Causes of Hass Avocado Fruit Rejection in Preharvest, Harvest, and Packinghouse: Economic Losses and Associated Variables

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material and Sampling

- n: sample size

- N: population size

- e: error range (10%)

- z: value based on the confidence level (90% = 1.65)

- P: probability (90%).

2.2. Characterization of Damage and Defects Associated with Pre-harvest, Harvest and Packinghouse Processes that Affect Avocado cv. Hass Quality and Cause Fruit Rejection

2.3. Economic Importance Associated with Damages and Defects in Farms and Packinghouses that Generate Fruit Selection and Rejection Criteria

- PTD: total losses due to rejected fruit in %.

- P: production losses due to rejection caused by factor i that affects external quality.

- PT: total production of the plot according to the technological level and region where it is located.

- n: amount of damage generated by fruit rejection.

- i: specific damage factor that affects the external quality of fruits and generates rejection.

- IEPD: economic importance of losses by fruit rejection.

- PTDpc: total fruit losses due to pre-harvest and harvest rejection.

- PTDe: total fruit losses due to packinghouse rejection.

- CP: fruit production costs according to the technological level and location of the plot.

- CT: transport cost from plot to packinghouse.

- CM: cost of fruit processing in packinghouse.

2.4. Data Analysis

2.5. Relation between Causes of Rejection and Environmental and Management Variables

3. Results

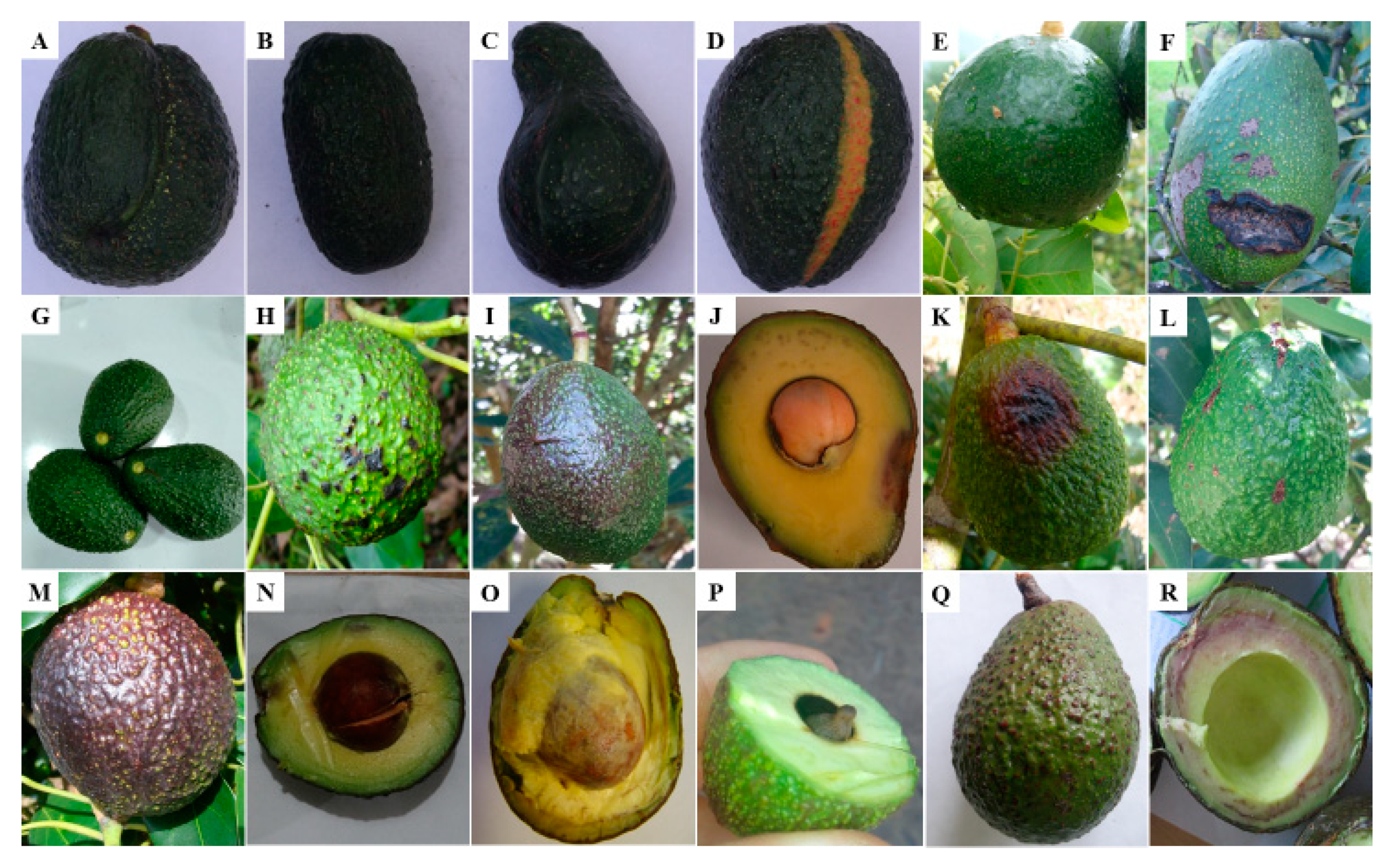

3.1. General Description of Damages Associated with the External Quality of Hass Avocado Fruits

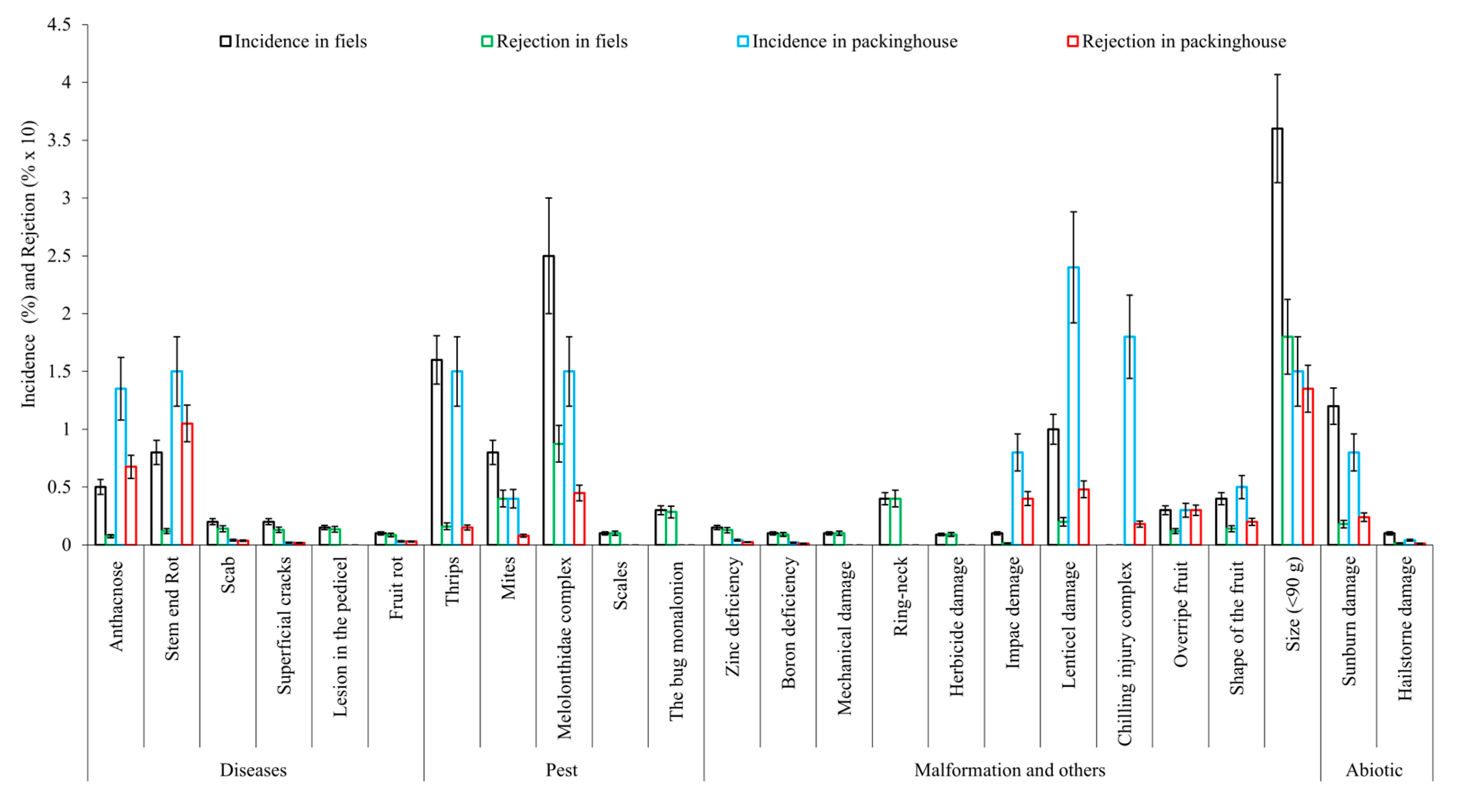

3.2. Incidence and Rejection Associated with the Main Damages in Pre-harvest, Harvest and Packinghouse that Affect Hass Avocado Quality

