Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions

Abstract

:1. Introduction

2. Rockburst in a SIETCS

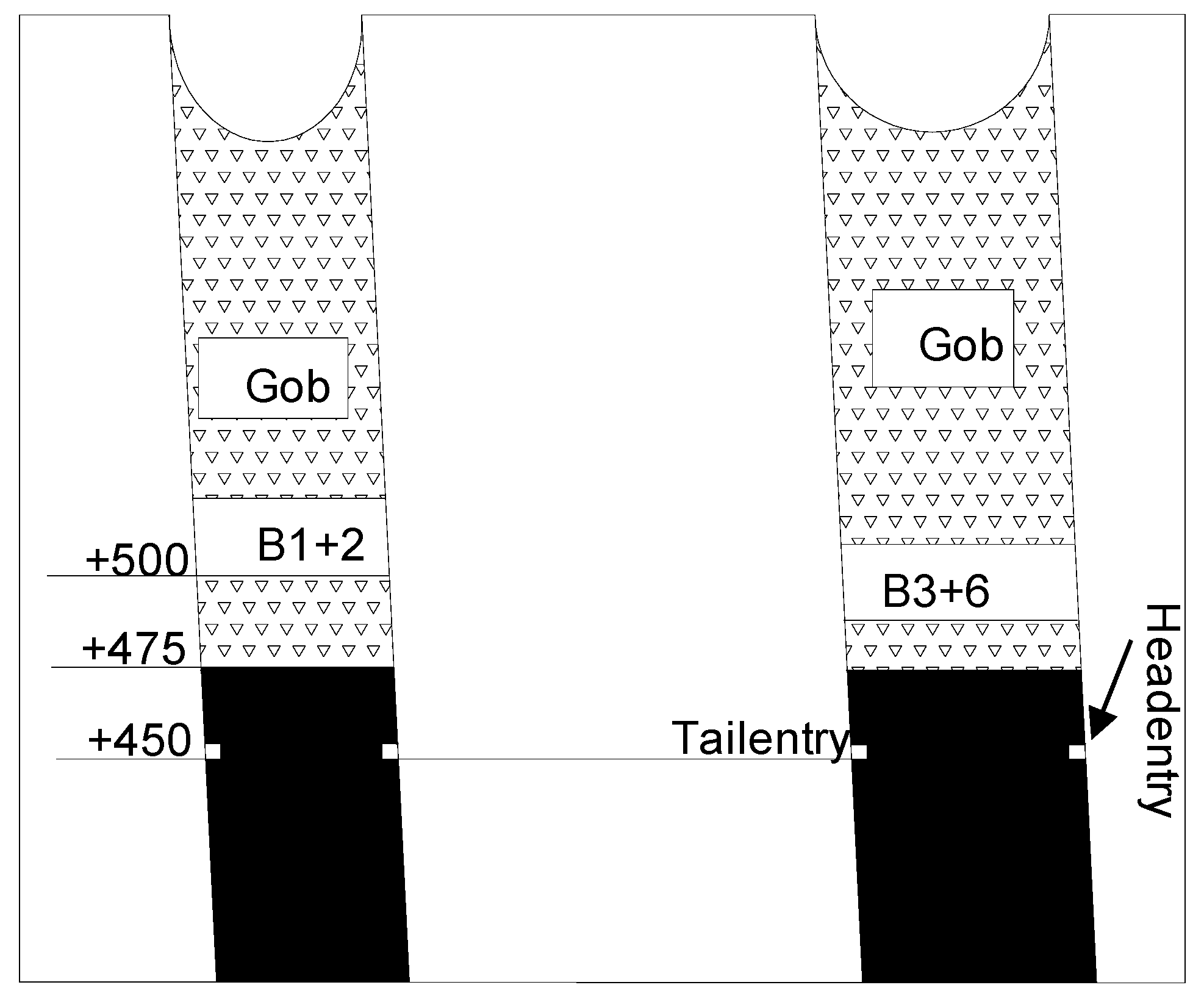

2.1. Basic Conditions of the Coal Seam

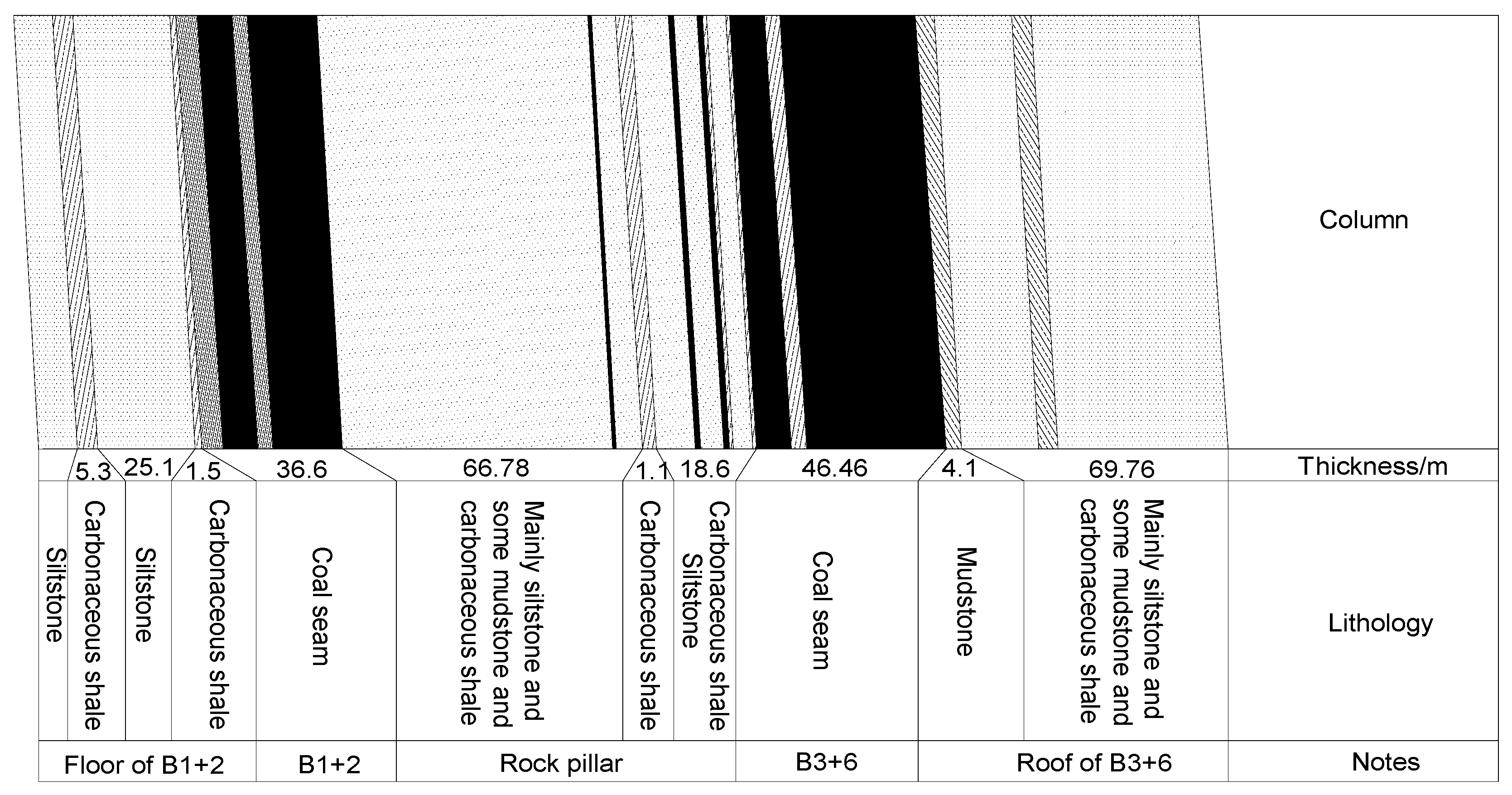

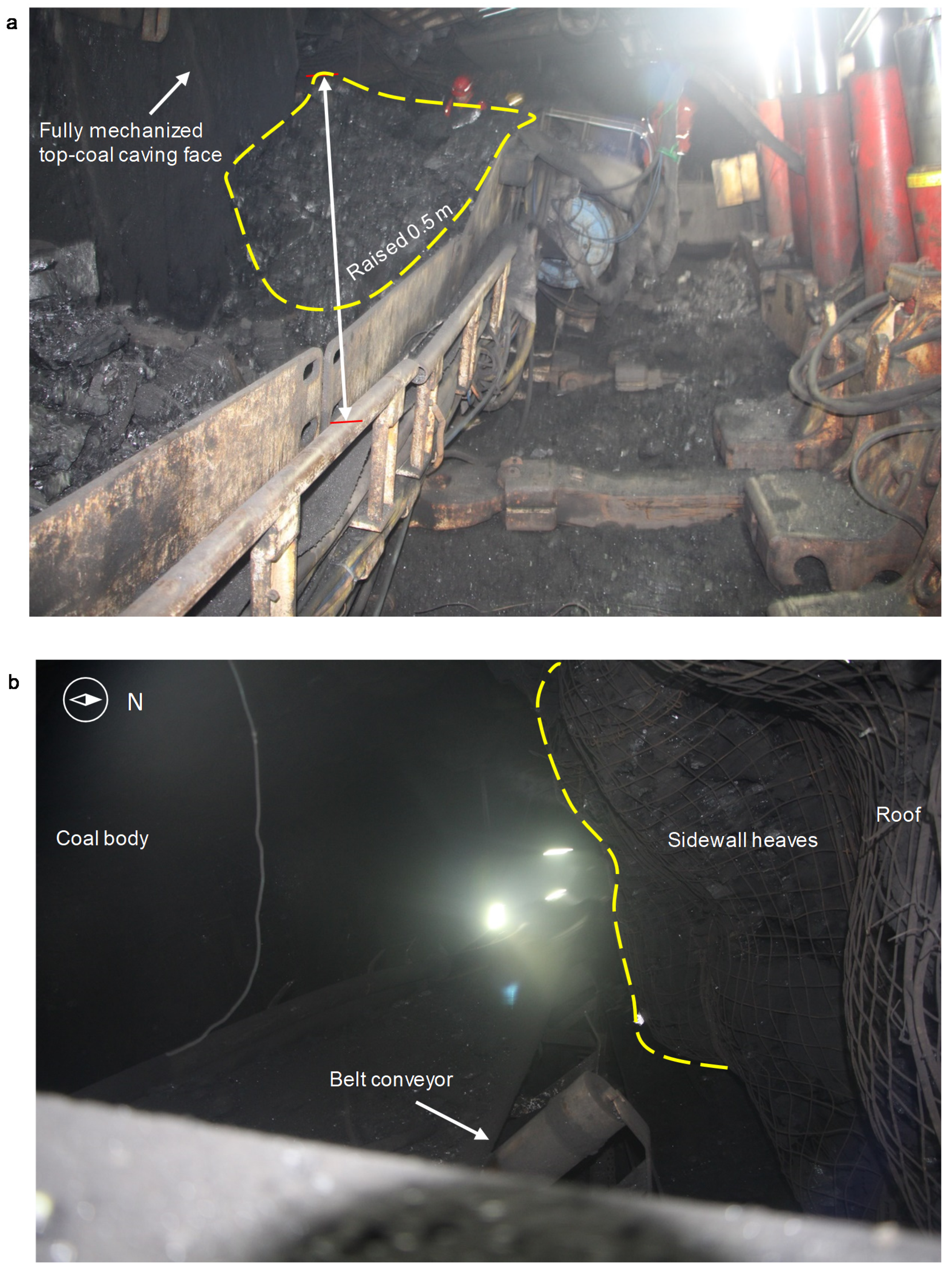

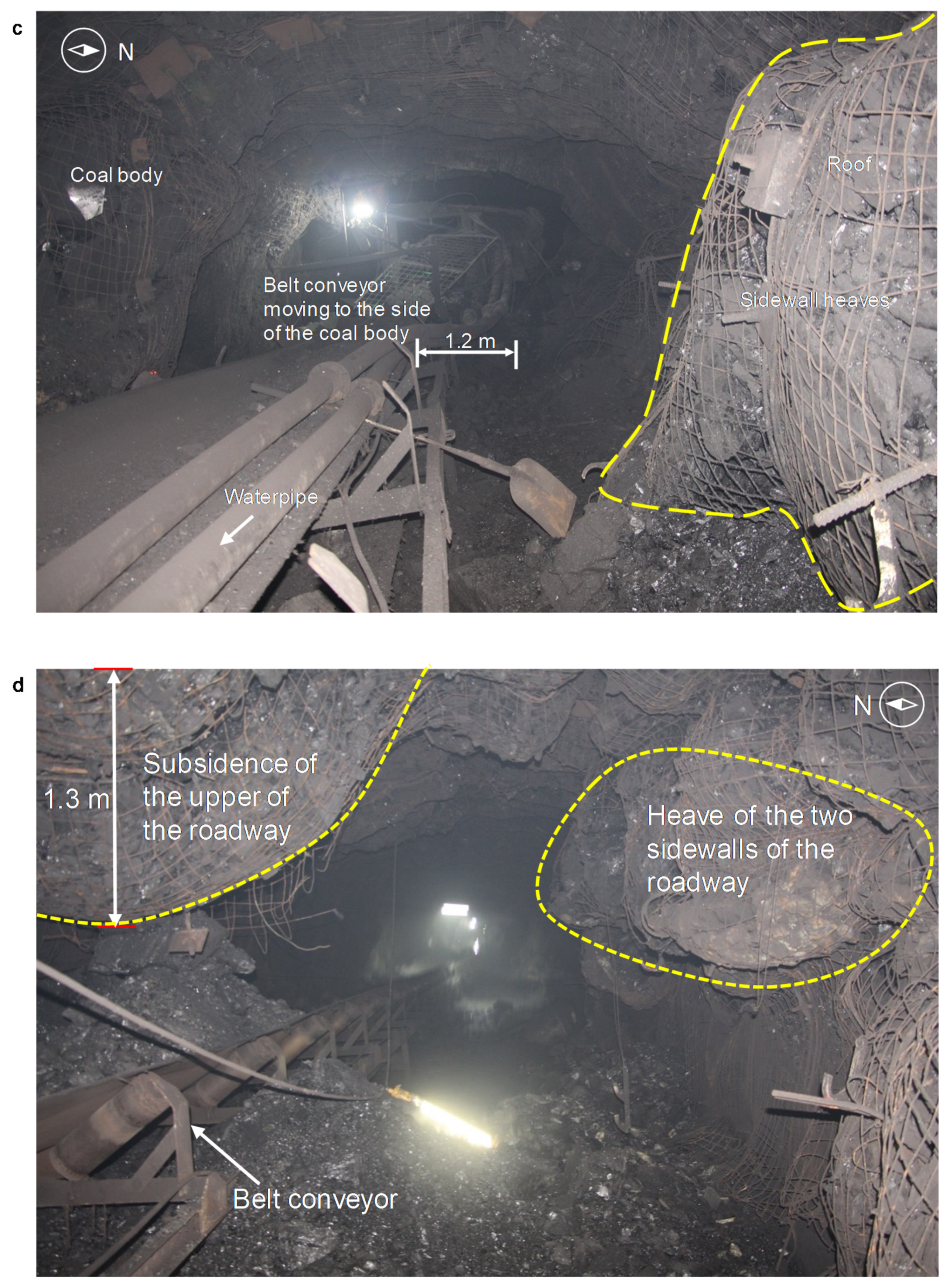

