Waste Gasification Technologies: A Brief Overview

Abstract

:1. Introduction

2. Thermal Gasification: General Principals

3. Gasification Technologies Used in Waste Conversion

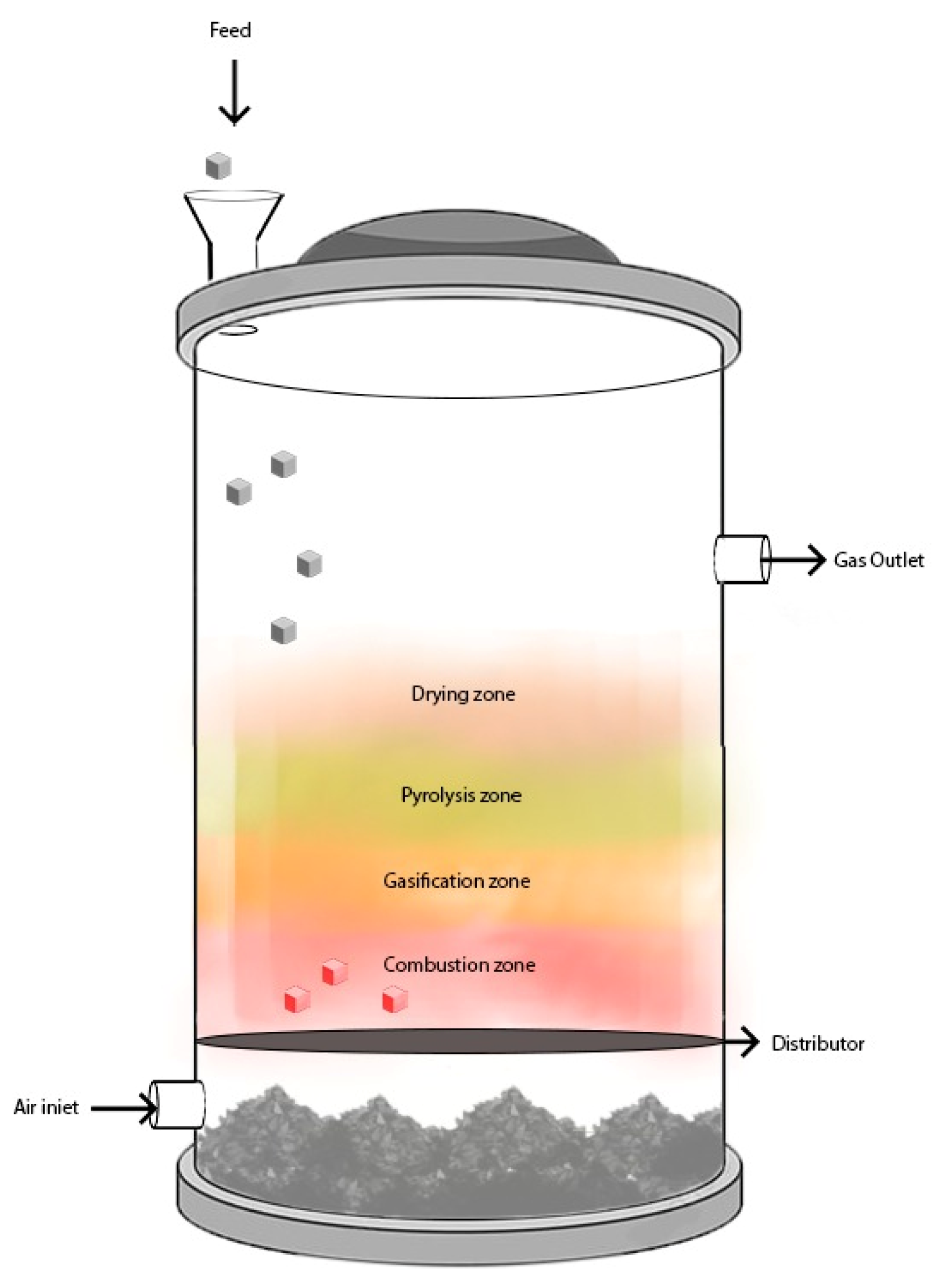

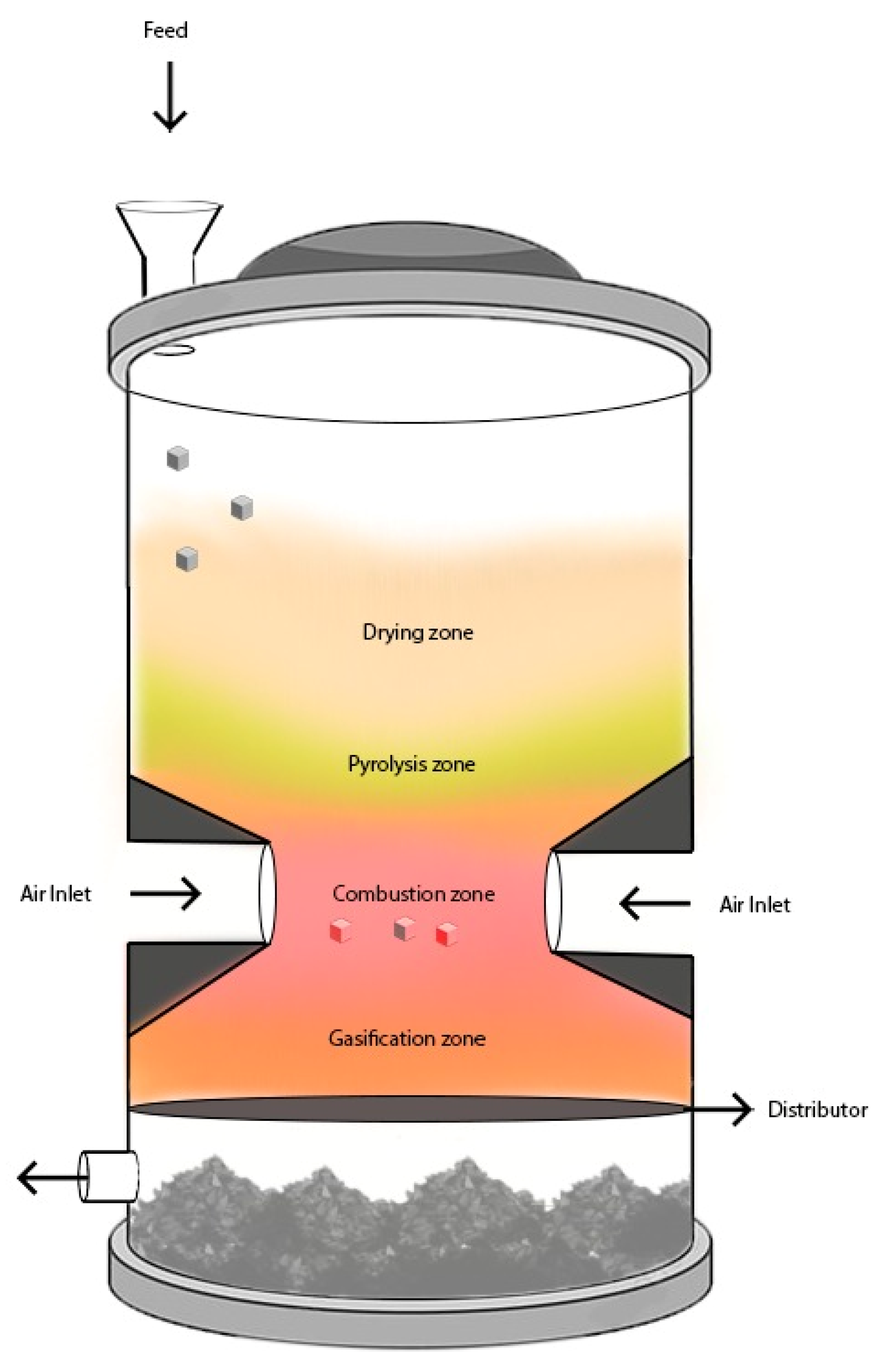

3.1. Fixed-Bed Reactors

3.2. Fluidized Bed Reactors

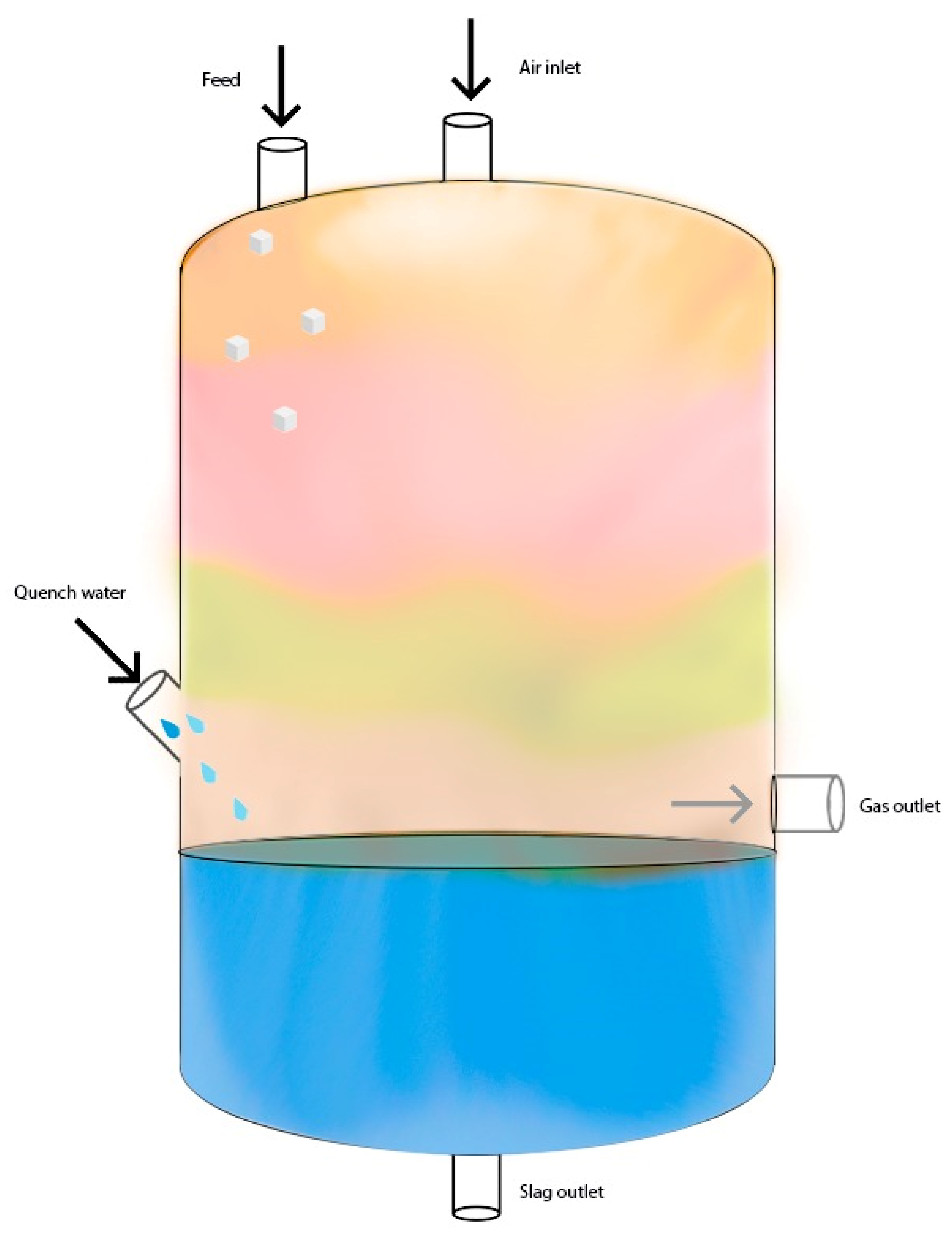

3.3. Entrained Flow Reactors

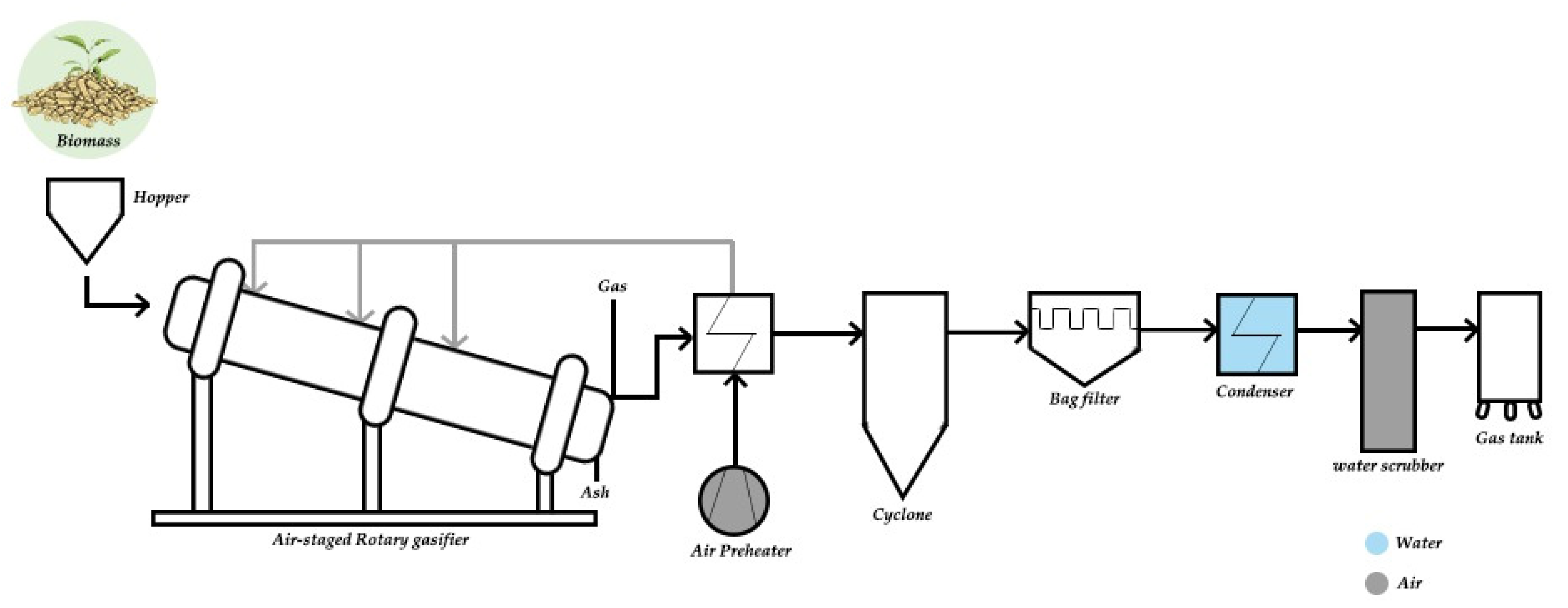

3.4. Rotary Kilns

3.5. Plasma Reactors

3.6. Emerging Gasification Technologies

4. Which Technology Is More Suitable for Waste Gasification?

4.1. Process Performance: Syngas Composition and Quality

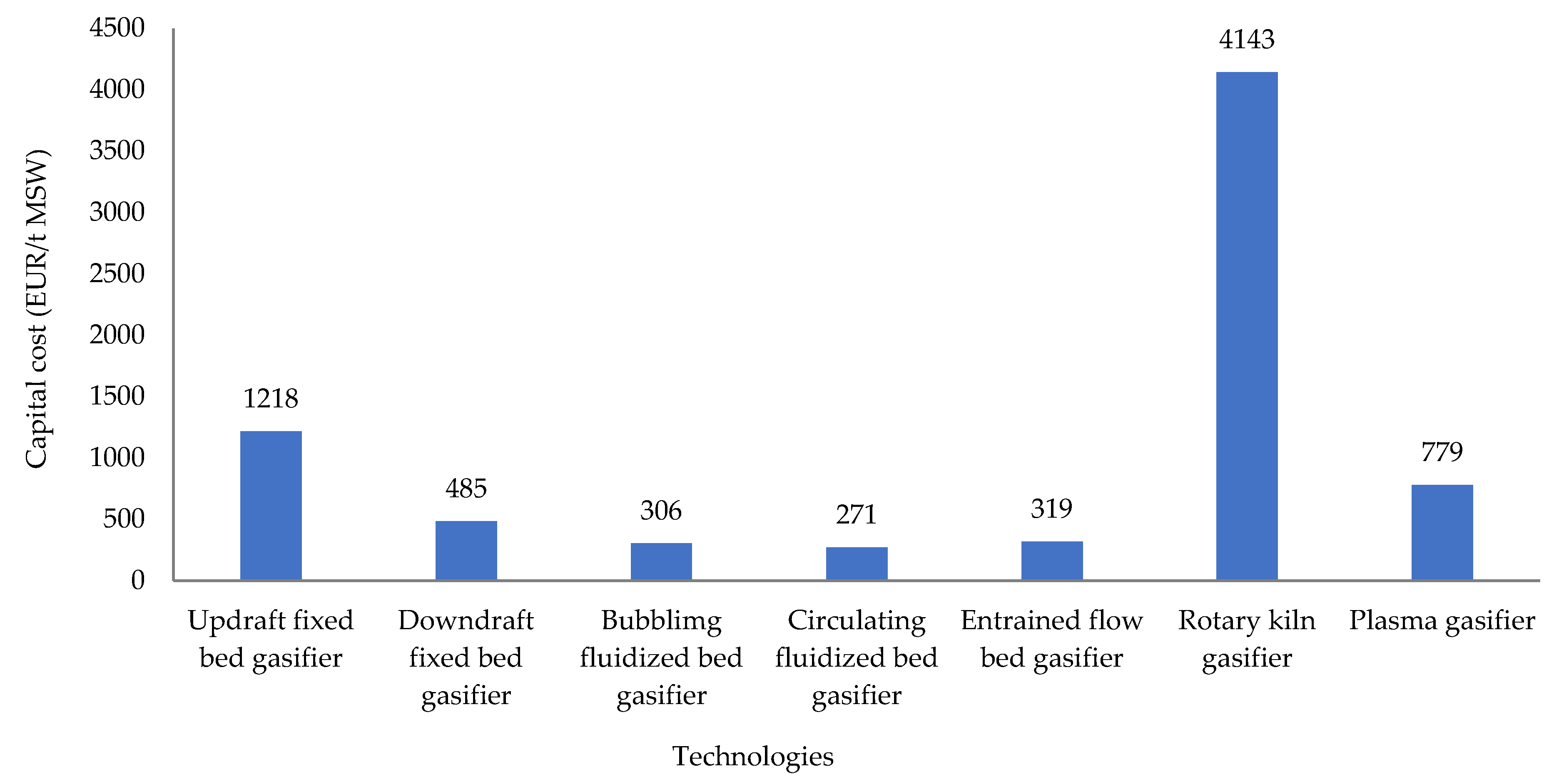

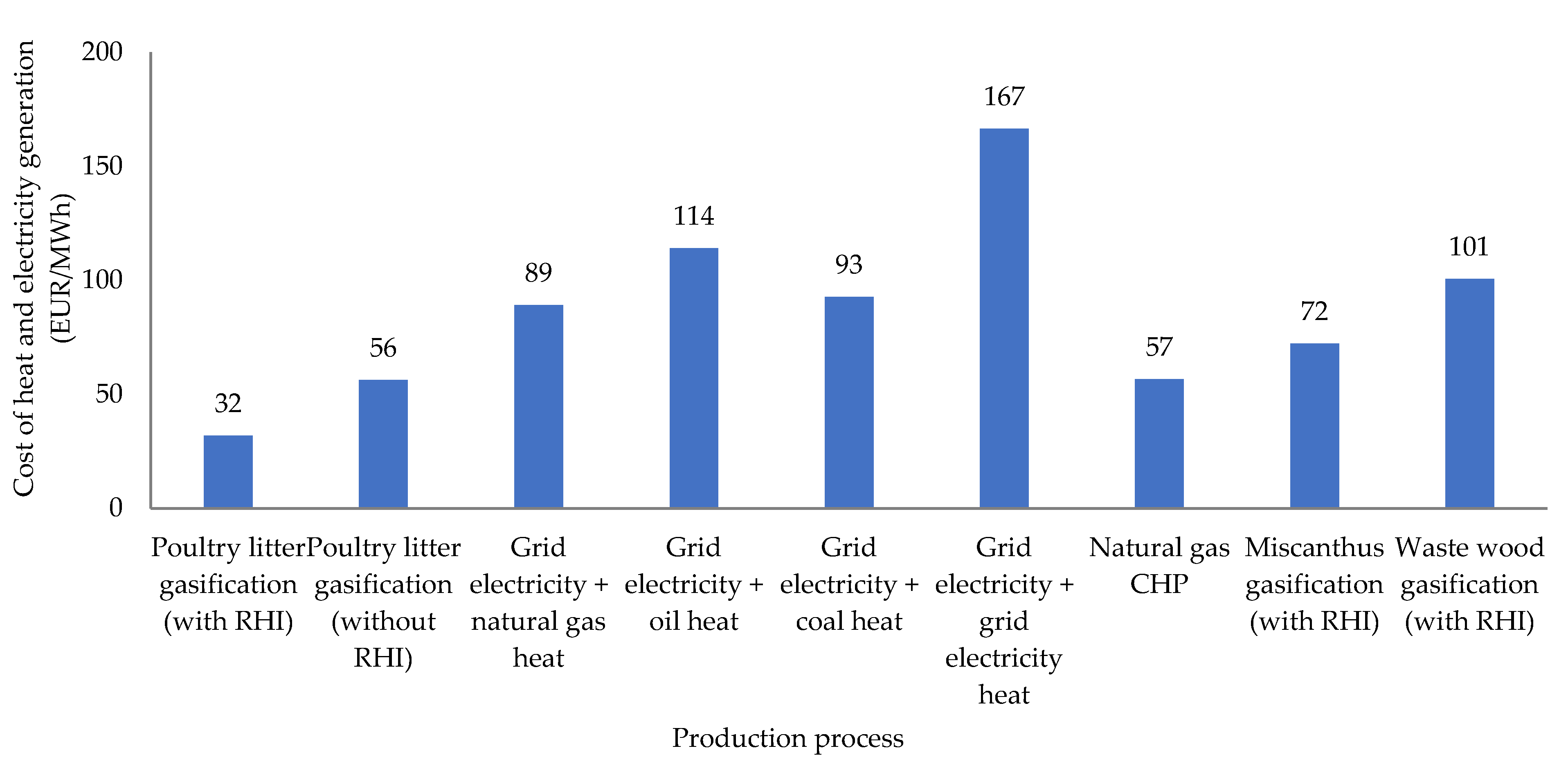

4.2. Economic Aspects of Waste Gasification Technologies

4.3. Advantages and Disadvantages of Different Waste Gasification Technologies

5. Commercial Scale Operational Waste Gasification Plants and Syngas Applications

5.1. Energy Works Hull

5.2. Enerkem Alberta Biofuels LP—Edmonton Waste-to-Biofuels Project

5.3. Lahti Energia Oy—Kymijärvi II

6. Operational Waste Gasification Projects (Lower TRL)

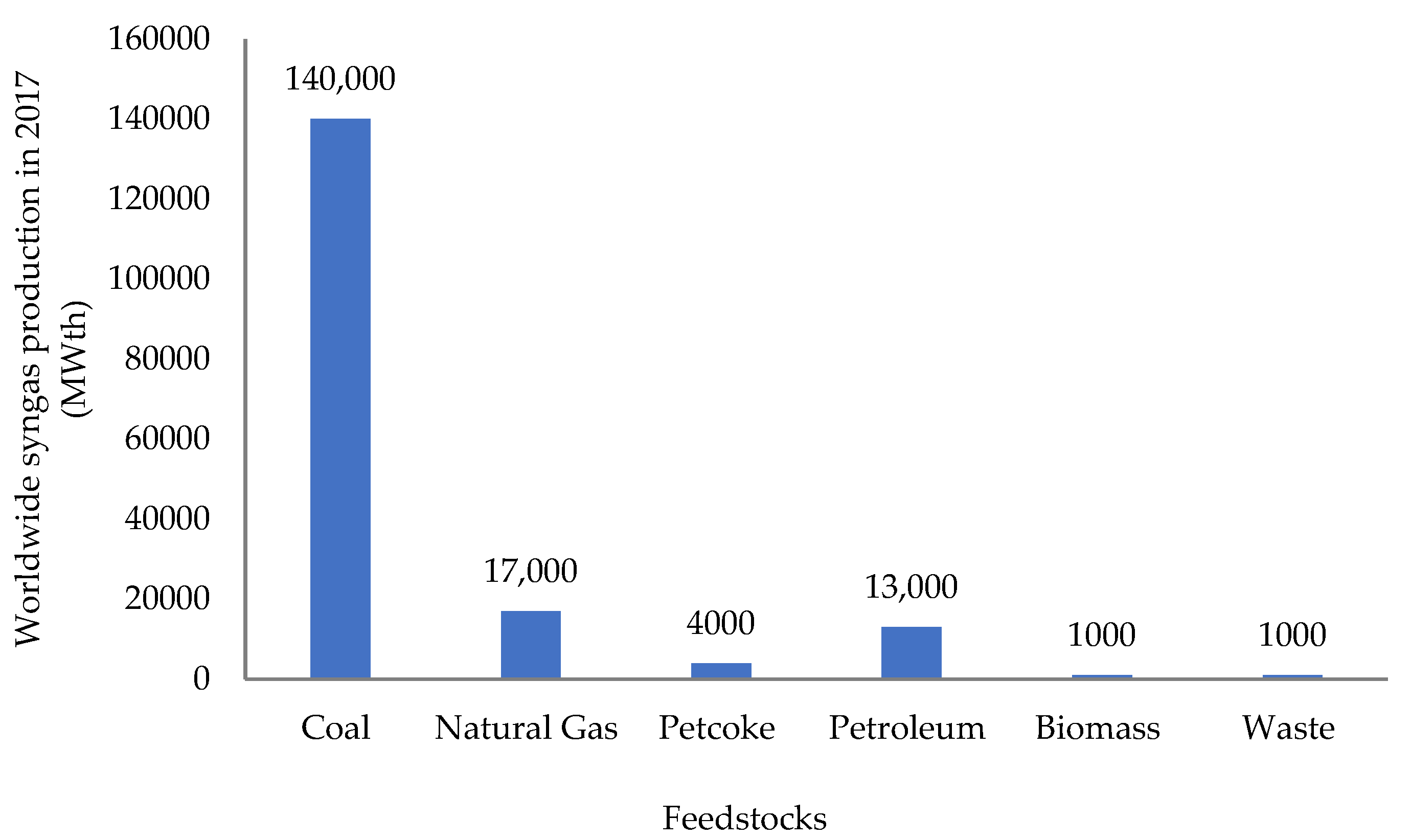

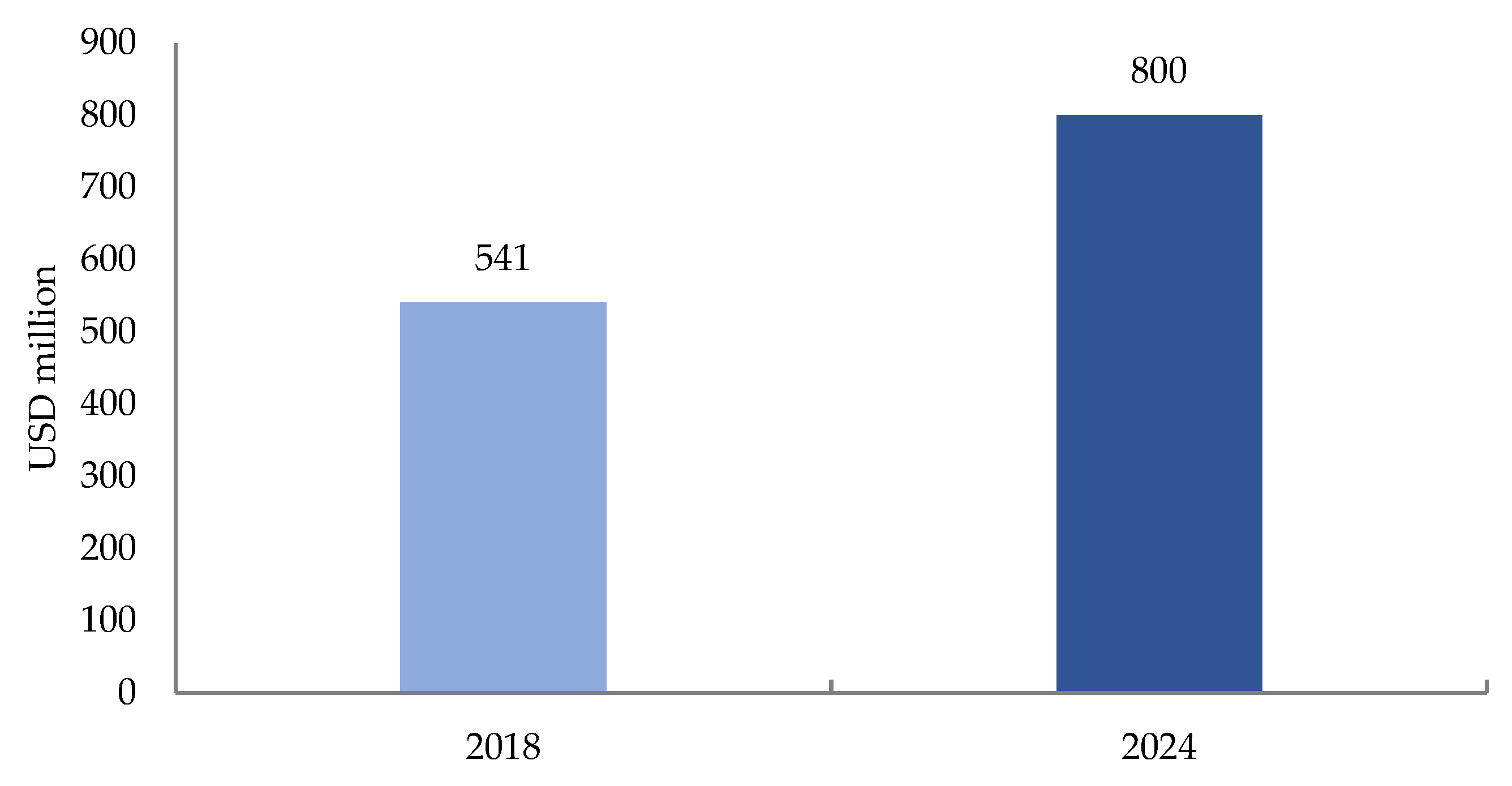

7. Outlook and Future Perspectives on Waste Gasification

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Tiseo, I. Global Waste Generation—Statistics & Facts. Available online: https://www.statista.com/topics/4983/waste-generation-worldwide (accessed on 13 October 2022).

- U.S. Environmental Agency. U.S. National Overview: Facts and Figures on Materials, Wastes and Recycling; U.S. Environmental Agency: Washington, DC, USA, 2018.

- Eurostat Municipal Waste Residues. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Municipal_waste_statistics (accessed on 5 October 2022).

