Advanced Triboelectric Applications of Biomass-Derived Materials: A Comprehensive Review

Abstract

1. Introduction

1.1. Introduction to Biomass-Derived Materials

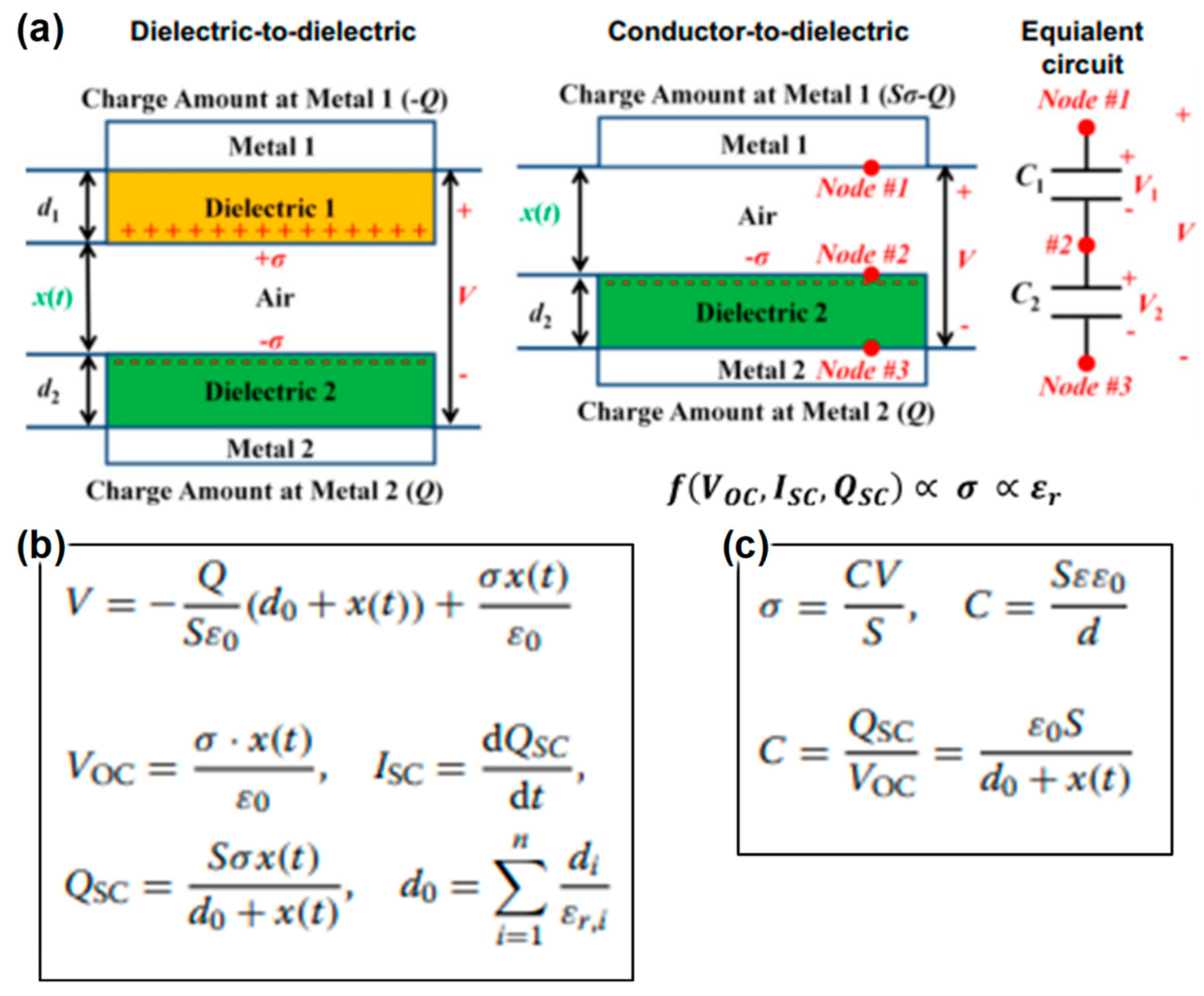

1.2. Triboelectric Devices: Definition and Mechanism

2. Biomass-Derived Triboelectric Devices

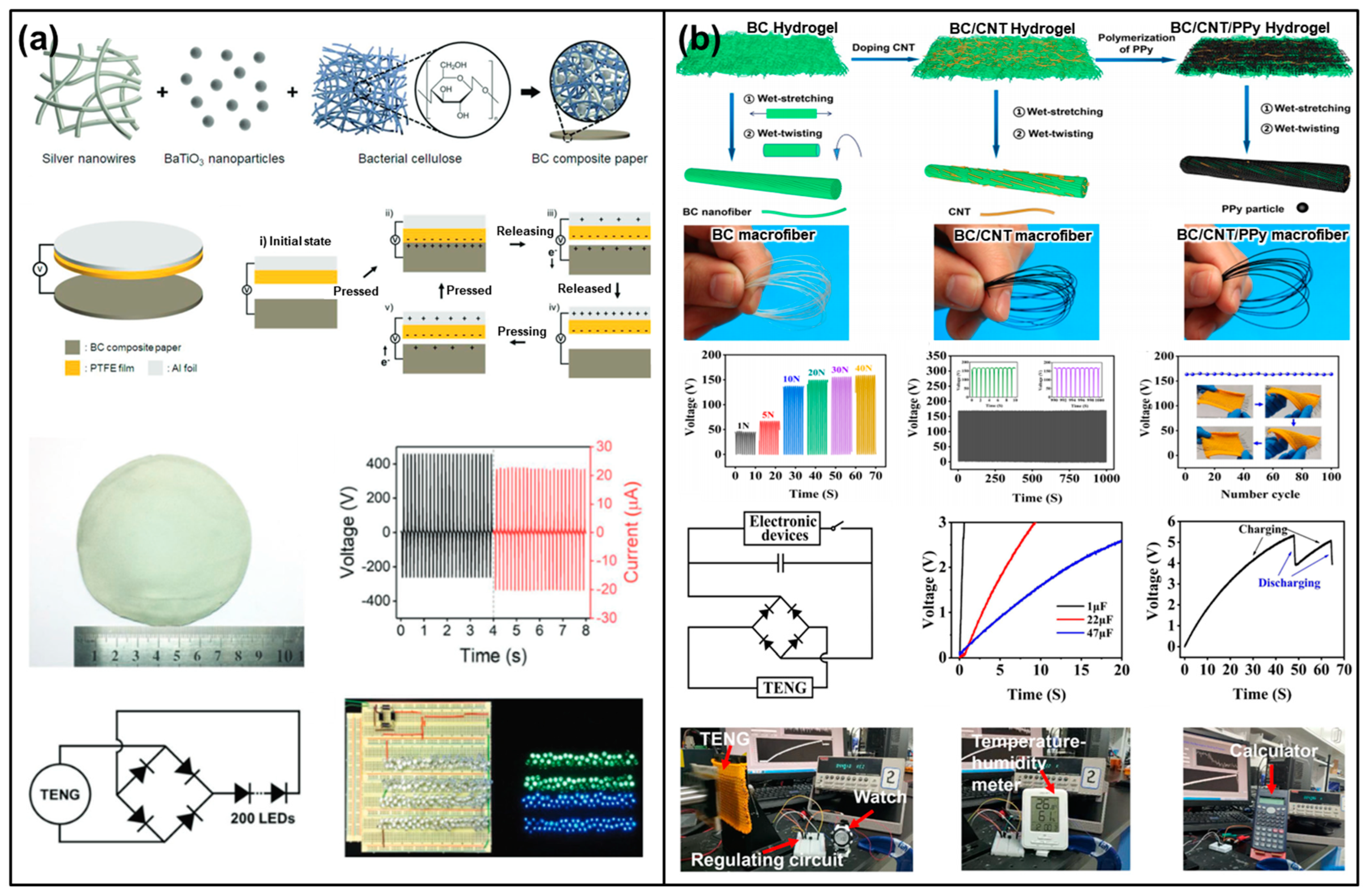

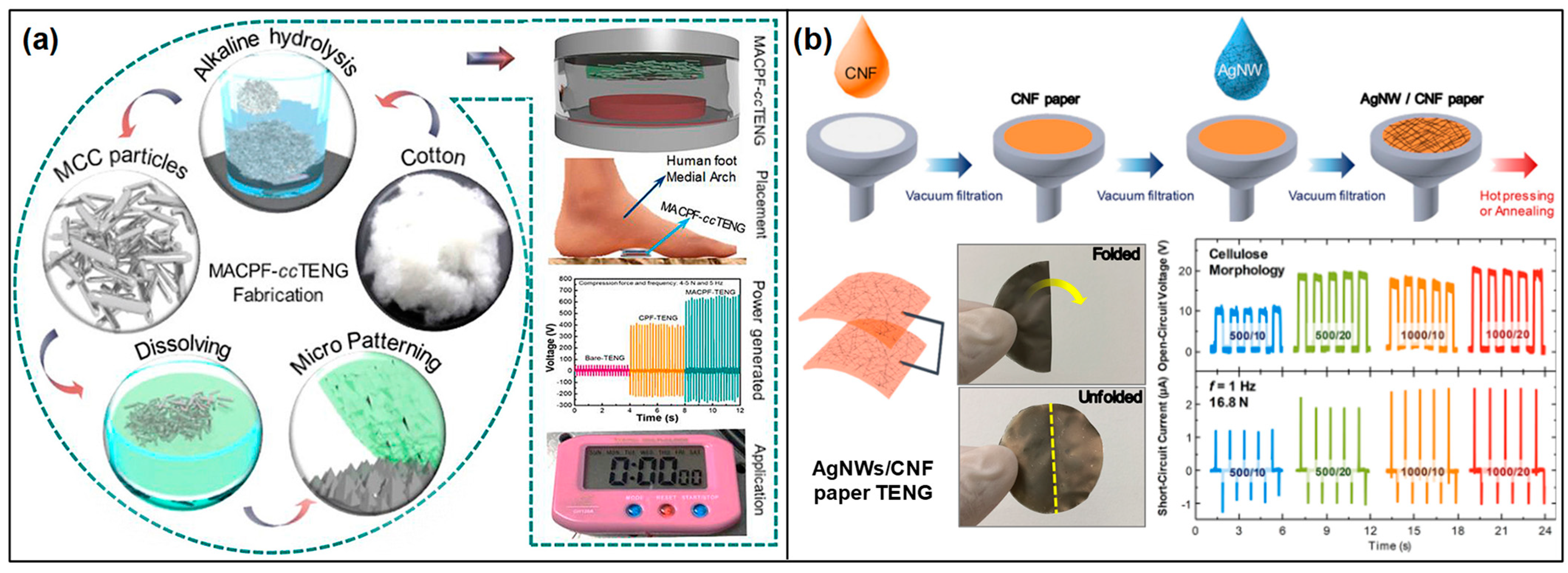

2.1. Cellulose-Based Triboelectric Devices

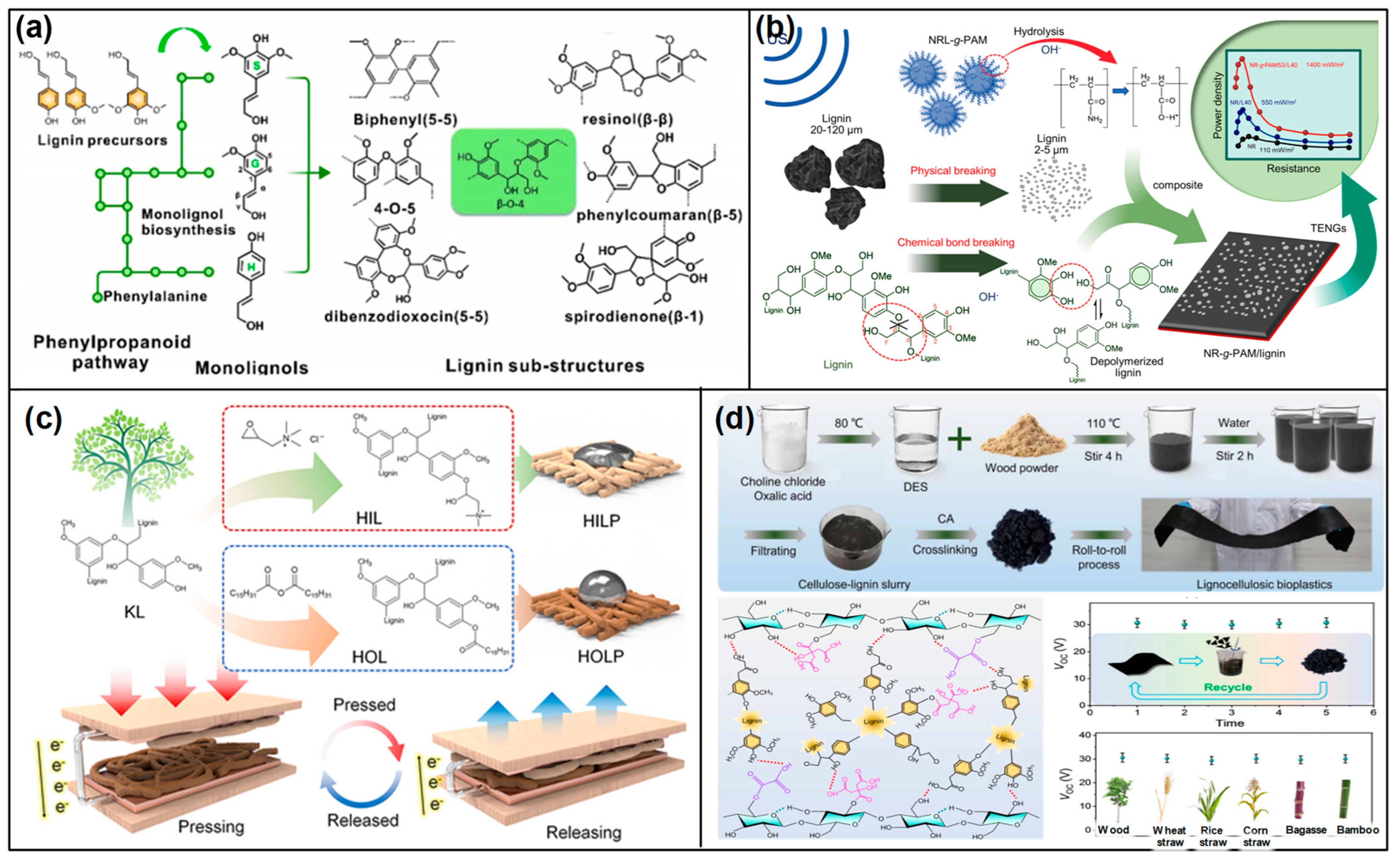

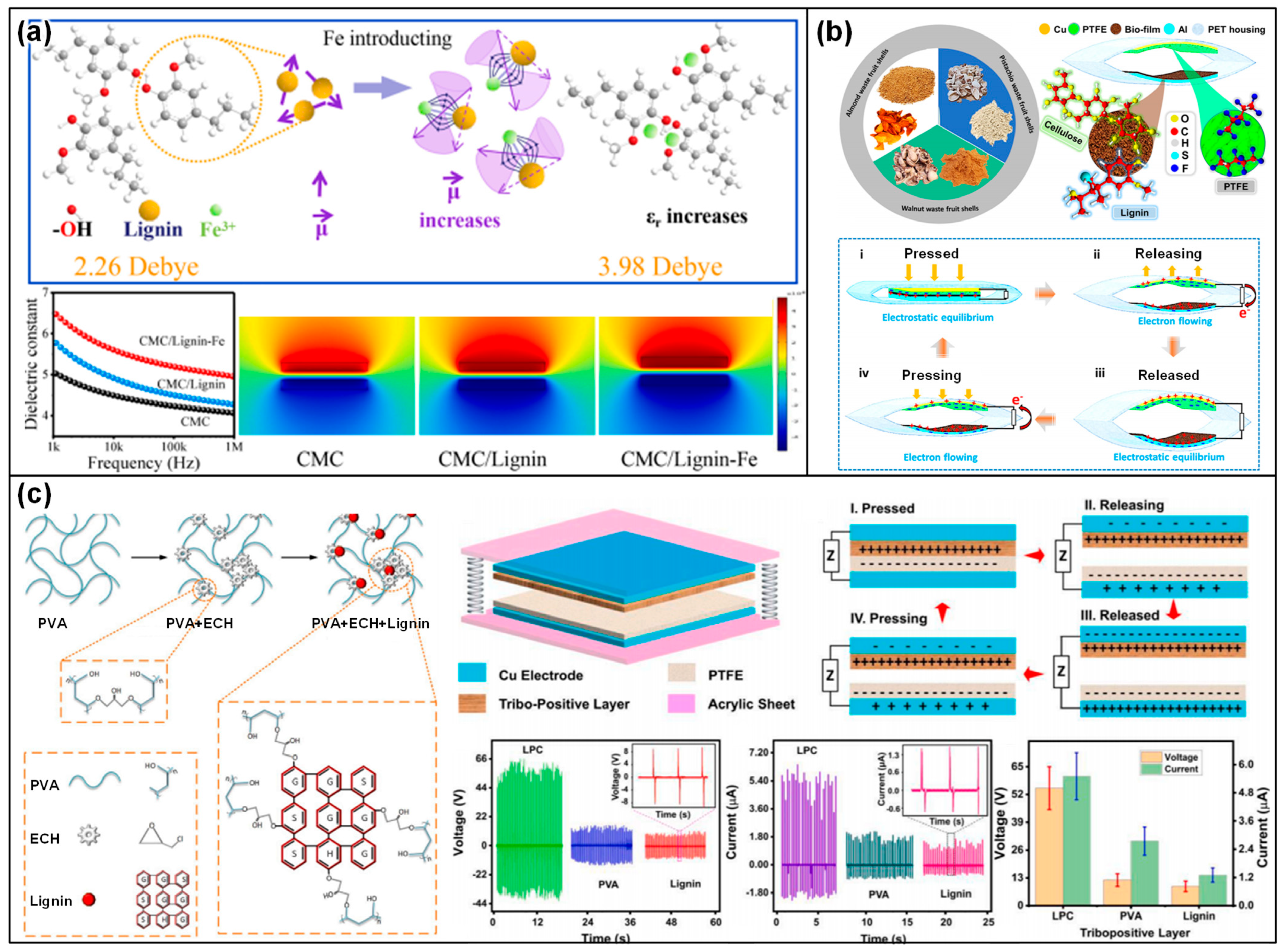

2.2. Lignin-Based Triboelectric Devices

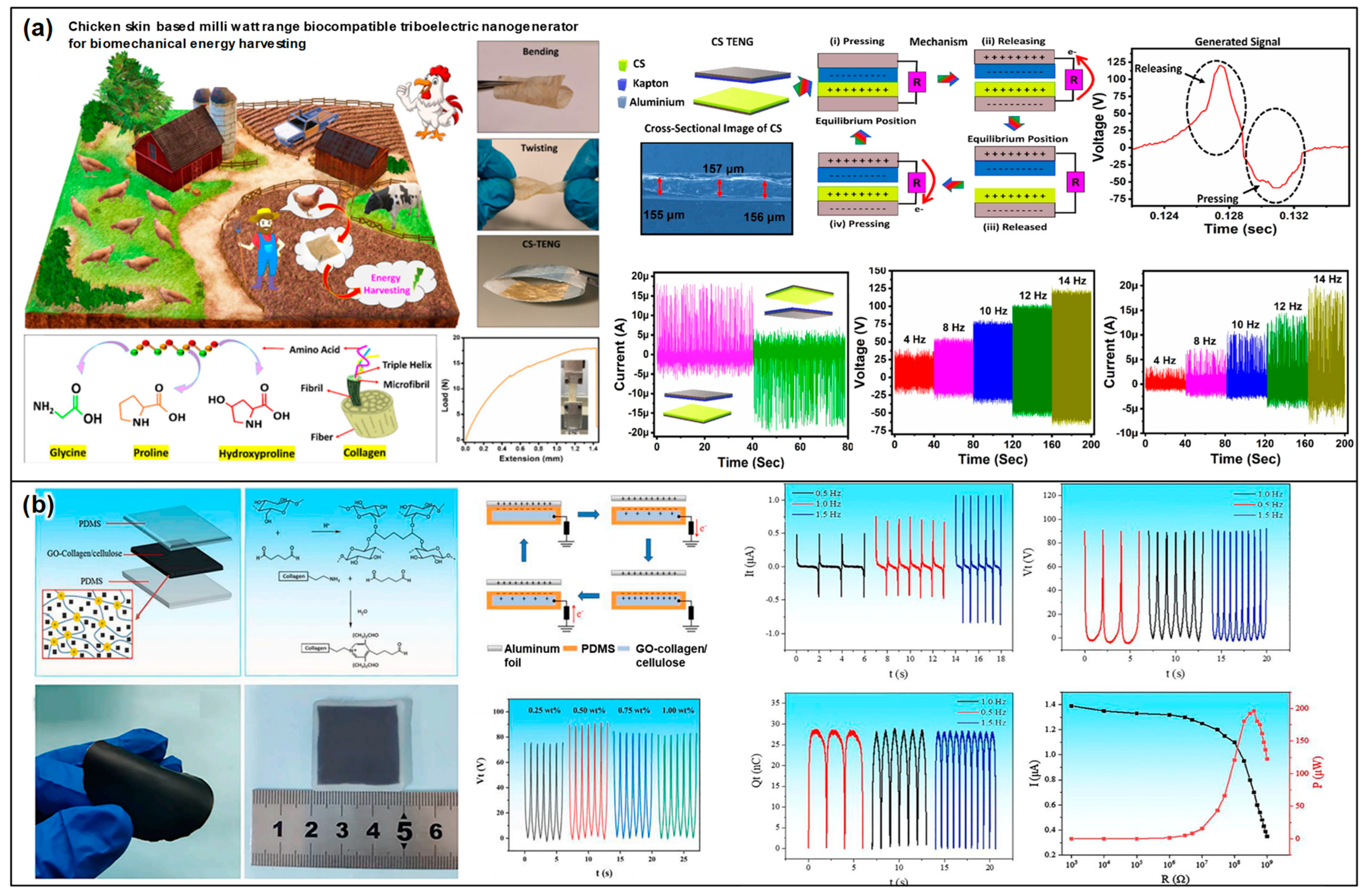

2.3. Collagen-Based Triboelectric Devices

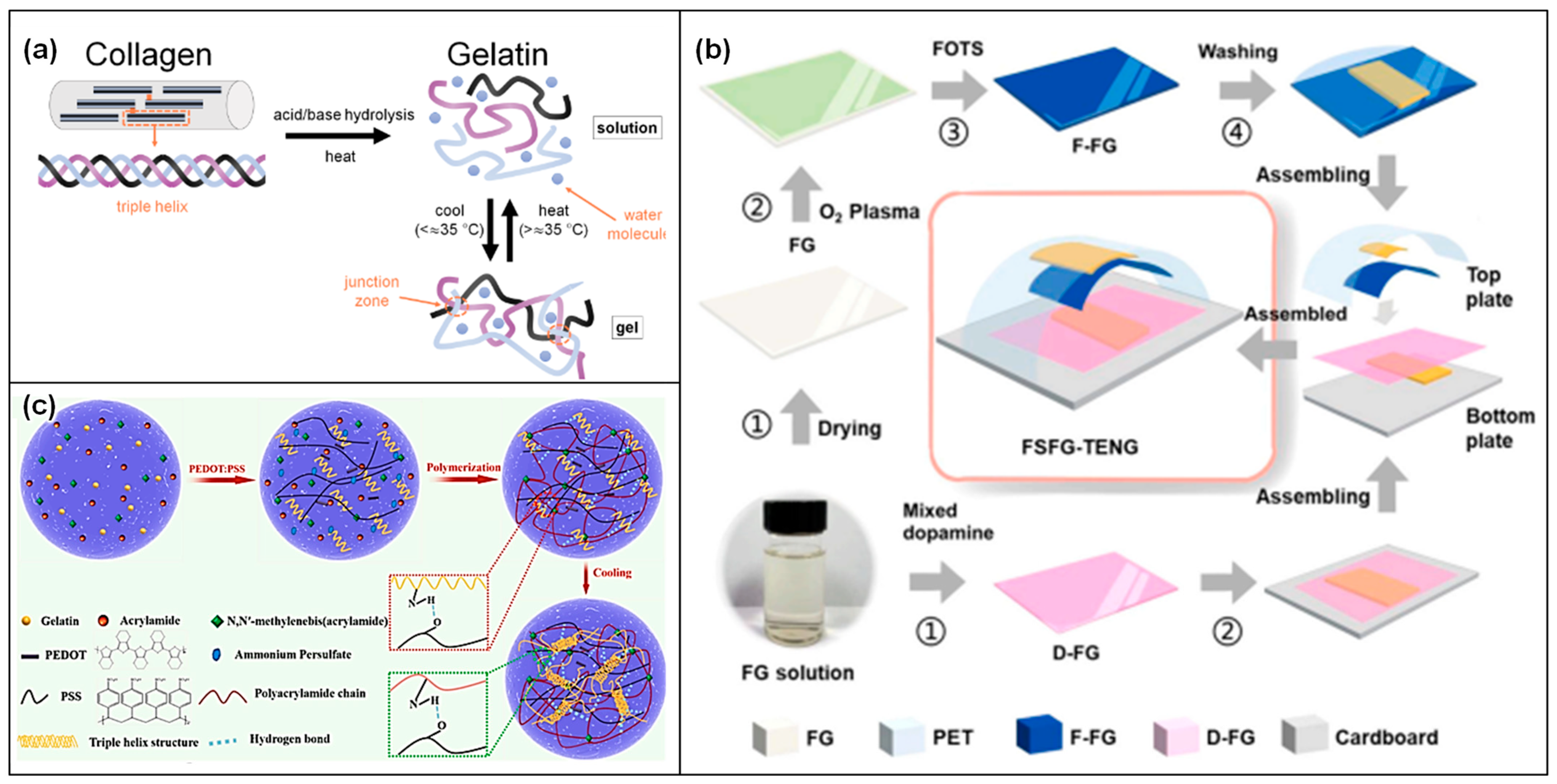

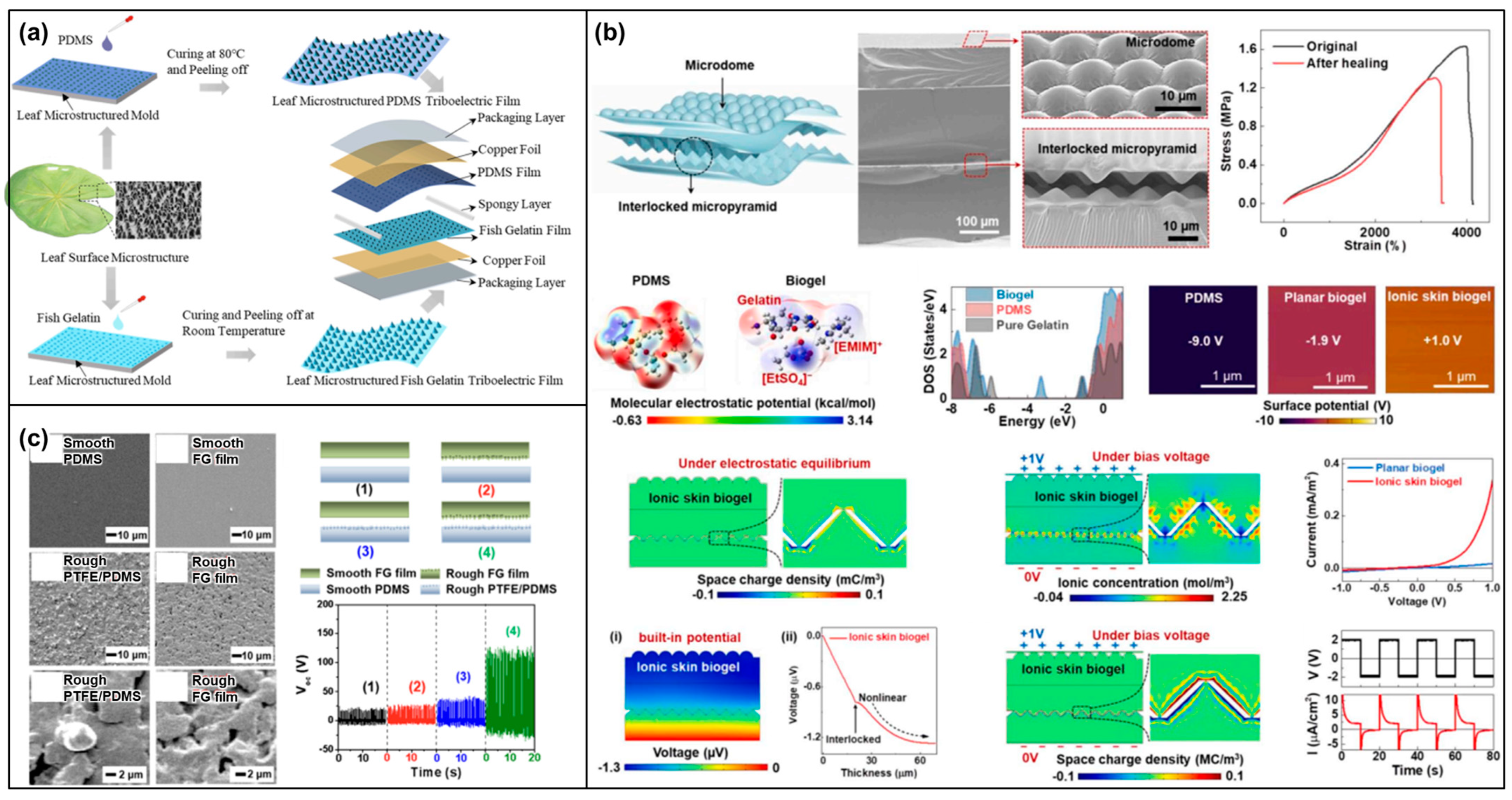

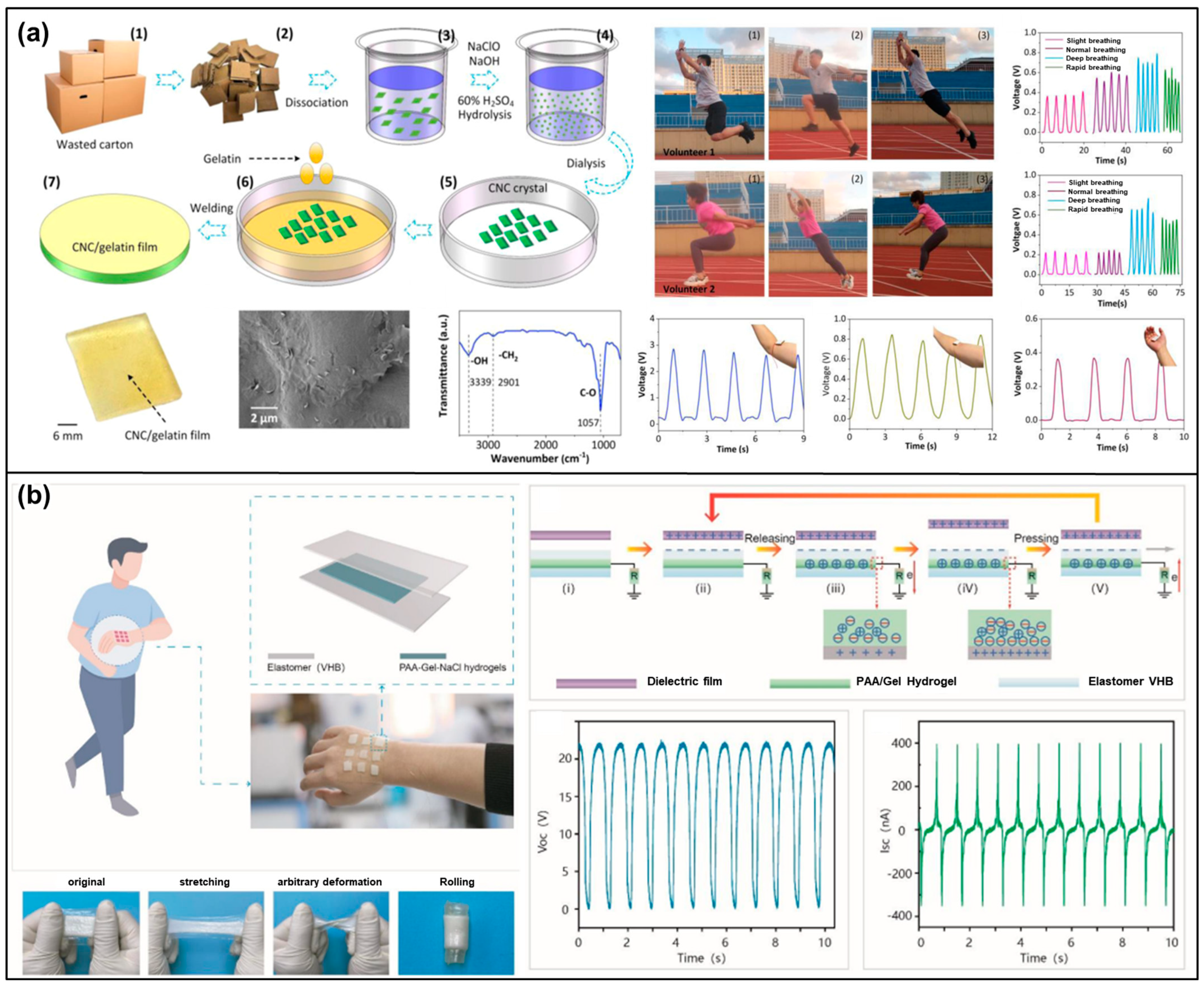

2.4. Gelatin-Based Triboelectric Devices

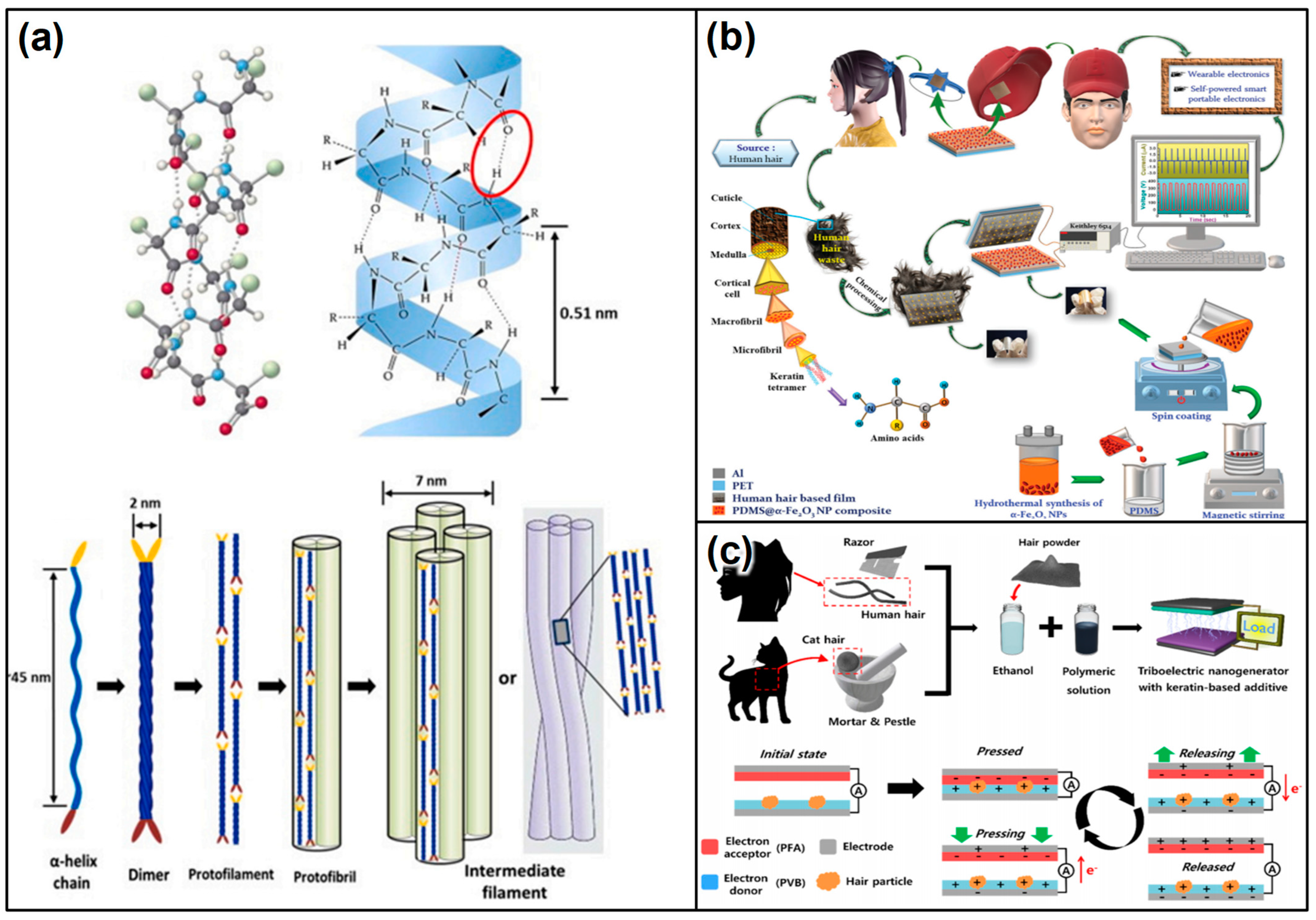

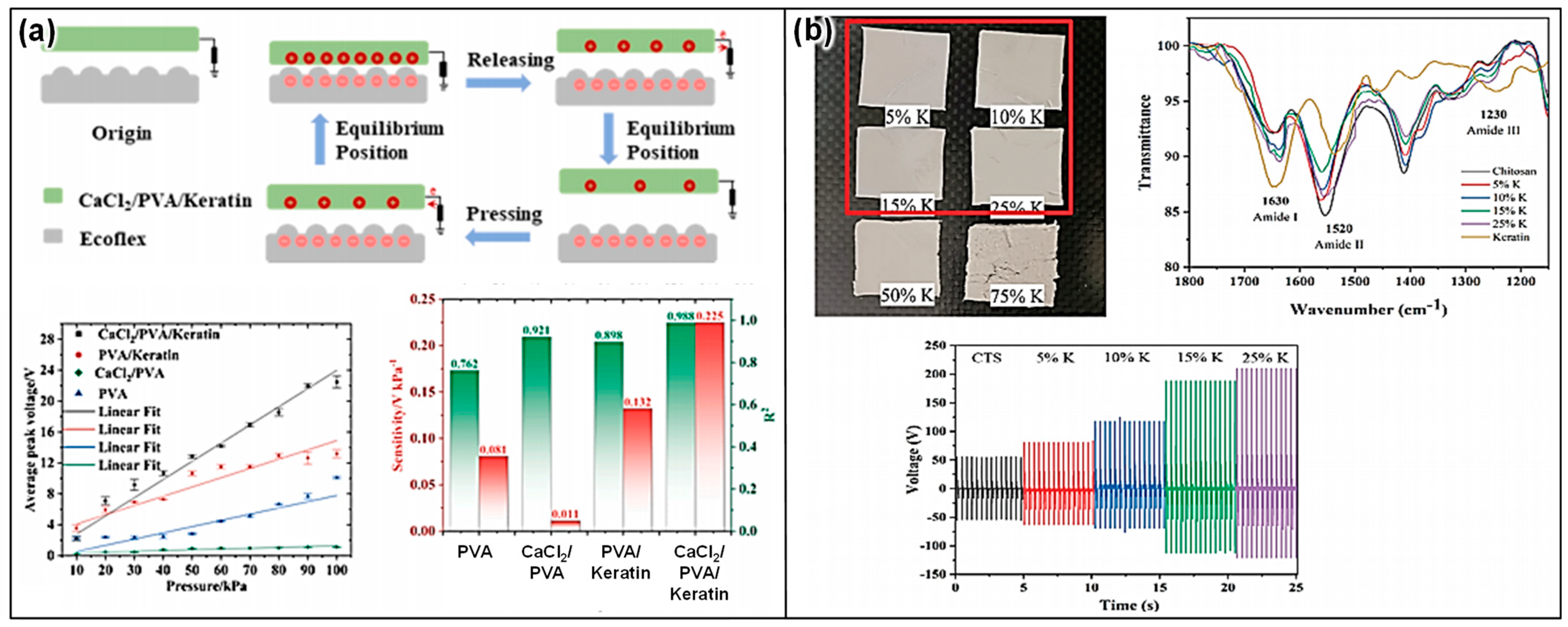

2.5. Keratin-Based Triboelectric Devices

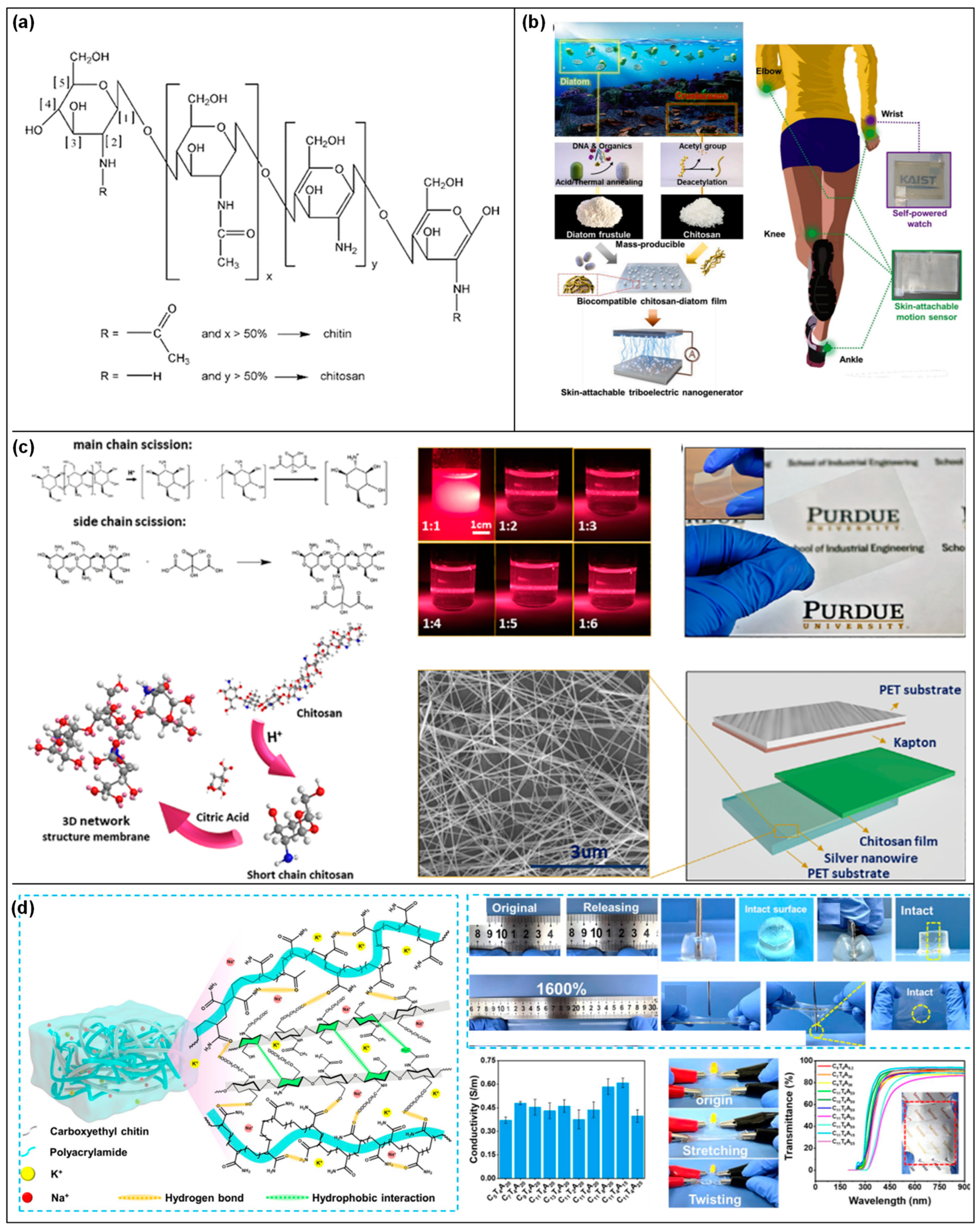

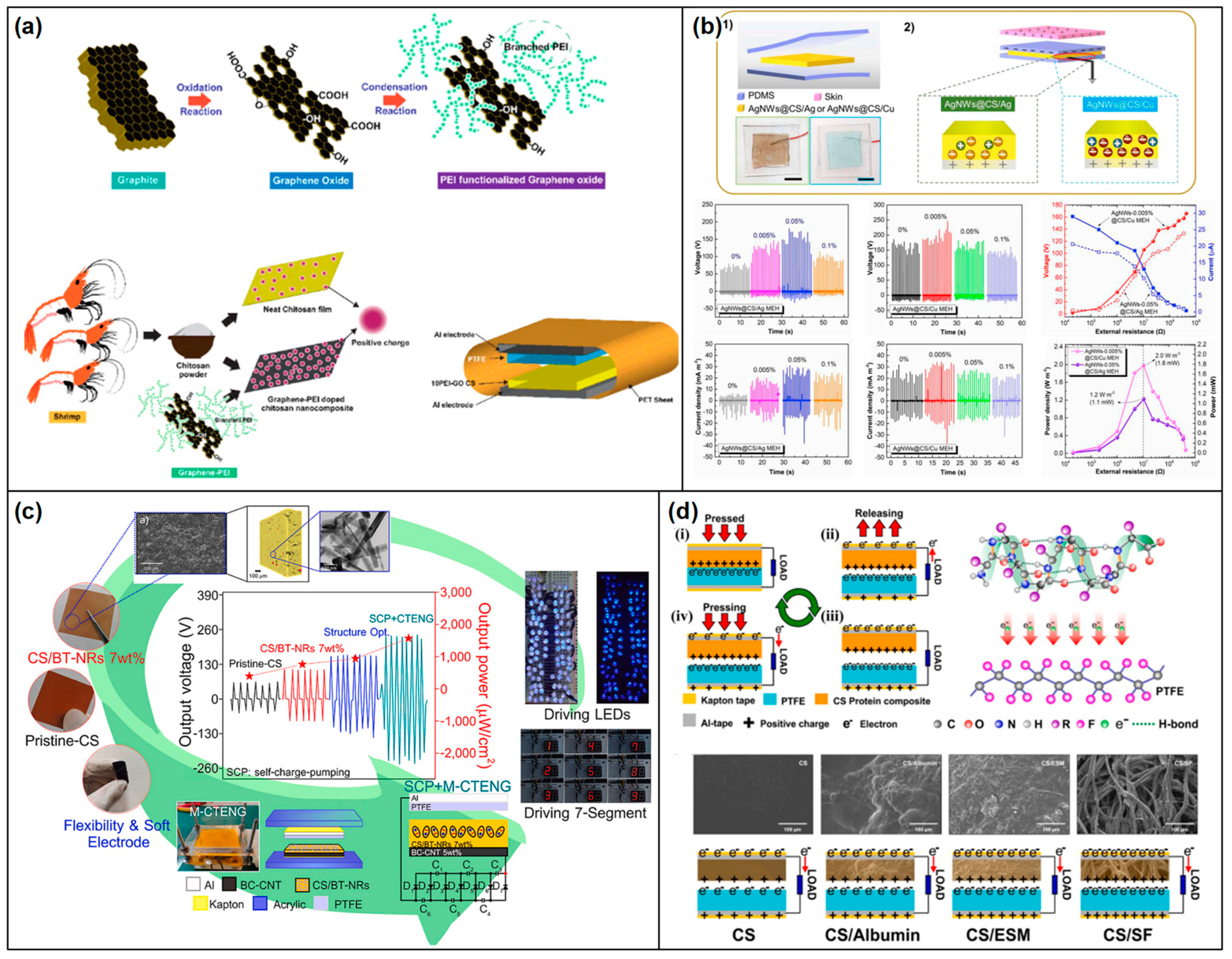

2.6. Chitin/Chitosan-Based Triboelectric Devices

3. Conclusions

4. Challenges and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Z.; Zhang, Y.; Song, N.; Li, X. Biomass-derived renewable carbon materials for electrochemical energy storage. Mater. Res. Lett. 2017, 5, 69–88. [Google Scholar] [CrossRef]

- Doǧan, H.; Taş, M.; Meşeli, T.; Elden, G.; Genc, G. Review on the Applications of Biomass-Derived Carbon Materials in Vanadium Redox Flow Batteries. ACS Omega 2023, 8, 34310–34327. [Google Scholar] [CrossRef]

