Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review

Abstract

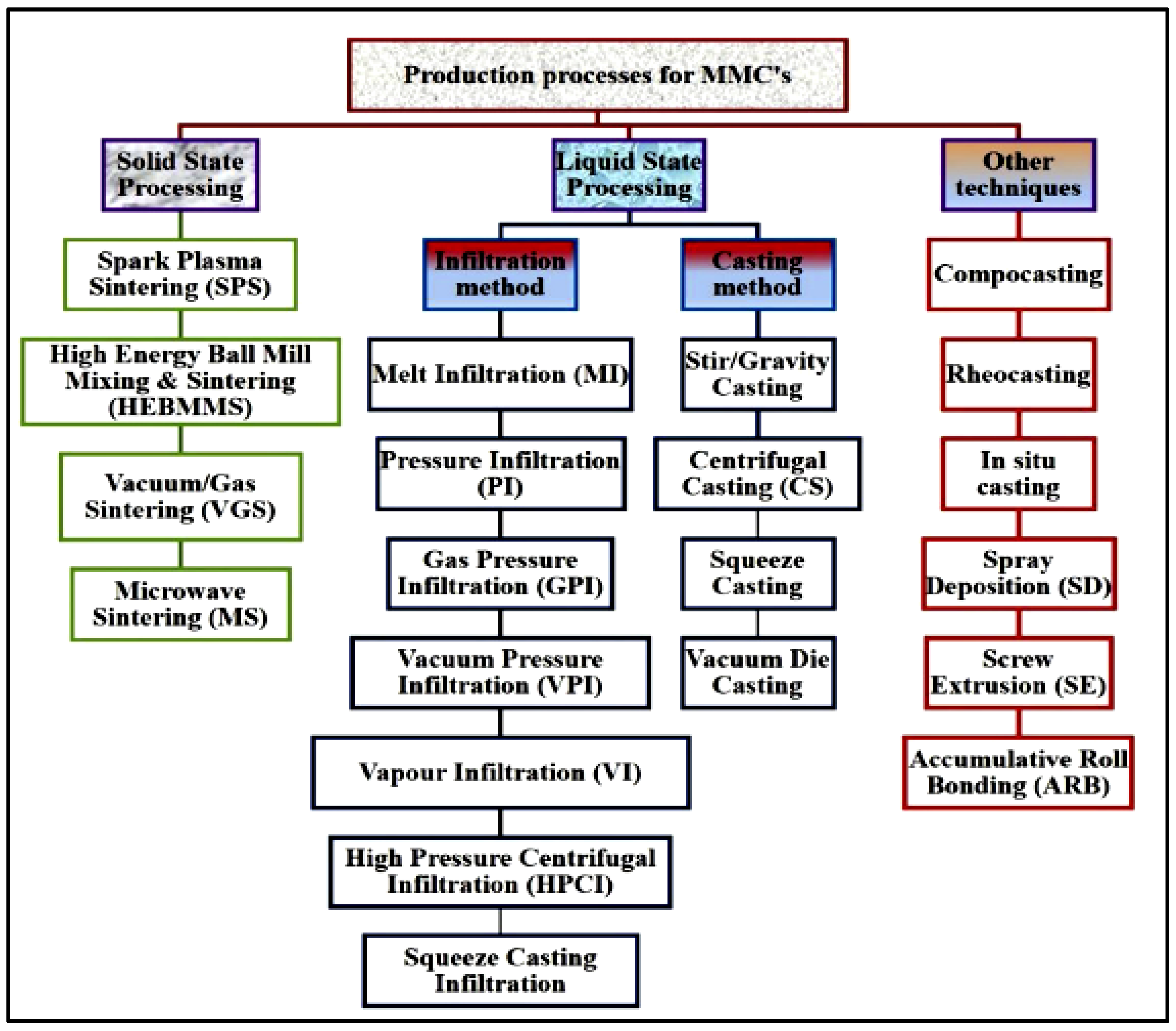

1. Introduction

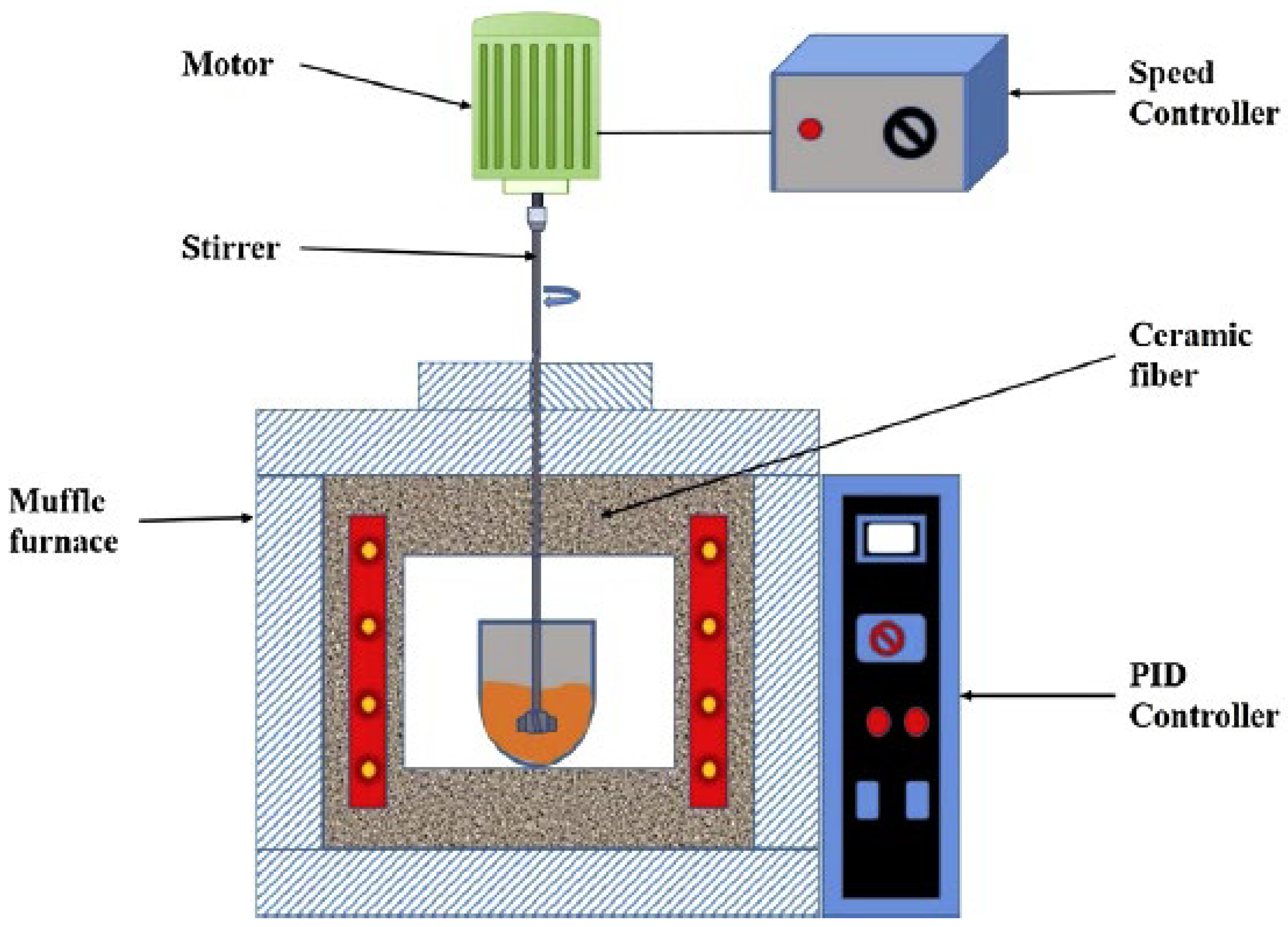

- Stir Casting

- Cost Drivers: Low equipment complexity, minimal consumables, and high production speed.

- Economic Trade-offs: While it is the most economical liquid-state method (∼50% cheaper than powder metallurgy), achieving uniform reinforcement distribution (e.g., SiC, CNTs) requires optimization. Agglomeration of reinforcements like CNTs increases scrap rates, indirectly raising costs.

- Best Suited For: High-volume automotive parts where moderate reinforcement homogeneity suffices.

- Powder Metallurgy (PM)

- Cost Drivers: High energy consumption during sintering, vacuum systems, and multi-step processing (mixing, pressing, sintering).

- Economic Trade-offs: Enables superior microstructural control for functionally graded AMMCs, enhancing properties like hardness (up to 45% increase with 15% SiC). However, costs rise ∼40% compared to casting, limiting use to aerospace/defense applications.

- Sustainability Note: Unit energy costs decrease at large scales, but initial capital investment remains prohibitive for SMEs.

- Additive Manufacturing (SLM/LMD)

- Cost Drivers: High laser-system costs, inert atmospheres, and slow build rates.

- Economic Trade-offs: Achieves exceptional strength (σy = 1147 MPa) via nano/micro hybrid reinforcements, reducing post-machining needs. However, energy consumption per unit mass is 3–5× higher than PM or casting, making it viable only for high-value components (e.g., aircraft fuselage) [13].

- Semi-Solid Processing (Thixoforming/Rheocasting)

- Cost Drivers: Precise temperature control and specialized tooling.

- Economic Trade-offs: Improves CNT dispersion and tensile strength (∼108%) but requires 30–50% longer cycle times than stir casting. Optimal for niche applications like electronics packaging [3].

- Hybrid Green Composites

- Cost Drivers: Use of low-cost agro-wastes (eggshell ash, cow dung ash) as partial reinforcements.

- Economic Trade-offs: Cuts material costs by ∼20% and enhances hardness (7.5 wt.% waste + SiC). Pre-treatment expenses (e.g., carbonization at 500 °C) offset savings marginally [8].

- Cost-Optimization Insights

- Volume Sensitivity: Stir casting dominates above 10,000 units/year; PM is competitive for batches <1000.

- Hidden Costs: Machining post-processing (e.g., wire EDM for SiC/Gr composites) increases costs by 15–30% due to tool wear.

- Emerging Trends: Computational-aided design reduces R&D costs by simulating reinforcement dispersion, slashing trial-and-error expenses [6].

