Novel Insights into Agro-Industrial Waste: Exploring Techno-Economic Viability as an Alternative Source of Water Recovery

Abstract

1. Introduction

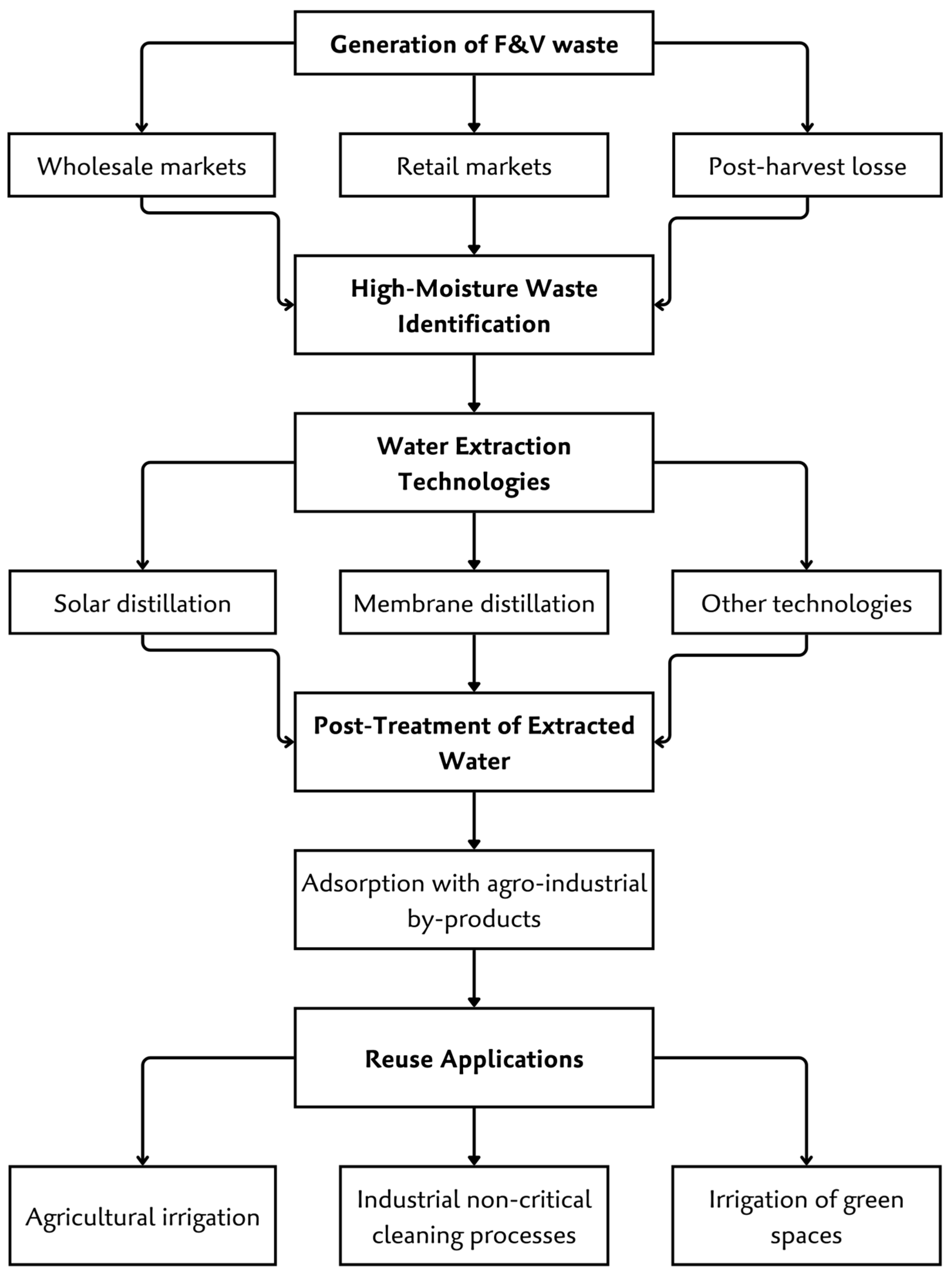

2. Potential of Agro-Industrial Wastes for Water Recovery

3. Potential Technologies for Water Recovery from Agro-Industrial Wastes

3.1. Solar Distillation

3.2. Membrane Distillation

3.3. Other Technologies

3.4. Post-Treatment of Water by Adsorption from Agro-Industrial Wastes

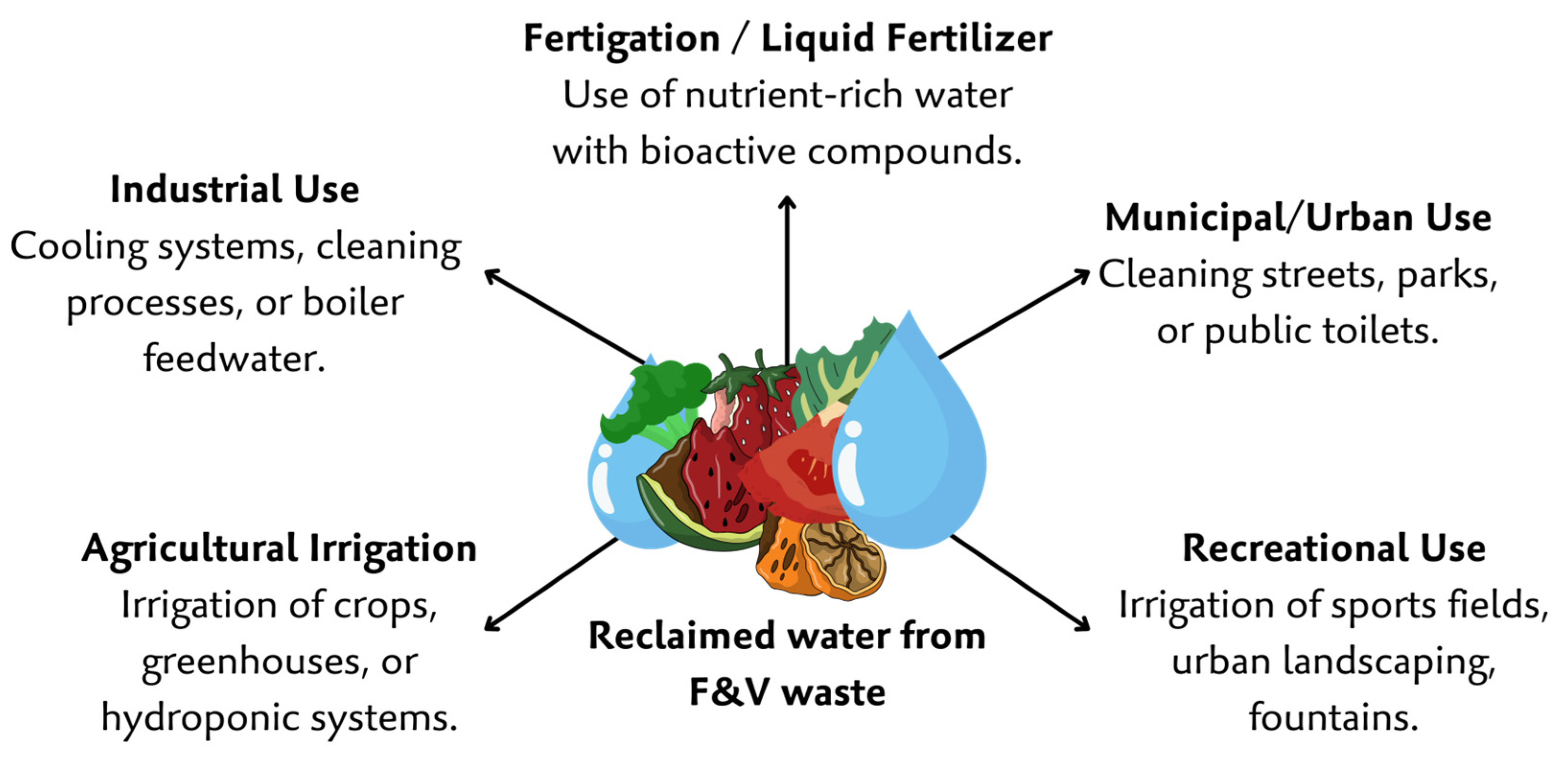

4. Uses and Applications of Water Extracted from Agro-Industrial Wastes

5. Environmental Impact of Water Recovery from Organic Waste

6. Technical Limitations and Challenges

7. Economic Viability

8. Future Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| F&V | Fruit and Vegetable |

| SDGs | Sustainable Development Goals |

| RO | Reverse Osmosis |

| UF | Ultrafiltration |

| MF | Microfiltration |

| NF | Nanofiltration |

| FO | Forward Osmosis |

| MD | Membrane Distillation |

| COD | Chemical Oxygen Demand |

| BOD | Biological Oxygen Demand |

| TDS | Total Dissolved Solids |

| ZLD | Zero Liquid Discharge |

| ISD | Interfacial Solar Distillation |

| NBS | Nature-Based Solutions |

References

- Fitton, N.; Alexander, P.; Arnell, N.; Bajzelj, B.; Calvin, K.; Doelman, J.; Gerber, J.; Havlík, P.; Hasegawa, T.; Herrero, M.; et al. The Percentage of Total Agricultural Area under Maize, Rice, Wheat, Vegetables, Pulses and Fruit Production, by Country, Subject to Water Scarcity in 2050 as Estimated from a Multi-Model Ensemble; Environmental Information Data Centre: Lancaster, UK, 2020. [Google Scholar]

