Investigation of the Impact of Testing Machine and Control Modes on the Portevin-Le Chatelier Effect in Aluminum Alloy with Diffusible Solute Magnesium

Abstract

1. Introduction

2. Materials and Methods

- MTS 793 series (MTS Systems Corporation, Minneapolis, MN, USA), 100 kN force, servohydraulic, equipped with FlexTest SE Plus electronic system (MTS Systems Corporation, Minneapolis, MN, USA); extensometer for strain measurement is model MTS 634.12F-25 with measuring base (L0) 25 mm.

- electromechanical MTS Criterion C43 (MTS Systems Corporation, Minneapolis, MN, USA), 50 kN force, equipped with TestSuite TW electronic system (MTS Systems Corporation, Minneapolis, MN, USA); extensometer for strain measurement is model MTS 632.12F-20 with measuring base (L0) 25 mm.

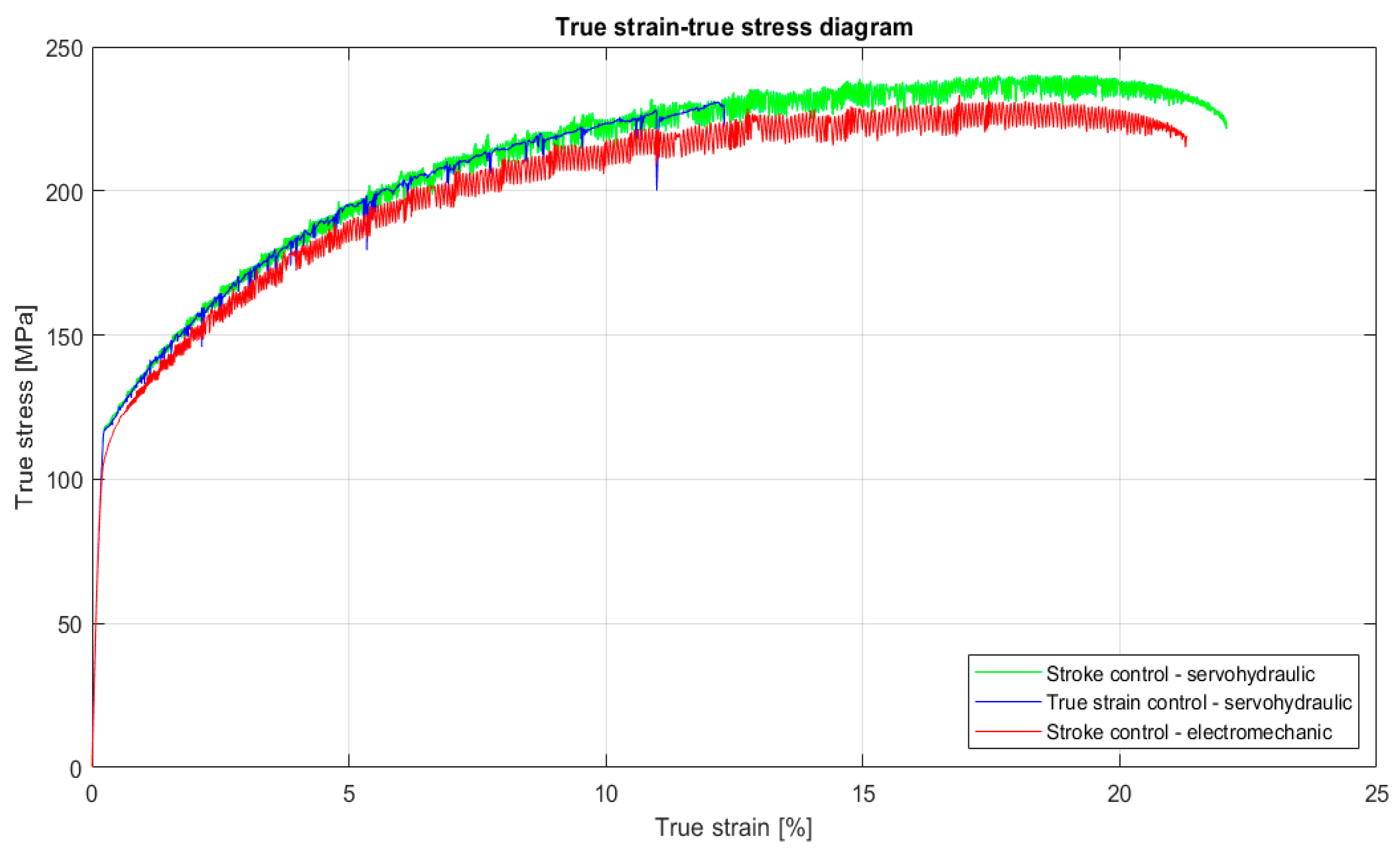

- (a)