2. Reinforcements Materials into AMMCs

2.1. Silicon Carbide (SiC)-Reinforced AMMCs

2.2. Aluminium Oxide-Reinforced AMMCs

2.3. Boron Carbide (B4C)-Reinforced AMMCs

2.4. Fiber-Reinforced AMMCs

2.5. Zircon-Reinforced AMMCs

2.6. Fly Ash (FA)-Reinforced AMMCs

3. Properties of AMMCs Produced Through Various Stir Casting Processes

4. Processing of Aluminum Metal Matrix Hybrid and Nano Composites

5. Properties of Aluminum Matrix Nano Composites (AMNCs)

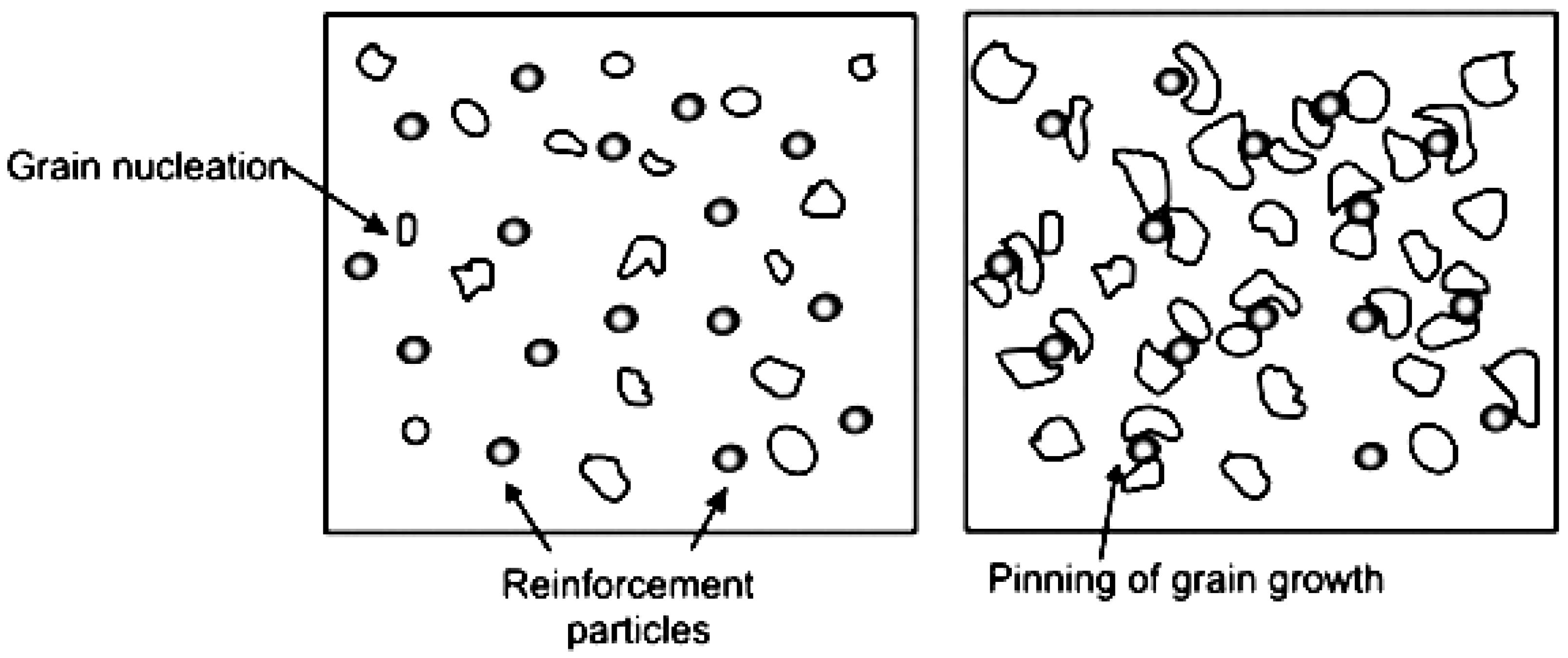

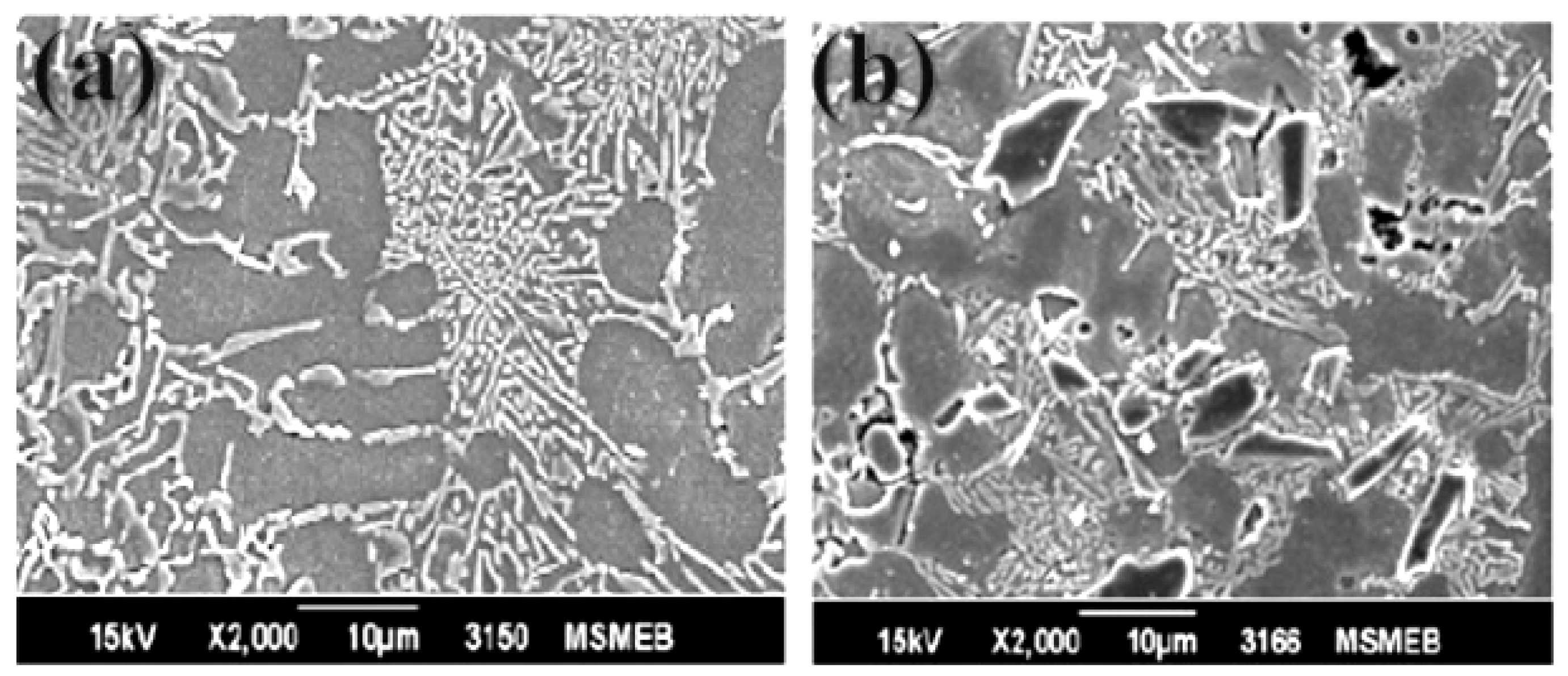

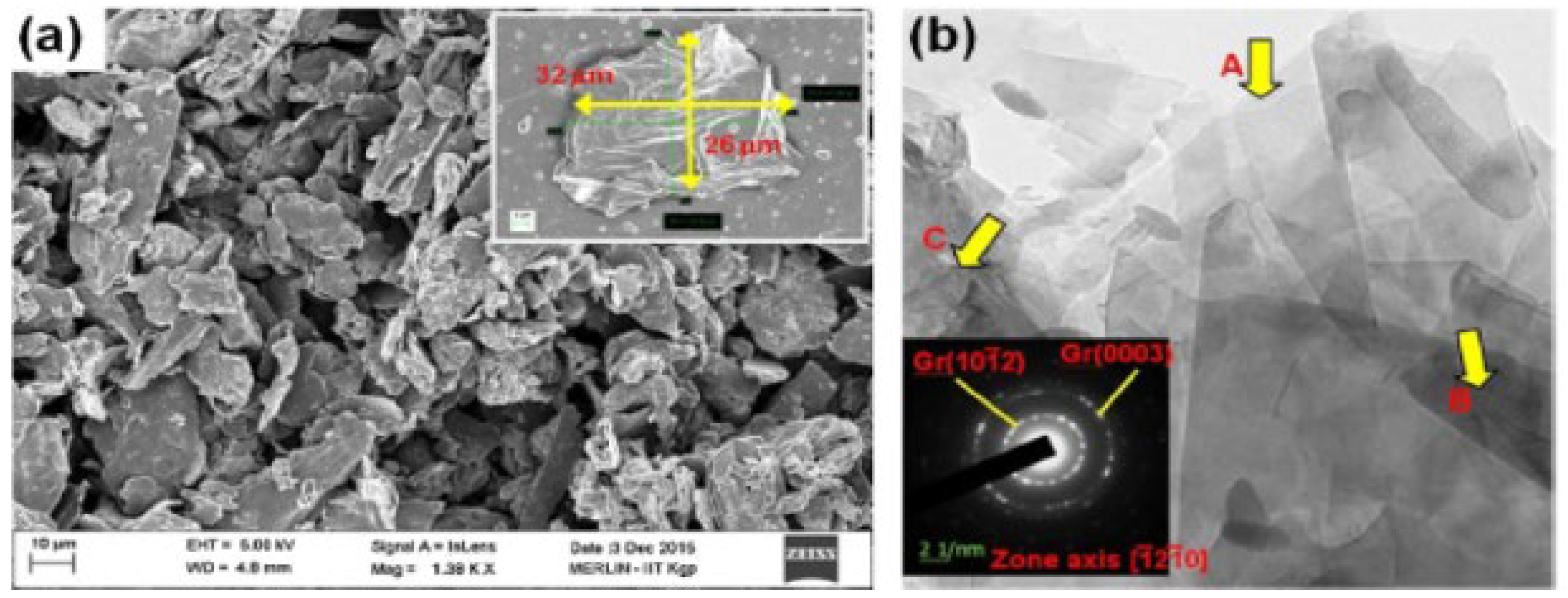

5.1. Microstructural Characteristics of AMMCs

5.2. Microhardness and Density

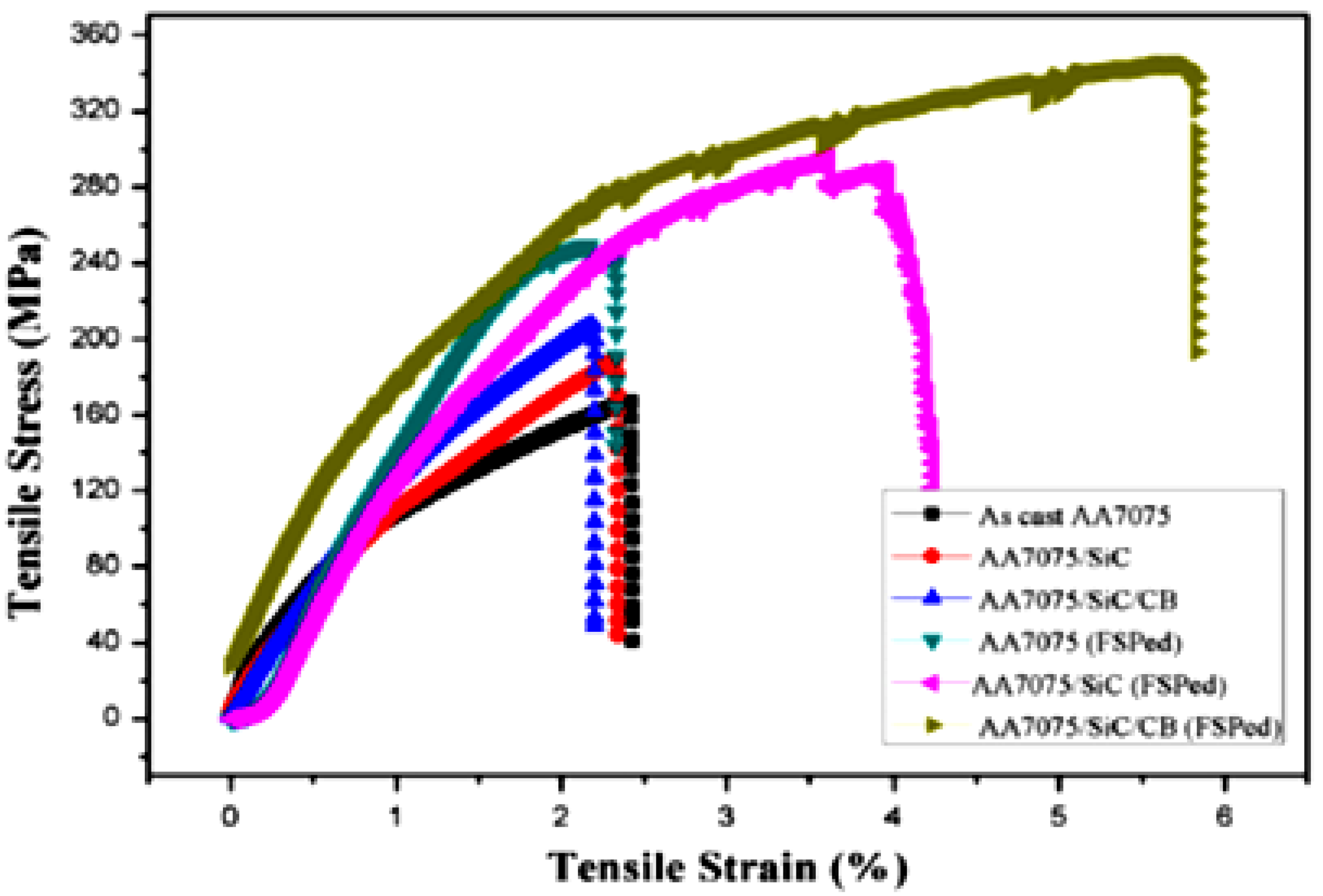

5.3. Tensile Strength of AMMCs

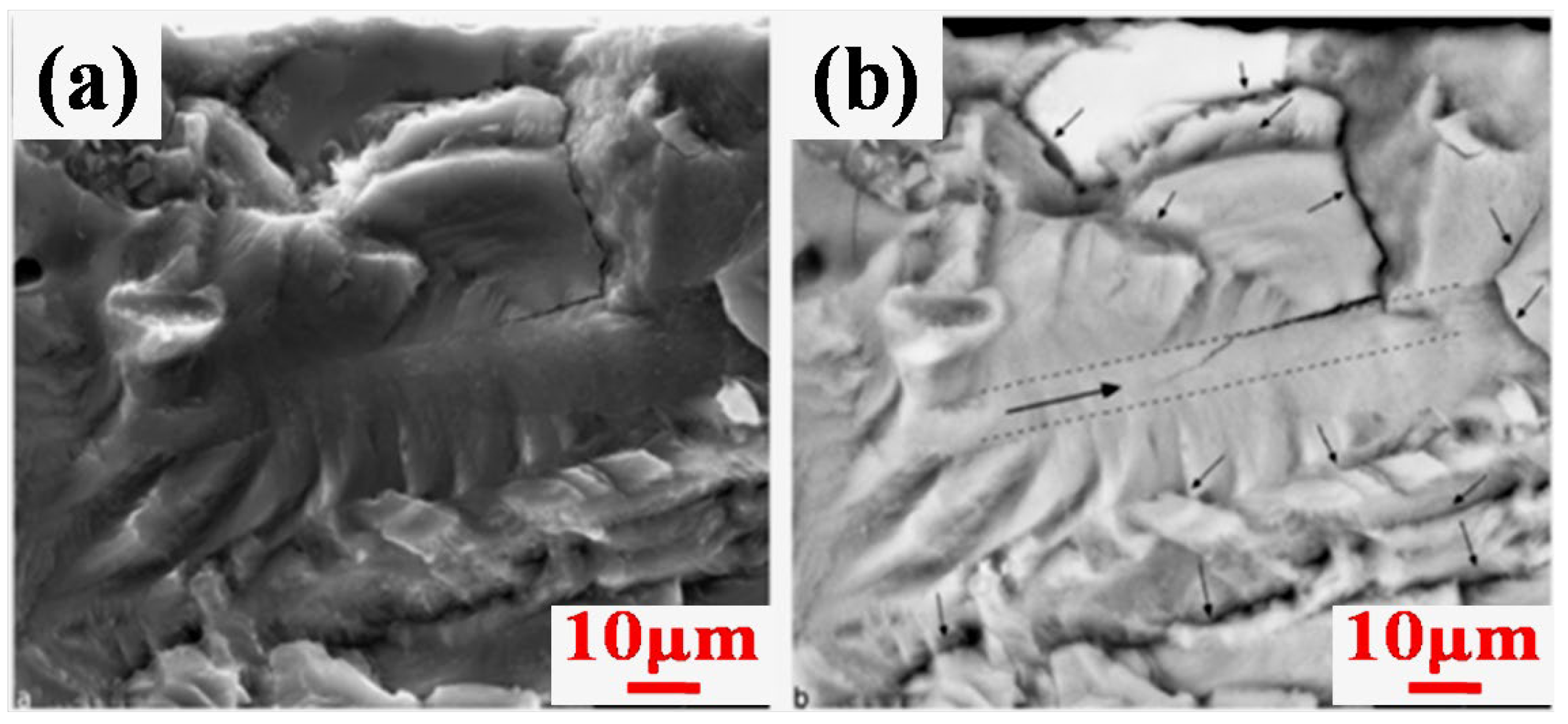

5.4. Fracture Analysis

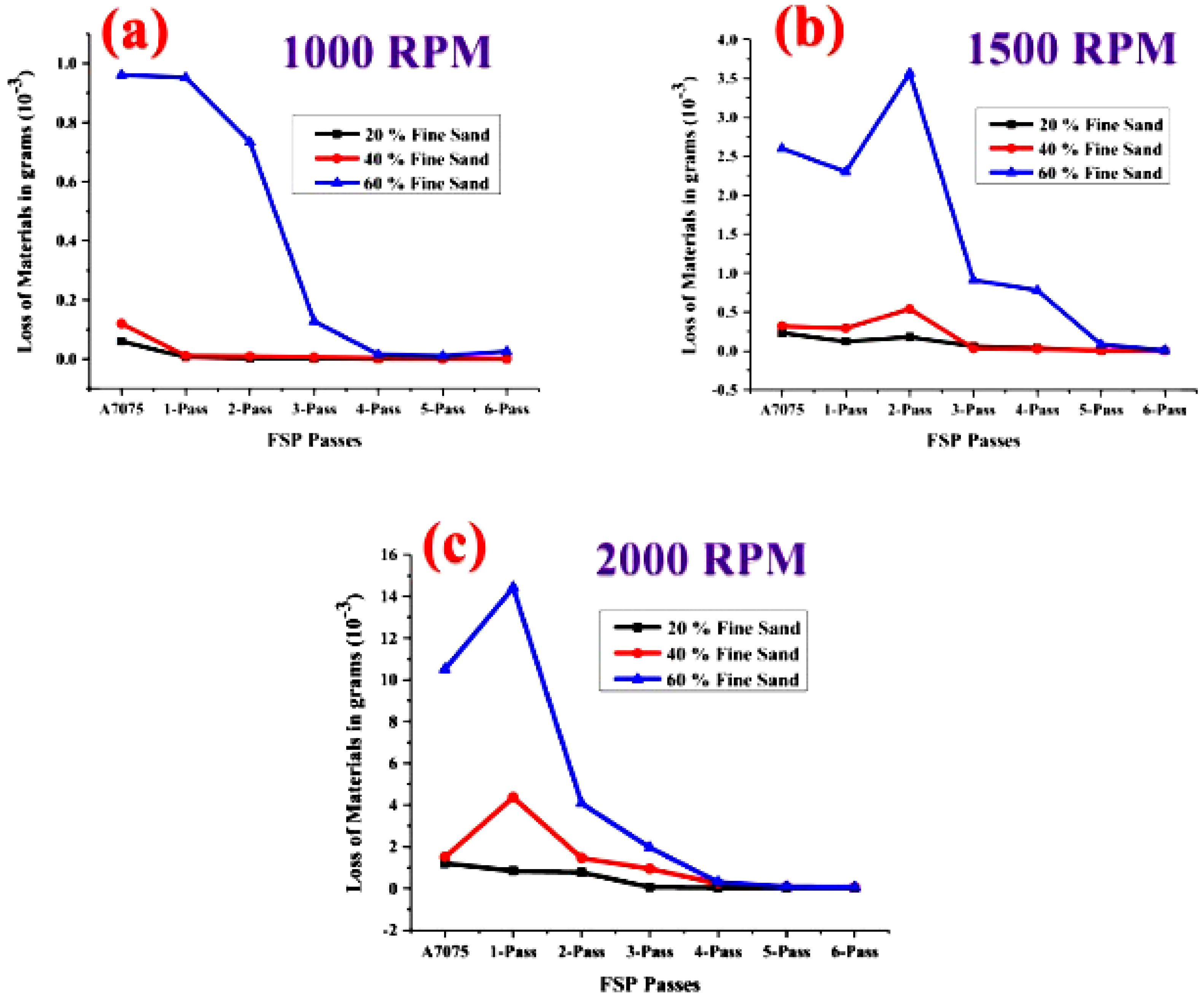

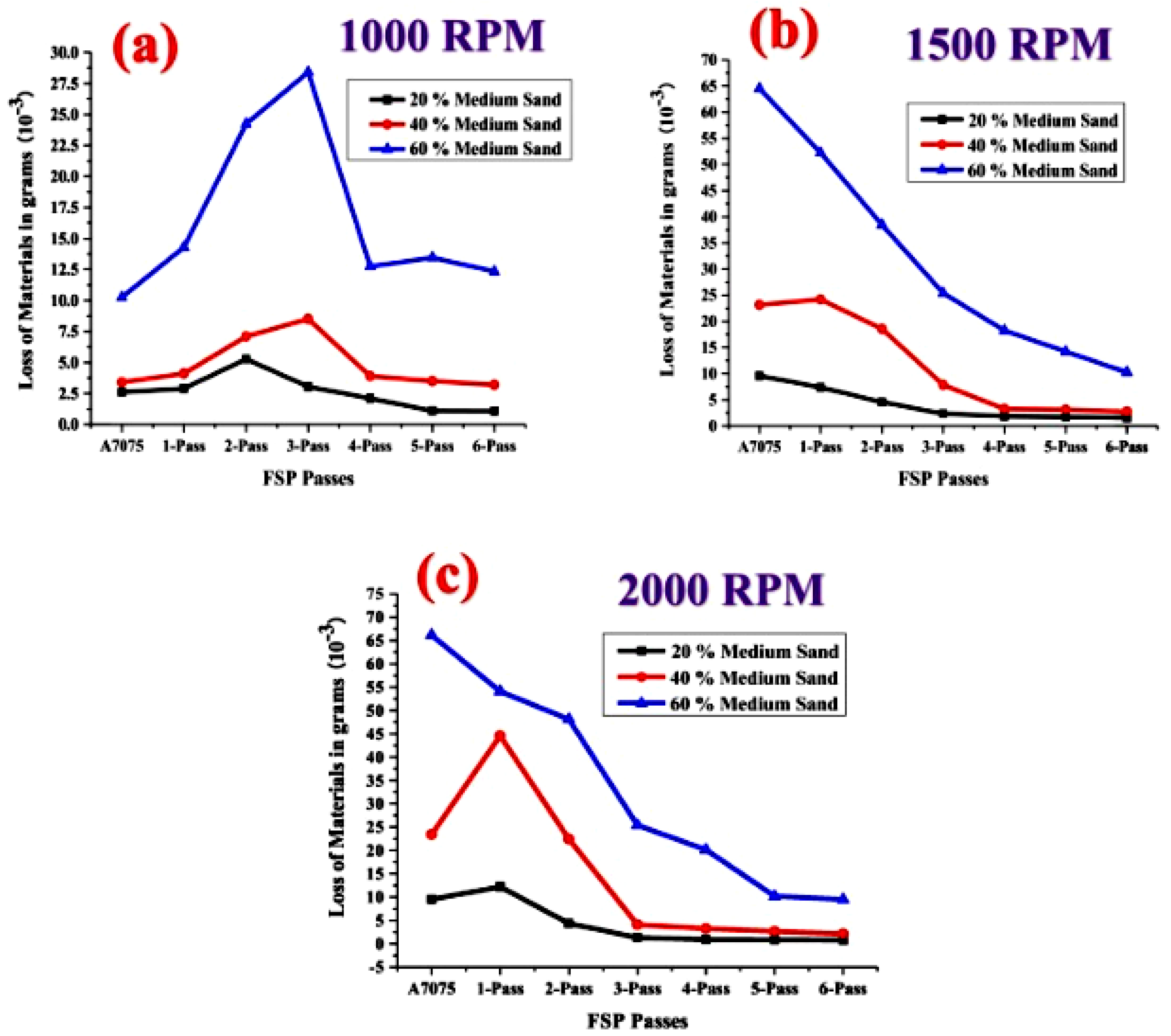

5.5. Wear Behaviour of AMMCs

6. Properties of Aluminium Metal Matrix Hybrid Composites (AMMHCs)

6.1. Microstructural Characterization of AMMHCs

6.2. Tensile Test of AMMHCs

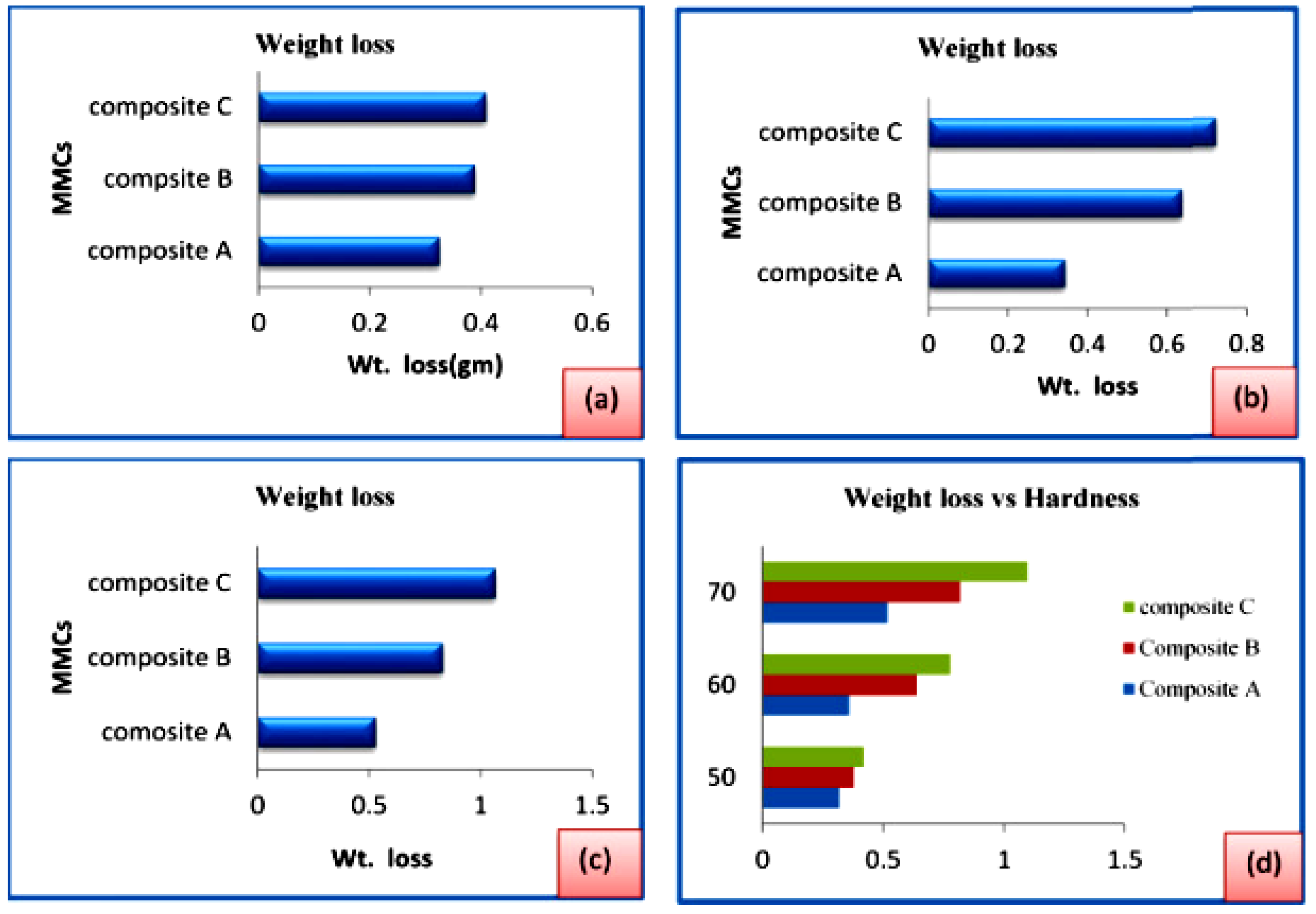

6.3. Wear Behaviour of AMMHCs

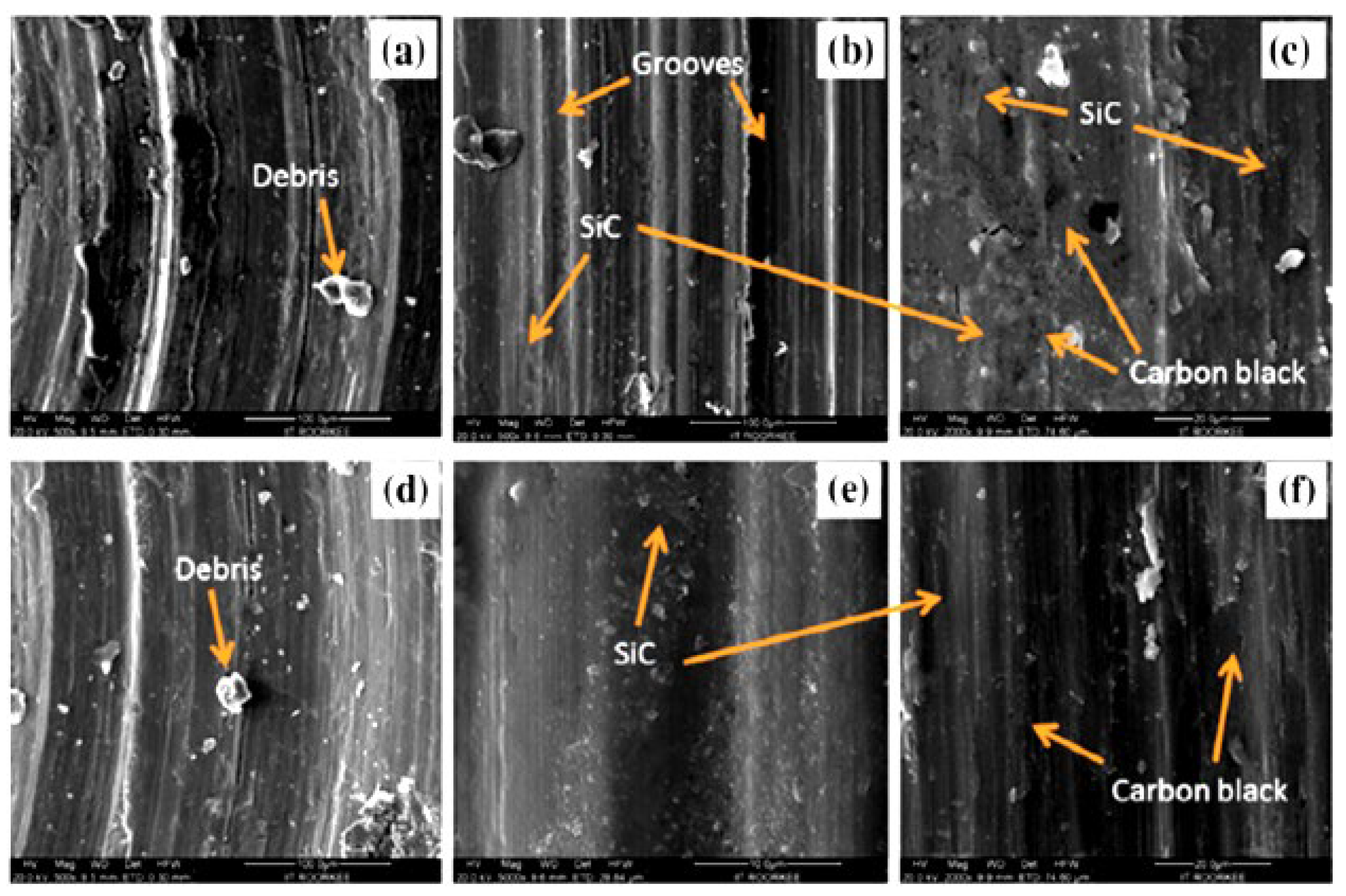

6.4. Morphology of AMMHC Worn Surfaces

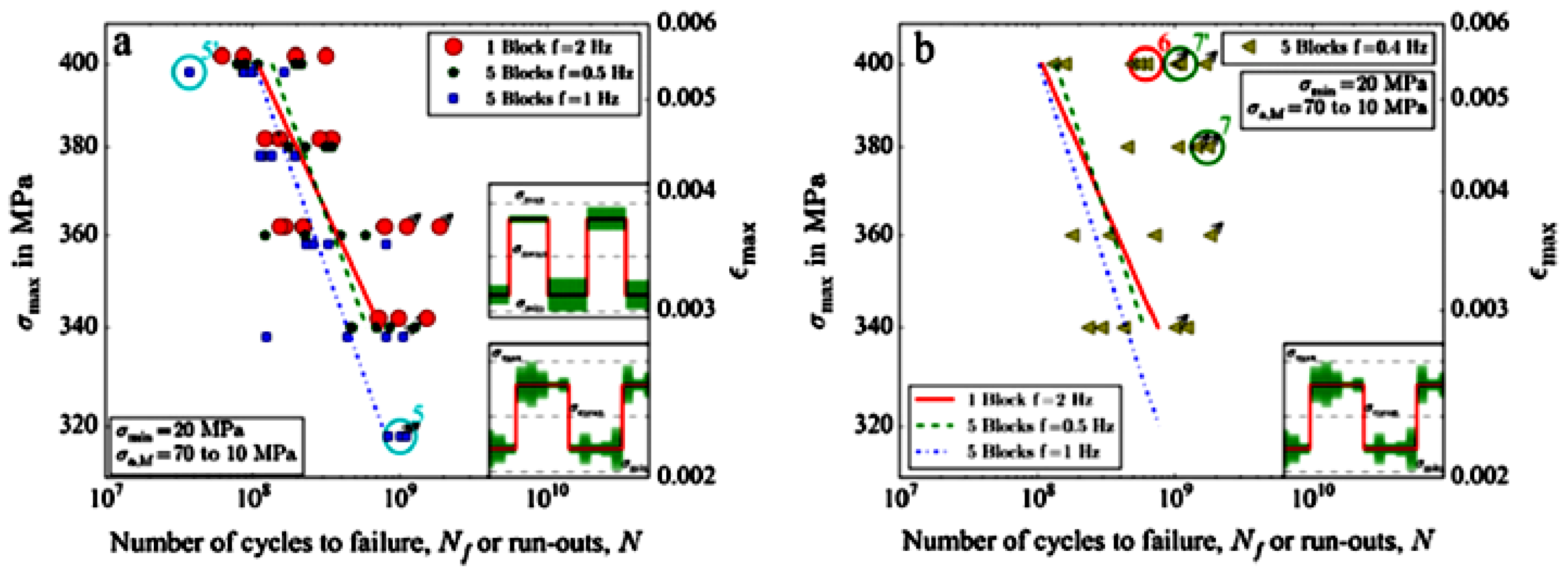

7. Fatigue Test and Fracture Analysis of AMMCs

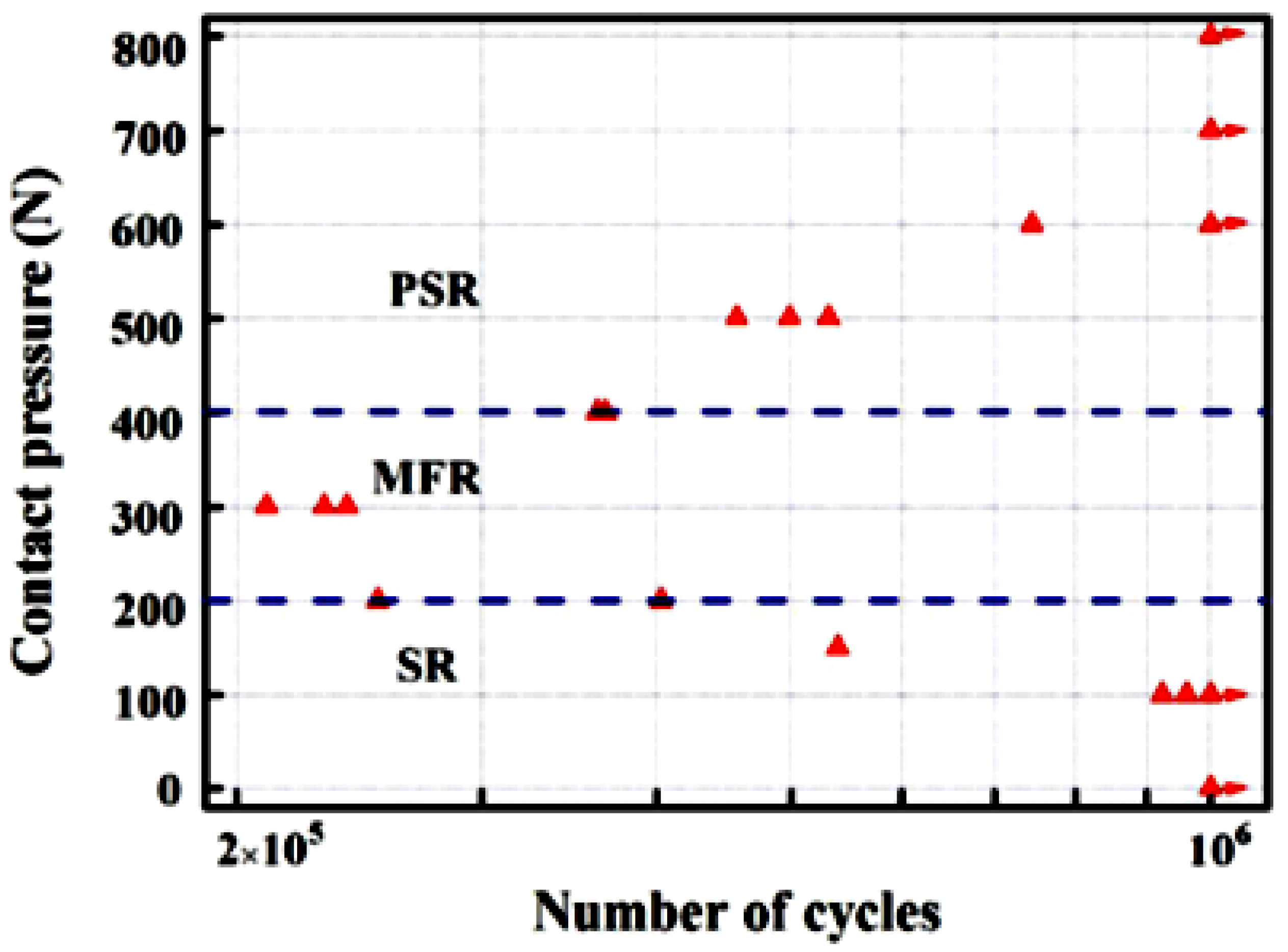

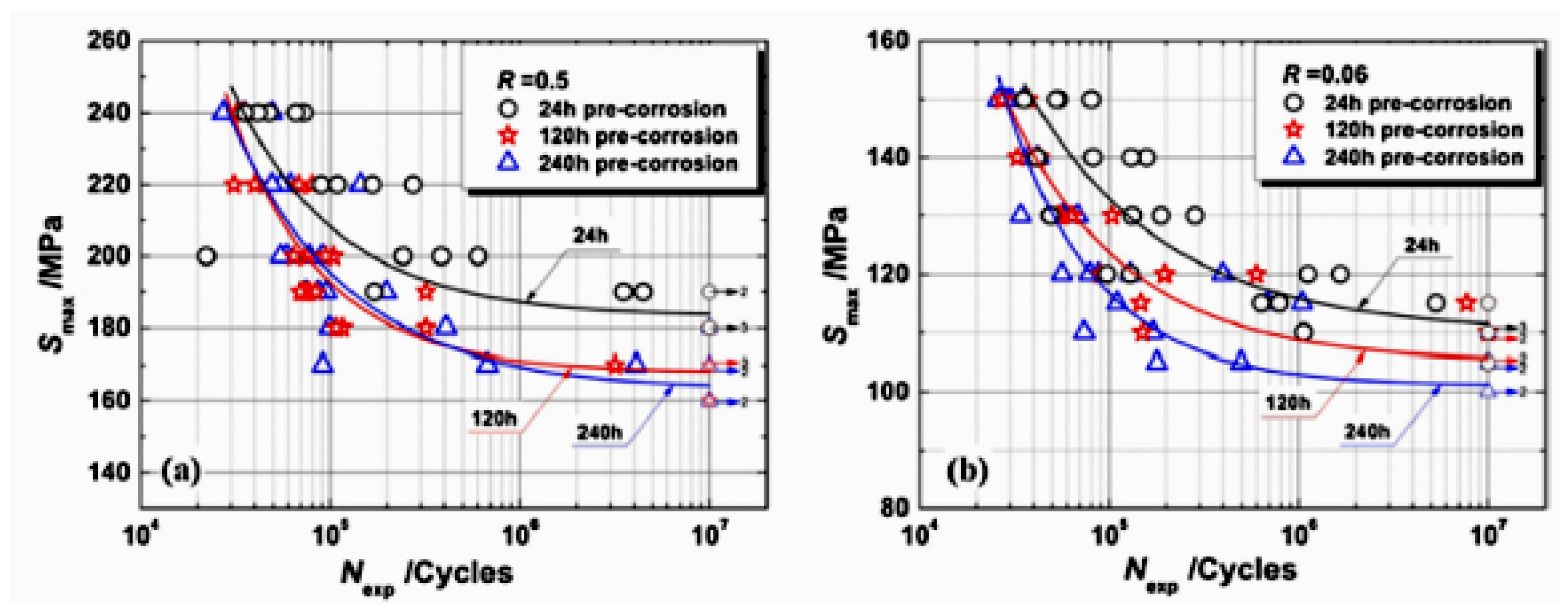

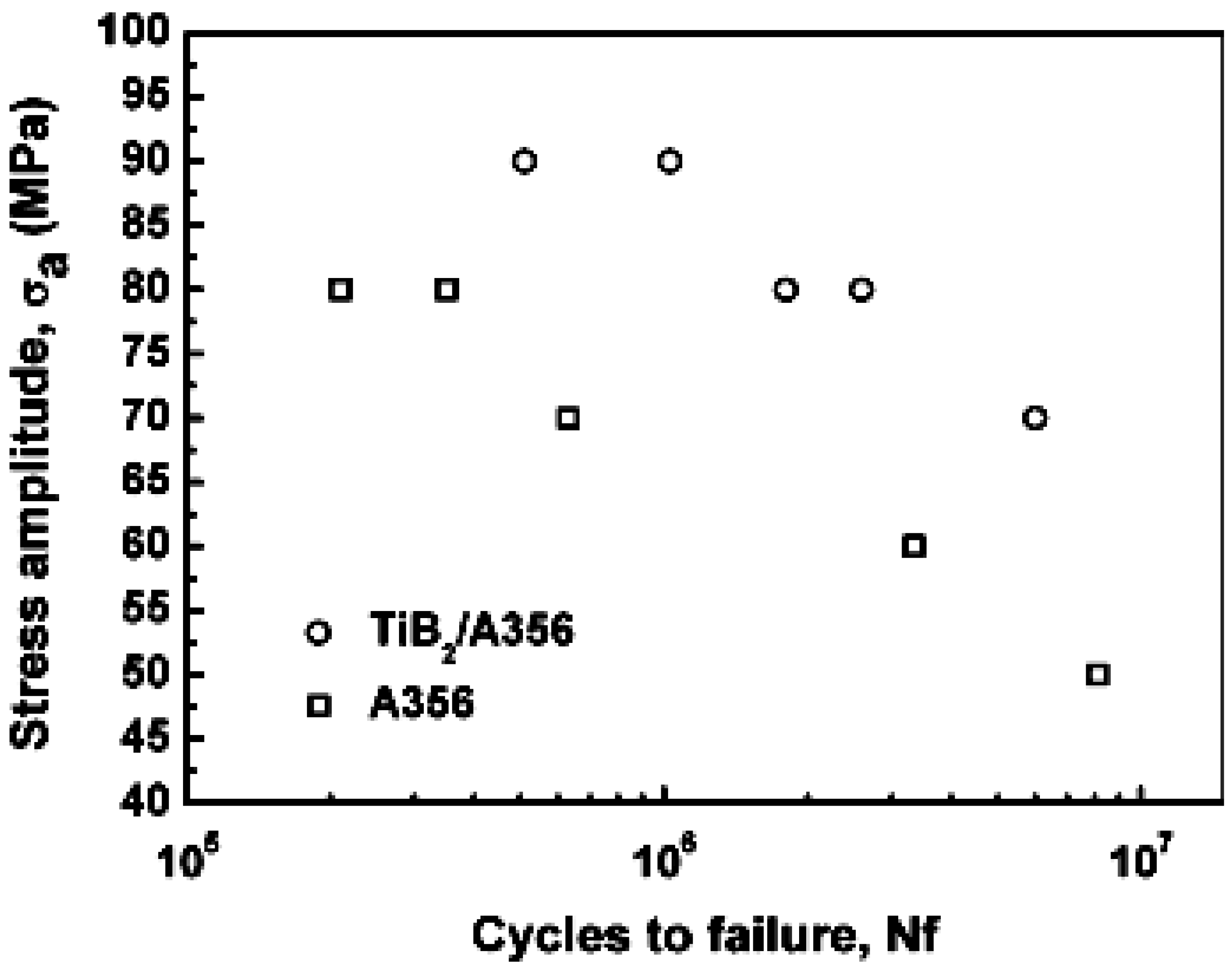

7.1. High Cycle Fatigue Behaviour of AMMCs

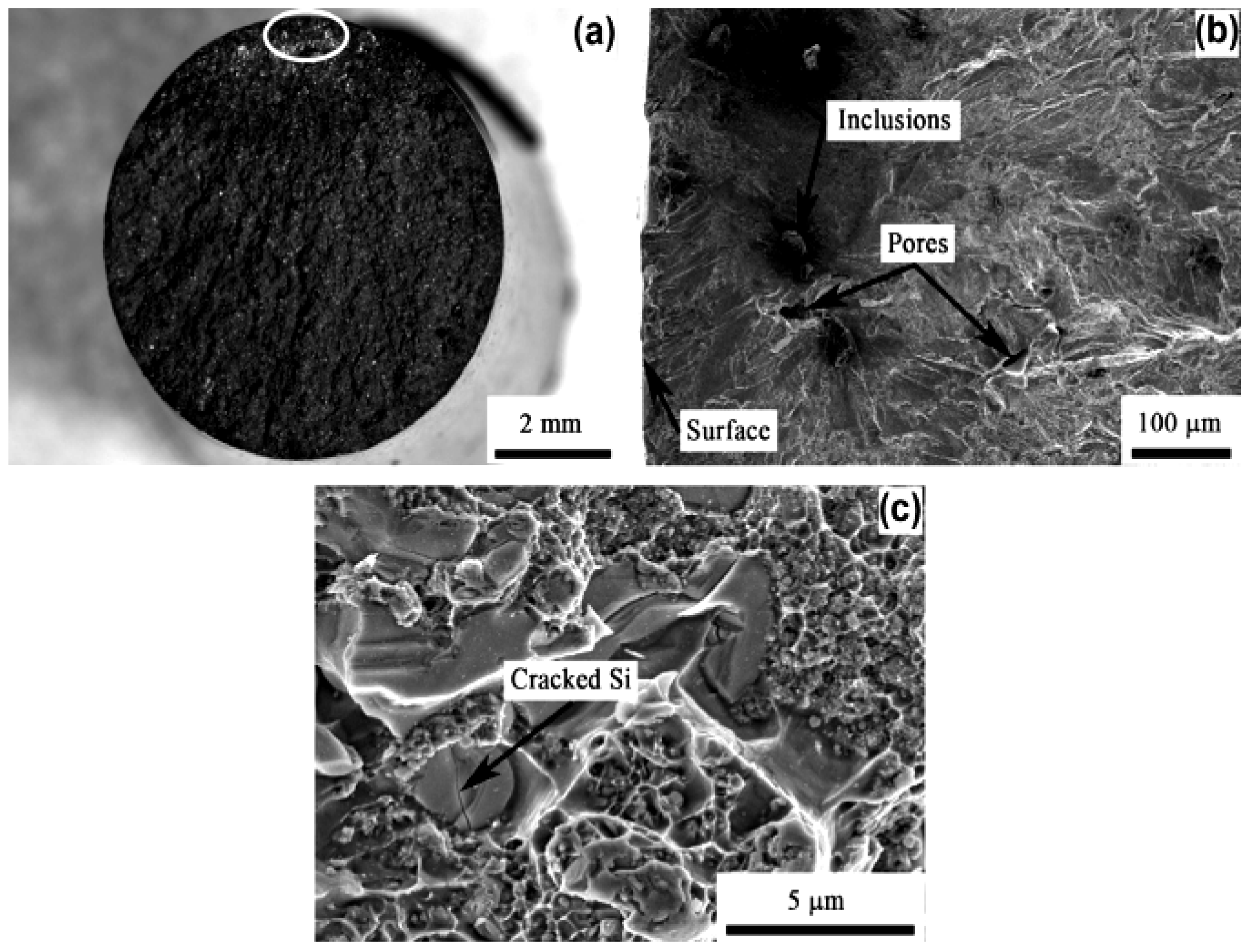

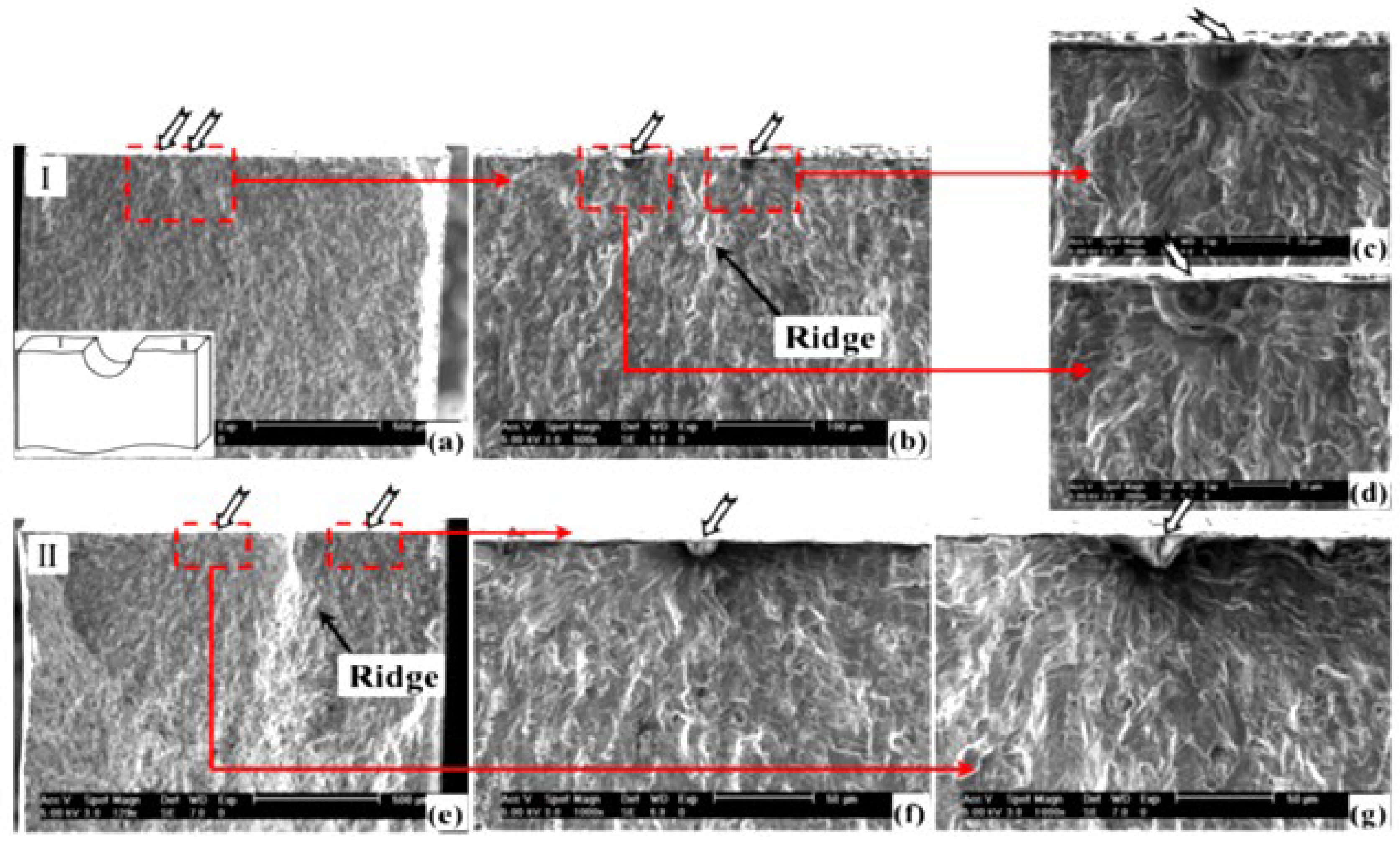

7.2. Study of Crack Initiation Under Fatigue

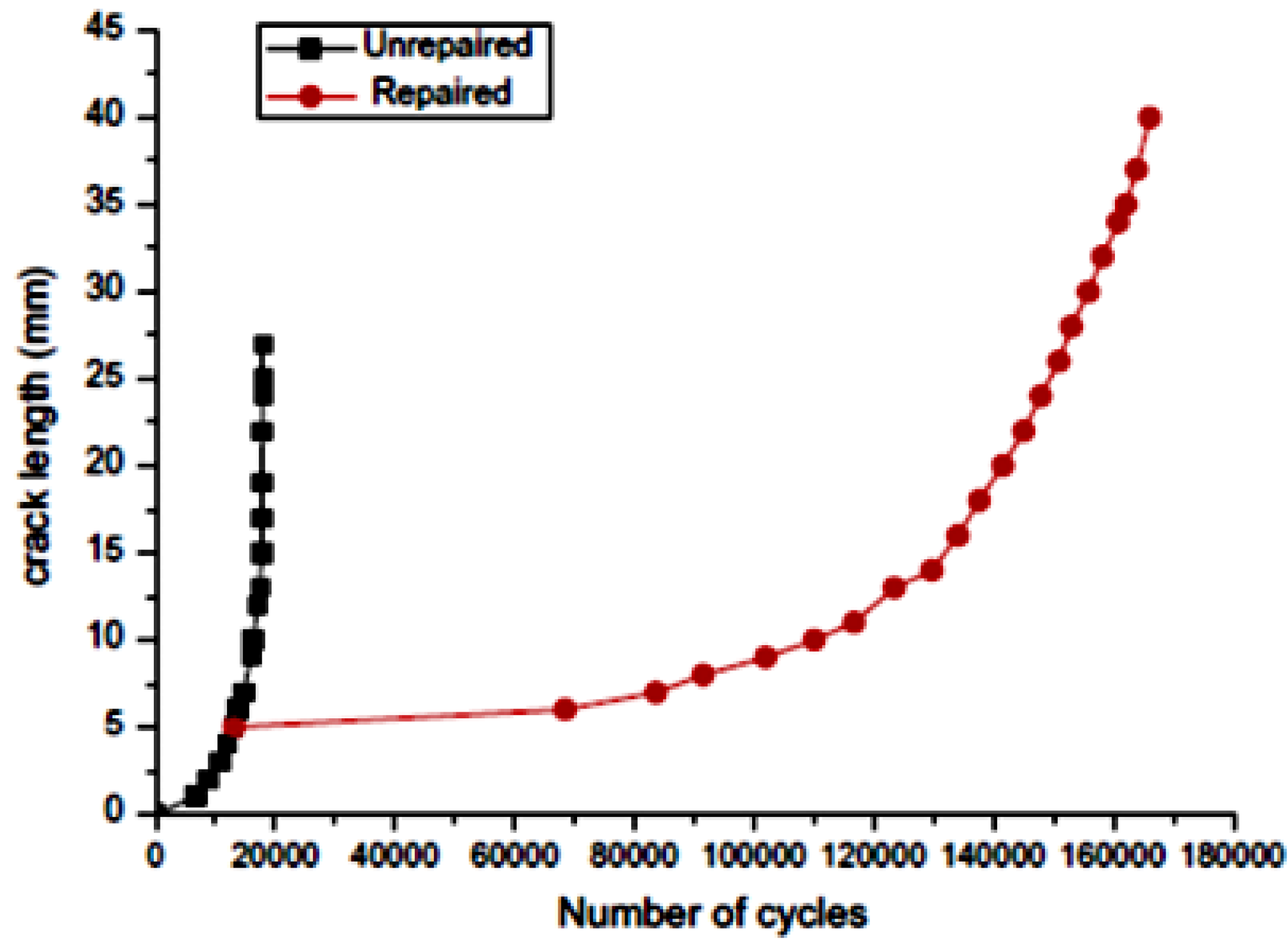

7.3. Growth Rate of Fatigue Crack

7.4. Crack Propagation Under Fatigue Failure

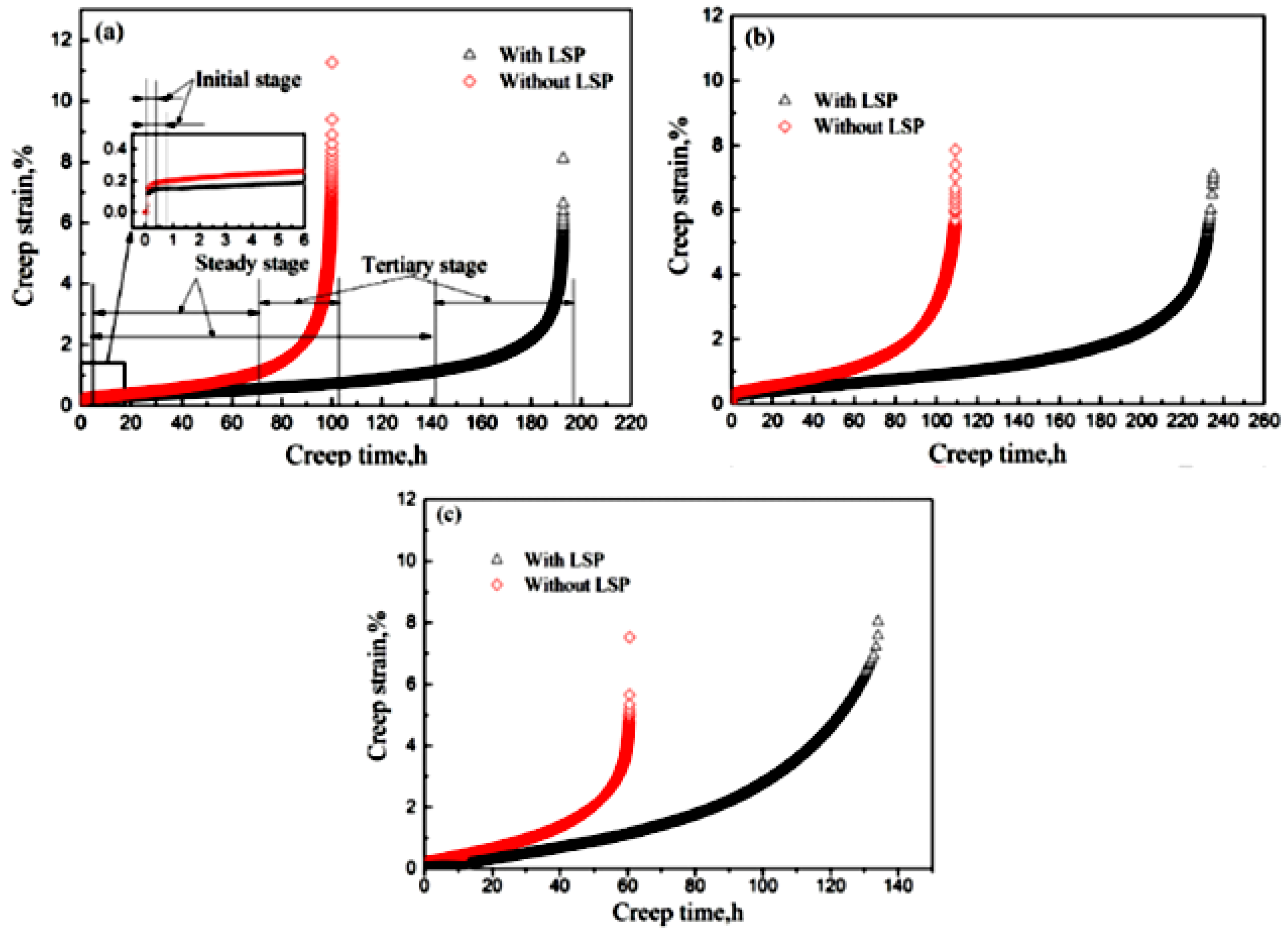

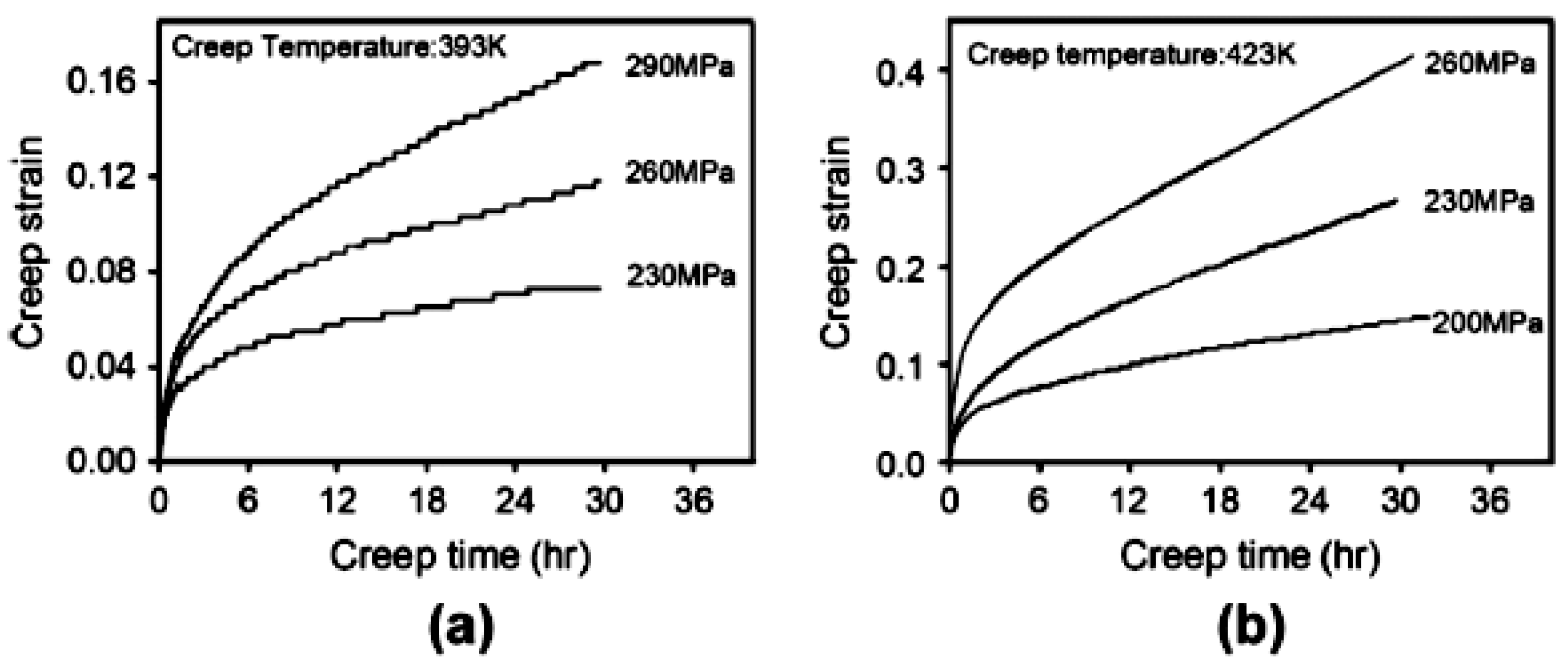

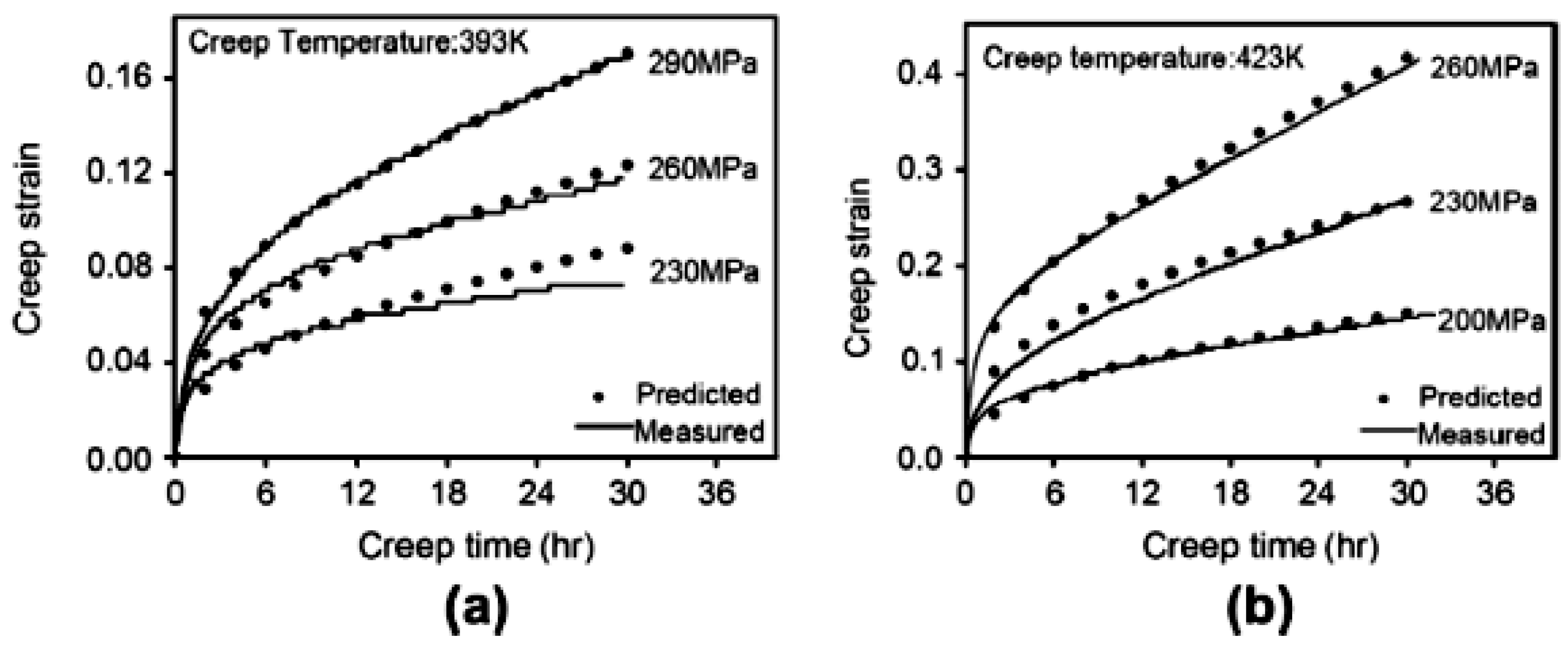

8. Creep Behaviour of AMMCs

Creep Failure Mechanisms of AMMCs

9. Applications and Challenges of AMMCs

- ➢

- Fatigue and Wear Resistance: Long-term structural integrity in AMCs relies heavily on fatigue resistance. Laser shock peening (LSP) significantly enhances high-cycle fatigue life (e.g., 131–259% improvement in SiC-reinforced AMCs) by inducing compressive residual stresses (−127 to −168 MPa), surface hardening (160 HV to 180 HV), and high-density dislocations. These modifications delay crack initiation under cyclic loads, critical for aerospace components. For wear-dominated applications (e.g., automotive parts), squeeze-cast hybrid AMCs with agro-waste reinforcements (e.g., coconut shell ash + SiC) exhibit >20% better wear resistance than base alloys. Optimized squeeze pressure and reinforcement distribution reduce material loss during friction [29].

- ➢

- High-Temperature Stability: AMCs face degradation above 300 °C due to matrix softening and interfacial reactions (e.g., Al4C3 formation in Cf/Al composites). Alloying with Fe, Mn, or Cr stabilizes high-temperature strength by forming thermally stable intermetallics, enabling use in engine components. Additively manufactured AMCs with Ti-based reinforcements retain exceptional strength (σy = 1147 MPa) at low density (3.7 g/cm3), overcoming traditional strength-density trade-offs in extreme environments [35].