- Mekonnen, M.M.; Hoekstra, A.Y. Sustainability: Four Billion People Facing Severe Water Scarcity. Sci. Adv. 2016, 2, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Hejazi, M.I.; Edmonds, J.; Clarke, L.; Kyle, P.; Davies, E.; Chaturvedi, V.; Wise, M.; Patel, P.; Eom, J.; Calvin, K. Integrated Assessment of Global Water Scarcity over the 21st Century under Multiple Climate Change Mitigation Policies. Hydrol. Earth Syst. Sci. 2014, 18, 2859–2883. [Google Scholar] [CrossRef]

- Ondrasek, G. Water Scarcity and Water Stress in Agriculture. In Physiological Mechanisms and Adaptation Strategies in Plants Under Changing Environment; Springer: Berlin/Heidelberg, Germany, 2014; Volume 1, pp. 75–96. [Google Scholar] [CrossRef]

- Schewe, J.; Heinke, J.; Gerten, D.; Haddeland, I.; Arnell, N.W.; Clark, D.B.; Dankers, R.; Eisner, S.; Fekete, B.M.; Colón-González, F.J.; et al. Multimodel Assessment of Water Scarcity under Climate Change. Proc. Natl. Acad. Sci. USA 2014, 111, 3245–3250. [Google Scholar] [CrossRef] [PubMed]

- Zahid, A.; Khedkar, R. Valorisation of Fruit & Vegetable Wastes: A Review. Curr. Nutr. Food Sci. 2021, 18, 315–328. [Google Scholar] [CrossRef]

- Arivazhagan, R.; Geetha, P.; Parthasarathy, R. Analysis of Sources of Fruit Wastages in Retail Outlets in Chennai, Tamilnadu, India. Int. J. Trade Econ. Financ. 2012, 3, 199–204. [Google Scholar] [CrossRef]

- Ismael, R.K. Quantification of Food Waste in Retail Operations: A Fruit and Vegetable Wastage Case in Paraguay. Environ. Chall. 2023, 10, 100665. [Google Scholar] [CrossRef]

- Devkota, A.R.; Dhakal, D.D.; Gautam, D.M.; Dutta, J.P. Assessment of Fruit and Vegetable Losses at Major Wholesale Markets in Nepal. Int. J. Appl. Sci. Biotechnol. 2014, 2, 559–562. [Google Scholar] [CrossRef]

- Lima, D.M.; Marsola, K.B.; Oliveira, A.D.L.; Belik, W. Strategies for Reducing the Waste of Fruit and Vegetable Supply Chains: The Search for Sustainable Wholesale Systems. Hortic. Bras. 2022, 40, 334–341. [Google Scholar] [CrossRef]