- Li, L.; Lu, S.; Fang, L.; Wei, Y.; Yang, S. Review on Biomass-Derived Carbon-Based Materials for Electrocatalytic Hydrogen Production: State of the Art and Outlook. Energy Fuels 2023, 37, 18485–18501. [Google Scholar] [CrossRef]

- Yadav, M.; Goel, G.; Hatton, F.L.; Bhagat, M.; Mehta, S.K.; Mishra, R.K.; Bhojak, N. A review on biomass-derived materials and their applications as corrosion inhibitors, catalysts, food and drug delivery agents. Curr. Res. Green Sustain. Chem. 2021, 4, 100153. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, Y. Recent progress in the conversion of biomass wastes into functional materials for value-added applications. Sci. Technol. Adv. Mater. 2020, 21, 787–804. [Google Scholar] [CrossRef]

- Luzier, W.D. Materials derived from biomass/biodegradable materials. Proc. Natl. Acad. Sci. USA 1992, 89, 839–842. [Google Scholar] [CrossRef]

- Varma, R.S. Biomass-Derived Renewable Carbonaceous Materials for Sustainable Chemical and Environmental Applications. ACS Sustain. Chem. Eng. 2019, 7, 6458–6470. [Google Scholar] [CrossRef]

- Pan, S.; Zhang, Z. Fundamental theories and basic principles of triboelectric effect: A review. Friction 2019, 7, 2–17. [Google Scholar] [CrossRef]

- Kim, W.-G.; Kim, D.-W.; Tcho, I.-W.; Kim, J.-K.; Kim, M.-S.; Choi, Y.-K. Triboelectric Nanogenerator: Structure, Mechanism, and Applications. ACS Nano 2021, 15, 258–287. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.L. Recent progress of triboelectric nanogenerators: From fundamental theory to practical applications. EcoMat 2020, 2, e12059. [Google Scholar] [CrossRef]

