Description and Classification of Tempering Materials Present in Pottery Using Digital X-Radiography

Abstract

1. Introduction

2. Materials and Methods

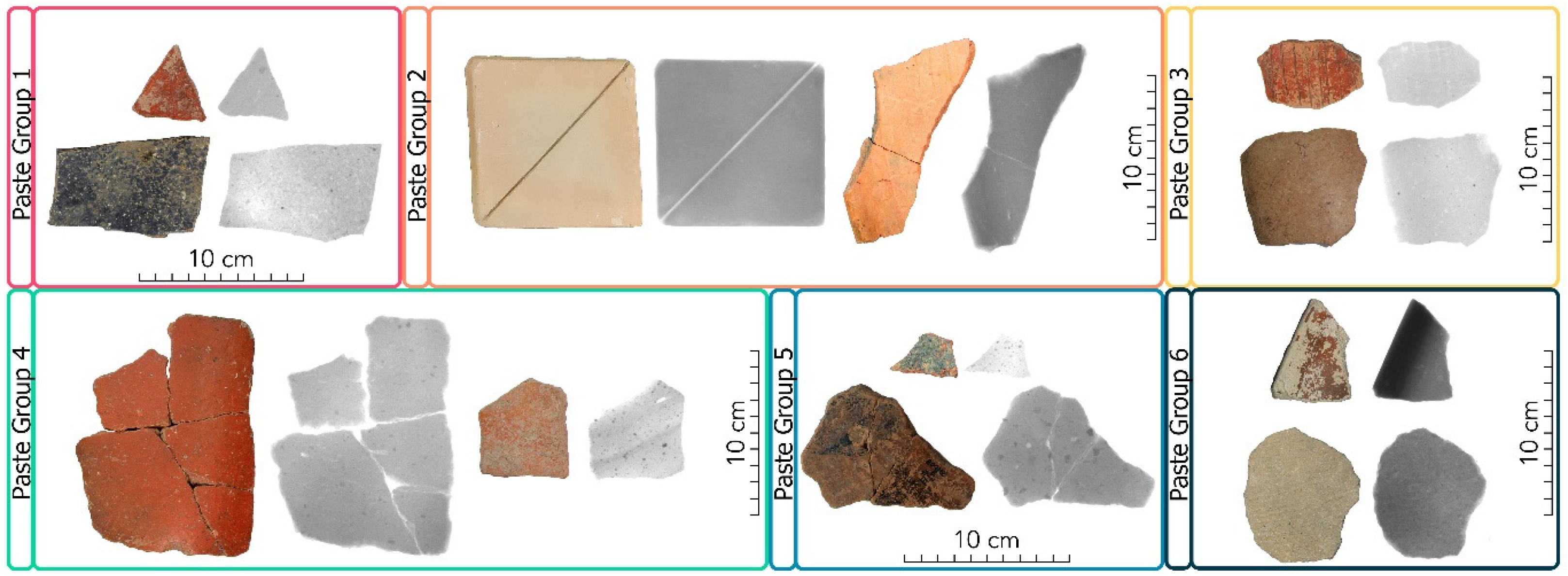