- Tedesco, D.E.A.; Scarioni, S.; Tava, A.; Panseri, S.; Zuorro, A. Fruit and Vegetable Wholesale Market Waste: Safety and Nutritional Characterisation for Their Potential Re-Use in Livestock Nutrition. Sustainability 2021, 13, 9478. [Google Scholar] [CrossRef]

- Patil, D. Agricultural Waste-Utilization and Management. In Sustainable Food Waste Management; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- de Brito Nogueira, T.B.; da Silva, T.P.M.; de Araújo Luiz, D.; de Andrade, C.J.; de Andrade, L.M.; Ferreira, M.S.L.; Fai, A.E.C. Fruits and Vegetable-Processing Waste: A Case Study in Two Markets at Rio de Janeiro, RJ, Brazil. Environ. Sci. Pollut. Res. 2020, 27, 18530–18540. [Google Scholar] [CrossRef]

- Buhion, R.P.; Barrion, A.S.; Lanorio, M.C. Fruit and Vegetable Waste Characteristics and Management Practices at Pasig Mega Market in Pasig City, Philippines. Int. J. Food Agric. Nat. Resour. 2024, 5, 8–14. [Google Scholar] [CrossRef]

- Devkota, R.; Dhakal, D.; Gautam, D.; Dutta, J. Assessment of Fruit and Vegetable Waste at Wholesale Markets in Nepal for Vermicomposting. Int. J. Res. 2014, 1, 1–9. [Google Scholar]

- Abadi, B.; Mahdavian, S.; Fattahi, F. The Waste Management of Fruit and Vegetable in Wholesale Markets: Intention and Behavior Analysis Using Path Analysis. J. Clean. Prod. 2021, 279, 123802. [Google Scholar] [CrossRef]

- Fredes, C.; García, F.; Pérez, M.I.; Fernández-Verdejo, R. Exploring Fruit and Vegetable Waste in Homeless Shelters That Receive Surplus Donation from a Wholesale Market in Chile. Sustainability 2020, 12, 8835. [Google Scholar] [CrossRef]

- Sagar, N.A.; Pareek, S.; Sharma, S.; Yahia, E.M.; Lobo, M.G. Fruit and Vegetable Waste: Bioactive Compounds, Their Extraction, and Possible Utilization. Compr. Rev. Food Sci. Food Saf. 2018, 17, 512–531. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, H.; Tian, J.; Shi, J.; Linhardt, R.J.; Ye, T.D.X.; Chen, S. Recovery of High Value-Added Nutrients from Fruit and Vegetable Industrial Wastewater. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1388–1402. [Google Scholar] [CrossRef]

- Asquer, C.; Pistis, A.; Scano, E. Characterization of Fruit and Vegetable Wastes as a Single Substrate for the Anaerobic Digestion. Environ. Eng. Manag. J. 2013, 12 (Suppl. S11), 89–92. [Google Scholar]

- Gupta, P.J.; Trivedi, M.J.; Soni, H.P. Proximate Analysis of Vegetable and Fruit Waste Collected from the Kadi Vegetable Market, Gujarat. Biosci. Biotechnol. Res. Asia 2023, 20, 673–679. [Google Scholar] [CrossRef]

- Kamau, J.M.; Mbui, D.N.; Mwaniki, J.M.; Mwaura, F.B. Proximate Analysis of Fruits and Vegetables Wastes from Nairobi County, Kenya. Res. J. Food Sci. Nutr. 2020, 5, 9–15. [Google Scholar] [CrossRef]

- Ghinea, C.; Prisacaru, A.; Lobiuc, A. Physico-Chemical and Microbiological Analysis of Fruits and Vegetables Waste. Ann. Food Sci. Technol. 2018, 19, 780–785. [Google Scholar]

- Li, Y.; Liu, H.; Xiao, K.; Liu, X.; Hu, H.; Li, X.; Yao, H. Correlations between the Physicochemical Properties of Hydrochar and Specific Components of Waste Lettuce: Influence of Moisture, Carbohydrates, Proteins and Lipids. Bioresour. Technol. 2019, 272, 482–488. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Li, H.; Chen, C.; Pang, Y.; Zhu, X. Detection of Water Content in Lettuce Canopies Based on Hyperspectral Imaging Technology under Outdoor Conditions. Agriculture 2022, 12, 1796. [Google Scholar] [CrossRef]

- Puccini, M.; Licursi, D.; Stefanelli, E.; Vitolo, S.; Galletti, A.M.R.; Heeres, H.J. Levulinic Acid from Orange Peel Waste by Hydrothermal Carbonization (HTC). Chem. Eng. Trans. 2016, 50, 223–228. [Google Scholar] [CrossRef]

- Park, S.Y.; Yoon, K.Y. Production of Enzymatic Hydrolysate Including Water-Soluble Fiber from Hemicellulose Fraction of Chinese Cabbage Waste. Korean J. Food Sci. Technol. 2015, 47, 6–12. [Google Scholar] [CrossRef]

- Choi, J.-H.; Chu, J.; Ryu, H. Quality Characteristics and Antioxidant Activities of Carrots Based on Pretreatment Conditions. J. Korean Soc. Food Cult. 2022, 37, 153–161. [Google Scholar]

- Burdon, J.N.; Moore, K.G.; Wainwright, H. The Peel of Plantain and Cooking Banana Fruits. Ann. Appl. Biol. 1993, 123, 391–402. [Google Scholar] [CrossRef]

- Silva, M.F.F.; da Silva, N.S.; Silva, J.V.F.; Caraschi, J.C.; Luna, C.M.R.; de Campos, C.I.; da Silva Viana, R. Energy Potential Evaluation of Agroindustrial Waste. Rev. Virtual Quim. 2022, 14, 46–49. [Google Scholar] [CrossRef]

- Thiviya, P.; Kapilan, R.; Madhujith, T. Bioconversion of Fruit Wastes of Papaya, Watermelon, and Banana into Single Cell Protein Production. Trop. Agric. Res. 2021, 32, 503. [Google Scholar] [CrossRef]

