Modal Passport Concept for Enhanced Non-Destructive Monitoring and Diagnostics of Wind Turbine Blades

Abstract

1. Introduction

2. Materials and Methods

2.1. Problem Analysis

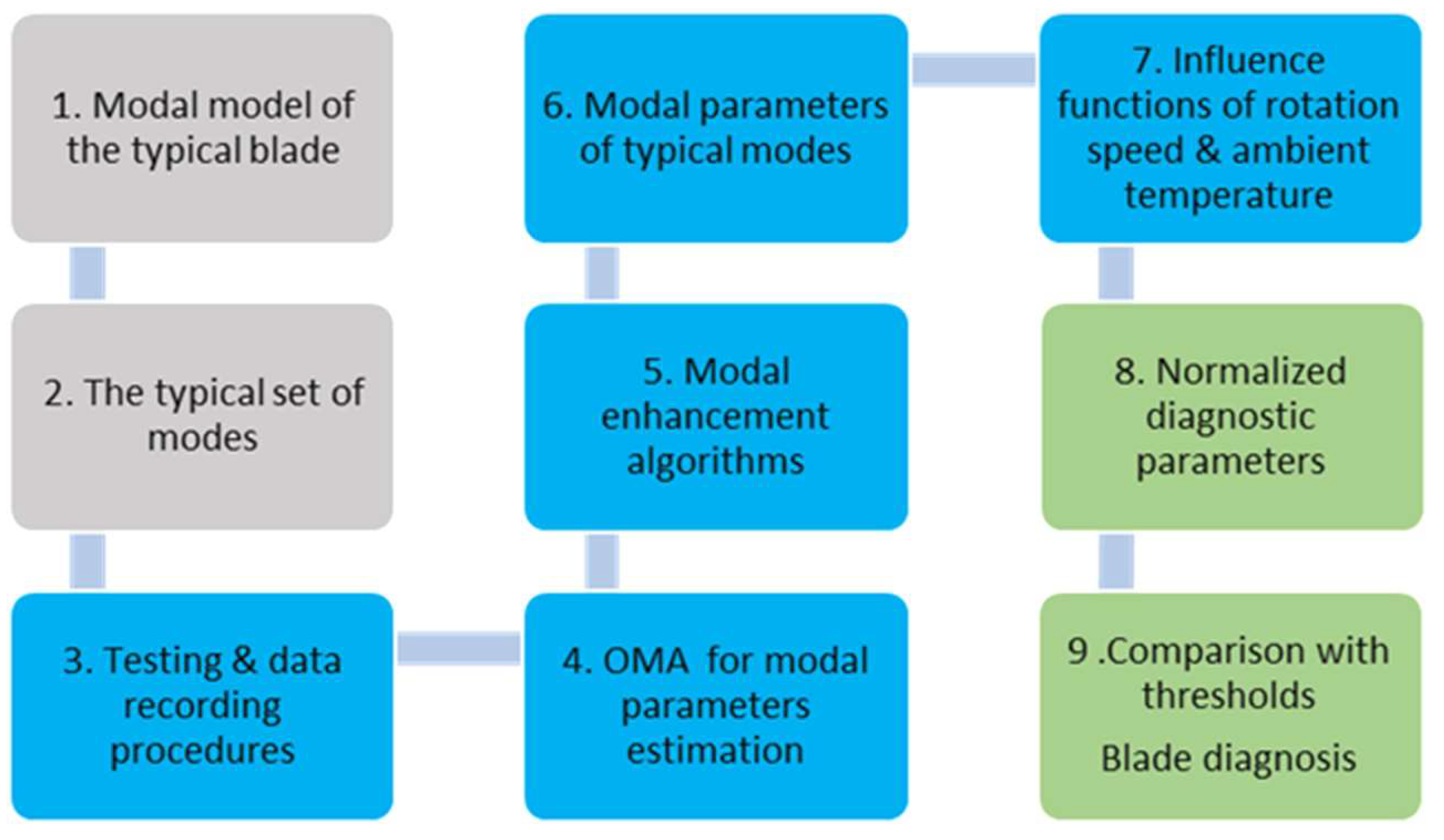

2.2. Modal Passport

2.2.1. Concept

2.2.2. Diagnostics in Modal Space

2.3. Blade Passport Preparation and Application

2.3.1. Blade’s Modal Model

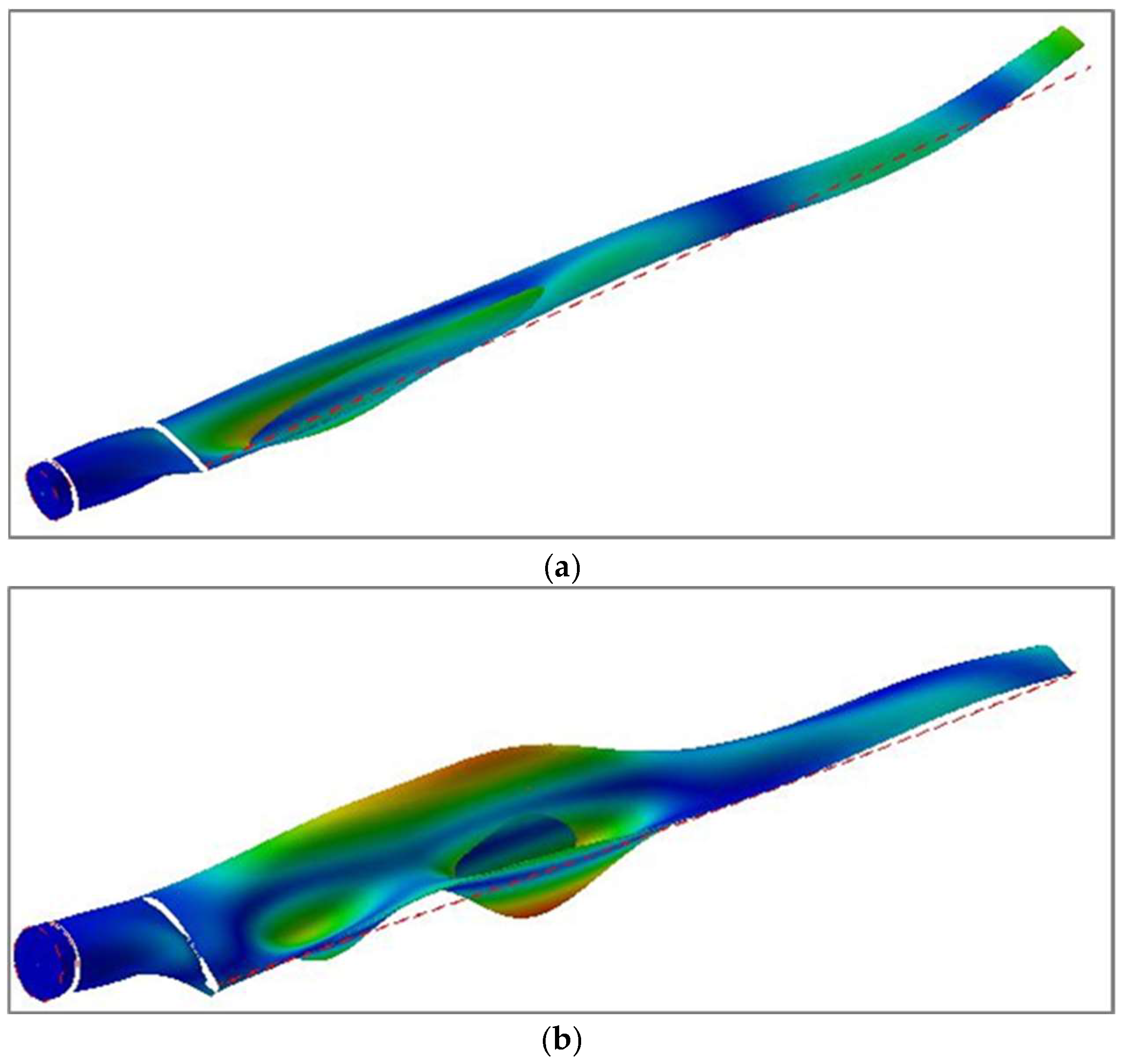

2.3.2. The Typical Set of Modes

2.3.3. Testing and Data Recording Procedures

2.3.4. Estimation of Modal Parameters

2.3.5. Modal Enhancement

2.3.6. Modal Parameters of Typical Modes

