The Potential of Bioethanol from Agricultural Crop Residues: A Case Study of Algeria

Abstract

1. Introduction

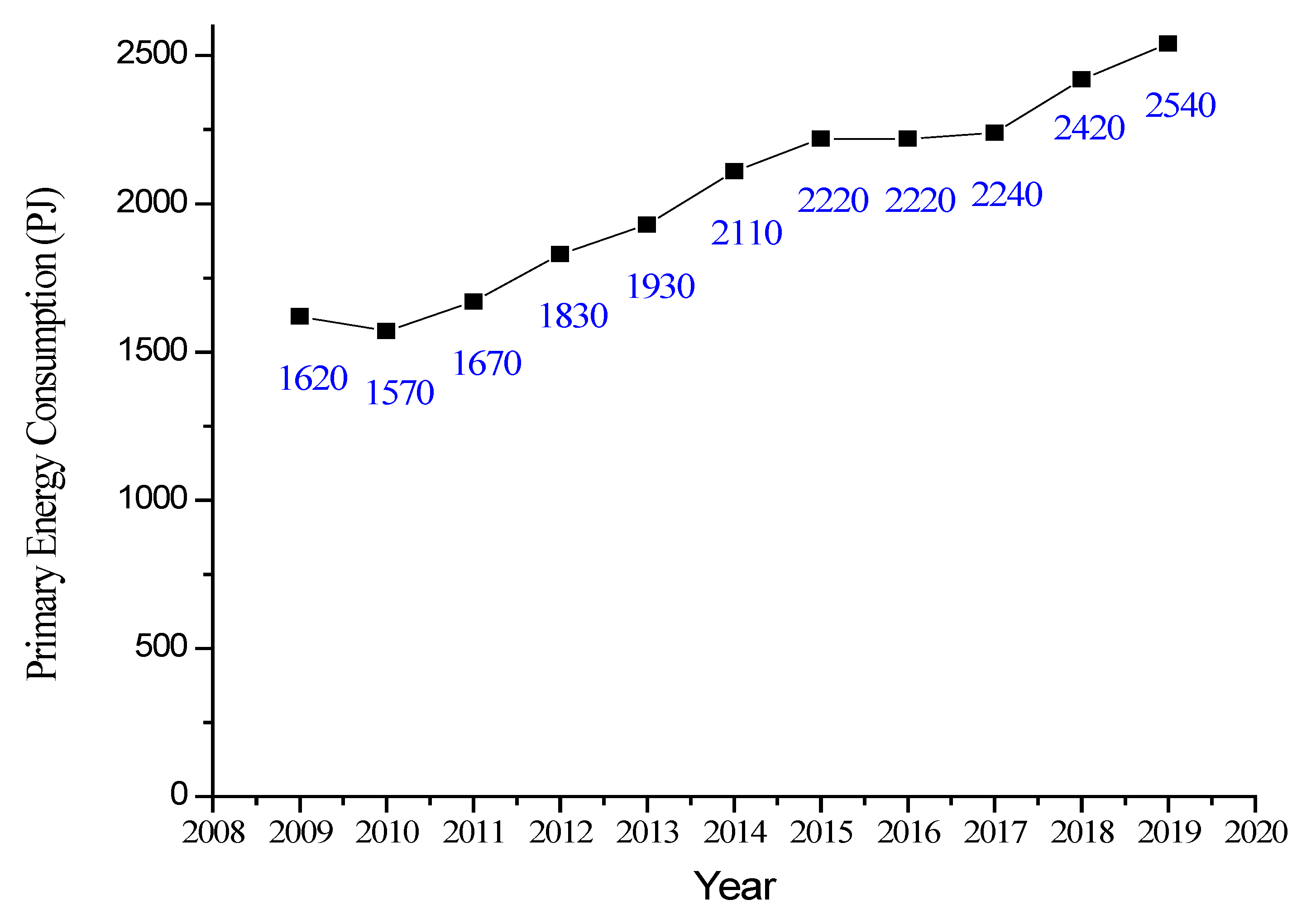

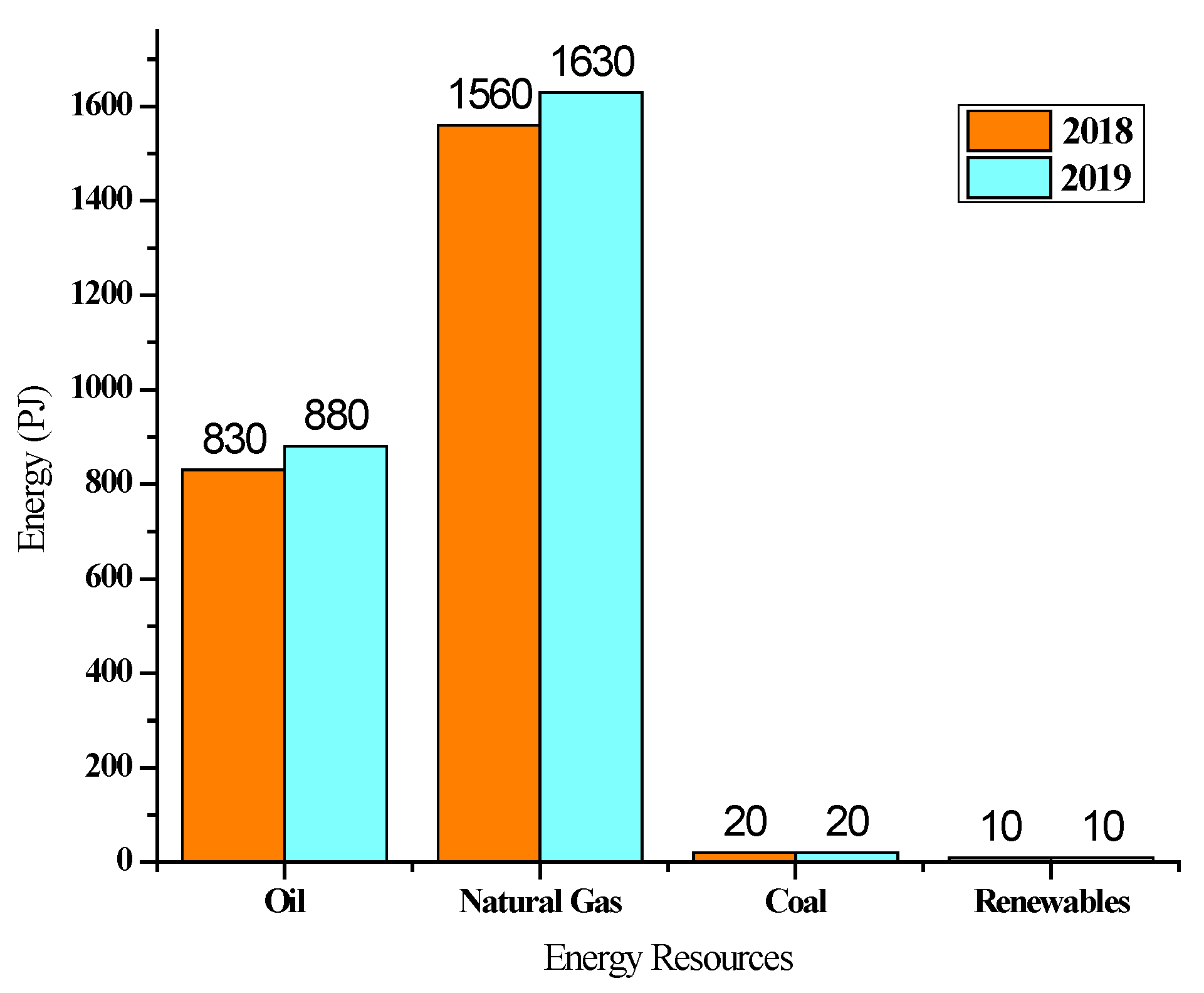

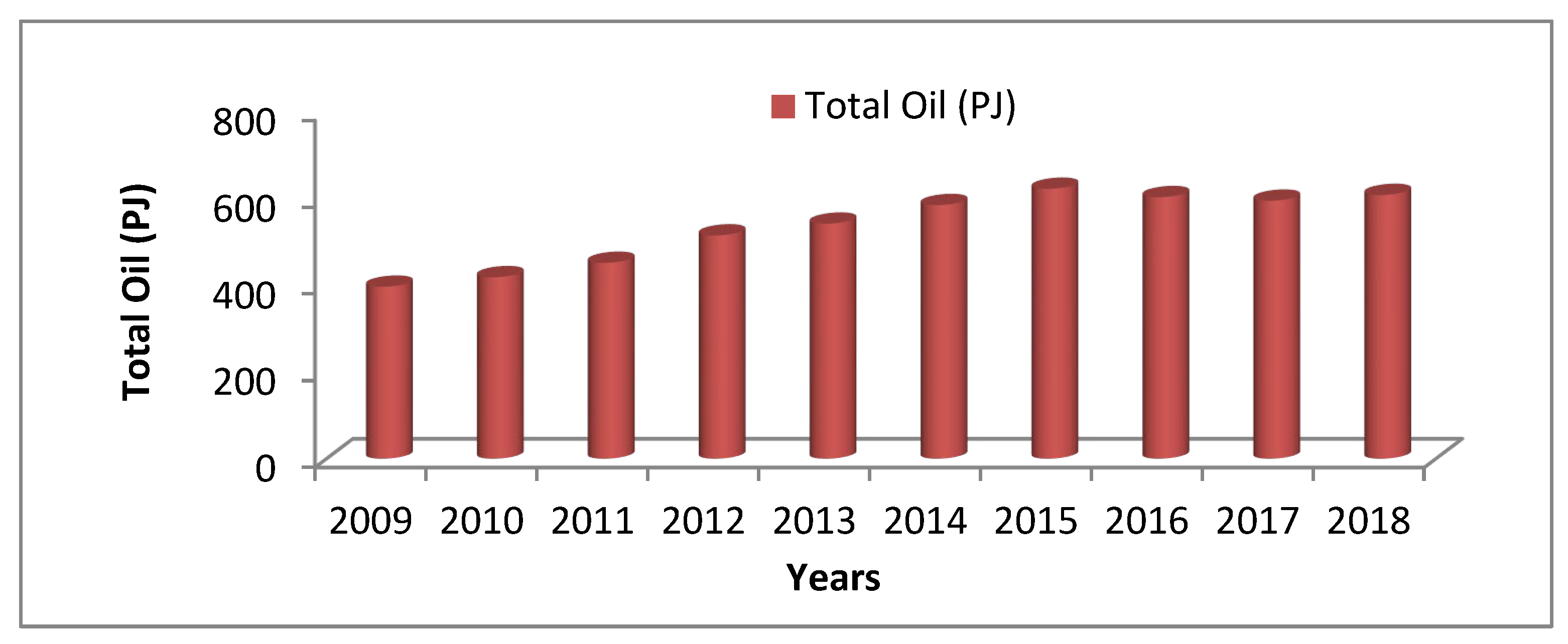

2. Topography and Energy Status of Algeria

2.1. Demographic Information

2.2. Bioenergy in Algeria

2.3. Bioethanol Generation

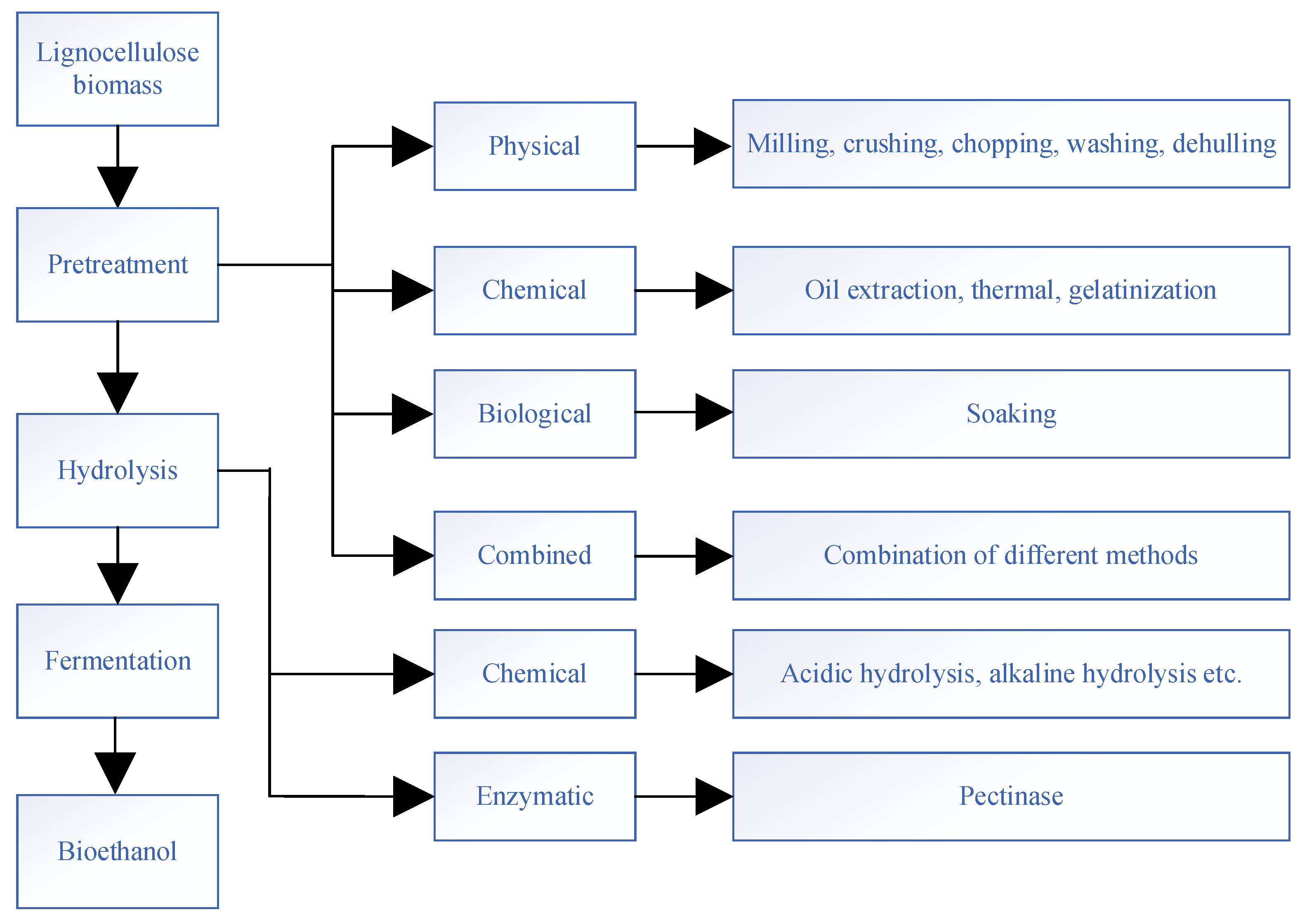

2.4. Technologies for Bioethanol Generation

3. Data and Methodologies

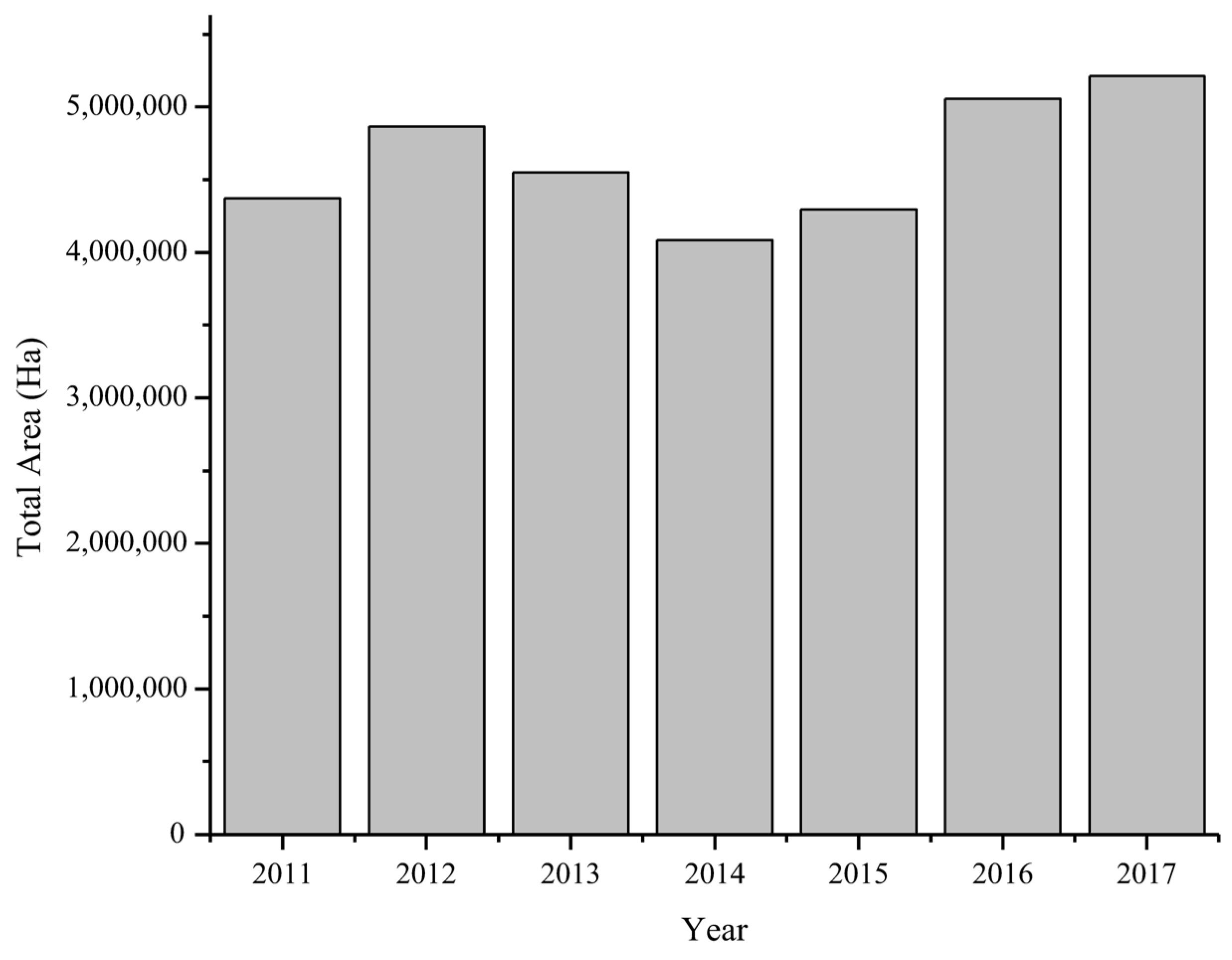

3.1. Agricultural Sector of Algeria

3.2. Agricultural Crop Percentage

3.3. Residue Recovery and Bioethanol Generation

3.4. Economic Evaluation

4. Results and Discussion

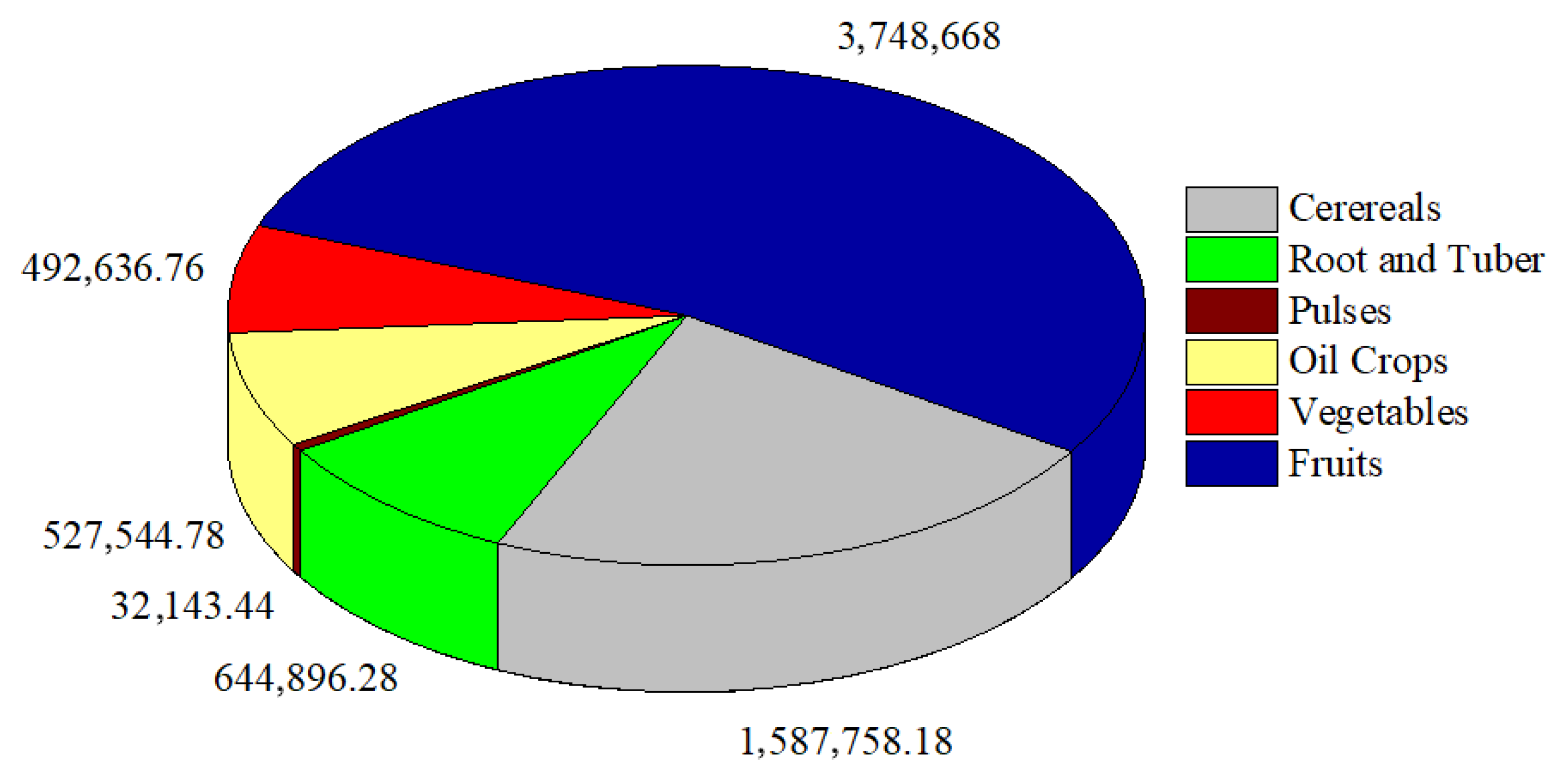

4.1. Agricultural Residues Recovery

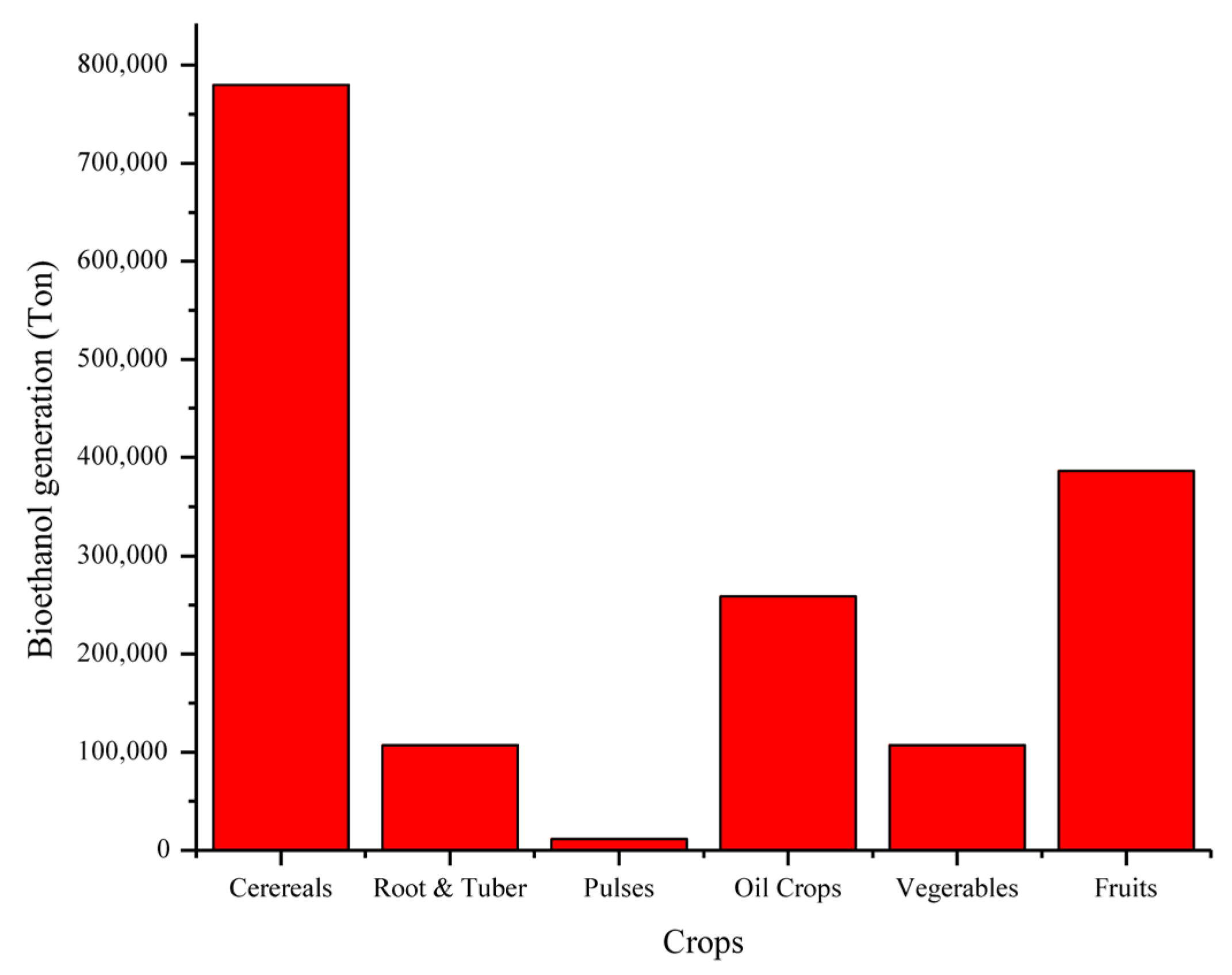

4.2. Agricultural Residue to Bioethanol

4.3. Contribution of Various Crops in Bioethanol Generation

4.4. Comparison with Other Studies

4.5. Limitations and Future Studies

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

Abbreviations

| Ac | Crop Production |

| B | Amount of Bioethanol |

| CI | Compression Ignition |

| CR | Conversion Rate of Bioethanol |

| E5 | 5% Ethanol Mixed with 95% Gasoline |

| E10 | 10% Ethanol Mixed with 90% Gasoline |

| Hg/ha | Hectogram/Hectare |

| kt | Kiloton |

| ktoe | Kiloton of Oil Equivalent |

| PJ | Peta Joule |

| Rc | Residue to Crop Ratio |

| SI | Spark Ignition |

References

- Miskat, M.I.; Ahmed, A.; Chowdhury, H.; Chowdhury, T.; Chowdhury, P.; Sait, S.M.; Yoon, K.P. Assessing the Theoretical Prospects of Bioethanol Production as a Biofuel from Agricultural Residues in Bangladesh: A Review. Sustainability 2020, 12, 8583. [Google Scholar] [CrossRef]

- Kiehbadroudinezhad, M.; Merabet, A.; Hosseinzadeh-Bandbafha, H. Health Impacts of Greenhouse Gases Emissions on Humans and the Environment. In Advances and Technology Development in Greenhouse Gases: Emission, Capture and Conversion; Elsevier: Amsterdam, The Netherlands, 2024; pp. 265–291. [Google Scholar] [CrossRef]

