Valorizing the Input and Output Waste Streams from Three PtX Case Studies in Denmark—Adopting a Symbiotic Approach

Abstract

:1. Introduction

1.1. Danish PtX Projects under Development and in the Pipeline

1.2. Problem Field

2. Materials and Methods

2.1. Data Retrieval

2.1.1. Exploratory Case Study

2.1.2. Case Study Design

2.1.3. Literature Study

2.2. Theoretical Outline

2.2.1. Symbiotic Approach

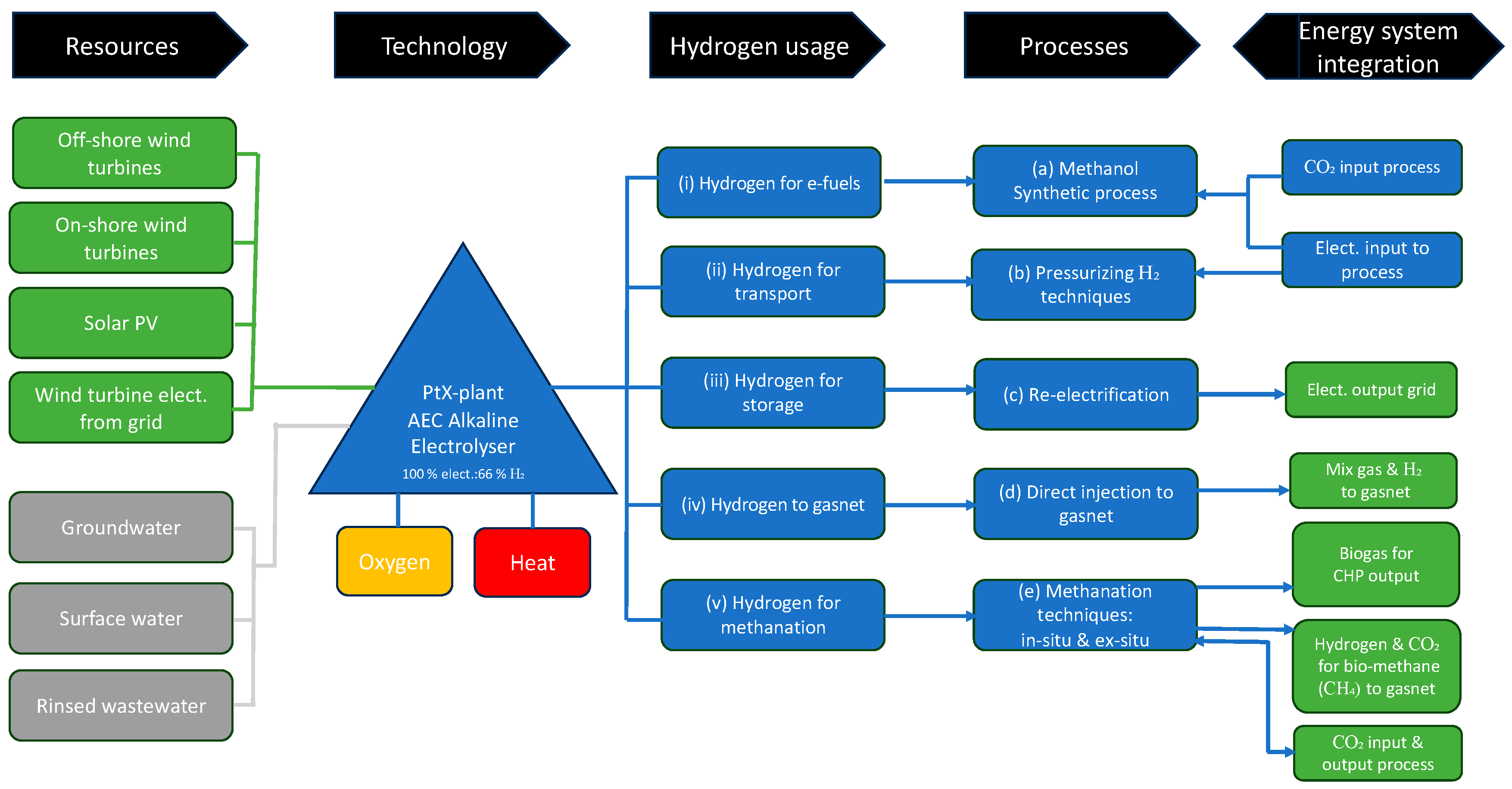

2.2.2. Systemic Elements Connected to PtX Plants

- (a)