- Zhang, R.; Olin, H. Material choices for triboelectric nanogenerators: A critical review. EcoMat 2020, 2, e12062. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; Zheng, H.; Chen, C.; Wang, A.C.; Xu, C.; et al. Quantifying the triboelectric series. Nat. Commun. 2019, 10, 1427. [Google Scholar] [CrossRef]

- Kim, S.-W.; Kim, J.-K.; Jung, S.; Lee, J.W.; Yang, C.; Baik, J.M. Choice of Materials for Triboelectric Nanogenerators. In Handbook of Triboelectric Nanogenerators; Wang, Z.L., Yang, Y., Zhai, J., Wang, J., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 455–504. [Google Scholar]

- Zhou, Y.; Deng, W.; Xu, J.; Chen, J. Engineering Materials at the Nanoscale for Triboelectric Nanogenerators. Cell Rep. Phys. Sci. 2020, 1, 100142. [Google Scholar] [CrossRef]

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, L.; Jiang, Y.; Lim, W.; Soh, S. Rationalizing the Triboelectric Series of Polymers. Chem. Mater. 2019, 31, 1473–1478. [Google Scholar] [CrossRef]

- Niu, S.; Wang, S.; Lin, L.; Liu, Y.; Zhou, Y.S.; Hu, Y.; Wang, Z.L. Theoretical study of contact-mode triboelectric nanogenerators as an effective power source. Energy Environ. Sci. 2013, 6, 3576–3583. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors—Principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef]

- Kim, M.P.; Um, D.-S.; Shin, Y.-E.; Ko, H. High-Performance Triboelectric Devices via Dielectric Polarization: A Review. Nanoscale Res. Lett. 2021, 16, 35. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, Q. Enhancing Surface Charge Density of Materials. In Handbook of Triboelectric Nanogenerators; Wang, Z.L., Yang, Y., Zhai, J., Wang, J., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 1411–1436. [Google Scholar]