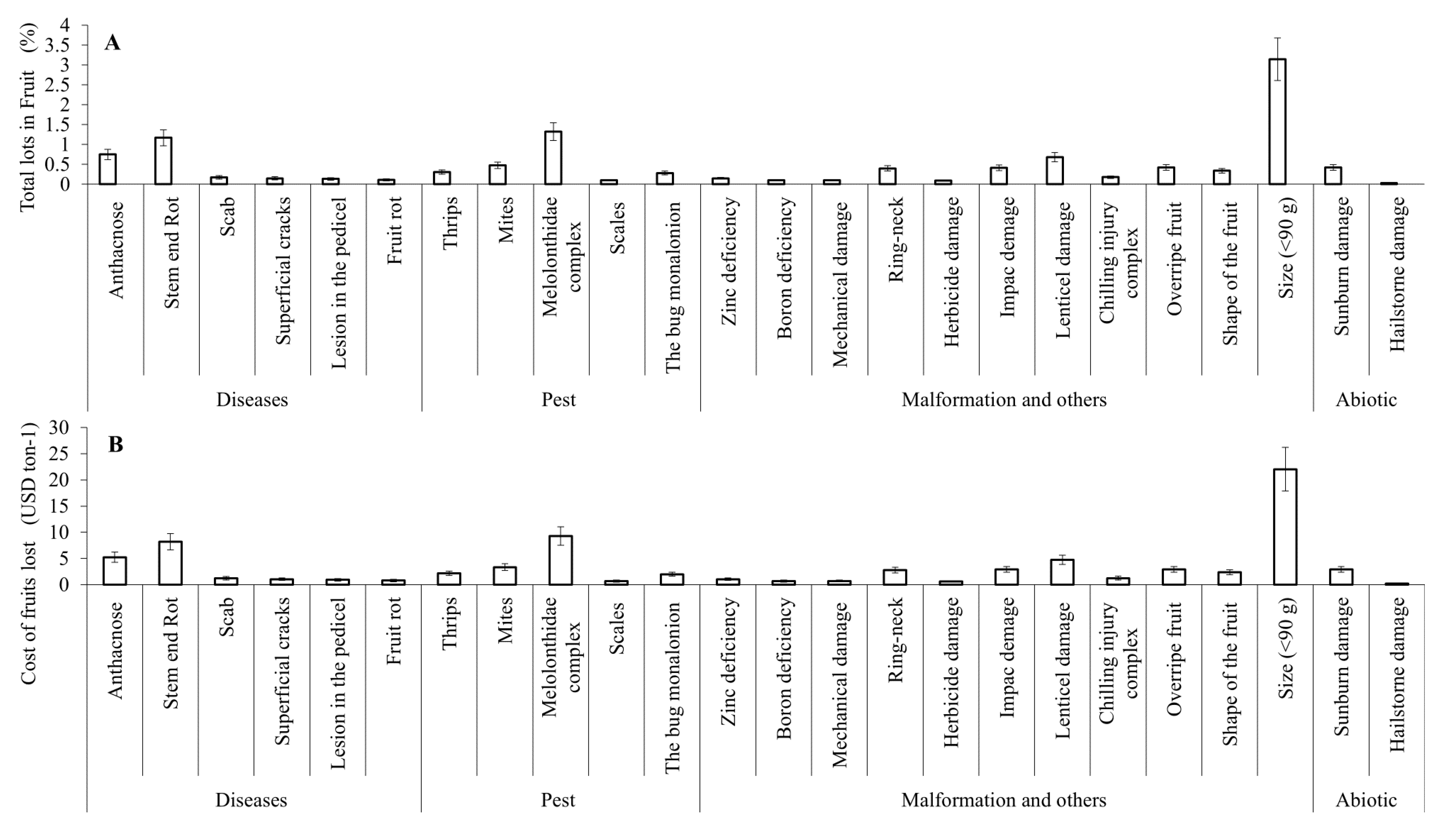

3.3. Economic Importance of Damages and Defects in Farms and Packinghouses that Generate Fruit Selection and Rejection Criteria

3.4. Relation between Causes of Rejection and Environmental and Management Variables

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bregh, B.; Ellstrand, N. Taxonomy of the avocado. Calif. Avocado Soc. Yearb. 1986, 70, 135–145. [Google Scholar]

- Chen, H.; Morrell, P.L.; Ashworth, V.E.T.M.; de la Cruz, M.; Clegg, M.T. Tracing the geographic origins of major avocado cultivars. J. Hered. 2009, 100, 56–65. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bost, J.B.; Smith, N.J.; Crane, J.H. History, distribution and uses. In The Avocado: Botany, Production and Uses, 2nd ed.; CABI Publ: Wallingford, UK, 2013; pp. 10–30. [Google Scholar]

- FAO. FAOSTAT. Available online: http://www.fao.org/faostat/es/#home (accessed on 9 January 2019).

- Ramírez-Gil, J. Avocado wilt complex disease, implications and management in Colombia. Rev. Fac. Nac. Agron. Medellín 2018, 71, 8525–8541. [Google Scholar] [CrossRef]

