Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP

Abstract

1. Introduction

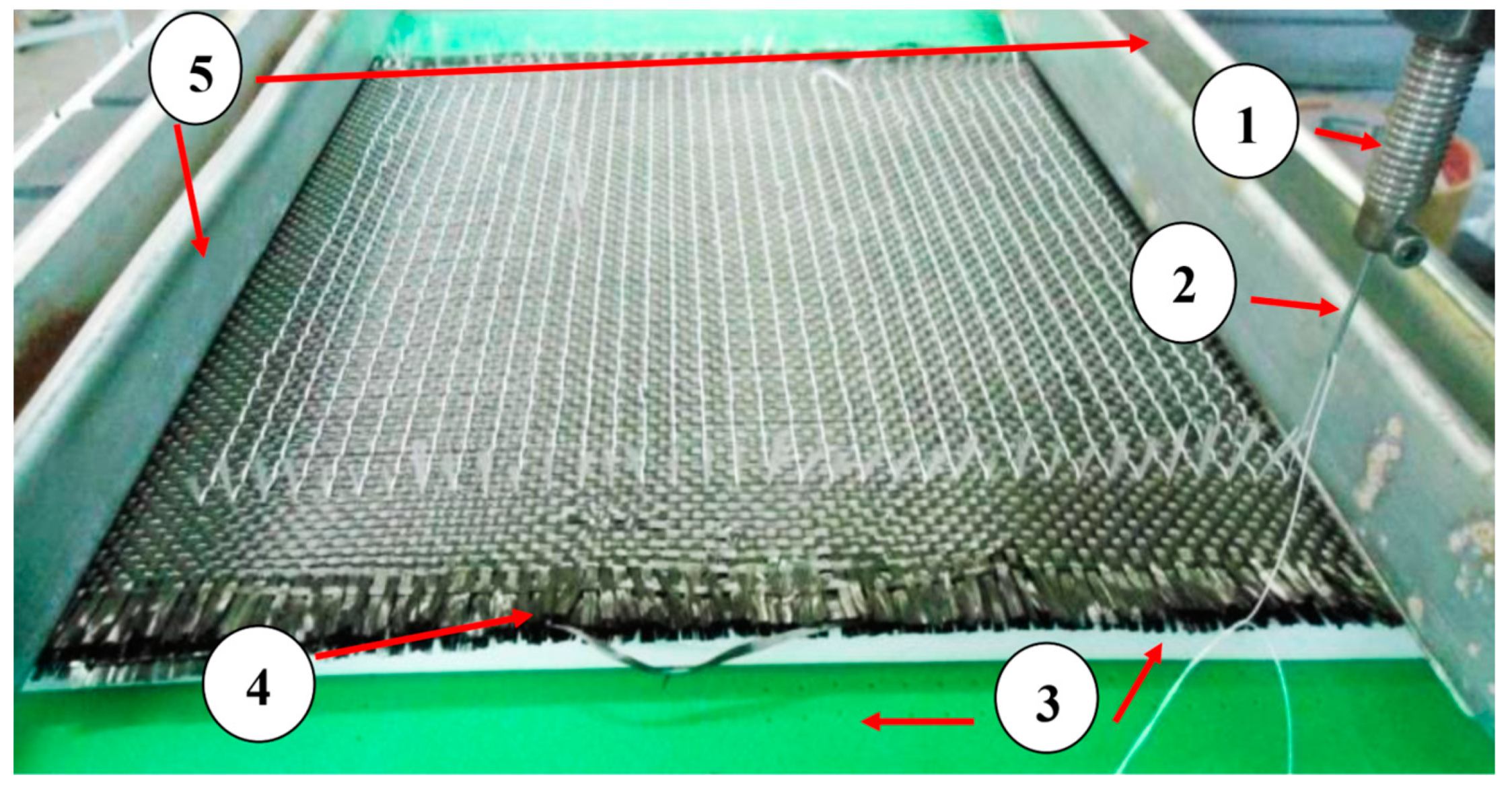