- Liang, Y.; Xu, X.; Zhao, L.; Lei, C.; Dai, K.; Zhuo, R.; Fan, B.; Cheng, E.; Hassan, M.A.; Gao, L.; et al. Advances of Strategies to Increase the Surface Charge Density of Triboelectric Nanogenerators: A Review. Small 2023, 20, 2308469. [Google Scholar] [CrossRef]

- Wang, J.; Wu, C.; Dai, Y.; Zhao, Z.; Wang, A.; Zhang, T.; Wang, Z.L. Achieving ultrahigh triboelectric charge density for efficient energy harvesting. Nat. Commun. 2017, 8, 88. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.P.; Lee, G.; Noh, B.; Kim, J.; Kwak, M.S.; Lee, K.J.; Ko, H. Enhancing energy harvesting performance of bilayered parylene triboelectric nanogenerators through interfacial polarization. Nano Energy 2024, 119, 109087. [Google Scholar] [CrossRef]

- Kim, M.P.; Lee, Y.; Hur, Y.H.; Park, J.; Kim, J.; Lee, Y.; Ahn, C.W.; Song, S.W.; Jung, Y.S.; Ko, H. Molecular structure engineering of dielectric fluorinated polymers for enhanced performances of triboelectric nanogenerators. Nano Energy 2018, 53, 37–45. [Google Scholar] [CrossRef]

- Chen, J.; Guo, H.; He, X.; Liu, G.; Xi, Y.; Shi, H.; Hu, C. Enhancing Performance of Triboelectric Nanogenerator by Filling High Dielectric Nanoparticles into Sponge PDMS Film. ACS Appl. Mater. Interfaces 2016, 8, 736–744. [Google Scholar] [CrossRef]

- Kang, X.; Pan, C.; Chen, Y.; Pu, X. Boosting performances of triboelectric nanogenerators by optimizing dielectric properties and thickness of electrification layer. RSC Adv. 2020, 10, 17752–17759. [Google Scholar] [CrossRef]