- Ramos-Datinguinoo, M.G.; Jacobe-Baes, D. Sweet Brine: Innovative Procedure to Convert Hard-Rinded Fruit Wastes to Bonbon Desserts. Philipp. J. Agric. Econ. 2019, 3, 40–51. [Google Scholar] [CrossRef]

- Biswas, S.; Ghosh, P.; Dutta, A.; Biswas, M.; Chatterjee, S. Comparative Analysis of Nutritional Constituents, Antioxidant and Antimicrobial Activities of Some Common Vegetable Wastes. Curr. Res. Nutr. Food Sci. J. 2021, 9, 62–74. [Google Scholar] [CrossRef]

- Jaladi, D.; Languri, E.; Piras, B. Sustainable Waste Water Treatment Using Solar Energy by Heat Localization Through Porous Media. In Proceedings of the Volume 8: Heat Transfer and Thermal Engineering, Salt Lake City, Utah, USA, 11–14 November 2019; Volume 8. [Google Scholar] [CrossRef]

- Shaikh, J.S.; Aswalekar, U.; Ismail, S.; Akhade, A. The Potential of Integrating Solar-Powered Membrane Distillation with a Humidification–Dehumidification System to Recover Potable Water from Textile Wastewater. Chem. Eng. Process. Process Intensif. 2024, 205, 110036. [Google Scholar] [CrossRef]

- Castro, L.M.C.; Moreira, V.R.; Morávia, M.C.S.A. Tecnologias Sustentáveis Para Recuperação de Água e Extração de Ácido Em Efluentes de Mineração de Ouro: Um Enfoque Em Destilação Por Membranas e Extração Líquido-Líquido Para Reúso; Universidade Federal de Minas Gerais: Belo Horizonte, Brazil, 2024. [Google Scholar]

- Tanvir, R.U.; Sujon, S.A.; Yi, P. Passive Permeate-Side-Heated Solar Thermal Membrane Distillation: Extracting Potable Water from Seawater, Surface Water, and Municipal Wastewater at High Single-Stage Solar Efficiencies. ACS EST Eng. 2021, 1, 770–779. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, T.; Kim, J.; Peng, H.; Ye, M.; Huang, C.H. Interfacial Solar Distillation for Freshwater Production: Fate of Volatile and Semivolatile Organic Contaminants. Environ. Sci. Technol. 2021, 55, 6248–6256. [Google Scholar] [CrossRef] [PubMed]

- Nahim-Granados, S.; Martínez-Piernas, A.B.; Rivas-Ibáñez, G.; Plaza-Bolaños, P.; Oller, I.; Malato, S.; Pérez, J.A.S.; Agüera, A.; Polo-López, M.I. Solar Processes and Ozonation for Fresh-Cut Wastewater Reclamation and Reuse: Assessment of Chemical, Microbiological and Chlorosis Risks of Raw-Eaten Crops. Water Res. 2021, 203, 117532. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mohite, R.B.; Jagannath, S.M.; Kumar, P.; Raskar, D.S.; Banerjee, M.K.; Singh, S.K.; Dogančić, D.; Đurin, B. Solar Thermal Technology Aided Membrane Distillation Process for Wastewater Treatment in Textile Industry—A Technoeconomic Feasibility Assessment. Eng 2023, 4, 2363–2374. [Google Scholar] [CrossRef]

- Yadav, A.; Labhasetwar, P.K.; Shahi, V.K. Membrane Distillation Crystallization Technology for Zero Liquid Discharge and Resource Recovery: Opportunities, Challenges and Futuristic Perspectives. Sci. Total Environ. 2022, 806, 150692. [Google Scholar] [CrossRef]

- Zhang, H.; Xian, H. Review of Hybrid Membrane Distillation Systems. Membranes 2024, 14, 25. [Google Scholar] [CrossRef]

- Ngo, M.T.T.; Bui, X.T.; Vo, T.K.Q.; Doan, P.V.M.; Nguyen, H.N.M.; Nguyen, T.H.; Ha, T.L.; Nguyen, H.V.; Vo, T.D.H. Mitigation of Thermal Energy in Membrane Distillation for Environmental Sustainability. Curr. Pollut. Rep. 2023, 9, 91–109. [Google Scholar] [CrossRef]

- Lutchmiah, K. Reclaiming Water from Wastewater Using Forward Osmosis; Mannheim University of Applied Sciences: Mannheim, Germany, 2014. [Google Scholar]

- Castro-Muñoz, R.; Boczkaj, G.; Gontarek, E.; Cassano, A.; Fíla, V. Membrane Technologies Assisting Plant-Based and Agro-Food by-Products Processing: A Comprehensive Review. Trends Food Sci. Technol. 2020, 95, 219–232. [Google Scholar] [CrossRef]

- Dagar, S.; Singh, S.K.; Gupta, M.K. Integration of Pre-Treatment with UF/RO Membrane Process for Waste Water Recovery and Reuse in Agro-Based Pulp and Paper Industry. Membranes 2023, 13, 199. [Google Scholar] [CrossRef]

- Siddique, I.J.; Bahar, R.; Ibrahim, S.; Al Hazza, M.H.F. Wastewater Treatment by Solar Air Gap Multi-Stage Membrane Distillation; European Water Resources Association: Munich, Germany, 2017; Volume 58. [Google Scholar]

- Arunkumar, T.; Sathyamurthy, R.; Denkenberger, D.; Lee, S.J. Solar Distillation Meets the Real World: A Review of Solar Stills Purifying Real Wastewater and Seawater. Environ. Sci. Pollut. Res. 2022, 29, 22860–22884. [Google Scholar] [CrossRef] [PubMed]

- Sambare, R.K.; Dewangan, S.K.; Gupta, P.K.; Joshi, S. Productivity Enhancement Techniques for Tubular Solar Still—A Review. Environ. Prog. Sustain. Energy 2024, 43, e14345. [Google Scholar] [CrossRef]

- Ngo, M.T.T.; Diep, B.Q.; Sano, H.; Nishimura, Y.; Boivin, S.; Kodamatani, H.; Takeuchi, H.; Sakti, S.C.W.; Fujioka, T. Membrane Distillation for Achieving High Water Recovery for Potable Water Reuse. Chemosphere 2022, 288, 132610. [Google Scholar] [CrossRef] [PubMed]

