An Improved Method for Measuring the Distribution of Water Droplets in Crude Oil Based on the Optical Microscopy Technique

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preliminary Experiment to Observe Water Droplets in Crude Oil

2.3. Plate Pressing (PP) Method

3. Results and Discussion

3.1. Appearance of Water Droplets Trapped in Crude Oil

3.2. Water Droplet Distribution in the Crude Oil

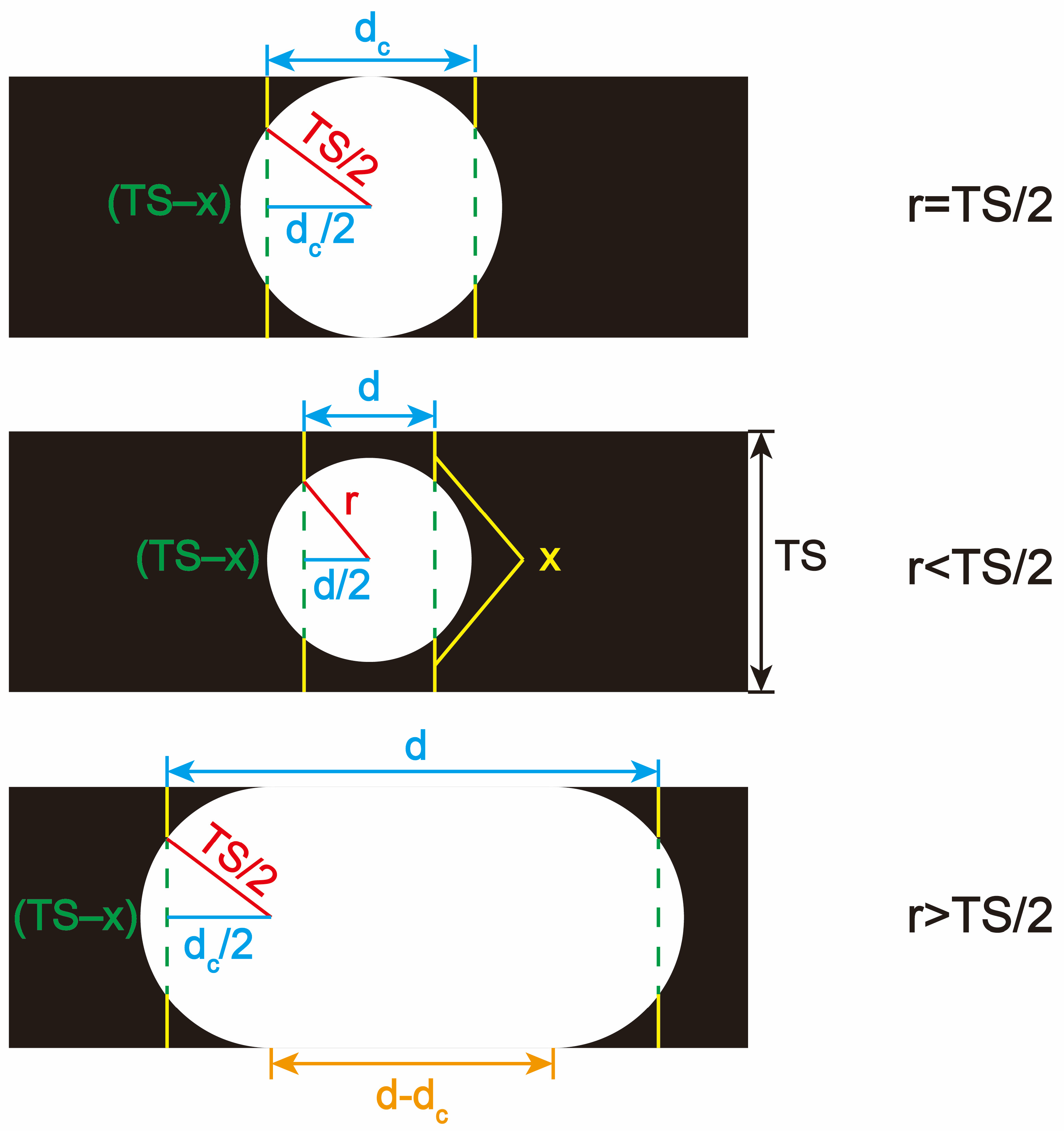

3.3. Data Processing for the PP Method

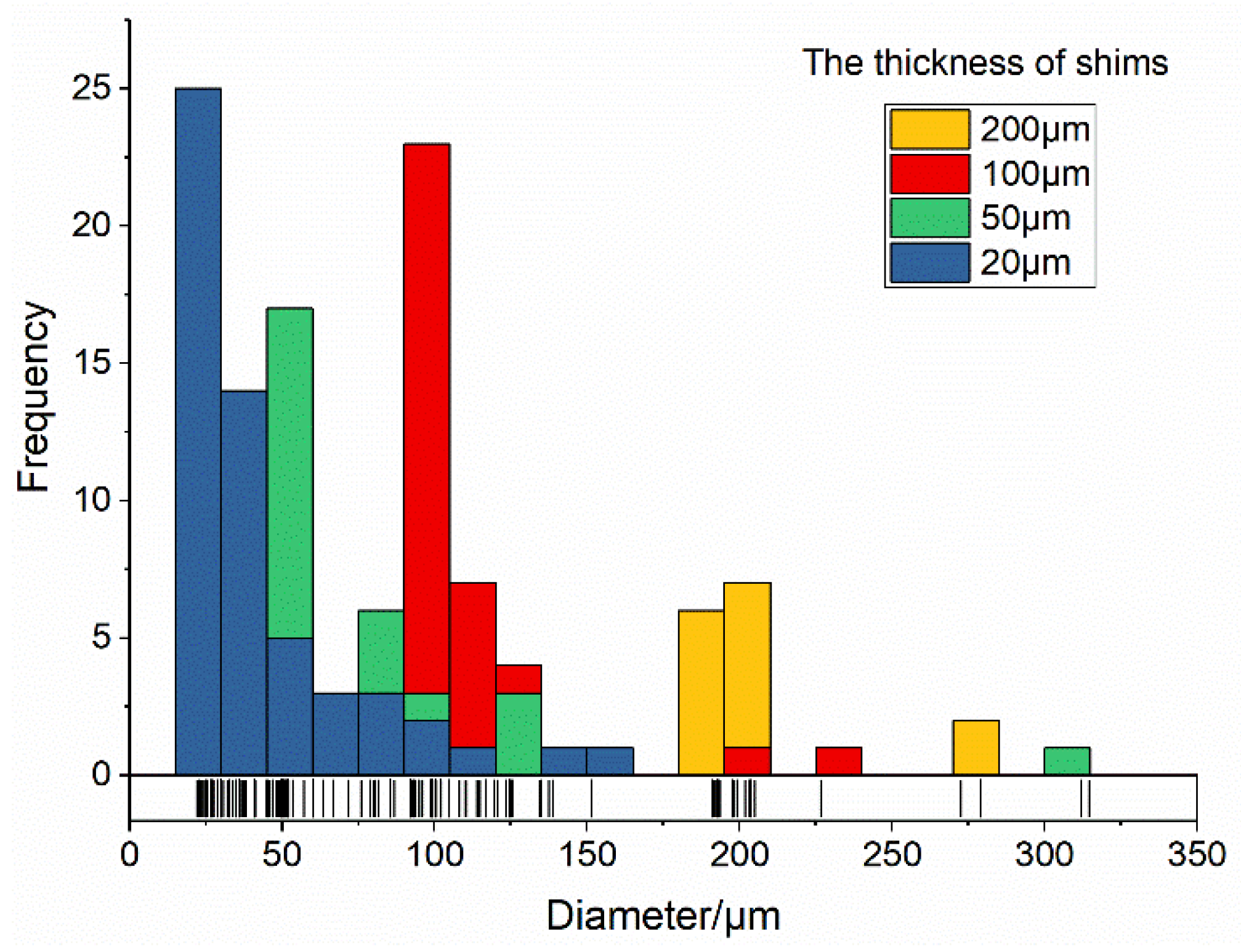

3.4. Determination of the Experimental Conditions for the PP Method

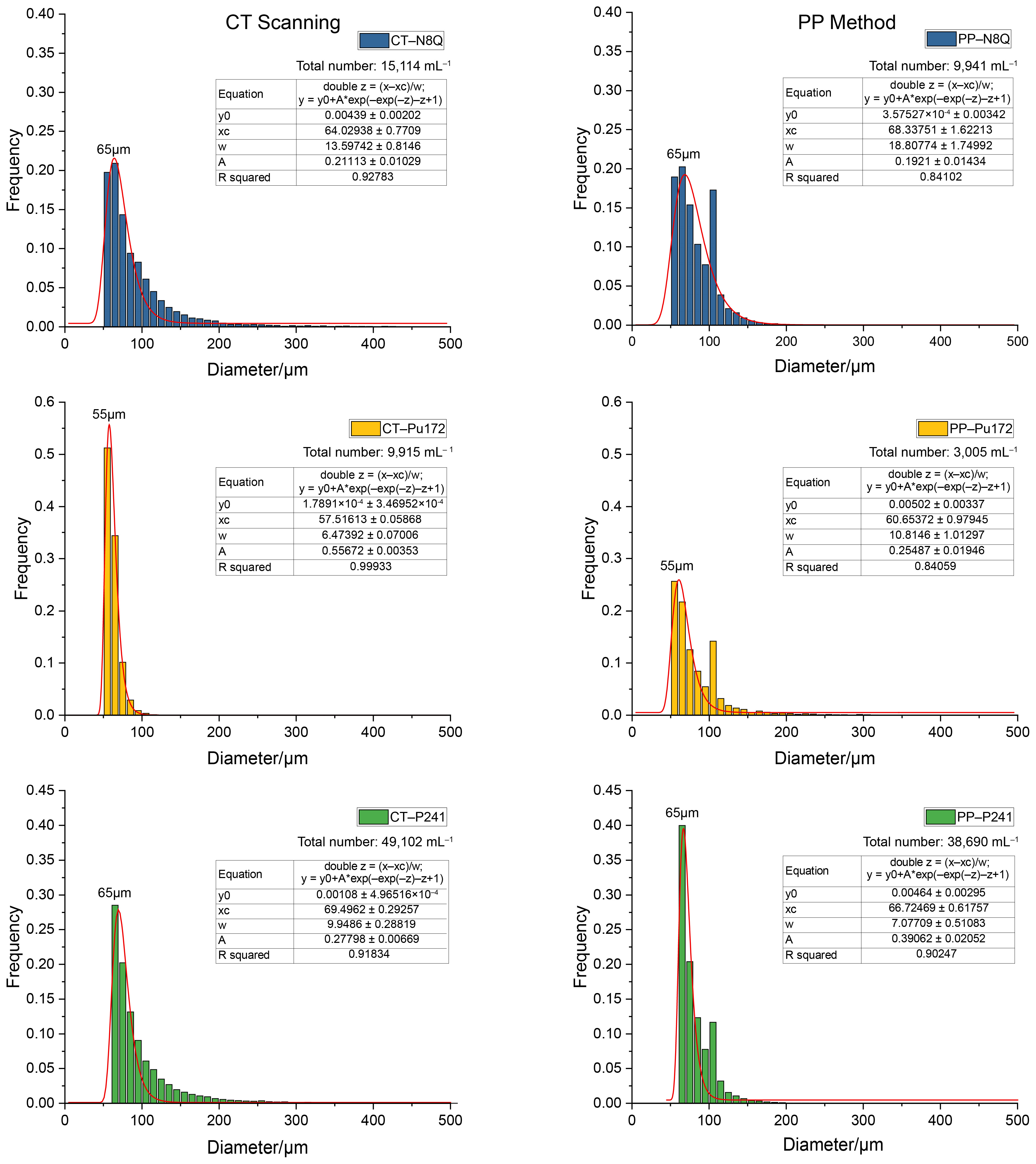

3.5. Reliability Analysis of the PP Method

3.6. Distribution of Water Droplets in Crude Oil from Different Oil Reservoirs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, L.; Zhong, L.; Ge, H.; Shen, Y. Effect of crude oil self-emulsification on the recovery of low permeability reservoir after well soaking. J. Pet. Sci. Eng. 2023, 220, 111201. [Google Scholar] [CrossRef]