- Lee, J.W.; Cho, H.J.; Chun, J.; Kim, K.N.; Kim, S.; Ahn, C.W.; Kim, I.W.; Kim, J.-Y.; Kim, S.-W.; Yang, C.; et al. Robust nanogenerators based on graft copolymers via control of dielectrics for remarkable output power enhancement. Sci. Adv. 2017, 3, e1602902. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, H.; Du, C.; Zhang, D.; Lin, H.; Chen, Y.; Xiong, J. Cellulose for Sustainable Triboelectric Nanogenerators. Adv. Energy Sustain. Res. 2021, 3, 2100161. [Google Scholar] [CrossRef]

- Jena, K.K.; Fatma, B.; Arya, S.S.; Alhassan, S.M.; Chan, V.; Pappa, A.M.; Pitsalidis, C. High performance flexible triboelectric nanogenerators using bio-derived films made of siloxane-modified castor oil. J. Mater. Chem. A 2024, 12, 8340–8349. [Google Scholar] [CrossRef]

- Tang, W.; Fu, C.; Xia, L.; Su, L.; Lyu, P.; Fu, Z.; Gong, J.; Li, L.; Zhang, C.; Xu, W. Biomass-derived multifunctional 3D film framed by carbonized loofah toward flexible strain sensors and triboelectric nanogenerators. Nano Energy 2023, 107, 108129. [Google Scholar] [CrossRef]

- Niu, Z.; Cheng, W.; Cao, M.; Wang, D.; Wang, Q.; Han, J.; Long, Y.; Han, G. Recent advances in cellulose-based flexible triboelectric nanogenerators. Nano Energy 2021, 87, 106175. [Google Scholar] [CrossRef]

- Meng, X.; Cai, C.; Luo, B.; Liu, T.; Shao, Y.; Wang, S.; Nie, S. Rational Design of Cellulosic Triboelectric Materials for Self-Powered Wearable Electronics. Nanomicro. Lett. 2023, 15, 124. [Google Scholar] [CrossRef]

- Vatankhah, E.; Tadayon, M.; Ramakrishna, S. Boosted output performance of nanocellulose-based triboelectric nanogenerators via device engineering and surface functionalization. Carbohydr. Polym. 2021, 266, 118120. [Google Scholar] [CrossRef]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Kim, H.-J.; Yim, E.-C.; Kim, J.-H.; Kim, S.-J.; Park, J.-Y.; Oh, I.-K. Bacterial Nano-Cellulose Triboelectric Nanogenerator. Nano Energy 2017, 33, 130–137. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, Q.; Mo, J.; Lu, Y.; Cai, C.; Luo, B.; Nie, S. Chemically tailored molecular surface modification of cellulose nanofibrils for manipulating the charge density of triboelectric nanogenerators. Nano Energy 2021, 89, 106369. [Google Scholar] [CrossRef]

- Lin, S.; Xu, C.; Xu, L.; Wang, Z.L. The Overlapped Electron-Cloud Model for Electron Transfer in Contact Electrification. Adv. Funct. Mater. 2020, 30, 1909724. [Google Scholar] [CrossRef]

- Nie, S.; Cai, C.; Lin, X.; Zhang, C.; Lu, Y.; Mo, J.; Wang, S. Chemically Functionalized Cellulose Nanofibrils for Improving Triboelectric Charge Density of a Triboelectric Nanogenerator. ACS Sustain. Chem. Eng. 2020, 8, 18678–18685. [Google Scholar] [CrossRef]

- Roy, S.; Ko, H.-U.; Maji, P.K.; Van Hai, L.; Kim, J. Large amplification of triboelectric property by allicin to develop high performance cellulosic triboelectric nanogenerator. Chem. Eng. J. 2020, 385, 123723. [Google Scholar] [CrossRef]

- Yao, C.; Yin, X.; Yu, Y.; Cai, Z.; Wang, X. Chemically Functionalized Natural Cellulose Materials for Effective Triboelectric Nanogenerator Development. Adv. Funct. Mater. 2017, 27, 1700794. [Google Scholar] [CrossRef]

- Zhang, C.; Lin, X.; Zhang, N.; Lu, Y.; Wu, Z.; Liu, G.; Nie, S. Chemically functionalized cellulose nanofibrils-based gear-like triboelectric nanogenerator for energy harvesting and sensing. Nano Energy 2019, 66, 104126. [Google Scholar] [CrossRef]

- Du, G.; Wang, J.; Liu, Y.; Yuan, J.; Liu, T.; Cai, C.; Luo, B.; Zhu, S.; Wei, Z.; Wang, S.; et al. Fabrication of Advanced Cellulosic Triboelectric Materials via Dielectric Modulation. Adv. Sci. 2023, 10, e2206243. [Google Scholar] [CrossRef]

- Sriphan, S.; Pharino, U.; Charoonsuk, T.; Pulphol, P.; Pakawanit, P.; Khamman, O.; Vittayakorn, W.; Vittayakorn, N.; Maluangnont, T. Tailoring charge affinity, dielectric property, and band gap of bacterial cellulose paper by multifunctional Ti2NbO7 nanosheets for improving triboelectric nanogenerator performance. Nano Res. 2023, 16, 3168–3179. [Google Scholar] [CrossRef]

- Lamanna, L.; Pace, G.; Ilic, I.K.; Cataldi, P.; Viola, F.; Friuli, M.; Galli, V.; Demitri, C.; Caironi, M. Edible cellulose-based conductive composites for triboelectric nanogenerators and supercapacitors. Nano Energy 2023, 108, 108168. [Google Scholar] [CrossRef]

- Oh, H.; Kwak, S.S.; Kim, B.; Han, E.; Lim, G.-H.; Kim, S.-W.; Lim, B. Highly Conductive Ferroelectric Cellulose Composite Papers for Efficient Triboelectric Nanogenerators. Adv. Funct. Mater. 2019, 29, 1904066. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, T.; Wei, Y.; Sun, X.; Zhang, S.; Wang, X.; Luo, L. Low-cost, environmentally friendly and high-performance cellulose-based triboelectric nanogenerator for self-powered human motion monitoring. Cellulose 2022, 29, 8733–8747. [Google Scholar] [CrossRef]

- Sun, W.; Liu, X.; Hua, W.; Wang, S.; Wang, S.; Yu, J.; Wang, J.; Yong, Q.; Chu, F.; Lu, C. Self-strengthening and conductive cellulose composite hydrogel for high sensitivity strain sensor and flexible triboelectric nanogenerator. Int. J. Biol. Macromol. 2023, 248, 125900. [Google Scholar] [CrossRef]

- Hu, S.; Han, J.; Shi, Z.; Chen, K.; Xu, N.; Wang, Y.; Zheng, R.; Tao, Y.; Sun, Q.; Wang, Z.L.; et al. Biodegradable, Super-Strong, and Conductive Cellulose Macrofibers for Fabric-Based Triboelectric Nanogenerator. Nanomicro. Lett. 2022, 14, 115. [Google Scholar] [CrossRef] [PubMed]

- Jakmuangpak, S.; Prada, T.; Mongkolthanaruk, W.; Harnchana, V.; Pinitsoontorn, S. Engineering Bacterial Cellulose Films by Nanocomposite Approach and Surface Modification for Biocompatible Triboelectric Nanogenerator. ACS Appl. Electron. Mater. 2020, 2, 2498–2506. [Google Scholar] [CrossRef]

- Zhang, C.; Mo, J.; Fu, Q.; Liu, Y.; Wang, S.; Nie, S. Wood-cellulose-fiber-based functional materials for triboelectric nanogenerators. Nano Energy 2021, 81, 105637. [Google Scholar] [CrossRef]

- Graham, S.A.; Dudem, B.; Mule, A.R.; Patnam, H.; Yu, J.S. Engineering squandered cotton into eco-benign microarchitectured triboelectric films for sustainable and highly efficient mechanical energy harvesting. Nano Energy 2019, 61, 505–516. [Google Scholar] [CrossRef]

- Kim, I.; Jeon, H.; Kim, D.; You, J.; Kim, D. All-in-one cellulose based triboelectric nanogenerator for electronic paper using simple filtration process. Nano Energy 2018, 53, 975–981. [Google Scholar] [CrossRef]

- Wang, Q.; Pan, X.; Lin, C.; Lin, D.; Ni, Y.; Chen, L.; Huang, L.; Cao, S.; Ma, X. Biocompatible, self-wrinkled, antifreezing and stretchable hydrogel-based wearable sensor with PEDOT:sulfonated lignin as conductive materials. Chem. Eng. J. 2019, 370, 1039–1047. [Google Scholar] [CrossRef]

- Zhong, J.; Zhang, Y.; Zhong, Q.; Hu, Q.; Hu, B.; Wang, Z.L.; Zhou, J. Fiber-Based Generator for Wearable Electronics and Mobile Medication. ACS Nano 2014, 8, 6273–6280. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Hu, S.; Shi, Z.; Wang, Y.; Lei, Y.; Han, J.; Xiong, Y.; Sun, J.; Zheng, L.; Sun, Q.; et al. Eco-friendly and recyclable all cellulose triboelectric nanogenerator and self-powered interactive interface. Nano Energy 2021, 89, 106354. [Google Scholar] [CrossRef]

- Jeon, S.-B.; Park, S.-J.; Kim, W.-G.; Tcho, I.-W.; Jin, I.-K.; Han, J.-K.; Kim, D.; Choi, Y.-K. Self-powered wearable keyboard with fabric based triboelectric nanogenerator. Nano Energy 2018, 53, 596–603. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, W.; Liu, Y.; Zhao, J.; Yuan, J.; Chi, M.; Meng, X.; Du, G.; Cai, C.; Wang, S.; et al. Cellulosic gel-based triboelectric nanogenerators for energy harvesting and emerging applications. Nano Energy 2023, 106, 108079. [Google Scholar] [CrossRef]

- Gu, L.; German, L.; Li, T.; Li, J.; Shao, Y.; Long, Y.; Wang, J.; Wang, X. Energy Harvesting Floor from Commercial Cellulosic Materials for a Self-Powered Wireless Transmission Sensor System. ACS Appl. Mater. Interfaces 2021, 13, 5133–5141. [Google Scholar] [CrossRef] [PubMed]

- Du, T.; Chen, Z.; Dong, F.; Cai, H.; Zou, Y.; Zhang, Y.; Sun, P.; Xu, M. Advances in Green Triboelectric Nanogenerators. Adv. Funct. Mater. 2024, 2313794. [Google Scholar] [CrossRef]

- Zhao, Z.; Mi, Y.; Lu, Y.; Zhu, Q.; Cao, X.; Wang, N. From Biochemical Sensor to Wearable Device: The Key Role of the Conductive Polymer in the Triboelectric Nanogenerator. Biosensors 2023, 13, 604. [Google Scholar] [CrossRef] [PubMed]

- Ponnusamy, V.K.; Nguyen, D.D.; Dharmaraja, J.; Shobana, S.; Banu, J.R.; Saratale, R.G.; Chang, S.W.; Kumar, G. A review on lignin structure, pretreatments, fermentation reactions and biorefinery potential. Bioresour. Technol. 2019, 271, 462–472. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Pourhashem, G.; Ullah, A.H.; Bajwa, S.G. A concise review of current lignin production, applications, products and their environmental impact. Ind. Crops Prod. 2019, 139, 111526. [Google Scholar] [CrossRef]

- Hasan, M.S.; Sardar, M.R.I.; Shafin, A.A.; Rahman, M.S.; Mahmud, M.; Hossen, M.M. A Brief Review on Applications of Lignin. J. Chem. Rev. 2023, 5, 56–82. [Google Scholar]

- Espinoza-Acosta, J.L.; Torres-Chávez, P.I.; Olmedo-Martínez, J.L.; Vega-Rios, A.; Flores-Gallardo, S.; Zaragoza-Contreras, E.A. Lignin in storage and renewable energy applications: A review. J. Energy Chem. 2018, 27, 1422–1438. [Google Scholar] [CrossRef]

- Wang, D.; Lee, S.H.; Kim, J.; Park, C.B. “Waste to Wealth”: Lignin as a Renewable Building Block for Energy Harvesting/Storage and Environmental Remediation. ChemSusChem 2020, 13, 2807–2827. [Google Scholar] [CrossRef]

- Beaucamp, A.; Muddasar, M.; Amiinu, I.S.; Moraes Leite, M.; Culebras, M.; Latha, K.; Gutiérrez, M.C.; Rodriguez-Padron, D.; del Monte, F.; Kennedy, T.; et al. Lignin for energy applications—State of the art, life cycle, technoeconomic analysis and future trends. Green Chem. 2022, 24, 8193–8226. [Google Scholar] [CrossRef]

- Saqib, Q.M.; Chougale, M.Y.; Khan, M.U.; Shaukat, R.A.; Kim, J.; Bhat, K.S.; Bae, J. Triboelectric nanogenerator based on lignocellulosic waste fruit shell tribopositive material: Comparative analysis. Mater. Today Sustain. 2022, 18, 100146. [Google Scholar] [CrossRef]

- Bao, Y.; Wang, R.; Lu, Y.; Wu, W. Lignin biopolymer based triboelectric nanogenerators. APL Mater. 2017, 5, 074109. [Google Scholar] [CrossRef]

- Tanguy, N.R.; Rana, M.; Khan, A.A.; Zhang, X.; Tratnik, N.; Chen, H.; Ban, D.; Yan, N. Natural lignocellulosic nanofibrils as tribonegative materials for self-powered wireless electronics. Nano Energy 2022, 98, 107337. [Google Scholar] [CrossRef]

- Nanthagal, K.; Khoonsap, S.; Harnchana, V.; Suphasorn, P.; Chanlek, N.; Sinthiptharakoon, K.; Lapawae, K.; Amnuaypanich, S. Unprecedented Triboelectric Effect of Lignin on Enhancing the Electrical Outputs of Natural-Rubber-Based Triboelectric Nanogenerators (TENGs). ACS Sustain. Chem. Eng. 2023, 11, 1311–1323. [Google Scholar] [CrossRef]