- Moreira, V.R.; Castro, L.M.C.; Amaral, M.C.S. Comparative Analysis of Direct Contact and Air–Gap Membrane Distillation Techniques for Water Recovery from Gold Mining Wastewater. Sep. Purif. Technol. 2024, 344, 127300. [Google Scholar] [CrossRef]

- Zhang, F.; Hou, W.; Yang, Z.; Wang, Z.; Chen, R.; Drioli, E.; Wang, X.; Cui, Z. Treatment of Aniline Wastewater by Membrane Distillation and Crystallization. Membranes 2023, 13, 561. [Google Scholar] [CrossRef]

- Wu, C.Y.; Mouri, H.; Chen, S.S.; Zhang, D.Z.; Koga, M.; Kobayashi, J. Removal of Trace-Amount Mercury from Wastewater by Forward Osmosis. J. Water Process Eng. 2016, 14, 108–116. [Google Scholar] [CrossRef]

- Pramanik, B.K.; Hai, F.I.; Ansari, A.J.; Roddick, F.A. Mining Phosphorus from Anaerobically Treated Dairy Manure by Forward Osmosis Membrane. J. Ind. Eng. Chem. 2019, 78, 425–432. [Google Scholar] [CrossRef]

- Salih, M.A.; Dhiaa, A.H. Performance Evaluation of The Reverse Osmosis Pilot Plant: Using Sodium Chloride and Magnesium Chloride. Kufa J. Eng. 2023, 14, 1–11. [Google Scholar] [CrossRef]

- Wang, Z.; Deshmukh, A.; Du, Y.; Elimelech, M. Minimal and Zero Liquid Discharge with Reverse Osmosis Using Low-Salt-Rejection Membranes. Water Res. 2020, 170, 115317. [Google Scholar] [CrossRef]

- Muñoz, P.; Pérez, K.; Cassano, A.; Ruby-Figueroa, R. Recovery of Anthocyanins and Monosaccharides from Grape Marc Extract by Nanofiltration Membranes. Molecules 2021, 26, 2003. [Google Scholar] [CrossRef]

- Garcia-Castello, E.M.; Conidi, C.; Cassano, A. A Membrane-Assisted Green Strategy for Purifying Bioactive Compounds from Extracted White Wine Lees. Sep. Purif. Technol. 2024, 336, 126183. [Google Scholar] [CrossRef]

- Mo, J.; Yang, Q.; Zhang, N.; Zhang, W.; Zheng, Y.; Zhang, Z. A Review on Agro-Industrial Waste (AIW) Derived Adsorbents for Water and Wastewater Treatment. J. Environ. Manag. 2018, 227, 395–405. [Google Scholar] [CrossRef] [PubMed]

- Simón, D.; Palet, C.; Costas, A.; Cristóbal, A. Agro-Industrial Waste as Potential Heavy Metal Adsorbents and Subsequent Safe Disposal of Spent Adsorbents. Water 2022, 14, 3298. [Google Scholar] [CrossRef]

- Aftab, R.A.; Yusuf, M.; Ahmad, F.; Danish, M.; Zaidi, S.; Vo, D.V.N.; Nguyen, A.-T.; Rahman, M.M.; Ibrahim, H. Green Technology Approach Towards the Removal of Heavy Metals, Dyes, and Phenols from Water Using Agro-Based Adsorbents: A Review. Chem. Asian J. 2024, 19, e202400154. [Google Scholar] [CrossRef]

- Monica, M.; Jayasree, R.; Hepzibha, J.I.B. Utilization of Agricultural Waste Through Conventional Technologies for the Treatment of Industrial Effluents: A Review. Bhartiya Krishi Anusandhan Patrika 2023, 38, 238–245. [Google Scholar] [CrossRef]

- Yunus, Z.M.; Yashni, G.; Al-Gheethi, A.; Othman, N.; Hamdan, R.; Ruslan, N.N. Advanced Methods for Activated Carbon from Agriculture Wastes; a Comprehensive Review. Int. J. Environ. Anal. Chem. 2022, 102, 134–158. [Google Scholar] [CrossRef]

- Edwin, G.A.; Poyyamoli, G. Climate Change and Sustainable Management of Water Resources. In Climate Change Management; Springer: Berlin/Heidelberg, Germany, 2012; pp. 431–447. [Google Scholar] [CrossRef]

- Zytner, R.G. Identifying Treatment Schemes for Fruit and Vegetable Wash-Water. J. Agric. Sci. Bot. 2020, 4, 1–2. [Google Scholar] [CrossRef]

- Peres, D.J.; Modica, R.; Cancelliere, A. Assessing Future Impacts of Climate Change on Water Supply System Performance: Application to the Pozzillo Reservoir in Sicily, Italy. Water 2019, 11, 2531. [Google Scholar] [CrossRef]

- Papadopoulou, M.P.; Charchousi, D. Water Availability: A Factor of Sustainability and Adaptation of Agriculture to Climate Change. In Proceedings of the 16th International Conference on Environmental Science and Technology, Global NEST International Conference on Environmental Science & Technology, Rhodes, Greece, 4–7 September 2019; Volume 16. [Google Scholar] [CrossRef]

- Pandey, B.C. Review: Reuse of Treated Wastewater. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 1915–1918. [Google Scholar] [CrossRef]

- Singh, R.P.; Kolok, A.S.; Bartelt-Hunt, S.L. Water Conservation, Recycling and Reuse: Issues and Challenges. In Water Conservation, Recycling and Reuse: Issues and Challenges; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–276. [Google Scholar] [CrossRef]

- Ghernaout, D. Increasing Trends Towards Drinking Water Reclamation from Treated Wastewater. World J. Appl. Chem. 2018, 3, 1. [Google Scholar] [CrossRef]

- Maeseele, C.; Roux, P. An LCA Framework to Assess Environmental Efficiency of Water Reuse: Application to Contrasted Locations for Wastewater Reuse in Agriculture. J. Clean. Prod. 2021, 316, 128151. [Google Scholar] [CrossRef]