- ➢

- Corrosion and Surface Degradation: In corrosive settings, AMCs reinforced with high-entropy alloy particles (HEAp) exhibit superior corrosion resistance due to improved interfacial stability and reduced galvanic coupling. HEAp also enhances ductility while maintaining hardness, mitigating stress-corrosion cracking. For localized repairs, friction stir processing (FSP) disperses Al2O3 particles uniformly in cold-sprayed coatings, reducing wear rates and enhancing hardness through grain refinement [5,7].

- ➢

- Future Challenges: Despite progress, long-term durability requires further attention to the following:

- Interfacial Degradation: Diffusion-controlled reactions at fiber/matrix interfaces at elevated temperatures [6].

- Hybrid Reinforcement Compatibility: Thermal expansion mismatches in multi-scale reinforcements (e.g., nano-SiC + micro-Ti) [35].

- Recyclability: Challenges in reprocessing AMCs with ceramic/HEAp inclusions.

10. Potential of Reinforcement Paradigm in AMMCs

- High-Entropy Alloy Particles (HEAp): defying the strength–ductility paradox, HEAp reinforcements (e.g., AlCoCrFeNi) enable exceptional interfacial stability with aluminum matrices due to their configurationally entropy-driven resistance to elemental diffusion. Unlike brittle ceramics, HEAp enhances yield strength by ∼29% while simultaneously improving ductility through crack-blunting mechanisms [27]. Critically, they mitigate galvanic corrosion by reducing electrochemical potential differences at interfaces, making them ideal for marine and aerospace applications. Their intrinsic toughness also suppresses wear rates under cyclic loading by 20–40% compared to SiC-reinforced AMCs [6,35].

- Agro-Waste Hybrids: as sustainable performance amplifiers, carbonized eggshells (WCE), cow dung ash (CDA), and snail shell ash (SSA) are emerging as low-cost, eco-friendly partial replacements for synthetic reinforcements. Optimized at 7.5 wt.%, these bio-derived ash particles, when combined with SiC or B4C, reduce material costs by 20% while enhancing hardness by 55% and tensile strength by 25% in Al6061 hybrids [48]. Pre-carbonization at 300–500 °C eliminates organic residues and improves wettability with molten aluminum. However, challenges persist in controlling particle size distribution and minimizing porosity in stir-cast composites [8].

- Nano-Scale Planar Defects: as part of the 3D printing revolution, laser powder bed fusion (L-PBF) now enables in situ generation of nano-scale strengthening defects stacking faults, twin boundaries, and9R phases within aluminum matrices. These defects, previously unattainable in bulk aluminum due to its high stacking fault energy, act as potent barriers to dislocation motion. Coupled with tri-modal grain structures (ultrafine equiaxed + fine equiaxed + columnar grains), they yield unprecedented strength-ductility combinations (as-printed: σ = 461 MPa and ε = 21%; post-aged: σ = 656 MPa and ε = 7.2%) [57]. This approach is particularly valuable for topology-optimized aerospace components requiring high specific strength.