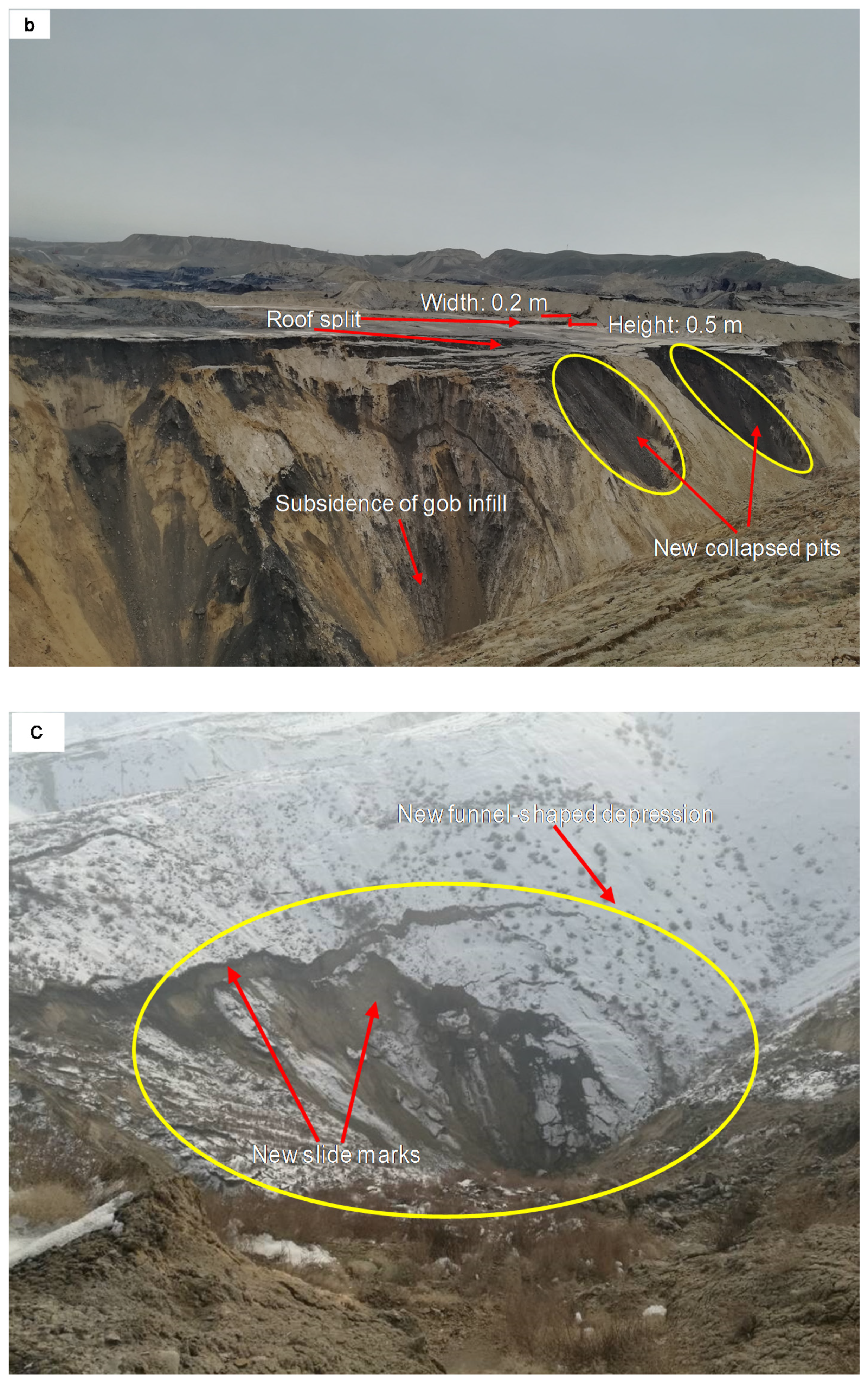

2.2. Analysis of the Rockburst Event

3. Rockburst Mechanism Analysis

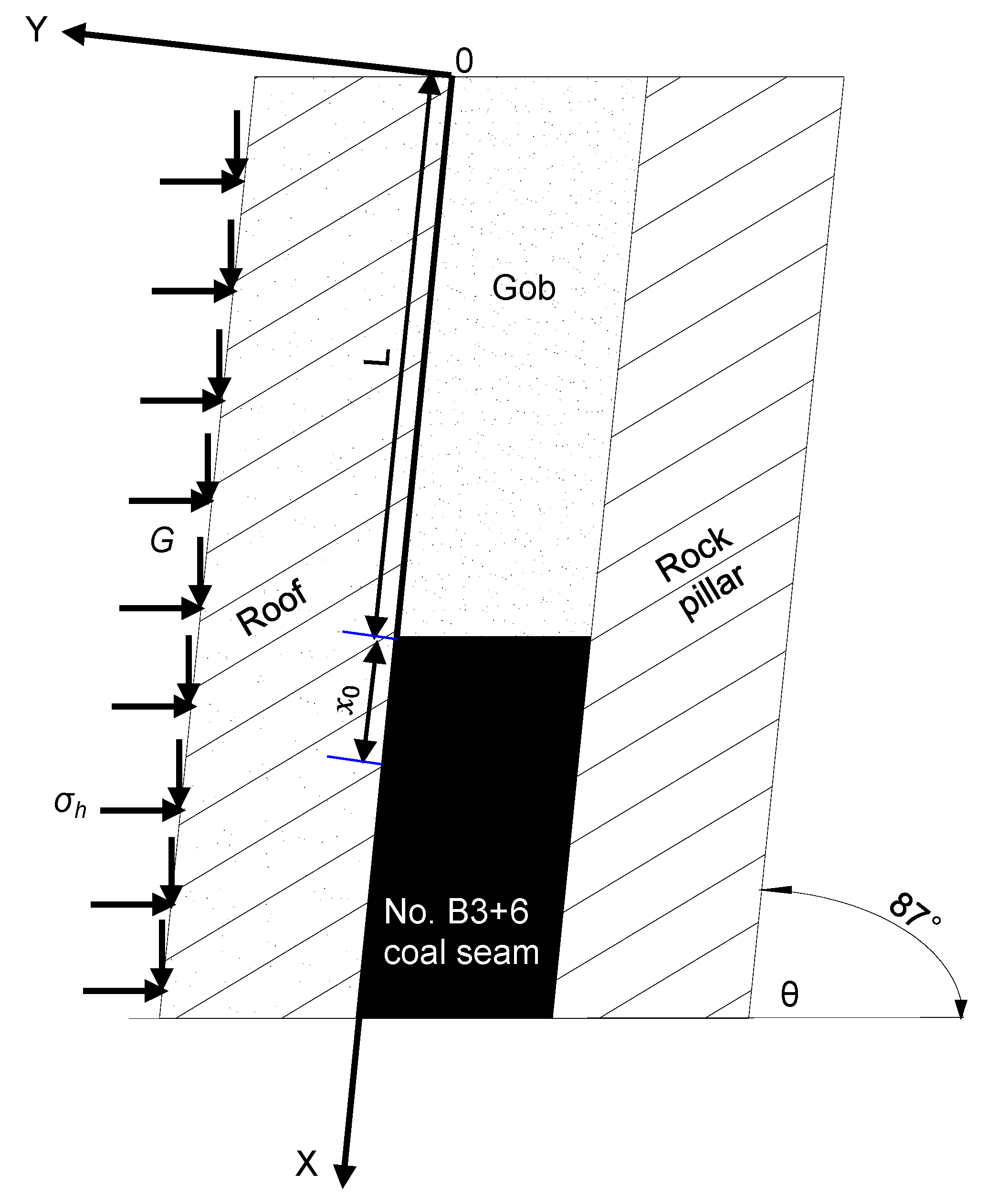

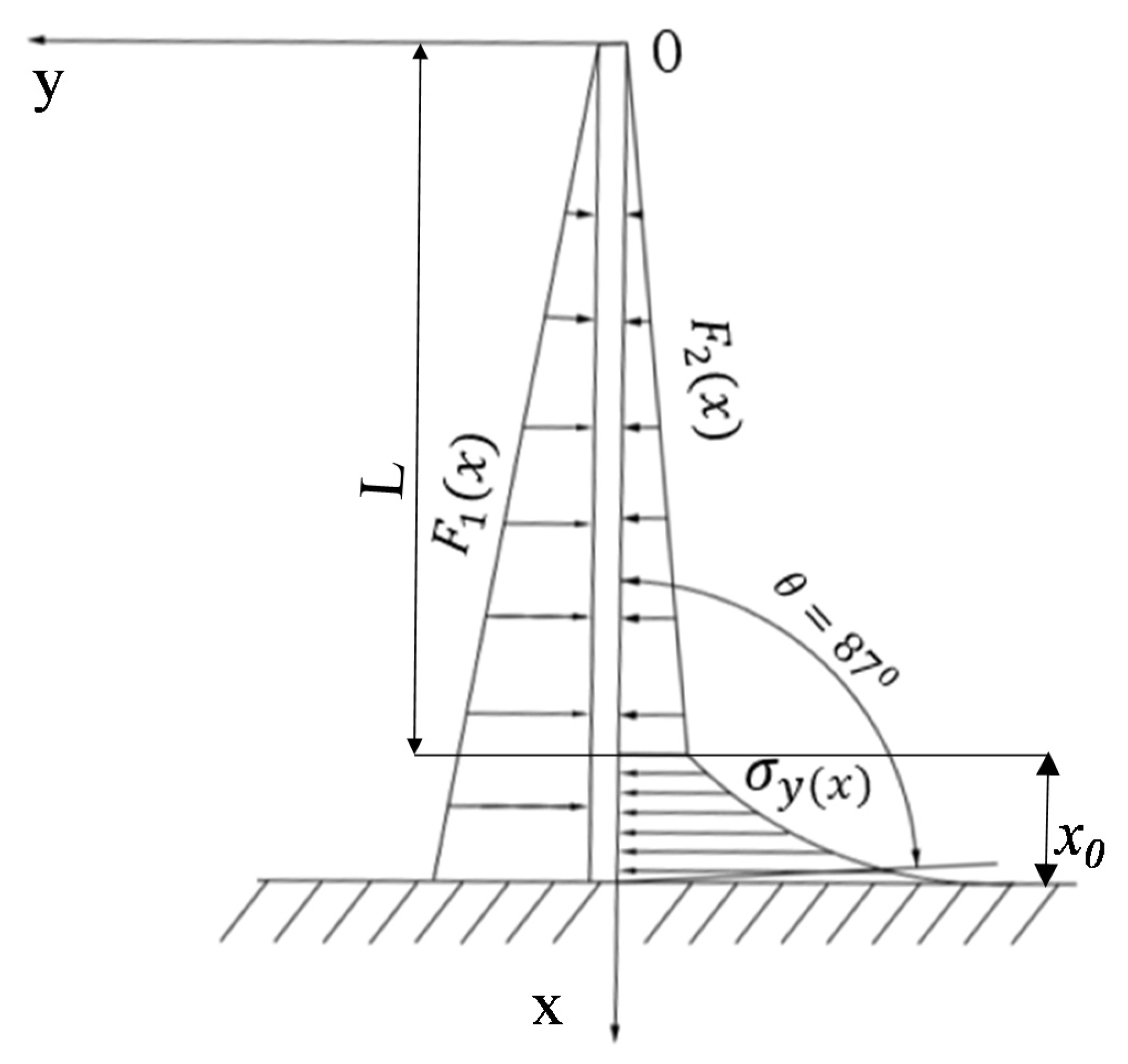

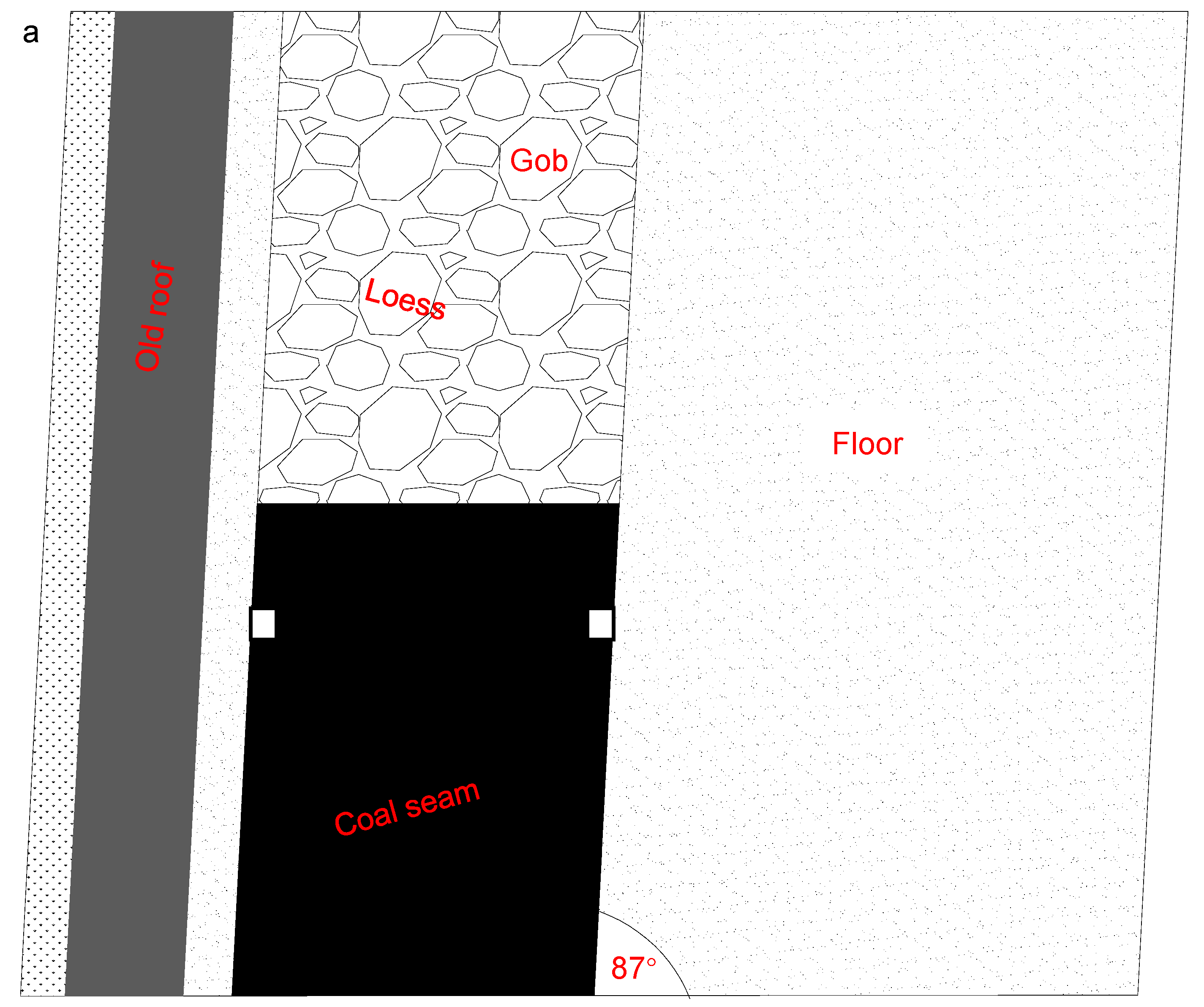

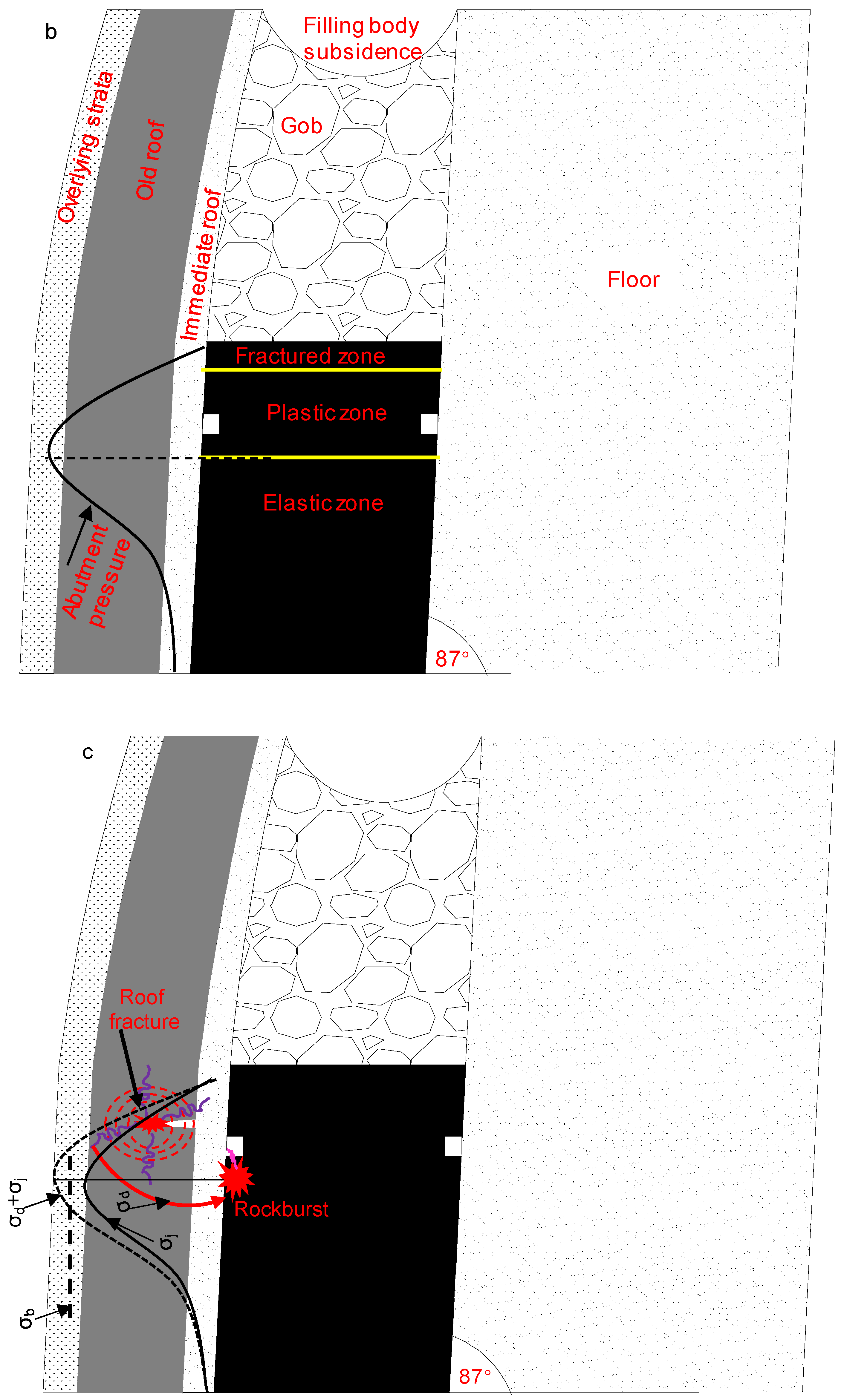