- Ministerio de Agricultura y Desarrollo Rural de Colombia. Cadena de Aguacate Indicadores e Instrumentos; Bogotá, Colombia, 2018.

- Bill, M.; Sivakumar, D.; Thompson, A.K.; Korsten, L. Avocado fruit quality management during the postharvest supply chain. Food Rev. Int. 2014, 30, 169–202. [Google Scholar] [CrossRef] [Green Version]

- Ferreyra, R.; Sellés, G.; Saavedra, J.; Ortiz, J.; Zúñiga, C.; Troncoso, C.; Rivera, S.A.; González-Agüero, M.; Defilippi, B.G. Identification of pre-harvest factors that affect fatty acid profiles of avocado fruit (Persea americana Mill) cv. ‘Hass’ at harvest. S. Afr. J. Bot. 2016, 104, 15–20. [Google Scholar] [CrossRef]

- Herrera-González, J.A.; Salazar-García, S.; Gutiérrez-Martínez, P.; González-Durán, I.J.L. El comportamiento poscosecha de frutos de aguacate ‘Hass’ es influenciado por el portainjerto. Rev. Mex. Cienc. Agríc. 2013, 4, 19–32. [Google Scholar] [CrossRef] [Green Version]

- Ochoa, S. Calidad pos-cosecha del fruto de aguacate Hass. IV Encuentro Nacional de la Cadena Productiva del Aguacate. In Proceedings of the Encuentro Cadena de Aguacate, Politécnico Colombiano Jaime Isaza Cadavid Medellín, Medellín, Colombia, 10 November 2012; pp. 1–30. [Google Scholar]