2.3.7. Influence Functions

2.3.8. Reduced and Normalized Modal Parameters

2.3.9. Blade Diagnosis

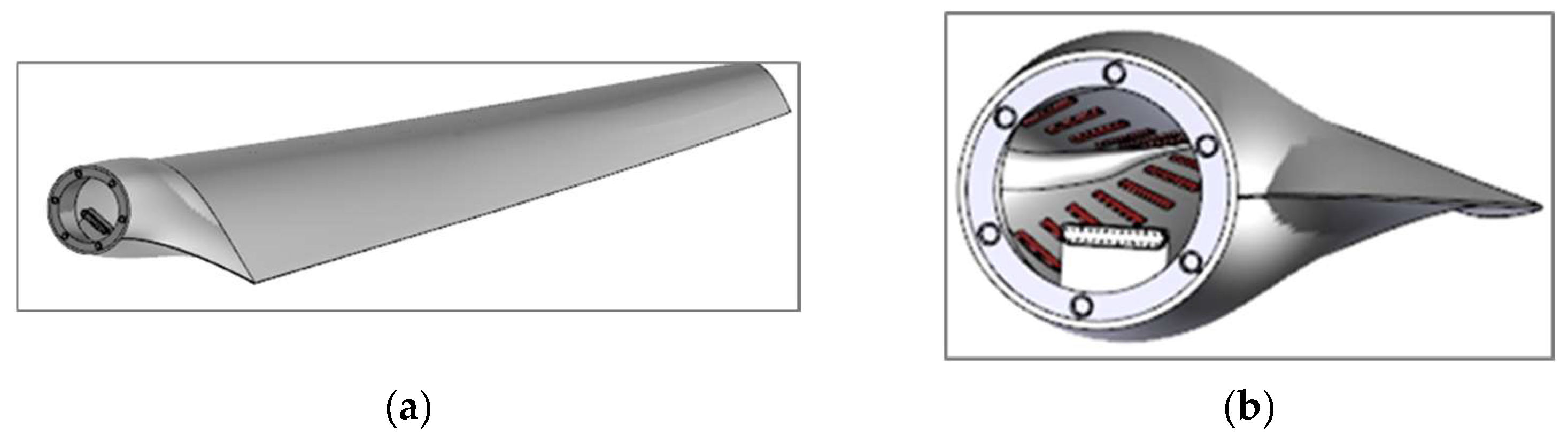

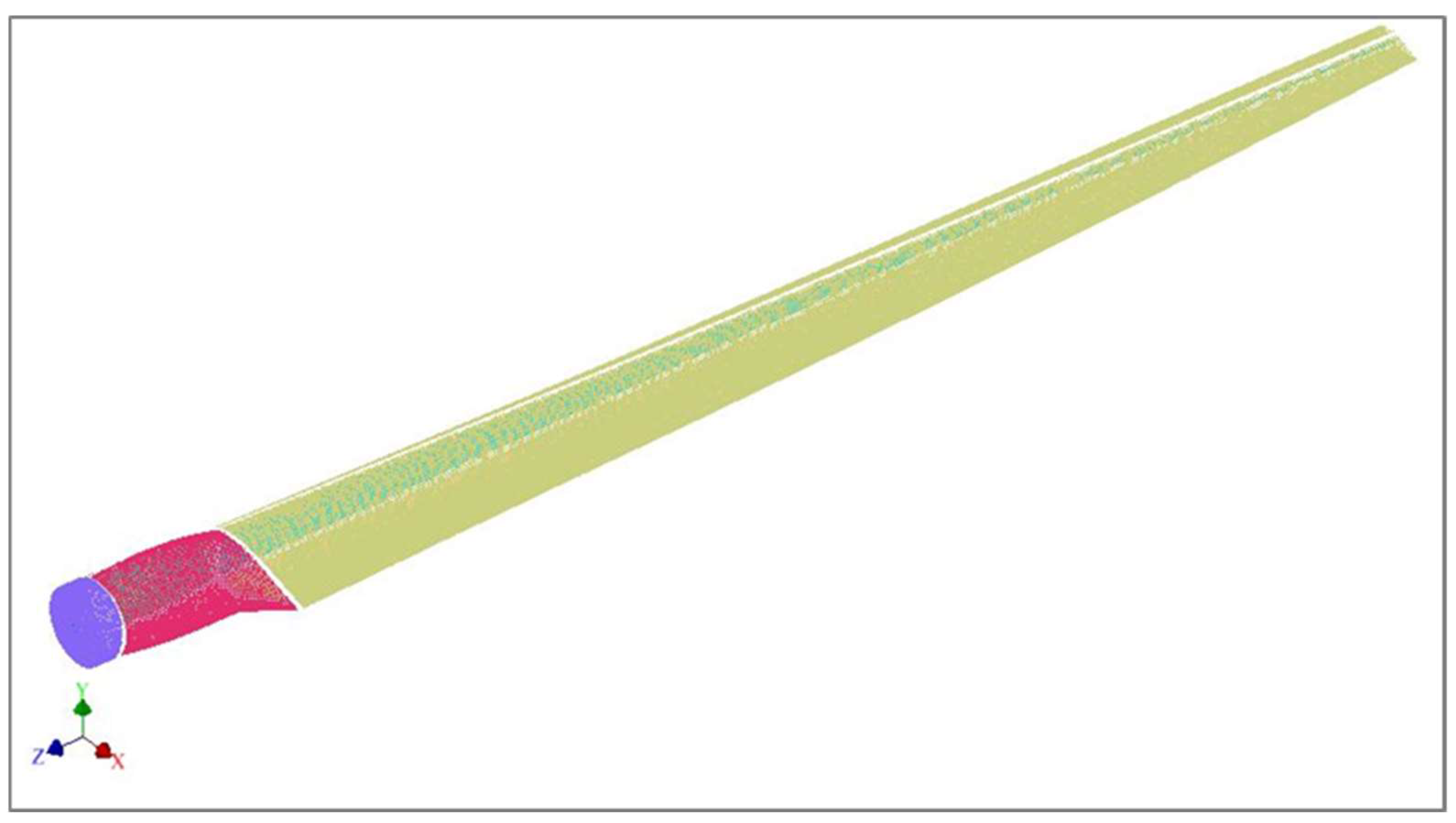

2.4. Testing Models of Blades

2.5. Testing and Measurement Systems

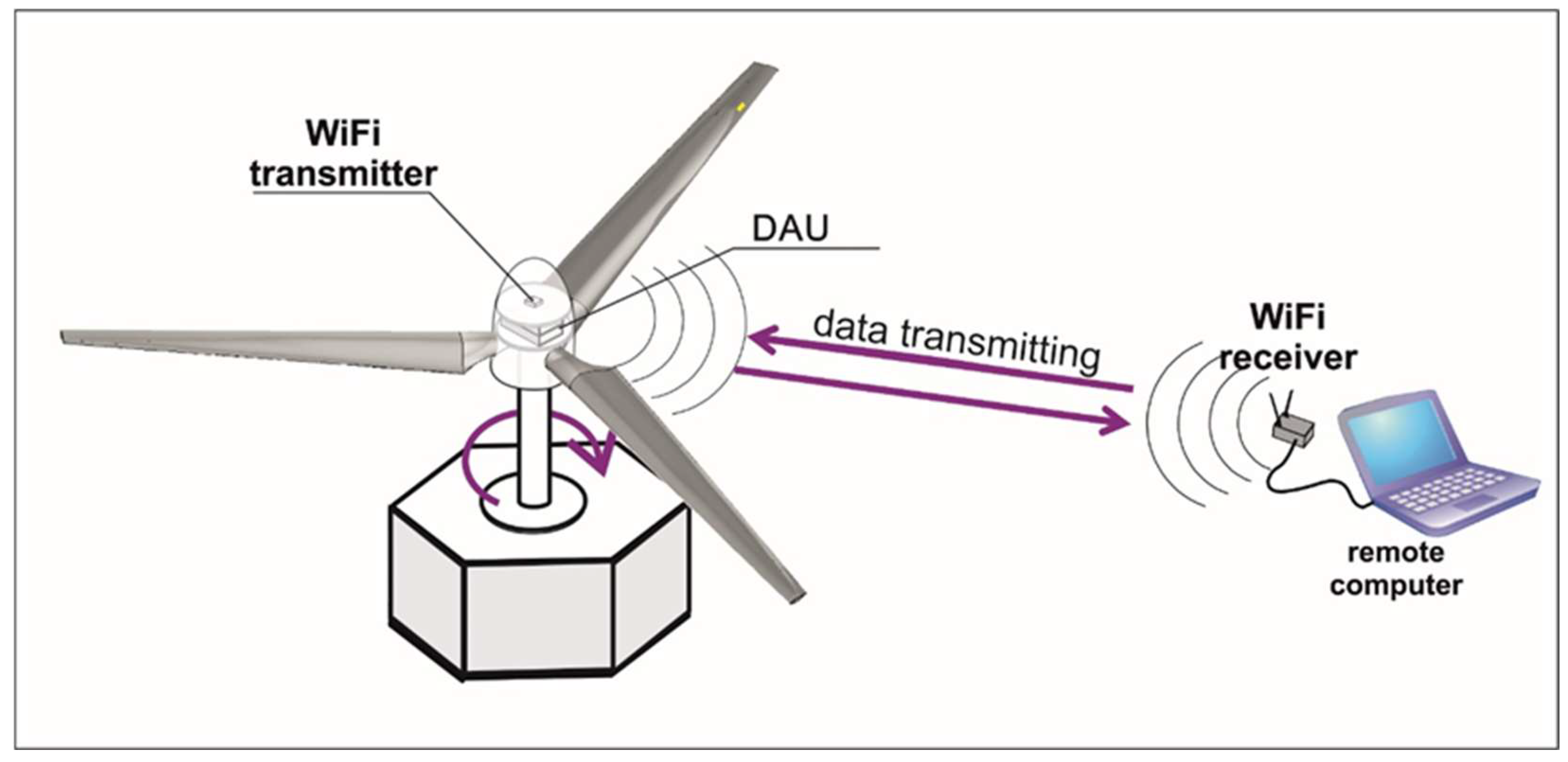

2.5.1. Rotating Test Rig

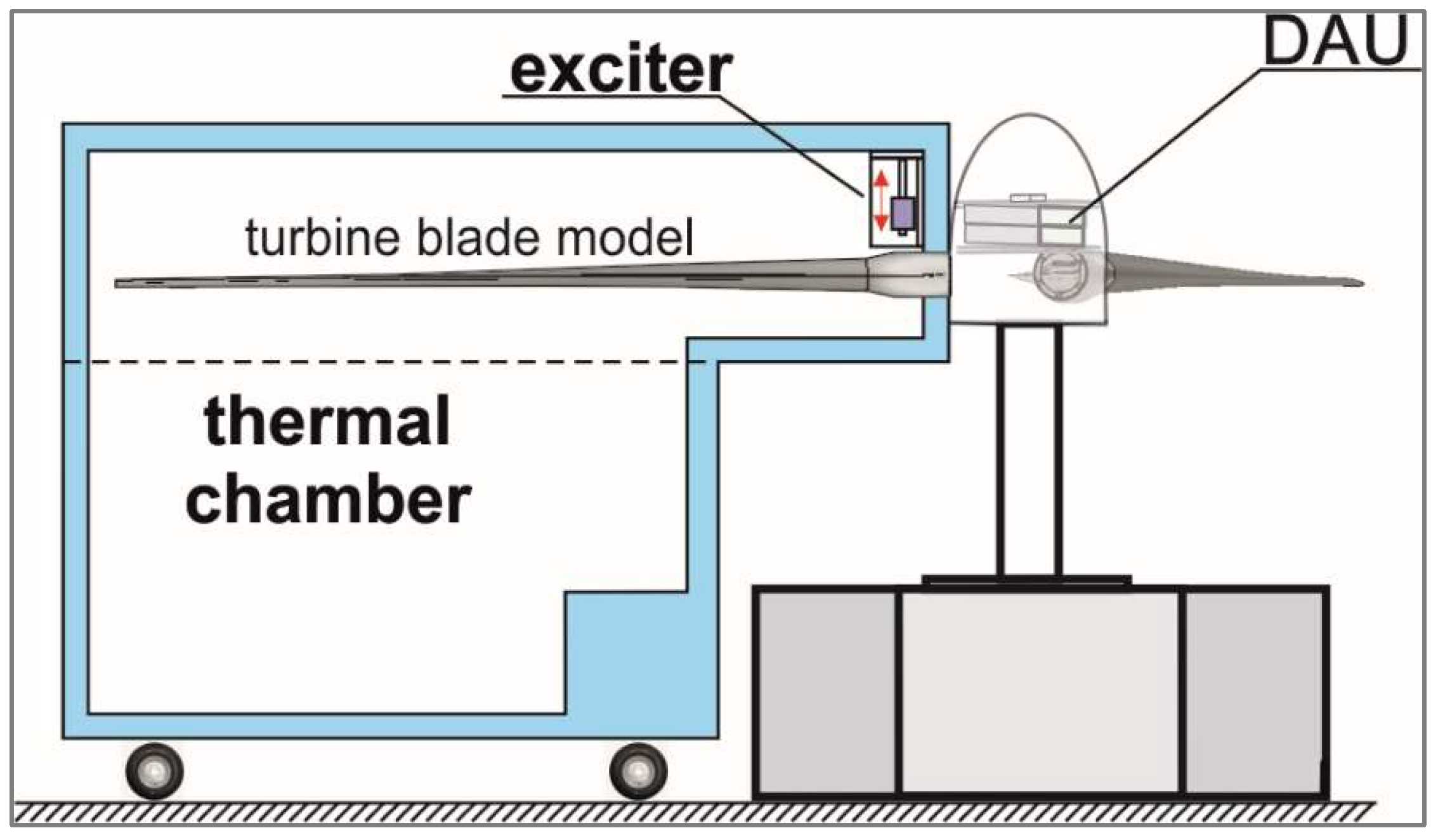

2.5.2. Thermal Testing Chamber

2.6. Measurement System

- 20 piezoelectric sensors, integrated into a blade model;

- Rotation speed sensor;

- Two 12-channel data acquisition units (DAUs) connected via the switch and powered by batteries;