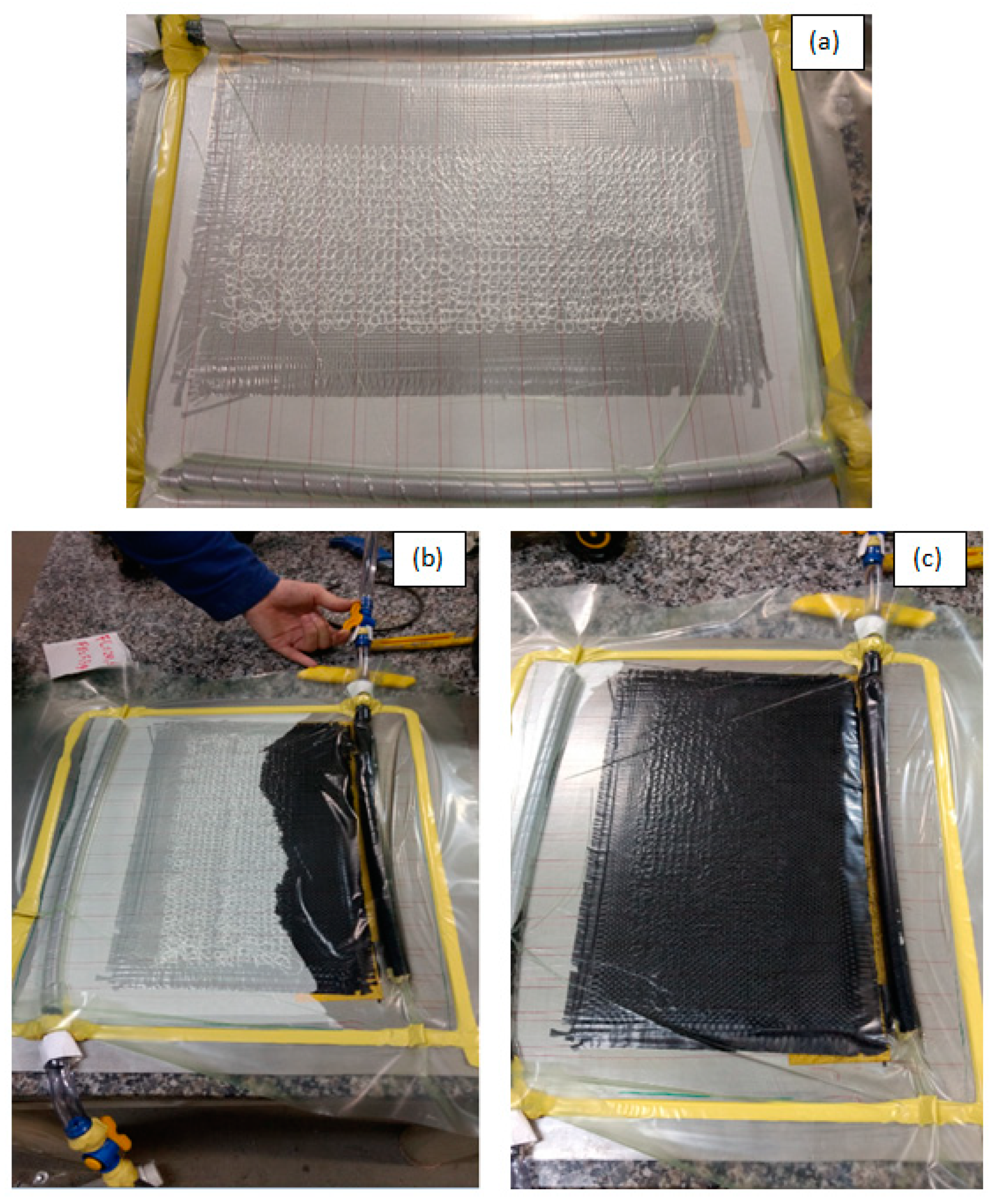

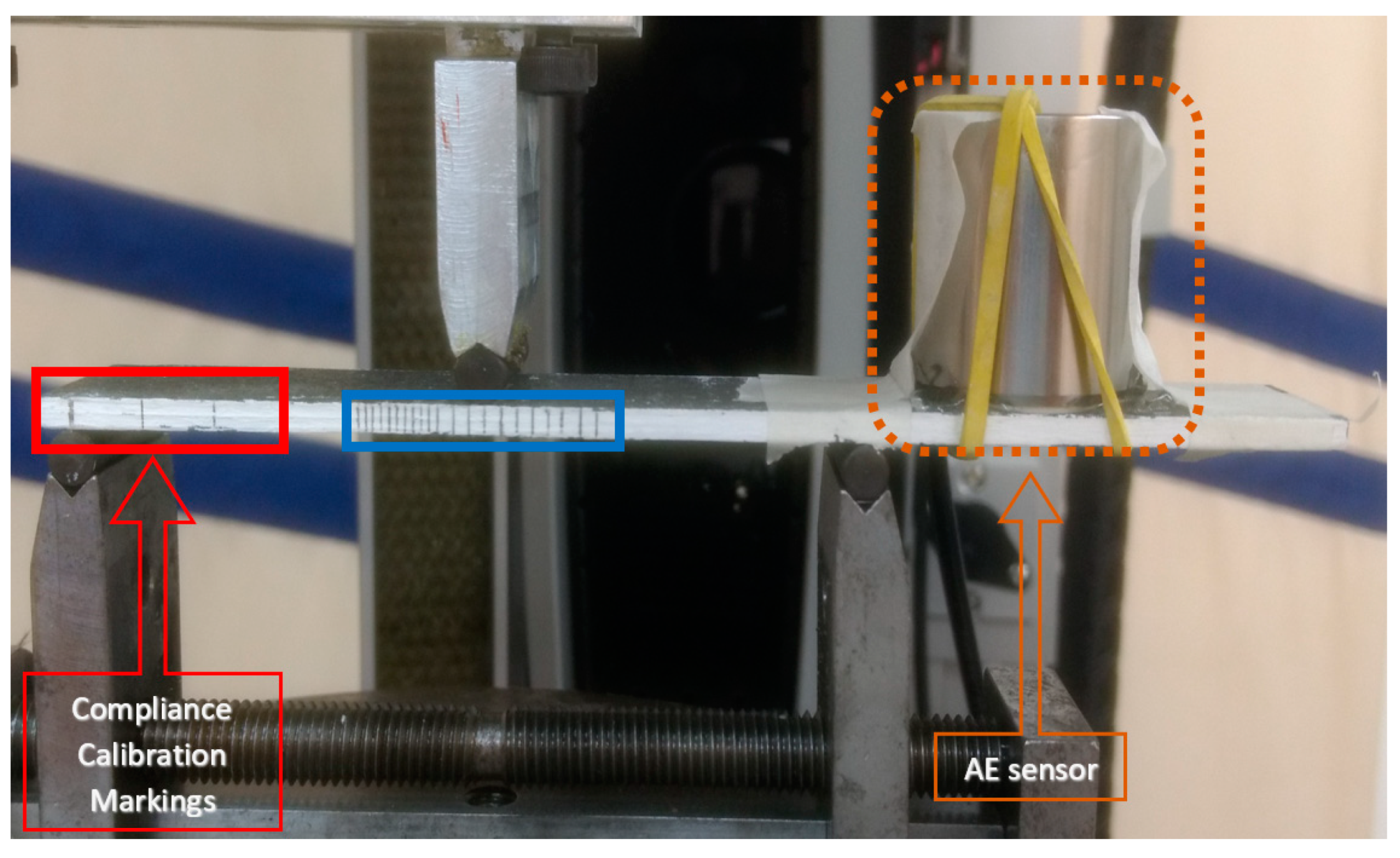

2. Materials and Methods

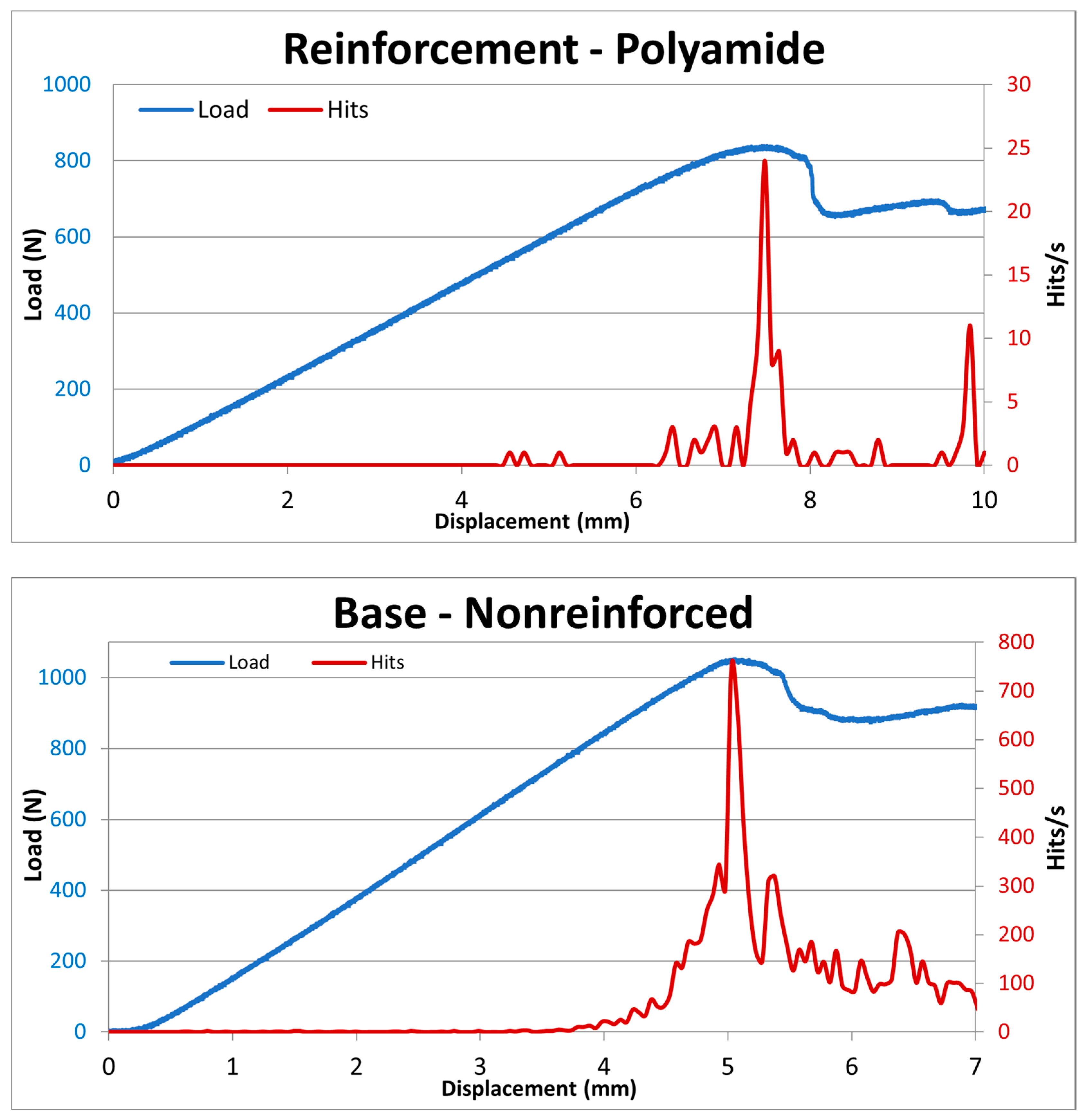