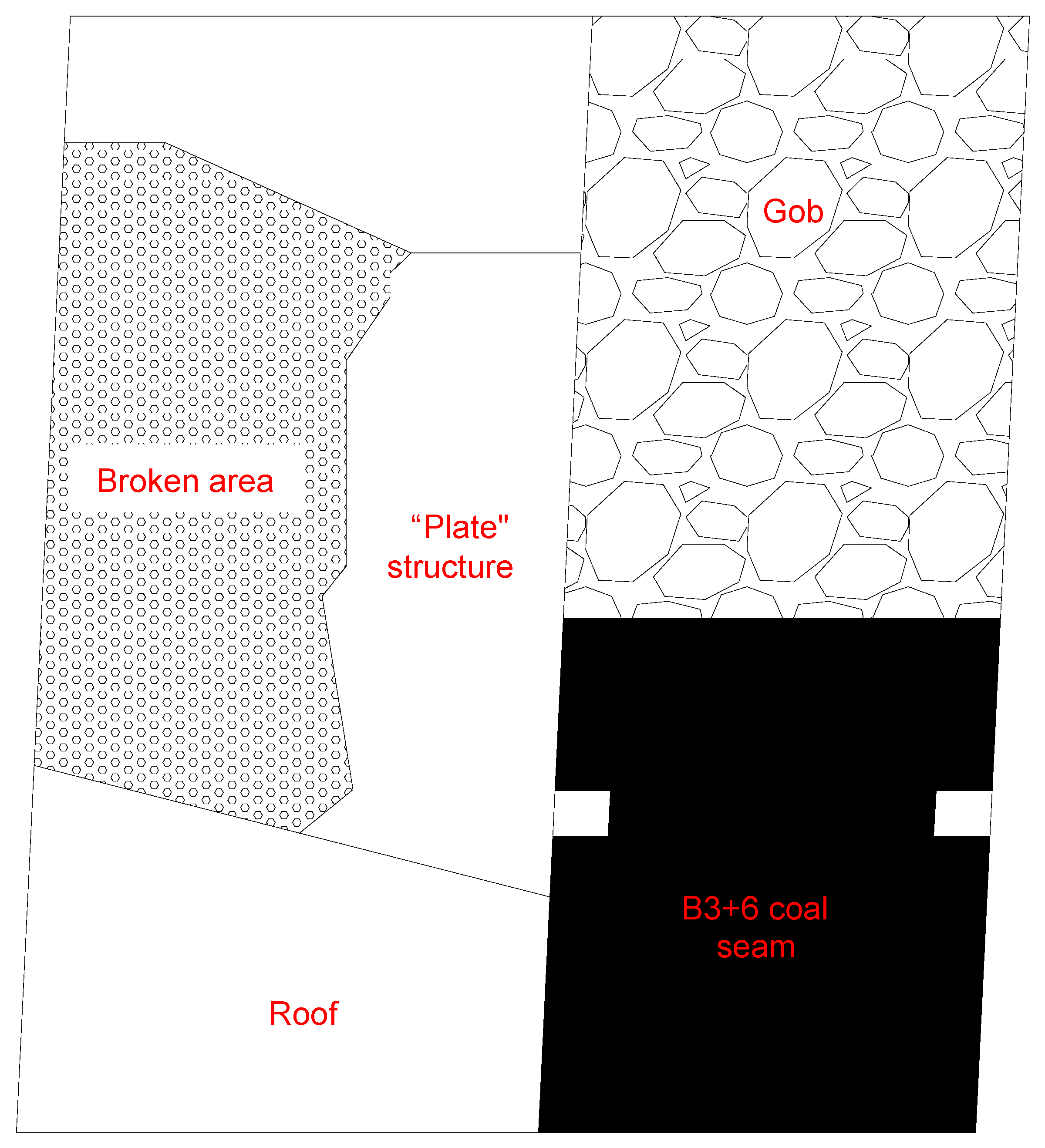

3.1. Mechanical Model of the “Steeply Inclined Suspended Roof Structure”

3.2. EDE Analysis of the Roof

3.3. Influence Factors of the EDE of the Overhanging Roof

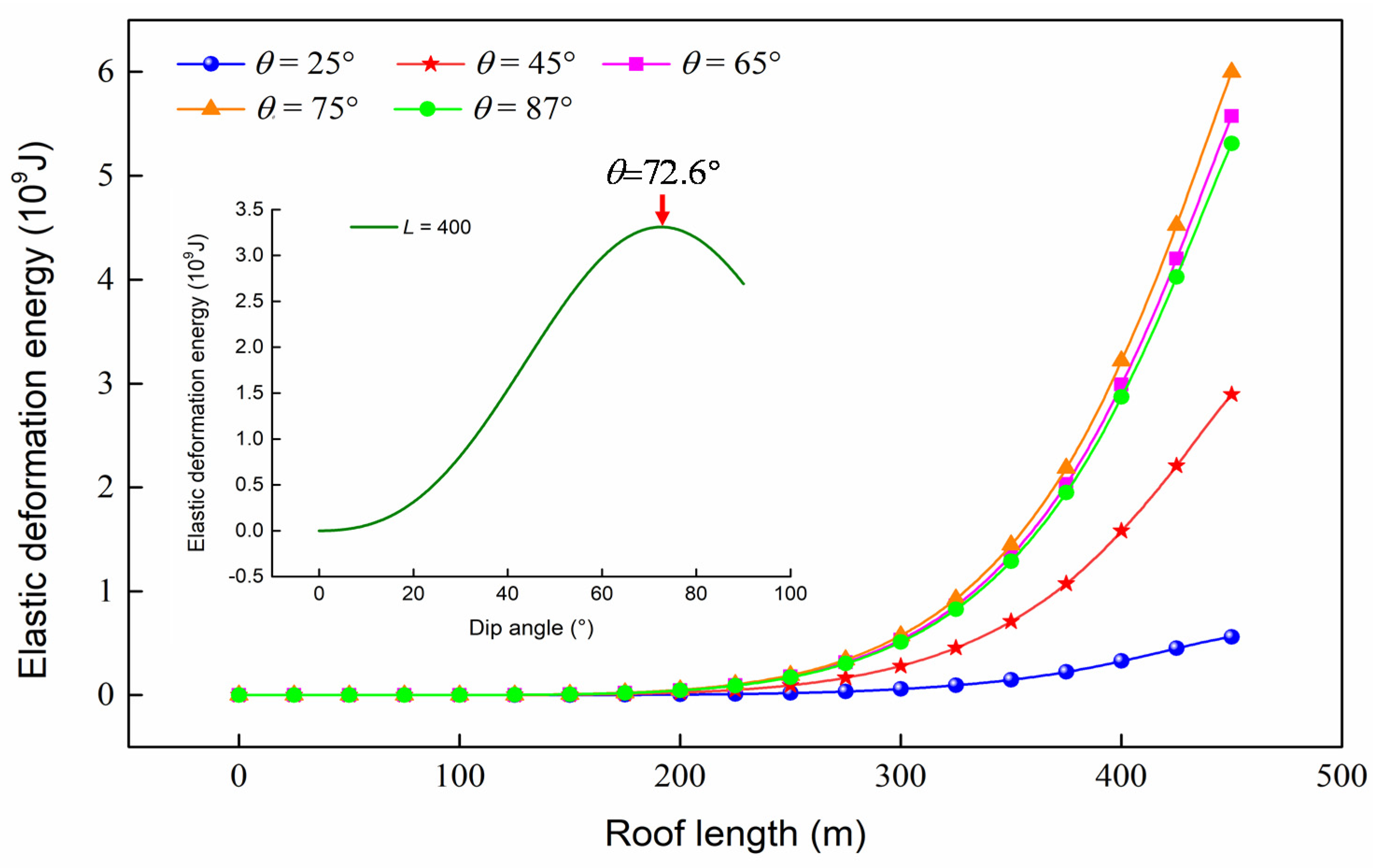

3.3.1. Analysis of Dip Angle

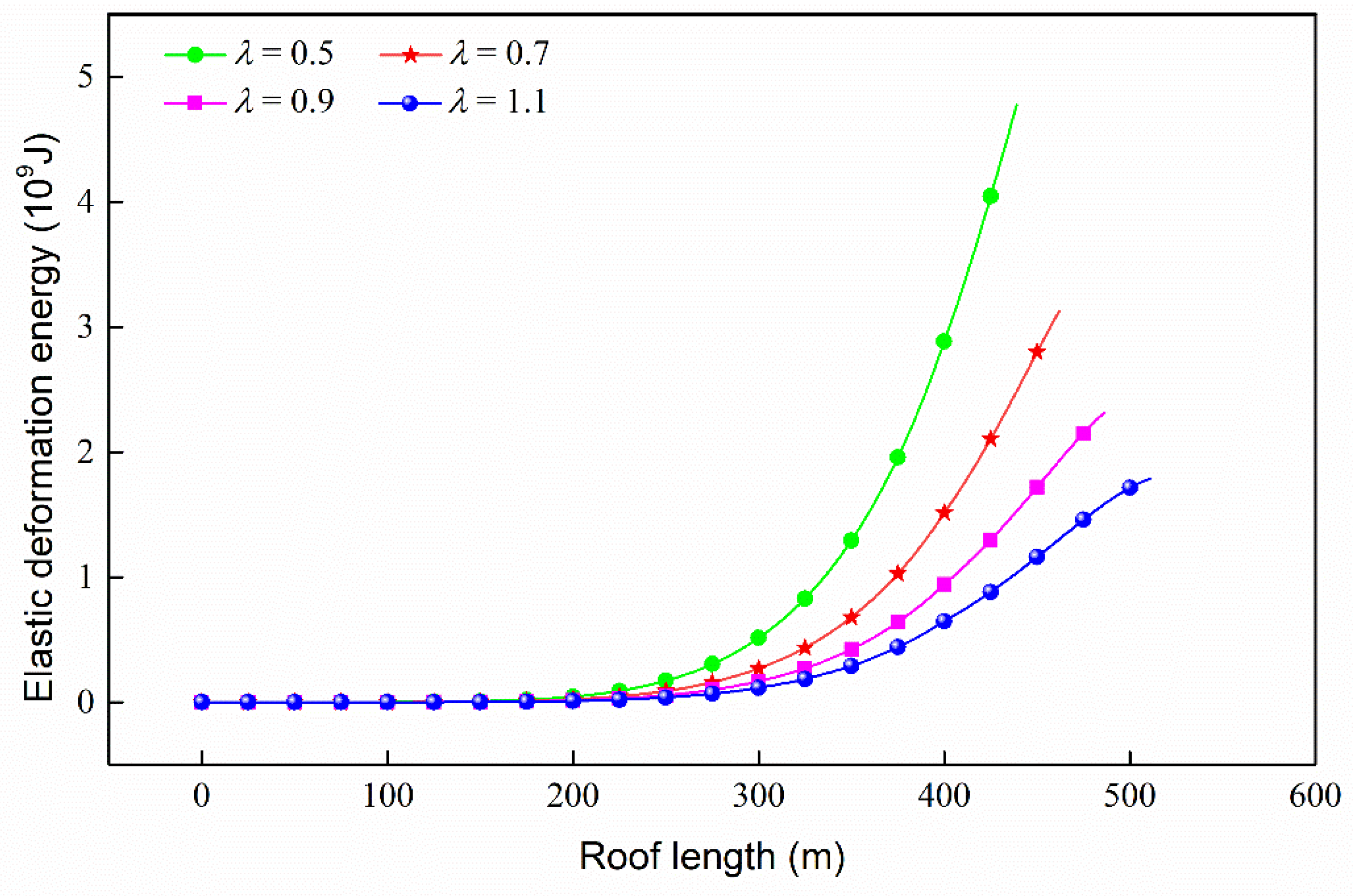