- EN. Directive (EU) 2018/850 of the European Parliament and of the Council of 30 May 2018 Amending Directive 1999/31/EC on the Landfill of Waste. Off. J. L. 2018, 150, 100–108.

- Ozbay, G.; Jones, M.; Gadde, M.; Isah, S.; Attarwala, T. Design and Operation of Effective Landfills with Minimal Effects on the Environment and Human Health. J. Environ. Public Health 2021, 2021, 6921607. [Google Scholar] [CrossRef] [PubMed]

- Kaur, P.; Kaur, G.J.; Routray, W.; Rahimi, J.; Nair, G.R.; Singh, A. Recent Advances in Utilization of Municipal Solid Waste for Production of Bioproducts: A Bibliometric Analysis. Case Stud. Chem. Environ. Eng. 2021, 4, 100164. [Google Scholar] [CrossRef]

- Pires, J.R.A.; Souza, V.G.L.; Fernando, A.L. Production of Nanocellulose from Lignocellulosic Biomass Wastes: Prospects and Limitations. Innov. Eng. Entrep. 2019, 505, 719–725. [Google Scholar] [CrossRef]

- Peng, Y.; Lu, S.; Li, X.; Yan, J.; Cen, K. Formation, Measurement, and Control of Dioxins from the Incineration of Municipal Solid Wastes: Recent Advances and Perspectives. Energy Fuels 2020, 34, 13247–13267. [Google Scholar] [CrossRef]

- Fan, Y.V.; Klemeš, J.J.; Lee, C.T.; Perry, S. Anaerobic Digestion of Municipal Solid Waste: Energy and Carbon Emission Footprint. J. Environ. Manag. 2018, 223, 888–897. [Google Scholar] [CrossRef]

- Li, Q.; Faramarzi, A.; Zhang, S.; Wang, Y.; Hu, X.; Gholizadeh, M. Progress in Catalytic Pyrolysis of Municipal Solid Waste. Energy Convers. Manag. 2020, 226, 113525. [Google Scholar] [CrossRef]

