Fatty Acid Composition and Lipid Oxidation in Plant-Based Meat Analogue Chicken Schnitzels Under Different Cooking Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

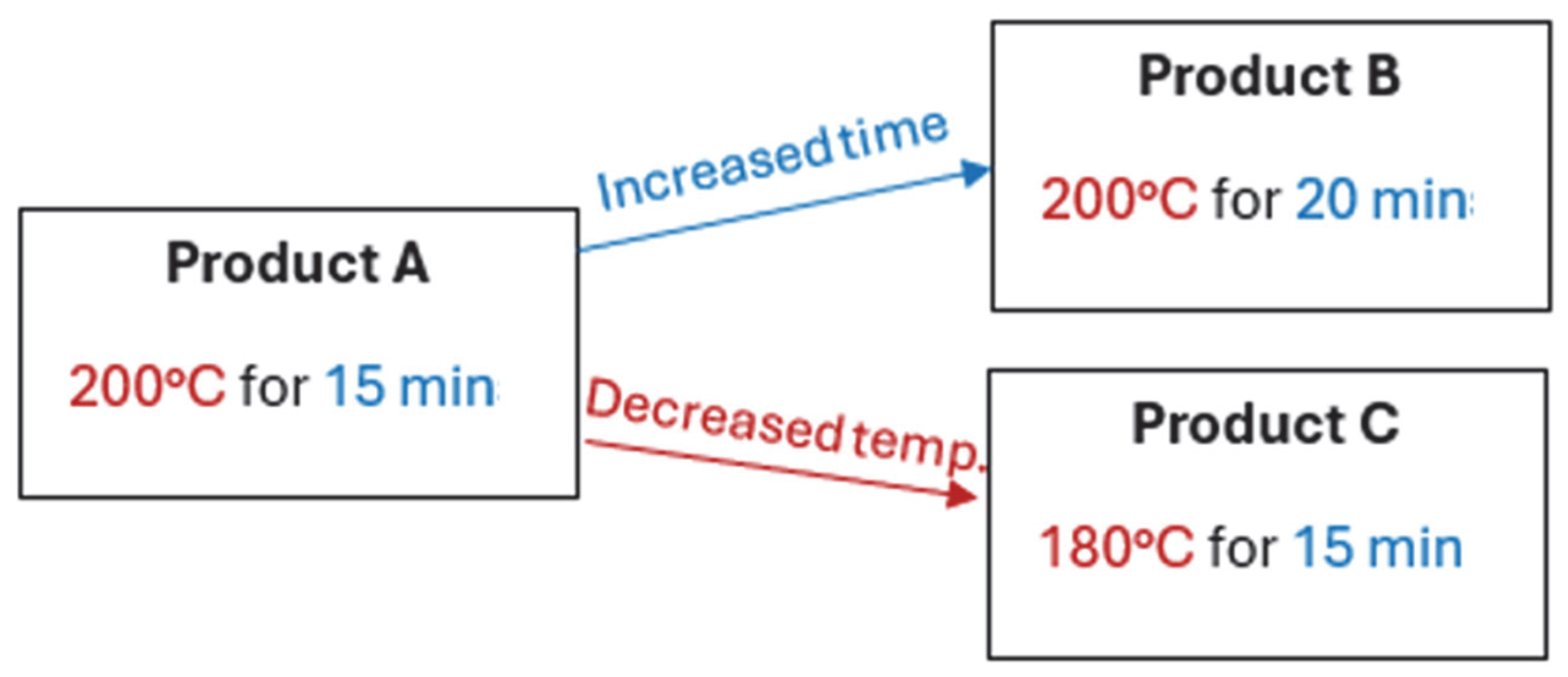

2.2. Plant-Based Meat Analogues and Sampling

2.3. Lipid Extraction

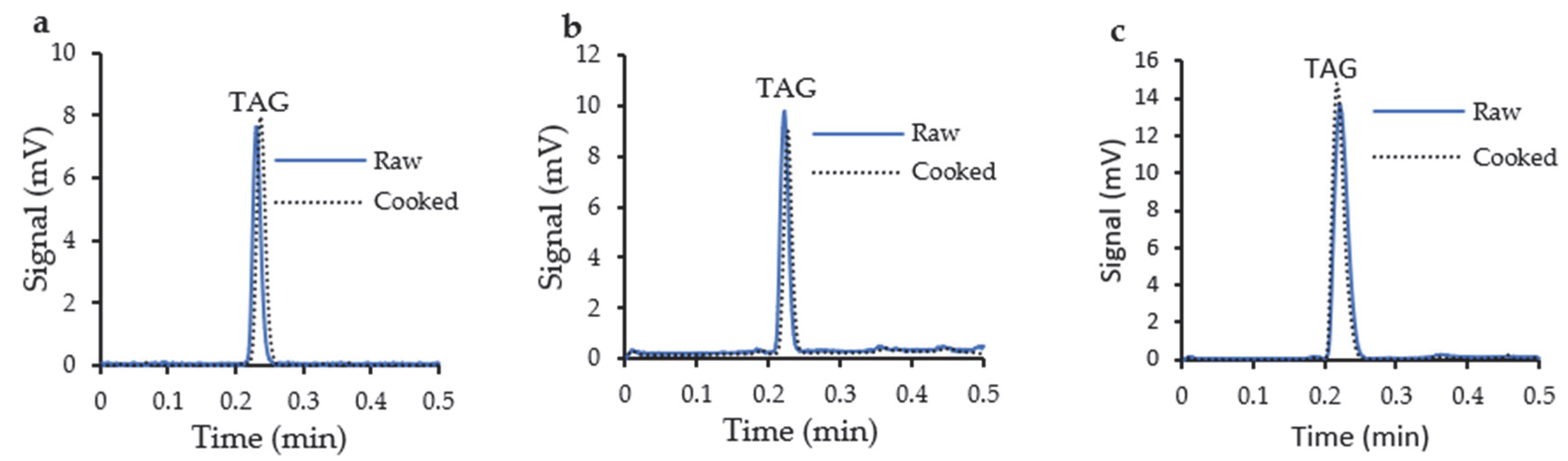

2.4. Analysis of Lipid Classes by Capillary Chromatography (Iatroscan-FID)

2.5. Analysis of Fatty Acid Composition by Gas Chromatography (GC)

2.6. Oxidation Stability Tests

2.7. Statistical Analysis

3. Results and Discussion

3.1. Lipid Content and Fatty Acid Composition of the PBMA Chicken Schnitzels

3.2. Effect of Cooking on Lipid Classes of the PBMA Chicken Schnitzels

3.3. Effect of Cooking on Lipid Classes and Oxidation for the PBMA Chicken Schnitzels

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AV | Acid value |

| DAG | Diacylglycerol |

| FFAs | Free fatty acids |

| FID | Flame ionisation detector |

| GC | Gas chromatography |

| MAG | Monoacylglycerol |

| MDA | Malondialdehyde |

| p-AV | p-Anisidine value |

| PBMA | Plant-based meat analogue |

| POV | Peroxide value |