- Dual-Structured Titanium Hybrids: in synergistic load transfer, core–shell reinforcements like Ti-encapsulated titanium cores create multi-mechanism strengthening: the ductile Ti core absorbs crack propagation energy; the hard shell provides Orowan strengthening. When combined with a dual-phase Al-Si matrix (Si-rich/Si-lean zones), these composites achieve σ = 1147 MPa at ρ = 3.7 g/cm3 surpassing conventional AMCs’ strength–density limits by >40% [13]. Computational models confirm optimal performance at shell-to-core thickness ratios of 0.89 ± 0.04 [2].

- Multi-Modal Graphene Architectures: Regarding multifunctional enhancement, though less covered in the provided results, graphene-reinforced AMCs (GRAMCs) exploit 2D carbon’s exceptional conductivity (thermal/electrical) and self-lubrication. Dispersing few-layer graphene at 0.5–2 wt.% can reduce coefficient of friction by 60% while doubling thermal conductivity versus monolithic aluminium, enabling applications in electronic heat sinks and wear-resistant bushings [10].

Future Trajectories and Challenges

- Recyclability: HEAp and Ti-reinforced AMCs face segregation issues during remelting, necessitating solid-state reprocessing [68].

- Scalability: Agro-waste consistency requires standardized pre-treatment protocols to ensure batch uniformity.

- AI-Driven Design: Machine learning models (linear regression with 93% accuracy) now predict optimal hybrid reinforcement ratios, accelerating development cycles [4].

11. Conclusions and Further Future Work on AMMCs

- Stir casting is a viable method for fabricating aluminum matrix composites with homogenous reinforcement particle dispersion. Achieving uniform distribution of strengthening phases within the Al matrix is critical for optimizing mechanical properties in these engineered materials.

- Dual and hybrid reinforcements impart superior mechanical and functional properties to aluminum composites compared to mono-reinforced systems. Their synergistic interaction enables multi-scale strengthening mechanisms, enhancing wear resistance, strength, and damage tolerance beyond single-phase composites.

- Hybrid reinforcement systems incorporating particles of differing densities mitigate processing-induced segregation in aluminum composites. This promotes more uniform dispersion of strengthening phases within the matrix, enhancing microstructural homogeneity and resultant mechanical properties compared to single-density reinforcements.

- Homogeneous dispersion of reinforcement particles significantly enhances key mechanical properties in composites, including hardness, tensile strength, and compressive strength. Uniform distribution optimizes load transfer and minimizes stress concentration, maximizing performance.

- Strong interfacial bonding between the matrix and reinforcement phases critically enhances the wear resistance of hybrid composites. This bonding minimizes particle pull-out and subsurface delamination during sliding contact, significantly reducing material loss.