- Hameed, Z.; Aslam, M.; Khan, Z.; Maqsood, K.; Atabani, A.E.; Ghauri, M.; Khurram, S.M.S.; Rehan, M.; Nizami, A.-S. Gasification of Municipal Solid Waste Blends with Biomass for Energy Production and Resources Recovery: Current Status, Hybrid Technologies and Innovative Prospects. Renew. Sustain. Energy Rev. 2021, 136, 110375. [Google Scholar] [CrossRef]

- Yi, S.; Jang, Y.-C.; An, A.K. Potential for Energy Recovery and Greenhouse Gas Reduction through Waste-to-Energy Technologies. J. Clean. Prod. 2018, 176, 503–511. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Rasul, M.G.; Akbar, D.; Narayanan, R.; Mofijur, M. Food Waste as a Source of Sustainable Energy: Technical, Economical, Environmental and Regulatory Feasibility Analysis. Renew. Sustain. Energy Rev. 2022, 166, 112577. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Azapagic, A. Assessing the Environmental Sustainability of Energy Recovery from Municipal Solid Waste in the UK. Waste Manag. 2016, 50, 346–363. [Google Scholar] [CrossRef]

- Ram, M.; Osorio-Aravena, J.C.; Aghahosseini, A.; Bogdanov, D.; Breyer, C. Job Creation during a Climate Compliant Global Energy Transition across the Power, Heat, Transport, and Desalination Sectors by 2050. Energy 2022, 238, 121690. [Google Scholar] [CrossRef]

- Zhang, Y.; Cui, Y.; Chen, P.; Liu, S.; Zhou, N.; Ding, K.; Fan, L.; Peng, P.; Min, M.; Cheng, Y.; et al. Gasification Technologies and Their Energy Potentials. In Sustainable Resource Recovery and Zero Waste Approaches; Elsevier: Amsterdam, The Netherlands, 2019; pp. 193–206. [Google Scholar]

- Alves, O.; Calado, L.; Panizio, R.M.; Gonçalves, M.; Monteiro, E.; Brito, P. Techno-Economic Study for a Gasification Plant Processing Residues of Sewage Sludge and Solid Recovered Fuels. Waste Manag. 2021, 131, 148–162. [Google Scholar] [CrossRef]

- Ksenia, V.; Nyashina, G.; Strizhak, P. Combustion, Pyrolysis, and Gasification of Waste-Derived Fuel. Appl. Sci. 2022, 12, 1039. [Google Scholar]

