Acoustic Emission Monitoring for Damage Assessment of a Magnetite Ultra-High-Performance Concrete (MUHPC) Block in a Bending Test

Abstract

1. Introduction

2. Experimental Setup

2.1. Material and Specimen

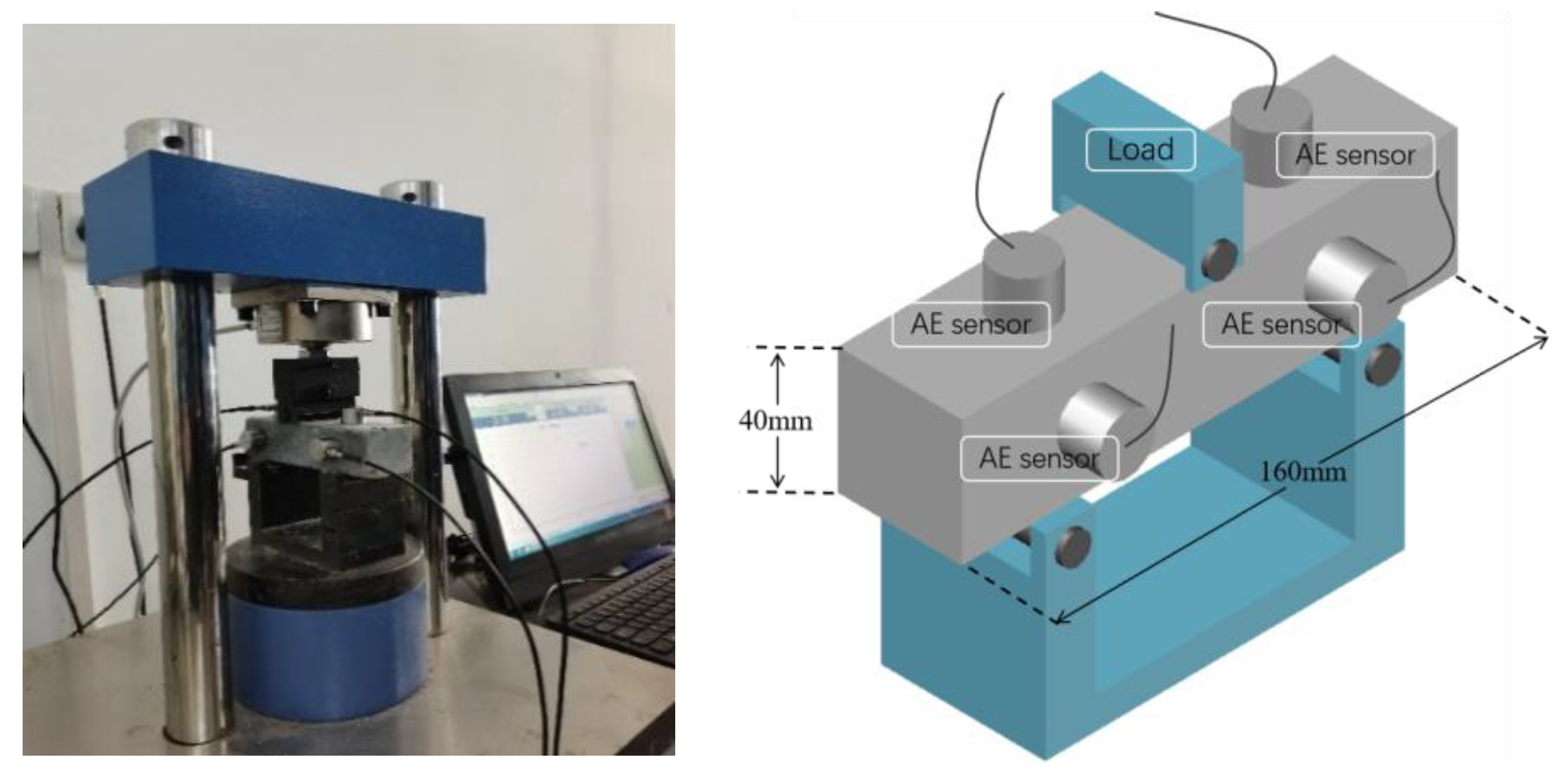

2.2. Test Setup

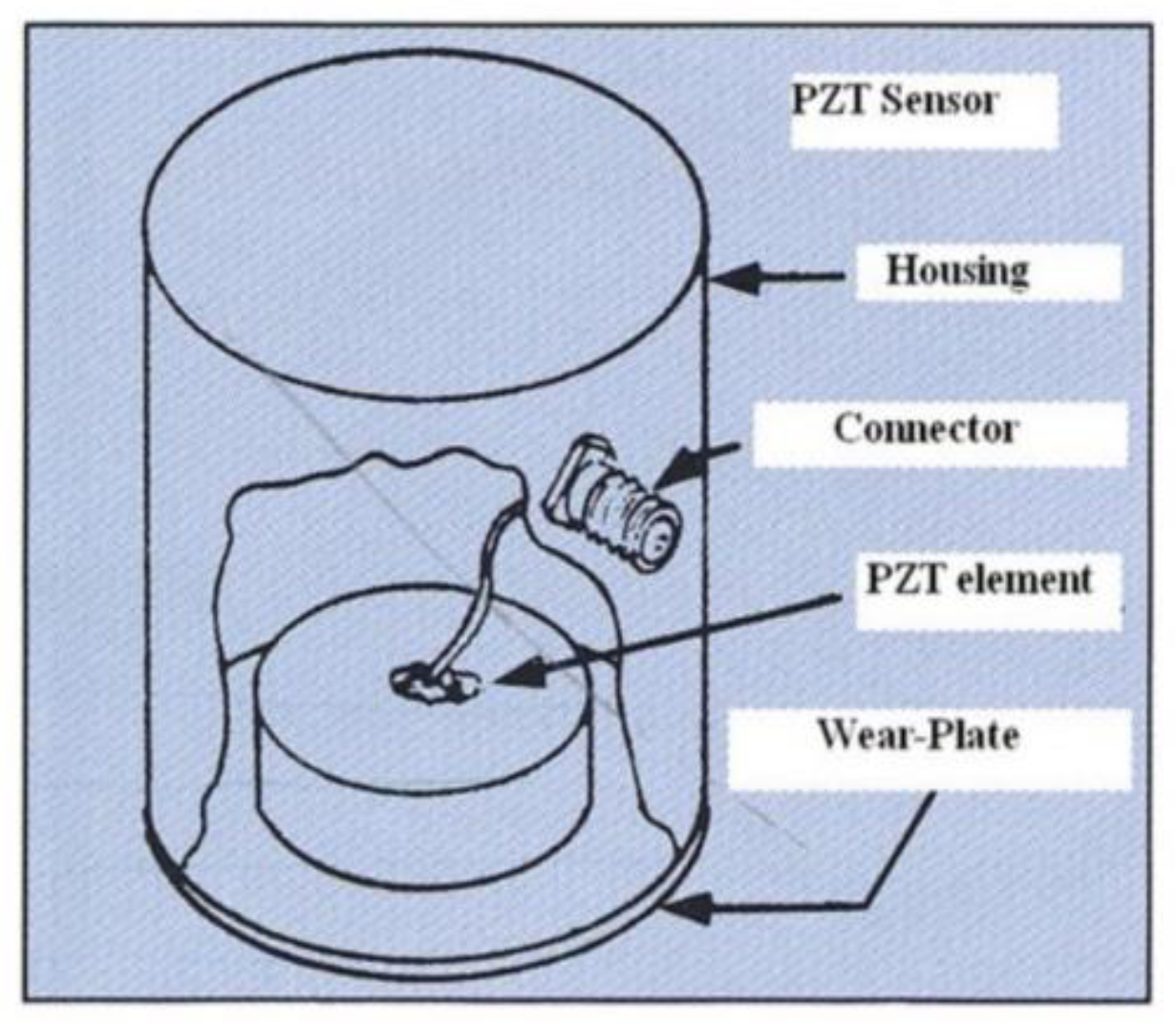

2.3. AE Monitoring

2.4. Data Acquisition System

3. Results

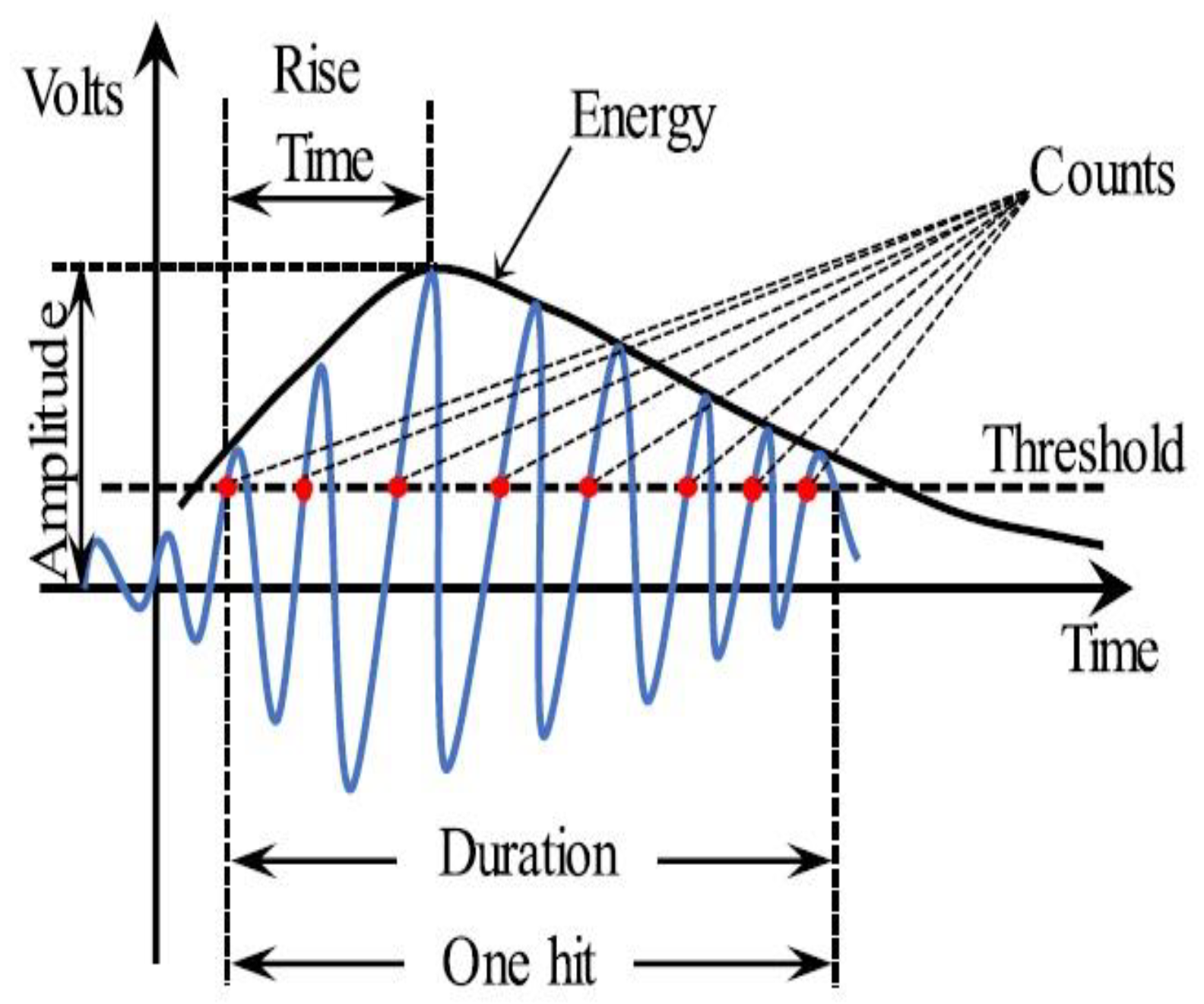

Analysis of Characteristics of AE Parameters