2.1. Materials

2.2. Methodology

2.2.1. X-Radiography Acquisition

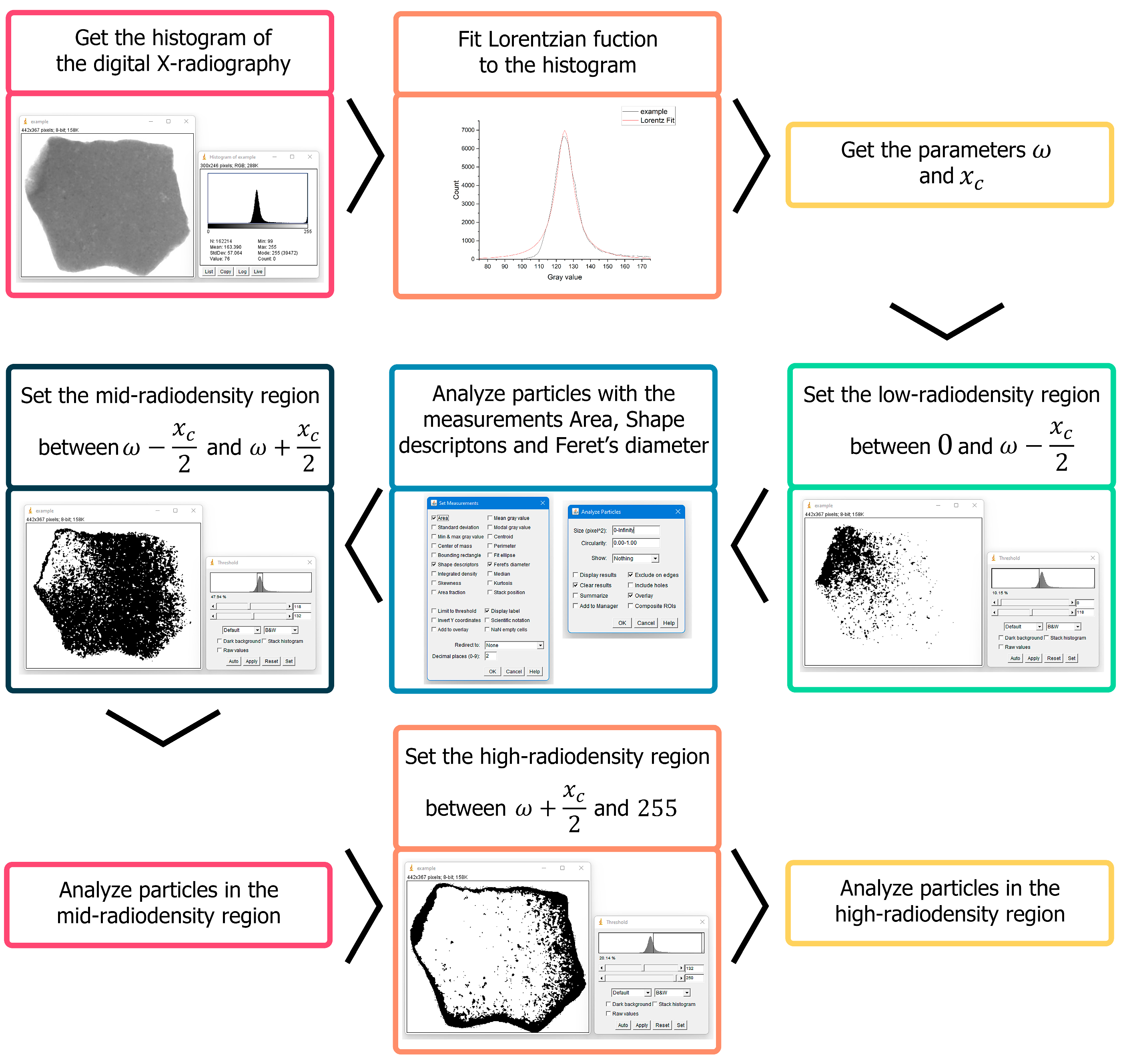

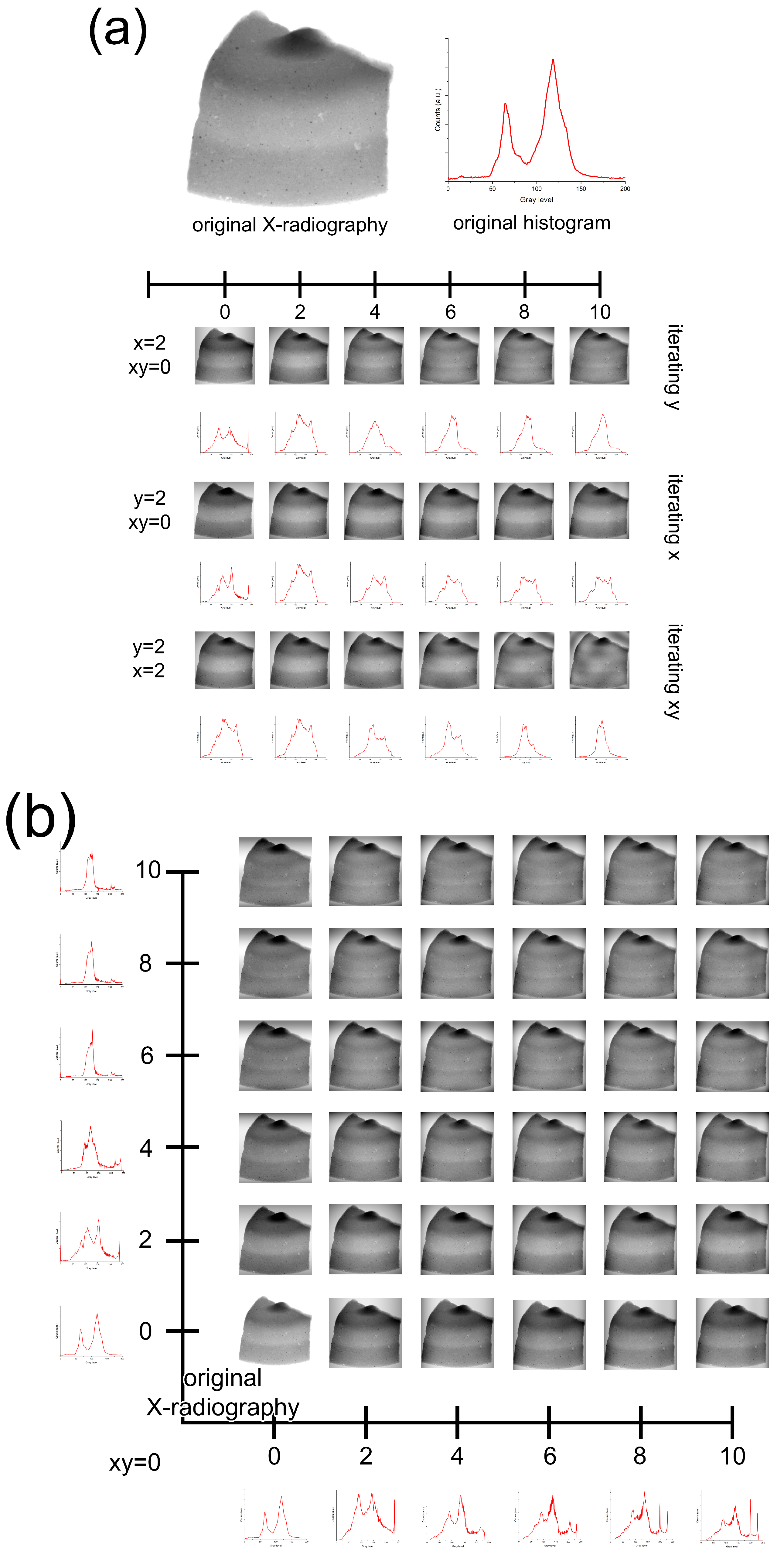