- Kokal, S. Crude-Oil Emulsions: A State-Of-The-Art Review. SPE Prod. Facil. 2005, 20, 5–13. [Google Scholar] [CrossRef]

- Sjöblom, J.; Mhatre, S.; Simon, S.; Skartlien, R.; Sørland, G. Emulsions in external electric fields. Adv. Colloid. Interface Sci. 2021, 294, 102455. [Google Scholar] [CrossRef] [PubMed]

- Langevin, D.; Poteau, S.; Hénaut, I.; Argillier, J.F. Crude Oil Emulsion Properties and Their Application to Heavy Oil Transportation. Oil Gas Sci. Technol. 2004, 59, 511–521. [Google Scholar] [CrossRef]

- Tim, T. Schowalter (2). Mechanics of Secondary Hydrocarbon Migration and Entrapment. Am. Assoc. Pet. Geol. Bull. 1979, 63, 723–760. [Google Scholar] [CrossRef]

- Umar, A.A.; Saaid, I.B.M.; Sulaimon, A.A.; Pilus, R.B.M. A review of petroleum emulsions and recent progress on water-in-crude oil emulsions stabilized by natural surfactants and solids. J. Pet. Sci. Eng. 2018, 165, 673–690. [Google Scholar] [CrossRef]

- Rane, J.P.; Harbottle, D.; Pauchard, V.; Couzis, A.; Banerjee, S. Adsorption kinetics of asphaltenes at the oil-water interface and nanoaggregation in the bulk. Langmuir 2012, 28, 9986–9995. [Google Scholar] [CrossRef] [PubMed]

- Czarnecki, J.; Moran, K. On the stabilization mechanism of water-in-oil emulsions in petroleum systems. Energy Fuels 2005, 19, 2074–2079. [Google Scholar] [CrossRef]

- Kilpatrick, P.K. Water-in-crude oil emulsion stabilization: Review and unanswered questions. Energy Fuels 2012, 26, 4017–4026. [Google Scholar] [CrossRef]

- Mironova, M.V.; Ilyin, S.O. Effect of silica and clay minerals on rheology of heavy crude oil emulsions. Fuel 2018, 232, 290–298. [Google Scholar] [CrossRef]

- Brauner, N.; Ullmann, A. Modeling of phase inversion phenomenon in two-phase pipe flows. Int. J. Multiph. Flow 2002, 28, 1177–1204. [Google Scholar] [CrossRef]

- Abdulredha, M.M.; Hussain, S.A.; Abdullah, L.C.; Hong, T.L. Water-in-oil emulsion stability and demulsification via surface-active compounds: A review. J. Pet. Sci. Eng. 2022, 209, 109848. [Google Scholar] [CrossRef]

- Subramanian, D.; May, N.; Firoozabadi, A. Functional Molecules and the Stability of Water-in-Crude Oil Emulsions. Energy Fuels 2017, 31, 8967–8977. [Google Scholar] [CrossRef]

- Chen, W.S.; Chen, Z.Y.; Chang, J.Y.; Chen, C.Y.; Zeng, Y.P. Ultrasound-assisted desalination of crude oil: The influence of mixing extent, crude oil species, chemical demulsifier and operation variables. Ultrason. Sonochem. 2022, 83, 105947. [Google Scholar] [CrossRef] [PubMed]

- Zadymova, N.M.; Skvortsova, Z.N.; Traskin, V.Y.; Yampol’skaya, G.P.; Mironova, M.V.; Frenkin, E.I.; Kulichikhin, V.G.; Malkin, A.Y. Heavy oil as an emulsion: Composition, structure, and rheological properties. Colloid J. 2016, 78, 735–746. [Google Scholar] [CrossRef]