- Ramírez-Gil, J.G.; Gilchrist Ramelli, E.; Morales Osorio, J.G. Economic impact of the avocado (cv. Hass) wilt disease complex in Antioquia, Colombia, crops under different technological management levels. Crop Prot. 2017, 101, 103–115. [Google Scholar] [CrossRef]

- Salazar-García, S.; Medina-Carrillo, R.E.; Álvarez-Bravo, A.; Salazar-García, S.; Medina-Carrillo, R.E.; Álvarez-Bravo, A. Evaluación inicial de algunos aspectos de calidad del fruto de aguacate ‘Hass’ producido en tres regiones de México. Rev. Mex. Cienc. Agríc. 2016, 7, 277–289. [Google Scholar]

- Bernal, J. Estudios Ecofisiológicos en Aguacate cv. Hass en Diferentes Ambientes Como Alternativa Productiva en Colombia. Ph.D. Thesis, Universidad Nacional de Colombia-Sede Medellín, Medellín, Colombia, 2016. [Google Scholar]

- Carvalho, C.P.; Velásquez, M.A.; Rooyen, Z.V. Determination of the minimum dry matter index for the optimum harvest of “Hass” avocado fruits in Colombia. Agron. Colomb. 2014, 32, 399–406. [Google Scholar] [CrossRef]

- Henao-Rojas, J.; Rodríguez, P. Evaluation of color during avocado (Persea americana Mill. cv. Hass) ripening. Agron. Colomb. 2016, 31, 876–879. [Google Scholar]

- Analdex. Los Retos del Aguacate Hass Colombiano en Los Mercados Internacionales; Analdex: Bogota, Colombia, 2017; pp. 1–29. [Google Scholar]

- Cochran, W. Sampling Techniques, 3rd ed.; John Wiley & Sons, Inc.: New York, NY, USA, 1977. [Google Scholar]

- Crowley, D.E.; Smith, W.; Faber, B.; Manthey, J.A. Zinc fertilization of avocado trees. HortScience 1996, 31, 224–229. [Google Scholar] [CrossRef] [Green Version]

- Whiley, A.W.; Smith, I.; Wolstenholme, B.N.; Saranah, J.B. Boron nutrition of avocados. S. Afr. Avocado Grow. Assoc. Yearb. 1996, 19, 1–7. [Google Scholar]

- Toerien, J. Seasonal incidence of ring-neck on avocados and possible causes. S. Afr. Avocado Grow. Assoc. Res. Rep. 1979, 3, 49–51. [Google Scholar]

- Everett, K.R.; Hallett, I.C.; Rees-George, J.; Chynoweth, R.W.; Pak, H.A. Avocado lenticel damage: The cause and the effect on fruit quality. Postharvest Biol. Technol. 2008, 48, 383–390. [Google Scholar] [CrossRef] [Green Version]

- Ginsberg, L. Posharvest physiological problema of avodados. S. Afr. Avocado Grow. Assoc. Yearb. 1985, 8, 8–11. [Google Scholar]

- Kassim, A.; Workneh, T.; Bezuidenhout, C. A review on postharvest handling of avocado fruit. Afr. J. Agric. Res. 2013, 8, 2385–2402. [Google Scholar]

- Ochoa, S. Calidad y manejo pos-cosecha del fruto de aguacate. In Proceedings of the III CongresoLatinoamericano del Aguacate, Medellín, Colombia, 24 August 2009; pp. 1–17. [Google Scholar]

- Van Rooyen, Z. Factors Affecting Mesocarp Discolouration Severity in “Pinkerton” Avocados (Persea americana MILL.). Ph.D. Thesis, University of Kwazulu Natal, Pietermaritzburg, South Africa, 2005. [Google Scholar]

- Barnett, H.L.; Hunter, B.B. Illustrated Genera of Imperfect Fungi; Burgess Publishing Company: Minneapolis, MN, USA, 1972. [Google Scholar]