- Al-based composites exhibit superior resistance to fatigue crack initiation but reduced crack growth resistance compared to unreinforced alloys. Cracks predominantly nucleate near porosity sites and fractured eutectic silicon particles during cyclic loading. While reinforcements hinder initial crack formation, they offer less impedance to subsequent propagation through the matrix.

- The observed creep fracture behaviour correlates directly with material deformation mechanisms. Stronger grain interiors in the Al-alloy promote intergranular rupture along boundaries. Conversely, lower-strength grain interiors enable transgranular void nucleation and coalescence, leading to transgranular crack propagation. This dichotomy governs the dominant failure mode under creep conditions.

Funding

Data Availability Statement

Conflicts of Interest

References

- Pargunde, D.; Tambuskar, D.; Kulkarni, S.S. Fabrication of metal matrix composite by stir casting method. Int. J. Adv. Eng. Res. Stud. 2013, 2, 49–51. [Google Scholar]

- Saravanan, P.; Priyan, M.S.; Raghuram, R. Investigation of Mechanical Properties of Aluminium Metal Matrix Composite. Int. J. Eng. Sci. Adv. Technol. 2015, 5, 112–117. [Google Scholar] [CrossRef]

- Borchardt, J.K. Unmanned aerial vehicles spur composites use. Reinf. Plast. 2004, 48, 28–31. [Google Scholar] [CrossRef]

- Surappa, M.K. Aluminium matrix composites: Challenges and opportunities. Sadhana-Acad. Proc. Eng. Sci. 2003, 28, 319–334. [Google Scholar] [CrossRef]

- Rana, R.; Purohit, R.; Das, S. Review of recent Studies in Al matrix composites. Int. J. Sci. Eng. Res. 2012, 3, 1–16. [Google Scholar]

- Rigney, J.D.; Singh, P.M.; Lewandowski, J.J. Environmental effects on ductile-phase toughening in Nb5Si3-Nb composites. JOM 1992, 44, 36–41. [Google Scholar] [CrossRef]

- Ozden, S.; Ekici, R.; Nair, F. Investigation of impact behaviour of aluminium based SiC particle reinforced metal-matrix composites. Compos. Part A: Appl. Sci. Manuf. 2007, 38, 484–494. [Google Scholar] [CrossRef]

- Ozben, T.; Kilickap, E.; Çakır, O. Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. J. Mater. Process. Technol. 2008, 198, 220–225. [Google Scholar] [CrossRef]

- Miyajima, T.; Iwai, Y. Effects of reinforcements on sliding wear behavior of aluminum matrix composites. Wear 2003, 255, 606–616. [Google Scholar] [CrossRef]

- Kiliçkap, E.; Çakır, O.; Aksoy, M.; Inan, A. Study of tool wear and surface roughness in machining of homogenized SiC-preinforced aluminium metal matrix composite. J. Mater. Process. Technol. 2005, 164–165, 862–867. [Google Scholar] [CrossRef]

- Sathishkumar, S.R.; Durairasan, M. Enhancing the capabilities of Mg–4Zn-1RE-0.7Zr alloy through synergistic integration of ceramic (ZrO2) & solid lubricant (BN/MoS2) reinforcements: A Taguchi-GRA optimization approach. Ceram. Int. 2024, 50, 21710–21725. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Panigrahi, S.K. Synergetic effect of in-situ TiB2 reinforcement and nano precipitation on wear behavior of ZE41 magnesium matrix composite. Wear 2025, 560–561, 205609. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M. Aluminium metal matrix composites—A review. Rev. Adv. Mater. Sci. 2014, 38, 55–60. [Google Scholar]