- Tollefson, J. What the War in Ukraine Means for Energy, Climate and Food. Nature 2022, 604, 232–233. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on Biomass Gasification: Gasifiers, Gasifying Mediums, and Operational Parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Hagos, F.Y.; Aziz, A.R.A.; Sulaiman, S.A. Trends of Syngas as a Fuel in Internal Combustion Engines. Adv. Mech. Eng. 2014, 6, 401587. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; Chacón-Pérez, Y.; Cardona-Alzate, A.C.A. Evaluation of Biogas and Syngas as Energy Vectors for Heat and Power Generation Using Lignocellulosic Biomass as Raw Material. Electron. J. Biotechnol. 2018, 33, 52–62. [Google Scholar] [CrossRef]

- Ding, L.; Yang, M.; Dong, K.; Vo, D.-V.N.; Hungwe, D.; Ye, J.; Ryzhkov, A.; Yoshikawa, K. Mobile Power Generation System Based on Biomass Gasification. Int. J. Coal Sci. Technol. 2022, 9, 34. [Google Scholar] [CrossRef]

- Zhai, P.; Li, Y.; Wang, M.; Liu, J.; Cao, Z.; Zhang, J.; Xu, Y.; Liu, X.; Li, Y.-W.; Zhu, Q.; et al. Development of Direct Conversion of Syngas to Unsaturated Hydrocarbons Based on Fischer-Tropsch Route. Chem 2021, 7, 3027–3051. [Google Scholar] [CrossRef]

- Xu, C.; Liao, B.; Pang, S.; Nazari, L.; Mahmood, N.; Tushar, S.M.S.H.K.; Dutta, A.; Ray, M.B. 1.19 Biomass Energy. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 770–794. [Google Scholar]

- Yang, Y.; Liew, R.K.; Tamothran, A.M.; Foong, S.Y.; Yek, P.N.Y.; Chia, P.W.; Van Tran, T.; Peng, W.; Lam, S.S. Gasification of Refuse-Derived Fuel from Municipal Solid Waste for Energy Production: A Review. Environ. Chem. Lett. 2021, 19, 2127–2140. [Google Scholar] [CrossRef] [PubMed]