- Making e-fuel via a synthetic process, such as methanol, which would require an input of carbon (CO2) and electricity from the energy system if not provided by local RES sources. The use of biogenetic CO2 in this process could be supplied by upgrading the existing facilities (extraction of CO2 from biogas to produce pure methane) connected to Danish biogas plants, or possibly from decentralized CHP plants fueled by biomass, such as residual straw or wood chips. The co-location of the PtX plant near such facilities would, hence, be beneficial. The use of biogenetic CO2 is important from a symbiotic perspective, as in almost all cases, it would otherwise simply be emitted to the atmosphere from the biogas plants when upgrading their facilities. Currently, 675,000 t of biogenetic CO2 are emitted annually from these energy plants [42], and thus not being valorized while also causing environmental issues, including contributing to global warming. Capturing and valorizing this output as a new input to the electrolysis process is therefore important, and carbon capture and utilization (CCU) could thus minimize this current wastage of biogenetic CO2, which could be facilitated within the PtX plant via a classical “inter-firm collaboration”.

- (b)

- Pressurizing hydrogen to make it suitable as an energy carrier for transportation purposes, but this is an energy-intensive technique and will, in many cases, require an input of energy from the energy system to fuel high-pressure equipment unless energy is supplied from local RES sources. This process does not require carbon input.

- (c)

- Storing hydrogen and eventually utilizing it for the generation of electricity, e.g., via re-electrification. In this way, it is possible to produce an output (electricity on demand) that could assist in stabilizing the fluctuating RES production.

- (d)

- Injecting hydrogen directly into the gasnet [43]. Up to a 15% (potentially 20% in newer gas pipes) mixture of hydrogen and gas (methane) could be supplied and hence “stored” in an already established gasnet [44]. The stored energy within the gasnet could then later be utilized for, e.g., electricity and heat production or industrial usage, thereby helping stabilize the fluctuating energy supply from RES.

- (e)

- Methanation, where hydrogen, for example, is converted to additional biogas via an in situ injection of electrolysis-produced hydrogen directly into the biogas’ reactor tank [17]. This was investigated by ref. [45], which reported that up to 80% of the hydrogen was converted to methane, and between 40–60% of the biogas’ content of CO2 was removed. Alternatively, new ex situ co-located technology—like a biological methanation facility—could be established separately, where biogenetic CO2 from an upgrading facility could be utilized and combined with hydrogen from the PtX plant in the following process [17,22]. According to ref. [46], such a separate (ex situ) methanation plant could typically increase the biogas yield by up to 42%.

2.2.3. Valorizing Waste Streams and Energy System Integration

- Renewable Energy Sources (RES): Where does the electricity come from?

- Carbon dioxide: Does the plant rely on CO2 from biogenetic or non-biogenetic sources?

- Water: Where does the water for the electrolysis processes come from?

- Waste heat: Is the surplus heat being utilized?

- Oxygen: Does pure oxygen have any usage?

- Energy system integration: Is the layout/design stabilizing the fluctuating RES within the energy system?