- El Mokh, S.; Ait Kaki, A.; Benaouda, H. Assessment of Agricultural and Environmental Impacts Using Remote Sensing and GIS Techniques: Case Study in Algeria. Medicon Agric. Environ. Sci. 2023, 3, 229. [Google Scholar]

- Moogi, S.; Nakka, L.; Potharaju, S.S.P.; Ahmed, A.; Farooq, A.; Jung, S.C.; Rhee, G.H.; Park, Y.K. Copper Promoted Co/MgO: A Stable and Efficient Catalyst for Glycerol Steam Reforming. Int. J. Hydrogen Energy 2021, 46, 18073–18084. [Google Scholar] [CrossRef]

- Golfam, P.; Ashofteh, P.-S. Environmental-economic analysis of regional energy system under different supply and demand side scenarios with LEAP model. Environ. Dev. Sustain. 2024, 1–22. [Google Scholar] [CrossRef]

- Nguyen, N.-T.; Nguyen, T.-H.; Hoang, T.-H.; Nguyen, T.-T.; Nguyen, T.-A.; Le, T.-H.; Le, T.-H.; Nguyen, T.-L.; Nguyen, T.-N. Solar Radiation Forecasting Based on Random Forest and XGBoost. In Proceedings of the 7th International Conference on Green Technology and Sustainable Development (GTSD), Ho Chi Minh City, Vietnam, 25–26 July 2024; pp. 136–140. [Google Scholar] [CrossRef]

- Wang, C.; Li, Y.; Wan, J.; Hu, Y. Analysis of CO2 Emissions Reduction via By-Product Hydrogen. Int. J. Hydrogen Energy 2024, 67, 942–948. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Hossain, N.; Ahmed, A.; Hossen, M.S.; Chowdhury, P.; Saidur, R.; Thirugnanasambandam, M. Latest Advancements on Livestock Waste Management and Biogas Production: Bangladesh’s Perspective. J. Clean. Prod. 2020, 272, 122818. [Google Scholar] [CrossRef]

- Khraief, N.; Shahbaz, M.; Mallick, H.; Loganathan, N. Estimation of Electricity Demand Function for Algeria: Revisit of Time Series Analysis. Renew. Sustain. Energy Rev. 2018, 82, 4221–4234. [Google Scholar] [CrossRef]

- Bouraiou, A.; Necaibia, A.; Boutasseta, N.; Mekhilef, S.; Dabou, R.; Ziane, A.; Sahouane, N.; Attoui, I.; Mostefaoui, M.; Touaba, O. Status of Renewable Energy Potential and Utilization in Algeria. J. Clean. Prod. 2020, 246, 119011. [Google Scholar] [CrossRef]