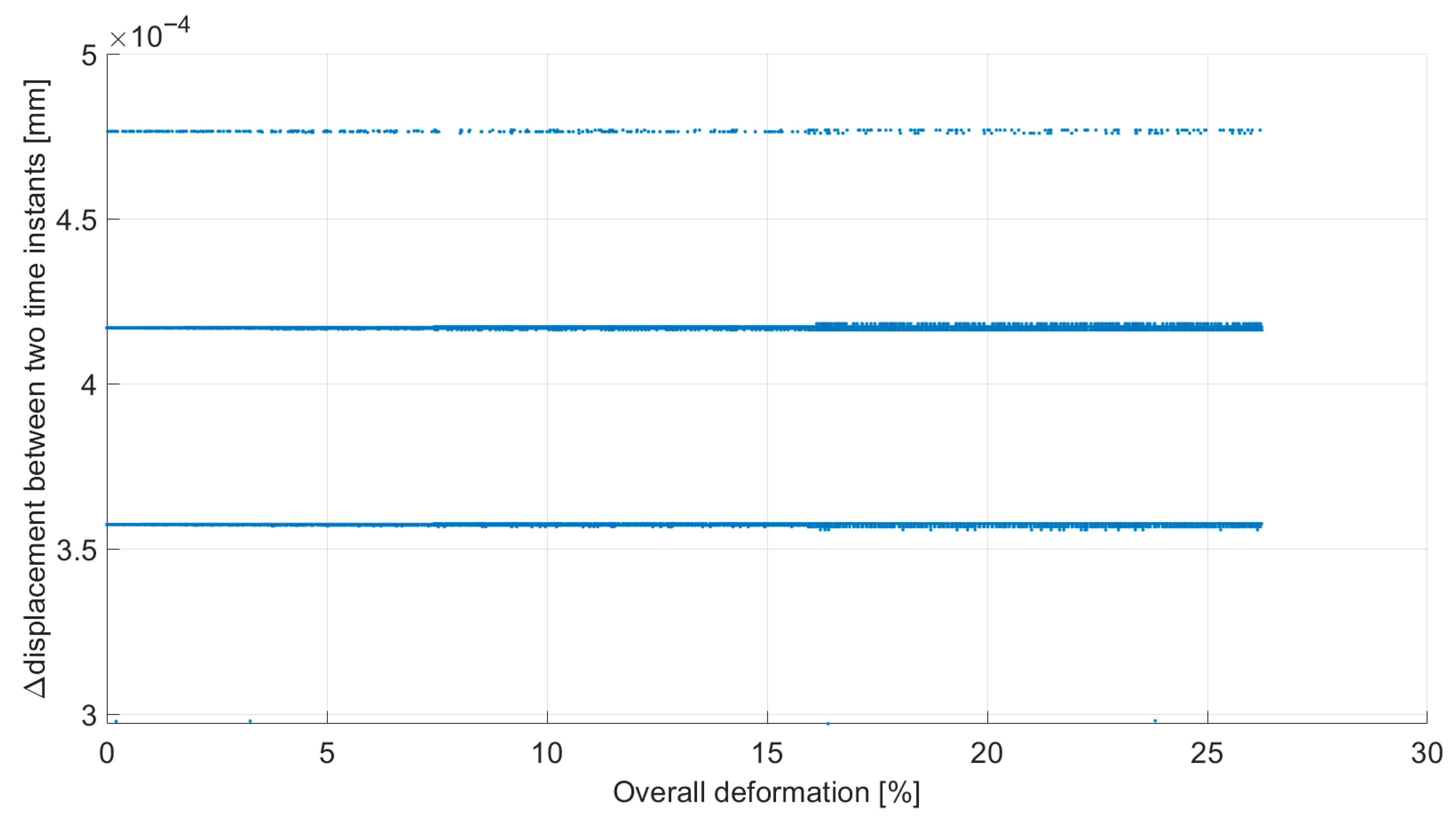

- using the electromechanical machine, the displacement of the moving crosshead, or stroke control, acts as the control channel to achieve the predetermined strain rate.