- Wi-Fi transmitter, connected to DAUs;

- Cables from the sensors connecting to DAUs.

3. Results and Discussion

4. Conclusions

5. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Drewry, M.; Georgiou, G. A review of NDT techniques for wind turbines. Insight 2007, 49, 137–141. [Google Scholar] [CrossRef]

- Dimitrova, M.; Aminzadeh, A.; Meiabadi, M.; Sattarpanah, K.; Sasan, S.K.; Taheri, H.; Ibrahim, H. A Survey on Non-Destructive Smart Inspection of Wind Turbine Blades Based on Industry 4.0 Strategy. Appl. Mech. 2022, 3, 1299–1327. [Google Scholar] [CrossRef]

- Shihavuddin, A.S.; Chen, X.; Fedorov, V.; Christensen, A.N.; Brogaard Riis, N.A.; Branner, K.; Bjorholm Dahl, A.; Reinhold Paulsen, R. Wind turbine surface damage detection by deep learning aided drone inspection analysis. Energies 2019, 12, 676. [Google Scholar] [CrossRef]

- Ahuir-Torres, J.I.; Bausch, N.; Farrar, A.; Webb, S.; Simandjuntak, S.; Nash, A.; Thomas, B.; Muna, J.; Jonsson, C.; Mathew, D. Benchmarking parameters for remote electrochemical corrosion detection and monitoring of offshore wind turbine structures. Wind Energy 2019, 22, 857–876. [Google Scholar] [CrossRef]