- Imene, B.; Nouria, K. The Shift towards Renewable Energies and Its Role in Sustainable Development in Algeria. WSEAS Trans. Environ. Dev. 2024, 20, 940–953. [Google Scholar] [CrossRef]

- British Petroleum Company. Statistical Review of World Energy. 2020. Available online: www.bp.com/statisticalreview (accessed on 1 June 2025).

- Kaid, I.; Hafaifa, A.; Guemana, M.; Hadroug, N.; Kouzou, A.; Mazouz, L. Photovoltaic System Failure Diagnosis Based on Adaptive Neuro Fuzzy Inference Approach: South Algeria Solar Power Plant. J. Clean. Prod. 2018, 204, 169–182. [Google Scholar] [CrossRef]

- Stambouli, A.B. Promotion of Renewable Energies in Algeria: Strategies and Perspectives. Renew. Sustain. Energy Rev. 2011, 15, 1169–1181. [Google Scholar] [CrossRef]

- Nacer, T.; Hamidat, A.; Nadjemi, O. A comprehensive method to assess the feasibility of renewable energy on Algerian dairy farms. J. Clean. Prod. 2016, 112, 3631–3642. [Google Scholar] [CrossRef]

- Roummani, K.; Hamouda, M.; Mazari, B.; Bendjebbar, M.; Koussa, K.; Ferroudji, F.; Necaibia, A. A new concept in direct-driven vertical axis wind energy conversion system under real wind speed with robust stator power control. Renew. Energy 2019, 143, 478–487. [Google Scholar] [CrossRef]

- Saba, D.; Sahli, Y.; Abanda, F.H.; Maouedj, R.; Tidjar, B. Development of new ontological solution for an energy intelligent management in Adrar city. Sustain. Comput. Inform. Syst. 2019, 21, 189–203. [Google Scholar] [CrossRef]

- Akbi, A.; Saber, M.; Aziza, M.; Yassaa, N. An overview of sustainable bioenergy potential in Algeria. Renew. Sustain. Energy Rev. 2017, 72, 240–245. [Google Scholar] [CrossRef]

- Kalloum, S.; Bouabdessalem, H.; Touzi, A.; Iddou, A.; Ouali, M.S. Biogas production from the sludge of the municipal wastewater treatment plant of Adrar city (southwest of Algeria). Biomass Bioenergy 2011, 35, 2554–2560. [Google Scholar] [CrossRef]