- (b)

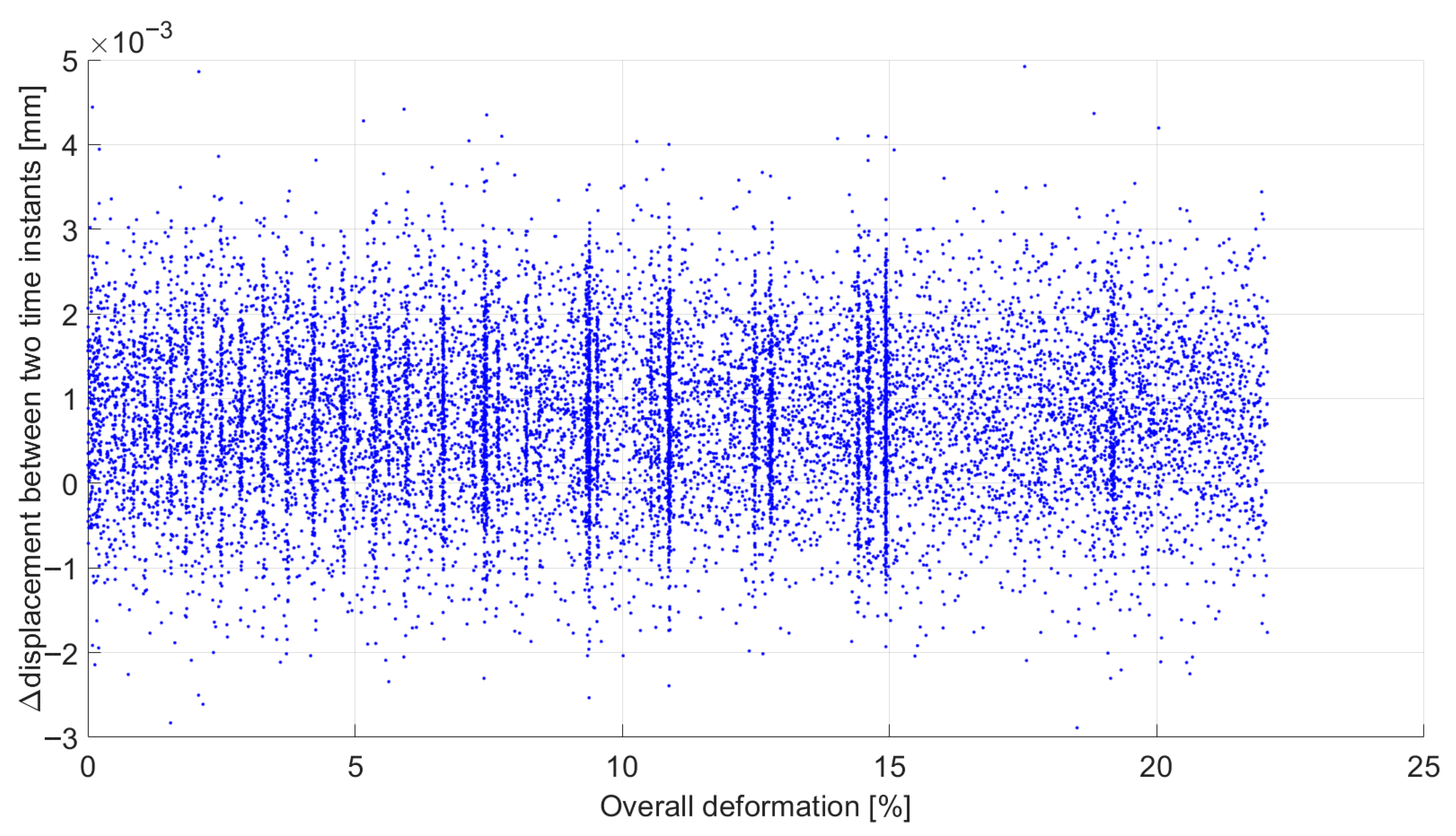

- using the servohydraulic machine, the displacement of the hydraulic actuator, or stroke control, serves as the control channel to achieve the predetermined strain rate.