- Nguyen, N.N.; Berger, R.; Butt, H.J. Premelting-Induced Agglomeration of Hydrates: Theoretical Analysis and Modeling. ACS Appl. Mater. Interfaces 2020, 12, 14599–14606. [Google Scholar] [CrossRef] [PubMed]

- Meckenstock, R.U.; von Netzer, F.; Stumpp, C.; Lueders, T.; Himmelberg, A.M.; Hertkorn, N.; Schmitt-Kopplin, P.; Harir, M.; Hosein, R.; Haque, S.; et al. Water droplets in oil are microhabitats for microbial life. Science 2014, 345, 673–676. [Google Scholar] [CrossRef]

- Pannekens, M.; Kroll, L.; Müller, H.; Mbow, F.T.; Meckenstock, R.U. Oil reservoirs, an exceptional habitat for microorganisms. N. Biotechnol. 2019, 49, 1–9. [Google Scholar] [CrossRef]

- Natalia, I.; de Oliveir, V.M. Microbial Hydrocarbon Degradation: Efforts to Understand Biodegradation in Petroleum Reservoirs. In Biodegradation—Engineering and Technology; InTech: London, UK, 2013. [Google Scholar] [CrossRef]

- Pannekens, M.; Voskuhl, L.; Meier, A.; Müller, H.; Haque, S.; Frösler, J.; Brauer, V.S.; Meckenstock, R.U. Densely populated water droplets in heavy-oil seeps. Appl. Environ. Microbiol. 2020, 86, e00164-20. [Google Scholar] [CrossRef]

- Cai, M.; Nie, Y.; Chi, C.-Q.; Tang, Y.-Q.; Li, Y.; Wang, X.-B.; Liu, Z.-S.; Yang, Y.; Zhou, J.; Wu, X.-L. Crude oil as a microbial seed bank with unexpected functional potentials. Sci. Rep. 2015, 5, 16057. [Google Scholar] [CrossRef] [PubMed]

- Liang, B.; Zhang, K.; Wang, L.-Y.; Liu, J.-F.; Yang, S.-Z.; Gu, J.-D.; Mu, B.-Z.; Liang, B.; Zhang, K.; Wang, L.-Y.; et al. Different diversity and distribution of archaeal community in the aqueous and oil phases of production fluid from high-temperature petroleum reservoirs. Front. Microbiol. 2018, 9, 841. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Liang, B.; Wang, L.-Y.; Liu, J.-F.; Mu, B.-Z.; Shim, H.; Gu, J.-D. Identifying the core bacterial microbiome of hydrocarbon degradation and a shift of dominant methanogenesis pathways in the oil and aqueous phases of petroleum reservoirs of different temperatures from China. Biogeosciences 2019, 16, 4229–4241. [Google Scholar] [CrossRef]

- Van Hamme, J.D.; Singh, A.; Ward, O.P. Recent Advances in Petroleum Microbiology. Microbiol. Mol. Biol. Rev. 2003, 67, 503–549. [Google Scholar] [CrossRef] [PubMed]

- Araujo, A.M.; Santos, L.M.; Fortuny, M.; Melo, R.L.F.V.; Coutinho, R.C.C.; Santos, A.F. Evaluation of water content and average droplet size in water-in-crude oil emulsions by means of near-infrared spectroscopy. Energy Fuels 2008, 22, 3450–3458. [Google Scholar] [CrossRef]

- Borges, G.R.; Farias, G.B.; Braz, T.M.; Santos, L.M.; Amaral, M.J.; Fortuny, M.; Franceschi, E.; Dariva, C.; Santos, A.F. Use of near infrared for evaluation of droplet size distribution and water content in water-in-crude oil emulsions in pressurized pipeline. Fuel 2015, 147, 43–52. [Google Scholar] [CrossRef]