- Eddine, B.T.; Salah, M.M. Solid waste as renewable source of energy: Current and future possibility in Algeria. Int. J. Energy Environ. Eng. 2012, 3, 17. [Google Scholar] [CrossRef]

- Mehani, I.; Boulal, A.; Bouchekima, B. Bio Fuel Production from Waste of Starting Dates in South Algeria. Int. J. Environ. Chem. Ecol. Geol. Geophys. Eng. 2013, 7, 8. [Google Scholar] [CrossRef]

- Mehani, I.; Bouchekima, B. Bioethanol production from renewable sources as alternative valorization of waste of starting dates in south Algeria. AIP Conf. Proc. 2018, 1968, 030023. [Google Scholar] [CrossRef]

- Laskri, N.; Nedjah, N.; Daas, D. Bioethanol production of the lignocellulosics wastes in Algeria. In Proceedings of the 8th International Conference on Research in Engineering, Science and Technology, Paris, France, 2–3 November 2018. [Google Scholar]

- Edjekouane, M.; Lansari, F.; Khelifi, O.; Boukheteche, I.; Laksaci, H. Production of bioethanol from a local natural resource. Alger. J. Renew. Energy Sustain. Dev. 2020, 2, 56–59. [Google Scholar] [CrossRef]

- Gares, M.; Hiligsmann, S.; Kacem Chaouche, N. Lignocellulosic biomass and industrial bioprocesses for the production of second generation bio-ethanol, does it have a future in Algeria? SN Appl. Sci. 2020, 2, 1680. [Google Scholar] [CrossRef]

- Hossain, A.K.; Badr, O. Prospects of renewable energy utilisation for electricity generation in Bangladesh. Renew. Sustain. Energy Rev. 2007, 11, 1617–1649. [Google Scholar] [CrossRef]

- Kamadje, S.D.A.; Nouadjep, N.S.; Gueguim Kana, E.B. Assessing renewable energy trends: A global bibliometric analysis of biomass, solar, wind, and geothermal resources with emphasis on Cameroon. Int. J. Energy Water Resour. 2025, 1–20. [Google Scholar] [CrossRef]

- Food and Agricultural Organisation of the United Nations. FAOSTAT Database. 2020. Available online: http://www.fao.org/faostat/en/#data (accessed on 1 November 2024).