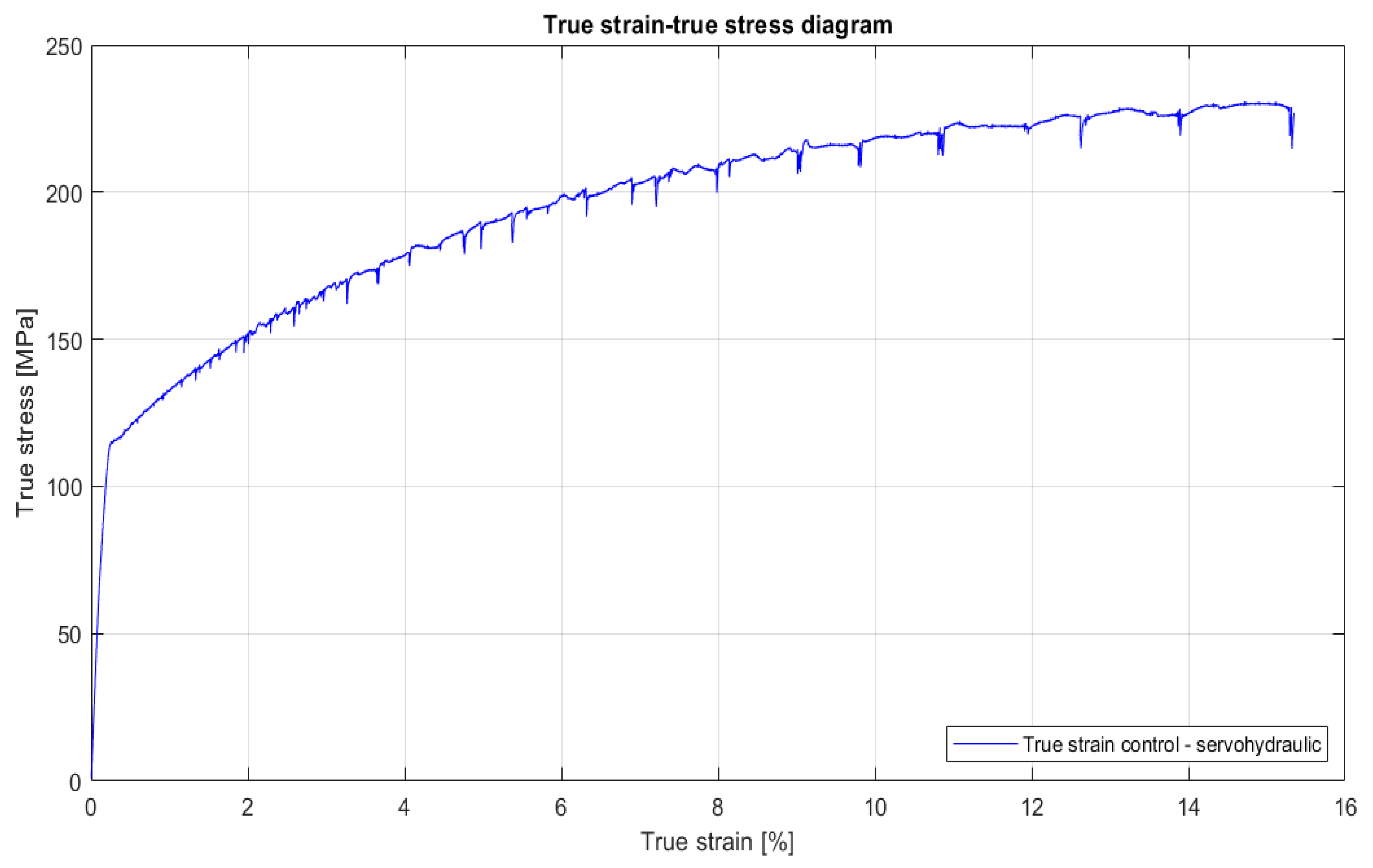

- (c)