- LeBlanc, B.; Niezrecki, C.; Avitabile, P.; Chen, J.; Sherwood, J. Damage detection and full surface characterization of a wind turbine blade using three-dimensional digital image correlation. Struct. Health Monit. 2013, 12, 430–439. [Google Scholar] [CrossRef]

- Karganroudi, S.S.; Aminzadeh, A.; Aminzadeh, A.; Ibrahim, H.; Rahmatabadi, D.; Francois, V.; Cuillière, J.-C. A Novel Automated Approach for Geometric Reconstruction and Flexible Remanufacturing of Spur Gears Using Point Cloud Mapping Analysis. Comp.-Aided Des. Appl. 2023, 20, 92–108. [Google Scholar] [CrossRef]

- Liu, Y.; Hajj, M.; Bao, Y. Review of robot-based damage assessment for offshore wind turbines. Renew. Sustain. Energy Rev. 2022, 158, 112187. [Google Scholar] [CrossRef]

- Marks, R.; Gillam, C.; Clarke, A.; Armstrong, J.; Pullin, R. Damage detection in a composite wind turbine blade using 3D scanning laser vibrometry. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 3024–3041. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Chacón, A.M.P. A review of non-destructive testing on wind turbines blades. Renew. Energy 2020, 161, 998–1010. [Google Scholar] [CrossRef]

- Available online: https://www.zetec.com/blog/wind-turbine-nondestructive-testing-what-you-need-to-know/ (accessed on 26 September 2024).