- Opher, T.; Friedler, E. Comparative LCA of Decentralized Wastewater Treatment Alternatives for Non-Potable Urban Reuse. J. Environ. Manag. 2016, 182, 464–476. [Google Scholar] [CrossRef] [PubMed]

- Hristov, J.; Barreiro-Hurle, J.; Salputra, G.; Blanco, M.; Witzke, P. Reuse of Treated Water in European Agriculture: Potential to Address Water Scarcity under Climate Change ☆. Agric. Water Manag. 2021, 251, 106872. [Google Scholar] [CrossRef]

- Ballesteros-Olza, M.; Blanco-Gutiérrez, I.; Esteve, P.; Gómez-Ramos, A.; Bolinches, A. Using Reclaimed Water to Cope with Water Scarcity: An Alternative for Agricultural Irrigation in Spain. Environ. Res. Lett. 2022, 17, 125002. [Google Scholar] [CrossRef]

- Ohgaki, S.; Sato, K. Use of Reclaimed Wastewater for Ornamental and Recreational Purposes. Water Sci. Technol. 1991, 23, 2109–2117. [Google Scholar] [CrossRef]

- Schwecke, M.A.; Simmons, B. The Use of Alternative Water Sources on Urban Playing Fields: Are They Acceptable from a Community Stance? Water Sci. Technol. Water Supply 2008, 8, 603–609. [Google Scholar] [CrossRef]

- Parra-Pacheco, B.; Cruz-Moreno, B.A.; Aguirre-Becerra, H.; García-Trejo, J.F.; Feregrino-Pérez, A.A. Bioactive Compounds from Organic Waste. Molecules 2024, 29, 2243. [Google Scholar] [CrossRef]

- Floridas-Galán, J.P.; Paredes-Concepción, P.; Floridas-Galán, J.P.; Paredes-Concepción, P. Bioactive Compounds from Agroindustrial Byproducts and Their Applications: From Traditional Methods to Green Technologies. Sci. Agropecu. 2024, 15, 461–476. [Google Scholar] [CrossRef]

- Helmecke, M.; Fries, E.; Schulte, C. Regulating Water Reuse for Agricultural Irrigation: Risks Related to Organic Micro-Contaminants. Environ. Sci. Eur. 2020, 32, 4. [Google Scholar] [CrossRef]

- Nahim-Granados, S.; Quon, H.; Polo-López, M.I.; Oller, I.; Agüera, A.; Jiang, S. Assessment of Antibiotic-Resistant Infection Risks Associated with Reclaimed Wastewater Irrigation in Intensive Tomato Cultivation. Water Res. 2024, 254, 121437. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Ren, H. Multi-Omic Studies on the Toxicity Variations in Effluents from Different Units of Reclaimed Water Treatment. Water Res. 2022, 208, 117874. [Google Scholar] [CrossRef] [PubMed]

- Troldborg, M.; Duckett, D.; Allan, R.; Hastings, E.; Hough, R.L. A Risk-Based Approach for Developing Standards for Irrigation with Reclaimed Water. Water Res. 2017, 126, 372–384. [Google Scholar] [CrossRef] [PubMed]

- Mohit Singh, R.; Shashi, B.; Sanjeev Kumar, P.; Preethi; Kavitha, S. Techno-Economic Analysis and Environmental Aspects of Food Waste Management. In Food Waste to Valuable Resources; Elsevier: Amsterdam, The Netherlands, 2020; pp. 325–342. [Google Scholar]

- Perwez, M.; Al Asheh, S. Valorization of Agro-Industrial Waste through Solid-State Fermentation: Mini Review. Biotechnol. Rep. 2025, 45, e00873. [Google Scholar] [CrossRef]

- Nath, P.C.; Ojha, A.; Debnath, S.; Sharma, M.; Nayak, P.K.; Sridhar, K.; Inbaraj, B.S. Valorization of Food Waste as Animal Feed: A Step towards Sustainable Food Waste Management and Circular Bioeconomy. Animals 2023, 13, 1366. [Google Scholar] [CrossRef]

- Sarker, A.; Ahmmed, R.; Ahsan, S.M.; Rana, J.; Ghosh, M.K.; Nandi, R. A Comprehensive Review of Food Waste Valorization for the Sustainable Management of Global Food Waste. Sustain. Food Technol. 2023, 2, 48–69. [Google Scholar] [CrossRef]

- Saqib, N.U.; Sharma, H.B.; Baroutian, S.; Dubey, B.; Sarmah, A.K. Valorisation of Food Waste via Hydrothermal Carbonisation and Techno-Economic Feasibility Assessment. Sci. Total Environ. 2019, 690, 261–276. [Google Scholar] [CrossRef]

- Chaher, N.E.H.; Nassour, A.; Nelles, M. The (FWE)2 Nexus: Bridging Food, Food Waste, Water, Energy, and Ecosystems for Circular Systems and Sustainable Development. Trends Food Sci. Technol. 2024, 154, 104788. [Google Scholar] [CrossRef]

- Branca, G.; Cacchiarelli, L.; Cardona, C.A.; Felix, E.; Gianvenuti, A.; Kojakovic, A.; Maltsoglou, I.; Martchamadol, J.; Rincon, L.; Rossi, A.; et al. Residuos Agrícolas y Residuos Ganaderos; Food and Agriculture Organisation: Rome, Italy, 2014. [Google Scholar]

- Winpenny, J.T.; Heinz, I.; Koo-Oshima, S. Reutilización Del Agua y Agricultura: Beneficios Para Todos? Food and Agriculture Organisation: Rome, Italy, 2013. [Google Scholar]

- Del Mar, M.; García, H. La Gestión Del Nexo Agua-Energía-Alimentos: La Clave Para El de-Sarrollo Sostenible. Cuad. Estrateg. 2017, 186, 119–158. [Google Scholar]

- Albusaimi, F.A.; Dabbous, M.S.A.; Yateem, R.A.; Pretorius, F.P. Circular Economy Practices Through Water Management. In Proceedings of the SPE International Health, Safety, Environment and Sustainability Conference and Exhibition, Abu Dhabi, United Arab Emirates, 10–12 September 2024. [Google Scholar] [CrossRef]