3.3.2. Analysis of Lateral Pressure Coefficient

3.3.3. Analysis of Supporting Force Coefficient

3.4. Risk Assessment for Rockbursts

4. Verification of Rockburst Mechanisms

4.1. Ground Destruction

4.2. Monitoring Results of Rockburst Source

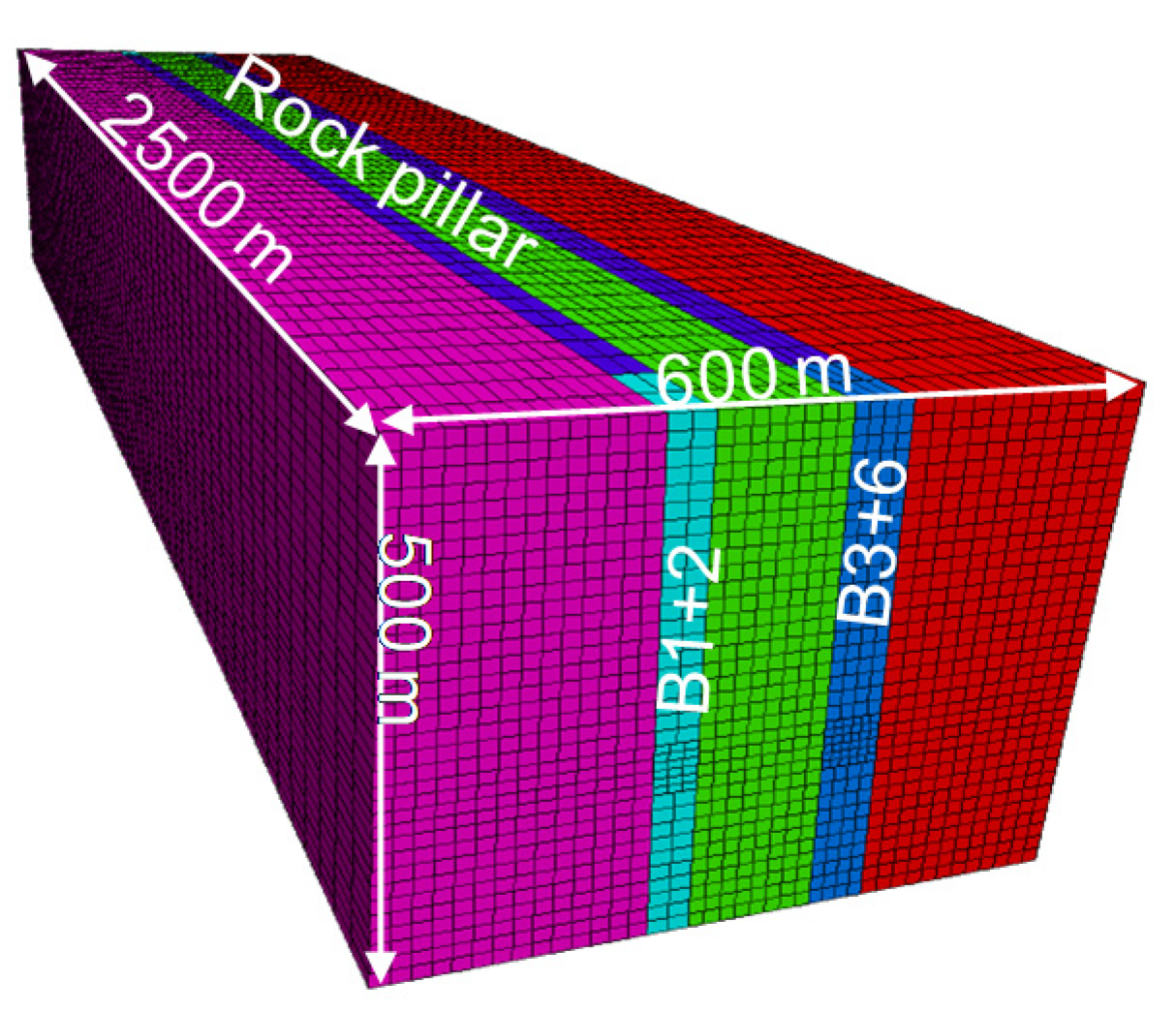