- Heidenreich, S.; Foscolo, P.U. New Concepts in Biomass Gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- García, G.; Arauzo, J.; Gonzalo, A.; Sánchez, J.L.; Ábrego, J. Influence of Feedstock Composition in Fluidised Bed Co-Gasification of Mixtures of Lignite, Bituminous Coal and Sewage Sludge. Chem. Eng. J. 2013, 222, 345–352. [Google Scholar] [CrossRef]

- Fuchs, J.; Schmid, J.C.; Müller, S.; Mauerhofer, A.M.; Benedikt, F.; Hofbauer, H. The Impact of Gasification Temperature on the Process Characteristics of Sorption Enhanced Reforming of Biomass. Biomass Convers. Biorefinery 2020, 10, 925–936. [Google Scholar] [CrossRef] [Green Version]

- Gallucci, F.; Liberatore, R.; Sapegno, L.; Volponi, E.; Venturini, P.; Rispoli, F.; Paris, E.; Carnevale, M.; Colantoni, A. Influence of Oxidant Agent on Syngas Composition: Gasification of Hazelnut Shells through an Updraft Reactor. Energies 2019, 13, 102. [Google Scholar] [CrossRef] [Green Version]

- Rupesh, C.; Muraleedharan, C.; Arun, P. Influence of Residence Time on Syngas Composition in CaO Enhanced Air–Steam Gasification of Biomass. Environ. Dev. Sustain. 2022, 24, 8363–8377. [Google Scholar] [CrossRef]

- Ling, M.; Esfahani, M.J.; Akbari, H.; Foroughi, A. Effects of Residence Time and Heating Rate on Gasification of Petroleum Residue. Pet. Sci. Technol. 2016, 34, 1837–1840. [Google Scholar] [CrossRef]

- Kumar, A.; Jones, D.; Hanna, M. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef] [Green Version]

- Raibhole, N.V.; Sapali, S.N. Simulation of Biomass Gasification with Oxygen/Air as Gasifying Agent by ASPEN Plus. Adv. Mater. Res. 2012, 622–623, 633–638. [Google Scholar] [CrossRef]

- Basu, P. Gasification Theory. In Biomass Gasification, Pyrolysis and Torrefaction; Elsevier: Amsterdam, The Netherlands, 2018; pp. 211–262. [Google Scholar]

- Parvez, A.M.; Afzal, M.T.; Victor Hebb, T.G.; Schmid, M. Utilization of CO2 in Thermochemical Conversion of Biomass for Enhanced Product Properties: A Review. J. CO2 Util. 2020, 40, 101217. [Google Scholar] [CrossRef]

- Mukherjee, D.; Park, S.-E.; Reddy, B.M. CO2 as a Soft Oxidant for Oxidative Dehydrogenation Reaction: An Eco Benign Process for Industry. J. CO2 Util. 2016, 16, 301–312. [Google Scholar] [CrossRef]

- Wang, P.; Massoudi, M. Slag Behavior in Gasifiers. Part I: Influence of Coal Properties and Gasification Conditions. Energies 2013, 6, 784–806. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 1. Phase-Mineral and Chemical Composition and Classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Heidenreich, S.; Müller, M.; Foscolo, P.U. Advanced Biomass Gasification; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780128042960. [Google Scholar]

- Mazaheri, N.; Akbarzadeh, A.H.; Madadian, E.; Lefsrud, M. Systematic Review of Research Guidelines for Numerical Simulation of Biomass Gasification for Bioenergy Production. Energy Convers. Manag. 2019, 183, 671–688. [Google Scholar] [CrossRef]

- Ramos, A.; Monteiro, E.; Silva, V.; Rouboa, A. Co-Gasification and Recent Developments on Waste-to-Energy Conversion: A Review. Renew. Sustain. Energy Rev. 2018, 81, 380–398. [Google Scholar] [CrossRef]

- Chanthakett, A.; Arif, M.T.; Khan, M.M.K.; Oo, A.M.T. Performance Assessment of Gasification Reactors for Sustainable Management of Municipal Solid Waste. J. Environ. Manag. 2021, 291, 112661. [Google Scholar] [CrossRef]

- Pio, D.T.; Tarelho, L.A.C. Industrial Gasification Systems (>3 MWth) for Bioenergy in Europe: Current Status and Future Perspectives. Renew. Sustain. Energy Rev. 2021, 145, 111108. [Google Scholar] [CrossRef]

- Materazzi, M.; Lettieri, P.; Mazzei, L.; Taylor, R.; Chapman, C. Thermodynamic Modelling and Evaluation of a Two-Stage Thermal Process for Waste Gasification. Fuel 2013, 108, 356–369. [Google Scholar] [CrossRef] [Green Version]

- Buragohain, B.; Mahanta, P.; Moholkar, V.S. Biomass Gasification for Decentralized Power Generation: The Indian Perspective. Renew. Sustain. Energy Rev. 2010, 14, 73–92. [Google Scholar] [CrossRef]

- Ruiz, J.A.; Juárez, M.C.; Morales, M.P.; Muñoz, P.; Mendívil, M.A. Biomass Gasification for Electricity Generation: Review of Current Technology Barriers. Renew. Sustain. Energy Rev. 2013, 18, 174–183. [Google Scholar] [CrossRef]

- Tremel, A.; Becherer, D.; Fendt, S.; Gaderer, M.; Spliethoff, H. Performance of Entrained Flow and Fluidised Bed Biomass Gasifiers on Different Scales. Energy Convers. Manag. 2013, 69, 95–106. [Google Scholar] [CrossRef]

- Mazzoni, L.; Janajreh, I.; Elagroudy, S.; Ghenai, C. Modeling of Plasma and Entrained Flow Co-Gasification of MSW and Petroleum Sludge. Energy 2020, 196, 117001. [Google Scholar] [CrossRef]

- Molino, A.; Iovane, P.; Donatelli, A.; Braccioa, G.; Chianese, S.; Musmarra, D. Steam Gasification of Refuse-Derived Fuel in a Rotary Kiln Pilot Plant: Experimental Tests. Chem. Eng. Trans. 2013, 32, 337–342. [Google Scholar]

- Arena, U. Process and Technological Aspects of Municipal Solid Waste Gasification. A Review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef] [PubMed]

- Ou, Z.; Guo, L.; Chi, C.; Zhao, J.; Jin, H.; Thévenin, D. Fully Resolved Direct Numerical Simulation of Single Coal Particle Gasification in Supercritical Water. Fuel 2022, 329, 125474. [Google Scholar] [CrossRef]

- Wang, T.; Xu, J.; Liu, X.; He, M. Co-Gasification of Waste Lignin and Plastics in Supercritical Liquids: Comparison of Water and Carbon Dioxide. J. CO2 Util. 2022, 66, 102248. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, C.; Guo, S.; Liu, S.; Du, M.; Chen, Y.; Guo, L. Thermodynamic and Environmental Analysis of Heat Supply in Pig Manure Supercritical Water Gasification System. Energy 2023, 263, 125694. [Google Scholar] [CrossRef]

- Chen, J.; Fu, L.; Tian, M.; Kang, S.; E, J. Comparison and Synergistic Effect Analysis on Supercritical Water Gasification of Waste Thermoplastic Plastics Based on Orthogonal Experiments. Energy 2022, 261, 125104. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Q.; Xu, Z.; E, J.; Leng, E.; Zhang, F.; Liao, G. Process in Supercritical Water Gasification of Coal: A Review of Fundamentals, Mechanisms, Catalysts and Element Transformation. Energy Convers. Manag. 2021, 237, 114122. [Google Scholar] [CrossRef]

- Lee, U.; Chung, J.N.; Ingley, H.A. High-Temperature Steam Gasi Fi Cation of Municipal Solid Waste, Rubber, Plastic and Wood. Energy Fuels 2014, 28, 4573–4587. [Google Scholar] [CrossRef]

- Pio, D.T.; Gomes, H.G.M.F.; Tarelho, L.A.C.; Vilas-Boas, A.C.M.; Matos, M.A.A.; Lemos, F.S.M.S. Superheated Steam Injection as Primary Measure to Improve Producer Gas Quality from Biomass Air Gasification in an Autothermal Pilot-Scale Gasifier. Renew. Energy 2022, 181, 1223–1236. [Google Scholar] [CrossRef]

- Luo, S.; Zhou, Y.; Yi, C. Syngas Production by Catalytic Steam Gasification of Municipal Solid Waste in Fixed-Bed Reactor. Energy 2012, 44, 391–395. [Google Scholar] [CrossRef]

- Vonk, G.; Piriou, B.; Felipe Dos Santos, P.; Wolbert, D.; Vaïtilingom, G. Comparative Analysis of Wood and Solid Recovered Fuels Gasification in a Downdraft Fixed Bed Reactor. Waste Manag. 2019, 85, 106–120. [Google Scholar] [CrossRef]

- Arena, U.; Di Gregorio, F. Fluidized Bed Gasification of Industrial Solid Recovered Fuels. Waste Manag. 2016, 50, 86–92. [Google Scholar] [CrossRef]

- Thamavithya, M.; Dutta, A. An Investigation of MSW Gasification in a Spout-Fluid Bed Reactor. Fuel Process. Technol. 2008, 89, 949–957. [Google Scholar] [CrossRef]

- Agon, N.; Hrabovský, M.; Chumak, O.; Hlína, M.; Kopecký, V.; Mašláni, A.; Bosmans, A.; Helsen, L.; Skoblja, S.; Van Oost, G.; et al. Plasma Gasification of Refuse Derived Fuel in a Single-Stage System Using Different Gasifying Agents. Waste Manag. 2016, 47, 246–255. [Google Scholar] [CrossRef]