- Figueredo, P.K.; Bhokare, M.P.A.; Mohite, M.N.A. Feasibility Study of Zero Discharge Concept in Sugar Industry After Anaerobic Treatment: Case Study of Solapur. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 108–113. [Google Scholar] [CrossRef]

- Lung, R.B.; Gledhil, J.; Graf, R.; Filippov, A. Energy Efficiency in the Water Industry. In Proceedings of the Water Environment Federation, Towson, MD, USA, 18–20 July 2012; Volume 2011, pp. 1287–1296. [Google Scholar] [CrossRef]

- Engida, T.; Mekonnen, A.; Wu, J.M.; Xu, D.; Wu, Z.B. Review Paper on Beverage Agro-Industrial Wastewater Treatment Plant Bio-Sludge for Fertilizer Potential in Ethiopa. Appl. Ecol. Environ. Res. 2020, 18, 33–57. [Google Scholar] [CrossRef]

- Hagenvoort, J.; Ortega-Reig, M.; Botella, S.; García, C.; de Luis, A.; Palau-Salvador, G. Reusing Treated Waste-Water from a Circular Economy Perspective—The Case of the Real Acequia de Moncada in Valencia (Spain). Water 2019, 11, 1830. [Google Scholar] [CrossRef]

- Taddeo, R.; Honkanen, M.; Kolppo, K.; Lepistö, R. Nutrient Management via Struvite Precipitation and Recovery from Various Agroindustrial Wastewaters: Process Feasibility and Struvite Quality. J. Environ. Manag. 2018, 212, 433–439. [Google Scholar] [CrossRef]

- Alegre, A.R. Integration of Membrane Technologies in Agro-Industrial Process Stages; La Universitat Politècnica de Catalunya (UPC): Catalunya, Spain, 2017. [Google Scholar]

- Skarli, R. Organic Waste Management at the Retail Sector: The Case Study of Central Grocery Market of Thessaloniki. Master’s Thesis, School of Economics, Business Administration & Legal Studies, Thessaloniki, Greece, 2019. [Google Scholar]

- Mozhiarasi, V. Overview of Pretreatment Technologies on Vegetable, Fruit and Flower Market Wastes Disintegration and Bioenergy Potential: Indian Scenario. Chemosphere 2022, 288, 132604. [Google Scholar] [CrossRef] [PubMed]

- Ali, G.; Nitivattananon, V.; Perera, R. Green Waste to Renewable Energy and Business; LAP LAMBERT Academic Publishing: Saarbrücken, Germany, 2010. [Google Scholar]

- Yepes, C.; Milena, S.; Naranjo, M.; Johana, L.; Sánchez, O. Revista Facultad Nacional de Agronomía-Medellín. Rev. Fac. Nac. Agron. Medellín 2008, 61, 4422–4431. [Google Scholar]

- Macías Aragonés, M.; Paez, D.; Domínguez, C.G.; Mayenco, M.U.; Moreno, J.C.G.; de la Viña Nieto, G.; Fajardo, M.N.; Chavrier, N.; Alegre, M.G. Tecnologías de Bioeconomía Para Valorizar Residuos y Desperdicios: Oportunidades de Negocio Para La Agricultura Familiar. Uniw. Śląski 2020, 7, 343–354. [Google Scholar]

- Colazo, J.A.; Porporato, M. Análisis de Inversión y Reducción de Costos En Un Contexto de Lean Accounting. Contab. Y Neg. 2023, 18, 87–114. [Google Scholar] [CrossRef]

- Navas, C.S.; Reboredo, M.M.; Granados, D.L. Comparative Study of Agroindustrial Wastes for Their Use in Polymer Matrix Composites. In Procedia Materials Science; Elsevier: Amsterdam, The Netherlands, 2015; Volume 8, pp. 778–785. [Google Scholar] [CrossRef]

- Alcántara-Revilla, A.R.; Mejía-Benavides, A.; Chávez-García, S.C.; Castillo-Llerena, D.E. Aprovechamiento de Los Residuos Agroindustriales y Su Impacto En El Medio Ambiente. Rev. Científica OGOLL 2022, 2, e29. [Google Scholar] [CrossRef]

- Alcazar-Ruiz, A.; Silva, L.S.; Dorado, F. Economic Viability Assessment of Bioenergy Production from Agroindustrial Wastes through Fast Pyrolysis. Energy 2024, 311, 133441. [Google Scholar] [CrossRef]

- Guido, S.I.M.; Garduño, L.F.M.; Gómez, M.A.A.; Ortiz, P.E.; López, B.I.B.; Ojeda, E.T.; Hernández, R.M.; Antonio, C.G. Revalorización Sustentable de Residuos Agroindustriales de La Producción de Jitomate. Perspect. De La Cienc. Y La Tecnol. 2024, 63–82. [Google Scholar] [CrossRef]

- Nobre, P.T.; Costa, R.G.; Dias-Silva, T.P.; Ribeiro, N.L.; Gurgel, A.L.C.; Beltrão, L.G.C.; Cruz, G.R.B.; Borges, I.; Lorenzo, J.M. Effect of Feeding Guava Agroindustrial Waste on Nutrient Utilization, Lamb Performance and Economic Analysis. Arch. Anim. Breed. 2024, 67, 541–549. [Google Scholar] [CrossRef]

| Waste Type | Moisture Content (%) | Water Activity | Technical Challenges and Processing Considerations | References |

|---|---|---|---|---|

| Lettuce | 95–96 | 0.99 | Fast microbial degradation; requires immediate processing. | [24,25] |

| Tomatoes | 93–95 | 0.98 | Pectin-rich consistency may require additional filtration steps. | [11,22] |

| Orange Peels | 70–75 | 0.94 | Lower moisture but can be used for hydrothermal treatments and bioactive compound extraction. | [23,26] |

| Cabbage Leaves | 94 | 0.98 | Tougher structure; enzymatic breakdown may be required for efficient extraction. | [22,27] |

| Carrot Peels | 86–90 | 0.97 | Fibrous nature reduces pressing efficiency; enzymatic hydrolysis needed. | [28] |