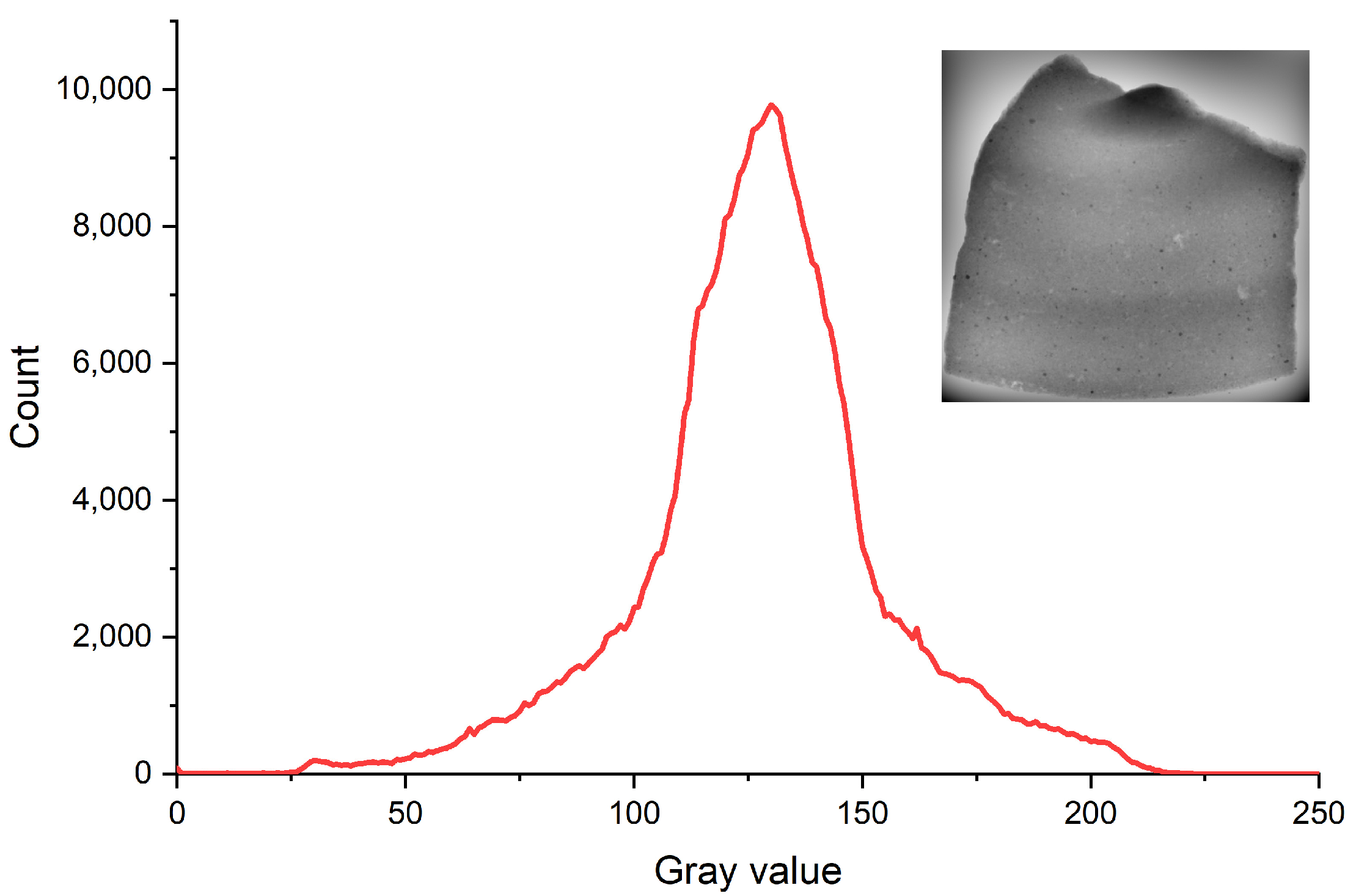

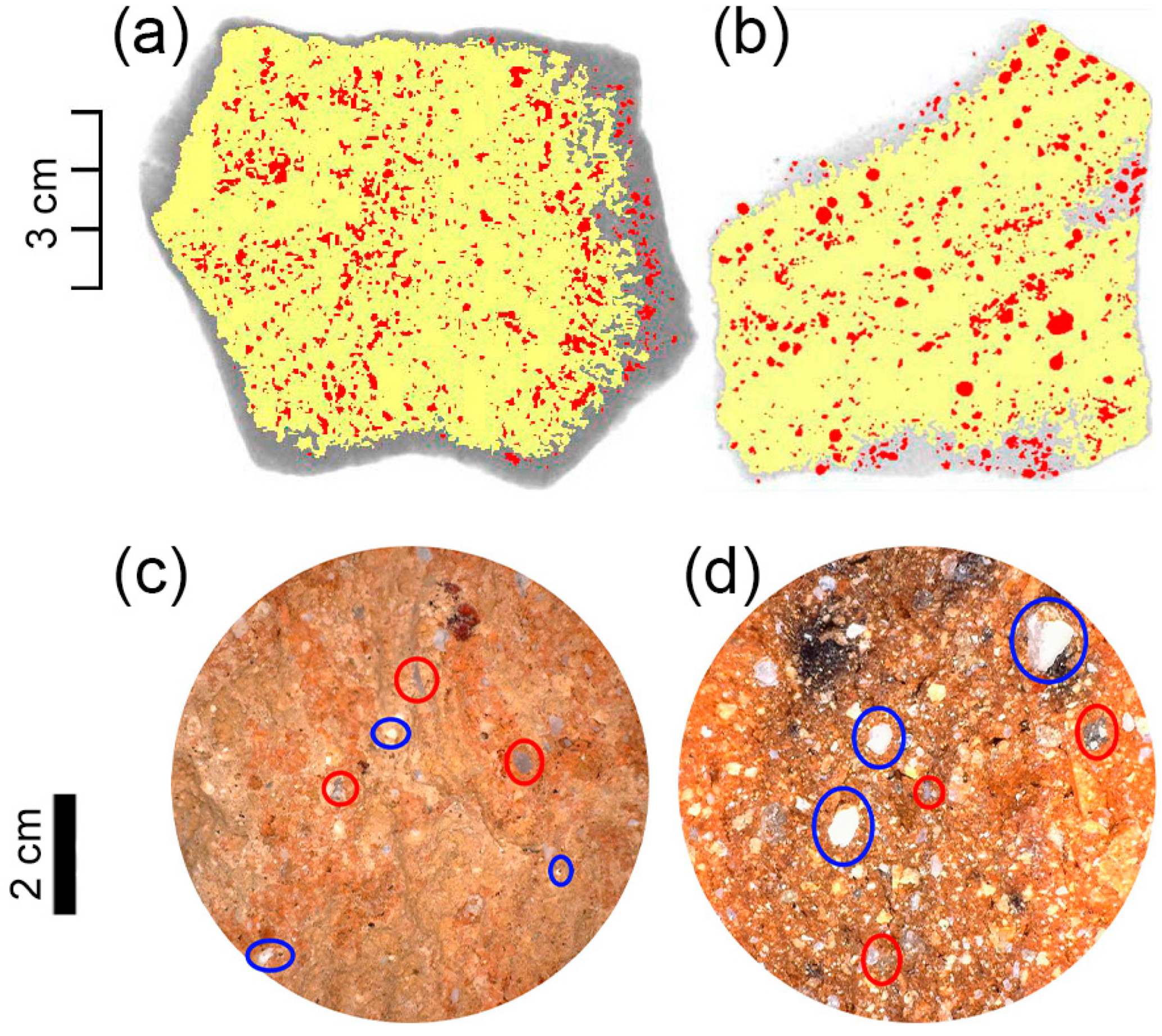

2.2.2. ImageJ Application

2.2.3. Analysis of Parameters

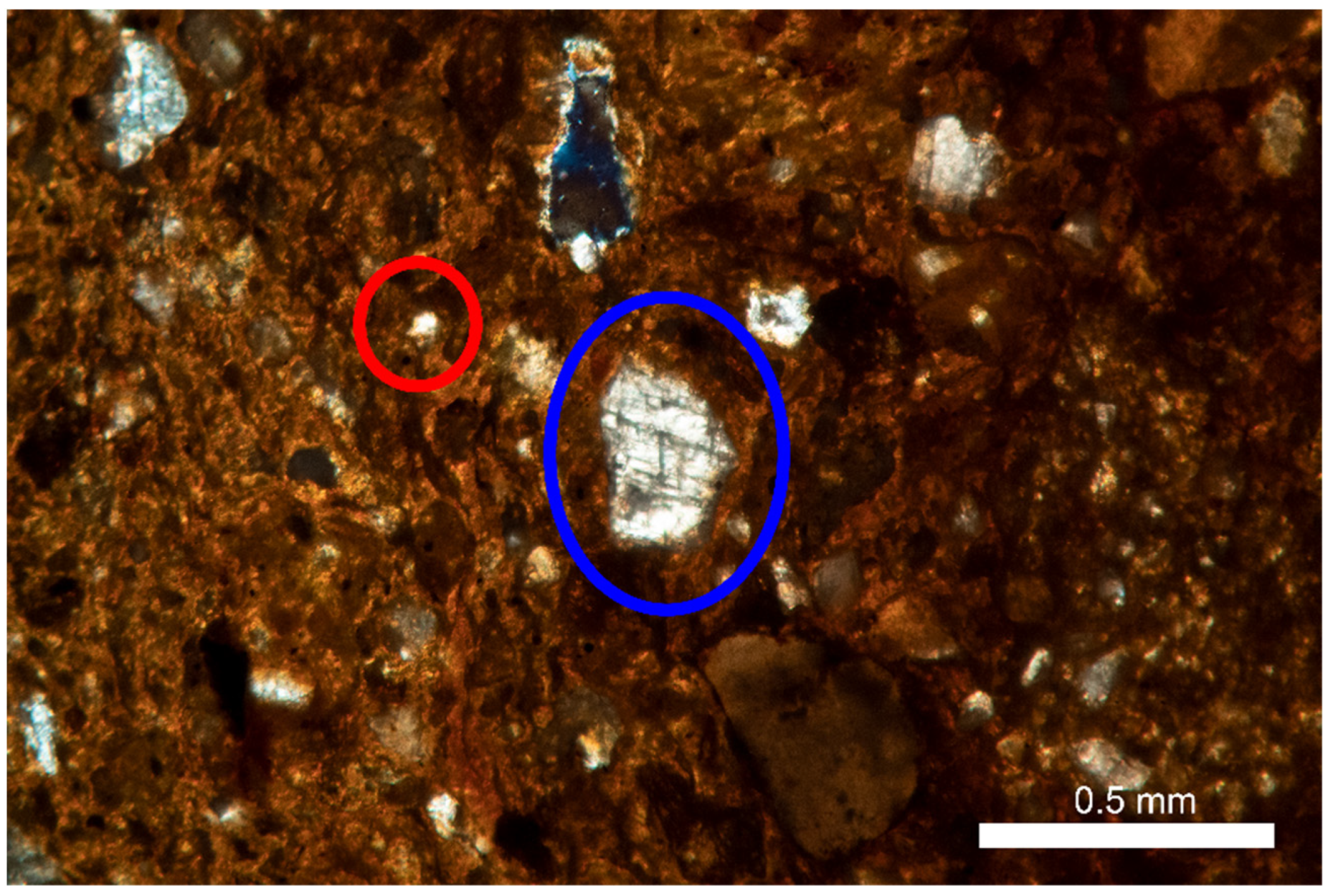

2.2.4. Digital Microscopy Images