| TAG | Triacylglycerol |

| TBARS | Thiobarbituric Acid Reactive Substance |

| TOTOX | Total oxidation |

| UPF | Ultra-processed food |

References

- Zahari, I.; Östbring, K.; Purhagen, J.K.; Rayner, M. Plant-Based Meat Analogues from Alternative Protein: A Systematic Literature Review. Foods 2022, 11, 2870. [Google Scholar] [CrossRef]

- Tyndall, S.M.; Maloney, G.R.; Cole, M.B.; Hazell, N.G.; Augustin, M.A. Critical food and nutrition science challenges for plant-based meat alternative products. Crit. Rev. Food Sci. Nutr. 2022, 64, 638–653. [Google Scholar] [CrossRef]

- Boukid, F. Plant-based meat analogues: From niche to mainstream. Eur. Food Res. Technol. 2021, 247, 297–308. [Google Scholar] [CrossRef]

- Miller, O.; Scarlett, C.J.; Adhikari, B.; Akanbi, T.O. Are plant-based meat analogues fulfilling their potentials? An Australian perspective. Future Foods 2024, 9, 100305. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, S.; Ahn, D.U. Protein oxidation: Basic principles and implications for meat quality. Crit. Rev. Food Sci. Nutr. 2013, 53, 1191–1201. [Google Scholar] [CrossRef] [PubMed]