- Fridjonsson, E.O.; Graham, B.F.; Akhfash, M.; May, E.F.; Johns, M.L. Optimized droplet sizing of water-in-crude oil emulsions using nuclear magnetic resonance. Energy Fuels 2014, 28, 1756–1764. [Google Scholar] [CrossRef]

- Xiong, C.; Ding, B.; Geng, X.; Guan, B.; Pan, J.; Dong, J.; Huang, B.; Yan, Y. Quantitative analysis on distribution of microcosmic residual oil in reservoirs by frozen phase and nuclear magnetic resonance (NMR) technology. J. Pet. Sci. Eng. 2020, 192, 107256. [Google Scholar] [CrossRef]

- Wang, Y.; Niu, F.; Zhang, X.; Xiao, J.; Xu, C. Super resolution reconstruction of digital core image based on transfer learning. Energy Rep. 2022, 8, 87–94. [Google Scholar] [CrossRef]

- Pannekens, M.; Voskuhl, L.; Mohammadian, S.; Köster, D.; Meier, A.; Köhne, J.M.; Kulbatzki, M.; Akbari, A.; Haque, S.; Meckenstock, R.U. Microbial Degradation Rates of Natural Bitumen. Environ. Sci. Technol. 2021, 55, 8700–8708. [Google Scholar] [CrossRef] [PubMed]

- Sjöblom, J.; Aske, N.; Auflem, I.H.; Brandal, Ø.; Havre, T.E.; Sæther, Ø.; Westvik, A.; Johnsen, E.E.; Kallevik, H. Our current understanding of water-in-crude oil emulsions. Adv. Colloid. Interface Sci. 2003, 100–102, 399–473. [Google Scholar] [CrossRef]

- Ni, X.; Shi, H.; Zhang, J.; Liu, R.; Wang, J.; Cheng, R. Modified Laponite synthesized with special wettability as a multifunctional additive in oil-based drilling fluids. J. Pet. Sci. Eng. 2023, 220, 111211. [Google Scholar] [CrossRef]

- Chodankar, S.; Aswal, V.K.; Hassan, P.A.; Wagh, A.G. Structure of protein-surfactant complexes as studied by small-angle neutron scattering and dynamic light scattering. Phys. B Condens. Matter 2007, 398, 112–117. [Google Scholar] [CrossRef]

- Curtis, D.B.; Aycibin, M.; Young, M.A.; Grassian, V.H.; Kleiber, P.D. Simultaneous measurement of light-scattering properties and particle size distribution for aerosols: Application to ammonium sulfate and quartz aerosol particles. Atmos. Environ. 2007, 41, 4748–4758. [Google Scholar] [CrossRef]

- Boxall, J.A.; Koh, C.A.; Sloan, E.D.; Sum, A.K.; Wu, D.T. Measurement and calibration of droplet size distributions in water-in-Oil emulsions by particle video microscope and a focused beam reflectance method. Ind. Eng. Chem. Res. 2010, 49, 1412–1418. [Google Scholar] [CrossRef]

- Kong, L.; Deng, J.; Zhou, X.; Cai, B.; Zhang, B.; Chen, X.; Chen, Z.; Wang, W. Sitagliptin activates the p62–Keap1–Nrf2 signalling pathway to alleviate oxidative stress and excessive autophagy in severe acute pancreatitis-related acute lung injury. Cell Death Dis. 2021, 12, 928. [Google Scholar] [CrossRef] [PubMed]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Myers, T.G.; Charpin, J.P.F. A mathematical model of the Leidenfrost effect on an axisymmetric droplet. Phys. Fluids 2009, 21, 063101. [Google Scholar] [CrossRef]

- Zhou, W.; Zhang, Y.; Qi, H.; Wang, Q.; Yao, B.; Li, D. Optical properties of crude oil with different temperatures. Optik 2019, 196, 162946. [Google Scholar] [CrossRef]

- Wu, B.; Gao, J. A Viscosity Reduction Study on Chinese Extra Heavy Oil by the Addition of Synthesized Novel Oil-Soluble Viscosity-Reducing Agents. Pet. Sci. Technol. 2010, 28, 1919–1935. [Google Scholar] [CrossRef]