- Abdoulmoumine, N.; Kulkarni, A.; Adhikari, S.; Taylor, S.; Loewenstein, E. Economic Analysis of Municipal Power Generation from Gasification of Urban Green Wastes: Case Study of Fultondale, Alabama, USA. Biofuels Bioprod. Biorefining 2012, 6, 521–533. [Google Scholar] [CrossRef]

- Luz, F.C.; Rocha, M.H.; Lora, E.E.S.; Venturini, O.J.; Andrade, R.V.; Leme, M.M.V.; del Olmo, O.A. Techno-Economic Analysis of Municipal Solid Waste Gasification for Electricity Generation in Brazil. Energy Convers. Manag. 2015, 103, 321–337. [Google Scholar] [CrossRef]

- Yassin, L.; Lettieri, P.; Simons, S.J.R.; Germanà, A. Techno-Economic Performance of Energy-from-Waste Fluidized Bed Combustion and Gasification Processes in the UK Context. Chem. Eng. J. 2009, 146, 315–327. [Google Scholar] [CrossRef]

- Ramos, A.; Monteiro, E.; Rouboa, A. Biomass Pre-Treatment Techniques for the Production of Biofuels Using Thermal Conversion Methods—A Review. Energy Convers. Manag. 2022, 270, 116271. [Google Scholar] [CrossRef]

- Subramanian, A.S.R.; Gundersen, T.; Adams, T.A. Technoeconomic Analysis of a Waste Tire to Liquefied Synthetic Natural Gas (SNG) Energy System. Energy 2020, 205, 117830. [Google Scholar] [CrossRef]

- Ramos, A.; Berzosa, J.; Espí, J.; Clarens, F.; Rouboa, A. Life Cycle Costing for Plasma Gasification of Municipal Solid Waste: A Socio-Economic Approach. Energy Convers. Manag. 2020, 209, 112508. [Google Scholar] [CrossRef]

- Jeswani, H.K.; Whiting, A.; Martin, A.; Azapagic, A. Environmental and Economic Sustainability of Poultry Litter Gasification for Electricity and Heat Generation. Waste Manag. 2019, 95, 182–191. [Google Scholar] [CrossRef] [PubMed]

- Banco de Portugal. Available online: https://www.bportugal.pt/ (accessed on 20 September 2022).

- Arafat, H.A.; Jijakli, K. Modeling and Comparative Assessment of Municipal Solid Waste Gasification for Energy Production. Waste Manag. 2013, 33, 1704–1713. [Google Scholar] [CrossRef] [PubMed]

- Warnecke, R. Gasification of Biomass: Comparison of Fixed Bed and Fluidized Bed Gasifier. Biomass Bioenergy 2000, 18, 489–497. [Google Scholar] [CrossRef]

- Susastriawan, A.A.P.; Saptoadi, H. Small-Scale Downdraft Gasi Fi Ers for Biomass Gasi Fi Cation: A Review. Renew. Sustain. Energy Rev. 2017, 76, 989–1003. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent Advances in the Gasification of Waste Plastics. A Critical Overview. Renew. Sustain. Energy Rev. 2018, 82, 576–596. [Google Scholar] [CrossRef]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of Lignocellulosic Biomass in Fluidized Beds for Renewable Energy Development: A Review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Valderrama Rios, M.L.; González, A.M.; Lora, E.E.S.; Almazán del Olmo, O.A. Reduction of Tar Generated during Biomass Gasification: A Review. Biomass Bioenergy 2018, 108, 345–370. [Google Scholar] [CrossRef]

- Situmorang, Y.A.; Zhao, Z.; Yoshida, A.; Abudula, A.; Guan, G. Small-Scale Biomass Gasification Systems for Power Generation (<200 KW Class): A Review. Renew. Sustain. Energy Rev. 2020, 117, 109486. [Google Scholar] [CrossRef]

- Nobre, C.; Longo, A.; Vilarinho, C.; Gonçalves, M. Gasification of Pellets Produced from Blends of Biomass Wastes and Refuse Derived Fuel Chars. Renew. Energy 2020, 154, 1294–1303. [Google Scholar] [CrossRef]

- George, J.; Arun, P.; Muraleedharan, C. Experimental Investigation on Co-Gasification of Coffee Husk and Sawdust in a Bubbling Fluidised Bed Gasifier. J. Energy Inst. 2019, 92, 1977–1986. [Google Scholar] [CrossRef]

- Xue, G.; Kwapinska, M.; Horvat, A.; Kwapinski, W.; Rabou, L.P.L.M.; Dooley, S.; Czajka, K.M.; Leahy, J.J. Gasification of Torrefied Miscanthus×giganteus in an Air-Blown Bubbling Fluidized Bed Gasifier. Bioresour. Technol. 2014, 159, 397–403. [Google Scholar] [CrossRef]

- Jeong, Y.-S.; Choi, Y.-K.; Park, K.-B.; Kim, J.-S. Air Co-Gasification of Coal and Dried Sewage Sludge in a Two-Stage Gasifier: Effect of Blending Ratio on the Producer Gas Composition and Tar Removal. Energy 2019, 185, 708–716. [Google Scholar] [CrossRef]

- Sarker, T.R.; Nanda, S.; Meda, V.; Dalai, A.K. Process Optimization and Investigating the Effects of Torrefaction and Pelletization on Steam Gasification of Canola Residue. Fuel 2022, 323, 124239. [Google Scholar] [CrossRef]

- Nobre, C. Thermochemical Upgrading of Refuse Derived Fuel; NOVA School of Science and Technology: Caparica, Portugal, 2019. [Google Scholar]

- Pio, D.T.; Tarelho, L.A.C.; Tavares, A.M.A.; Matos, M.A.A.; Silva, V. Co-Gasification of Refused Derived Fuel and Biomass in a Pilot-Scale Bubbling Fluidized Bed Reactor. Energy Convers. Manag. 2020, 206, 112476. [Google Scholar] [CrossRef]

- Pinto, F.; Lopes, H.; André, R.N.; Gulyurtlu, I.; Cabrita, I. Effect of Catalysts in the Quality of Syngas and By-Products Obtained by Co-Gasification of Coal and Wastes. 1. Tars and Nitrogen Compounds Abatement. Fuel 2007, 86, 2052–2063. [Google Scholar] [CrossRef]

- Status Report on Thermal Gasification of Biomass and Waste. Available online: https://www.ieabioenergy.com/blog/task/thermal-gasification-of-biomass (accessed on 11 October 2022).

- Kota, B.K.; Shenbagaraj, S.; Sharma, P.K.; Sharma, P.K.; Ghodke, P.K.; Ghodke, P.K. Biomass Torrefaction: An Overview of Process and Technology Assessment Based on Global Readiness Level. Fuel 2022, 324, 124663. [Google Scholar] [CrossRef]

- Sajid, M.; Raheem, A.; Ullah, N.; Asim, M.; Ur Rehman, S.M.S.; Ali, N. Gasification of Municipal Solid Waste: Progress, Challenges, and Prospects. Renew. Sustain. Energy Rev. 2022, 168, 112815. [Google Scholar] [CrossRef]

- Energy Works. Available online: http://energyworkshull.co.uk/about/ (accessed on 7 October 2022).

- Production Facilities. Available online: https://www.etipbioenergy.eu/databases/production-facilities (accessed on 22 July 2022).

- ENERKEM. Available online: https://enerkem.com/ (accessed on 28 September 2022).

- Fulcrum Bioenergy. Available online: https://www.fulcrum-bioenergy.com/sierra-biofuels (accessed on 7 October 2022).

- Valmet Gasifier for Biomass and Waste. Available online: https://www.valmet.com/energyproduction/gasification/ (accessed on 28 September 2022).

- E4tech Review of Technologies for Gasification of Biomass and Wastes. Available online: https://www.e4tech.com/uploads/files/NNFCC_final_report_E4tech_090609.pdf (accessed on 7 October 2022).

- The Montgomery Project. Available online: http://www.taylorbiomassenergy.com/taylorbiomass04_mont_mn.html (accessed on 7 October 2022).

- Estatus Report on Thermal Biomass Gasification in Countries Participating in IEA Bioenergy Task 33. Available online: https://www.ieabioenergy.com/blog/publications/status-report-on-thermal-biomass-gasification-in-countries-participating-in-iea-bioenergy-task-33/ (accessed on 28 September 2022).

- Commercial Ethanol Production Start at Enerkem’s MSW to Biofuels Facility. Available online: https://bioenergyinternational.com/commercial-ethanol-production-start-enerkems-msw-biofuels-facility/ (accessed on 16 September 2017).

- LAHTI ENERGIA. Available online: https://www.lahtienergia.fi/ (accessed on 7 October 2022).