3. Results

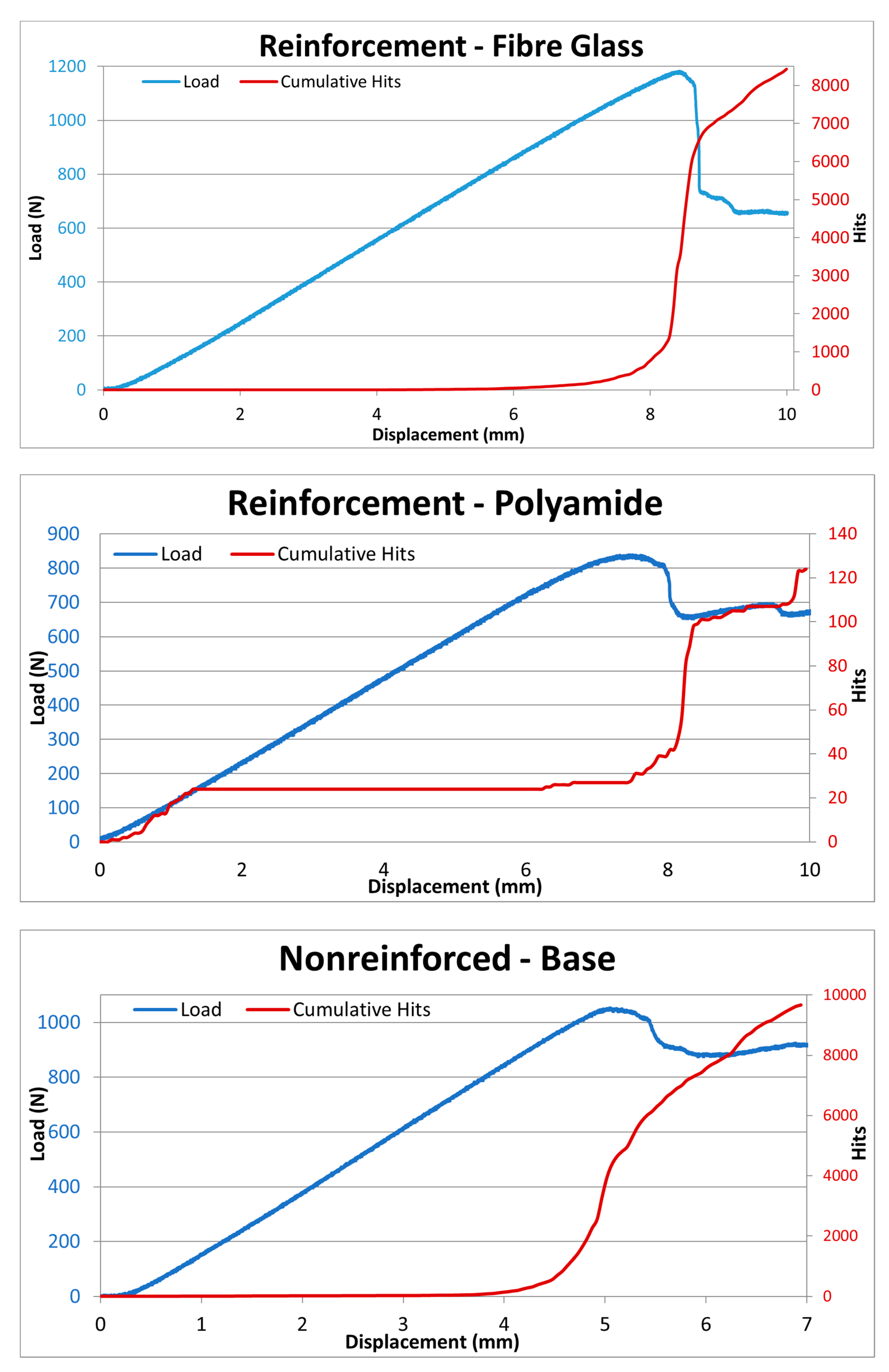

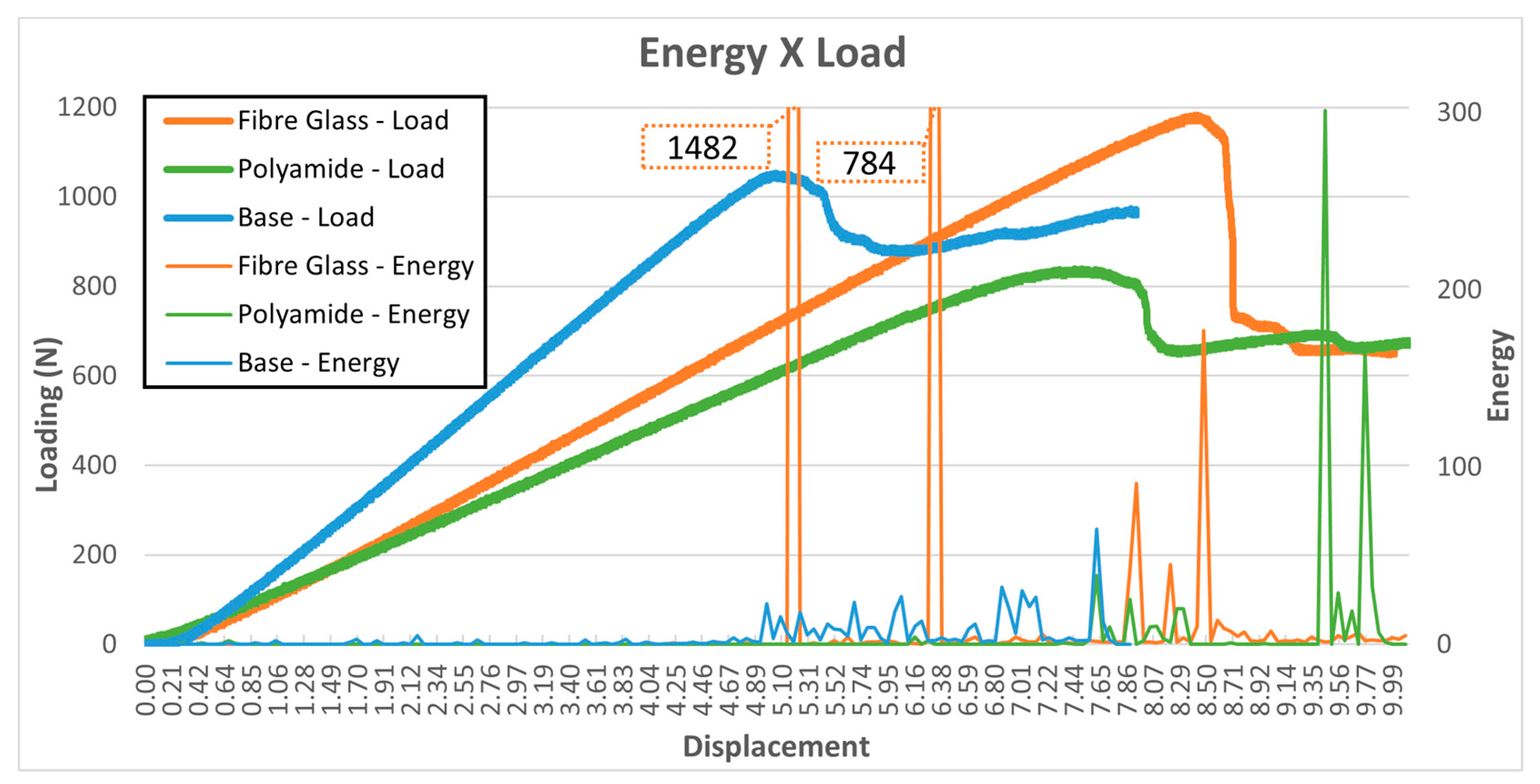

3.1. Acoustic Emission Signals