- Laguerre, M.; Bily, A.; Birtić, S. Lipid oxidation in food. In Lipids and Edible Oils; Elsevier: Amsterdam, The Netherlands, 2020; pp. 243–287. [Google Scholar]

- Ahmed, M.; Pickova, J.; Ahmad, T.; Liaquat, M.; Farid, A.; Jahangir, M. Oxidation of lipids in foods. Sarhad J. Agric. 2016, 32, 230–238. [Google Scholar] [CrossRef]

- Abeyrathne, E.D.N.S.; Nam, K.; Ahn, D.U. Analytical methods for lipid oxidation and antioxidant capacity in food systems. Antioxidants 2021, 10, 1587. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Ahn, D.U. Lipid oxidation and its implications to meat quality and human health. Food Sci. Biotechnol. 2019, 28, 1275–1285. [Google Scholar] [CrossRef]

- Loi, M.; Paciolla, C. Plant antioxidants for food safety and quality: Exploring new trends of research. Antioxidants 2021, 10, 972. [Google Scholar] [CrossRef]

- Irwin, J.; Hedges, N. Measuring lipid oxidation. In Understanding and Measuring Shelf Life of Food; Woodhead Publishing: Cambridge, UK, 2004; pp. 289–316. [Google Scholar]

- Kunyaboon, S.; Thumanu, K.; Park, J.W.; Khongla, C.; Yongsawatdigul, J. Evaluation of lipid oxidation, volatile compounds and vibrational spectroscopy of silver carp (Hypophthalmichthys molitrix) during ice storage as related to the quality of its washed mince. Foods 2021, 10, 495. [Google Scholar] [CrossRef]

- Knothe, G. Structure indices in FA chemistry. How relevant is the iodine value? J. Am. Oil Chem. Soc. 2002, 79, 847–854. [Google Scholar] [CrossRef]

- Grau, A.; Guardiola, F.; Boatella, J.; Baucells, M.D.; Codony, R. Evaluation of lipid ultraviolet absorption as a parameter to measure lipid oxidation in dark chicken meat. J. Agric. Food Chem. 2000, 48, 4128–4135. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, D.; Liu, D.; Fang, Z.; Chen, J.; Hu, Y.; Ye, X. Effect of cooking styles on the lipid oxidation and fatty acid composition of grass carp (Ctenopharynyodon idellus) fillet. J. Food Biochem. 2013, 37, 212–219. [Google Scholar] [CrossRef]

- Rasinska, E.; Rutkowska, J.; Czarniecka-Skubina, E.; Tambor, K. Effects of cooking methods on changes in fatty acids contents, lipid oxidation and volatile compounds of rabbit meat. LWT 2019, 110, 64–70. [Google Scholar] [CrossRef]

- Shahidi, F.; Wanasundara, U.N. Methods for measuring oxidative rancidity in fats and oils. In Food Lipids; CRC Press: Boca Raton, FL, USA, 2002; pp. 484–507. [Google Scholar]

- Abdullah, F.A.A.; Dordevic, D.; Kabourkova, E. Oxidation status and antioxidant activity of analogue meat products in modified atmosphere packaging. Appl. Sci. 2024, 14, 6713. [Google Scholar] [CrossRef]

- Miller, O.; Scarlett, C.J.; Akanbi, T.O. Lipid stability profiles of uncooked plant-based meat analogue burger patties and comparison of their textural and sensory properties with traditional beef burger patties. J. Food Compos. Anal. 2025, 147, 108002. [Google Scholar] [CrossRef]

- Opaluwa, C.; De Angelis, D.; Summo, C.; Karbstein, H.P. Effect of different vegetable oils on extruded plant-based meat analogs: Evaluation of oxidative degradation, textural, rheological, tribological and sensory properties. Food Hydrocoll. 2025, 163, 111038. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, Y.; Tian, X.; Wang, X.; Liu, H.; Jia, F.; Zhang, X.; Wang, J. Effect of oil oxidation on aggregation of wheat gluten–peanut oil complexes during extrusion. Int. J. Food Sci. Technol. 2022, 57, 2467–2478. [Google Scholar] [CrossRef]