- Lee, R.P.; Seidl, L.G.; Huang, Q.; Meyer, B. An Analysis of Waste Gasification and Its Contribution to China’s Transition towards Carbon Neutrality and Zero Waste Cities. J. Fuel Chem. Technol. 2021, 49, 1057–1076. [Google Scholar] [CrossRef]

- Vaish, B.; Sharma, B.; Srivastava, V.; Singh, P.; Ibrahim, M.H.; Singh, R.P. Energy Recovery Potential and Environmental Impact of Gasification for Municipal Solid Waste. Biofuels 2019, 10, 87–100. [Google Scholar] [CrossRef]

- Maitlo, G.; Ali, I.; Mangi, K.H.; Ali, S.; Maitlo, H.A.; Unar, I.N.; Pirzada, A.M. Thermochemical Conversion of Biomass for Syngas Production: Current Status and Future Trends. Sustainability 2022, 14, 2596. [Google Scholar] [CrossRef]

- Thomson, R.; Kwong, P.; Ahmad, E.; Nigam, K.D.P. Clean Syngas from Small Commercial Biomass Gasifiers; a Review of Gasifier Development, Recent Advances and Performance Evaluation. Int. J. Hydrogen Energy 2020, 45, 21087–21111. [Google Scholar] [CrossRef]

- Mishra, R.; Singh, E.; Kumar, A.; Ghosh, A.; Lo, S.-L.; Kumar, S. Co-Gasification of Solid Waste and Its Impact on Final Product Yields. J. Clean. Prod. 2022, 374, 133989. [Google Scholar] [CrossRef]

- Lee, D.J. Gasification of Municipal Solid Waste (MSW) as a Cleaner Final Disposal Route: A Mini-Review. Bioresour. Technol. 2022, 344, 126217. [Google Scholar] [CrossRef]

- Shen, Y.; Yoshikawa, K. Recent Progresses in Catalytic Tar Elimination during Biomass Gasification or Pyrolysis—A Review. Renew. Sustain. Energy Rev. 2013, 21, 371–392. [Google Scholar] [CrossRef]

- Papadis, E.; Tsatsaronis, G. Challenges in the Decarbonization of the Energy Sector. Energy 2020, 205, 118025. [Google Scholar] [CrossRef]

- Gasification: A Sustainable Technology for Circular Economies. Scaling up to Reach Net-Zero by 2050. Available online: https://www.europeanbiogas.eu/new-paper-proves-potential-of-gasification-to-scale-up-and-support-net-zero-by-2050/ (accessed on 21 October 2022).

- Syngas & Derivatives Market by Production Technologies, Gasifier Type, Feedstock (Coal, Natural Gas, Petroleum Byproducts, Biomass/Waste), Application (Chemical, Fuel, and Electricity), and Regions- Global Forecast to 2025. Available online: https://www.marketsandmarkets.com/Market-Reports/syngas-market-1178.html (accessed on 21 October 2022).

- The Global Gasification Market Is Projected to Grow from USD 464.05 Billion in 2021 to USD 663.72 Billion in 2028 at a CAGR of 5.3% in the 2021–2028 Period. Available online: https://www.fortunebusinessinsights.com/gasification-market-103487 (accessed on 21 October 2022).

- Shahabuddin, M.; Alam, T. Gasification of Solid Fuels (Coal, Biomass and MSW): Overview, Challenges and Mitigation Strategies. Energies 2022, 15, 4444. [Google Scholar] [CrossRef]

- Global Waste-to-Energy Market Is Projected to Grow at a CAGR of 3.3% by 2032: Visiongain Reports Ltd. Available online: https://www.globenewswire.com/news-release/2022/08/11/2496400/0/en/Global-Waste-to-Energy-market-is-projected-to-grow-at-a-CAGR-of-3-3-by-2032-Visiongain-Reports-Ltd.html (accessed on 21 October 2022).

- Biomass Gasification Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027. Available online: https://www.imarcgroup.com/biomass-gasification-plant (accessed on 21 October 2022).

- Porshnov, D. Evolution of Pyrolysis and Gasification as Waste to Energy Tools for Low Carbon Economy. WIREs Energy Environ. 2022, 11, e421. [Google Scholar] [CrossRef]

- Chan, Y.H.; Syed Abdul Rahman, S.N.F.; Lahuri, H.M.; Khalid, A. Recent Progress on CO-Rich Syngas Production via CO2 Gasification of Various Wastes: A Critical Review on Efficiency, Challenges and Outlook. Environ. Pollut. 2021, 278, 116843. [Google Scholar] [CrossRef]

| Reaction | Name | Mechanism |

|---|---|---|

| O2 → CO | Partial oxidation | Endotermic |

| C + CO2 → 2CO | Boudouard reaction | Endotermic |

| C + H2O → CO + H2 | Water gas reaction | Endotermic |

| C + 2H2 → C H4 | Methanation reaction | Endotermic |

| O2 → CO2 | Complete oxidation | Endotermic |

| O2 → H2O | Oxidation of H2 | Endotermic |

| CO + H2O → CO2 + H2 | Water gas shift reaction | Endotermic |

| CH4 + H2O → CO + 3 H2 | Steam reforming reaction | Exotermic |

| Reactor Type | Feedstock | Gas Composition (%vol., db) | Tar Concentration | LHV(MJ/kg) | Reference | ||||

|---|---|---|---|---|---|---|---|---|---|

| CO | CO2 | H2 | CH4 | N2 | |||||

| Updraft fixed-bed | MSW (Steam atmosphere) | 11–23 | 21–38 | 34–54 | 1–10 | - | 0–8% | [59] | |

| Downdraft fixed-bed | SRF (Based on MSW) | 13–14 | 13–15 | 10–15 | 2–3 | 53–60 | 67–140 g/m3 | 4–5 MJ/Nm3 | [60] |

| Bubbling fluidized bed | SRF (80%plastics, 20% cellulose) | 6.6 | 12.7 | 6.0 | 6.5 | 63.4 | 34 g/Nm3 | 7.4 MJ/Nm3 | [61] |

| Circulating fluidized bed | MSW | 15–19 | 17–18 | 7–10 | ~3 | - | 11–15 g/Nm3 | 4.4–4.59 MJ/Nm3 | [62] |

| Entrained flow bed | MSW | 23–43% (mole fraction) | - | 11–22% (mole fraction) | - | - | - | 3.5–7.5 MJ/kg syngas | [49] |

| Rotary kiln | RDF (steam atmosphere) | 2.2–16.8 | 20.1–25.3 | 59.1–66.9 | 3–5.6 | - | - | 15–16 MJ/kg syngas | [50] |

| Plasma | RDF | 27–46 | 4–18 | 26–52 | 2–4 | - | 132–543 mg/Nm3 | 9–10.9 MJ/Nm3 | [63] |

| Reactor | Feed | Plant Description | Remark | Reference |

|---|---|---|---|---|

| Updraft fixed-bed | Green waste | The reactor efficiencies assumed are 0.65, operating at 85% of its maximum capacity and 1811 t/y; power generation capacity 100 kWe. | Leveled unit cost of electricity of 41 ¢/kWh. Updraft gasification system resulted in a higher cost of electricity, owing to its higher capital investment and production costs. | [64] |

| Downdraft fixed-bed | MSW/SRF | The installed power ranges from 96 kW with 3.35 t of MSW/day to 35,000 kW with 2665 t of MSW/day; project life of 20 years; The net electrical power produced ranges from 391 kWhe/t dry waste to 1232 kWhe/t dry waste. | Income with sale of electricity (USD 8146–20,311,897 million per year). Economic performance of a MSW gasification facility is largely dependent on its size; the larger the plant in capacity, the higher the installed power, the capacity utilization factor, the electrical efficiency, and the overall economic performance. | [65] |

| Bubbling fluidized bed | MSW/RDF | Fluidized bed gasifier for small and medium scale (50 and 100 kt/y) power generation from MSW. Comparison to an equivalent combustion unit was performed. Overall system efficiency, net generated electricity, and capital costs ranged from 23–27%, 7–16 MWe, and EUR 28–45 million, respectively. | The results show that gasification systems represent the cheapest option and showed better results than the combustion unit. Fluidized bed gasification coupled with a combined cycle gas turbine offers the most energy efficient treatment option and is the most attractive treatment option in terms of gate fees and levelized costs of waste treatment. | [66] |

| Circulating fluidized bed | Cork waste | Gasification plant projected with the capacity to treat 12 kg/day to produce 10 kW of electrical (kWe) energy and 20 kW of thermal (kWth) energy. | Char valorization depicted the most sustainable profile, amongst other scenarios. Gasification strategy entails lower costs than the conventional scheme of energy production and allows net savings in the order of several hundred thousand euros, for a 20-year lifespan of the plant. | [67] |

| Entrained flow bed | Biomass | Oxygen entrained flow gasifier from 10 MWth to 500 MWth, including a 260 °C torrefaction unit. Net efficiency is from 65–71%; gas output is from 6.45–354.0 MW; gas product cost is from EUR 4.2–7.3 cents per kWh. Comparison to a fluidized bed gasifier unit was performed. | Both gasification technologies show a similar performance. However, the entrained flow reactor might be advantageous due to its simpler operation and higher reliability. The plant scale is an important parameter for the production costs of gas. Due to the specific lower investment costs, a larger gasifier throughput is favorable. The entrained flow reactor is also competitive technology for biomass gasification on a smaller scale. | [48] |

| Rotary kiln | Waste tires | Production of liquefied synthetic natural gas (SNG) from waste tires via a rotary kiln gasification process; 26.3 kg/s of waste tire are processed; overall fuel efficiency of 54.2%; for each kg of waste tire converted, 0.37 kg of liquefied SNG is obtained The liquefied SNG produced contains at least 99.5 mol% CH4. | Minimum selling prices of USD 16.7 per GJLHV SNG are required. This price may become competitive under certain regulatory conditions (such as recent public policy movement in British Columbia, Canada, requiring public utilities to purchase natural gas made from renewables at prices up to USD 30 per GJLHV, SNG). The minimum selling price reduces substantially with process scale and with levying tipping fees. | [68] |

| Plasma | MSW | Plasma gasification plant with a useful life of 20 years; Capacity 750 t/d | Plasma gasification depicted high capital costs while enabling higher revenues. The most advantageous situation was the combination of selling electricity and vitrified slag (rather than electricity alone), which afforded revenues over 113 € per ton of treated MSW, lowering the final treatment cost from EUR 23 to 1.74 per ton. Although the plasma gasification project presented feasibility, Portugal was seen as the least favorable country (of some European countries). | [69] |