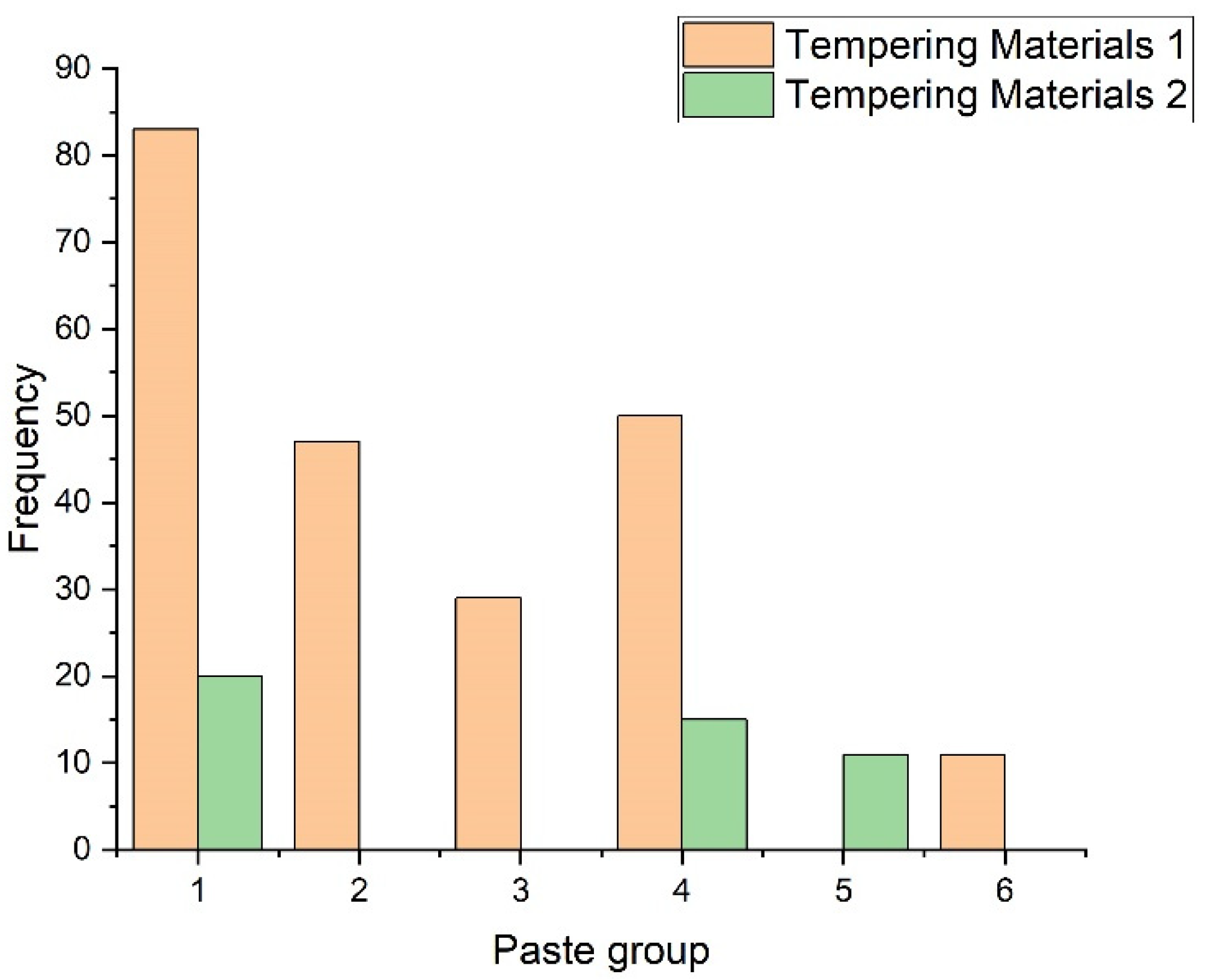

3. Results and Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Object | Temporality | Paste Type | Tempering Material Type |