3. Results

3.1. Case Presentation

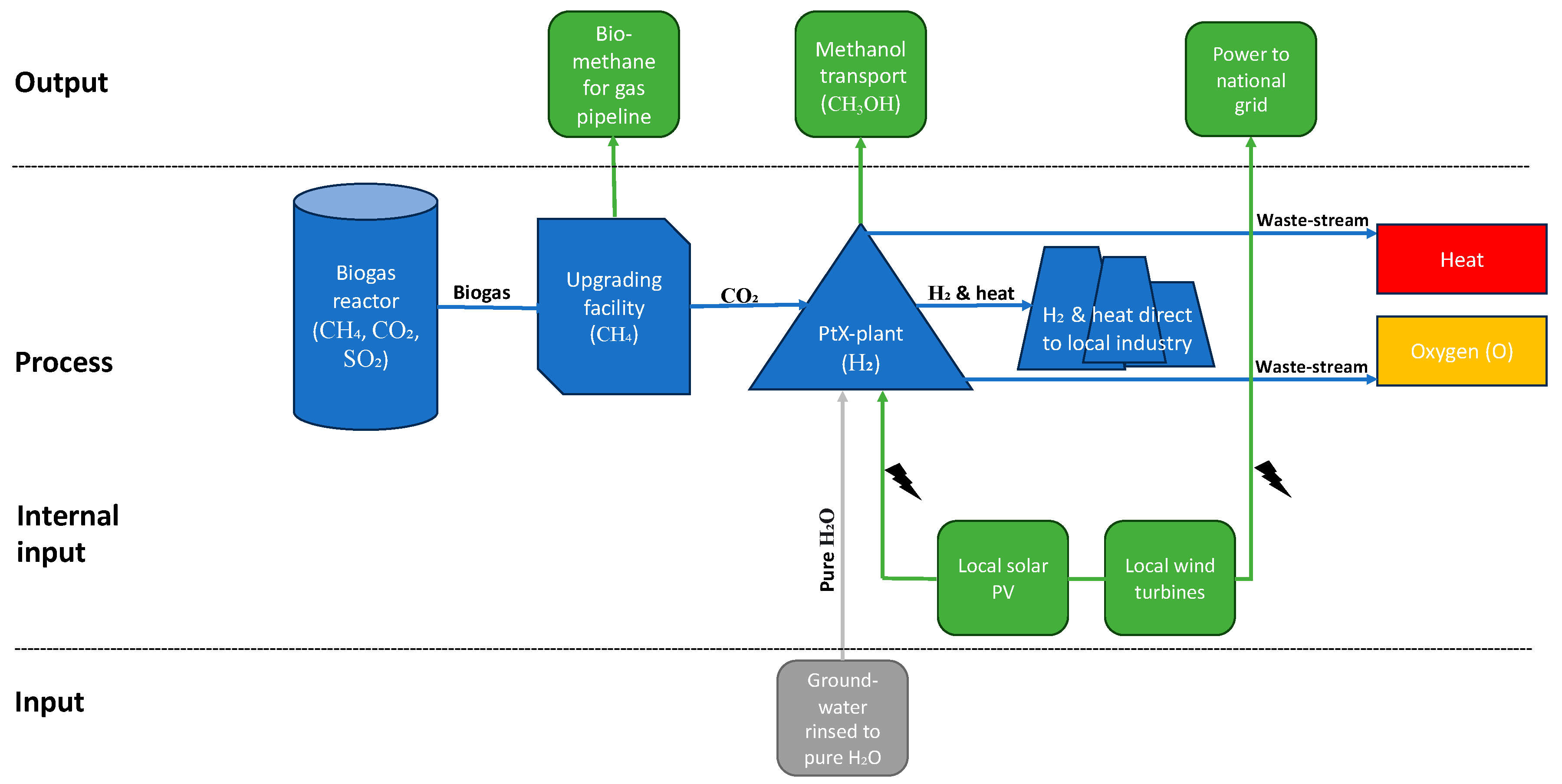

3.1.1. Case Study 1: EnergyLab Skive and PtX Plant (the Energy Hub Case, Figure 2)

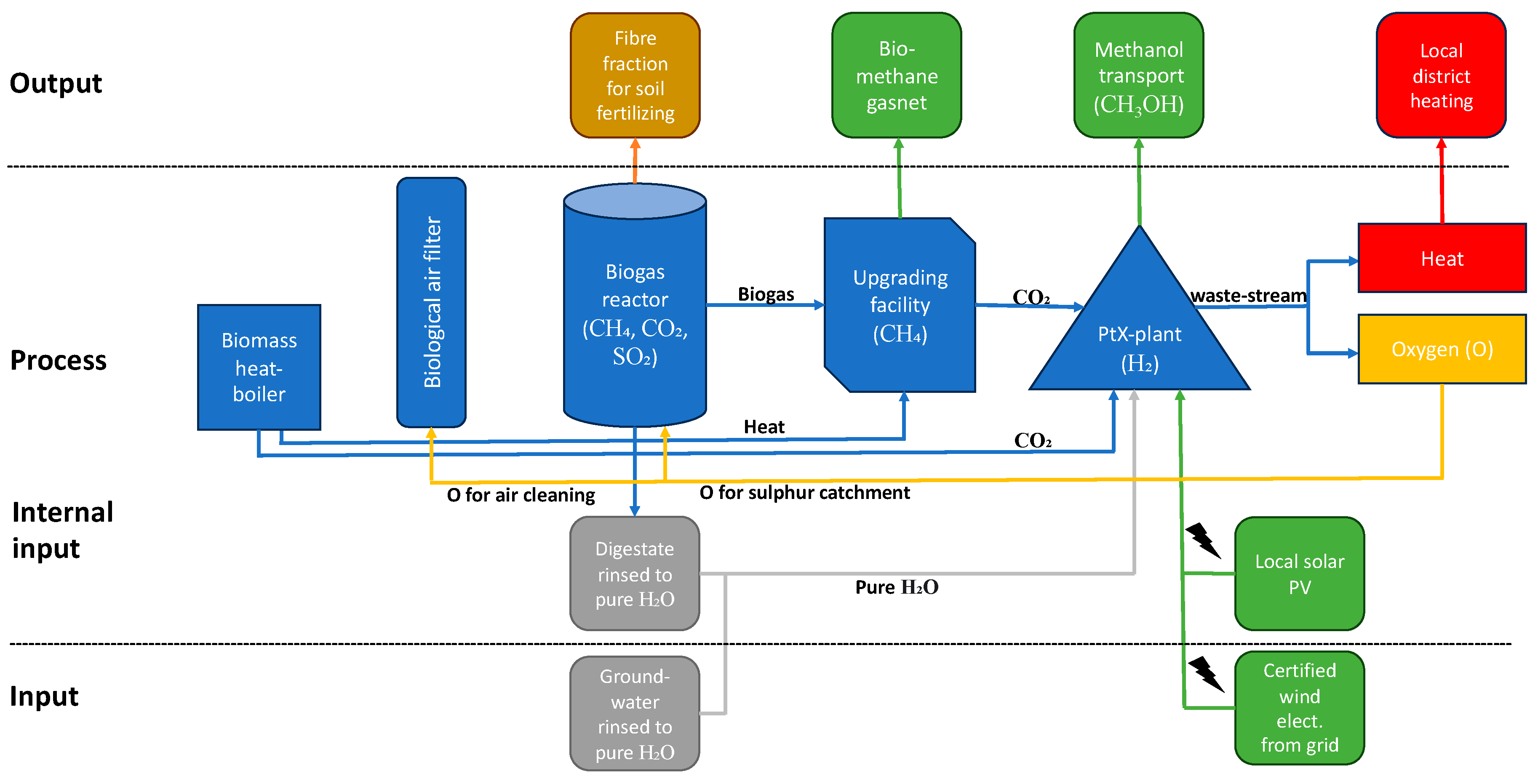

3.1.2. Case 2: Vinkel Bioenergy and PtX Plant (‘the Rural Case’, Figure 3)

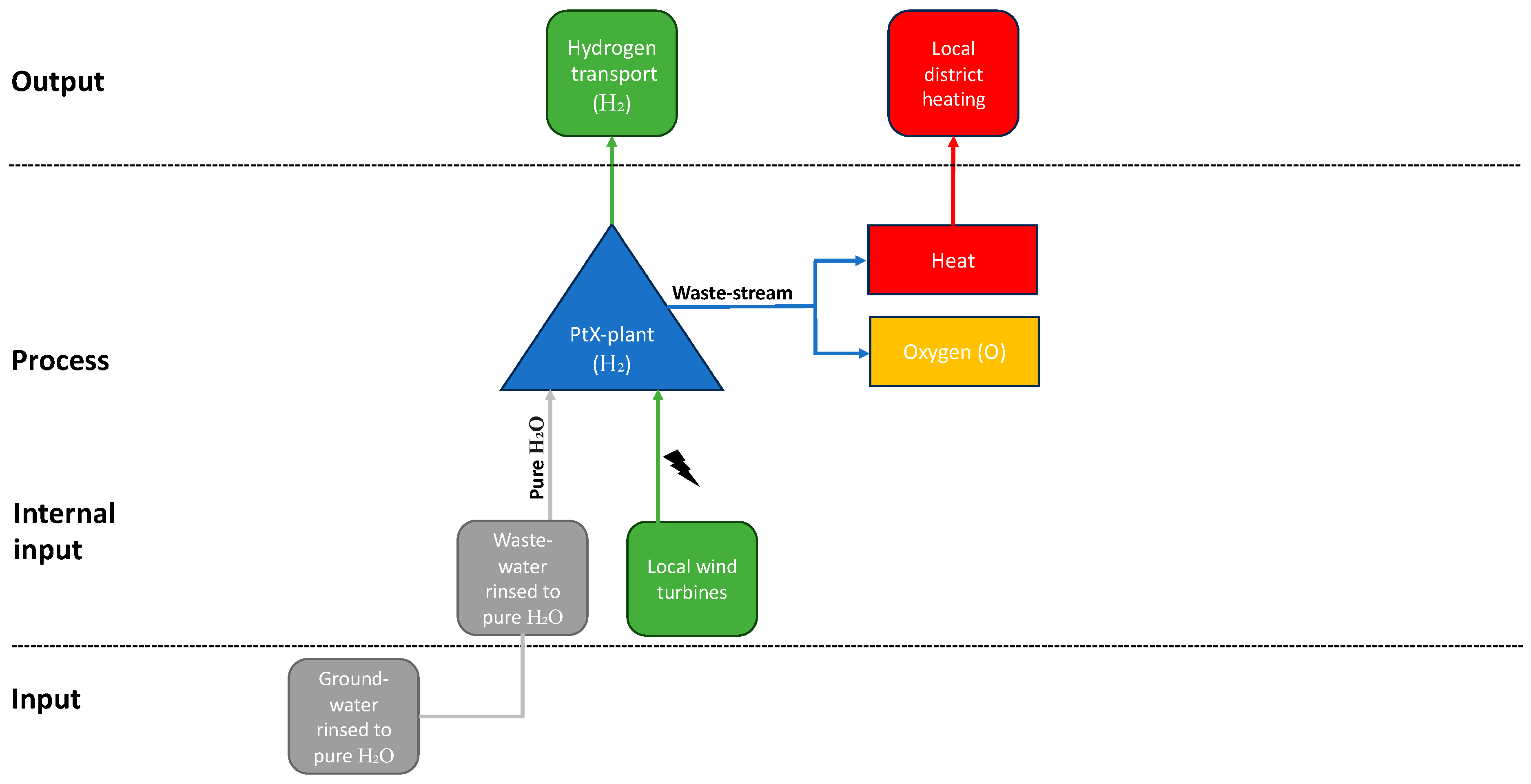

3.1.3. Case 3: DIN Forsyning and PtX Plant (‘the City Case’, Figure 4)

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A. Questionnaire for Interviews

- When was the PtX plant erected/planned to be erected?

- What was the motivation for implementing the technology?

- What types of energy carriers are produced?

- Are there any public grants or the like connected to the technology deployment?

- Where do the renewable energy sources (RES) come from? Do you have your own supply of RES from wind turbines or solar PV? Others?

- From where does the water for the electrolysis processes come from? Rinsed wastewater or groundwater resources? Others?

- Does the PtX plant rely on CO2 from biogenetic or non-biogenetic sources?

- How is waste heat being utilized, if at all? And, is this important?

- Pure oxygen outputs: Does the oxygen have any usage? Is this important?

- How does the layout/design of the PtX plant assist in stabilizing the fluctuating RES within the existing energy system?

- What are the future plans in relation to the PtX plant? To expand the production?