- Yoganarasimhaswamy, I.N.; Panagodage, Y.; Agyei, D.; English, M.; Kebede, B. The impact of consumer in-home cooking methods on the physicochemical, sensory, and nutritional attributes of plant-based meat analogues (PBMAs) and meat: A review. Food Prod. Process. Nutr. 2025, 7, 45. [Google Scholar] [CrossRef]

- Kaleem, A.; Aziz, S.; Iqtedar, M. Investigating changes and effect of peroxide values in cooking oils subject to light and heat. FUUAST J. Biol. 2015, 5, 191–196. [Google Scholar]

- Vieira, T.M.; Regitano-d’Arce, M.A. Canola oil thermal oxidation during oven test and microwave heating. LWT-Food Sci. Technol. 2001, 34, 215–221. [Google Scholar] [CrossRef]

- Gharby, S.; Asbbane, A.; Ahmed, M.N.; Gagour, J.; Hallouch, O.; Oubannin, S.; Bijla, L.; Goh, K.W.; Bouyahya, A.; Ibourki, M. Vegetable oil oxidation: Mechanisms, impacts on quality, and approaches to enhance shelf life. Food Chem. X 2025, 28, 102541. [Google Scholar] [CrossRef] [PubMed]

- Wroniak, M.; Raczyk, M.; Kruszewski, B.; Symoniuk, E.; Dach, D. Effect of deep frying of potatoes and tofu on thermo-oxidative changes of cold pressed rapeseed oil, cold pressed high oleic rapeseed oil and palm olein. Antioxidants 2021, 10, 1637. [Google Scholar] [CrossRef]

- Moigradean, D.; Poiana, M.-A.; Alda, L.-M.; Bordean, D.-M.; Stoin, D.; Raba, D.-N. A review. Coconut oil-as functional food oil. J. Agroaliment. Process. Technol. 2021, 27, 490–493. [Google Scholar]

- Sivakanthan, S.; Bopitiya, D.; Madhujith, T. A comparative study on stability of different types of coconut (Cocos nucifera) oil against autoxidation and photo-oxidation. Afr. J. Food Sci. 2018, 12, 216–229. [Google Scholar] [CrossRef]

- Bhatnagar, A.S.; Prasanth Kumar, P.; Hemavathy, J.; Gopala Krishna, A. Fatty acid composition, oxidative stability, and radical scavenging activity of vegetable oil blends with coconut oil. J. Am. Oil Chem. Soc. 2009, 86, 991–999. [Google Scholar] [CrossRef]

- McConnell, B.; Farag, I.H. Kinetics study of the solvent extraction of lipids from Chlorella vulgaris. Int. J. Eng. Tech. Res. 2013, 1, 28–37. [Google Scholar]

- Akanbi, T.O.; Adcock, J.L.; Barrow, C.J. Selective concentration of EPA and DHA using Thermomyces lanuginosus lipase is due to fatty acid selectivity and not regioselectivity. Food Chem. 2013, 138, 615–620. [Google Scholar] [CrossRef]

- Barriuso, B.; Astiasarán, I.; Ansorena, D. A review of analytical methods measuring lipid oxidation status in foods: A challenging task. Eur. Food Res. Technol. 2013, 236, 1–15. [Google Scholar] [CrossRef]

- Przybylski, R.; Mag, T. Canola/rapeseed oil. In Vegetable Oils in Food Technology: Composition, Properties and Uses; John Wiley & Sons: Hoboken, NJ, USA, 2002; pp. 107–136. [Google Scholar]

- Dayrit, F.M. The properties of lauric acid and their significance in coconut oil. J. Am. Oil Chem. Soc. 2015, 92, 1–15. [Google Scholar] [CrossRef]

- Moore, E.M.; Wagner, C.; Komarnytsky, S. The enigma of bioactivity and toxicity of botanical oils for skin care. Front. Pharmacol. 2020, 11, 785. [Google Scholar] [CrossRef] [PubMed]

- Singh, Y.; Cullere, M.; Kovitvadhi, A.; Chundang, P.; Dalle Zotte, A. Effect of different killing methods on physicochemical traits, nutritional characteristics, in vitro human digestibility and oxidative stability during storage of the house cricket (Acheta domesticus L.). Innov. Food Sci. Emerg. Technol. 2020, 65, 102444. [Google Scholar] [CrossRef]