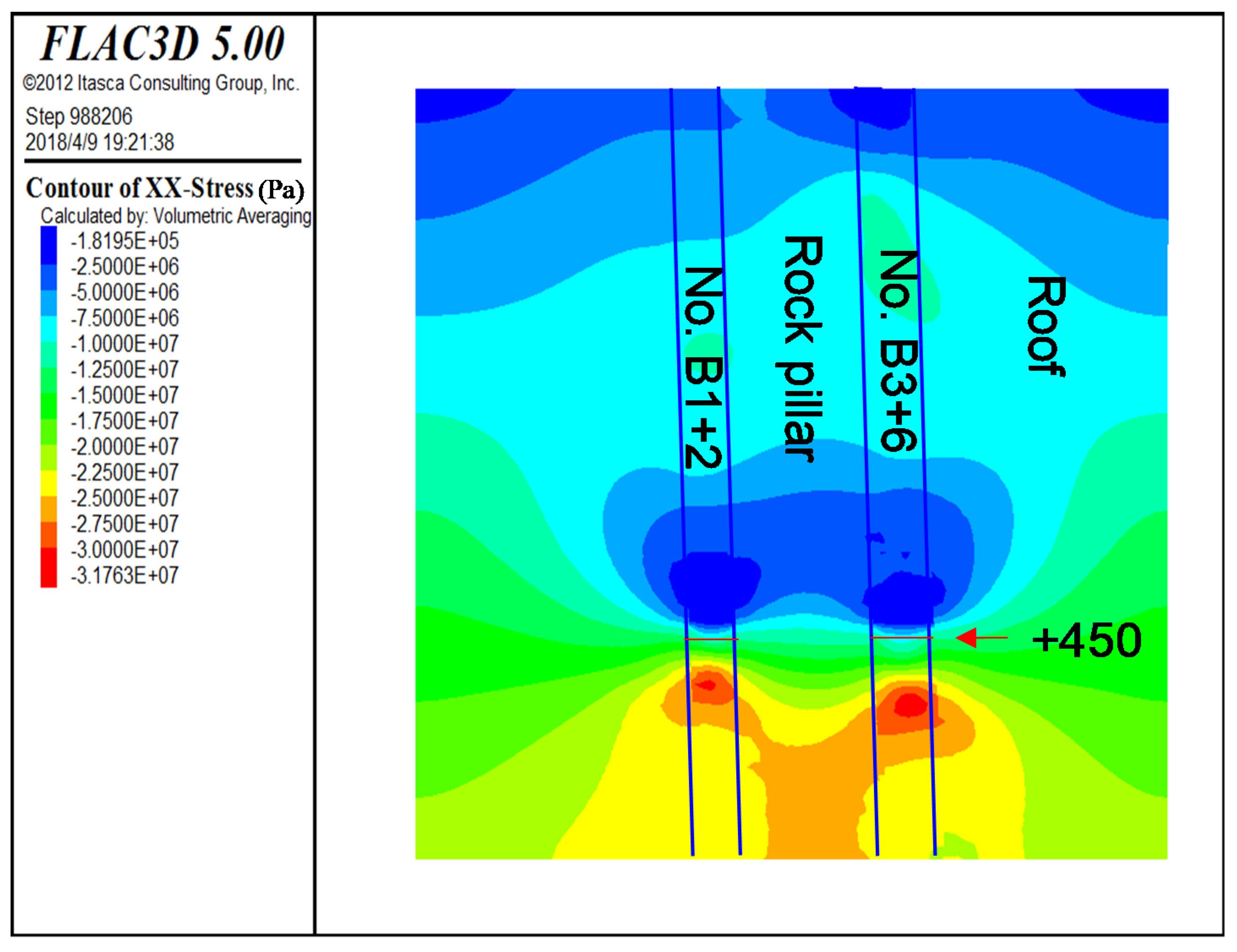

4.3. Numerical Simulation Reveals the Stress Concentration Area

5. Induced Process of Rockburst

6. Controlling Measures and Effects

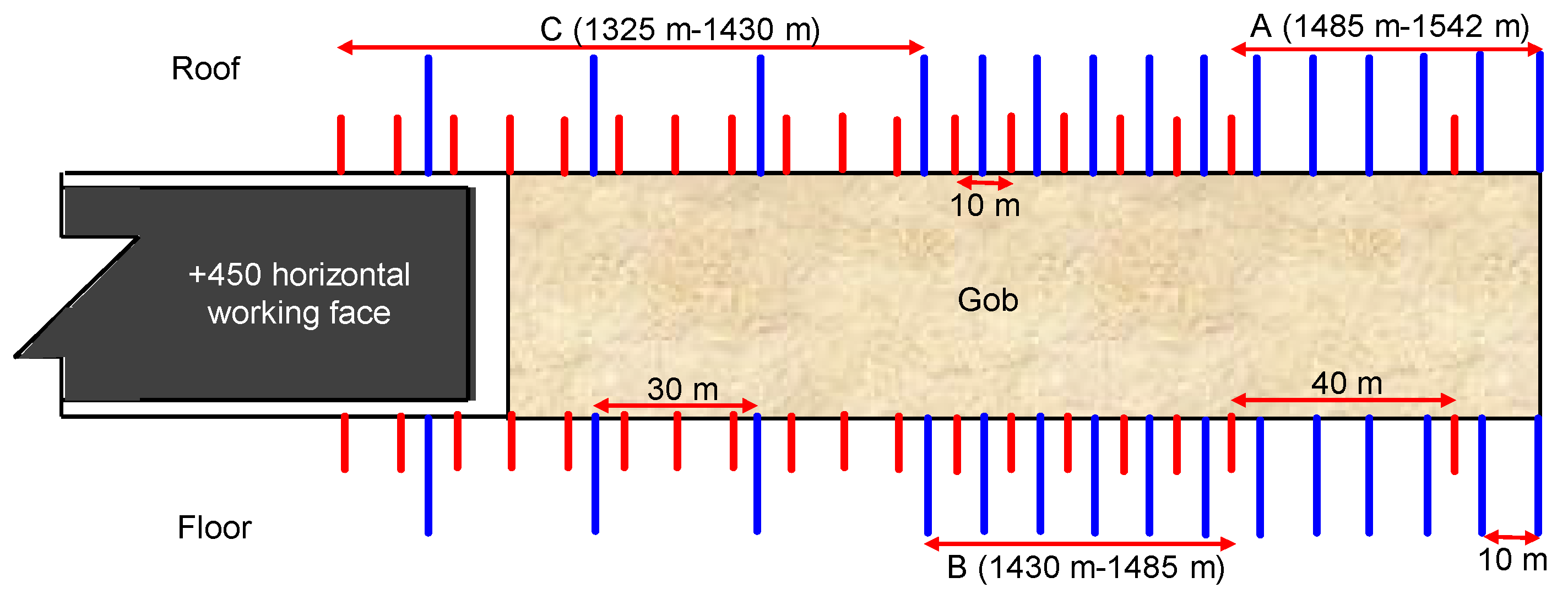

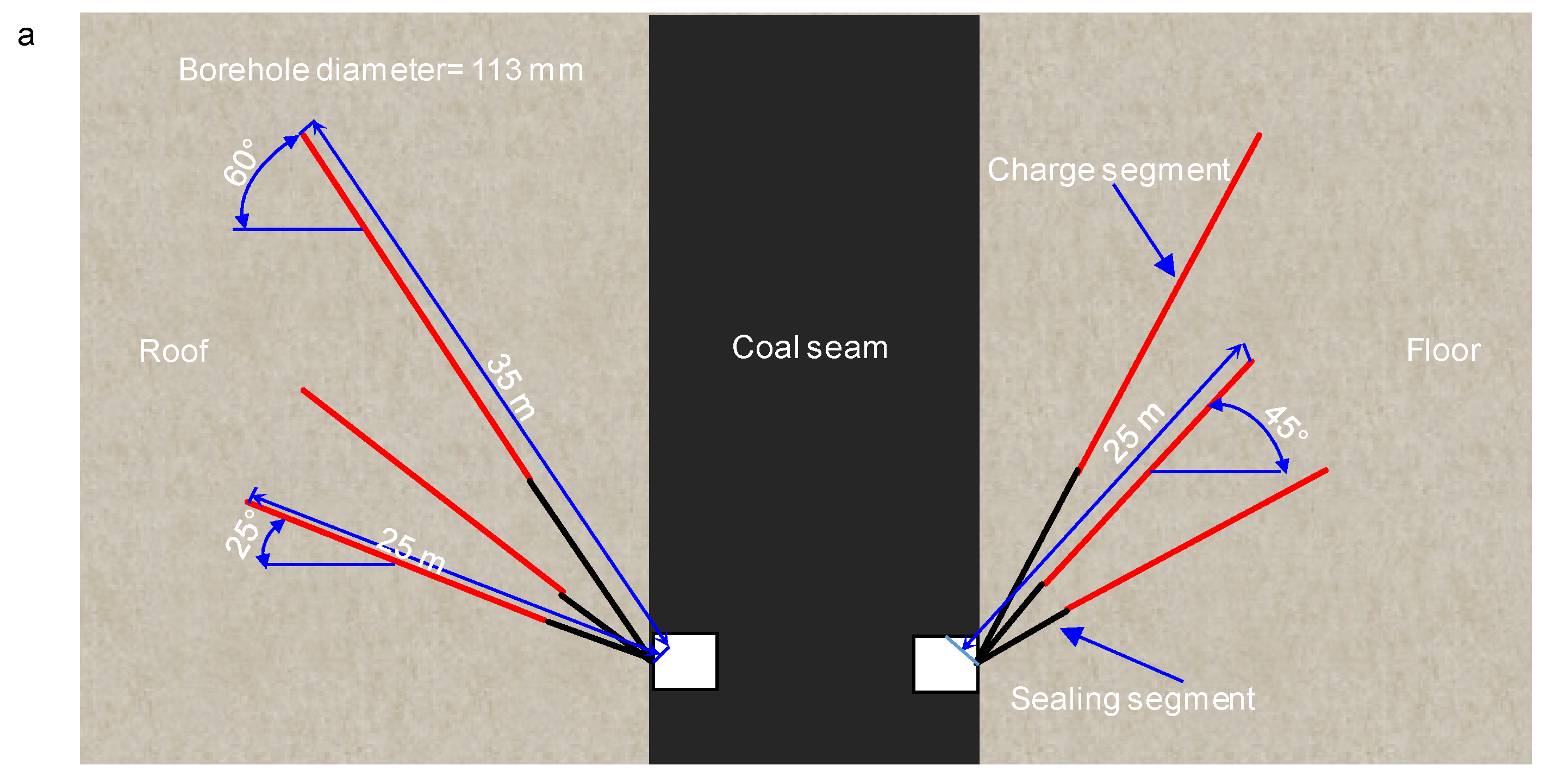

6.1. Controlling Engineering

6.2. Pressure Relief Effectiveness

7. Conclusions

- (1)

- The damage characteristics of the rockburst in the SIETCS shows an obvious directionality from roof side to coal side. The unstable bending and breaking of the steeply inclined suspended roof are the main factors for these directional damage characteristics.