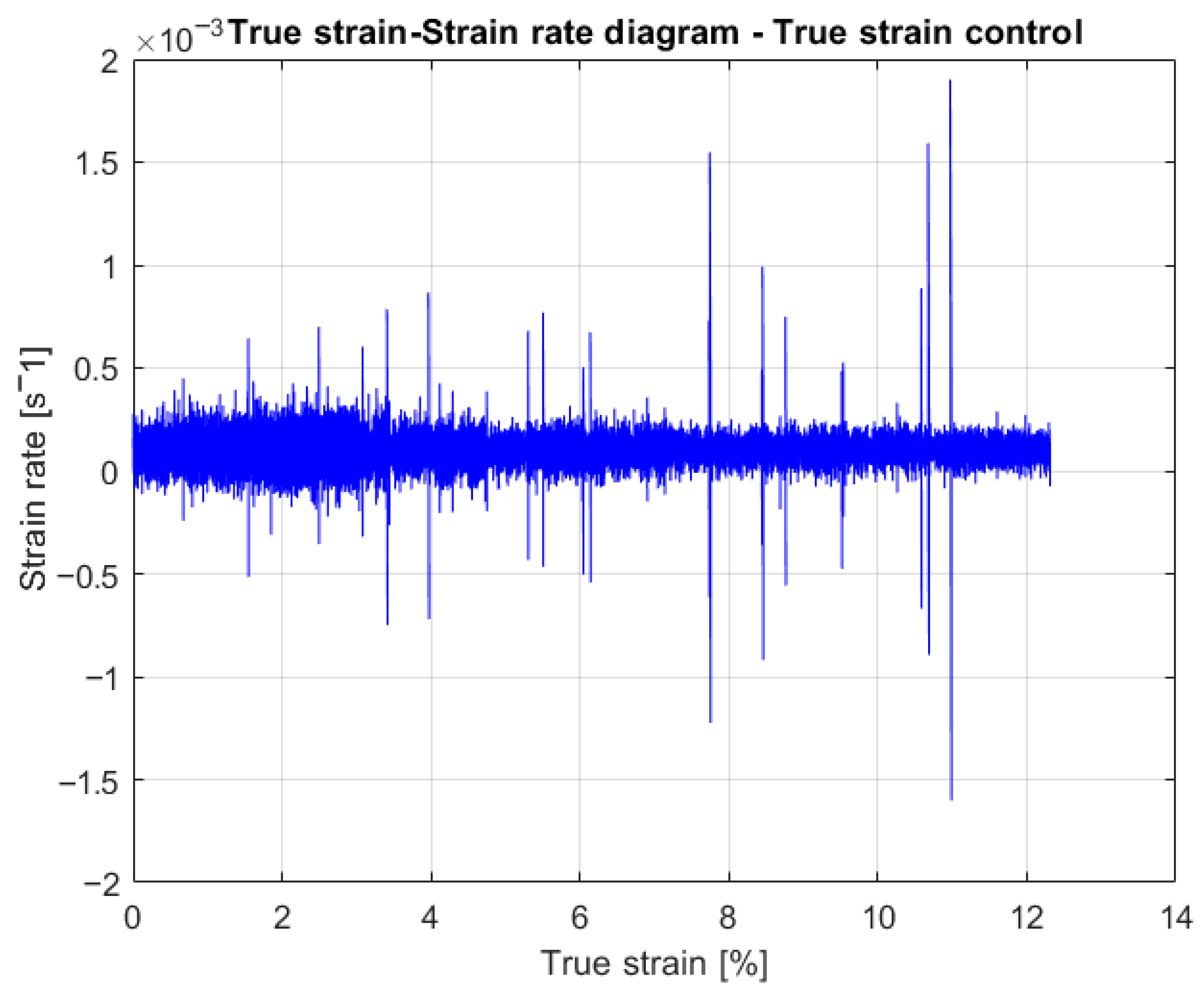

- using a servohydraulic machine, we utilized a virtual true strain channel; this was formulated through an equation using the extensometer signal, which represents the engineering strain, serving as the control channel to achieve the predetermined strain rate.

3. Results

4. Discussion

- The bands form and eventually propagate, sometimes within the zone monitored by the extensometer and sometimes outside of it, often near the connections of the calibrated central zone with the sample heads due to the local notch effect.

- The strain rate within the bands is significantly higher than that imposed by the machine.