in Interlaminar Mode II Fracture Testing

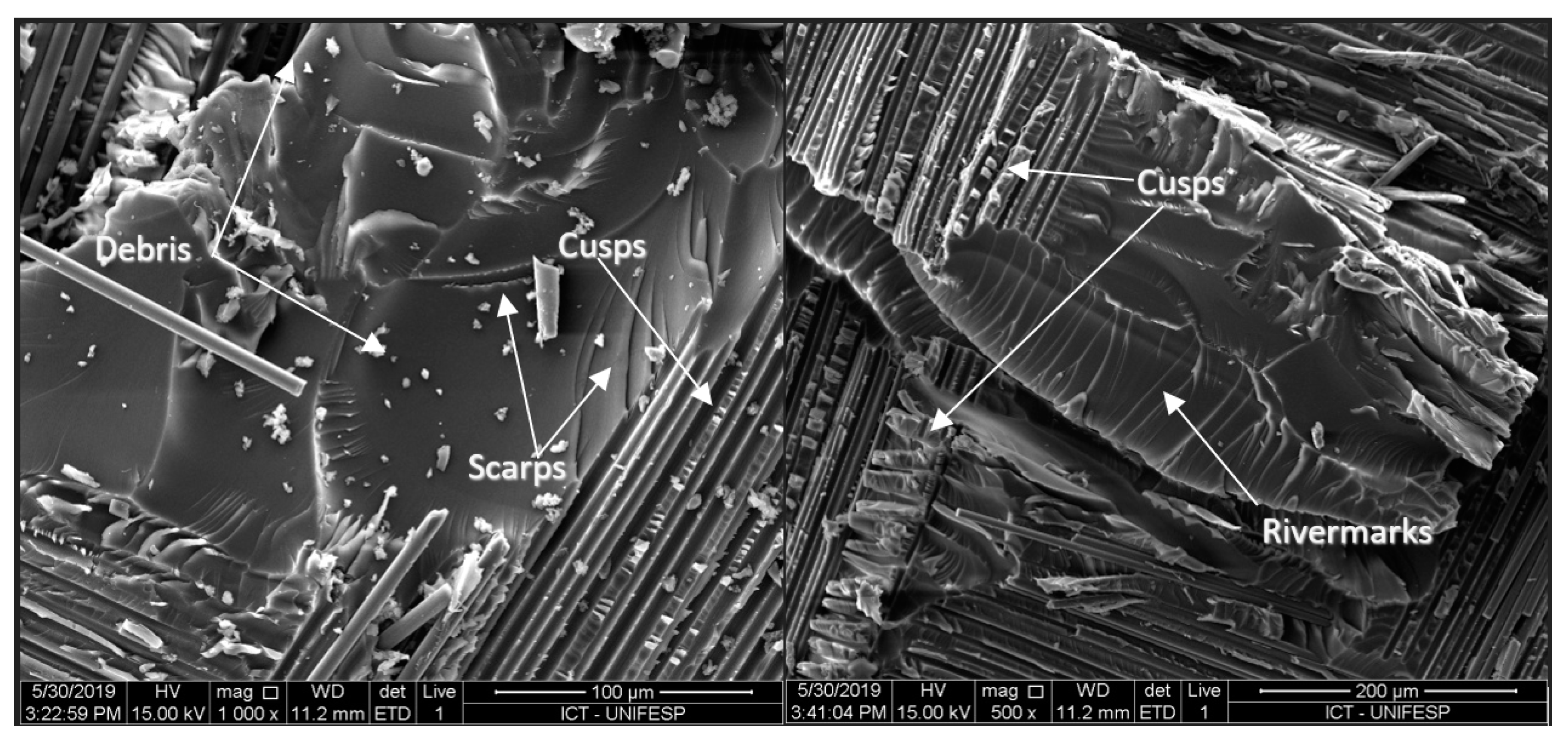

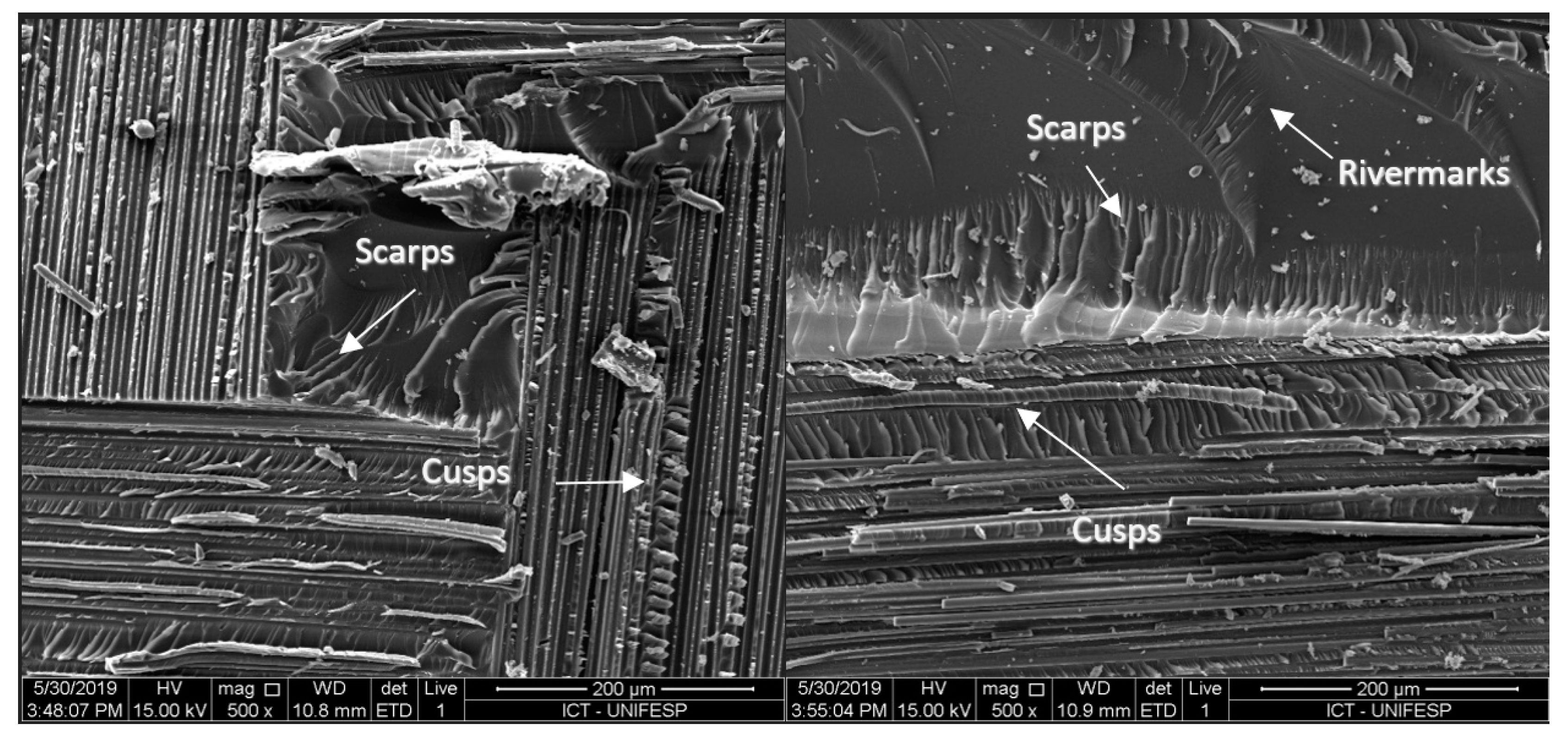

3.2. Fractographic Analysis

4. Discussion

5. Conclusions

- Tufting significantly influenced out-of-plane resistance in composite materials;