|---|---|---|---|

| C001 | Middle Preclassic | 1 | 1 |

| C002 | 4 | 1 | |

| C003 | Middle Preclassic | 1 | 1 |

| C004 | Middle Preclassic | 4 | 2 |

| C005 | Middle Preclassic to Early Classic | 1 | 1 |

| C006 | Middle Preclassic to Early Classic | 4 | 1 |

| C007 | Middle Preclassic | 1 | 1 |

| C008 | Middle Preclassic | 4 | 1 |

| C009 | 4 | 1 | |

| C010 | Middle Preclassic | 1 | 1 |

| C011 | Middle Preclassic | 4 | 1 |

| C012 | Middle Preclassic | 4 | 1 |

| C013 | Middle Preclassic | 1 | 1 |

| C014 | Middle Preclassic | 1 | 1 |

| C015 | Middle Preclassic | 1 | 1 |

| C016 | Middle Preclassic | 1 | 1 |

| C017 | Middle Preclassic | 1 | 2 |

| C018 | Middle Preclassic | 1 | 2 |

| C019 | Early Classic | 1 | 2 |

| C020 | Middle Preclassic | 4 | 2 |

| C021 | Middle Preclassic | 4 | 1 |

| C022 | Middle Preclassic | 1 | 1 |

| C023 | Middle Preclassic | 1 | 1 |

| C024 | Middle Preclassic | 3 | 1 |

| C025 | Middle Preclassic | 2 | 1 |

| C026 | Middle Preclassic | 1 | 1 |

| C027 | Middle Preclassic | 1 | 1 |

| C028 | Middle Preclassic | 1 | 1 |

| C029 | 2 | 1 | |

| C030 | Middle Preclassic | 4 | 1 |

| C031 | Middle Preclassic | 1 | 1 |

| C032 | Middle Preclassic | 1 | 1 |

| C033 | Middle Preclassic | 4 | 1 |

| C034 | Middle Preclassic | 1 | 1 |

| C035 | Middle Preclassic | 3 | 1 |

| C036 | Middle Preclassic | 1 | 1 |

| C037 | Middle Preclassic | 1 | 1 |

| C038 | Middle Preclassic | 4 | 1 |

| C039 | Middle Preclassic | 4 | 1 |

| C040 | 1 | 1 | |

| C041 | Middle Preclassic | 2 | 1 |

| C042 | Middle Preclassic | 4 | 2 |

| C043 | Middle Preclassic | 1 | 2 |

| C044 | Middle Preclassic | 1 | 2 |

| C045 | Middle Preclassic | 1 | 1 |

| C046 | Middle Preclassic | 1 | 2 |

| C047 | 1 | 1 | |

| C048 | Middle Preclassic | 1 | 1 |

| C049 | Middle Preclassic | 2 | 1 |

| C050 | Middle Preclassic | 2 | 1 |

| C051 | Middle Preclassic | 3 | 1 |

| C052 | Middle Preclassic | 1 | 1 |

| C053 | Middle Preclassic | 1 | 1 |

| C054 | Middle Preclassic | 1 | 1 |

| C055 | Middle Preclassic | 1 | 1 |

| C056 | Middle Preclassic | 4 | 2 |

| C057 | Middle Preclassic | 1 | 1 |

| C058 | Middle Preclassic | 1 | 2 |

| C059 | Middle Preclassic | 1 | 1 |

| C060 | Middle Preclassic | 1 | 1 |

| C061 | Middle Preclassic | 1 | 2 |

| C062 | Middle Preclassic | 2 | 1 |

| C063 | Middle Preclassic | 1 | 1 |

| C064 | Middle Preclassic | 4 | 1 |

| C065 | Middle Preclassic | 1 | 2 |

| C066 | Middle Preclassic | 5 | 2 |

| C067 | Middle Preclassic | 3 | 1 |

| C068 | Middle Preclassic | 1 | 2 |

| C069 | Late Preclassic | 1 | 1 |

| C070 | Late Preclassic | 1 | 1 |

| C071 | Late Preclassic | 6 | 1 |

| C072 | Late Preclassic | 1 | 1 |

| C073 | Late Preclassic | 4 | 2 |

| C074 | Late Preclassic | 1 | 1 |

| C075 | Late Preclassic | 1 | 1 |

| C076 | Middle Preclassic | 1 | 1 |

| C077 | Late Preclassic | 4 | 2 |

| C078 | Late Preclassic | 1 | 1 |

| C079 | Late Preclassic | 3 | 1 |

| C080 | Late Preclassic | 1 | 1 |

| C081 | Late Preclassic | 3 | 1 |

| C082 | Late Preclassic | 3 | 1 |

| C083 | Late Preclassic | 2 | 1 |

| C084 | Late Preclassic | 2 | 1 |

| C085 | Late Preclassic | 1 | 1 |

| C086 | Late Preclassic | 4 | 1 |

| C087 | Late Preclassic | 1 | 1 |

| C088 | Late Preclassic | 4 | 1 |

| C089 | Late Preclassic | 1 | 1 |

| C090 | Late Preclassic | 1 | 1 |

| C091 | Late Preclassic | 4 | 1 |

| C092 | Late Preclassic | 1 | 1 |

| C093 | Late Preclassic | 1 | 1 |

| C094 | 3 | 1 | |

| C095 | Middle Preclassic | 1 | 1 |

| C096 | Middle Preclassic | 1 | 1 |

| C097 | Middle Preclassic | 1 | 1 |

| C098 | Middle Preclassic | 1 | 1 |

| C099 | Middle Preclassic | 1 | 1 |

| C100 | Late Preclassic | 3 | 1 |

| C101 | Early Classic | 6 | 1 |

| C102 | Late Preclassic | 3 | 1 |

| C103 | Late Preclassic | 3 | 1 |

| C104 | Late Preclassic | 3 | 1 |

| C105 | 5 | 2 | |

| C106 | Early Classic | 4 | 1 |

| C107 | Early Classic | 1 | 1 |

| C108 | Early Classic | 1 | 1 |

| C109 | Early Classic | 1 | 1 |

| C110 | Early Classic | 4 | 1 |

| C111 | Late Preclassic | 3 | 1 |

| C112 | 3 | 1 | |

| C113 | Early Classic | 1 | 2 |

| C114 | 1 | 1 | |

| C115 | Late Preclassic | 3 | 1 |

| C116 | 4 | 1 | |

| C117 | Late Preclassic | 1 | 1 |

| C118 | Early Classic | 1 | 1 |

| C119 | Early Classic | 2 | 1 |

| C120 | Early Classic | 4 | 1 |