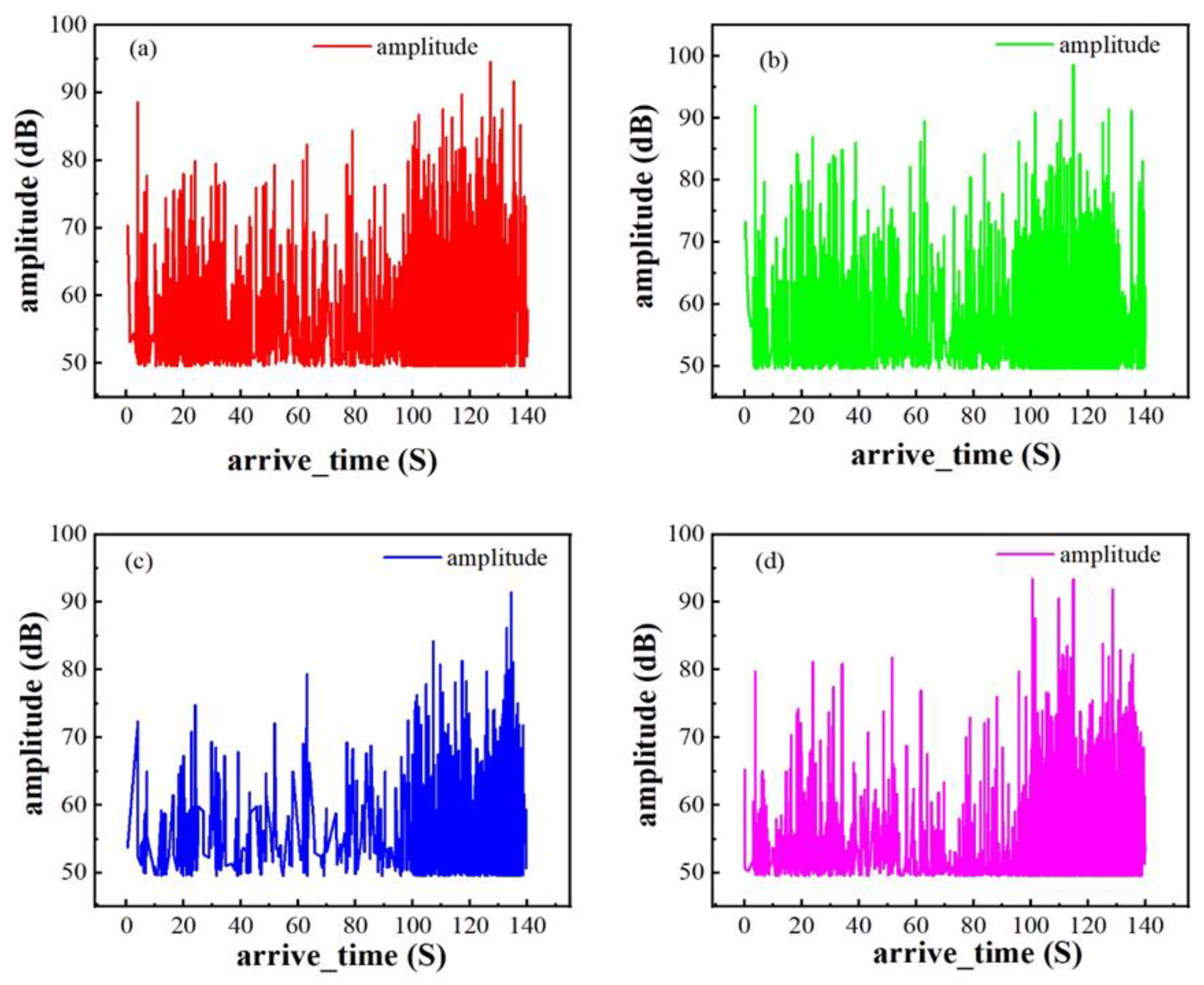

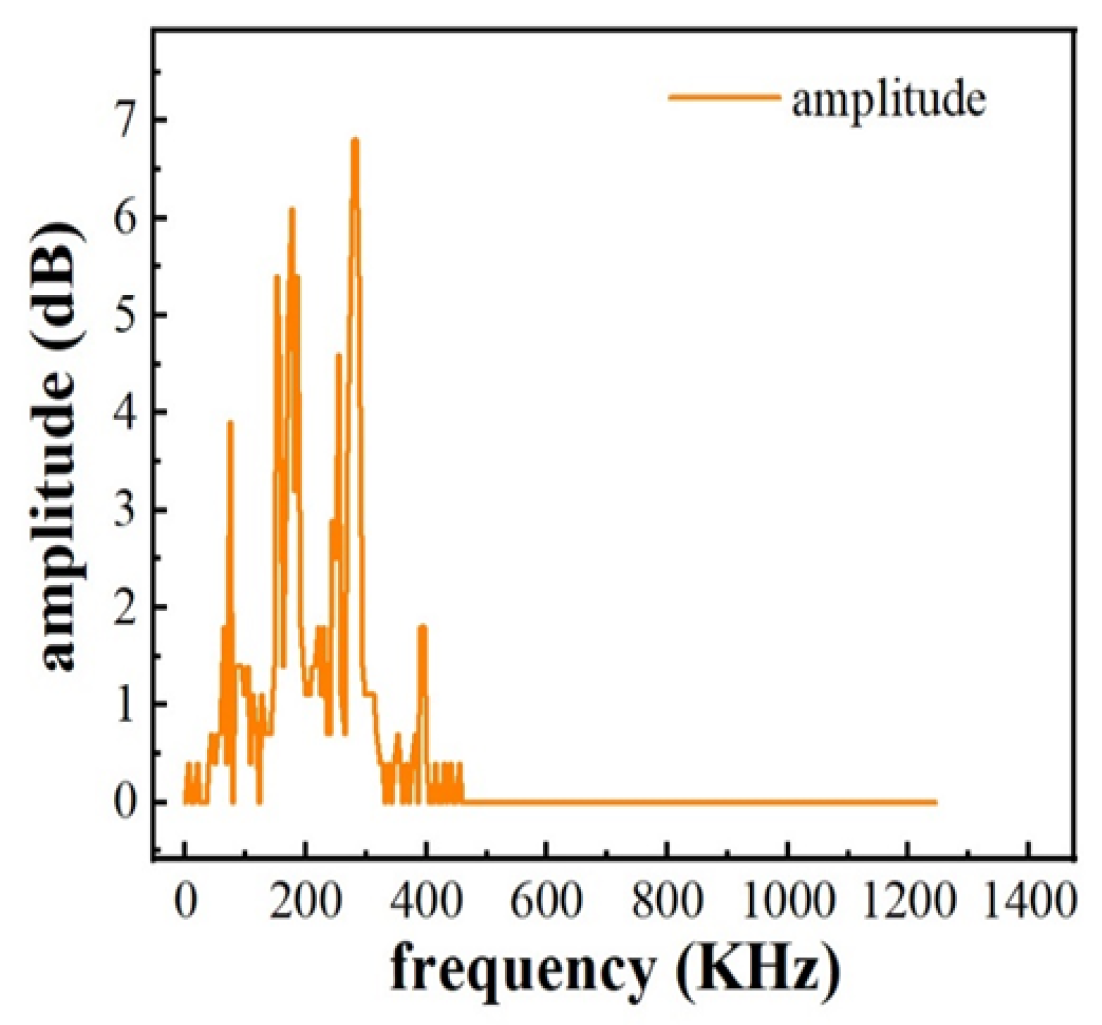

- Amplitude and frequency

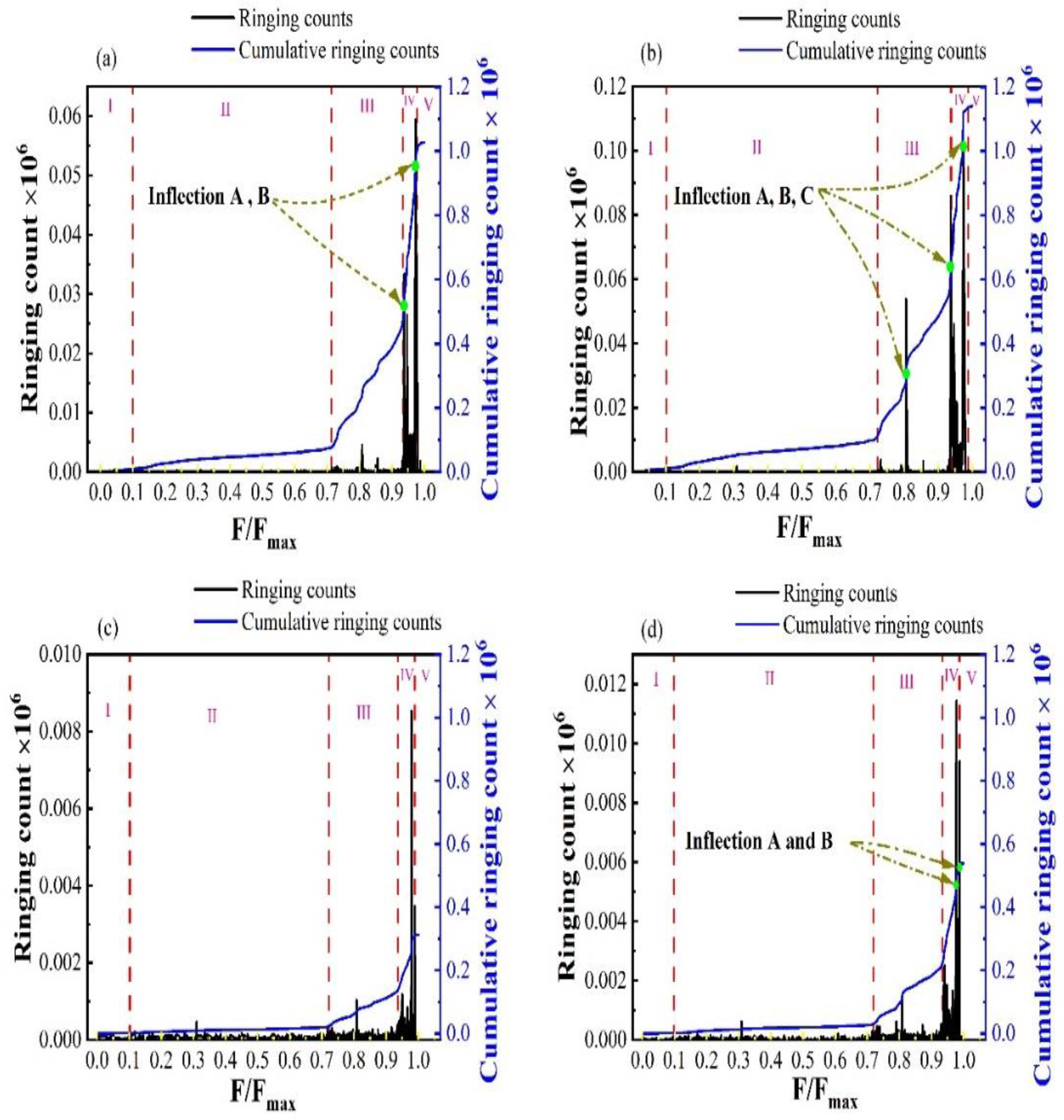

- Acoustic Emission Ringing Count

- Early inflection points: This indicates that the onset of damage occurs at lower levels of applied force.

- A steeper slope in cumulative ringing counts indicates a higher rate of damage occurring within a smaller range of loads.

- Increased overall ringing counts indicate a higher frequency of acoustic emissions and possibly more extensive damage.

- Decreased ringing counts: A reduction in the number of acoustic emissions may represent a decrease in activity inside the material, indicating a lower occurrence of damaging events.

- Gradual cumulative increase: A smoother and steady upward trend in the cumulative ringing count line indicates a regular rate of sound emission without abrupt spikes, which are usually linked to instances of damage.