- Ghorab, A.; Boudahmane, S.; Ait Kaki, M.; Bouchekima, A.; Bouchekima, S.; Benali, M.; Boudahmane, A. Melissopalinology of Algerian Honeys: From the Plant to the Jar. In Advances in Food Science and Technology; IGI Global: Hershey, PA, USA, 2024; pp. 1–15. [Google Scholar] [CrossRef]

- de l’Énergie, M. Algérie. 2020. Available online: https://www.energy.gov.dz (accessed on 11 September 2025).

- World Bank’s Urban Development and Local Government Unit of the Sustainable and Development Network. A Global Review of Solid Waste Management. 2012. Available online: http://documents1.worldbank.org/curated/en/302341468126264791/pdf/68135-REVISED-What-a-Waste-2012-Final-updated.pdf (accessed on 7 December 2024).

- National Waste Agency. Indicateurs, États des Lieux et Perspectives. Ministry of Environment and Renewable Energy. 2017. Available online: http://and.dz/indicateursdechets-en-algerie (accessed on 11 September 2025).

- Al-Widyan, M.I.; Tashtoush, G.; Hamasha, A.M. Combustion and emissions of pulverised olive cake in tube furnace. Energy Convers. Manag. 2006, 47, 1588–1596. [Google Scholar] [CrossRef]

- Miranda, T.; Esteban, A.; Rojas, S.; Montero, I.; Ruiz, A. Combustion analysis of different olive residues. Int. J. Mol. Sci. 2008, 9, 512–525. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, H.; Chowdhury, T.; Chowdhury, P.; Islam, M.; Saidur, R.; Sait, S.M. Integrating sustainability analysis with sectoral exergy analysis: A case study of rural residential sector of Bangladesh. Energy Build. 2019, 202, 109397. [Google Scholar] [CrossRef]

- Al-Hamamre, Z.; Saidan, M.; Hararah, M.; Rawajfeh, K.; Alkhasawneh, H.E.; Al-Shannag, M. Wastes and biomass materials as sustainable-renewable energy resources for Jordan. Renew. Sustain. Energy Rev. 2017, 67, 295–314. [Google Scholar] [CrossRef]

- Khandaker, T.; Islam, T.; Nandi, A.; Anik, M.A.A.M.; Hossain, M.S.; Hasan, M.K.; Hossain, M.S. Biomass-Derived Carbon Materials for Sustainable Energy Applications: A Comprehensive Review. Sustain. Energy Fuels 2025, 9, 693–723. [Google Scholar] [CrossRef]

- Balat, M.; Ayar, G. Biomass energy in the world, use of biomass and potential trends. Energy Sources 2005, 27, 931–940. [Google Scholar] [CrossRef]

- Pode, R. Potential applications of rice husk ash waste from rice husk biomass power plant. Renew. Sustain. Energy Rev. 2016, 53, 1468–1485. [Google Scholar] [CrossRef]

- Chowdhury, T.; Chowdhury, H.; Chowdhury, P.; Barua, P.; Miskat, I. Economic Viability of Biomass Power Plant in Bangladesh. In Proceedings of the 5th International Conference on Mechanical, Industrial and Energy Engineering 2018, Khulna, Bangladesh, 23–24 December 2018; pp. 18–21. [Google Scholar]

- Cardoso, J.; Silva, V.; Eusébio, D. Techno-economic analysis of a biomass gasification power plant dealing with forestry residues blends for electricity production in Portugal. J. Clean. Prod. 2019, 212, 741–753. [Google Scholar] [CrossRef]

- REN21. Renewables 2018—Global Status Report. In Proceedings of the REN21 Secretariat, Paris, France, 4 June 2018. [Google Scholar]

- Hernández, L.; Kafarov, V. Use of bioethanol for sustainable electrical energy production. Int. J. Hydrogen Energy 2009, 34, 7041–7050. [Google Scholar] [CrossRef]

- Swain, M.R.; Mohanty, S.K. Bioethanol Production from Food Crops; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol production from renewable sources: Current perspectives and technological progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Grover, S. Energy Values and Technologies for Non woody Biomass: As a clean source of Energy. IOSR J. Electr. Electron. Eng. 2012, 1, 10–14. [Google Scholar] [CrossRef]

- Abdel-Hamid, A.M.; Solbiati, J.O.; Cann, I.K.O. Insights into Lignin Degradation and its Potential Industrial Applications. In Advances in Applied Microbiology; Academic Press Inc.: Cambridge, MA, USA, 2013; Volume 82, pp. 1–28. [Google Scholar]

- Al Azkawi, A.S.; Sivakumar, N.; Al Bahry, S. Bioprocessing of cardboard waste for cellulase production. Biomass Convers. Biorefinery 2018, 8, 597–606. [Google Scholar] [CrossRef]

- Maurya, D.P.; Singla, A.; Negi, S. An overview of key pretreatment processes for biological conversion of lignocellulosic biomass to bioethanol. 3 Biotech 2015, 5, 597–609. [Google Scholar] [CrossRef]

- Cheah, W.Y.; Sankaran, R.; Show, P.L.; Ibrahim, T.N.B.T.; Chew, K.W.; Culaba, A.; Chang, J.S. Pretreatment methods for lignocellulosic biofuels production: Current advances, challenges and future prospects. Biofuel Res. J. 2020, 7, 1115–1127. [Google Scholar] [CrossRef]

- Menon, V.R.; Rao, M. Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept. Prog. Energy Combust. Sci. 2012, 38, 522–550. [Google Scholar] [CrossRef]

- Rezania, S.; Oryani, B.; Cho, J.; Talaiekhozani, A.; Sabbagh, F.; Hashemi, B.; Mohammadi, A.A.; Rupani, P.F. Different pretreatment technologies of lignocellulosic biomass for bioethanol production: An overview. Energy 2020, 199, 117457. [Google Scholar] [CrossRef]

- Jiang, Z.; Fei, B.; Li, Z. Pretreatment of bamboo by ultra-high pressure explosion with a high-pressure homogenizer for enzymatic hydrolysis and ethanol fermentation. Bioresour. Technol. 2016, 214, 876–880. [Google Scholar] [CrossRef]

- Bak, J.S.; Ko, J.K.; Han, Y.H.; Lee, B.C.; Choi, I.-G.; Kim, K.H. Improved enzymatic hydrolysis yield of rice straw using electron beam irradiation pretreatment. Bioresour. Technol. 2009, 100, 1285–1290. [Google Scholar] [CrossRef]

- Song, B.; Buendia-Kandia, F.; Yu, Y.; Dufour, A.; Wu, H. Importance of lignin removal in enhancing biomass hydrolysis in hot-compressed water. Bioresour. Technol. 2019, 288, 121522. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, J.; Cao, J.; Wang, Z. Pretreatment with concurrent UV photocatalysis and alkaline H2O2 enhanced the enzymatic hydrolysis of sisal waste. Bioresour. Technol. 2018, 267, 517–523. [Google Scholar] [CrossRef]

- Maniet, G.; Schmetz, Q.; Jacquet, N.; Temmerman, M.; Gofflot, S.; Richel, A. Effect of steam explosion treatment on chemical composition and characteristics of organosolv fescue lignin. Ind. Crops Prod. 2017, 99, 79–85. [Google Scholar] [CrossRef]

- Bonfiglio, F.; Cagno, M.; Rey, F.; Torres, M.; Bothig, S.; Menendez, P.; Mussatto, S.I. Pretreatment of switchgrass by steam explosion in a semi-continuous pre-pilot reactor. Biomass Bioenergy 2019, 121, 41–47. [Google Scholar] [CrossRef]

- Tabka, M.G.; Herpoël-Gimbert, I.; Monod, F.; Asther, M.; Sigoillot, J. Enzymatic saccharification of wheat straw for bioethanol production by a combined cellulase, xylanase, and feruloyl esterase treatment. Enzym. Microb. Technol. 2006, 39, 897–902. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Kuan, W.-H.; Chang, C.-Y. Effects of particle size, pretreatment, and catalysis on microwave pyrolysis of corn stover. Energy 2018, 143, 696–703. [Google Scholar] [CrossRef]

- Li, H.; Qu, Y.; Yang, Y.; Chang, S.; Xu, J. Microwave irradiation—A green and efficient way to pretreat biomass. Bioresour. Technol. 2016, 199, 34–41. [Google Scholar] [CrossRef] [PubMed]

- Ooshima, H.; Aso, K.; Harano, Y.; Yamamoto, T. Microwave treatment of cellulosic materials for their enzymatic hydrolysis. Biotechnol. Lett. 1984, 6, 289–294. [Google Scholar] [CrossRef]