- Ghoshal, A.; Sundaresan, M.J.; Schulz, M.J.; Pai, P.F. Structural health monitoring techniques for wind turbine blades. J. Wind. Eng. Ind. Aerodyn. 2000, 85, 309–324. [Google Scholar] [CrossRef]

- Bouzid, O.M.; Tian, G.Y.; Cumanan, K.; Moore, D. Structural Health Monitoring of Wind Turbine Blades: Acoustic Source Localization Using Wireless Sensor Networks. J. Sen. 2015, 2015, 139695. [Google Scholar] [CrossRef]

- Chen, B.; Yu, S.; Yu, Y.; Zhou, Y. Acoustical damage detection of wind turbine blade using the improved incremental support vector data description. Renew. Energy 2020, 156, 548–557. [Google Scholar] [CrossRef]

- Feng, W.; Yang, D.; Du, W.; Li, Q. In Situ Structural Health Monitoring of Full-Scale Wind Turbine Blades in Operation Based on Stereo Digital Image Correlation. Sustainability 2023, 15, 13783. [Google Scholar] [CrossRef]

- Maia, N.M.M.; Silva, J.M.M. Theoretical and Experimental Modal Analysis; Research Studies Press: Taunton, UK; New York, NY, USA, 1997. [Google Scholar]

- Kim, H.-C.; Kim, M.-H.; Choe, D.-E. Structural health monitoring of towers and blades for floating offshore wind turbines using operational modal analysis and modal properties with numerical-sensor signals. Ocean. Eng. 2019, 188, 106226. [Google Scholar] [CrossRef]

- Tcherniak, D.; Larsen, G. Application of OMA to an operating wind turbine: Now including vibration data from the blades. In Proceedings of the 5th International Operational Modal Analysis Conference, IOMAC 2013, Guimaraes, Portugal, 13–15 May 2013. [Google Scholar]

- Mironov, A.; Kovalovs, A.; Chate, A.; Safonovs, A. Static Loads Influence on Modal Properties of the Composite Cylindrical Shells with Integrated Sensor Network. Sensors 2023, 23, 3327. [Google Scholar] [CrossRef]

- Mironov, A.; Chate, A.; Safonovs, A.; Kuzmickis, V.; Doronkin, P. SHM System Prototype for Serial Structures Operating Under Different Conditions. In Proceedings of the International Conference on Experimental Vibration Analysis for Civil Engineering Structures, Milan, Italy, 30 August–1 September 2023. [Google Scholar] [CrossRef]

- Mironov, A.; Safonovs, A.; Mironovs, D.; Doronkin, P.; Kuzmickis, V. Health Monitoring of Serial Structures Applying Piezoelectric Film Sensors and Modal Passport. Sensors 2023, 23, 1114. [Google Scholar] [CrossRef]

- Mironov, A.; Doronkin, P. The Demonstrator of Structural Health Monitoring System of Helicopter Composite Blades. Procedia Struct. Integr. 2022, 37, 241–249. [Google Scholar] [CrossRef]

- Arsenault, T.J.; Achuthan, A.; Marzocca, P.; Grappasonni, C.; Coppotelli, G. Development of a FBG based distributed strain sensor system for wind turbine structural health monitoring. Smart Mater. Struct. 2013, 22, 075027. [Google Scholar] [CrossRef]

- Weber, S.; Kissinger, T.; Chehura, E.; Staines, S.; Barrington, J.; Mullaney, K.; Zanotti, F.L.; Petrunin, I.; James, S.; Lone, M.; et al. Application of fibre optic sensing systems to measure rotor blade structural dynamics. Mech. Syst. Signal Process. 2021, 158, 107758. [Google Scholar] [CrossRef]

- Mironov, A.; Doronkin, P. Piezoelectric Films Application for Vibration Diagnostics. In Reliability and Statistics in Transportation and Communication; Kabashkin, I., Yatskiv, I., Prentkovskis, O., Eds.; RelStat 2022. Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2022; Volume 640. [Google Scholar] [CrossRef]

- Allemang, R. The Modal Assurance Criterion (MAC): Twenty Years of Use and Abuse. Sound Vib. 2003, 37, 14–23. [Google Scholar]

- Tortorici, D.; Toto, E.; Santonicola, M.G.; Laurenzi, S. Effects of UV-C exposure on composite materials made of recycled carbon fibers. Acta Astronaut. 2024, 220, 367–373. [Google Scholar] [CrossRef]