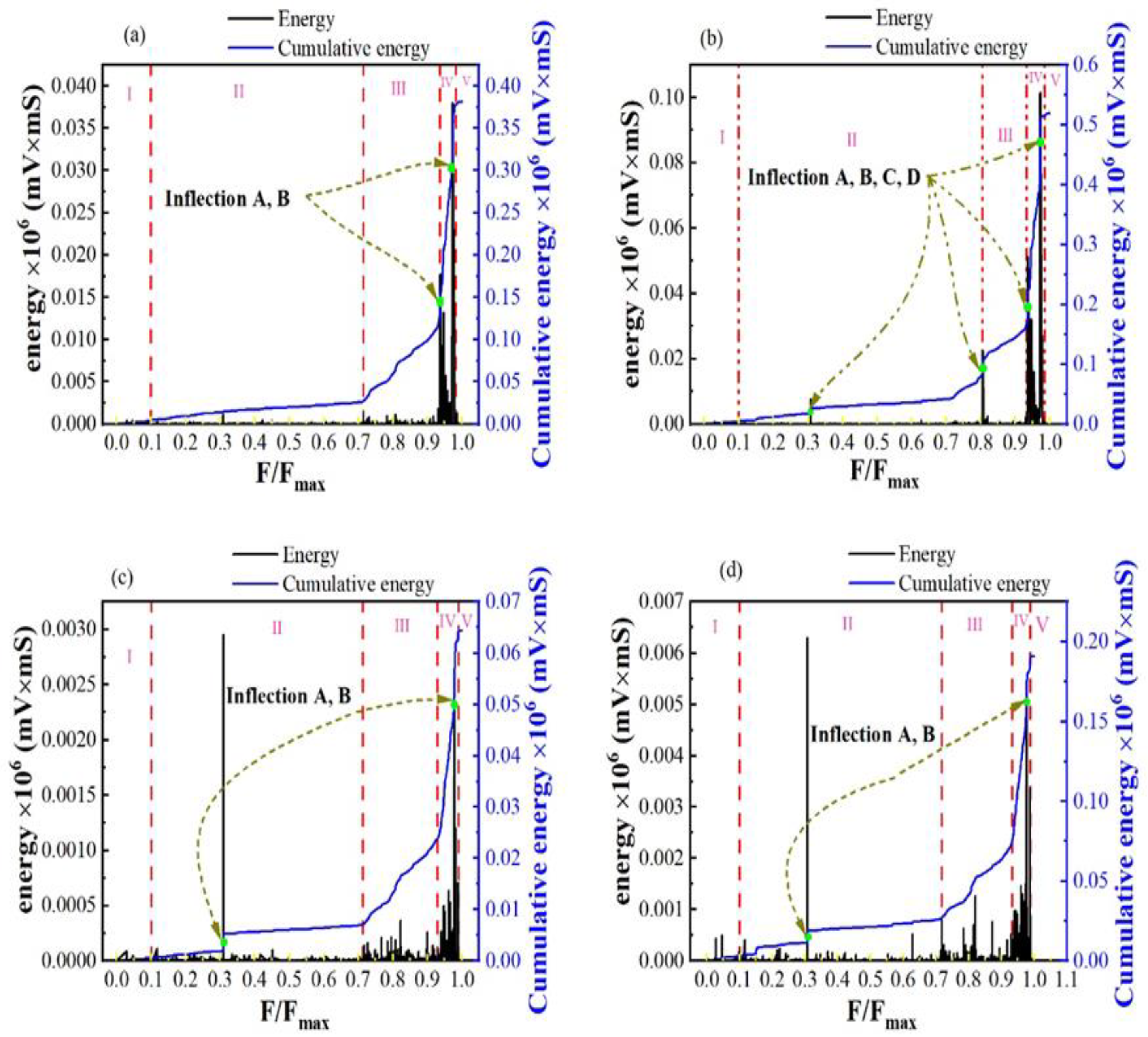

- Acoustic Emission Energy

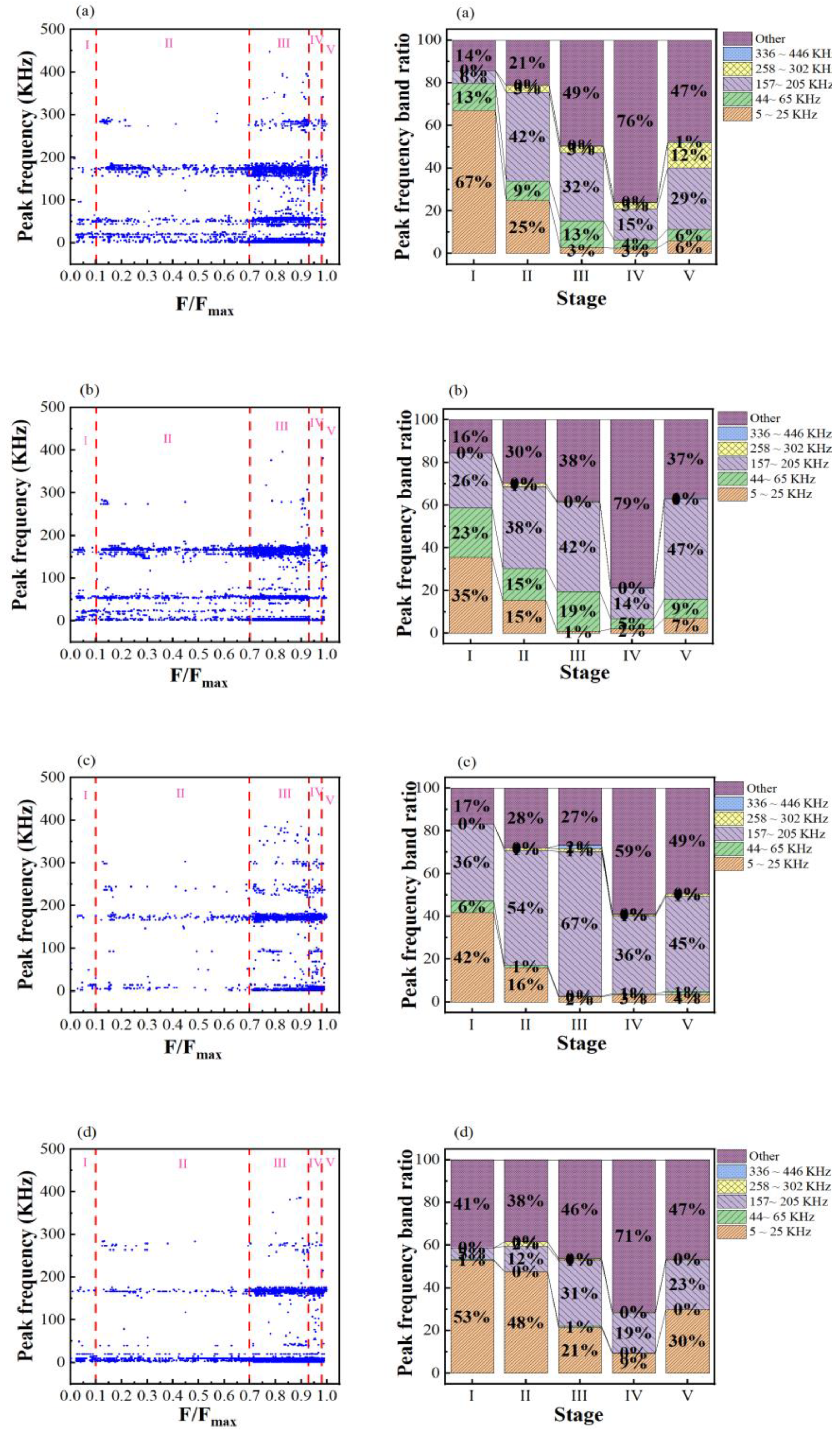

- Peak Frequency

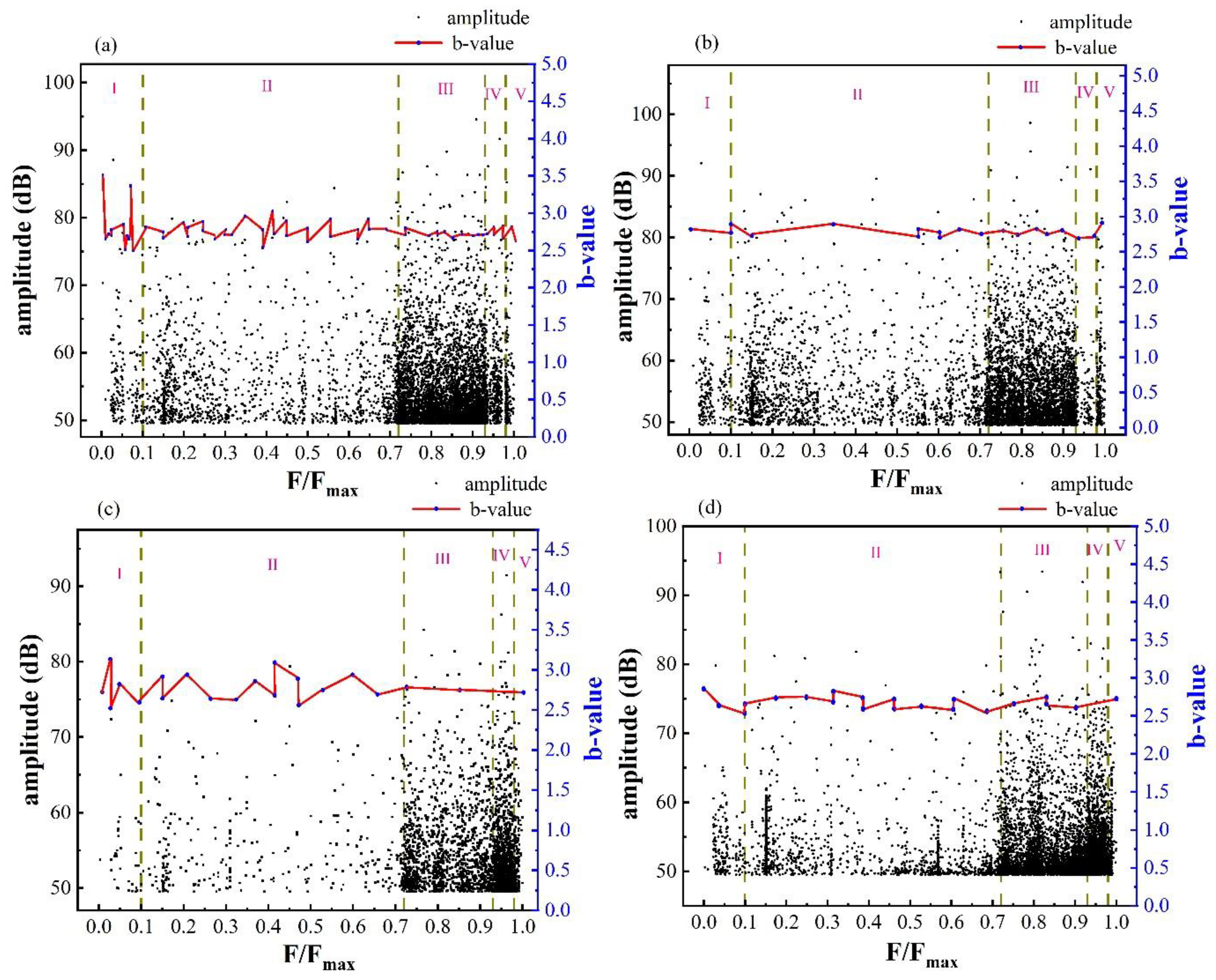

- b-value

- It only confronts the peak amplitude of the AE signal and does not consider the energy from the low amplitude part. Consequently, the assessment of structural fracture propagation using this method is not without flaws [67].

- The principle underlying this is the Gutenberg–Richter law, which asserts that the magnitude of acoustic emissions diminishes as damage progresses [68].

- This method may lack effectiveness in accurately discerning the exact attributes of stress waves released from particular sources [69].

- The b-value in reinforced concrete beams reaches its minimum point around the peak load and falls when micro-fractures merge together. However, it may not offer a complete evaluation of the extent of damage [70].

- The amplitude distribution of impacts in rock under stress is not strongly concentrated around a particular value, which can further complicate the application of the b-value method [71].

- A higher b-value indicates a greater number of low-amplitude AE hits relative to high-amplitude ones. This is typically linked to smaller micro-fractures and less serious damage.

- A lower b-value indicates a higher frequency of high-amplitude AE hits, which often correspond to more substantial damage, such as greater cracks or failures.

- A decreasing b-value indicates that the material is transitioning to more severe damage states, with greater AE occurrences becoming more frequent.

- Increasing the b-value indicates a shift towards less severe damage states, with a higher occurrence of mild AE occurrences.