- Li, H.; Xu, J. Optimization of microwave-assisted calcium chloride pretreatment of corn stover. Bioresour. Technol. 2013, 127, 112–118. [Google Scholar] [CrossRef]

- Behera, S.; Arora, R.; Nandhagopal, N.; Kumar, S. Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2014, 36, 91–106. [Google Scholar] [CrossRef]

- Perumal, P.K.; Rajendran, S.; Ramasamy, S.; Thirugnanam, M.; Kumar, R.; Sundaram, S.; Kumar, S.; Suresh, R.; Karthikeyan, R.; Rajendran, K.; et al. Harnessing Ulva ohnoi for eco-friendly bioethanol production: Hydrothermal pretreatment and fermentation. Renew. Energy 2024, 197, 1234–1245. [Google Scholar] [CrossRef]

- Rabemanolontsoa, H.; Saka, S. Various pretreatments of lignocellulosics. Bioresour. Technol. 2016, 199, 83–91. [Google Scholar] [CrossRef]

- Gonzales, R.R.; Sivagurunathan, P.; Kim, S.-H. Effect of severity on dilute acid pretreatment of lignocellulosic biomass and the following hydrogen fermentation. Int. J. Hydrogen Energy 2016, 41, 21678–21684. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Romero-García, J.M.; Martínez-Patiño, J.C.; Ruiz-Ramos, E.; Castro-Galiano, E.; Cardona-Alzate, C.A. Acid pretreatment of lignocellulosic biomass for energy vectors production: A review focused on operational conditions and techno-economic assessment for bioethanol production. Renew. Sustain. Energy Rev. 2019, 107, 587–601. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48. [Google Scholar] [CrossRef]

- Bali, G.; Meng, X.; Deneff, J.I.; Sun, Q.; Ragauskas, A.J. The effect of alkaline pretreatment methods on cellulose structure and accessibility. ChemSusChem 2015, 8, 275–279. [Google Scholar] [CrossRef] [PubMed]

- Shuai, L.; Luterbacher, J. Organic solvent effects in biomass conversion reactions. ChemSusChem 2016, 9, 133–155. [Google Scholar] [CrossRef]

- Espinoza-Acosta, J.L.; Torres-Chavez, P.I.; Carvajal-Millan, E.; Ramírez-Wong, B.; Bello-Perez, L.A.; Montano Leyva, B. Ionic liquids and organic solvents for recovering lignin from lignocellulosic biomass. BioResources 2014, 9, 3660–3687. [Google Scholar] [CrossRef]

- Zhao, X.; Cheng, K.; Liu, D. Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl. Microbiol. Biotechnol. 2009, 82, 815–827. [Google Scholar] [CrossRef]

- Brandt, A.; Gräsvik, J.; Hallett, J.P.; Welton, T. Deconstruction of lignocellulosic biomass with ionic liquids. Green Chem. 2013, 15, 550–583. [Google Scholar] [CrossRef]

- Zavrel, M.; Bross, D.; Funke, M.; Büchs, J.; Spiess, A.C. High-throughput screening for ionic liquids dissolving (ligno-)cellulose. Bioresour. Technol. 2009, 100, 2580–2587. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, H.; Moniruzzaman, M.; Iqbal, T.; Khan, M.J. Recent advances in the pretreatment of lignocellulosic biomass for biofuels and value-added products. Curr. Opin. Green Sustain. Chem. 2019, 20, 18–24. [Google Scholar] [CrossRef]

- Kululo, W.W.; Habtu, N.G.; Abera, M.K.; Sendekie, Z.B.; Fanta, S.W.; Yemata, T.A. Advances in Various Pretreatment Strategies of Lignocellulosic Substrates for the Production of Bioethanol: A Comprehensive Review. Discover Appl. Sci. 2025, 7, 476. [Google Scholar] [CrossRef]

- Millati, R.; Syamsiah, S.; Niklasson, C.; Cahyanto, M.N.; Lundquist, K.; Taherzadeh, M.J.; Isroi. Biological pretreatment of lignocelluloses with white-rot fungi and its applications: A review. BioResources 2011, 6, 5224–5259. [Google Scholar] [CrossRef]

- Sharma, H.K.; Xu, C.; Qin, W. Biological pretreatment of lignocellulosic biomass for biofuels and bioproducts: An overview. Waste Biomass Valorization 2019, 10, 235–251. [Google Scholar] [CrossRef]

- Sharma, V.; Nargotra, P.; Bajaj, B.K. Ultrasound and surfactant assisted ionic liquid pretreatment of sugarcane bagasse for enhancing saccharification using enzymes from an ionic liquid tolerant Aspergillus assiutensis VS34. Bioresour. Technol. 2019, 285, 121319. [Google Scholar] [CrossRef]

- Shrestha, S.; Fonoll, X.; Khanal, S.K.; Raskin, L. Biological strategies for enhanced hydrolysis of lignocellulosic biomass during anaerobic digestion: Current status and future perspectives. Bioresour. Technol. 2017, 245, 1245–1257. [Google Scholar] [CrossRef]

- Wagner, A.; Lackner, N.; Mutschlechner, M.; Prem, E.; Markt, R.; Illmer, P. Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies 2018, 11, 1797. [Google Scholar] [CrossRef]

- Zabed, H.M.; Akter, S.; Yun, J.; Zhang, G.; Awad, F.N.; Qi, X.; Sahu, J. Recent advances in biological pretreatment of microalgae and lignocellulosic biomass for biofuel production. Renew. Sustain. Energy Rev. 2019, 105, 105–128. [Google Scholar] [CrossRef]

- Wang, Z.; Dien, B.S.; Rausch, K.D.; Tumbleson, M.E.; Singh, V. Fermentation of undetoxified sugarcane bagasse hydrolyzates using a two-stage hydrothermal and mechanical refining pretreatment. Bioresour. Technol. 2018, 261, 313–321. [Google Scholar] [CrossRef]

- Wu, X.; Huang, C.; Zhai, S.; Liang, C.; Huang, C.; Lai, C.; Yong, Q. Improving enzymatic hydrolysis efficiency of wheat straw through sequential autohydrolysis and alkaline post-extraction. Bioresour. Technol. 2018, 251, 374–380. [Google Scholar] [CrossRef]

- Yuan, Z.; Wen, Y.; Kapu, N.S. Ethanol production from bamboo using mild alkaline pre-extraction followed by alkaline hydrogen peroxide pretreatment. Bioresour. Technol. 2018, 247, 242–249. [Google Scholar] [CrossRef]

- Nargotra, P.; Sharma, V.; Gupta, M.; Kour, S.; Bajaj, B.K. Application of ionic liquid and alkali pretreatment for enhancing saccharification of sunflower stalk biomass for potential biofuel-ethanol production. Bioresour. Technol. 2018, 267, 560–568. [Google Scholar] [CrossRef]

- Verardi, A.; Blasi, A.; Marino, T.; Molino, A.; Calabrò, V. Effect of steam-pretreatment combined with hydrogen peroxide on lignocellulosic agricultural wastes for bioethanol production: Analysis of derived sugars and other by-products. J. Energy Chem. 2018, 27, 535–543. [Google Scholar] [CrossRef]

- Martínez-Patiño, J.C.; Lu-Chau, T.A.; Gullon, B.; Ruiz, E.; Romero, I.; Castro, E.; Lema, J.M. Application of a combined fungal and diluted acid pretreatment on olive tree biomass. Ind. Crop Prod. 2018, 121, 10–17. [Google Scholar]

- Iqbal, S.; Tirpanalan-Staben, Ö.; Franke, K. Modification of Dietary Fibers to Valorize the By-Products of Cereal, Fruit and Vegetable Industry—A Review on Treatment Methods. Plants 2022, 11, 3466. [Google Scholar] [CrossRef]

- Kazemi Shariat Panahi, H.; Dehhaghi, M.; Aghbashlo, M.; Karimi, K.; Tabatabaei, M. Conversion of residues from agro-food industry into bioethanol in Iran: An under-valued biofuel additive to phase out MTBE in gasoline. Renew. Energy 2020, 145, 699–710. [Google Scholar]

- International Energy Agency (IEA). Algeria. IEA. 2025. Available online: https://www.iea.org/countries/algeria (accessed on 24 August 2025).