- (2)

- The mechanical model and the EDE distribution function of a “steeply inclined suspended roof structure” was developed. The EDE increases with an increasing dip angle of the coal seam between 0° to 72.6° and then decreases as the dip angle continually increases. Furthermore, the EDE increases as the lateral pressure coefficient and the supporting force coefficient decrease and is proportional to the inclination length of the suspended roof.

- (3)

- Through theoretical analysis, the ground destruction measurement, MS monitoring and numerical simulation, the stress concentration areas of the coal and rock mass are obtained. The main rockburst triggering factor in the SIETCS of the WCM is the dynamic stress caused by the breakage of the suspended roof and the high static stress in the compressive area. The mechanisms of the rockburst on fully mechanized top-coal caving mining under gob filling conditions in an SIETCS are presented in this paper, i.e., “high compressive stress concentration plus breakage of the suspended roof induced stress” rockbursts.

- (4)

- The safe and reasonable breaking span of the suspended roof has been obtained. The alternate deep and shallow hole-blasting mode is more suitable for rockburst prevention and pressure relief in an SIETCS by comparing three kinds of pressure relief projects: i.e., deep hole-blasting companied with auxiliary shallow hole-blasting, alternate deep and shallow hole-blasting and shallow hole-blasting accompanied with auxiliary deep hole-blasting.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yan, H.; Zhang, J.X.; Feng, R.M.; Wang, W.; Lan, Y.W.; Xu, Z.J. Surrounding rock failure analysis of retreating roadways and the control technique for extra-thick coal seams under fully-mechanized top caving and intensive mining conditions: A case study. Tunn. Undergr. Space Technol. 2020, 97, 103241. [Google Scholar] [CrossRef]

- Kaiser, P.K. Canadian Rockburst Support Handbook: 1996; Geomechanics Research Centre: Sudbury, ON, Canada, 1996. [Google Scholar]

- Mazaira, A.; Konicek, P. Intense rockburst impacts in deep underground construction and their prevention. Can. Geotech. J. 2015, 52, 1426–1439. [Google Scholar] [CrossRef]

- Chen, B.R.; Feng, X.T.; Li, Q.P.; Luo, R.Z.; Li, S.J. Rockburst intensity classification based on the radiated energy with damage intensity at jinping II hydropower station, China. Rock Mech. Rock Eng. 2015, 48, 289–303. [Google Scholar] [CrossRef]

- Zhu, S.T.; Feng, Y.; Jiang, F.X. Determination of abutment pressure in coal mines with extremely thick alluvium stratum: A typical kind of rockburst mines in china. Rock Mech. Rock Eng. 2016, 49, 1943–1952. [Google Scholar] [CrossRef]

- Cao, A.Y.; Dou, L.M.; Wang, C.B.; Yao, X.X.; Dong, J.Y.; Gu, Y. Microseismic precursory characteristics of rockburst hazard in mining areas near a large residual coal pillar: A case study from xuzhuang coal mine, xuzhou, China. Rock Mech. Rock Eng. 2016, 49, 4407–4422. [Google Scholar] [CrossRef]

- Heib, M.A. Numerical and geophysical tools applied for the prediction of mine induced seismicity in French Coalmines. Int. J. Geosci. 2012, 3, 834–846. [Google Scholar] [CrossRef] [Green Version]

- Zhu, S.T.; Feng, Y.; Jiang, F.X.; Liu, J.H. Mechanism and risk assessment of overall-instability-induced rockbursts in deep island longwall panels. Int. J. Rock Mech. Min. Sci. 2018, 106, 342–349. [Google Scholar] [CrossRef]

- Cook, N.G.W. The seismic location of rockbursts. In Proceedings of the 5th Symposium on Rock Mechanics, Minneapolis, MN, USA, May 1962; pp. 493–516. [Google Scholar]

- Neyman, B.Z.; Szecowka, Z.; Zuberek, W. Effective methods for fighting rockbursts in polish collieries. In Proceedings of the 5th International Strata Control Conference, London, UK, 21 August 1972. [Google Scholar]

- Singh, S.P. Burst energy release index. Rock Mech. Rock Eng. 1988, 21, 149–155. [Google Scholar] [CrossRef]

- Dou, L.M.; Mu, Z.L.; Li, Z.L.; Cao, A.Y.; Gong, S.Y. Research progress of monitoring, forecasting, and prevention of rockburst in underground coal mining in China. Int. J. Coal Sci. Technol. 2014, 1, 278–288. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.L.; Dou, L.M.; Cai, W.; Wang, G.F.; He, J.; Gong, S.Y.; Ding, Y.L. Investigation and analysis of the rockburst mechanism induced within fault-pillars. Int. J. Rock Mech. Min. Sci. 2014, 70, 192–200. [Google Scholar] [CrossRef]

- Guo, W.Y.; Zhao, T.B.; Tan, Y.L.; Yu, F.H.; Hu, S.C.; Yang, F.Q. Progressive mitigation method of rockbursts under complicated geological conditions. Int. J. Rock Mech. Min Sci. 2017, 96, 11–22. [Google Scholar] [CrossRef]

- Lu, C.P.; Liu, G.J.; Liu, Y.; Zhang, H. Mechanisms of rockburst triggered by slip and fracture of coal-parting-coal structure discontinuities. Rock Mech. Rock Eng. 2019, 52, 3279–3292. [Google Scholar] [CrossRef]

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Cai, W.; Yuan, X.Y.; Fan, C.J. Rockburst mechanism and control in coal seam with both syncline and hard strata. Saf. Sci. 2019, 115, 320–328. [Google Scholar] [CrossRef]

- He, J.; Dou, L.M.; Cao, A.Y.; Gong, S.Y.; Lü, J.W. Rockburst induced by roof breakage and its prevention. J. Cent. South Univ. 2012, 19, 1086–1091. [Google Scholar] [CrossRef]

- He, J.; Dou, L.M.; Gong, S.Y.; Li, J.; Ma, Z.Q. Rockburst assessment and prediction by dynamic and static stress analysis based on micro-seismic monitoring. Int. J. Rock Mech. Min Sci. 2017, 93, 46–53. [Google Scholar] [CrossRef]

- Szwedzicki, T. Rock mass behaviour prior to failure. Int. J. Rock Mech. Min Sci. 2003, 40, 573–584. [Google Scholar] [CrossRef]

- Wang, H.W.; Jiang, Y.D.; Xue, S.; Pang, X.F.; Lin, Z.N.; Deng, D.X. Investigation of intrinsic and external factors contributing to the occurrence of coal bumps in the mining area of Western Beijing, China. Rock Mech. Rock Eng. 2017, 50, 1033–1047. [Google Scholar] [CrossRef]

- Cai, W.; Dou, L.M.; Si, G.Y.; Cao, A.Y.; He, J.; Liu, S. A principal componentanalysis/fuzzy comprehensive evaluation model for coal burst liability assessment. Int. J. Rock Mech. Min Sci. 2016, 81, 62–69. [Google Scholar] [CrossRef]

- Islam, M.R.; Hayashi, D.; Kamruzzaman, A.B.M. Finite element modeling of stress distributions and problems for multi-slice long wall mining in Bangladesh, with special reference to the Barapukuria coal mine. Int. J. Coal Geol. 2009, 78, 91–109. [Google Scholar] [CrossRef]

- Sirait, B.; Wattimena, R.K.; Widodo, N.P. Rockburst prediction of a cut and fill mine by using energy balance and induced stress. Procedia Earth Planet. Sci. 2013, 6, 426–434. [Google Scholar] [CrossRef] [Green Version]

- Driad-Lebeau, L.; Lahaie, F.; Al Heib, A.; Josien, J.P.; Bigarre, P.; Noirel, J.F. Seismic and geotechnical investigations following a rockburst in a complex French mining district. Int. J. Coal Geol. 2005, 64, 66–78. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Wang, H.W.; Xue, S.; Zhao, Y.X.; Zhu, J.; Pang, X.F. Assessment and mitigation of coal bump risk during extraction of an island longwall panel. Int. J. Coal Geol. 2012, 95, 20–33. [Google Scholar] [CrossRef]

- Wang, H.W.; Jiang, Y.D.; Zhao, Y.X.; Zhu, J.; Liu, S. Numerical investigation of the dynamic mechanical state of a coal pillar during longwall mining panel extraction. Rock Mech. Rock Eng. 2013, 46, 1211–1221. [Google Scholar] [CrossRef]

- Marcak, H. Seismicity in mines due to roof layer bending. Arch. Min. Sci. 2012, 57, 229–250. [Google Scholar]

- Lai, X.P.; Yang, Y.R.; Chen, J.Q. Control of dynamic hazards induced by mining stress distortion in extremely steep and thick coal seams. J. China Coal Soc. 2016, 41, 1610–1616. [Google Scholar]

- Brauner, G. Rockbursts in Coal Mines and Their Prevention; Balkema, A.A., Ed.; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Li, Z.L.; He, X.Q.; Dou, L.M.; Song, D.Z. Comparison of rockburst occurrence during extraction of thick coal seams using top-coal caving versus slicing mining methods. Can. Geotech. J. 2018, 55, 1433–1450. [Google Scholar] [CrossRef]