References

- Araya, S.S.; Cui, X.; Li, N.; Liso, V.; Sahlin, S.L. Power-to-X Technology Overview, Possibilities, and Challenges; Research Report by AAU Energy; Ålborg University: Ålborg, Denmark, 2022. [Google Scholar]

- Sorrenti, I.; Rasmussen, T.B.H.; Yiu, S.; Wu, Q. The role of power-to-X in hybrid renewable energy systems: A comprehensive review. Renew. Sustain. Energy Rev. 2022, 165, 112380. [Google Scholar] [CrossRef]

- Incer-Valverde, J.; Patino-Arevola, L.J.; Tsatsaronis, G.; Morosul, T. Hydrogen-driven Power-to-X: State of the art and multicriteria evaluation of a case study. Energy Convers. Manag. 2022, 266, 115814. [Google Scholar] [CrossRef]

- Genovese, M.; Schluter, A.; Scionti, E.; Piraino, F.; Corigliano, O.; Fragiacomo, P. Power-to-hydrogen and hydrogen-to-X energy systems for the industry of the future in Europe. Int. J. Hydrog. Energy 2023, 48, 16545–16568. [Google Scholar] [CrossRef]

- Danish Government. A Green and Sustainable World—The Danish Governments Long-Term Strategy for Global Climate Actions; The Danish Government: Copenhagen, Denmark, 2021; ISBN 978-87-93823-44-0. [Google Scholar]

- Goodstein, J. Brintproduktion og fjernvarme skal have fælles fremtid. In Fjernvarmen; nr. 2.; Dansk Fjernvarme Publ.: Kolding, Denmark, 2023; ISSN 0106-6234. [Google Scholar]

- Ministry of Climate, Energy and Distribution. Regeringens Strategi for POWER-TO-X; Danish Government: Copenhagen, Denmark, 2021; Available online: https://ens.dk/sites/ens.dk/files/ptx/strategy_ptx.pdf. (accessed on 17 June 2023).

- European Commission (EC). REPowerEU Plan; EC: Brussels, Belgium, 2022. [Google Scholar]

- Kountouris, I.; Langer, L.; Bramstoft, R.; Münster, M.; Keles, D. Power-to-X in energy hubs: A Danish case study of renewable fuel production. Energy Policy 2023, 175, 113439. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Net Zero Emissions by 2050; Technical Report; IEA: Paris, France, 2021. [Google Scholar]

- European Commission (EC). A Hydrogen Strategy for a Climate-Neutral Europe, 2020; EC: Brussels, Belgium, 2020. [Google Scholar]

- Fuel Cells and Hydrogen joint undertaking (FCH JU); EU. Hydrogen Roadmap Europe—A Sustainable Pathway for the European Energy Transition; EU: Luxemburg, 2019. [Google Scholar]

- Nørskov, P. I GW-Skala: Her Kommer de 7 Største PtX-Anlæg i Danmark Til at Ligge. Ingeniøren 2023. Available online: https://ing.dk/artikel/i-gw-skala-her-kommer-de-7-stoerste-ptx-anlaeg-i-danmark-til-ligge?check_logged_in=1 (accessed on 4 April 2023).

- Godske, B.; Hildebrandt, S. Mens vi Venter på Energiøen: Vores Nordsø-Naboer Rykker. Ingeniøren 2023, 23, 23–24. Available online: https://ing.dk/artikel/mens-vi-venter-paa-energioeen-vores-nordsoe-naboer-rykker (accessed on 19 April 2023).

- Gea-Bermúdez, J.; Kitzing, L.; Koivisto, M.; Das, K.; Murcia León, J.P.; Sørensen, P. The Value of Sector Coupling for the Development of Offshore Power Grids. Energies 2022, 15, 747. [Google Scholar] [CrossRef]

- European Commission (EC). Powering a Climate-Neutral Economy: An EU Strategy for Energy System Integration; EC: Brussels, Belgium, 2020. [Google Scholar]

- Sharif, S.; Rasmi, A.R.; Nebat, M.H.; Liu, J.J.; Arabkooshar, A.; Shahbakhti, M. Power-to-X. In Future Grid-Scale Energy Storage Solutions; Ahmad, A., Ed.; Elsevier: London, UK, 2023; Chapter 16; ISBN 0323907865. [Google Scholar]

- Nady, S.; El Fadil, H.; Koundi, M.; Hamed, A.; Giri, F. Power to X Systems: STATE-OF-THE-ART (PTX). IFAC PapersOnLine 2022, 55, 300–305. [Google Scholar] [CrossRef]