5. Conclusions

- The stiffness of the machine moderately affects the Portevin-Le Chatelier (PLC) effect, especially regarding serrations;

- No method of control, whether stroke control or true strain control, can consistently guarantee the nominal strain rate in the specimen;

- Stroke control tends to inhibit the development of plastic bands during jerky flow;

- An electromechanical machine that controls the applied strain rate using electric pulse servomotors minimizes the development of these bands and delays breaking, resulting in greater elongations;

- True strain rate control places fewer limitations on plastic band formation, resulting in more widely spaced serrations, each representing an individual plastic band;

- True strain control is the most effective control mode for achieving an applied strain rate that closely approximates the nominal value, thereby allowing for a better observation of the PLC effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Liu, G.; Sun, J. A critical review on the Portevin-Le Chatelier effect in aluminum alloys. J. Central South Univ. 2022, 29, 744–766. [Google Scholar] [CrossRef]

- Scott, V.; Franklin, F.; Mertens, M.M. Portevin–Le Chatelier effect. Phys. Rev. E 2000, 62, 8195–8206. [Google Scholar] [CrossRef]

- Tamimi, S.; Andrade-Campos, A.; Pinho-Da-Cruz, J. Modelling the Portevin-Le Chatelier effects in aluminium alloys: A review. J. Mech. Behav. Mater. 2015, 24, 67–78. [Google Scholar] [CrossRef]

- Yilmaz, A. The Portevin–Le Chatelier effect: A review of experimental findings. Sci. Technol. Adv. Mater. 2011, 12, 063001. [Google Scholar] [CrossRef] [PubMed]

- Lebyodkin, M.A.; Lebedkina, T.A. The Portevin-Le Chatelier Effect and Beyond. In High-Entropy Materials: Theory, Experiments, and Applications; Brechtl, J., Liaw, P.K., Eds.; Springer Nature: Cham, Switzerland, 2021; ISBN 978-3-030-77640-4. [Google Scholar]

- Jiang, H.; Zhang, Q.; Chen, X.; Chen, Z.; Jiang, Z.; Wu, X.; Fan, J. Three types of Portevin–Le Chatelier effects: Experiment and modelling. Acta Mater. 2007, 55, 2219–2228. [Google Scholar] [CrossRef]

- Hähner, P.; Rizzi, E. On the kinematics of Portevin–Le Chatelier bands: Theoretical and numerical modelling. Acta Mater. 2003, 51, 3385–3397. [Google Scholar] [CrossRef]

- Rizzi, E.; Hähner, P. On the Portevin–Le Chatelier effect: Theoretical modeling and numerical results. Int. J. Plast. 2004, 20, 121–165. [Google Scholar] [CrossRef]

- Hähner, P.; Ziegenbein, A.; Rizzi, E.; Neuhäuser, H. Spatiotemporal analysis of Portevin–Le Châtelier deformation bands: Theory, simulation, and experiment. Phys. Rev. B 2002, 65, 134109. [Google Scholar] [CrossRef]

- Mansouri, L.Z.; Thuillier, S.; Manach, P.Y. Thermo-mechanical modeling of Portevin–Le Châtelier instabilities under various loading paths. Int. J. Mech. Sci. 2016, 115–116, 676–688. [Google Scholar] [CrossRef]

- Lebedkin, M.A.; Dunin-Barkovskii, L.R. Dynamic mechanism of the temperature dependence of the Portevin-Le Châtelier effect. Phys. Solid State 1998, 40, 447–452. [Google Scholar] [CrossRef]

- Wang, W.M.; Sluys, L.J.; De Borst, R. Viscoplasticity for Instabilities Due to Strain Softening and Strain-Rate Softening. Int. J. Numer. Methods Eng. 1997, 40, 3839–3864. [Google Scholar] [CrossRef]

- Cui, C.; Zhang, R.; Zhou, Y.; Sun, X. Portevin-Le Châtelier effect in wrought Ni-based superalloys: Experiments and mechanisms. J. Mater. Sci. Technol. 2020, 51, 16–31. [Google Scholar] [CrossRef]

- Rowlands, B.S.; Rae, C.; Galindo-Nava, E. The Portevin-Le Chatelier effect in nickel-base superalloys: Origins, consequences and comparison to strain ageing in other alloy systems. Prog. Mater. Sci. 2023, 132, 101038. [Google Scholar] [CrossRef]

- Vinogradov, A. Signatures of Plastic Instabilities and Strain Localization in Acoustic Emission Time-Series. Metals 2025, 15, 46. [Google Scholar] [CrossRef]