- Jingura, R.M.; Matengaifa, R. The potential for energy production from crop residues in Zimbabwe. Biomass Bioenergy 2008, 32, 1287–1292. [Google Scholar] [CrossRef]

- Fang, Y.R.; Wu, Y.; Xie, G.H. Crop residue utilizations and potential for bioethanol production in China. Renew. Sustain. Energy Rev. 2019, 113, 109288. [Google Scholar] [CrossRef]

- Gatkal, N.R.; Nalawade, S.M.; Sahni, R.K.; Walunja, A.A.; Kadam, P.B.; Bhanage, G.B.; Datta, R. Present trends, sustainable strategies and energy potentials of crop residue management in India: A review. Heliyon 2024, 10, e39815. [Google Scholar] [CrossRef]

- Fatima, S.; Zeeshan, M. Energy potential assessment and geospatial site suitability for crop residue-based bioethanol production in Pakistan. Sustain. Prod. Consum. 2024, 45, 488–508. [Google Scholar] [CrossRef]

- Ilić, M.; Grubor, B.; Tesic, M. The state of biomass energy in Serbia. Therm. Sci. 2004, 8, 5–19. [Google Scholar] [CrossRef]

- OECD, Organization for Economic Co-operation and Development. Biomass for Energy; OECD Publications and Information Center distributor: Washington, DC, USA, 1984. [Google Scholar]

- Food and Agricultural Organisation of the United Nations. Natural Resources—Biomass Potential Assessment. 2017. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/58fe36c1-b29a-45d7-b684-d3b3287f3f60/content (accessed on 1 November 2024).

- Kim, H.M.; Choi, I.S.; Lee, S.; Yang, J.E.; Jeong, S.G.; Park, J.H.; Ko, S.H.; Hwang, I.M.; Chun, H.H.; Wi, S.G.; et al. Biorefining process of carbohydrate feedstock (agricultural onion waste) to acetic acid. ACS Omega 2019, 4, 22438–22444. [Google Scholar] [CrossRef]

- Yesmin, M.N.; Azad, M.A.K.; Kamruzzaman, M.; Uddin, M.N. Bioethanol production from corn, pumpkin and carrot of Bangladesh as renewable source using yeast Saccharomyces cerevisiae. Acta Chem. Malays. 2020, 4, 45–54. [Google Scholar] [CrossRef]

- Khandaker, M.M.; Qiamuddin, K.; Majrashi, A.; Dalorima, T.; Hailmi, M.S.; Sajil, M.H.; Hossain, A.B.M.S. Bio-ethanol production from fruit and vegetable waste by using Saccharomyces cerevisiae. Biosci. Res. 2018, 15, 1703–1711. [Google Scholar]

- Canilha, L.; Carvalho, W.; De Almeida Felipe, M.D.G.; De Almeida E Silva, J.B.; Giulietti, M. Ethanol production from sugarcane bagasse hydrolysate using Pichia stipitis. Appl. Biochem. Biotechnol. 2010, 161, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Boluda-Aguilar, M.; López-Gómez, A. Production of bioethanol by fermentation of lemon (Citrus limon L.) peel wastes pretreated with steam explosion. Ind. Crops Prod. 2013, 41, 188–197. [Google Scholar] [CrossRef]

- Boluda-Aguilar, M.; García-Vidal, L.; del Pilar González-Castañeda, F.; López-Gómez, A. Mandarin peel wastes pretreatment with steam explosion for bioethanol production. Bioresour. Technol. 2010, 101, 3506–3513. [Google Scholar] [CrossRef]

- Jahanbakhshi, A.; Salehi, R. Processing watermelon waste using Saccharomyces cerevisiae yeast and the fermentation method for bioethanol production. J. Food Process Eng. 2019, 42, e13283. [Google Scholar] [CrossRef]

- Fathy, N. Review of Ethanol production from fruit Wastes. In Proceedings of the Research World International Conference, Rome, Italy, 25–26 June 2018. [Google Scholar]

- Taghizadeh-Alisaraei, A.; Assar, H.A.; Ghobadian, B.; Motevali, A. Potential of biofuel production from pistachio waste in Iran. Renew. Sustain. Energy Rev. 2017, 72, 510–522. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E. Global potential bioethanol production from wasted crops and crop residues. Biomass Bioenergy 2004, 26, 361–375. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Energy Consumption. 2020. Available online: https://www.iea.org/data-and-statistics/charts/oil-demand-growth-in-selected-countries-and-regions-2009-2019 (accessed on 3 September 2024).

- Office National de Statistiques. Répartition du Parc National Automobile Selon le Genre et la Wilaya (The distribution of the National Car Park According to the Gender and the Wilaya). 2010. Available online: www.ons.dz/IMG/pdf/Wil_an_2010.pdf (accessed on 31 December 2024).

- Rahmouni, S.; Settou, N.; Negrou, B.; Gouareh, A. GIS-based method for future prospect of hydrogen demand in the Algerian road transport sector. Int. J. Hydrogen Energy 2016, 41, 2128–2143. [Google Scholar] [CrossRef]

- Bhuvaneswari, M.; Sivakumar, N. Bioethanol Production from Fruit and Vegetable Wastes. In Bioprocessing for Biomolecules Production; John Wiley & Sons, Ltd.: Chichester, UK, 2019; pp. 417–427. Available online: http://doi.wiley.com/10.1002/9781119434436.ch20 (accessed on 2 November 2024).

- Gebregergs, A.; Gebresemati, M.; Sahu, O. Industrial ethanol from banana peels for developing countries: Response surface methodology. Pac. Sci. Rev. A Nat. Sci. Eng. 2016, 18, 22–29. [Google Scholar] [CrossRef]

- Umamaheswari, M.; Jayakumari, M.; Maheswari, K.; Subashree, M.; Mala, P.; Sevanthi, T.; Manikandan, T. Bioethanol production from cellulosic materials. Asian J. Sci. Technol. 2010, 1, 005–011. [Google Scholar]

- Hossain, S.F.; Bint-E-Naser, M.S.K. A Case Study: A Review on Prospects and Constraints of Bioethanol Production in Bangladesh. In Biofuels: Advances & Perspectives; Kaushik, A.E., Chaturvedi, G., Chel, S., Eds.; Studium Press LLC: Houston, TX, USA, 2017; pp. 69–86. [Google Scholar]

- European Biomass Industry Association. Bioethanol. 2020. Available online: https://www.eubia.org/cms/wiki-biomass/biofuels/bioethanol/#content (accessed on 3 November 2024).

- Zerroug, A.; Refoufi, L.; Dzelzitis, E. Energy Consumption Trends for Industry Segments in Northern Africa. Constr. Sci. 2015, 17, 24–30. [Google Scholar] [CrossRef]

- GlobalPetrolPrices.com. Algeria Gasoline Prices. 2021. Available online: https://www.globalpetrolprices.com/Algeria/gasoline_prices/ (accessed on 1 February 2025).

- Mujtaba, M.; Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; Araujo de Medeiros, G.; do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- Ahmed, A.; Abu Bakar, M.S.; Hamdani, R.; Park, Y.K.; Lam, S.S.; Sukri, R.S.; Hussain, M.; Majeed, K.; Phusunti, N.; Jamil, F.; et al. Valorization of underutilized waste biomass from invasive species to produce biochar for energy and other value-added applications. Environ. Res. 2020, 186, 109596. [Google Scholar] [CrossRef]

- Reza, S.; Ahmed, A.; Caesarendra, W.; Bakar, M.S.A.; Shams, S.; Saidur, R.; Aslfattahi, N.; Azad, A.K. Acacia Holosericea: An Invasive Species for Bio-char, Bio-oil, and Biogas Production. Bioengineering 2019, 6, 33. [Google Scholar] [CrossRef]

- Radenahmad, N.; Morni, N.A.; Ahmed, A.; Abu Bakar, M.; Zaini, J.; Azad, A. Characterization of rice husk as a potential renewable energy source. In Proceedings of the 7th Brunei International Conference on Engineering and Technology (BICET 2018), Bandar Seri Begawan, Brunei, 12–14 November 2018; pp. 1–4. [Google Scholar]

- Hoey, M.; Clark, R.; Webb, E.; Lynd, L. Scale Sensitivity of Ethanol Production via Consolidated Bioprocessing with Consideration of Feedstock Cost. Biofuels Bioprod. Biorefining 2025, 19, 9–17. [Google Scholar] [CrossRef]

| Country | Tons |

|---|---|

| World | 79,246,960 |

| USA | 45,597,500 |

| Brazil | 21,812,050 |

| Europe | 4,117,230 |

| China | 2,526,550 |

| Canada | 1,303,640 |

| Rest of the world | 3,889,990 |

| Feedstock | Main Components | Pretreatment Methods | Hydrolysis Methods |

|---|---|---|---|

| Cereals | Starch | Milling, gelatinization | α-amylase, glucoamylase |

| Roots/Tubers | Starch | Washing, chopping, gelatinization | α-amylase, glucoamylase |

| Pulses | Starch, protein | Dehulling, soaking, milling | α-amylase, glucoamylase, proteases |

| Oil Crops | Oil, protein | Oil extraction, milling | Cellulases, hemicellulases (meal) |

| Vegetables | Fiber, sugars | Washing, chopping, thermal | Cellulases, pectinases |

| Fruits | Simple sugars, pectin | Washing, crushing, pectinase | Direct fermentation, pectinases |