- Fibre glass reinforced and nonreinforced samples exhibited higher maximum loads compared to polyamide-reinforced ones;

- Tufting with fibre glass threads resulted in higher displacement compared to polyamide-reinforced and nonreinforced samples;

- Six key AE features (amplitude, duration, energy, cumulative energy, number of hits, cumulative number of hits) played a crucial role in assessing delamination mode II tests;

- AE hits, particularly around 8–9 mm displacement, coincided with the materials’ maximum loading, emphasizing their correlation with failure stages;

- Differences in 3D reinforcements, particularly with fibre glass and polyamide, significantly influenced composite behavior;

- Although the forces needed to start delamination were smaller for the through-thickness reinforced composite, adding 3D reinforcement helped mitigate and slow down crack propagation, especially in fibre glass reinforced samples where higher energy and displacement were required for delamination initiation and crack propagation;

- Fractographic analysis served to identify main failure morphologies in matrix-rich regions, attributed to failure propagation, including shear cusp aspects representative of pure shear.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zimmermann, N.; Haowang, P. A review of failure modes and fracture analysis of aircraft composite materials. Eng. Fail. Anal. 2020, 115, 104692. [Google Scholar] [CrossRef]

- Narayana, K.J.; Burela, R.G. A review of recent research on multifunctional composite materials and structures with their applications. Mater. Today Proc. 2018, 5, 5580–5590. [Google Scholar] [CrossRef]

- Norris, C.; Bond, I.; Trask, R. The role of embedded bioinspired vasculature on damage formation in self-healing carbon fibre reinforced composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 639–648. [Google Scholar] [CrossRef]

- Post, W.; Kersemans, M.; Solodov, I.; Abeele, K.V.D.; García, S.; van der Zwaag, S. Non-destructive monitoring of delamination healing of a CFRP composite with a thermoplastic ionomer interlayer. Compos. Part A 2017, 101, 243–253. [Google Scholar] [CrossRef]

- Dell’anno, G.; Treiber, J.W.G.; Partridge, I.K. Manufacturing of composite parts reinforced through-thickness by tufting. Robot. Comput. Integr. Manuf. 2016, 37, 262–272. [Google Scholar] [CrossRef]

- Wysmulski, P. The effect of load eccentricity on the compressed CFRP Z-shaped columns in the weak post-critical state. Compos. Struct. 2022, 301, 116184. [Google Scholar] [CrossRef]

- Seibert, J.F. Composite Fiber Hazards; Air Force Occupational and Environmental Health Laboratory (AFSC): Brooks Air Force Base, TX, USA, 1990. [Google Scholar]

- Yang, Y.; Boom, R.; Irion, B.; Heerden, D.; Kuiper, P.; Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Tatiparthi, A. Investigation of Microcrack Growth in [0/90]s Graphite Epoxy Composite Laminates Using X-ray Microtomography. Master’s Thesis, University of New Orleans, New Orleans, LA, USA, 2004. [Google Scholar]

- Fotouhi, M.; Najafabadi, M.A. Acoustic emission-based study to characterize the initiation of delamination in composite materials. J. Thermoplast. Compos. Mater. 2014, 29, 519–537. [Google Scholar] [CrossRef]

- Labanieh, A.R.; Legrand, X.; Vladan, K.; Soulat, D. Development in the multiaxis 3D weaving technology. J. Reinf. Plast. Compos. 2013, 32, 700–712. [Google Scholar] [CrossRef]

- Ravandi, M.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. The effects of through-the-thickness stitching on the Mode I interlaminar fracture toughness of flax/epoxy composite laminates. Mater. Des. 2016, 105, 659–669. [Google Scholar] [CrossRef]

- Bortoluzzi, D.B. Desenvolvimento de Reforços Tridimensional por Meio de Costura em Compósitos de Fibra de Carbono/Epóxi. Master’s Thesis, Universidade Federal de Itajubá, Itajubá, Brasil, 2017. [Google Scholar]

- M’membe, B.; Gannon, S.; Yasaee, M.; Hallett, S.R.; Partridge, I.K. Mode II delamination resistance of composites reinforced with inclined Z-pins. Mater. Des. 2016, 94, 565–572. [Google Scholar] [CrossRef]

- Kusaka, T.; Watanabe, K.; Hojo, M.; Fukuoka, T.; Ishibashi, M. Fracture behavior and toughening mechanism in Zanchor reinforced composites under mode II loading. Compos. Sci. Technol. 2009, 69, 2323–2330. [Google Scholar] [CrossRef]

- Dell’Anno, G.; Cartié, D.D.; Partridge, I.K.; Rezai, A. Exploring mechanical property balance in tufted carbon fabric/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2366–2373. [Google Scholar] [CrossRef]

- Henao, A.; Carrera, M.; Miravete, A.; Castejón, L. Mechanical performance of through-thickness tufted sandwich structures. Compos. Struct. 2010, 92, 2052–2059. [Google Scholar] [CrossRef]

- Hartley, J.W.; Kratz, J.; Ward, C.; Partridge, I.K. Effect of tufting density and loop length on the crushing behaviour of tufted sandwich specimens. Compos. Part B Eng. 2017, 112, 49–56. [Google Scholar] [CrossRef][Green Version]

- Cartié, D.D.R.; Dell’Anno, G.; Poulin, E.; Partridge, I.K. 3D reinforcement of stiffener-to-skin T-joints by Z-pinning and tufting. Eng. Fract. Mech. 2006, 73, 2532–2540. [Google Scholar] [CrossRef]