- Erwin, D.C.; Ribeiro, O.K. Phytophthora Diseases Worldwide; American Phytopathological Society: St. Paul, MN, USA, 1996. [Google Scholar]

- White, T.; Bruns, T.; Lee, S.; Taylor, L. Amplification and direct sequencing of fungal ribosomal RNA genes for phylogenetics. In PCR Protocols: A Guide to Methods and Applications; Academic Press: San Diego, CA, USA, 1990; pp. 315–322. [Google Scholar]

- Shaad, N.; Jones, J.; Chun, W. (Eds.) Laboratory Guide for Identification of Plant Pathogenic Bacteria; American Phytopathological Society: St. Paul, MN, USA, 2001. [Google Scholar]

- Diaz Grisales, V.; Caicedo Vallejo, A.M.; Carabalí Muñoz, A.; Diaz Grisales, V.; Caicedo Vallejo, A.M.; Carabalí Muñoz, A. Ciclo de vida y descripción morfológica de Heilipus lauri Boheman (Coleoptera: Curculionidae) en Colombia. Acta Zoológica Mex. 2017, 33, 231–242. [Google Scholar] [CrossRef] [Green Version]

- Londoño, M.E.; Kondo, T.; Carabali, A.; Varon, E.; Caicedo, A. Insectos y acaros. In Actualización Tecnológica y Buenas Prácticas Agrícolas (BPA) en el Cultivo de Aguacate; CORPOICA: Antioquia, Colombia, 2014; pp. 228–283. [Google Scholar]

- Torres-Jaimes, L.F.; Cartagena-Valenzuela, J.R.; Correa-Londoño, G.A.; Monsalve-García, D.A.; Londoño-Zuluaga, M.E. Relación entre la presencia y el daño de Monalonion velezangeli Carvalho & Costa y algunos factores climáticos en cultivos de aguacate cv. Hass. Cienc. Tecnol. Agropecu. 2015, 16, 79–85. [Google Scholar]

- Valencia Arias, C.; Martínez Osorio, A.; Morales Osorio, J.G.; Ramírez-Gil, J.G. Spatial Analysis of Presence, Injury, and Economic Impact of the Melolonthidae (Coleoptera: Scarabaeoidea) Complex in Avocado Crops. Neotrop. Entomol. 2019, 48, 583–593. [Google Scholar] [CrossRef]

- Gagné, R.J.; Posada, F.; Zulma, N.G. A new species of Bruggmanniella (Diptera: Cecidomyiidae) aborting young fruit of avocado, Persea americana (Lauraceae), in Colombia and Costa Rica. Proc. Entomol. Soc. Wash. 2004, 106, 547–553. [Google Scholar]

- Krantz, G.; Walter, D. A Manual of Acarology, 3rd ed.; Texas Tech University Press: Lubbock, TX, USA, 2009. [Google Scholar]

- Lambdin, P.; Kosztarab, M. Morphology and Systematics of the Adult Females of the Genus Cerococcus (Homoptera: Coccoidea: Cerococcidae). In Studies on the Morphology and Systematics of Scale Insects; Virginia Polytechnic Institute and State University: Virginia, CA, USA, 1997. [Google Scholar]

- Morón, M.Á.; Neita-Moreno, J.C. Nuevas especies colombianas de Phyllophaga Harris (Coleoptera: Melolonthidae: Melolonthinae). Caldasia 2014, 36, 203–216. [Google Scholar] [CrossRef] [Green Version]

- Mound, L.; Marrullo, R. The thrips of Central and South America: An Introduction (Insecta: Thysanoptera). In Memories of Entomology; Associated Pub.: Liverpool, UK, 1996. [Google Scholar]

- Soto-Rodríguez, G.A.; Rodríguez-Arrieta, J.A.; González Muñoz, C.; Cambero-Campos, J.; Retana-Salazar, A.P.; Soto-Rodríguez, G.A.; Rodríguez-Arrieta, J.A.; González Muñoz, C.; Cambero-Campos, J.; Retana-Salazar, A.P. Key to the identification of genera of Thrips (Insecta: Thysanoptera) commonly associated with ornamental plants in Central America. Acta Zoológica Mex. 2017, 33, 454–463. [Google Scholar] [CrossRef]