| Reactor | Technical Conditions | Advantage | Disadvantage | References | |

|---|---|---|---|---|---|

| Fixed-bed | Updraft | Moisture content < 50%; bulk density > 400 kg/m3; ash content < 15% db. | High thermal efficiency. Product gas suitable for direct firing. | Product gas contains tar, oil, phenols, and ammonia (require separation and cleanup steams). Extensive gas clean-up needed for engines. | [51,73] |

| Downdraft | Moisture content < 20%; bulk density > 500 kg/m3; ash content < 5% db. | Suitable for small-scale applications. Easy fabrication and operation. Low tar content in producer gas. Relatively clean gas is produced. Low catalyst attrition. | Suitable only for raw materials with low moisture content. Limitation in raw-material size. High dust content in product gas. | [51,73,74] | |

| Fluidized bed | Bubbling | Moisture content < 55%; bulk density > 100 kg/m3; ash content < 25% db. | Easy operation. High heat and mass transfer rates, excellent gas–solid contact, good control of temperature, solid mixing regime and flexibility. Good scale-up potential. Continues in-bed catalytic processing possible. Greater tolerance to particle size range than fixed-beds. Varying water content tolerable. Low investment. | High investment cost, limitations in particle size in both bed and feed, defluidization problems. and entrainment of unreacted material. Catalyst attrition can be critical. Slow oxygen diffusion rate, which creates an oxidizing condition in the whole bed reducing the gasification efficiency. | [51,73,75,76] |

| Circulating | Moisture content < 55%; bulk density > 100 kg/m3; ash content < 25% db. | Allow obtaining high conversion and low tar yields. Very good scale-up potential. Variety of particle sizes can be handled. | Operation can be more difficult then fixed-bed. Pressure drop is higher than bubbling bed. In-bed catalytic processing hardly possible. High energy requirement for fans (for fluidizing air). Need to add solid separation and return equipment, which increases investment costs as well as process control problems. | [73,75,76] | |

| Entrained flow | Moisture content < 15%; bulk density > 400 kg/m3; ash content < 20% db. | The higher availability, the higher throughput and the better product gas quality. Higher efficiency (Cold Gas Efficiency and liquid) when operated at larger scale (100–500 MWth). Suitable for high capacities. | Higher costs, complex, fuel size restrictions. Solid feedstock needs to be ground to a small particle size because the residence time of the fuel particles in the hot reaction zone is short (less than 10 s). | [42,48] | |

| Rotary kiln | No problem with moisture content; bulk density > 100 kg/m3; ash content < 40% db. | No problems with waste characteristics (flexible moisture content and feedstock size). Low capital cost. Simple operation. | Issues on starting and controlling the temperature. High energy supply. Low energy output and a high amount of residue. Some problems on scale-up. | [43,61] | |

| Plasma | No problem with moisture content; bulk density >100 kg/m3; no problem with ash content. | Various types of raw materials can be decomposed without the need for pre-processing and pre-treatment. Reaches high temperature, which promotes an almost complete cracking of tar compounds and, therefore, high gas yields. Significant low emission. Higher efficiency. | Need of high temperature condition of this gasification can increase the operational cost of the reactor. Requires a very large amount of electricity in the system, roughly from 1200–2500 MJ per ton of MSW, so it would be a critical point using as a commercial MSW gasification. Security issues. | [43,61,75] |

| Owner/Project Name | Country | Feedstock | Output | TRL | Reference |

|---|---|---|---|---|---|

| Emamejeriet AB/Emamejeriet (Ema dairy) | Sweden | Forest residues | Electricity (0.04 MWel) | 8 | [87] |

| Heat (0.1 MWth) | |||||

| Cooling (70 kW) | |||||

| Energy Works/Energy Works Hull | United Kingdom (UK) | Commercial and industrial waste (240 kt/y) | Electricity (28 MWel) | 8 | [87,90] |

| Steam (10 MWth) | |||||

| Levenseat Renewable Energy Ltd./Levenseat EfW | UK | Commercial and industrial waste (215 kt/y) | Electricity (12.5 MWel) | 8 | [87] |

| River Ridge/Full Circle Energy Facility | UK | Commercial and industrial waste (150 kt/y) | Electricity (15 MWel) | 8 | |

| Surrey Municipality/Surrey Biofuel facility | Canada | Organic residues and waste streams | SNG (240 t/y) | 8 | [91] |

| Sindal District Heating Company/Dall Energy CHP plant in Sindal—Denmark | Denmark | Forestry by-products, wood processing industry by-products, garden and park waste (20–60% moisture content) | Electricity (0.8 MWel) | 8 | [87] |

| Heat (5 MWth) | |||||

| Enerkem Alberta Biofuels LP/Edmonton Waste-to-Biofuels Project | Canada | Municipal solid waste (100 kt/y) | Biofuels (38 kt/y) | 8 | [87,92] |

| ZAB Balingen/KSV Balingen | Germany | Sewage sludge | Heat (0.46 MWth) | 8 | [87] |

| Fulcrum (Sierra Biofuels)/Sierra | United States of America (USA) | MSW (175,000 t/y) | Fischer–Tropsch liquids (30,000 t/y) | 8 | [91,93] |

| Sustainable aviation fuels (11 Mgallons/y) | |||||

| Eska Graphic Board/Waste Paper Rejects Gasification | Netherlands | Paper reject (3–3.5 t/h) | Heat (12 MWth) | 9 | [87] |

| Metso Fibre/Bioproduct Mill Aanekoski | Finland | Bark | Heat (87 MWth) | 9 | |

| Metso Fibre Oy, Joutseno Mill/Lime kiln gasifier | Finland | Bark | Heat (48 MWth) | 9 | |

| OKI/OKI Pulp and Paper Mill-APP | Indonesia | Acacia bark | Heat (110 MWth) | 9 | [87,94] |

| Guascor Italia/Rossano Calabro (CS) | Italy | Olive husks, industry wood, agro-forestry waste | Electricity (4.2 MWel) | 9 | [87] |

| Stora Enso/Gasifier at Varkaus paper mill (former Corenso) | Finland | Plastic waste | Heat (50 MWth) | 9 | [87,89,95] |

| Tylor Biomass Energy/The Montgomery Project | USA | Municipal solid waste (500 t/day) | 20 MW of clean energy | 9 | [89,96] |

| Lahti Energia Oy/Kymijärvi II | Finland | SRF (250 Mt/day) | Electricity (50 MWel) | 9 | [94,97] |

| Heat (90 MWth) |

| Owner/Project Name | Country | Feedstock | Output | TRL | Reference |

|---|---|---|---|---|---|

| Ecoloop GmbH | Germany | Wood chips (28 kg/h) and EPS (expanded polystyrene) (11.4 kg/h) | Electricity (0.068 MWel) | 6–7 | [87] |

| Heat (0.123 MWth) | |||||

| Enerkem/Westbury commercial demonstration facility | Canada | MSW and wood waste (48 t/d) | Cellulosic ethanol (4000 t/y) | 6–7 | [87,91] |

| Methanol (1000 t/y) | |||||

| ThermoChem Recovery International (TRI)/Fully Integrated BioRefinery | United States | Organic residues and waste streams (4 t/y) | Fischer–Tropsch liquids (1 t/y) | 6–7 | [91] |

| Enerkem/Synthesis Enerkem Sherbrooke | Canada | MSW, spent plastics, wood waste, sludge, petroleum coke, and wheat straw | Cellulosic ethanol (375 t/y) | 4–5 | [87,91] |

| Methanol (475 m3/y) | |||||

| Thermochem Recovery International (TRI)/Technology development laboratory and pilot plant—thermochemical | United States | MSW, lignocellulosic materials, and syngas (4 t/day) | Fischer–Tropsch liquids (0.002 t/y) | 4–5 | [87,91] |

| DBI-Virtuhcon GmbH/FlexiEntrained (GSP) Pilot plant | Germany | MSW, sewage sludge, RDF, biomass, char, coke, lignite, and hard coal (450 kg/h) | Heat (5 MWth) | 4–5 | [87] |

| Institute of Energy Process Engineering and Chemical Engineering (IEC), TU Bergakademie Freiberg/FlexiSlag Pilot Plant | Germany | MSW and plastic waste (2 t/h) | Heat (10 MWth) | 4–5 | [87] |

| Biomass waste (2 t/h) | Gas (2300 m3/h) | ||||

| Coal and petcoke (2 t/h) | |||||

| TU Dresden/TC2 Process | Germany | Sewage sludge | Electricity (1 MWel) | 4–5 | [87] |

| TU Freiberg/FlexiCOORVED Pilot Plant | Germany | Sewage sludge as well as biomass-containing waste with high ash content. | Heat (0.06 MWth) | 4–5 | [87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, S.M.; Assis, A.C.; Gomes, L.; Nobre, C.; Brito, P. Waste Gasification Technologies: A Brief Overview. Waste 2023, 1, 140-165. https://doi.org/10.3390/waste1010011

Santos SM, Assis AC, Gomes L, Nobre C, Brito P. Waste Gasification Technologies: A Brief Overview. Waste. 2023; 1(1):140-165. https://doi.org/10.3390/waste1010011

Chicago/Turabian StyleSantos, Santa Margarida, Ana Carolina Assis, Leandro Gomes, Catarina Nobre, and Paulo Brito. 2023. "Waste Gasification Technologies: A Brief Overview" Waste 1, no. 1: 140-165. https://doi.org/10.3390/waste1010011