| Class | Crops | Area (ha) | Yield (hg/ha) | Production (Tons/Year) |

|---|---|---|---|---|

| Cereals | Barley | 1,303,149 | 7441 | 969,696 |

| Maize | 2025 | 13,007 | 2634 | |

| Oats | 87,816 | 7290 | 64,018 | |

| Rice and paddy | 155 | 20,179 | 313 | |

| Sorghum | 312 | 159,391 | 4973 | |

| Wheat | 2,118,469 | 11,501 | 2,436,503 | |

| Roots and Tubers | Potato | 148,822 | 309,524 | 4,606,402 |

| Pulses | Beans (dry) | 1902 | 7781 | 1480 |

| Broad beans, horse beans (dry) | 40,361 | 11,609 | 46,856 | |

| Oil Crops | Groundnuts | 3666 | 27,745 | 10,171 |

| Olives | 432,959 | 15,809 | 684,461 | |

| Rapeseed | 11,590 | 19,802 | 22,950 | |

| Seed cotton | 260 | 3077 | 80 | |

| Sunflower seed | 191 | 4501 | 86 | |

| Vegetables | Beans (green) | 11,434 | 85,712 | 98,003 |

| Carrots and turnips | 16,963 | 239,565 | 406,374 | |

| Onions (dry) | 48,301 | 294,054 | 1,420,310 | |

| Pumpkins, squash, and gourds | 13,085 | 235,278 | 307,861 | |

| Tomatoes | 23,977 | 536,467 | 1,286,286 | |

| Fruits | Apples | 44,620 | 110,767 | 494,239 |

| Bananas | 16 | 199,881 | 315 | |

| Dates | 167,643 | 63,143 | 1,058,559 | |

| Grapefruit (including pomelos) | 88 | 215,691 | 1897 | |

| Grapes | 69,569 | 81,441 | 566,579 | |

| Lemons and limes | 4234 | 183,646 | 77,757 | |

| Oranges | 49,942 | 203,025 | 1,013,951 | |

| Tangerines, mandarins, clementines, and satsumas | 14,414 | 173,902 | 250,669 | |

| Watermelons | 57,343 | 329,818 | 1,891,274 |

| Crops | Types of Residues |

|---|---|

| Cereals | Stover, cobs, straw |

| Root and Tubers | Peel, cull, green immature potatoes |

| Pulses | straw |

| Oil Crops | Pomance, straw |

| Vegetables | Pomace, peel, cull, |

| Fruits | Peel, pomace, stem, bagasse, waste fruits |

| Company Name | Type of Activity | Notes |

|---|---|---|

| Sonatrach | National oil and gas company | Exploring biofuel production from oleaginous plants; no operational bioethanol plant. |

| Cevital | Conglomerate with interest in bioethanol | Plans to build a corn-based ethanol plant in Brazil; no bioethanol plant in Algeria. |

| Global Bioenergies | Biotechnology company | Developing renewable isobutene and bioethanol; no operational bioethanol plant in Algeria. |

| Petroser Services Algérie (PSA) | Oil and gas services company | No known involvement in bioethanol production. |

| Bioethanol Algérie | Proposed bioethanol company | No operational bioethanol plant yet |

| Class | Crops | Residue (Tons/Year) | Residue Recovery (Tons/Year) | Residue to Crop Ratio |

|---|---|---|---|---|

| Cereals | Barley | 1,309,089 | 458,181 | 1.35 |

| Maize | 5162 | 1806 | 1.96 | |

| Oats | 90,905 | 31,816 | 1.42 | |

| Rice, paddy | 416 | 145 | 1.33 | |

| Sorghum | 12,154 | 4253 | 2.44 | |

| Wheat | 3,118,723 | 1,091,553 | 1.28 | |

| Roots and Tubers | Potato | 1,842,560 | 644,896 | 0.4 |

| Pulses | Beans (dry) | 2812 | 984 | 1.9 |

| Broad beans, horse beans (dry) | 89,026 | 31,159 | 1.9 | |

| Oil Crops | Groundnuts | 21,359 | 7475 | 2.1 |

| Olives | 1,437,368 | 503,078 | 2.1 | |

| Rapeseed | 48,195 | 16,868 | 2.1 | |

| Seed cotton | 168 | 58 | 2.1 | |

| Sunflower seed | 180 | 63 | 2.1 | |

| Vegetables | Beans (green) | 39,201 | 13,720 | 0.4 |

| Carrots and turnips | 162,549 | 56,892 | 0.4 | |

| Onions (dry) | 568,124 | 198,843 | 0.4 | |

| Pumpkins, squash, and gourds | 123,144 | 43,100 | 0.4 | |

| Tomatoes | 514,514 | 180,080 | 0.4 | |

| Fruits | Apples | 988,478 | 345,967 | 2 |

| Bananas | 630 | 220 | 2 | |

| Dates | 2,117,118 | 740,991 | 2 | |

| Grapefruit (including pomelos) | 3794 | 1327 | 2 | |

| Grapes | 1,133,158 | 396,605 | 2 | |

| Lemons and limes | 155,514 | 54,429 | 2 | |

| Oranges | 2,027,902 | 709,765 | 2 | |

| Tangerines, mandarins, clementines, satsumas | 501,338 | 175,468 | 2 | |

| Watermelons | 3,782,548 | 1,323,891 | 2 |

| Class | Crops | Bioethanol Conversion from Residue (g/kg) | Bioethanol (Tons/Year) |

|---|---|---|---|

| Cereals | Barley | 498.91 | 228,591 |

| Maize | 487.89 | 881 | |

| Oats | 498.91 | 15,873 | |

| Rice, paddy | 521.09 | 75 | |

| Sorghum | 498.91 | 2122 | |

| Wheat | 487.89 | 532,557 | |

| Roots and Tubers | Potato | 166.479 | 107,361 |

| Pulses | Beans (dry) | 363.51 | 357 |

| Broad beans, horse beans (dry) | 363.51 | 11,326 | |

| Oil Crops | Groundnuts | 492.19 | 3679 |

| Olives | 492.19 | 247,610 | |

| Rapeseed | 460.2 | 7762 | |

| Seed cotton | 492.19 | 28.9 | |

| Sunflower seed | 492.19 | 31 | |

| Vegetables | Beans (green) | 363.51 | 4987.5 |

| Carrots and turnips | 178.98 | 10,182.6 | |

| Onions (dry) | 327 | 65,021 | |

| Pumpkins, squash, and gourds | 416.05 | 17,931.9 | |

| Tomatoes | 50.67 | 9124 | |

| Fruits | Apples | 190.149 | 65,785 |

| Bananas | 175 | 38 | |

| Dates | 197.25 | 146,160 | |

| Grapefruit (including pomelos) | 53.652 | 71 | |

| Grapes | 53.652 | 21,278 | |

| Lemons and limes | 36.11 | 1965 | |

| Oranges | 134.919 | 95,760 | |

| Tangerines, mandarins, clementines, satsumas | 47.1 | 8264 | |

| Watermelons | 35.5 | 46,998 |

| Fuel | Percentage of Vehicles Run of Fuels | Total Amount (ktoe) |

|---|---|---|

| Diesel | 66% | 8716 |

| Gasoline | 31% | 4050 |

| LPG | 03% | 366 |

| Parameter | E0 | E5 | E10 |

|---|---|---|---|

| Total gasoline (Kt) | 2698.22 | 2563.31 | 2428.4 |

| CO2 emission (Kt) | 8904.1 | 8458.9 | 8013.7 |

| Bioethanol (Kt) | 0 | 202.36 | 404.73 |

| CO2 emission of bioethanol (Kt) | 0 | 386.51 | 773.03 |

| Total CO2 emission (Kt) | 8904.1 | 8845.41 | 8786.73 |

| In percentage (%) | 0 | 0.6 | 1.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miskat, M.I.; Chowdhury, A.; Sait, S.M.; Islam, R. The Potential of Bioethanol from Agricultural Crop Residues: A Case Study of Algeria. Bioresour. Bioprod. 2025, 1, 3. https://doi.org/10.3390/bioresourbioprod1010003

Miskat MI, Chowdhury A, Sait SM, Islam R. The Potential of Bioethanol from Agricultural Crop Residues: A Case Study of Algeria. Bioresources and Bioproducts. 2025; 1(1):3. https://doi.org/10.3390/bioresourbioprod1010003

Chicago/Turabian StyleMiskat, Monirul Islam, Aditta Chowdhury, Sadiq M. Sait, and Rabiul Islam. 2025. "The Potential of Bioethanol from Agricultural Crop Residues: A Case Study of Algeria" Bioresources and Bioproducts 1, no. 1: 3. https://doi.org/10.3390/bioresourbioprod1010003

APA StyleMiskat, M. I., Chowdhury, A., Sait, S. M., & Islam, R. (2025). The Potential of Bioethanol from Agricultural Crop Residues: A Case Study of Algeria. Bioresources and Bioproducts, 1(1), 3. https://doi.org/10.3390/bioresourbioprod1010003