- Vallejo, F.; Morón, M.A. Description of the immature stages and redescription of the adults of Ancognatha scarabaeoides Erichson (Coleoptera: Scarabaeidae: Dynastinae), a member of the soil white grub assemblage in Colombia. Coleopt. Bull. 2008, 62, 154–164. [Google Scholar] [CrossRef]

- R Development Core Team. The R Project for Statistical Computing. Available online: https://www.r-project.org/ (accessed on 9 June 2019).

- Gudmundsson, J.; Hammar, M.; van Kreveld, M. Higher order delaunay triangulations. Comput. Geom. Theory Appl. 2002, 23, 85–98. [Google Scholar] [CrossRef] [Green Version]

- Arias Bustos, C.; Moors, E.H.M. Reducing post-harvest food losses through innovative collaboration: Insights from the Colombian and Mexican avocado supply chains. J. Clean. Prod. 2018, 199, 1020–1034. [Google Scholar] [CrossRef] [Green Version]

- Duvenhage, J. The influence of wet picking on post harvest diseases and disorders of avocado fruit. S. Afr. Avocado Grow. Assoc. Yearb. 1993, 16, 77–79. [Google Scholar]

- Rivera, S.A.; Ferreyra, R.; Robledo, P.; Selles, G.; Arpaia, M.L.; Saavedra, J.; Defilippi, B.G. Identification of preharvest factors determining postharvest ripening behaviors in ‘Hass’ avocado under long term storage. Sci. Hortic. 2017, 216, 29–37. [Google Scholar] [CrossRef]

- Hershkovitz, V.; Friedman, H.; Goldschmidt, E.E.; Feygenberg, O.; Pesis, E. Induction of ethylene in avocado fruit in response to chilling stress on tree. J. Plant Physiol. 2009, 166, 1855–1862. [Google Scholar] [CrossRef]

- Giovannoni, J. Molecular biology of fruit and maturation and ripening. Annu. Rev. Plant Physiol. Plant Mol. Biol. 2001, 52, 725–749. [Google Scholar] [CrossRef]

- Seymour, G.; Tucker, G. Avocado. In Biochemistry of Fruit Ripening; Chapman and Hall: London, UK, 1993; pp. 53–81. [Google Scholar]

- Hartill, W.F.T.; Everett, K.R. Inoculum sources and infection pathways of pathogens causing stem-end rots of ‘Hass’ avocado (Persea americana). N. Z. J. Crop Hortic. Sci. 2002, 30, 249–260. [Google Scholar] [CrossRef]

- Sharma, G.; Maymon, M.; Freeman, S. Epidemiology, pathology and identification of Colletotrichum including a novel species associated with avocado (Persea americana) anthracnose in Israel. Sci. Rep. 2017, 7, 15839. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramírez-Gil, J.G.; López, J.H.; Henao-Rojas, J.C. Causes of Hass Avocado Fruit Rejection in Preharvest, Harvest, and Packinghouse: Economic Losses and Associated Variables. Agronomy 2020, 10, 8. https://doi.org/10.3390/agronomy10010008

Ramírez-Gil JG, López JH, Henao-Rojas JC. Causes of Hass Avocado Fruit Rejection in Preharvest, Harvest, and Packinghouse: Economic Losses and Associated Variables. Agronomy. 2020; 10(1):8. https://doi.org/10.3390/agronomy10010008

Chicago/Turabian StyleRamírez-Gil, Joaquín Guillermo, Jaime Horacio López, and Juan Camilo Henao-Rojas. 2020. "Causes of Hass Avocado Fruit Rejection in Preharvest, Harvest, and Packinghouse: Economic Losses and Associated Variables" Agronomy 10, no. 1: 8. https://doi.org/10.3390/agronomy10010008