- Jo, H.; Park, D.; Joo, M.; Choi, D.; Kang, J.; Ha, J.-M.; Kim, K.H.; Kim, K.H.; An, S. Performance-enhanced eco-friendly triboelectric nanogenerator via wettability manipulation of lignin. EcoMat 2023, 5, e12413. [Google Scholar] [CrossRef]

- Shi, X.; Chen, P.; Han, K.; Li, C.; Zhang, R.; Luo, J.; Wang, Z.L. A strong, biodegradable, and recyclable all-lignocellulose fabricated triboelectric nanogenerator for self-powered disposable medical monitoring. J. Mater. Chem. A 2023, 11, 11730–11739. [Google Scholar] [CrossRef]

- Yu, S.; Wu, S.; Liu, Y.; Li, L.; Ge, X. Highly effective esterification of lignin to produce a pharmaceutical intermediate using novel silica mesoporous molecular sieves as catalysts. J. Taiwan Inst. Chem. Eng. 2020, 109, 26–34. [Google Scholar] [CrossRef]

- Liu, L.-Y.; Chen, S.; Ji, L.; Jang, S.-K.; Renneckar, S. One-pot route to convert technical lignin into versatile lignin esters for tailored bioplastics and sustainable materials. Green Chem. 2021, 23, 4567–4579. [Google Scholar] [CrossRef]

- Komisarz, K.; Majka, T.M.; Pielichowski, K. Chemical and Physical Modification of Lignin for Green Polymeric Composite Materials. Materials 2023, 16, 16. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Feng, Y.; Sun, S.; Yu, J.; Jia, S.; Dang, C.; Hao, X.; Yang, J.; Ren, W.; Sun, R.; et al. Transparent, Self-Adhesive, Conductive Organohydrogels with Fast Gelation from Lignin-Based Self-Catalytic System for Extreme Environment-Resistant Triboelectric Nanogenerators. Adv. Funct. Mater. 2022, 32, 2201335. [Google Scholar] [CrossRef]

- Deng, P.; Chen, F.; Zhang, H.; Chen, Y.; Zhou, J. Conductive, Self-Healing, Adhesive, and Antibacterial Hydrogels Based on Lignin/Cellulose for Rapid MRSA-Infected Wound Repairing. ACS Appl. Mater. Interfaces 2021, 13, 52333–52345. [Google Scholar] [CrossRef]

- Gan, D.; Shuai, T.; Wang, X.; Huang, Z.; Ren, F.; Fang, L.; Wang, K.; Xie, C.; Lu, X. Mussel-Inspired Redox-Active and Hydrophilic Conductive Polymer Nanoparticles for Adhesive Hydrogel Bioelectronics. Nano-Micro Lett. 2020, 12, 169. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Xia, R.; Cao, X.; Wang, N. Nutshell Powder-Based Green Triboelectric Nanogenerator for Wind Energy Harvesting. Adv. Mater. Interfaces 2022, 9, 2200293. [Google Scholar] [CrossRef]

- Khan, S.A.; Ahmed, M.A.; Baig, M.M.; Rehman, M.M.; Yang, Y.; Lee, S.G.; Choi, J.W.; Kim, W.Y. 3D hierarchical microcubic morphological composite and its application for Bi-functional Humidity/Pressure sensing in TENG architecture. Chem. Eng. J. 2024, 485, 149660. [Google Scholar] [CrossRef]

- Saqib, Q.M.; Shaukat, R.A.; Khan, M.U.; Chougale, M.; Bae, J. Biowaste Peanut Shell Powder-Based Triboelectric Nanogenerator for Biomechanical Energy Scavenging and Sustainably Powering Electronic Supplies. ACS Appl. Electron. Mater. 2020, 2, 3953–3963. [Google Scholar] [CrossRef]

- Nie, S.; Fu, Q.; Lin, X.; Zhang, C.; Lu, Y.; Wang, S. Enhanced performance of a cellulose nanofibrils-based triboelectric nanogenerator by tuning the surface polarizability and hydrophobicity. Chem. Eng. J. 2021, 404, 126512. [Google Scholar] [CrossRef]

- Chen, W.; Li, C.; Tao, Y.; Lu, J.; Du, J.; Wang, H. Modulating spatial charge distribution of lignin for eco-friendly and recyclable triboelectric nanogenerator. Nano Energy 2023, 116, 108802. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Zhuang, J.; Xiang, Z.; Jiang, W.; He, S.; Xiao, H. Conductive Hydrogels Based on Industrial Lignin: Opportunities and Challenges. Polymers 2022, 14, 3739. [Google Scholar] [CrossRef] [PubMed]

- Funayama, R.; Hayashi, S.; Terakawa, M. Laser-Induced Graphitization of Lignin/PLLA Composite Sheets for Biodegradable Triboelectric Nanogenerators. ACS Sustain. Chem. Eng. 2023, 11, 3114–3122. [Google Scholar] [CrossRef]

- Troncoso, O.P.; Corman-Hijar, J.I.; Torres, F.G. Lignocellulosic Biomass for the Fabrication of Triboelectric Nano-Generators (TENGs)—A Review. Int. J. Mol. Sci. 2023, 24, 15784. [Google Scholar] [CrossRef]

- Zheng, M.; Wang, X.; Chen, Y.; Yue, O.; Bai, Z.; Cui, B.; Jiang, H.; Liu, X. A Review of Recent Progress on Collagen-Based Biomaterials. Adv. Healthc. Mater. 2023, 12, 2202042. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Zhu, J.; Ma, P.; Jie, Y.; Wang, Z.L.; Cao, X. Fish Bladder Film-Based Triboelectric Nanogenerator for Noncontact Position Monitoring. ACS Energy Lett. 2020, 5, 3005–3011. [Google Scholar] [CrossRef]

- Kaur, J.; Singh, H. Fabrication of composite material based nanogenerator for electricity generation enhancement of food waste by-product. Mater. Chem. Phys. 2020, 256, 123331. [Google Scholar] [CrossRef]

- Cai, T.; Liu, X.; Ju, J.; Lin, H.; Ruan, H.; Xu, X.; Lu, S.; Li, Y. Flexible cellulose/collagen/graphene oxide based triboelectric nanogenerator for self-powered cathodic protection. Mater. Lett. 2022, 306, 130904. [Google Scholar] [CrossRef]

- Song, B.; Fan, X.; Shen, J.; Gu, H. Ultra-stable and self-healing coordinated collagen-based multifunctional double-network organohydrogel e-skin for multimodal sensing monitoring of strain-resistance, bioelectrode, and self-powered triboelectric nanogenerator. Chem. Eng. J. 2023, 474, 145780. [Google Scholar] [CrossRef]

- Carr, B.P.; Chen, Z.; Chung, J.H.Y.; Wallace, G.G. Collagen Alignment via Electro-Compaction for Biofabrication Applications: A Review. Polymers 2022, 14, 4270. [Google Scholar] [CrossRef]

- Li, L.; Zhang, J.; Wang, M.; Zhang, J.; Zeng, X.-F.; Wang, J.-X.; Le, Y. Electrospun hydrolyzed collagen from tanned leather shavings for bio-triboelectric nanogenerators. Mater. Adv. 2022, 3, 5080–5086. [Google Scholar] [CrossRef]

- Khan, M.U.; Mohammad, E.; Abbas, Y.; Rezeq, M.; Mohammad, B. Chicken skin based Milli Watt range biocompatible triboelectric nanogenerator for biomechanical energy harvesting. Sci. Rep. 2023, 13, 10160. [Google Scholar] [CrossRef] [PubMed]

- Juárez-Moreno, J.A.; Ávila-Ortega, A.; Oliva, A.I.; Avilés, F.; Cauich-Rodríguez, J.V. Effect of wettability and surface roughness on the adhesion properties of collagen on PDMS films treated by capacitively coupled oxygen plasma. Appl. Surf. Sci. 2015, 349, 763–773. [Google Scholar] [CrossRef]

- Bera, S.; Guerin, S.; Yuan, H.; O’Donnell, J.; Reynolds, N.P.; Maraba, O.; Ji, W.; Shimon, L.J.W.; Cazade, P.-A.; Tofail, S.A.M.; et al. Molecular engineering of piezoelectricity in collagen-mimicking peptide assemblies. Nat. Commun. 2021, 12, 2634. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Ronsin, O.; Gravez, B.; Farman, N.; Baumberger, T.; Jaisser, F.; Coradin, T.; Hélary, C. Nanostructured Dense Collagen-Polyester Composite Hydrogels as Amphiphilic Platforms for Drug Delivery. Adv. Sci. 2021, 8, 2004213. [Google Scholar] [CrossRef] [PubMed]

- Mai, Z.; Liu, Q.; Bian, Y.; Wang, P.; Fu, X.; Lin, D.; Kong, N.; Huang, Y.; Zeng, Z.; Li, D.; et al. PCL/Collagen/UA Composite Biomedical Dressing with Ordered Microfiberous Structure Fabricated by a 3D Near-Field Electrospinning Process. Polymers 2023, 15, 223. [Google Scholar] [CrossRef] [PubMed]

- Sionkowska, A. Collagen blended with natural polymers: Recent advances and trends. Prog. Polym. Sci. 2021, 122, 101452. [Google Scholar] [CrossRef]

- Feng, Y.; Shi, Y.; Tian, Y.; Yang, Y.; Wang, J.; Guo, H.; Banitaba, S.N.; Khademolqorani, S.; Li, J. The Collagen-Based Scaffolds for Bone Regeneration: A Journey through Electrospun Composites Integrated with Organic and Inorganic Additives. Processes 2023, 11, 2105. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Li, L.; Zheng, X.; Tang, K.; Pei, Y. Collagen-Based Flexible Electronic Devices for Electrochemical Energy Storage and Sensing. Macromol. Rapid Commun. 2023, 44, 2200977. [Google Scholar] [CrossRef]

- Rather, J.A.; Akhter, N.; Ashraf, Q.S.; Mir, S.A.; Makroo, H.A.; Majid, D.; Barba, F.J.; Khaneghah, A.M.; Dar, B.N. A comprehensive review on gelatin: Understanding impact of the sources, extraction methods, and modifications on potential packaging applications. Food Packag. Shelf Life 2022, 34, 100945. [Google Scholar] [CrossRef]

- Alipal, J.; Mohd Pu’ad, N.A.S.; Lee, T.C.; Nayan, N.H.M.; Sahari, N.; Basri, H.; Idris, M.I.; Abdullah, H.Z. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today Proc. 2021, 42, 240–250. [Google Scholar] [CrossRef]

- Mi, Y.; Lu, Y.; Shi, Y.; Zhao, Z.; Wang, X.; Meng, J.; Cao, X.; Wang, N. Biodegradable Polymers in Triboelectric Nanogenerators. Polymers 2023, 15, 222. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Wei, Y.; Yan, R.; Hu, L.; Zhi, J.; Tang, B.; Li, Y.; Yao, Z.; Shi, C.; Yu, H.-D.; et al. Leaf surface-microstructure inspired fabrication of fish gelatin-based triboelectric nanogenerator. Nano Energy 2023, 109, 108231. [Google Scholar] [CrossRef]

- Cao, V.A.; Kim, M.; Cao Van, P.; Jeong, J.-R.; Kim, S.Y.; Nah, J. A triboelectric nanogenerator using degradable surface-modified cellulose acetate and ferroelectric gelatin composite nanofibers. J. Mater. Chem. A 2024, 12, 3142–3150. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, L.; Yue, X.; Zhang, L.; Ren, G.; Li, D.; Wang, H.; Han, Y.; Xiao, L.; Lu, G.; et al. Fully sustainable and high-performance fish gelatin-based triboelectric nanogenerator for wearable movement sensing and human-machine interaction. Nano Energy 2021, 89, 106329. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, Y.; Wang, C.; Zhou, K.; Yan, C.; Zheng, G.; Huang, J.; Dai, K.; Liu, C.; Shen, C. Ultra-Stretchable, durable and conductive hydrogel with hybrid double network as high performance strain sensor and stretchable triboelectric nanogenerator. Nano Energy 2020, 76, 105035. [Google Scholar] [CrossRef]

- Campiglio, C.E.; Contessi Negrini, N.; Farè, S.; Draghi, L. Cross-Linking Strategies for Electrospun Gelatin Scaffolds. Materials 2019, 12, 2476. [Google Scholar] [CrossRef]

- Sharma, A.K.; Priya; Kaith, B.S.; Bhagya, S.; Simran; Saiyam. Borax mediated synthesis of a biocompatible self-healing hydrogel using dialdehyde carboxymethyl cellulose-dextrin and gelatin. React. Funct. Polym. 2021, 166, 104977. [Google Scholar] [CrossRef]

- Fan, H.Y.; Duquette, D.; Dumont, M.-J.; Simpson, B.K. Salmon skin gelatin-corn zein composite films produced via crosslinking with glutaraldehyde: Optimization using response surface methodology and characterization. Int. J. Biol. Macromol. 2018, 120, 263–273. [Google Scholar] [CrossRef]

- Wu, T.; Zhang, Q.; Ren, W.; Yi, X.; Zhou, Z.; Peng, X.; Yu, X.; Lang, M. Controlled release of gentamicin from gelatin/genipin reinforced beta-tricalcium phosphate scaffold for the treatment of osteomyelitis. J. Mater. Chem. B 2013, 1, 3304–3313. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Kim, M.P.; Na, S.; Lee, Y.; Park, J.; Cho, S.; Cho, J.; Kim, J.J.; Ko, H. Ultra-stretchable yet tough, healable, and biodegradable triboelectric devices with microstructured and ionically crosslinked biogel. Nano Energy 2022, 100, 107438. [Google Scholar] [CrossRef]