4. Conclusions and Discussion

- (1)

- The observation of the five unique stages of loading was made based on the comparison between cumulative ringing count and F/Fmax, or cumulative energy and F/Fmax. Based on their distinctive features, they may be categorized into the following stages: initial stage (pre-cracking), hardening stage, critical transition stage, pull-out stage, and failure stage. Each level possesses a distinct gradient that can serve as a criterion for comprehending the commencement of each stage. The pull-out stage exhibited the greatest slope, indicating a distinct increase in ringing count or energy. During the critical and failure stages, the slopes transitioned from positive values to zero, which are referred to as inflection points. Inflection points are locations that indicate the initiation of cracks or transitional stages, which can be considered a shift from elastic to plastic deformation. Typically, the occurrence of an inflection point before the pull-out stage may indicate the presence of micro-cracks, whereas the pull-out stage and failure stage are indicative of macro-cracks.

- (2)

- Throughout the loading process, the dominant frequencies of AE peaks were primarily found in the low-frequency range (5–25 kHz), the upper-low-frequency range (44–65 kHz), the middle-frequency range (157–205 kHz), the upper-middle-frequency range (258–302 kHz), and the high-frequency range (336–446 kHz). Initially, the dominant frequencies seen for all sensors were in the low-frequency band ratios. Sensors 1 to 3 measured the middle-frequency band ratio during the hardening stage, critical transition stage, and failure stage. Sensor 4 measured the low frequency, specifically during the hardening stage. As previously stated, the failure stage was consistent across all sensors. During the initial stage of loading, the sensors primarily detected low-frequency band ratios. However, for the subsequent loading stages, the sensors recorded medium frequencies.

- The presence of a maintained peak frequency range during the loading phases indicates stability in the damage mechanism, suggesting that there have been no significant changes with increasing load. On the contrary, an increase in peak frequency or a shift towards higher frequencies may indicate a transition from less severe forms of damage, such as plastic deformation (typically associated with lower frequencies), to more severe forms, such as fracture propagation (associated with higher frequencies).

- (3)

- The abrupt change in b-value points indicates the shift in the mechanical mechanism throughout different stages of the bending resistance test. The mechanical response of the specimen to withstand shear stress varies at different phases. The variability in b-value measurements can indicate distinct levels of structural deterioration.

- A decrease in the b-value indicates an increase in the occurrence of high-amplitude AE hits, which are generally associated with more significant damage, such as larger cracks or failures. Conversely, a higher b-value signifies a larger quantity of low-amplitude AE hits compared to high-amplitude ones. This is commonly associated with few micro-fractures and less severe harm.

- A declining b-value suggests that the material is shifting towards more critical damage states, with an increasing frequency of acoustic emission (AE) events. An increased b-value implies a shift towards less severe damage states, with a greater frequency of mild AE events.

- It should be noted that despite fluctuation and verification of the b-value graph, magnetite is still a durable additive to UHPC, whereas for both the micro-cracking stage and macro-cracking stage, the recorded amplitudes were close together, and black dots of amplitude dispersal demonstrated the lower amplitudes between 60 dB to 70 dB.

- Since magnetite has not been used in any other scientific research when added to UHPC, and there is no adequate research that has observed the damage mechanism of this additive, it is highly suggested that additional research should be conducted to develop new MUHPC blocks with a wide range of additives with different mix ratios in order to understand the damage mechanism and make comprehensive comparisons.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UHPC | ultra-high-performance concrete |

| MUHPC | magnetite ultra-high-performance concrete |

| AE | acoustic emission |

| F/Fmax | applied load ratio to the maximum applied load |

References

- Xu, X.; Jin, Z.; Yu, Y.; Li, N. Damage source and its evolution of ultra-high performance concrete monitoring by digital image correlation and acoustic emission technologies. J. Build. Eng. 2023, 65, 105734. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Zhu, Y.; Shao, X. Experimental study on flexural behavior of damaged reinforced concrete (RC) beam strengthened by toughness-improved ultra-high performance concrete (UHPC) layer. Compos. Part B Eng. 2020, 186, 107834. [Google Scholar] [CrossRef]

- Gu, C.; Ye, G.; Sun, W. Ultrahigh performance concrete-properties, applications and perspectives. Sci. China Technol. Sci. 2015, 58, 587–599. [Google Scholar] [CrossRef]

- Green, B.H.; Moser, R.D.; Scott, D.A.; Long, W.R. Ultra-high performance concrete history and usage by the Corps of Engineers. Adv. Civil. Eng. Mater. 2015, 4, 132–143. [Google Scholar] [CrossRef]

- Resplendino, J.; Toulemonde, F. Designing and Building with UHPFRC; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Aaleti, S.; Sritharan, S. Quantifying bonding characteristics between UHPC and normal-strength concrete for bridge deck application. J. Bridge Eng. 2019, 24, 04019041. [Google Scholar] [CrossRef]

- Tazarv, M.; Saiidi, M.S. Design and construction of UHPC-filled duct connections for precast bridge columns in high seismic zones. Struct. Infrastruct. Eng. 2017, 13, 743–753. [Google Scholar] [CrossRef]

- Tazarv, M.; Saiidi, M.S. UHPC-filled duct connections for accelerated bridge construction of RC columns in high seismic zones. Eng. Struct. 2015, 99, 413–422. [Google Scholar] [CrossRef]

- Perry, V. Ultra-high-performance-concrete advancements and industrialization—The need for standard testing. Adv. Civil. Eng. Mater. 2015, 4, 1–16. [Google Scholar] [CrossRef]

- Luo, D.; Lu, T.; Chen, Y.F. Application of ultra-high-performance concrete in prefabricated buildings. Mater. Test. 2021, 63, 1174–1183. [Google Scholar] [CrossRef]

- Shao, Y.; Billington, S. Utilizing full UHPC compressive strength in steel reinforced UHPC beams. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: Ames, IA, USA, 2019. [Google Scholar]

- Yao, Y.; Silva, F.A.; Butler, M.; Mechtcherine, V.; Mobasher, B. Tensile and flexural behavior of ultra-high performance concrete (UHPC) under impact loading. Int. J. Impact Eng. 2021, 153, 103866. [Google Scholar] [CrossRef]

- Muzenski, S.; Graybeal, B. Structural Performance of UHPC Overlays. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: Ames, IA, USA, 2023. [Google Scholar]

- Kostelecká, M. Monitoring the Degradation of UHPC Boards. Appl. Mech. Mater. 2015, 752, 518–521. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. Part B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Özkılıç, Y.O.; Akeed, M.H. Application of ultra-high-performance concrete in bridge engineering: Current status, limitations, challenges, and future prospects. Buildings 2023, 13, 185. [Google Scholar] [CrossRef]

- Shao, R.; Wu, C.; Li, J.; Liu, Z. Development of sustainable steel fibre-reinforced dry ultra-high performance concrete (DUHPC). J. Clean. Prod. 2022, 337, 130507. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Makul, N.; Tang, W.; Alluqmani, A.E. Sustainable development of eco-friendly ultra-high performance concrete (UHPC): Cost, carbon emission, and structural ductility. Constr. Build. Mater. 2023, 398, 132477. [Google Scholar] [CrossRef]

- Sitnikov, V. Ice formwork for high-performance concrete: A model of lean production for prefabricated concrete industry. In Structures; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Ganapathe, L.S.; Mohamed, M.A.; Yunus, R.M.; Berhanuddin, D.D. Magnetite (Fe3O4) nanoparticles in biomedical application: From synthesis to surface functionalisation. Magnetochemistry 2020, 6, 68. [Google Scholar] [CrossRef]

- Belousov, A. Spectrum of application magnetite nanopaticles in medicine. Nanotech 2009, 2, 154–157. [Google Scholar]

