaxial deformations along fibers in different spatial directions [

24,

25]. However, the computational cost of this workaround is very large, and the efficiency is low. Therefore, we want to focus here on a frame-independent tensor formulation of the stress-softening part of the DFM for fast and efficient FEM simulations.

In a first step we put the strain amplification factor

in front of the deformation invariants, appearing in the free energy density of the extended non-affine tube model Equation (2) and replace the internal strain

by the external strain

. This follows the ideas of Einstein [

37] and Domurath et al. [

38] and is done in close correlation to the evaluations in [

22]. The free energy density reads:

with the (frame-independent) first invariant of the left Cauchy–Green tensor:

and the (frame-independent) generalized invariant:

Here,

is the external strain of the sample. A frame-independent formulation of the strain amplification factor

is obtained similar to Equation (5) by replacing the relative stress

used for the calculation of the boundary cluster size

by the Frobenius norm

of the engineering stress.

The iteration procedure for the evaluation of stresses (compare Equation (21a) or (21b) together with Equation (5)) is then replaced by its tensorial analog:

The free energy density Equation (29) can be used in a standard continuum mechanical sense for the evaluation of stresses and tangent vectors. It can be further simplified by omitting the logarithmic term, which gives a minor contribution to the stress upturn. In addition. The generalized invariant can be approximated by the square root of the second invariant, which avoids the calculation of eigenvalues [

39].