- Han, Y.; Han, Y.; Zhang, X.; Li, L.; Zhang, C.; Liu, J.; Lu, G.; Yu, H.-D.; Huang, W. Fish Gelatin Based Triboelectric Nanogenerator for Harvesting Biomechanical Energy and Self-Powered Sensing of Human Physiological Signals. ACS Appl. Mater. Interfaces 2020, 12, 16442–16450. [Google Scholar] [CrossRef] [PubMed]

- Landi, G.; Sorrentino, A.; Iannace, S.; Neitzert, H.C. Differences between graphene and graphene oxide in gelatin based systems for transient biodegradable energy storage applications. Nanotechnology 2017, 28, 054005. [Google Scholar] [CrossRef] [PubMed]

- Su, Z.; Ma, X. A triboelectric nanogenerator based on CNC/gelatin for running and jumping training monitoring. AIP Adv. 2024, 14, 015348. [Google Scholar] [CrossRef]

- Han, X.; Jiang, D.; Qu, X.; Bai, Y.; Cao, Y.; Luo, R.; Li, Z. A Stretchable, Self-Healable Triboelectric Nanogenerator as Electronic Skin for Energy Harvesting and Tactile Sensing. Materials 2021, 14, 1689. [Google Scholar] [CrossRef] [PubMed]

- Pan, R.; Xuan, W.; Chen, J.; Dong, S.; Jin, H.; Wang, X.; Li, H.; Luo, J. Fully biodegradable triboelectric nanogenerators based on electrospun polylactic acid and nanostructured gelatin films. Nano Energy 2018, 45, 193–202. [Google Scholar] [CrossRef]

- Wang, Z.; Hao, C.; Cai, M.; Cui, J.; Zheng, Y.; Xue, C. A highoutput PDMS-MXene/gelatin triboelectric nanogenerator with the petal surface-microstructure. Nano Research 2023, 17, 4151–4162. [Google Scholar] [CrossRef]

- Feroz, S.; Muhammad, N.; Ratnayake, J.; Dias, G. Keratin—Based materials for biomedical applications. Bioact. Mater. 2020, 5, 496–509. [Google Scholar] [CrossRef]

- Lee, H.; Noh, K.; Lee, S.C.; Kwon, I.-K.; Han, D.-W.; Lee, I.-S.; Hwang, Y.-S. Human hair keratin and its-based biomaterials for biomedical applications. Tissue Eng. Regen. Med. 2014, 11, 255–265. [Google Scholar] [CrossRef]

- Yao, G.; Jiang, D.; Li, J.; Kang, L.; Chen, S.; Long, Y.; Wang, Y.; Huang, P.; Lin, Y.; Cai, W.; et al. Self-Activated Electrical Stimulation for Effective Hair Regeneration via a Wearable Omnidirectional Pulse Generator. ACS Nano 2019, 13, 12345–12356. [Google Scholar] [CrossRef]

- Fu, J.; Xia, K.; Xu, Z. A triboelectric nanogenerator based on human fingernail to harvest and sense body energy. Microelectron. Eng. 2020, 232, 111408. [Google Scholar] [CrossRef]

- Zhang, R.; Hummelgård, M.; Örtegren, J.; Olsen, M.; Andersson, H.; Yang, Y.; Zheng, H.; Olin, H. The triboelectricity of the human body. Nano Energy 2021, 86, 106041. [Google Scholar] [CrossRef]

- Jayaweera, E.N.; Wijewardhana, K.R.; Ekanayaka, T.K.; Shahzad, A.; Song, J.-K. Triboelectric Nanogenerator Based on Human Hair. ACS Sustain. Chem. Eng. 2018, 6, 6321–6327. [Google Scholar] [CrossRef]

- Chakraborty, I.; Lai, S.-N.; Wu, M.-C.; Lin, H.-Y.; Li, C.; Wu, J.M.; Lai, C.-S. Charge trapping with α-Fe2O3 nanoparticles accompanied by human hair towards an enriched triboelectric series and a sustainable circular bioeconomy. Mater. Horiz. 2021, 8, 3149–3162. [Google Scholar] [CrossRef]

- Jachowicz, J.; Garcia, M.; Wis-Surel, G. Relationship Between Triboelectric Charging and Surface Modification of Human Hair: Polymeric Versus Monomeric Long Alkyl Chain Quaternary Ammonium Salts. Text. Res. J. 1987, 57, 543–548. [Google Scholar] [CrossRef]

- Fernández-d’Arlas, B. Tough and Functional Cross-linked Bioplastics from Sheep Wool Keratin. Sci. Rep. 2019, 9, 14810. [Google Scholar] [CrossRef]

- Joo, S.; Kim, J.H.; Lee, C.-E.; Kang, J.; Seo, S.; Kim, J.-H.; Song, Y.-K. Eco-Friendly Keratin-Based Additives in the Polymer Matrix to Enhance the Output of Triboelectric Nanogenerators. ACS Appl. Bio. Mater. 2022, 5, 5706–5715. [Google Scholar] [CrossRef]

- Zhang, S.; Meng, S.; Zhang, K.; Wang, Z.; Xu, X.; Zhi, C.; Shi, S.; Hu, J. A high-performance S-TENG based on the synergistic effect of keratin and calcium chloride for finger activity tracking. Nano Energy 2023, 112, 108443. [Google Scholar] [CrossRef]

- Motora, K.G.; Wu, C.-M.; Jose, C.R.M.; Rani, G.M. Waste-to-Energy: Development of a Highly Efficient Keratin Enhanced Chitosan Bio-Waste-Derived Triboelectric Nanogenerator for Energy Harvesting and Real Applications. Adv. Funct. Mater. 2024, 2315069. [Google Scholar] [CrossRef]

- Ravi Kumar, M.N.V. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Zargar, V.; Asghari, M.; Dashti, A. A Review on Chitin and Chitosan Polymers: Structure, Chemistry, Solubility, Derivatives, and Applications. ChemBioEng Rev. 2015, 2, 204–226. [Google Scholar] [CrossRef]

- Chen, H.; Lu, Q.; Cao, X.; Wang, N.; Wang, Z.L. Natural polymers based triboelectric nanogenerator for harvesting biomechanical energy and monitoring human motion. Nano Res. 2022, 15, 2505–2511. [Google Scholar] [CrossRef]

- Ma, C.; Gao, S.; Gao, X.; Wu, M.; Wang, R.; Wang, Y.; Tang, Z.; Fan, F.; Wu, W.; Wan, H.; et al. Chitosan biopolymer-derived self-powered triboelectric sensor with optimized performance through molecular surface engineering and data-driven learning. InfoMat 2019, 1, 116–125. [Google Scholar] [CrossRef]

- Kim, J.-N.; Lee, J.; Go, T.W.; Rajabi-Abhari, A.; Mahato, M.; Park, J.Y.; Lee, H.; Oh, I.-K. Skin-attachable and biofriendly chitosan-diatom triboelectric nanogenerator. Nano Energy 2020, 75, 104904. [Google Scholar] [CrossRef]

- Le Tien, C.; Lacroix, M.; Ispas-Szabo, P.; Mateescu, M.-A. N-acylated chitosan: Hydrophobic matrices for controlled drug release. J. Control. Release 2003, 93, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.Y.; Chun, J.; Lee, J.-H.; Kim, K.N.; Kang, N.-R.; Kim, J.-Y.; Kim, M.H.; Shin, K.-S.; Gupta, M.K.; Baik, J.M.; et al. Hydrophobic Sponge Structure-Based Triboelectric Nanogenerator. Adv. Mater. 2014, 26, 5037–5042. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Gihar, S.; Shrivash, M.K.; Kumar, P.; Kundu, P.P. A review on the synthesis of graft copolymers of chitosan and their potential applications. Int. J. Biol. Macromol. 2020, 163, 2097–2112. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y.; Zhang, L.; Zhou, J.; Lu, A. Transparent, Ultra-Stretching, Tough, Adhesive Carboxyethyl Chitin/Polyacrylamide Hydrogel Toward High-Performance Soft Electronics. Nano-Micro Lett. 2022, 15, 8. [Google Scholar] [CrossRef] [PubMed]

- Hong, F.; Qiu, P.; Wang, Y.; Ren, P.; Liu, J.; Zhao, J.; Gou, D. Chitosan-based hydrogels: From preparation to applications, a review. Food Chem. X 2024, 21, 101095. [Google Scholar] [CrossRef]

- Thambiliyagodage, C.; Jayanetti, M.; Mendis, A.; Ekanayake, G.; Liyanaarachchi, H.; Vigneswaran, S. Recent Advances in Chitosan-Based Applications—A Review. Materials 2023, 16, 2073. [Google Scholar] [CrossRef]

- Wang, R.; Gao, S.; Yang, Z.; Li, Y.; Chen, W.; Wu, B.; Wu, W. Engineered and Laser-Processed Chitosan Biopolymers for Sustainable and Biodegradable Triboelectric Power Generation. Adv. Mater. 2018, 30, 1706267. [Google Scholar] [CrossRef] [PubMed]

- Yar, A.; Okbaz, A.; Parlayıcı, Ş. A biocompatible, eco-friendly, and high-performance triboelectric nanogenerator based on sepiolite, bentonite, and kaolin decorated chitosan composite film. Nano Energy 2023, 110, 108354. [Google Scholar] [CrossRef]

- Jao, Y.-T.; Yang, P.-K.; Chiu, C.-M.; Lin, Y.-J.; Chen, S.-W.; Choi, D.; Lin, Z.-H. A textile-based triboelectric nanogenerator with humidity-resistant output characteristic and its applications in self-powered healthcare sensors. Nano Energy 2018, 50, 513–520. [Google Scholar] [CrossRef]

- Shyju, S.; Chandran, A.M.; Varun, S.; Kumar, M.V.P.; Mural, P.K.S. Chitosan Nanocomposite-Based Triboelectric Nanogenerators with Enhanced Electrical Performance: An Opportunity for Bioelectronics. ACS Appl. Electron. Mater. 2024, 6, 887–900. [Google Scholar]

- Wang, L.; Daoud, W.A. Hybrid conductive hydrogels for washable human motion energy harvester and self-powered temperature-stress dual sensor. Nano Energy 2019, 66, 104080. [Google Scholar] [CrossRef]

- Pongampai, S.; Charoonsuk, T.; Pinpru, N.; Pulphol, P.; Vittayakorn, W.; Pakawanit, P.; Vittayakorn, N. Triboelectric-piezoelectric hybrid nanogenerator based on BaTiO3-Nanorods/Chitosan enhanced output performance with self-charge-pumping system. Compos. Part B Eng. 2021, 208, 108602. [Google Scholar] [CrossRef]

- Pongampai, S.; Charoonsuk, T.; Pinpru, N.; Muanghlua, R.; Vittayakorn, W.; Vittayakorn, N. High Performance Flexible Tribo/Piezoelectric Nanogenerators based on BaTiO3/Chitosan Composites. Integr. Ferroelectr. 2021, 223, 137–151. [Google Scholar] [CrossRef]

- Charoonsuk, T.; Pongampai, S.; Pakawanit, P.; Vittayakorn, N. Achieving a highly efficient chitosan-based triboelectric nanogenerator via adding organic proteins: Influence of morphology and molecular structure. Nano Energy 2021, 89, 106430. [Google Scholar] [CrossRef]

- Zhang, J.; Hu, Y.; Lin, X.; Qian, X.; Zhang, L.; Zhou, J.; Lu, A. High-performance triboelectric nanogenerator based on chitin for mechanical-energy harvesting and self-powered sensing. Carbohydr. Polym. 2022, 291, 119586. [Google Scholar] [CrossRef]

- Jing, X.; Feng, P.; Chen, Z.; Xie, Z.; Li, H.; Peng, X.-F.; Mi, H.-Y.; Liu, Y. Highly Stretchable, Self-Healable, Freezing-Tolerant, and Transparent Polyacrylic Acid/Nanochitin Composite Hydrogel for Self-Powered Multifunctional Sensors. ACS Sustain. Chem. Eng. 2021, 9, 9209–9220. [Google Scholar] [CrossRef]

| Biomass for Triboelectric Devices (Published Year) | Contact Pair Materials | Mechanical Property | Triboelectric Mode | Triboelectric Outputs | Cycle Test | Degradation Test | Applications | Ref. |

|---|---|---|---|---|---|---|---|---|

| Cellulose composites (2017–2023) | Bacterial nanocellulose Copper | - | Contact-separation | 13 V under 16.8 N and 1 Hz 8.1 μC/m2 4.8 mW/m2 at 1 MΩ | - | - | - | [35] |

| Amino-CNF FEP | - | Contact-separation | 155 V, 17.5 μA, 65 nC 0.22 W/m2 | 10,000 cycles | - | - | [38] | |

| Allicin-modified CNF PVDF | - | Contact-separation | 7.9 V, 1.28 µA/cm2, 11.53 μC/m2 18.2 µW/cm2 at 10 MΩ | 7000 cycles 90 days | - | LED lighting | [39] | |

| Nitro-CNF Methyl-CNF | - | Contact-separation | 8 V, 9 µA | 50,000 cycles | - | - | [40] | |

| CNF-PEI-Ag FEP | - | Contact-separation and relative sliding | 100 V, 1.1 µA, 30 nC under 10 N and 2 Hz 0.43 W/m2 at 50 MΩ | 10,000 cycles | - | LED lighting Touch sensor | [41] | |

| BC/BTO NP/Ag composite PTFE | - | Contact-separation | 460 V, 23 µA 180 µW/cm2 at 50 MΩ | 10,000 cycles | - | LED lighting | [45] | |