- Kumar, S.S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Bilbao, D.C. Valorization of waste heat given off in a system alkaline electrolyzer-photovoltaic array to improve hydrogen production performance: Case study Antofagasta, Chile. Int. J. Hydrog. Energy 2021, 46, 31108–31121. [Google Scholar] [CrossRef]

- Hu, Q.L.; Zeng, Q.; Fu, C.; Li, J. Optimal control of a hydrogen microgrid based on an experiment validated P2HH model. IET Renew Power Gener 2019, 14, 364–371. [Google Scholar] [CrossRef]

- Frank, E.; Gorre, J.; Ruoss, F.; Friedl, M.J. Calculation and analysis of efficiencies and annual performance of Power-to-Gas systems. Appl. Energy 2018, 218, 217–231. [Google Scholar] [CrossRef]

- van der Roest, E.; Bol, R.; Fens, T.; van Wijk, A. Utilisation of waste heat from PEM electrolysers—Unlocking local optimization. Int. J. Hydrog. Energy 2023, 48, 27872–27891. [Google Scholar] [CrossRef]

- Hermedmann, M.; Grübel, K.; Scherotzki, L.; Müller, T.E. Promising pathways: The geographic and energetic potential of power-to-x technologies based on regeneratively obtained hydrogen. Renew. Sustain. Rev. 2012, 138, 110644. [Google Scholar] [CrossRef]

- Bailera, M.; Lisbona, P.; Romeo, L.M.; Espatolero, S. Power to gas project review: Lab, pilot, and demo plants for storing renewable energy and CO2. Renew. Sustain. Rev. 2017, 69, 292–312. [Google Scholar] [CrossRef]

- Andersen, I. Valg af Organisations-Sociologiske Metoder; Samfundslitteratur Publ.: Frederiksberg, Denmark, 1990; ISBN 87-593-0229-3/8759302293. [Google Scholar]

- Yin, R. Case Study Research: Design and Methods, 5th ed.; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Yin, R. Case Study Research and Applications; Sage Publications, Inc.: Thousand Oaks, CA, USA, 2017. [Google Scholar]

- Kvale, S.; Brinkman, S. Interview—Det Kvalitative Forskningsinterview som Håndværk, 3rd ed.; Hans Reich Publ.: Copenhagen, Denmark, 2015. [Google Scholar]

- Bates, M.E. Finding Articles Online; Boulder Publ.: Boulder, CO, USA, 2006; Available online: https://www.searchenginewatch.com/2006/02/14/finding-articles-online// (accessed on 21 May 2023).

- Frosch, R.A.; Gallopoulos, N.E. Strategies for Manufacturing: Waste from one industrial process can serve as a raw material for another, thereby reducing the impact of industry on the environment. Sci. Am. 1989, 261, 144–152. [Google Scholar] [CrossRef]

- Jelenski, L.W.; Graedel, T.E.; Laudise, R.A.; McCall, D.W.; Patel, C.K.N. Industrial Ecology: Concept and Approaches. Proc. Natl. Acad. Sci. USA 1991, 89, 793–797. [Google Scholar] [CrossRef]

- Gertler, N. Industrial Ecosystems: Developing Sustainable Industrial Structures; Massachusetts Institute of Technology: Cambridge, MA, USA, 1995. [Google Scholar]

- Chertow, M. “Uncovering” Industrial Symbiosis. J. Clean. Prod. 2007, 11, 11–30. [Google Scholar]

- Albino, V.; Fraccascia, L.; Giannoccaro, I. Exploring the role of contrast to support the emergence of selforganized industrial symbiosis networks: An agent-based simulation study. J. Clean. Prod. 2016, 112, 4353–4366. [Google Scholar] [CrossRef]

- Petrikova, K.; Borsekova, K.; Blam, N. Industrial Symbiosis in European policy: Overview of recent progress. Folia Oeconomica 2016, 2, 87–100. [Google Scholar] [CrossRef]

- Li, X. Industrial Ecology and Industrial Symbiosis for Environmental Sustainability—Definitions, Frameworks and Applications, 1st ed.; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; ISBN 3-319-67501-X. [Google Scholar]

- Danish Energy Agency. Technology Data Renewable Fuels, 8th ed.; Technical report; Danish Energy Agency and Energinet: Copenhagen, Denmark, 2022. [Google Scholar]