| Banana Peels | 70–90 | 0.96 | High sugar and starch content complicates recovery; enzymatic pre-treatment required. | [22,29] |

| Papaya Peels | 85–90 | 0.96 | Significant soluble sugars and pectin; enzyme-assisted pressing recommended. | [30,31] |

| Watermelon Rinds | 92–94 | 0.99 | Soft structure allows high-efficiency pressing with minimal processing. | [32] |

| Potato Peels | 80–85 | 0.94 | Dense composition; enzymatic pre-treatment needed for effective pressing. | [22,33] |

| Technology | Estimated Recovery Efficiency | Reported Technical Indicators | Key Benefits | Key Limitations | Practical Applicability | Cost vs. Efficiency | References |

|---|---|---|---|---|---|---|---|

| Solar distillation | 40–65% | T = 60–80 °C; water yield: 2–6 L/m2·day | Low cost, solar powered, ideal for rural areas | Low productivity, dependence on climate | Small scale, areas with high solar radiation | High (low cost, low efficiency) | [47,48,49] |

| Membrane distillation | 70–90% | T = 60–80 °C; recovery up to 98%; flux 5.4–7.1 L/m2·h | High efficiency, suitable for high-organic-load wastewater | Membrane fouling, high initial cost | Medium to large agro-industries | Medium (high cost, high efficiency) | [50,51] |

| Crystallization by MD | ~90% | Operates at 60 °C; salt recovery ≥ 95%; flux: 20 L/m2·h | Enables ZLD and simultaneous salt and bioactive recovery | Operational complexity, limited commercial availability | Specialized applications | Low (very high cost, high efficiency) | [41,52] |

| Forward osmosis | 50–80% | Flux: 2–10 LMH; >95% rejection; NaCl/MgCl2 draw | Low energy consumption, treatment of complex waste | Need for extraction solution, incomplete water recovery | Experimental and pilot use | Average (moderate efficiency) | [53,54] |

| Reverse osmosis | >90% | P = 4–8 bar; >99% salt rejection; stable output | High quality treated water, mature technology | High energy consumption, sensitive to dissolved solids | Industrial use, demanding applications | High (high efficiency vs. high energy cost) | [55,56] |

| Ultrafiltration/Nanofiltration | 60–85% | Ambient T, low P; MWCO: 300–1000 Da | Water recovery + bioactive compounds | Requires pre-treatment, sensitive to soiling | Complementary in hybrid schemes | High (favorable ratio in hybrid systems) | [57,58] |

| Country/Author | Description | General Benefits | Economic Analysis of the Project | Potential Economic Benefits | Reference |

|---|---|---|---|---|---|

| Peru | Proposal for an agro-industrial waste processing plant for the production of compost. | Decrease in environmental impact. Reduction of costs for the acquisition of fertilizers and fertilizers. Processing of 100 tons of solid agro-industrial waste per day. | Implementation costs: Investment: US$1,000,000.00. Fixed investment: US$500,000.00 dollars Intangible assets: US$50,000.00 dollars Working capital: US$120,000.00 dollars Financing: 15 years Interest rate: 12%. | Reduction in daily agro-industrial waste costs of 138.7 metric tons. Approximate annual landfill costs: US$2,000,000.00. | [106] |

| Spain | Proposal for the generation of bioenergy from olive, almond and pistachio residues. | Bioenergy generation through biomass pyrolysis. Reduction of greenhouse gases. Sustainable practices. Reuse of agro-industrial waste. | Profitability (pistachio): Net Present Value (NPV): 178.48 million euros. Internal Rate of Return (IRR): 185.15%. | High economic viability. Investment payback in two years. | [107] |

| Mexico | Proposal for the generation of green energy from tomato waste to provide heat in greenhouses. | Biofuel generation. Reduction of 87% of ecological footprint per production period. Reduction in the use of fossil resources. | Fossil energy production. LP gas heating cost: US$1189. Production with green energy Heating cost of tomato pellets: 61 dollars. Supplementary LP gas heating cost: US$271. Cost reduction greater than US$918 per production cycle. | Economic feasibility with a 71% savings in the cost of providing heat in the greenhouses during each production period. | [108] |

| Brazil | Integration of guava residues in sheep feed. | Increased product quality. Increased productive performance of the consumer. | Effective operating cost: US$515 Gross revenues: US$732 Gross margin: US$217 Rate of return: US$0.13 Safety margin: 9%. Daily cost benefit: US$0.43. | Economic viability: 30% decrease in selling price. 1 dollar of investment = 0.43 dollars of return. | [109] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano-Gómez, C.I.; Wong-Arguelles, C.; Hinojosa-López, J.I.; Muñiz-Márquez, D.B.; Wong-Paz, J.E. Novel Insights into Agro-Industrial Waste: Exploring Techno-Economic Viability as an Alternative Source of Water Recovery. Waste 2025, 3, 15. https://doi.org/10.3390/waste3020015

Cano-Gómez CI, Wong-Arguelles C, Hinojosa-López JI, Muñiz-Márquez DB, Wong-Paz JE. Novel Insights into Agro-Industrial Waste: Exploring Techno-Economic Viability as an Alternative Source of Water Recovery. Waste. 2025; 3(2):15. https://doi.org/10.3390/waste3020015

Chicago/Turabian StyleCano-Gómez, Christian I., Cynthia Wong-Arguelles, Jessica Ivonne Hinojosa-López, Diana B. Muñiz-Márquez, and Jorge E. Wong-Paz. 2025. "Novel Insights into Agro-Industrial Waste: Exploring Techno-Economic Viability as an Alternative Source of Water Recovery" Waste 3, no. 2: 15. https://doi.org/10.3390/waste3020015

APA StyleCano-Gómez, C. I., Wong-Arguelles, C., Hinojosa-López, J. I., Muñiz-Márquez, D. B., & Wong-Paz, J. E. (2025). Novel Insights into Agro-Industrial Waste: Exploring Techno-Economic Viability as an Alternative Source of Water Recovery. Waste, 3(2), 15. https://doi.org/10.3390/waste3020015