- Belousov, A.N. The use of magnetite nanoparticles in applied medicine. In Materials Science Forum; Trans Tech Publications: Stafa-Zurich, Switzerland, 2011. [Google Scholar]

- Nie, Y.M.; Lu, X.L.; Dai, Q.H.; Wang, B. Mineral processing experiment research of low grade magnetite. Adv. Mater. Res. 2013, 641, 448–451. [Google Scholar] [CrossRef]

- Belov, K. On the nature of a low-temperature transition in magnetite. J. Exp. Theor. Phys. C/C Zhurnal Eksperimental’noi I Teor. Fiz. 1996, 83, 1152–1155. [Google Scholar]

- Kasama, T.; Harrison, R.J.; Church, N.S.; Nagao, M.; Feinberg, J.M.; Dunin-Borkowski, R.E. Ferrimagnetic/ferroelastic domain interactions in magnetite below the Verwey transition. Part I: Electron holography and Lorentz microscopy. Phase Transit. 2013, 86, 67–87. [Google Scholar] [CrossRef]

- Švindrych, Z.; Janů, Z.; Kozłowski, A.; Honig, J.M. Low-Temperature Magnetic Anomaly in Magnetite; 2012. Available online: https://journals.aps.org/prb/abstract/10.1103/PhysRevB.86.214406 (accessed on 7 January 2024).

- Kobori, H.; Ohnishi, K.; Sugimura, A.; Taniguchi, T. Reversal magnetoresistance and unusual localized-spin freezing in magnetite sinter made from low size-dispersion hematite nano-particles with high temperature calcination. Phys. Status Solidi C 2006, 3, 4204–4207. [Google Scholar] [CrossRef]

- Han, J.; Xi, Z.; Yu, R.; Guan, J.; Lv, Y.; Li, G. Preparation and comprehensive properties of a high-radiation-shielding UHPC by using magnetite fine aggregate. Materials 2022, 15, 978. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Qsymah, A.; Peng, Y.; Margetts, L.; Sharma, R. 4D characterisation of damage and fracture mechanisms of ultra high performance fibre reinforced concrete by in-situ micro X-Ray computed tomography tests. Cem. Concr. Compos. 2020, 106, 103473. [Google Scholar] [CrossRef]

- Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-destructive evaluation for corrosion monitoring in concrete: A review and capability of acoustic emission technique. Sensors 2015, 15, 19069–19101. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Jiang, L.; Liaw, P.K.; Brooks, C.R.; Seeley, R.; Klarstrom, D.L. Using acoustic emission in fatigue and fracture materials research. JOM 1998, 50, 1–14. [Google Scholar]

- Li, W.; Xu, C.; Ho, S.C.M.; Wang, B.; Song, G. Monitoring concrete deterioration due to reinforcement corrosion by integrating acoustic emission and FBG strain measurements. Sensors 2017, 17, 657. [Google Scholar] [CrossRef] [PubMed]

- Carrasco, Á.; Méndez, F.; Leaman, F.; Vicuña, C.M. Short review of the use of acoustic emissions for detection and monitoring of cracks. Acoust. Aust. 2021, 49, 273–280. [Google Scholar] [CrossRef]

- Ospitia, N.; Korda, E.; Kalteremidou, K.-A.; Lefever, G.; Tsangouri, E.; Aggelis, D.G. Recent developments in acoustic emission for better performance of structural materials. Dev. Built Environ. 2023, 13, 100106. [Google Scholar] [CrossRef]

- Guo, J.-Y.; Wang, J.-Y.; Bian, C. Cyclic tensile behavior of high strain hardening UHPC analyzed by acoustic emission techniques. Constr. Build. Mater. 2021, 267, 121797. [Google Scholar] [CrossRef]

- Wang, J.-Y.; Guo, J.-Y. Damage investigation of ultra high performance concrete under direct tensile test using acoustic emission techniques. Cem. Concr. Compos. 2018, 88, 17–28. [Google Scholar] [CrossRef]

- Bian, C.; Wang, J.-Y.; Guo, J.-Y. Damage mechanism of ultra-high performance fibre reinforced concrete at different stages of direct tensile test based on acoustic emission analysis. Constr. Build. Mater. 2021, 267, 120927. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- Aggelis, D.; Mpalaskas, A.; Ntalakas, D.; Matikas, T. Effect of wave distortion on acoustic emission characterization of cementitious materials. Constr. Build. Mater. 2012, 35, 183–190. [Google Scholar] [CrossRef]

- Scholey, J.J.; Wilcox, P.D.; Wisnom, M.R.; Friswell, M.I. Quantitative experimental measurements of matrix cracking and delamination using acoustic emission. Compos. Part. A Appl. Sci. Manuf. 2010, 41, 612–623. [Google Scholar] [CrossRef]

- De Groot, P.J.; Wijnen, P.A.; Janssen, R.B. Real-time frequency determination of acoustic emission for different fracture mechanisms in carbon/epoxy composites. Compos. Sci. Technol. 1995, 55, 405–412. [Google Scholar] [CrossRef]

- Unnþórsson, R. Hit detection and determination in AE bursts. In Acoustic Emission-Research and Applications; INTECH: Atyrau, Kazakhstan, 2013; pp. 1–20. [Google Scholar]

- Wu, Y.; Li, S. Damage degree evaluation of masonry using optimized SVM-based acoustic emission monitoring and rate process theory. Measurement 2022, 190, 110729. [Google Scholar] [CrossRef]

- Bahari, N.; Shahidan, S.; Shukri, M.; Zuki, S.S.M.; Norbazlan, M.; Ibrahim, M.; Nazri, F.M. Identifying the crack nature using b-value acoustic emission signal analysis. In Proceedings of the AICCE’19: Transforming the Nation for a Sustainable Tomorrow 4; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Carnì, D.L.; Scuro, C.; Lamonaca, F.; Olivito, R.S.; Grimaldi, D. Damage analysis of concrete structures by means of b-Value Technique. Int. J. Comput. 2017, 16, 82–88. [Google Scholar] [CrossRef]

- Abdul Kudus, S.; Bunnori, N.M.; Mustaffa, N.K.; Jamadin, A. Investigation on acoustic emission parameters due to fatigue damage of concrete beams with variable notched depth. Int. J. Concr. Struct. Mater. 2022, 16, 29. [Google Scholar] [CrossRef]

- Mandal, D.D.; Bentahar, M.; El Mahi, A.; Brouste, A.; El Guerjouma, R.; Montresor, S.; Cartiaux, F.-B. Acoustic Emission Monitoring of Progressive Damage of Reinforced Concrete T-Beams under Four-Point Bending. Materials 2022, 15, 3486. [Google Scholar] [CrossRef] [PubMed]

- Abouhussien, A.A.; Hassan, A.A. The use of acoustic emission intensity analysis for the assessment of cover crack growth in corroded concrete structures. J. Nondestruct. Eval. 2016, 35, 52. [Google Scholar] [CrossRef]

- Grosse, C.U.; Ohtsu, M.; Aggelis, D.G.; Shiotani, T. Acoustic Emission Testing: Basics for Research–Applications in Engineering; Springer Nature: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Finlayson, R.D.; Luzio, M.A.; Miller, R.K.; Pollock, A.A. Continuous health monitoring of graphite epoxy motorcases (GEM). In Nondestructive Evaluation and Health Monitoring of Aerospace Materials and Composites II; SPIE: Bellingham, WA, USA, 2003. [Google Scholar]

- Available online: http://www.aesoftland.com/en/intro/intro_36.html (accessed on 25 January 2024).