- Choi, B.J.; Kim, I.Y.; Lee, Y.Z.; Kim, Y.J. Microstructure and friction/wear behavior of (TiB+TiC) particulate-reinforced titanium matrix composites. Wear 2014, 318, 68–77. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Pietrzak, K.; Wlosiński, W. Production and application of metal matrix composite materials. J. Mater. Process. Technol. 2000, 106, 58–67. [Google Scholar] [CrossRef]

- Alaneme, K.K.; Olubambi, P.A. Corrosion and wear behaviour of rice husk ash—Alumina reinforced Al-Mg-Si alloy matrixhybrid composites. J. Mater. Res. Technol. 2013, 2, 188–194. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Tjong, S.C.; Li, Y.L. The performance of aluminium-matrix composites with nano metric particulate Si-N-C reinforcement. Compos. Sci. Technol. 1999, 59, 263–270. [Google Scholar] [CrossRef]

- Pandi, G.; Muthusamy, S. A review on machining and tribological behaviors of aluminium hybrid composites. Procedia Eng. 2012, 38, 1399–1408. [Google Scholar] [CrossRef]

- Vasamsetti, S.; Dumpala, L.; Subbarao, V.V. Synthesis, characterization and hardness studies of nano rice husk reinforced Al6061 nanocomposite. J. Eng. Sci. Technol. 2018, 13, 2916–2929. [Google Scholar]

- Mirzadeh, H. Surface metal-matrix composites based on AZ91 magnesium alloy via friction stir processing: A review. Int. J. Miner. Metall. Mater. 2023, 30, 1278–1296. [Google Scholar] [CrossRef]

- Kmar, A.; Lal, S.; Kumar, S. Fabrication and characterization of A359/Al2O3 metal matrix composite using electromagnetic stir casting method. J. Mater. Res. Technol. 2013, 2, 250–254. [Google Scholar] [CrossRef]

- Ajibola, W.A.; Fakeye, A.B. Production and Characterization of Zinc-Aluminium, Silicon Carbide Reinforced with Palm Kernel Shell Ash. Int. J. Eng. Trends Technol. 2016, 41, 318–325. [Google Scholar] [CrossRef]

- Sahin, Y. Wear behaviour of aluminium alloy and its composites reinforced by SiC particles using statistical analysis. Mater. Des. 2003, 24, 95–103. [Google Scholar] [CrossRef]

- Skolianos, S.; Kattamis, T.Z. Tribological properties of SiCp-reinforced Al-4.5%Cu-1.5% Mg alloy composites. Mater. Sci. Eng. A 1993, 163, 107–113. [Google Scholar] [CrossRef]

- Anish, R.; Singh, G.R.; Sivapragash, M. Techniques for processing metal matrix composite: A survey. Procedia Eng. 2012, 38, 3846–3854. [Google Scholar] [CrossRef]

- Moona, G.; Walia, R.S.; Rastogi, V.; Sharma, R. Aluminium metal matrix composites: A retrospective investigation. Indian J. Pure Appl. Phys. 2018, 56, 164–175. [Google Scholar]

- Saravanan, C.; Subramanian, K.; Sivakumar, D.B.; Shankara, R. Fabrication of Aluminium Metal Matrix Composite–A Review. J. Chem. Pharm. Sci. 2015, 7, 82–87. [Google Scholar]

- Muley, A.V.; Aravindan, S.; Singh, I.P. Mechanical and tribological studies on nanoparticles reinforced hybrid aluminum based composite. Manuf. Rev. 2015, 2, 26. [Google Scholar] [CrossRef]