| C121 | Late Preclassic | 5 | 2 |

| C122 | Early Classic | 1 | 1 |

| C123 | Early Classic | 1 | 1 |

| C124 | Early Classic | 4 | 2 |

| C125 | Early Classic | 1 | 2 |

| C126 | Early Classic | 1 | 1 |

| C127 | Early Classic | 4 | 1 |

| C128 | Early Classic | 1 | 1 |

| C129 | Early Classic | 1 | 1 |

| C130 | Early Classic | 1 | 1 |

| C131 | Early Classic | 1 | 2 |

| C132 | Early Classic | 1 | 2 |

| C133 | Early Classic | 1 | 2 |

| C134 | Early Classic | 3 | 1 |

| C135 | Early Classic | 2 | 1 |

| C136 | Late Classic | 1 | 1 |

| C137 | Late Classic | 1 | 1 |

| C138 | Late Classic | 1 | 1 |

| C139 | Late Classic | 1 | 2 |

| C140 | Late Classic | 1 | 1 |

| C141 | Late Classic | 1 | 1 |

| C142 | Late Classic | 1 | 1 |

| C143 | Early Classic | 1 | 1 |

| C144 | Early Classic | 5 | 2 |

| C145 | 6 | 1 | |

| C146 | Late Classic | 6 | 1 |

| C147 | Late Classic | 4 | 1 |

| C148 | Late Classic | 4 | 1 |

| C149 | Terminal Classic | 1 | 1 |

| C150 | Terminal Classic | 1 | 1 |

| C151 | Terminal Classic | 1 | 2 |

| C152 | Late Classic | 5 | 2 |

| C153 | Late Classic | 1 | 1 |

| C154 | Late Classic | 1 | 2 |

| C155 | Late Classic | 1 | 1 |

| C156 | Late Classic | 4 | 1 |

| C157 | Late Classic | 4 | 1 |

| C158 | Late Classic | 3 | 1 |

| C159 | Late Classic | 2 | 1 |

| C160 | 1 | 1 | |

| C161 | Late Classic | 1 | 1 |

| C162 | Late Classic | 1 | 1 |

| C163 | Terminal Classic | 1 | 2 |

| C164 | Late Classic | 6 | 1 |

| C165 | Late Classic | 2 | 1 |

| C166 | Late Classic | 3 | 1 |

| C167 | Terminal Classic | 1 | 2 |

| C168 | Terminal Classic | 1 | 1 |

| C169 | Late Classic | 3 | 1 |

| C170 | 4 | 1 | |

| C171 | Late Classic | 4 | 1 |

| C172 | Late Classic | 4 | 1 |

| C173 | Late Classic | 4 | 1 |

| C174 | Late Classic | 4 | 1 |

| C175 | Late Classic | 1 | 1 |

| C176 | Late Classic | 4 | 1 |

| C177 | Late Classic | 1 | 1 |

| C178 | Late Classic | 1 | 1 |

| C179 | Postclassic | 2 | 1 |

| C180 | Postclassic | 2 | 1 |

| C181 | Postclassic | 2 | 1 |

| C182 | Postclassic | 1 | 1 |

| C183 | Postclassic | 1 | 1 |

| C184 | Late Classic | 1 | 1 |

| C185 | Late Classic | 2 | 1 |

| C186 | Late Classic | 6 | 1 |

| C187 | Late Classic | 2 | 1 |

| C188 | 3 | 1 | |

| C189 | Early Classic | 5 | 2 |

| C190 | Early Classic | 5 | 2 |

| C191 | Early Classic | 6 | 1 |

| C192 | Middle Preclassic | 3 | 1 |

| C193 | Middle Preclassic | 3 | 1 |

| C194 | 6 | 1 | |

| C195 | 6 | 1 | |

| C196 | 4 | 1 | |

| C197 | 4 | 1 | |

| C198 | 3 | 1 | |

| C199 | 6 | 1 | |

| C200 | 6 | 1 | |

| C201 | 5 | 2 | |

| D001 | Middle Preclassic | 4 | 2 |

| D002 | Middle Preclassic | 4 | 2 |

| D003 | Middle Preclassic | 4 | 1 |

| D004 | Middle Preclassic | 4 | 2 |

| D005 | Middle Preclassic | 4 | 2 |

| D008 | Late Preclassic | 6 | 1 |

| D009 | Late Preclassic | 3 | 1 |

| D013 | Late Preclassic | 3 | 1 |

| D014 | Early Classic | 3 | 1 |

| D016 | Early Classic | 3 | 1 |

| D017 | Early Classic | 4 | 1 |

| D019 | Early Classic | 3 | 1 |

| D020 | Early Classic | 3 | 1 |

| D022 | Early Classic | 4 | 1 |

| D023A | Early Classic | 4 | 1 |

| D025 | Early Classic | 4 | 1 |

| D025 | Early Classic | 4 | 1 |

| D027 | Early Classic | 4 | 1 |

| D028 | Late Classic | 4 | 2 |

| D029 | Late Classic | 4 | 2 |

| D030 | Late Classic | 4 | 1 |

| D031 | Late Classic | 4 | 1 |

| D031 | Late Classic | 4 | 1 |

| D033 | Late Classic | 4 | 1 |

| D033 | Late Classic/Terminal Classic | 4 | 2 |

| D035 | Late Classic/Terminal Classic | 4 | 2 |

| D036 | Late Classic/Terminal Classic | 4 | 1 |

| D036 | Late Classic/Terminal Classic | 4 | 1 |

| D039 | Late Classic/Terminal Classic | 4 | 1 |

| D041 | Late Classic/Terminal Classic | 4 | 1 |

| D042 | Late Classic/Terminal Classic | 6 | 1 |

| D043 | Late Classic/Terminal Classic | 6 | 1 |

| D044 | Late Classic/Terminal Classic | 3 | 1 |

| D046 | Late Classic/Terminal Classic | 3 | 1 |

| D047 | Late Classic/Terminal Classic | 3 | 1 |

| D048 | Late Classic/Terminal Classic | 3 | 1 |

| D049 | Terminal Classic | 3 | 1 |

| D050 | Terminal Classic | 4 | 1 |

| D051 | Terminal Classic | 5 | 2 |

| E001 | Mock-ups | 2 | 1 |

| E002 | Mock-ups | 2 | 1 |

| E003 | Mock-ups | 2 | 1 |

| E004 | Mock-ups | 2 | 1 |

| E005 | Mock-ups | 2 | 1 |

| E006 | Mock-ups | 2 | 1 |

| E007 | Mock-ups | 2 | 1 |

| E008 | Mock-ups | 2 | 1 |