- Tong, W.; Zhang, N. On Serrated Plastic Flow in an AA5052-H32 Sheet. J. Eng. Mater. Technol. 2007, 129, 332–341. [Google Scholar] [CrossRef][Green Version]

- Wang, H.D.; Berdin, C.; Mazière, M.; Forest, S.; Prioul, C.; Parrot, A.; Le-Delliou, P. Experimental and numerical study of dynamic strain ageing and its relation to ductile fracture of a C–Mn steel. Mater. Sci. Eng. A 2012, 547, 19–31. [Google Scholar] [CrossRef]

- Yamasaki, S.; Miike, T.; Mitsuhara, M.; Nakashima, H.; Akiyoshi, R.; Nakamura, T.; Kimura, S. Quantitative analysis of the Portevin–Le Chatelier effect by combining digital image correlation and dead-weight-type tensile test. Mater. Sci. Eng. A 2021, 816, 141277. [Google Scholar] [CrossRef]

- Guillermin, N.; Besson, J.; Köster, A.; Lacourt, L.; Mazière, M.; Chalons, H.; Forest, S. Experimental and numerical analysis of the Portevin–Le Chatelier effect in a nickel-base superalloy for turbine disks application. Int. J. Solids Struct. 2023, 264, 112076. [Google Scholar] [CrossRef]

- Luo, S.; Xiao, L.; Jiang, J.; Li, J.; Zeng, L. Influence of Machine Stiffness on the Portevin–Le Chatelier Effect of Ti-12Mo Alloy Based on a Modified McCormick Constitutive Model. Met. Mater. Int. 2024, 30, 2685–2698. [Google Scholar] [CrossRef]

- Tretyakova, T.; Tretyakov, M. Spatial-Time Inhomogeneity Due to the Portevin-Le Chatelier Effect Depending on Stiffness. Metals 2023, 13, 1054. [Google Scholar] [CrossRef]

- Tretyakova, T.V.; Wildemann, V.E. Influence the loading conditions and the stress concentrators on the spatial-time inhomogeneity due to the yield delay and the jerky flow: Study by using the digital image correlation and the infrared analysis. Fract. Struct. Integr. 2017, 11, 303–314. [Google Scholar] [CrossRef]

- Doglione, R.; Ashtiani, P.H.; Berdin, C. Rolling Effect on Serrated Flow in an Al-Li-Cu-Mg Alloy Plate. Mater. Perform. Charact. 2015, 4, 73–86. [Google Scholar] [CrossRef]

- Mohammed, S.M.A.K.; Chen, D.L. Effect of Auto-Tuning on Serrated Flow Behavior. Metals 2019, 9, 845. [Google Scholar] [CrossRef]

- Tretyakova, T.V.; Wildemann, V.E.; Lomakin, E.V. Studying the influence of the loading system on the spatialtime inhomogeneity of inelastic deformation in metals by analyzing strain and temperature fields. AIP Conf. Proc. 2016, 1785, 4967053. [Google Scholar] [CrossRef]

- Tretyakova, T.V.; Wildemann, V.E. Interrelation between local strain jumps and temperature bursts due to the jerky flow in metals under the complicate loading conditions: Experimental study by using the DIC-technique and the IR-analysis. Procedia Struct. Integr. 2016, 2, 3393–3398. [Google Scholar] [CrossRef]

- Sheikh, H. Investigation into Characteristics of Portevin-Le Chatelier Effect of an Al-Mg Alloy. J. Mater. Eng. Perform. 2010, 19, 1264–1267. [Google Scholar] [CrossRef]

- Zdunek, J.; Brynk, T.; Mizera, J.; Pakieła, Z.; Kurzydłowski, K.J. Digital Image Correlation investigation of Portevin–Le Chatelier effect in an aluminium alloy. Mater. Charact. 2008, 59, 1429–1433. [Google Scholar] [CrossRef]

- Kang, J.; Wilkinson, D.S.; Jain, M.; Embury, J.D.; Beaudoin, A.J.; Kim, S.; Mishira, R.; Sachdev, A.K. On the sequence of inhomogeneous deformation processes occurring during tensile deformation of strip cast AA5754. Acta Mater. 2006, 54, 209–218. [Google Scholar] [CrossRef]