- Shah, S.P.; Olaya, M.N.; Plaka, E.; McDonald, J.; Hansen, C.J.; Maiarù, M. Effect of moisture absorption on curing of wind blades during repair. Compos. Part A Appl. Sci. Manuf. 2023, 173, 107706. [Google Scholar] [CrossRef]

- Maheri, M.R. The effect of layup and boundary conditions on the modal damping of FRP composite panels. J. Compos. Mater. 2010, 45, 1411–1422. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, Y.; Li, J.; Song, Z. Modal Parameter Identification and Damage Localization of Composite Helicopter Rotor Blades Based on AR/PR Identification. Int. J. Aerosp. Eng. 2024, 1, 5716604. [Google Scholar] [CrossRef]

- Mironov, A.; Doronkin, P. An Analysis of Sensitivity of the Monitoring System of Helicopters to Faults of their Blades. Mech. Compos. Mater. 2021, 57, 233–246. [Google Scholar] [CrossRef]

| No | Position | Technical Solution |

|---|---|---|

| 1 | Specimen quantity, pcs, min | 6 |

| 2 | Model length, mm | 2000 |

| 3 | Sensors | |

| type | piezoelectric film PVDF | |

| size, mm | 16 × 73 | |

| quantity | 24 | |

| wiring | varnished copper wire | |

| placing | interior surface of the hollow model | |

| protection | sensors & wires protected by voile/epoxide resin | |

| 4 | Testing operation range | |

| temperature, °C rotation frequency, rpm | −15 … +45 0 … 900 |

| Mode | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Frequency, Hz | 21 | 38 | 70 | 147 | 171 | 204 | 211 | 257 | 259 | 291 | 303 | 339 | 352 | 358 | 380 | 404 |

| Mode index | 1F | 1R | 2F | 3F | 2R | 4F | 1S | 5F | 2S | 3RS | 6F | 7F | 8F | 2TS | 3S | 9F |

| No | Test Series | Conditions | Quantity | Modal Datasets | ||

|---|---|---|---|---|---|---|

| Models | Tests | Estimates | ||||

| 1 | Testing and data recording procedure development total | −15 °C; n = 0 +15 °C; n = 0 +45 °C; n = 0 +15 °C; n = 900 rpm | 2 2 2 2 | 10 10 10 10 40 | 50 50 50 50 200 | 1500 1500 1500 1500 6000 |

| 2 | Typical modal parameters | +15 °C; n = 0 | 6 | 18 | 90 | 2700 |

| 3 | Temperature influence functions total | −15 °C; n = 0 −5 °C; n = 0 +5 °C; n = 0 +15 °C; n = 0 +25 °C; n = 0 +35 °C; n = 0 +45 °C; n = 0 | 3 3 3 3 3 3 3 | 15 15 15 15 15 15 15 105 | 75 75 75 75 75 75 75 525 | 2250 2250 2250 2250 2250 2250 2250 15750 |

| 4 | Rotation frequency influence functions total | +15 °C; n = 600 rpm +15 °C; n = 700 rpm +15 °C; n = 800 rpm +15 °C; n = 900 rpm | 3 3 3 3 | 15 15 15 15 60 | 75 75 75 75 300 | 2250 2250 2250 2250 9000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mironov, A.; Doronkin, P.; Safonovs, A. Modal Passport Concept for Enhanced Non-Destructive Monitoring and Diagnostics of Wind Turbine Blades. NDT 2025, 3, 9. https://doi.org/10.3390/ndt3020009

Mironov A, Doronkin P, Safonovs A. Modal Passport Concept for Enhanced Non-Destructive Monitoring and Diagnostics of Wind Turbine Blades. NDT. 2025; 3(2):9. https://doi.org/10.3390/ndt3020009

Chicago/Turabian StyleMironov, Aleksey, Pavel Doronkin, and Aleksejs Safonovs. 2025. "Modal Passport Concept for Enhanced Non-Destructive Monitoring and Diagnostics of Wind Turbine Blades" NDT 3, no. 2: 9. https://doi.org/10.3390/ndt3020009

APA StyleMironov, A., Doronkin, P., & Safonovs, A. (2025). Modal Passport Concept for Enhanced Non-Destructive Monitoring and Diagnostics of Wind Turbine Blades. NDT, 3(2), 9. https://doi.org/10.3390/ndt3020009