- Ambigai, R.; Prabhu, S. Optimization of friction and wear behaviour of Al–Si3N4 nano composite and Al–Gr–Si3N4 hybrid composite under dry sliding conditions. Trans. Nonferrous Met. Soc. China 2017, 27, 986–997. [Google Scholar] [CrossRef]

- Selvam, J.D.R.; Smart, D.R.; Dinaharan, I. Microstructure and some mechanical properties of fly-ash particulate reinforced AA6061 aluminum alloy composites prepared by compocasting. J. Mater. Des. 2013, 49, 28–34. [Google Scholar] [CrossRef]

- Anvari, S.R.; Karimzadeh, F.; Enayati, M.H. Wear characteristics of Al-Cr-O surface nano-composite layer fabricated on Al6061 plate by friction stir processing. Wear 2013, 304, 144–151. [Google Scholar] [CrossRef]

- Ni, D.R.; Wang, J.J.; Zhou, Z.N.; Ma, Z.Y. Fabrication and mechanical properties of bulk NiTip/Al composites prepared by friction stir processing. J. Alloys Compd. 2014, 586, 368–374. [Google Scholar] [CrossRef]

- Guo, J.F.; Liu, J.; Sun, C.N.; Maleksaeedi, S.; Bi, G.; Tan, M.; Wei, J. Effects of nano-Al2O3 particle addition on grain structure evolution and mechanical behaviour of friction-stir-processed Al. Mater. Sci. Eng. A 2014, 602, 143–149. [Google Scholar] [CrossRef]

- Premnath, A.A.; Alwarsamy, T.; Rajmohan, T.; Prabhu, R. The influence of alumina on mechanical and tribological characteristics of graphite particle reinforced hybrid Al-MMC. J. Mech. Sci. Technol. 2014, 28, 4737–4744. [Google Scholar] [CrossRef]

- Barenji, R.V.; Khojastehnezhad, V.M.; Pourasl, H.H.; Rabiezadeh, A. Wear properties of Al-Al2O3/TiB2 surface hybrid composite layer prepared byfriction stirprocess. J. Compos. Mater. 2016, 50, 1457–1466. [Google Scholar] [CrossRef]

- Fatchurrohman, N.; Farhana, N.; Marini, C.D. Investigation on the Effect of Friction Stir Processing Parameters on Micro-structure and Micro-Hardness of Rice Husk Ash Reinforced Al6061 Metal Matrix Composites. Mater. Sci. Eng. 2018, 319, 012032. [Google Scholar] [CrossRef]

- Kumar, H.G.P.; Xavior, M.A.; Ashwath, P. Ultrasonication and microwave processing of aluminum alloy-Graphene—Al2O3 nanocomposite. Mater. Manuf. Process. 2018, 33, 13–18. [Google Scholar] [CrossRef]

- Patel, K.M.; Pandey, P.M.; Rao, P.V. Determination of an optimum parametric combination using a surface roughness prediction model for EDM of Al2O3/SiCw/TiC ceramic composite. Mater. Manuf. Process. 2009, 24, 675–682. [Google Scholar] [CrossRef]

- Ning, Z.L.; Wang, H.; Sun, J.F. Deformation behavior of semisolid A356 alloy prepared by low temperature pouring. Mater. Manuf. Process. 2010, 25, 648–653. [Google Scholar] [CrossRef]

- Agarwal, M.; Srivastava, R. Influence of Solid Fraction Casting on Microstructure of Aluminum Alloy 6061. Mater. Manuf. Process. 2016, 31, 1958–1967. [Google Scholar] [CrossRef]

- Agarwal, M.; Srivastava, R. Influence of processing parameters on microstructure and mechanical response of a high-pressure die cast aluminum alloy. Mater. Manuf. Process. 2019, 34, 462–472. [Google Scholar] [CrossRef]

- Agrawal, S.S.; Yadava, V. Modeling and prediction of material removal rate and surface roughness in surface-electrical discharge diamond grinding process of metal matrix composites. Mater. Manuf. Process. 2013, 28, 381–389. [Google Scholar] [CrossRef]

- Ahmad, A.H.; Naher, S.; Brabazon, D. The effect of direct thermal method, temperature and time on microstructure of a cast aluminum alloy. Mater. Manuf. Process. 2014, 29, 134–139. [Google Scholar] [CrossRef]

- Akhtar, M.; Qamar, S.Z.; Muhammad, M.; Nadeem, A. Optimum heat treatment of aluminum alloy used in manufacturing of automotive piston components. Mater. Manuf. Process. 2018, 33, 1874–1880. [Google Scholar] [CrossRef]

- Amirkhanlou, S.; Jamaati, R.; Niroumand, B.; Toroghinejad, M.R. Manufacturing of high performance Al356/SiCp composite by CAR process. Mater. Manuf. Process. 2011, 26, 902–907. [Google Scholar] [CrossRef]

- Arisoy, Y.M.; Özel, T. Machine learning based predictive modeling of machining induced microhardness and grain size in Ti-6Al-4V alloy. Mater. Manuf. Process. 2015, 30, 425–433. [Google Scholar] [CrossRef]

- Auradi, V.; Rajesh, G.L.; Kori, S.A. Preparation and evaluation of mechanical properties of 6061Al-B4Cp composites produced via two-stage melt stirring. Mater. Manuf. Process. 2014, 29, 194–200. [Google Scholar] [CrossRef]

- Bains, P.S.; Sidhu, S.S.; Payal, H.S. Fabrication and Machining of Metal Matrix Composites: A Review. Mater. Manuf. Process. 2016, 31, 553–573. [Google Scholar] [CrossRef]

- Bajakke, P.A.; Malik, V.R.; Deshpande, A.S. Particulate metal matrix composites and their fabrication via friction stir processing—A review. Mater. Manuf. Process. 2019, 34, 833–881. [Google Scholar] [CrossRef]

- Balamurugan, P.; Uthayakumar, M. Influence of process parameters on Cu-flyash composite by powder metallurgy technique. Mater. Manuf. Process. 2015, 30, 313–319. [Google Scholar] [CrossRef]

- Basavarajappa, S. Tool wear in turning of graphitic hybrid metal matrix composites. Mater. Manuf. Process. 2009, 24, 484–487. [Google Scholar] [CrossRef]

- Carcea, I.; Nedelcu, D. Technology for obtaining composite material with metallic matrix and Si-C particles. Mater. Manuf. Process. 2012, 27, 694–701. [Google Scholar] [CrossRef]

- Baazamat, S.; Tajally, M.; Borhani, E. Fabrication and characteristic of Al-based hybrid nanocomposites reinforced with WO3 and SiC by accumulative roll bonding process. J. Alloys Compd. 2015, 653, 39–46. [Google Scholar] [CrossRef]

- Yin, Z.; Yuan, J.; Huang, C.; Wang, Z.; Huang, L.; Cheng, Y. Friction and wear behaviors of Al2O3/TiC micro-nano-composite ceramic sliding against metal sand hard materials. Ceram. Int. 2016, 42, 1982–1989. [Google Scholar] [CrossRef]

- Chaira, D.; Sangal, S.; Mishra, B.K. Synthesis of aluminium-cementite metal matrix composite by mechanical alloying. Mater. Manuf. Process. 2007, 22, 492–496. [Google Scholar] [CrossRef]

- Chauhan, S.R.; Dass, K. Optimization of machining parameters in turning of titanium (Grade-5) alloy using response surface methodology. Mater. Manuf. Process. 2012, 27, 531–537. [Google Scholar] [CrossRef]

- Chetan Ghosh, S.; Rao, P.V. Environment Friendly Machining of Ni-Cr-Co Based Super Alloy using Different Sustainable Techniques. Mater. Manuf. Process. 2016, 31, 852–859. [Google Scholar] [CrossRef]

- Faraji, G.; Dastani, O.; Mousavi, S.A.A.A. Effect of process parameters on microstructure and micro-hardness of AZ91/Al2O3 surface composite produced by FSP. J. Mater. Eng. Perform. 2011, 20, 1583–1590. [Google Scholar] [CrossRef]

- Yadav, P.K.; Patel, S.K.; Singh, V.P.; Verma, M.K.; Singh, R.K.; Kuriachen, B.; Dixit, G. Effect of different reinforced metal-matrix composites on mechanical and fracture behaviour of aluminium piston alloy. J. Bio- Tribo-Corros. 2021, 7, 54. [Google Scholar] [CrossRef]

- Yadav, P.K.; Dixit, G.; Kuriachen, B.; Verma, M.K.; Patel, S.K.; Singh, R.K. Effect of reinforcement sand abrasive size on high-stress tribological behaviour of aluminium piston matrix composites. J. Bio- Tribo-Corros. 2020, 6, 23. [Google Scholar] [CrossRef]

- Mishra, P.; Mishra, P.; Rana, R.S. Effect of Rice Husk ash Reinforcements on Mechanical properties of Aluminium alloy (LM6) Matrix Composites. Mater. Today: Proc. 2018, 5, 6018–6022. [Google Scholar] [CrossRef]

- Saravanan, S.D.; Kumar, M.S. Effect of mechanical properties on rice husk ash reinforced aluminum alloy (AlSi10Mg) matrix composites. Procedia Eng. 2013, 64, 1505–1513. [Google Scholar] [CrossRef]

- Sakthivelu, S.; Meignanamoorthy, M.; Ravichandran, M.; Sethusundaram, P.P. Tribological Behavior of AA7050-ZrSiO4 Composites Synthesized by Stir Casting Technique. Mech. Mech. Eng. 2019, 23, 198–201. [Google Scholar] [CrossRef]

- Abdulwahab, M.; Dodo, R.M.; Suleiman, I.Y.; Gebi, A.I.; Umar, I. Wear behavior of Al-7%Si-0.3%Mg/melon shell ash particulate composites. Heliyon 2017, 3, e00375. [Google Scholar] [CrossRef] [PubMed]

- Gnanavelbabu, A.; Rajkumar, K.; Saravanan, P. Investigation on the cutting quality characteristics of abrasive water jet machining of AA6061-B4C-hBN hybrid metal matrix composites. Mater. Manuf. Process. 2018, 33, 1313–1323. [Google Scholar] [CrossRef]

- Guo, Q.; Chang, L.; Ye, L.; Wang, Y.; Feng, H.; Cao, Y.; Lian, Q.; Li, Y. Residual stress, nanohardness, and microstructure changes in whirlwind milling of GCr15 steel. Mater. Manuf. Process. 2013, 28, 1047–1052. [Google Scholar] [CrossRef]

- Gurusamy, P.; Prabu, S.B.; Paskaramoorthy, R. Influence of processing temperatures on mechanical properties and microstructure of squeeze cast aluminum alloy composites. Mater. Manuf. Process. 2015, 30, 367–373. [Google Scholar] [CrossRef]

- Hajjari, E.; Divandari, M.; Arabi, H. Effect of applied pressure and nickel coating on microstructural development in continuous carbon fiber-reinforced aluminum composites fabricated by squeeze casting. Mater. Manuf. Process. 2011, 26, 599–603. [Google Scholar] [CrossRef]

- Hassanpour, H.; Sadeghi, M.H.; Rezaei, H.; Rasti, A. Experimental Study of Cutting Force, Microhardness, Surface Roughness, and Burr Size on Micro milling of Ti6Al4V in Minimum Quantity Lubrication. Mater. Manuf. Process. 2016, 31, 1654–1662. [Google Scholar] [CrossRef]

- Hu, Q.; Zhao, H.; Li, F. Effects of Manufacturing Processes on Microstructure and Properties of Al/A356–B4C Composites. Mater. Manuf. Process. 2016, 31, 1292–1300. [Google Scholar] [CrossRef]

- Poria, S.; Sahoo, P.; Sutradhar, G. Tribological Characterization of Stir-cast Aluminium-TiB2 Metal Matrix Composites. Silicon 2016, 8, 591–599. [Google Scholar] [CrossRef]

- Wu, S.Q.; Wang, H.Z.; Tjong, S.C. Mechanical and wear behavior of an Al/Si alloy metal-matrix composite reinforced with aluminosilicate fiber. Compos. Sci. Technol. 1996, 56, 1261–1270. [Google Scholar] [CrossRef]

- Lee, I.S.; Kao, P.W.; Ho, N.J. Microstructure and mechanical properties of an Al-Fe insitu nano composite produced by friction stir processing. Intermetallics 2008, 16, 1104–1108. [Google Scholar] [CrossRef]

- Qian, J.; Li, J.; Xiong, J.; Zhang, F.; Lin, X. In situ synthesizing Al3Ni for fabrication of intermetallic-reinforced aluminum alloy composites by friction stir processing. Mater. Sci. Eng. A 2012, 550, 279–285. [Google Scholar] [CrossRef]

- Mahmoud, T.S.; Mohamed, S.S. Improvement of microstructural, mechanical and tribological characteristics of A413 cast Al alloys using friction stir processing. Mater. Sci. Eng. A 2012, 558, 502–509. [Google Scholar] [CrossRef]

- Sekban, D.M.; Saray, O.; Aktarer, S.M.; Purcek, G.; Ma, Z.Y. Microstructure, mechanical properties and formability of friction stir processed interstitial-free steel. Mater. Sci. Eng. A 2015, 642, 57–64. [Google Scholar] [CrossRef]

- Cygan, T.; Wozniak, J.; Kostecki, M.; Adamczyk-cieslak, B.; Olszyna, A. Influence of graphene addition and sintering temperature on physical properties of Si3N4 matrix composites. Int. J. Refract. Met. Hard Mater. 2016, 57, 19–23. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Ahamed, A.; Channabasappa, B.H.; Keshavamurthy, R. Development of Al6063-TiB2 in situ composites. Mater. Des. 2010, 31, 2230–2236. [Google Scholar] [CrossRef]

- Kathiresan, M.; Sornakumar, T. EDM Studies on Aluminum Alloy-Silicon Carbide Composites Developed by Vortex Technique and Pressure Die Casting. J. Miner. Mater. Charact. Eng. 2010, 9, 79–88. [Google Scholar] [CrossRef]

- Premnath, A.A.; Alwarsamy, T.; Rajmohan, T. Experimental investigation and optimization of process parameters in milling of hybrid metal matrix composites. Mater. Manuf. Process. 2012, 27, 1035–1044. [Google Scholar] [CrossRef]

- Priyadarshi, D.; Sharma, R.K. Optimization for Turning of Al-6061-SiC-Gr Hybrid Nanocomposites Using Response Surface Methodologies. Mater. Manuf. Process. 2016, 31, 1342–1350. [Google Scholar] [CrossRef]

- Selvaraj, M.; Murali, V.; Rao, S.R.K. Mechanism of weld formation during friction stir welding of aluminum alloy. Mater. Manuf. Process. 2013, 28, 595–600. [Google Scholar] [CrossRef]

- Raj, R.E.; Daniel, B.S.S. Aluminum melt foam processing for light-weight structures. Mater. Manuf. Process. 2007, 22, 525–530. [Google Scholar] [CrossRef]

- Rajamuthamilselvan, M.; Ramanathan, S. Hot-working behavior of 7075Al/15%SiCp composites. Mater. Manuf. Process. 2012, 27, 260–266. [Google Scholar] [CrossRef]

- Muthaiah, V.R.; Meka, S.; Kumar, B.V.M. Processing of heat-treated silicon carbide-reinforced aluminum alloy composites. Mater. Manuf. Process. 2019, 34, 312–320. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K. Experimental investigation and analysis of thrust force in drilling hybrid metal matrix composites by coated carbide drills. Mater. Manuf. Process. 2011, 26, 961–968. [Google Scholar] [CrossRef]