- Neto, D.M.; Sad, C.M.; Silva, M.; Santos, F.D.; Pereira, L.B.; Corona, R.R.; Barbosa, L.R.; Silva, S.R.; Bassane, J.F.; Castro, E.V.; et al. Rheological study of the behavior of water-in-oil emulsions of heavy oils. J. Pet. Sci. Eng. 2019, 173, 1323–1331. [Google Scholar] [CrossRef]

- Wang, C.; An, S.; Li, Z.; Chen, H.; Yan, Z.; Tan, Y. Novel epigallocatechin gallate-based polyether surfactants: Synthesis, characterization and demulsification properties. Colloids Surf. A Physicochem. Eng. Asp. 2021, 623, 126757. [Google Scholar] [CrossRef]

- Wang, Z.; Shu, L.; Su, X.; Niu, S. Evaluating Particle Deposition in the Artificial Groundwater Recharge Process by Physical and CT Imaging Experiments. Water Resour. Manag. 2021, 35, 4789–4807. [Google Scholar] [CrossRef]

- Moradi, M.; Alvarado, V.; Huzurbazar, S. Effect of Salinity on Water-in-Crude Oil Emulsion: Evaluation through Drop-Size Distribution Proxy. Energy Fuels 2011, 25, 260–268. [Google Scholar] [CrossRef]

- Gibbons, S.M.; Caporaso, J.G.; Pirrung, M.; Field, D.; Knight, R.; Gilbert, J.A. Evidence for a persistent microbial seed bank throughout the global ocean. Proc. Natl. Acad. Sci. USA 2013, 110, 4651–4655. [Google Scholar] [CrossRef]

- Lennon, J.T.; Jones, S.E. Microbial seed banks: The ecological and evolutionary implications of dormancy. Nat. Rev. Microbiol. 2011, 9, 119–130. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.Y.; Ke, W.J.; Sun, X.B.; Liu, J.F.; Gu, J.D.; Mu, B.Z. Comparison of bacterial community in aqueous and oil phases of water-flooded petroleum reservoirs using pyrosequencing and clone library approaches. Appl. Microbiol. Biotechnol. 2014, 98, 4209–4221. [Google Scholar] [CrossRef] [PubMed]

| P241 | N8Q | Pu172 | SS5301 | Y19 | 35-454 | |

|---|---|---|---|---|---|---|

| Oilfield | Daqing | Daqing | Daqing | Daqing | Changqing | Shengli |

| Temperature (°C) | 45 | 45 | 59.4 | 44.5–49.4 | 45 | 55–60 |

| Water flooding (years) | <20 | <20 | 0 | <20 | 0 | >20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Liu, Y.; Zhou, L.; Yang, S.; Gu, J.; Mu, B. An Improved Method for Measuring the Distribution of Water Droplets in Crude Oil Based on the Optical Microscopy Technique. Laboratories 2025, 2, 1. https://doi.org/10.3390/laboratories2010001

Wang Q, Liu Y, Zhou L, Yang S, Gu J, Mu B. An Improved Method for Measuring the Distribution of Water Droplets in Crude Oil Based on the Optical Microscopy Technique. Laboratories. 2025; 2(1):1. https://doi.org/10.3390/laboratories2010001

Chicago/Turabian StyleWang, Qiaohui, Yifan Liu, Lei Zhou, Shizhong Yang, Jidong Gu, and Bozhong Mu. 2025. "An Improved Method for Measuring the Distribution of Water Droplets in Crude Oil Based on the Optical Microscopy Technique" Laboratories 2, no. 1: 1. https://doi.org/10.3390/laboratories2010001

APA StyleWang, Q., Liu, Y., Zhou, L., Yang, S., Gu, J., & Mu, B. (2025). An Improved Method for Measuring the Distribution of Water Droplets in Crude Oil Based on the Optical Microscopy Technique. Laboratories, 2(1), 1. https://doi.org/10.3390/laboratories2010001