- Mouritz, A.P. Review of z-pinned composite laminates. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2383–2397. [Google Scholar] [CrossRef]

- Gnaba, I.; Legrand, X.; Wang, P.; Soulat, D. Literature review of tufted reinforcement for composite. Mater. Sci. Eng. 2017, 254, 042011. [Google Scholar] [CrossRef]

- Karbhari, V.M. Introduction: The future of non-destructive evaluation (NDE) and structural health monitoring (SHM). In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites; Woodhead Publishing Limited: Arlington, TX, USA, 2013; Chapter 1; pp. 3–11. [Google Scholar]

- Katunin, A.; Dragan, K.; Dziendzikowski, M. Damage identification in aircraft composite structures: A case study using various non-destructive testing techniques. Comp. Struct. 2015, 127, 1–9. [Google Scholar] [CrossRef]

- Cantwell, W.J.; Morton, J. The significance of damage and defects and their detection in composite materials: A review. J. Strain Anal. Eng. Des. 1992, 27, 29–42. [Google Scholar] [CrossRef]

- Hanhan, I.; Agyei, R.; Xiao, X.; Sangid, M.D. Comparing non-destructive 3D X-ray computed tomography with destructive optical microscopy for microstructural characterization of fiber reinforced composites. Compos. Sci. Technol. 2019, 184, 10. [Google Scholar] [CrossRef]

- Rozylo, P. Comparison of Failure for Thin-Walled Composite Columns. Materials 2022, 15, 167. [Google Scholar] [CrossRef] [PubMed]

- Bohsea, J.; Brunner, J. 8—Acoustic emission in delamination investigation. In Delamination Behaviour of Composites; Sridharan, S., Ed.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2008; pp. 217–277. [Google Scholar]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- ASTM 1316; Standard Terminology for Nondestructive Examinations. American Society for Testing and Materials: West Conshohocken, PA, USA, 2023.

- Lissek, F.; Haeger, A.; Knoblauch, V.; Hloch, S.; Pude, F.; Kaufeld, M. Acoustic emission for interlaminar toughness testing of CFRP: Evaluation of the crack growth due to burst analysis. Compos. Part B 2018, 136, 55–62. [Google Scholar] [CrossRef]

- Tan, X.; Abu-Obeidah, A.; Nassif, H.; Masreddine, W. Measurement and visualization of strains and cracks in CFRP post-tensioned fiber reinforced concrete beams using distributed fiber optic sensors. Autom. Constr. 2021, 124, 103604. [Google Scholar] [CrossRef]

- Oliveira, T.L.L.; Zitoune, R.; Ancelotti, A.C., Jr.; Cunha, S.S., Jr. Smart machining: Monitoring of CFRP milling using AE and IR. Compos. Struct. 2020, 249, 112611. [Google Scholar] [CrossRef]

- Munoz, V.; Valès, B.; Perrin, M.; Pastor, M.L.; Welemane, H.; Cantarel, A.; Karama, M. Damage detection in CFRP by coupling acoustic emission and infrared thermography. Compos. Part B Eng. 2016, 85, 68–75. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Damage characterization in composite materials using acoustic emission signal-based and parameter-based data. Compos. Part B 2019, 178, 107469. [Google Scholar] [CrossRef]

- Baril, C. Innovative mechanical characterization of CFRP by using acoustic emission technique. Eng. Fract. Mech. 2019, 210, 414–421. [Google Scholar] [CrossRef]

- Mohammadi, R.; Saeedifar, M.; Najafabadi, M.; Toudeshky, H.H. Acoustic Emission based Methodology to Evaluate the Fracture Toughness in carbon/epoxy composites. Amirkabir J. Mech. Eng. 2017, 49, 379–386. [Google Scholar]

- Carvelli, V.; D’Ettorre, A.; Lomov, S.V. Acoustic emission and damage mode correlation in textile reinforced PPS composites. Compos. Struct. 2017, 163, 399–409. [Google Scholar] [CrossRef]

- Martínez-Jequier, J.; Gallego, A.; Suárez, E.; Juanes, F.J.; Valea, Á. Real-time damage mechanisms assessment in CFRP samples via acoustic emission Lamb wave modal analysis. Compos. Part B Eng. 2015, 68, 317–326. [Google Scholar] [CrossRef]

- Barbosa, L.C.M.; Bortoluzzi, D.B.; Ancelotti, J.A.C. Analysis of fracture toughness in mode II and fractographic study of composites based on Elium® 150 thermoplastic matrix. Compos. Part B Eng. 2019, 175, 107082. [Google Scholar] [CrossRef]

- ASTM D2256-02; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- ASTM D7905:2014; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- Cândido, G.M.; Rezende, M.C.; Donadon, M.V.; Almeida, S.F.M. Fractografia de Compósito Estrutural Aeronáutico Submetido ao Ensaio de Tenacidade à Fratura Interlaminar em Modo II. Polímeros Ciência E Tecnol. 2014, 24, 65–71. [Google Scholar] [CrossRef][Green Version]

- Bortoluzzi, D.B.; Gomes, G.F.; Hirayama, G.F.; Ancelotti, A.C. Development of a 3D reinforcement by tufting in carbon fiber/epoxy composites. Int. J. Adv. Manuf. Technol. 2019, 100, 1593–1603. [Google Scholar] [CrossRef]

- Osmiani, C.; Mohamed, G.; Treiber, J.W.G.; Allegri, G.; Partridge, I.K. Exploring the influence of micro-structure on the mechanical properties and crack bridging mechanisms of fibrous tufts. Compos. Part A Appl. Sci. Manuf. 2016, 91, 409–419. [Google Scholar] [CrossRef]

- Zhang, X.; Khellil, K.; Aboura, Z. Mechanical Behavior of stitched 3D composites. In Proceedings of the 15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012; pp. 24–28. [Google Scholar]

- Bravo, A.; Toubal, L.; Koffi, D.; Erchiqui, F. Characterization of Tensile Damage for a Short Birch Fiber-reinforced Polyethylene Composite with Acoustic Emission. Int. J. Mater. Sci. 2013, 3, 3. [Google Scholar]