| BC/CNT/PPy macrofiber PDMS | Tensile strength 449 MPa Young’s modulus 52.2 GPa | Contact-separation | 170 V, 0.115 µA/cm2, and 0.92 nC/cm2 at 4 Hz 54.14 mW/m2 at 75 MΩ | 1000 cycles | within 108 h | Monitoring human motions | [48] | |

| 5 vol.% Ti2NbO7 NS/BC composite Al electrode | - | Contact-separation | ~36 V and ~8.8 μA 28 µW at 5 MΩ | 5000 cycles | - | LED lighting | [43] | |

| Ethyl cellulose Teflon | Young’s modulus ~84 Gpa | Contact-separation | 60 V, 0.12 µA/cm2 Instant power 6.8 μW/cm2 at 5 Hz RMS power 2.5 μW/cm2 at 5 Hz | - | - | - | [44] | |

| PDA/CNF composite FEP | - | Contact-separation | ~205 V, ~20 µA under 60 kPa, 2 Hz ~48.75 μW/cm2 at 10 MΩ | 10,000 cycles | - | LED lighting Monitoring human motion | [46] | |

| HECM/PAA/PPy composite hydrogel | G′ (6887.2 Pa) and G″ (1091.1 Pa) Toughness 149.8 KJ/m3 Stretchability 316.2% Compressive strength 1.19 Mpa at 78.7% strain | Single-electrode | 7.12 V at 1 Hz | >1000 cycles | Strain sensor Powering electronic devices | [47] | ||

| BC/ZnO (ZBC) nanocomposite | - | Single-electrode | 57.6 V and 5.78 μA under 2 N, 5 Hz 42 mW/m2 at 5 MΩ | 1000 cycles | - | - | [49] | |

| MACPF composite Al electrode | - | Contact-separation | ~600 V, 50 μA under 4–5 N, 5 Hz 84.5 W/m2 at 200 MΩ | >10,000 cycles | Water droplet after 30 min | Powering electronic devices Monitoring human motion | [51] | |

| CNF paper AgNW | - | Contact-separation | 21 V, 2.5 µA 693 mW/m2 at 10 MΩ | - | sonicator for 30 min | LED lighting Capacitor charging | [52] | |

| BC membrane BC-CNT-PPY membrane | - | Contact-separation | 29 V, 0.6 μA 3 μW at 25 MΩ | 10,000 cycles | Sugar solution after 8 h | Powering electronic devices | [55] | |

| Lignin composites (2017–2023) | Lignin-starch composite Kapton | - | Contact-separation | 1.04 V/cm2, 3.96 nA/cm2 173.5 nW/cm2 | 1800 cycles | - | - | [68] |

| Lignin CNF composite Cu electrode | Storage modulus ~8 Gpa under 100 °C | Contact-separation | 360 V, 28 µA under 20.8 N, 5 Hz 52 µW/cm2 at 8 MΩ | 72,000 cycles | - | Capacitor charging | [69] | |

| NR-g-PAM/lignin | Storage modulus ~9300 MPa | Single-electrode | 92 V, 5.21 mA/m2 1411 mW/m2 | 5000 cycles | - | LED lighting | [70] | |

| lignin/polycaprolactone nanofiber (hydrophilic or hydrophonic lignin) | Young’s modulus Hydrophilic lignin ~15.95 ± 4.32 MPa Hydrophonic lignin, Y ~11.8 ± 1.81 MPa | Contact-separation | 95 V under 9 N, 9 Hz, 19.2 nC 157 mW/m2 at 20 MΩ | 100,000 cycles | - | Monitoring human motion (walking and running) | [71] | |

| Lignocellulosic bioplastic | Tensile strength of 99 Mpa | Single-electrode | 31 V, 0.2 mA, and 8 nC at 3.5 kPa 10 mW/m2 at 80 MΩ | 100,000 cycles | after 12 days by microorganisms | Smart ward and medical monitoring | [72] | |

| Al-Cu@W/EG-PAM organohydrogel | tensile strength (31.4 ± 3.8 kPa) Stretchability (~800% elongation) Self-adhesion (~31.4 kPa) | Single-electrode | 220 V, 4.5 pA, and 0.07 pC | 6000 cycles | - | Monitoring human motion (finger- and wrist-bending) | [76] | |

| Peanut shell powder PTFE | - | In-plane sliding | 171.3 V, 24.8 µA 365 mW/m2 at 8 MΩ | 3000 cycles | - | Powering electronic devices Metal surface anti-corrosion system | [79] | |

| Lignin/PVA/EPCH composite film PTFE | - | Contact-separation | 65 V, 6.44 μA at 3~5 Hz 135.4 mW/m2 | 9000 cycles | - | Self-powered humidity- and pressure-sensing | [80] | |

| Peanut shell powder PET | - | Contact-separation | 910 V, 104.5 μA, and 12 mW by hand excitation force 390 V, 14 μA, and 1.3 mW at 10 Hz | 6000 cycles | - | Self-powered pressure-sensing Powering electronic devices | [81] | |

| CMC/lignin-Fe PVDF | - | Contact-separation | 110 V, 8.97 µA, 15.3 nC at 1 Hz 147.19 mW/m2 | 10,000 cycles | - | - | [83] | |

| Liginin/PLLA composite sheet by laser-induced graphitization | - | Single-electrode | ~1.98 mW/m2 at 200 MΩ | - | - | Sensing water and plants | [85] | |

| Collagen composites (2021–2023) | Fish bladder film | - | Single-electrode | 106 V, 4.56 mA/m2, 25 μC/m2 200 mW/m2 at 10 MΩ | 850 cycles Stable during 12 months | - | Powering electronic devices | [88] |

| Eggshell membrane/ZnO composite PTFE | - | Contact-separation | 1.2 μA at 2.3 MΩ | 3400 cycles | - | - | [89] | |

| cellulose/collagen/graphene oxide | - | Single-electrode | 91.4 V, 0.75 μA, 28.7 nC 31.36 W/m2 at 400 MΩ | - | - | LED lighting | [90] | |

| PCOBE organohydrogel | fracture strength 2.15 MPa, ductility 880% toughness 7.63 MJ/m3 Storage modulus 4.84 kPa | Single-electrode | 80 V, 5 μA, 50 nC | - | - | Monitoring human motion (EMG, ECG, walking, running, speaking, grasping) | [91] | |

| Electrospun collagen/PVA/Ag NWs composite PVDF | tensile strength of 3 MPa 90% strain | Contact-separation | 118 V, 3.8 nA, 52 nC 21.06 mW/m2 at 1GO | 1000 cycles | - | Working electronic calculator | [93] | |

| Collagen/glycine, proline, and hydroxyproline composite film Kapton | Holding 17.5 N load under stress condition (1.4 mm) | Contact-separation | 123 V, 20 µA 0.2 mW/cm2 at 20 MΩ | >52,000 cycles | - | Powering electronic devices | [94] | |

| Gelatin composites (2020–2024) | Cellulose acetate nanofiber Gelatin/ImClO4/Ti3C2 composite nanofiber | - | Contact-separation | 300 V, 10 mA/cm2, 18 mC/cm2 500 mW/cm2 at 10 MΩ | 5000 cycles | within approximately 60 days | - | [106] |

| Dopamine-dope fish gelatin FOTS-treated fish gelatin | - | Contact-separation | 500 V, 4 μA under 5 N and 5 Hz 100 μW/cm2 | 10,000 cycles | degraded in the soil for 25 days | Human–machine interaction | [107] | |

| PAM/gelatin/PEDOT: PSS conductive hydrogel | stretchability over 2850% strain) | Single-electrode | 383.8 V, 26.9 μA, 92 nC 1250 mW/m2 at 30 MΩ | 16,000 cycles | - | Monitoring human motions and muscle movements | [108] | |

| Microdome-structured ionic biogel | E ~104 Mpa stretchability (~4000%), tough (~13,462 J/m2) | Single-electrode | 11 V, 3 mA/m2, 115 µC/m2 ~325 mW/m2 | 24,000 cycles | PBS buffer (pH~7.4) solution at 37 °C for 1 h | LCD power Acoustic wave sensing | [113] | |

| Rough fish gelatin film Rough PTFE/PDMS | - | Contact-separation | 130 V, 0.35 μA, 45.8 μW/cm2 at 10 MΩ | 10,000 cycles | - | Monitoring human body motions | [114] | |

| CNC/gelatin | - | Single-electrode | 248 V, 30 μA, 175 μC/m2 583 μW at 20 MΩ | >30,000 cycles | - | Running and jumping, training monitoring | [116] | |

| PAA-Gel-NaCl hydrogel | 800% (uniaxial strain) Storage modulus 10~20 kPa | Single-electrode | ~6 nC, ~22 V, and ~400 nA ~2.9 µW/cm2 at ~140 MΩ | 12,000 cycles | - | Touch/pressure-sensing | [117] | |

| Nanostructured gelatin films Electrospun PVA | - | Contact-separation | 900 V, 10.6 mA/m2 under 50 N, 5 Hz 5 W/m2 at 80 MΩ | 15,000 cycles | Natural water completely in about 40 days | - | [118] | |

| Microstructured gelatin PDMS/Mxene | - | Contact-separation | 417.39 V, 12.01 μA 170 μW/cm2 at 10 MΩ | 10,000 cycles | 150 s in water at a constant temperature of 75 °C | Powering electronic devices Forefoot and heel applications | [119] | |

| Keratin composites (2020–2024) | Hair particle-embedded PVB PFA | - | Contact-separation | 296 V, 37.6 μA 0.6 mW/cm2 at 10 MΩ | 9000 cycles | - | Powering electronic devices | [129] |

| CaCl2/PVA/Keratin | Strain (~300%) Stretchability (200%) | Single-electrode | 24 V, 0.225 V/kPa | 18,000 cycles | - | Sensor location layout and wearable data acquisition system | [130] | |

| Chitosan/ketratin composite PTFE | - | Contact-separation | 322 V, 32.2 μA 14.4 W/m2 at 0.1 MΩ | 8000 cycles | Powering electronic devices | [131] | ||

| Chitin/Chitosan composites (2018–2023) | Chemically treated chitosan Kapton | - | Contact-separation | 16.2 V, 125 uA/m2, 6.8 uC/m2 | - | - | Data-driven learning for car speed sensing | [135] |

| Chitosan–diatom film FEP | - | Contact-separation | 150 V 15.7 mW/m2 at 100 MΩ | - | - | Self-powered watch and skin-attachable motion sensor | [136] | |

| Carboxyethyl chitin/polyacrylamide hydrogel | strain (1586%), self-adhesion (113 kPa for pigskin) toughness 1299.71 kJ/m3 Elastic modulus 66.62 kPa | Single-electrode | 58 V, 52 nC, 1.2 μA 1.17 W/m2 at 1.5 GΩ | 10,000 cycles | - | Human–machine interface | [140] | |

| Chitosan with glycol Ecoflex | - | Contact-separation | 13.5 V, 42 nA 17.5 µW/m2 | - | - | - | [143] | |

| Chitosan/1 wt% Kaolin Silicone | - | Contact-separation | 996 V, 26.5 W/m2 at 1.1 MΩ | - | - | - | [144] | |

| Chitosan–glycerol film PTFE | - | Contact-separation | ~130 V, 90 μC/m2 | 10,000 cycles | - | Self-powered sweat sensor Self-powered gait phase detector | [145] | |

| AgNWs@CS/Ag hydrogel AgNWs@CS/Cu hydrogel | - | Single-electrode | 175 V, 25.1 mA/m2, 1.2 W/m2 at 10.5 MΩ 218 V, 34.44 mA/m2, 2 W/m2 at 10.5 MΩ | Reduced within 24 h (22 °C, RH of 58%) | - | Self-powered temperature–stress dual sensor | [147] | |

| CS/BT-NRs PTFE | Tensile strength 15.7 Mpa Elongation at break 259.1% | Contact-separation | 111.4 V, 21.6 μA 756 μW/cm2 at 4 MΩ | 3000 cycles | - | Powering electronic devices | [148] | |

| BT-NPs embedded into CS PTFE | - | Contact-separation | 110.8 V and 10 μA 431.8 μW at 6 MΩ | 2000 cycles | - | LED lighting | [149] | |

| CS protein composite PTFE | - | Contact-separation | ~77 V and ~13 µA 22.4 μW/cm2 at 3 MΩ | - | long-term stability within 9 weeks | LED lighting | [150] | |

| Chitin-hydrogel film | Tensile strength 84.7 MPa elongation at break 14.5% Young’s modulus 2.4 Gpa | Single-electrode | 182.4 V, 4.8 μA 1.25 W/m2 at 3 Hz | 2000 cycles | after burying in soil for 25 days | Powering electronic devices Monitored real-time pulse signals from carotid artery human–machine interface with non-contact sensation | [151] | |

| Polyacrylic acid/nanochitin composite hydrogel | 400 kPa tensile strength strain range of 0–500% | Single-electrode | 71 V, 7.8 μA 1.06 W/m2 at 5 MΩ | 200 cycles | - | pressure sensor | [152] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, C.H.; Kim, M.P. Advanced Triboelectric Applications of Biomass-Derived Materials: A Comprehensive Review. Materials 2024, 17, 1964. https://doi.org/10.3390/ma17091964

Park CH, Kim MP. Advanced Triboelectric Applications of Biomass-Derived Materials: A Comprehensive Review. Materials. 2024; 17(9):1964. https://doi.org/10.3390/ma17091964

Chicago/Turabian StylePark, Chan Ho, and Minsoo P. Kim. 2024. "Advanced Triboelectric Applications of Biomass-Derived Materials: A Comprehensive Review" Materials 17, no. 9: 1964. https://doi.org/10.3390/ma17091964

APA StylePark, C. H., & Kim, M. P. (2024). Advanced Triboelectric Applications of Biomass-Derived Materials: A Comprehensive Review. Materials, 17(9), 1964. https://doi.org/10.3390/ma17091964