| E009 | Mock-ups | 2 | 1 |

| E010 | Mock-ups | 2 | 1 |

| E011 | Mock-ups | 2 | 1 |

| E012 | Mock-ups | 2 | 1 |

| E013 | Mock-ups | 2 | 1 |

| E014 | Mock-ups | 2 | 1 |

| E015 | Mock-ups | 2 | 1 |

| E016 | Mock-ups | 2 | 1 |

| E017 | Mock-ups | 2 | 1 |

| E018 | Mock-ups | 2 | 1 |

| E019 | Mock-ups | 2 | 1 |

| E020 | Mock-ups | 2 | 1 |

| E021 | Mock-ups | 2 | 1 |

| E022 | Mock-ups | 2 | 1 |

| E023 | Mock-ups | 2 | 1 |

| E024 | Mock-ups | 2 | 1 |

| E025 | Mock-ups | 2 | 1 |

| E026 | Mock-ups | 2 | 1 |

| E027 | Mock-ups | 2 | 1 |

| E028 | Mock-ups | 2 | 1 |

| E029 | Mock-ups | 2 | 1 |

| E030 | Mock-ups | 2 | 1 |

| E031 | Mock-ups | 2 | 1 |

| E032 | Mock-ups | 2 | 1 |

| E033 | Mock-ups | 2 | 1 |

| E034 | Mock-ups | 2 | 1 |

| E035 | Mock-ups | 2 | 1 |

Appendix B

References

- Rice, P. Pottery Analysis: A Sourcebook; University of Chicago Press: Chicago, IL, USA, 2006; pp. 309–446. [Google Scholar]

- Quinn, P.S.; Zhang, S.; Xia, Y.; Li, X. Building the terracotta army: Ceramic craft technology and organisation of production at qin shihuang’s mausoleum complex. Antiquity 2017, 91, 966–979. [Google Scholar] [CrossRef]

- Titterrington, P.F. Certain bluff mounds of western jersey county, Illinois. Am. Antiq. 1935, 1, 6–46. [Google Scholar] [CrossRef]

- Ikeoka, R.A.; Appoloni, C.R.; Scorzelli, R.B.; Santos, E.D.; Rizzutto, M.D.A.; Bandeira, A.M. Study of ancient pottery from the brazilian amazon coast by edxrf, pixe, xrd, mössbauer spectroscopy and computed radiography. Minerals 2022, 12, 1302. [Google Scholar] [CrossRef]

- McCarthy, B. Examination of processing techniques in cultural heritage objects with radiography. Am. Ceram. Soc. Bull. 2020, 99, 24–29. [Google Scholar]

- Norris, D.; Watson, O. Illuminating the imperceptible, researching mina’i ceramics with digital imaging techniques. J. Imaging 2021, 7, 233. [Google Scholar] [CrossRef]

- Okońska-Bulas, M.; Mikołajska, A. Wheel-made pottery of the przeworsk culture in the light of digital radiography examinations. Preliminary study of vessels from the microregion to the east of the lower raba river. Acta Archaeol. Carpathica 2022, 57, 115–142. [Google Scholar] [CrossRef]

- Thér, R. Ceramic technology. How to reconstruct and describe pottery-forming practices. Archaeol. Anthropol. Sci. 2020, 12, 172. [Google Scholar] [CrossRef]

- Müller, N.S.; Vekinis, G.; Day, P.M.; Kilikoglou, V. The influence of microstructure and texture on the mechanical properties of rock tempered archaeological ceramics. J. Eur. Ceram. Soc. 2015, 35, 831–843. [Google Scholar] [CrossRef]

- Sterba, J.H.; Mommsen, H.; Staeinhauser, G.; Bichler, M. The influence of different tempers on the composition of pottery. J. Archaeol. Sci. 2009, 36, 1582–1589. [Google Scholar] [CrossRef]

- Berg, I. Looking through pots: Recent advances in ceramics x-radiography. J. Archeol. Sci. 2008, 35, 1177–1188. [Google Scholar] [CrossRef]

- Soares Batista, S.; Panzarella, F.K.; Tavano, O.; Filho, A.M.; Junqueira, J.L.C. Image adjustments on digital panoramic radiographs using adobe photoshop CS3 software. RSBO Rev. Sul-Bras. Odontol. 2013, 10, 394–401. [Google Scholar] [CrossRef]

- Lu, W.; Zhang, N.; Ren, N.; Ding, Z.; Yang, F.; Hu, Q.; Li, J. Bubble-induced formation of new intermetallic compounds in an al–mn alloy during heating observed by synchrotron radiography. Materialia 2021, 15, 1000991. [Google Scholar] [CrossRef]

- Martins, A.; Davis, E.; Kwartler, T. Max ernst’s woman, old man, and flower (1923–1924): Four paintings in one revealed by technical imaging. Heritage 2021, 4, 2224–2236. [Google Scholar] [CrossRef]

- Yahaghi, E.; Garcia, J.A.M.; Movafeghi, A. Fracture and internal structure detection of ceramic objects using improved digital radiography images. J. Cult. Herit. 2020, 44, 152–162. [Google Scholar] [CrossRef]

- Gozes, O.; Greenspan, H. Bone structures extraction and enhancement in chest radiographs via cnn trained on synthetic data. In Proceedings of the 2020 IEEE 17th International Symposium on Biomedical Imaging (ISBI), Iowa City, IA, USA, 3–7 April 2020; pp. 858–861. [Google Scholar] [CrossRef]

- Greene, A.F.; Hartley, C.W.; Dupuy, P.N.D.; Chinander, M. The digital radiography of archaeological pottery: Program and protocols for the analysis of production. J. Archaeol. Sci. 2017, 78, 120–133. [Google Scholar] [CrossRef]