- El Mahi, A.E.A. Analyse par émission acoustique de l’endommagement des matériaux éco-composites. In Proceedings of the 10ème Congrès Français d’Acoustique, Lyon, France, 12–16 April 2010. [Google Scholar]

- Kotsikos, G.; Evans, J.T.; Gibson, A.G.; Hale, J. Use of Acoustic Emission to Characterize Corrosion Fatigue Damage Accumulation in Glass Fiber Reinforced Polyester Laminates. Polym. Compos. 2004, 8, 689–696. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C. Fracture Behavior of Unidirectional Composites Analyzed by Acoustic Emissions Technique. In Fracture, Fatigue, Failure and Damage Evolution, Volume 7: Proceedings of the 2017 Annual Conference on Experimental and Applied Mechanics; Springer: Cham, Switzrland, 2018; pp. 121–128. [Google Scholar]

- Daneshjoo, Z.; Shokrieh, M.M.; Fakoor, M.; Alderliesten, R.; Zarouchas, D. Physics of delamination onset in unidirectional composite laminates under mixed-mode I/II loading. Eng. Fract. Mech. 2019, 211, 82–98. [Google Scholar] [CrossRef]

- Park, J.Y.; Cho, H.D.; Han, S.H.; Choi, M.Y. Detection of Crack Source Location on RC Structures Strengthened with CFRP Plate for Health Monitoring System. Key Eng. Mater. 2004, 270, 1971–1976. [Google Scholar] [CrossRef]

- Roques, A.; Browne, M.; Thompson, J.; Rowland, C.; Taylor, A. Investigation of fatigue crack growth in acrylic bone cement using the acoustic emission technique. Biomaterials 2004, 25, 769–778. [Google Scholar] [CrossRef] [PubMed]

- Barile, C.; Casabola, G.; Pappalettera, G. Acoustic emission waveform analysis in CFRP under Mode I test. Eng. Fract. Mech. 2019, 210, 408–413. [Google Scholar] [CrossRef]

- Momon, S.; Moevus, M.; Godin, N.; R’mili, M.; Reynaud, P.; Fantozzi, G.; Fayolle, G. Acoustic emission and lifetime prediction during static fatigue tests on ceramic-matrix-composite at high temperature under air. Compos. Part A Appl. Sci. Manuf. 2010, 41, 913–918. [Google Scholar] [CrossRef]

- Kang, J.-J.; Xu, B.-S.; Wang, H.-D.; Wang, C.-B.; Zhu, L.-N. Delamination failure monitoring of plasma sprayed composite ceramic coatings in rolling contact by acoustic emission. Eng. Fail. Anal. 2018, 86, 131–141. [Google Scholar] [CrossRef]

- Aslan, M. Investigation of damage mechanism of flax fibre LPET commingled composites by acoustic emission. Compos. Part B Eng. 2013, 54, 289–297. [Google Scholar] [CrossRef]

- Karger-Kpcis, J.; Czigány, T. Fracture behaviour of glass-fibre mat-reinforced structural nylon RIM composite studied by microscopic and acoustic emission techniques. J. Mater. Sci. 1993, 28, 2438–2448. [Google Scholar] [CrossRef]

- Nimdum, P.; Renard, J. Use of acoustic emission to discriminate damage modes in carbon fibre reinforced epoxy laminate during tensile and buckling loading. In Proceedings of the CCM 15—15th European Conference on Composite Material, Venice, Italy, 24–28 June 2012; pp. 8–17. [Google Scholar]

- Malolan, V.; Wuriti, G.; Srinivasa Gopal, A.S.; Thomas, T. Comparison of acoustic emission parameters for fiber breakage and de-lamination failure mechanisms in carbon epoxy composites. J. Eng. Technol. Res. 2016, 8, 21–30. [Google Scholar]

- Purslow, D. Matrix fractography of fibre-reinforced thermoplastics, part 1. peel failures. Composites 1987, 18, 365–374. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Soulioti, D.V.; Sapouridiz, N.M.; Barkoula, A.S.; Paipetis, A.S.; Matikas, T.E. Acoustic emission characterization of the fracture process in fibre reinforced concrete. Constr. Build. Mater. 2011, 25, 4126–4131. [Google Scholar] [CrossRef]

- Barbosa, L.C.M. Mechanical characterization of composites based on a novel vacuum-infused thermoplastic matrix. Ph.D. Thesis, Universidade Federal de Itajubá, Itajubá, Brazil, 2020. [Google Scholar]

- Greenhalgh, E.S. Failure Analysis and Fractography of Polymer Composites, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2009. [Google Scholar]

| Properties | Polyamide | Fiberglass |

|---|---|---|

| Filament specific mass (g/cm3) | 1.15 | 2.54 |

| Ultimate strength (kgf) | 4 | 6.8 |

| Elongation (mm/mm) | 36.8 | 2.8 |

| Tex (g/km) | 66.8 | 136 |

| Fiber/strands | 1 | 4 |

| Threads/filaments | - | 250 |

| Number of filaments | - | 1000 |

| Thread diameter (mm) | 0.25 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliveira, T.L.L.; Bortoluzzi, D.B.; Barbosa, L.C.M.; Ancelotti, A.C., Jr. Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP. NDT 2024, 2, 32-52. https://doi.org/10.3390/ndt2010003

Oliveira TLL, Bortoluzzi DB, Barbosa LCM, Ancelotti AC Jr. Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP. NDT. 2024; 2(1):32-52. https://doi.org/10.3390/ndt2010003

Chicago/Turabian StyleOliveira, Thiago Luiz Lara, Daniel Brighenti Bortoluzzi, Lorena Cristina Miranda Barbosa, and Antônio Carlos Ancelotti, Jr. 2024. "Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP" NDT 2, no. 1: 32-52. https://doi.org/10.3390/ndt2010003

APA StyleOliveira, T. L. L., Bortoluzzi, D. B., Barbosa, L. C. M., & Ancelotti, A. C., Jr. (2024). Acoustic Emission Analysis of Mode II Interlaminar Fracture Toughness of 3D Reinforced CFRP. NDT, 2(1), 32-52. https://doi.org/10.3390/ndt2010003