- Joshi, S.P.; Eberl, C.; Cao, B.; Ramesh, K.T.; Hemker, K.J. On the Occurrence of Portevin–Le Châtelier Instabilities in Ultrafine-Grained 5083 Aluminum Alloys. Exp. Mech. 2009, 49, 207–218. [Google Scholar] [CrossRef]

- Wen, W.; Morris, J.G. The effect of cold rolling and annealing on the serrated yielding phenomenon of AA5182 aluminum alloy. Mater. Sci. Eng. A 2004, 373, 204–216. [Google Scholar] [CrossRef]

- Samuel, E.; Jonas, J.J.; Samuel, F.H. Serrated Flow and Enhanced Ductility in Coarse-Grained Al-Mg Alloys. Met. Mater. Trans. A 2011, 42, 1028–1037. [Google Scholar] [CrossRef][Green Version]

- Saad, G.; Fayek, S.A.; Fawzy, A.; Soliman, H.N.; Nassr, E. Serrated flow and work hardening characteristics of Al-5356 alloy. J. Alloys Compd. 2010, 502, 139–146. [Google Scholar] [CrossRef]

- Kang, J.; Wilkinson, D.S.; Bruhis, M.; Jain, M.; Wu, P.D.; Embury, J.D.; Mishra, R.K.; Sachdev, A.K. Shear Localization and Damage in AA5754 Aluminum Alloy Sheets. J. Mater. Eng. Perform. 2008, 17, 395–401. [Google Scholar] [CrossRef]

- Ait-Amokhtar, H.; Boudrahem, S.; Fressengeas, C. Spatiotemporal aspects of jerky flow in Al–Mg alloys, in relation with the Mg content. Scr. Mater. 2006, 54, 2113–2118. [Google Scholar] [CrossRef]

- Zdunek, J.; Spychalski, W.L.; Mizera, J.; Kurzydłowski, K.J. The influence of specimens geometry on the PLC effect in Al–Mg–Mn (5182) alloy. Mater. Charact. 2007, 58, 46–50. [Google Scholar] [CrossRef]

- Abbadi, M.; Hähner, P.; Zeghloul, A. On the characteristics of Portevin–Le Chatelier bands in aluminum alloy 5182 under stress-controlled and strain-controlled tensile testing. Mater. Sci. Eng. A 2002, 337, 194–201. [Google Scholar] [CrossRef]

| Mg | Mn | Cr | Si | Fe | Cu | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 4.62 | 0.67 | 0.13 | 0.28 | 0.21 | 0.06 | 0.18 | 0.12 | Bal. |

| Testing Control | R0.2 [MPa] | Rm [MPa] | A% | A% Standard Deviation | Δσmax [MPa] |

|---|---|---|---|---|---|

| true strain | 128 | 244 | 14 | 1.46 | 16 |

| stroke, servohydraulic | 124 | 245 | 17 | 0.96 | 11 |

| stroke, electromechanical | 120 | 245 | 21 | 0.94 | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doglione, R.; Tanucci, F. Investigation of the Impact of Testing Machine and Control Modes on the Portevin-Le Chatelier Effect in Aluminum Alloy with Diffusible Solute Magnesium. J. Exp. Theor. Anal. 2025, 3, 25. https://doi.org/10.3390/jeta3030025

Doglione R, Tanucci F. Investigation of the Impact of Testing Machine and Control Modes on the Portevin-Le Chatelier Effect in Aluminum Alloy with Diffusible Solute Magnesium. Journal of Experimental and Theoretical Analyses. 2025; 3(3):25. https://doi.org/10.3390/jeta3030025

Chicago/Turabian StyleDoglione, Roberto, and Francesco Tanucci. 2025. "Investigation of the Impact of Testing Machine and Control Modes on the Portevin-Le Chatelier Effect in Aluminum Alloy with Diffusible Solute Magnesium" Journal of Experimental and Theoretical Analyses 3, no. 3: 25. https://doi.org/10.3390/jeta3030025

APA StyleDoglione, R., & Tanucci, F. (2025). Investigation of the Impact of Testing Machine and Control Modes on the Portevin-Le Chatelier Effect in Aluminum Alloy with Diffusible Solute Magnesium. Journal of Experimental and Theoretical Analyses, 3(3), 25. https://doi.org/10.3390/jeta3030025