- Esfahani, S.T.; Zamindar, N.; Esmaeili, Y.; Sharifian, S. Effect of initial quality of oil and thermal processing on oxidation indexes in canned tuna. Appl. Food Res. 2024, 4, 100553. [Google Scholar] [CrossRef]

- Aladedunye, F.; Dellaporta, R. Two new chemical methods for quantifying carbonyl secondary oxidation products in frying oils and their correlation with the p-anisidine value. J. Am. Oil Chem. Soc. 2025, 102, 913–921. [Google Scholar] [CrossRef]

- Schaich, K.M. Oxidative Stability and Shelf Life of Foods Containing Oils and Fats; Hu, M., Jacobsen, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Zhang, X.; Huang, W.; Xie, J. Effect of different packaging methods on protein oxidation and degradation of grouper (Epinephelus coioides) during refrigerated storage. Foods 2019, 8, 325. [Google Scholar] [CrossRef]

- Abdullah, F.A.A.; Buchtová, H. Selected freshness indices of skin and wings from organic chicken packaged in modified atmosphere. Acta Vet. Brno 2020, 89, 97–105. [Google Scholar] [CrossRef]

| Product | Protein (g/100 g) | Total Fat (g/100 g) | Saturated Fat (g/100 g) | Lipids Included * |

|---|---|---|---|---|

| Product A | 15.0 | 21.2 | 2.7 | Internal: Canola oil (3rd) Coating: Canola oil, coconut fat powder |

| Product B | 9.7 | 8.2 | 1.3 | Vegetable oil (Sunflower, canola; 3rd) |

| Product C | 9.0 | 14.3 | 5.9 | Internal: Coconut oil (4th), canola oil (15th) Coating: Canola oil (7th), olive oil (9th), rice bran oil (14th) |

| Product | Condition | TBARS | p-AV | AV | POV | TOTOX |

|---|---|---|---|---|---|---|

| A | Raw | 1.04 ± 0.03 a | 9.33 ± 0.72 a | 2.04 ± 0.64 a | 4.16 ± 0.29 a | 9.36 ± 0.55 a |

| Cooked | 1.31 ± 0.15 b | 11.82 ± 2.48 a | 1.93 ± 0.54 a | 4.34 ± 0.27 a | 9.99 ± 0.64 a | |

| B | Raw | 1.03 ± 0.07 a | 9.46 ± 1.78 a | 3.33 ± 0.55 a | 2.43 ± 0.36 a | 5.88 ± 0.80 a |

| Cooked | 1.19 ± 0.05 b | 9.84 ± 0.88 a | 3.22 ± 0.67 a | 2.50 ± 0.23 a | 6.19 ± 0.45 a | |

| C | Raw | 1.03 ± 0.11 a | 2.76 ± 1.87 a | 1.83 ± 0.95 a | 5.14 ± 0.24 a | 11.31 ± 0.58 a |

| Cooked | 1.06 ± 0.11 a | 11.06 ± 1.17 b | 2.06 ± 0.65 a | 5.43 ± 0.53 a | 11.92 ± 1.14 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miller, O.; Scarlett, C.J.; Akanbi, T.O. Fatty Acid Composition and Lipid Oxidation in Plant-Based Meat Analogue Chicken Schnitzels Under Different Cooking Conditions. Lipidology 2025, 2, 23. https://doi.org/10.3390/lipidology2040023

Miller O, Scarlett CJ, Akanbi TO. Fatty Acid Composition and Lipid Oxidation in Plant-Based Meat Analogue Chicken Schnitzels Under Different Cooking Conditions. Lipidology. 2025; 2(4):23. https://doi.org/10.3390/lipidology2040023

Chicago/Turabian StyleMiller, Owen, Christopher J. Scarlett, and Taiwo O. Akanbi. 2025. "Fatty Acid Composition and Lipid Oxidation in Plant-Based Meat Analogue Chicken Schnitzels Under Different Cooking Conditions" Lipidology 2, no. 4: 23. https://doi.org/10.3390/lipidology2040023

APA StyleMiller, O., Scarlett, C. J., & Akanbi, T. O. (2025). Fatty Acid Composition and Lipid Oxidation in Plant-Based Meat Analogue Chicken Schnitzels Under Different Cooking Conditions. Lipidology, 2(4), 23. https://doi.org/10.3390/lipidology2040023