- Singh, A.K.; Singh, R.; Maiti, J.; Kumar, R.; Mandal, P.K. Assessment of mining induced stress development over coal pillars during depillaring. Int. J. Rock Mech. Min Sci. 2011, 48, 794–804. [Google Scholar] [CrossRef]

- Wang, G.F.; Gong, S.Y.; Dou, L.M.; Cai, W.; Jin, F.; Fan, C.J. Behaviour and bursting failure of roadways based on a pendulum impact test facility. Tunn. Undergr. Space Technol. 2019, 92, 103042. [Google Scholar] [CrossRef]

- Huang, B.X.; Liu, J.W.; Zhang, Q. The reasonable breaking location of overhanging hard roof for directional hydraulic fracturing to control strong strata behaviors of gob-side entry. Int. J. Rock Mech. Min Sci. 2018, 103, 1–11. [Google Scholar] [CrossRef]

- Fan, J.; Dou, L.M.; He, H.; Du, T.T.; Zhang, S.B.; Gui, B.; Sun, X.L. Directional hydraulic fracturing to control hard-roof rockburst in coal mines. Int. J. Min. Sci. Tech. 2012, 22, 177–181. [Google Scholar] [CrossRef]

- Feng, X.J.; Wang, E.Y.; Shen, R.X.; Wei, M.Y.; Chen, Y.; Cao, X.Q. The dynamic impact of rockburst induced by the fracture of the thick and hard key stratum. Procedia Eng. 2011, 26, 457–465. [Google Scholar]

- Chen, G.X.; Dou, L.M.; Xu, X. Research on prevention of rockburst with relieving shot in roof. Procedia Eng. 2012, 45, 904–909. [Google Scholar] [CrossRef] [Green Version]

- Lai, X.P.; Li, Y.P.; Wang, N.B.; Liu, Y.H.; Yan, P.J. Roof deformation characteristics with full-mechanized caving face based on beam structure in extremely inclined coal seam. J. Min. Saf. Eng. 2015, 32, 871–876. [Google Scholar]

- Wang, Z.Y.; Dou, L.M.; Wang, G.F. Coal burst induced by horizontal section mining of a steeply inclined, extra-thick coal seam and its prevention: A case study from Yaojie No. 3 coal mine. China. Shock Vib. 2019, 2019, 8469019. [Google Scholar] [CrossRef]

- He, S.Q.; Song, D.Z.; Li, Z.L.; He, X.Q.; Chen, J.Q.; Li, D.H.; Tian, X.H. Precursor of spatio-temporal evolution law of MS and AE activities for rockburst warning in steeply-inclined and extremely-thick coal seams under caving mining conditions. Rock Mech. Rock Eng. 2019, 52, 1–21. [Google Scholar] [CrossRef]

- Hou, C.J.; Ma, N.J. Stress in in-seam roadway sides and limit equilibrium zone. J. China Coal Soc. 1989, 7, 21–29. [Google Scholar]

- Lai, X.P.; Cai, M.F.; Ren, F.H.; Shan, P.F.; Cui, F.; Cao, J.T. Study on dynamic disaster in steeply deep rock mass condition in Urumchi Coalfield. Shock Vib. 2015, 2015, 465017. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.S.; Feng, Z.C.; Chang, Z.X. The least energy principle of dynamical rock failure. Chin. J. Rock Mech. Eng. 2002, 21, 1931–1933. [Google Scholar]

- Zhang, H.W.; Rong, H.; Chen, J.Q.; Han, J.; Sun, B.C.; Huo, B.J.; Qi, T. Risk assessment of rockburst based on geo-dynamic division method in suberect and extremely thick coal seam. J. China Coal Soc. 2015, 40, 2755–2762. [Google Scholar]

- Feng, G.L.; Feng, X.T.; Chen, B.R.; Xiao, Y.X.; Zhao, Z.N. Effects of structural planes on the microseismicity associated with rockburst development processes in deep tunnels of the Jinping-II Hydropower Station, China. Tunn. Undergr. Space Technol. 2019, 84, 273–280. [Google Scholar] [CrossRef]

- Li, Z.L. Principle and Application of Rockburst Control by Weakening Static and Dynamic Loading Using Top-Coal Caving in the Mining of Thick Coal Seams. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2016. [Google Scholar]

- Pan, J.F.; Ning, Y.; Mao, D.B.; Lan, H.; Du, T.T.; Peng, Y.W. Theory of rockburst start-up during coal mining. Chin. J. Rock Mech. Eng. 2012, 31, 586–596. [Google Scholar]

- Orlecka-Sikora, B. The role of static stress transfer in mining induced seismic events occurrence, a case study of the Rudna mine in the Legnica-Glogow Copper District in Poland. Geophys. J. Int. 2010, 182, 1087–1095. [Google Scholar] [CrossRef] [Green Version]

- Ge, M. Efficient mine microseismic monitoring. Int. J. Coal Geol. 2005, 64, 44–56. [Google Scholar] [CrossRef]

- Xu, N.W.; Tang, C.A.; Li, L.C.; Zhou, Z.; Sha, C.; Liang, Z.Z.; Yang, J.Y. Microseismic monitoring and stability analysis of the left bank slope in Jinping first stage hydropower station in southwestern China. Int. J. Rock Mech. Min Sci. 2011, 48, 950–963. [Google Scholar] [CrossRef]

- Jiang, Q.A.; Feng, X.T.; Xiang, T.B.; Su, G.S. Rockburst characteristics and numerical simulation based on a new energy index: A case study of a tunnel at 2500 m depth. Bull. Eng. Geol. Environ. 2010, 69, 381–388. [Google Scholar] [CrossRef]

- Labuz, J.F.; Zang, A. Mohr-coulomb failure criterion. In The ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 2007–2014; Springer: Berlin/Heidelberg, Germany, 2012; pp. 227–231. [Google Scholar]

- Saharan, M.R.; Mitri, H. Destress blasting as a mines safety tool. Some fundamental challenges for successful applications. Procedia Eng. 2011, 26, 37–47. [Google Scholar] [CrossRef]

- Konicek, P.; Soucek, K.; Stas, L.; Singh, R. Long-hole destress blasting for rockburst control during deep underground coal mining. Int. J. Rock Mech. Min. Sci. 2013, 61, 141–153. [Google Scholar] [CrossRef]

- Wojtecki, Ł.; Konicek, P. Estimation of active rockburst prevention effectiveness during longwall mining under disadvantageous geological and mining conditions. J. Sustain. Min. 2016, 15, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Wojtecki, Ł.; Mendecki, M.J.; Zuberek, W.M. Determination of destress blasting effectiveness using seismic source parameters. Rock Mech. Rock Eng. 2017, 50, 3233–3244. [Google Scholar] [CrossRef] [Green Version]

| Dynamic Failure Time DT (s) | Burst Energy Index KE | Elastic Energy Index WET | Compressive Strength RC (Pa) | Type of Rock Burst Liability |

|---|---|---|---|---|

| 0.14 | 2.08 | 5.86 | 1.24 × 106 | Weak |

| Strata Name | Unit Weight γ (N·m−3) | Compressive Strength RC (Pa) | Tensile Strength σt (Pa) | Elasticity Modulus E (Pa) | Poisson’s Ratio υ | Cohesion c (Pa) |

|---|---|---|---|---|---|---|

| Coal | 1.31 × 104 | 1.24 × 107 | 1.21 × 106 | 2.12 × 109 | 0.21 | 2.42 × 106 |

| Rock (roof) | 2.76 × 104 | 8.24 × 107 | 5.78 × 106 | 2.7 × 1010 | 0.28 | 7.01 × 106 |

| Roadway | Damage Length (m) | Roof Subsidence (m) | Floor Heave (m) | North Wall of Roadway Heave (m) | South Wall of Roadway Heave (m) | Description (Main Damage) |

|---|---|---|---|---|---|---|

| Headentry | 194 | 0.7–1 | - | 0.5–1.3 | 0.3–0.7 | Roof moved: roof subsidence and the appearance of a string bag with a size of 2 × 2 × 1 m, belt conveyor moved from roof side to coal side and damage to the hydraulic prop. |

| Tailentry | 18 | - | 0.2 | 0.3–0.5 | - | Lower wall moved 0.3–0.5 m, floor heaved 0.2 m and damage to the hydraulic props. |

| # | Borehole Length (m) | Borehole Diameter (mm) | Angle (°) | Charge Segment Length (m) | Sealing Segment Length (m) |

|---|---|---|---|---|---|

| 1# | 25 | 0.113 | 25 | 15 | 10 |

| 2# | 25 | 0.113 | 45 | 15 | 10 |

| 3# | 35 | 0.113 | 60 | 23 | 12 |

| # | Borehole Length (m) | Borehole Diameter (mm) | Angle (°) | Charge Segment Length (m) | Sealing Segment Length (m) |

|---|---|---|---|---|---|

| 1# | 50 | 0.113 | 25 | 20 | 30 |

| 2# | 50 | 0.113 | 35 | 20 | 30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, S.; Song, D.; Li, Z.; He, X.; Chen, J.; Zhong, T.; Lou, Q. Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions. Energies 2020, 13, 1362. https://doi.org/10.3390/en13061362

He S, Song D, Li Z, He X, Chen J, Zhong T, Lou Q. Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions. Energies. 2020; 13(6):1362. https://doi.org/10.3390/en13061362

Chicago/Turabian StyleHe, Shengquan, Dazhao Song, Zhenlei Li, Xueqiu He, Jianqiang Chen, Taoping Zhong, and Quan Lou. 2020. "Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions" Energies 13, no. 6: 1362. https://doi.org/10.3390/en13061362

APA StyleHe, S., Song, D., Li, Z., He, X., Chen, J., Zhong, T., & Lou, Q. (2020). Mechanism and Prevention of Rockburst in Steeply Inclined and Extremely Thick Coal Seams for Fully Mechanized Top-Coal Caving Mining and Under Gob Filling Conditions. Energies, 13(6), 1362. https://doi.org/10.3390/en13061362