- Poon, H. Applications of data acquisition systems. Comput. Ind. 1989, 13, 49–59. [Google Scholar] [CrossRef]

- Willis, R.R. DAS: An automated system to support design analysis. In Proceedings of the 15th Design Automation Conference, Las Vegas, NV, USA, 19–21 June 1978; IEEE: Piscataway, NJ, USA, 1978. [Google Scholar]

- Zhao, T.; Tang, J.; Chen, X. A data acquisition system in intelligent environmental monitoring device for industrial field. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2018. [Google Scholar]

- Li, S.-L.; Kang, Z.-Z.; Wu, G.-M.; Guo, P.; Gu, S. Acoustic emission-based transition monitoring of mechanical mechanism for bolted shear connection in GFRP–UHPC hybrid beams. Measurement 2022, 198, 111358. [Google Scholar] [CrossRef]

- Li, S.; Liang, Z.; Zhang, L. Corrosion evaluation of prestressed high-strength steel wires with impressed current cathodic protection based on acoustic emission technique. Struct. Control. Health Monit. 2022, 29, e2934. [Google Scholar] [CrossRef]

- Kageyama, K.; Kojima, K.; Nakamura, T. Ae measurement approach for activity monitoring of foliage plants. In Proceedings of the 2017 IEEE 6th Global Conference on Consumer Electronics (GCCE), Nagoya, Japan, 24–27 October 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Chen, Y.; Zhao, Z. Correlation between shear induced asperity degradation and acoustic emission energy in single granite fracture. Eng. Fract. Mech. 2020, 235, 107184. [Google Scholar] [CrossRef]

- Aldahdooh, M.; Bunnori, N.M.; Johari, M.M. Damage evaluation of reinforced concrete beams with varying thickness using the acoustic emission technique. Constr. Build. Mater. 2013, 44, 812–821. [Google Scholar] [CrossRef]

- Li, S.; Zhang, L.; Guo, P.; Zhang, P.; Wang, C.; Sun, W.; Han, S. Characteristic analysis of acoustic emission monitoring parameters for crack propagation in UHPC-NC composite beam under bending test. Constr. Build. Mater. 2021, 278, 122401. [Google Scholar] [CrossRef]

- McCrory, J.P.; Al-Jumaili, S.K.; Crivelli, D.; Pearson, M.R.; Eaton, M.J.; Featherston, C.A.; Guagliano, M.; Holford, K.M.; Pullin, R. Damage classification in carbon fibre composites using acoustic emission: A comparison of three techniques. Compos. Part. B Eng. 2015, 68, 424–430. [Google Scholar] [CrossRef]

- Sharon, M.; Kurzon, I.; Wetzler, N.; Sagy, A.; Marco, S.; Ben-Avraham, Z. Variations of the seismic b-value along the Dead Sea transform. Front. Earth Sci. 2022, 10, 1074729. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Niccolini, G. Critical behaviour in concrete structures and damage localization by acoustic emission. Key Eng. Mater. 2006, 312, 305–310. [Google Scholar] [CrossRef]

- Ulmer, K.; Green, R.; Rodriguez-Marek, A. Recommended b-value for computing number of equivalent stress cycles and magnitude scaling factors for simplified liquefaction triggering evaluation procedures. J. Geotech. Geoenvironmental Eng. 2022, 148, 04022113. [Google Scholar] [CrossRef]

- Zhang, X.; Shan, W.; Zhang, Z.; Li, B. AE monitoring of reinforced concrete squat wall subjected to cyclic loading with information entropy-based analysis. Eng. Struct. 2018, 165, 359–367. [Google Scholar] [CrossRef]

- Iturrioz, I.; Lacidogna, G.; Carpinteri, A. Acoustic Emission Detection in Concrete Specimens: Experimental Analysis and Simulations by a lattice model. Int. J. Damage Mech. 2014, 23, 327–358. [Google Scholar] [CrossRef]

- Green, R.E.J. Acoustic emission source identification. J. Acoust. Soc. Am. 1980, 68, S103. [Google Scholar] [CrossRef]

- Vidya Sagar, R.; Prasad, B.R.; Kumar, S.S. Comparison of acoustic emission b-values with strains in reinforced concrete beams for damage evaluation. In Proceedings of the Institution of Civil Engineers—Bridge Engineering; Thomas Telford Ltd.: London, UK, 2012. [Google Scholar]

- Liu, X.-l.; Li, X.-b.; Hong, L.; Yin, T.-b.; Rao, M. Acoustic emission characteristics of rock under impact loading. J. Cent. South. Univ. 2015, 22, 3571–3577. [Google Scholar] [CrossRef]

| Item | Silica Fume | Cement | Fly Ash | River Sand/mm | Magnetite/mm | Water | Water Reducer | Steel Fiber | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 0–0.6 | 0.6–1.18 | 0–0.6 | 0.6–1.18 | |||||||

| R20 | 101 | 803 | 181 | 574 | 210 | 287 | 105 | 206 | 30 | 156 |

| Type | Diameter | Height | Port | Shell Material | Contact Surface Material | Frequency Range | Center Frequency | Temperature |

|---|---|---|---|---|---|---|---|---|

| RS-2A | 18.8 mm | 15 mm | M5-KY | Stainless Steel | Ceramics | 50–400 KHz | 150 KHz | −20~130 °C |

| Sensor 1 | Sensor 2 | Sensor 3 | Sensor 4 | |

|---|---|---|---|---|

| Initial Stage (Pre-Cracking) | 0.11 | 0.13 | 0.02 | 0.02 |

| Hardening Stage | 0.09 | 0.14 | 0.03 | 0.04 |

| Critical Transition stage | 1.67 | 2.13 | 0.5 | 0.85 |

| Pull-Out stage | 11.3 | 10.7 | 3.09 | 5.7 |

| Failure stage | 0.86 | 0.66 | 0.21 | 0.14 |

| Sensor 1 | Sensor 2 | Sensor 3 | Sensor 4 | |

|---|---|---|---|---|

| Initial Stage (Pre-Cracking) | 0.05 | 0 | 0.56 | 0.38 |

| Hardening Stage | 0.03 | 0.87 | 1.16 | 0.37 |

| Critical Transition stage | 0.4 | 4.05 | 7.70 | 2.13 |

| Pull-Out stage | 5.34 | 6.61 | 0.71 | 2.05 |

| Failure stage | 0.23 | 0.17 | 0.01 | 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bourbour, C. Acoustic Emission Monitoring for Damage Assessment of a Magnetite Ultra-High-Performance Concrete (MUHPC) Block in a Bending Test. NDT 2024, 2, 87-107. https://doi.org/10.3390/ndt2020006

Bourbour C. Acoustic Emission Monitoring for Damage Assessment of a Magnetite Ultra-High-Performance Concrete (MUHPC) Block in a Bending Test. NDT. 2024; 2(2):87-107. https://doi.org/10.3390/ndt2020006

Chicago/Turabian StyleBourbour, Cyrus. 2024. "Acoustic Emission Monitoring for Damage Assessment of a Magnetite Ultra-High-Performance Concrete (MUHPC) Block in a Bending Test" NDT 2, no. 2: 87-107. https://doi.org/10.3390/ndt2020006

APA StyleBourbour, C. (2024). Acoustic Emission Monitoring for Damage Assessment of a Magnetite Ultra-High-Performance Concrete (MUHPC) Block in a Bending Test. NDT, 2(2), 87-107. https://doi.org/10.3390/ndt2020006