- de Vasconcelos, B.R.; Lavoie, J.M. Recent advances in power-to-X technology for the production of fuels and chemicals. Front. Chem. 2019, 7, 1–24. [Google Scholar] [CrossRef]

- Saulnier, R.; Minnich, K.; Sturgess, P.K. Water for the Hydrogen Economy; Water Management Solutions—Water Smart Solutions Ltd.; Calgary Publ.: Calgary, AB, Canada, 2020; Available online: https://watersmartsolutions.ca/wp-content/uploads/2020/12/Water-for-the-Hydrogen-Economy_WaterSMART-Whitepaper_November-2020.pdf (accessed on 29 May 2023).

- Madsen, K. Manager at ’DIN Forsyning’. Interview and company visit in Esbjerg on the 6th of May 2023.

- Lillevang, L.B. CO2 Fra Biogas Kan Blive en Vigtig Ressource. Ingeniøren 2022, 11–13. Available online: https://ing.dk/artikel/co2-fra-biogas-kan-give-negative-udledninger-saadan-goer-vi (accessed on 27 July 2023).

- Wulf, C.; LinBen, J.; Zapp, P. Review of Power-to-Gas projects in Europe. Energy Procedia 2018, 155, 367–378. [Google Scholar] [CrossRef]

- Erdener, B.C.; Sergi, B.; Guerra, O.J.; Chueca, A.L.; Pambour, K.; Brancucci, C.; Hodge, B.M. A review of technical and regulatory limits for hydrogen blending in natural gas pipelines. Int. J. Hydrog. Energy 2023, 48, 5595–5617. [Google Scholar] [CrossRef]

- Angelidaki, I.; Luo, G.; Lyhne, P. Metangas Kan Blive en Genvej Til Brintsamfundet. In Forskning i Bioenergi, Brint & Brændselsceller; nr. 37; BioPress Publ.: Århus, Danmark, 2011; Available online: https://lemvigbiogas.com/wp-content/uploads/2021/01/FiB_37-2011.pdf (accessed on 23 June 2023).

- Wahid, R.; Horn, S.J. Impact of operational conditions on methane yield and microbial community composition during biological mechanization in in-situ and hybrid reactor systems. Biotechnol. Biofuels 2021, 14, 170. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, P.J. Biogas—Green Energy; Århus University: Åhus, Denmark, 2009. [Google Scholar]

- Bak, C.L.; da Silva, F.F. Pres Ikke Danmarkshistoriens Største Investering Igennem. Ingeniøren 2023, 15, 56–57. Available online: https://ing.dk/holdning/energioeer-pres-ikke-danmarkshistoriens-stoerste-investering-igennem (accessed on 25 August 2023).

- Larsen, A.B. Manager at GreenLab Skive. Interview and company visit in Spøttrup on the 4th of May 2023.

- Holst, T. Manager at Vinkel Bioenergy Plant. Interview and company visit in Vinkel on the 5th of May 2023.

- Danish Energy Agency. Biomassens Rolle i Power-to-X; Danish Energy Agency: Copenhagen, Denmark, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lybæk, R.; Kjær, T. Valorizing the Input and Output Waste Streams from Three PtX Case Studies in Denmark—Adopting a Symbiotic Approach. Waste 2023, 1, 884-900. https://doi.org/10.3390/waste1040051

Lybæk R, Kjær T. Valorizing the Input and Output Waste Streams from Three PtX Case Studies in Denmark—Adopting a Symbiotic Approach. Waste. 2023; 1(4):884-900. https://doi.org/10.3390/waste1040051

Chicago/Turabian StyleLybæk, Rikke, and Tyge Kjær. 2023. "Valorizing the Input and Output Waste Streams from Three PtX Case Studies in Denmark—Adopting a Symbiotic Approach" Waste 1, no. 4: 884-900. https://doi.org/10.3390/waste1040051

APA StyleLybæk, R., & Kjær, T. (2023). Valorizing the Input and Output Waste Streams from Three PtX Case Studies in Denmark—Adopting a Symbiotic Approach. Waste, 1(4), 884-900. https://doi.org/10.3390/waste1040051