- Schneider, C.; Rasband, W.; Eliceiri, K. Nih image to imagej: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Geiger, M.; Blem, G.; Ludwig, A. Evaluation of imagej for relative bone density measurement and clinical application. J Oral J. Oral Health Craniofacial Sci. 2016, 1, 12–21. [Google Scholar] [CrossRef]

- Satir, S.; Buyukcavus, M.H.; Orhan, K. A novel approach to radiographic detection of bucco-palatal/lingual dilacerations: A preliminary study with imageJ. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2021, 235, 1310–1314. [Google Scholar] [CrossRef]

- Harman, J. Using decorrelation stretch to enhance rock art images. Am. Rock Art Res. Assoc. Annu. Meet. 2005, 28, 1–4. [Google Scholar]

- Saunders, D.; Collmann, R.; Borda, A. Reflectance transformation imaging and imagej: Comparing imaging methodologies for cultural heritage artefacts. In Electronic Visualisation and the Arts (EVA 2017); BCS Learning & Development: Swindon, UK, 2017. [Google Scholar]

- Nagaya, A.; Tlacuilo, R.; de Lucio, O.; Ortiz, S. Desarrollo de un método de clasificación de pastas cerámicas basado en el análisis de imágenes de radiografía digital. Boletín La Soc. Geológica Mex. 2024, 76, A101223. [Google Scholar] [CrossRef]

- Reedy, C.L.; Anderson, J.; Reedy, T.J. Quantitative porosity studies of archaeological ceramics by petrographic image analysis. MRS Online Proc. Libr. 2014, 1656, 9–14. [Google Scholar] [CrossRef]

- Sbalzarini, I.F.; Koumoutsakos, P. Feature point tracking and trajectory analysis for video imaging in cell biology. J. Struct. Biol. 2005, 151, 182–195. [Google Scholar] [CrossRef] [PubMed]

- Kuru, K. Optimization and enhancement of H&E stained microscopical images by applying bilinear interpolation method on lab color mode. Theor. Biol. Med Model. 2014, 11, 9. [Google Scholar] [CrossRef]

- Smith, R.E. The Pottery of Mayapan Including Studies of Ceramic Material from Uxmal, Kabah, and Chichen Itza; Peabody Museum of Archaeology and Ethnology, Harvard University: Cambridge, MA, USA, 1971. [Google Scholar]

- Peraza Lope, C.; Masson, M.A.; Cruz Alvarado, W.; Russell, B.W. Effigy Censer and Figurine Production at the Postclassic Maya City of Mayapan, Mexico. Anc. Mesoam. 2023, 34, 455–475. [Google Scholar] [CrossRef]

- Cruz Alvarado Wilberth, A. Distribución y Cronología de sitios Arqueológicos del Centro-sur de Yucatán. Bachelor’s Thesis, Universidad Autónoma de Yucatán, Mérida, México, 2010. [Google Scholar]

- Tomaszewski, P.E. The uncertainty in the grain size calculation from X-ray diffraction data. Phase Transit. 2013, 86, 260–266. [Google Scholar] [CrossRef]

- Virto, I.; Moni, C.; Swanston, C.; Chenu, C. Turnover of intra- and extra-aggregate organic matter at the silt-size scale. Geoderma 2010, 156, 1–10. [Google Scholar] [CrossRef]

- Sheppard, P.; Walter, R.; Dickinson, W.; Felgate, M.; Ross-Sheppard, C.; Azemard, C. A solomon sea interaction sphere. In The Lapita Cultural Complex in Time and Space: Expansion Routes, Chronologies and Typologies; Archeologia Pasifika, Institut d’archaeologie de la Novelle-Caledonie et du Pacific: Noumea, New Caledonia, 2015; pp. 63–80. [Google Scholar]

- Eramo, G. Ceramic technology: How to recognize clay processing. Archaeol. Anthropol. Sci. 2020, 12, 164. [Google Scholar] [CrossRef]

- Maritan, L.; Ganzarolli, G.; Antonelli, F.; Rigo, M.; Kapatza, A.; Bajnok, K.; Coletti, C.; Mazzoli, C.; Lazzarini, L.; Vedovetto, P.; et al. What kind of calcite? Disclosing the origin of sparry calcite temper in ancient ceramics. J. Archaeol. Sci. 2021, 105358, 129. [Google Scholar] [CrossRef]

- Allegreta, I.; Pinto, D.; Giacomo, E. Effects of grain on the reactivity of limestone temper in a kaolinitic clay. Appl. Clay Sci. 2016, 126, 223–234. [Google Scholar] [CrossRef]

- Kilikoglou, V.; Vekinis, G.; Maniatis, Y.; Day, P.M. Mechanical performance of quartz-tempered ceramics: Part I, strength and toughness. Archaeometry 1998, 40, 261–279. [Google Scholar] [CrossRef]

- Allegretta, I.; Eramo, G.; Pinto, D.; Hein, A. The effect of temper on the thermal conductivity of traditional ceramics: Nature, percentage and granulometry. Thermochim. Acta 2014, 581, 100–109. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagaya, A.; de Lucio, O.G.; Ortiz Ruiz, S.; Uc González, E.; Peraza Lope, C.; Cruz Alvarado, W. Description and Classification of Tempering Materials Present in Pottery Using Digital X-Radiography. NDT 2024, 2, 456-473. https://doi.org/10.3390/ndt2040028

Nagaya A, de Lucio OG, Ortiz Ruiz S, Uc González E, Peraza Lope C, Cruz Alvarado W. Description and Classification of Tempering Materials Present in Pottery Using Digital X-Radiography. NDT. 2024; 2(4):456-473. https://doi.org/10.3390/ndt2040028

Chicago/Turabian StyleNagaya, Alan, Oscar G. de Lucio, Soledad Ortiz Ruiz, Eunice Uc González, Carlos Peraza Lope, and Wilberth Cruz Alvarado. 2024. "Description and Classification of Tempering Materials Present in Pottery Using Digital X-Radiography" NDT 2, no. 4: 456-473. https://doi.org/10.3390/ndt2040028

APA StyleNagaya, A., de Lucio, O. G., Ortiz Ruiz, S., Uc González, E., Peraza Lope, C., & Cruz Alvarado, W. (2024). Description and Classification of Tempering Materials Present in Pottery Using Digital X-Radiography. NDT, 2(4), 456-473. https://doi.org/10.3390/ndt2040028