- Prashant, S.N.; Nagaral, M.; Auradi, V. Preparation and evaluation of mechanical and wear properties of Al6061 reinforced with graphite and SiC. Int. J. Mech. Eng. Rob. Res. 2012, 1, 106–112. [Google Scholar]

- Alaneme, K.K.; Bodunrin, M.O. Mechanical behaviour of alumina reinforced A6063 metal matrix composites developed by two step—Stir casting process. Bull. Eng. 2013, 6, 105–110. [Google Scholar]

- Clement, J.P.; Rack, H.J.; Wu, K.T.; Spencer, H.G. Interfacial modification in metal matrix composites by the sol-gel process. Mater. Manuf. Process. 1990, 5, 17–33. [Google Scholar] [CrossRef]

- Collot, J. Review of new process technologies in the aluminum die-casting industry. Mater. Manuf. Process. 2001, 16, 595–617. [Google Scholar] [CrossRef]

- Dong, G.; Zhang, H.; Zhou, M.; Zhang, Y. Experimental investigation on ultrasonic vibration-assisted turning of SiCp/Al composites. Mater. Manuf. Process. 2013, 28, 999–1002. [Google Scholar] [CrossRef]

- Dragatogiannis, D.A.; Koumoulos, E.P.; Kartsonakis, I.A.; Pantelis, D.I.; Karakizis, P.N.; Charitidis, C.A. Dissimilar Friction Stir Welding Between 5083 and 6082 Al Alloys Reinforced with TiC Nanoparticles. Mater. Manuf. Process. 2016, 31, 2101–2114. [Google Scholar] [CrossRef]

- Du, J.; Zhou, L.; Li, J.; Yao, Y. Analysis of chip formation mechanism in mill-grinding of SiCp/Al composites. Mater. Manuf. Process. 2014, 29, 1353–1360. [Google Scholar] [CrossRef]

- Dwivedi, D.K.; Sharma, A.; Rajan, T.V. Influence of silicon morphology and mechanical properties of piston alloys. Mater. Manuf. Process. 2005, 20, 777–791. [Google Scholar] [CrossRef]

- Rajkumar, S.E.; Palanikumar, K.; Pitchandi, K.; Latha, B. Subsurface integrity studies on the drilling of Al/B4C/mica hybrid metal matrix composites. Mater. Manuf. Process. 2020, 35, 52–60. [Google Scholar] [CrossRef]

- Zhang, J.; Guan, R.G.; Tie, D.; Wang, X.; Guan, X.H.; Chen, B.C.; Chen, Y. Effects of technical parameters of semi-solid stiring and Rheo-rolling on microstructure of A356-5wt.%B4C composite strip. Mater. Manuf. Process. 2015, 30, 340–345. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V.; Valliappan, M. Effect of tool pin profile and tool rotational speed on mechanical properties of friction stir welded AA6061 aluminium alloy. Mater. Manuf. Process. 2008, 23, 251–260. [Google Scholar] [CrossRef]

- Etemadi, R.; Wang, B.; Pillai, K.M.; Niroumand, B.; Omrani, E.; Rohatgi, P. Pressure infiltration processes to synthesize metal matrix composites–A review of metal matrix composites, the technology and process simulation. Mater. Manuf. Process. 2018, 33, 1261–1290. [Google Scholar] [CrossRef]

- Fan, S.; Jiang, W.; Li, G.; Mo, J.; Fan, Z. Fabrication and microstructure evolution of Al/Mg bimetal using a near-net forming process. Mater. Manuf. Process. 2017, 32, 1391–1397. [Google Scholar] [CrossRef]

- Ghandvar, H.; Farahany, S.; Idris, J. Wettability enhancement of SiCp in cast A356/SiCp composite using semisolid process. Mater. Manuf. Process. 2015, 30, 1442–1449. [Google Scholar] [CrossRef]

- Zuhailawati, H.; Samayamutthirian, P.; Haizu, C.H.M. Fabrication of low cost of aluminium, matrix composite reinforced with silica sand. J. Phys. Sci. 2007, 18, 47–55. [Google Scholar]

- Viswanatha, B.M.; Prasanna, M.; Kumar, S.B.; Kiran, T.S. Mechanical property evaluation of A356/SiCp/Gr metal matrix composites. J. Eng. Sci. Technol. 2013, 8, 754–763. [Google Scholar]

- Xiu, Z.Y.; Chen, G.Q.; Wu, G.H.; Yang, W.S.; Liu, Y.M. Effect of volume fraction on microstructure and mechanical properties of Si3N4/Al composites. Trans. Nonferrous Met. Soc. China 2011, 21 (Suppl. S2), S285–S289. [Google Scholar] [CrossRef]

- Ezatpour, H.R.; Sajjadi, S.A.; Sabzevar, M.H.; Huang, Y. Investigation of microstructure and mechanical properties of Al6061-nanocomposite fabricated by stir casting. Mater. Des. 2014, 55, 921–928. [Google Scholar] [CrossRef]

- Baradeswaran, A.; Vettivel, S.C.; Perumal, A.E.; Selvakumar, N.; Issac, R.F. Experimental investigation on mechanical behaviour, modeling and optimization of wear parameters of B4C and graphite reinforced aluminium hybrid composites. Mater. Des. 2014, 63, 620–632. [Google Scholar] [CrossRef]

- Sidhu, S.S.; Batish, A.; Kumar, S. Study of surface properties in particulate- reinforced metal matrix composites (MMCs) using powder-mixed electrical discharge machining (EDM). Mater. Manuf. Process. 2014, 29, 46–52. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, J.; Kumar, S. Influences of Process Parameters on MRR Improvement in Simple and Powder-Mixed EDM of AA6061/10%SiC Composite. Mater. Manuf. Process. 2015, 30, 303–312. [Google Scholar] [CrossRef]

- Singh, B.; Kumar, J.; Kumar, S. Investigation of the Tool Wear Rate in Tungsten Powder Mixed Electric Discharge Machining of AA6061/10%SiCp Composite. Mater. Manuf. Process. 2016, 31, 456–466. [Google Scholar] [CrossRef]

- Singla, A.K.; Singh, J.; Sharma, V.S. Processing of materials at cryogenic temperature and its implications in manufacturing: A review. Mater. Manuf. Process. 2018, 33, 1603–1640. [Google Scholar] [CrossRef]

- Siva, S.B.V.; Ganguly, R.I.; Srinivasarao, G.; Sahoo, K.L. Machinability of aluminum metal matrix composite reinforced with in-situ ceramic composite developed from mines waste colliery shale. Mater. Manuf. Process. 2013, 28, 1082–1089. [Google Scholar] [CrossRef]

- Sivaprakasam, P.; Hariharan, P.; Gowri, S. Optimization of micro-WEDM process of aluminum matrix composite (A413-B4C): A response surface approach. Mater. Manuf. Process. 2013, 28, 1340–1347. [Google Scholar] [CrossRef]

- Soltani, N.; Sadrnezhaad, S.K.; Bahrami, A. Manufacturing wear-resistant 10ce-tzp/Al2O3 nanoparticle aluminum composite by powder metallurgy processing. Mater. Manuf. Process. 2014, 29, 1237–1244. [Google Scholar] [CrossRef]

- Song, Y.F.; Xiao, L.R.; Zhao, X.J.; Zhou, H.; Zhang, W.; Guo, L.; Wang, Y.H. Fabrication, Microstructure and Shear Properties of Al Foam Sandwich. Mater. Manuf. Process. 2016, 31, 1046–1051. [Google Scholar] [CrossRef]

- Suneesh, E.; Sivapragash, M. Comprehensive studies on processing and characterization of hybrid magnesium composites. Mater. Manuf. Process. 2018, 33, 1324–1345. [Google Scholar] [CrossRef]

- Suresha, C.N.; Rajaprakash, B.M.; Upadhya, S. A study of the effect of tool pin profiles on tensile strength of welded joints produced using friction stir welding process. Mater. Manuf. Process. 2011, 26, 1111–1116. [Google Scholar] [CrossRef]

- Suthar, J.; Patel, K.M. Processing issues, machining, and applications of aluminum metal matrix composites. Mater. Manuf. Process. 2018, 33, 499–527. [Google Scholar] [CrossRef]

- Dao, V.; Zhao, S.; Lin, W.; Zhang, C. Effect of process parameters on microstructure and mechanical properties in AlSi9Mg connecting-rod fabricated by semi-solid squeeze casting. Mater. Sci. Eng. A 2012, 558, 95–102. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. Metal matrix composites: Production by the stir casting method. J. Mater. Process. Technol. 1999, 92–93, 1–7. [Google Scholar] [CrossRef]

- Taha, M.A. Industrialization of cast aluminum matrix composites (AMCCs). Mater. Manuf. Process. 2001, 16, 619–641. [Google Scholar] [CrossRef]

- Anthymidis, K.; David, K.; Agrianidis, P.; Trakali, A. Production of Al metal matrix composites by the stir-casting method. Key Eng. Mater. 2014, 592–593, 614–617. [Google Scholar] [CrossRef]

- Yong, M.S.; Clegg, A.J. Process optimization for a squeeze cast magnesium alloy metal matrix composite. J. Mater. Process. Technol. 2005, 168, 262–269. [Google Scholar] [CrossRef]

- Umunakwe, I.J. Effects of Stirring Time and Particles Preheating on Porosity, Mechanical Properties and Microstructure of Periwinkle Shell-Aluminium Metal Matrix Composite (PPS-Al mmc). Int. J. Eng. 2017, 3, 133–141. [Google Scholar]

- Pal, T.K. Joining of aluminium metal matrix composites. Mater. Manuf. Process. 2005, 20, 717–726. [Google Scholar] [CrossRef]

- Hashim, J. The Production of Cast Metal Matrix Composite by a Modified Stir Casting Method. J. Teknol. 2001, 35, 9–20. [Google Scholar] [CrossRef]

- Parikh, V.K.; Badgujar, A.D.; Ghetiya, N.D. Joining of metal matrix composites using friction stir welding: A review. Mater. Manuf. Process. 2019, 34, 123–146. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Kumar, N.; Kuriachen, B. Parametric effect on dissimilar friction stir welded steel-magnesium alloys joints: A review. Sci. Technol. Weld. Join. 2019, 24, 653–684. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Kuriachen, B. Mechanical and microstructural properties evolutions of various alloys welded through cooling assisted friction-stir welding: A review. Intermetallics 2021, 133, 107122. [Google Scholar] [CrossRef]

- Yadav, P.K.; Dixit, G.; Dixit, S.; Singh, V.P.; Patel, S.K.; Purohit, R.; Kuriachen, B. Effect of eutectic silicon and silicon carbide particles on high stress scratching wear of aluminium composite for various testing parameters. Wear 2021, 482–483, 203921. [Google Scholar] [CrossRef]

- Lee, K.B.; Sim, H.S.; Cho, S.Y.; Kwon, H. Reaction products of A1-Mg/B4C composite fabricated by pressure less infiltration technique. Mater. Sci. Eng. A 2001, 302, 227–234. [Google Scholar] [CrossRef]

- Murugan, N.; Kumar, B.A. Prediction of tensile strength of friction stir welded stir cast AA6061-T6/AlNp composite. Mater. Des. 2013, 51, 998–1007. [Google Scholar] [CrossRef]

- Fernandus, M.J.; Senthilkumar, T.; Balasubramanian, V.; Rajakumar, S. Optimising diffusion bonding parameters to maximize the strength of AA6061 aluminium and AZ31B magnesium alloy joints. Mater. Des. 2012, 33, 31–41. [Google Scholar] [CrossRef]

- Guan, L.; Geng, L.; Zhang, H.; Huang, L. Effects of stirring parameters on microstructure and tensile properties of (ABOw+SiCp)/6061Al composites fabricated by semi-solid stirring technique. Trans. Nonferrous Met. Soc. China 2011, 21 (Suppl. S2), s274–s279. [Google Scholar] [CrossRef]

- Gladston, J.A.K.; Sheriff, N.M.; Dinaharan, I.; Selvam, J.D.R. Production and characterization of rich husk ash particulate reinforced AA6061 aluminum alloy composites by compocasting. Trans. Nonferrous Met. Soc. China 2015, 25, 683–691. [Google Scholar] [CrossRef]

- Moses, J.J.; Dinaharan, I.; Sekhar, S.J. Prediction of influence of process parameters on tensile strength of AA6061/TiC aluminum matrix composites produced using stir casting. Trans. Nonferrous Met. Soc. China 2016, 26, 1498–1511. [Google Scholar] [CrossRef]

- Shankar, M.R.; Chandrasekar, S.; Compton, W.D.; King, A.H. Characteristics of aluminum 6061-T6 deformed to large plastic strains by machining. Mater. Sci. Eng. A 2005, 410–411, 364–368. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Pan, C.; Male, A.T. Improved microstructure and properties of 6061 aluminum alloy weldments using a double-sided arc welding process. Metall. Mater. Trans. A 2000, 31, 2537–2543. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Kumar, S.; Scudino, S.; Murty, B.S.; Eckert, J. Fabrication and response of Al70Y16Ni10Co4 glass reinforced metal matrix composites. Mater. Manuf. Process. 2011, 26, 1242–1247. [Google Scholar] [CrossRef]

- Prater, T. Solid-state joining of metal matrix composites: A survey of challenges and potential solutions. Mater. Manuf. Process. 2011, 26, 636–648. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Laoui, T.; Haseeb, A.S.M.A.; Celis, J.P.; Froyen, L. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study. J. Mater. Process. Technol. 2003, 142, 738–743. [Google Scholar] [CrossRef]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Predicting tensile strength, hardness and corrosion rate of friction stir welded AA6061-T6 aluminium alloy joints. Mater. Des. 2011, 32, 2878–2890. [Google Scholar] [CrossRef]

- Rajakumar, S.; Muralidharan, C.; Balasubramanian, V. Establishing empirical relationships to predict grain size and tensile strength of friction stir welded AA6061-T6 aluminium alloy joints. Trans. Nonferrous Met. Soc. China 2010, 20, 1863–1872. [Google Scholar] [CrossRef]

- Jha, A.K.; Prasad, S.V.; Upadhyaya, G.S. Dry sliding wear of sintered 6061 aluminium alloy-graphite particle composites. Tribol. Int. 1989, 22, 321–327. [Google Scholar] [CrossRef]

- Patel, K.M.; Pandey, P.M.; Rao, P.V. Understanding the role of weight percentage and size of silicon carbide particulate reinforcement on electro-discharge machining of aluminium-based composites. Mater. Manuf. Process. 2008, 23, 665–673. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Kuriachen, B. Friction stir processing of alloys with secondary phase particles: An overview. Mater. Manuf. Process. 2019, 34, 1429–1457. [Google Scholar] [CrossRef]

- Poovazhagan, L.; Kalaichelvan, K.; Sornakumar, T. Processing and Performance Characteristics of Aluminum-Nano Boron Carbide Metal Matrix Nanocomposites. Mater. Manuf. Process. 2016, 31, 1275–1285. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Roy, B.S.; Kuriachen, B. Recent research progresses in Al-7075 based in-situ surface composite fabrication through friction stir processing: A review. Mater. Sci. Eng. B 2020, 262, 114708. [Google Scholar] [CrossRef]

- Prasad, V.V.B.; Bhat, B.V.R.; Mahajan, Y.R.; Ramakrishnan, P. Effect of extrusion parameters on structure and properties of 2124 aluminum alloy matrix composites. Mater. Manuf. Process. 2001, 16, 841–853. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Murty, B.S. Production, kinetic study and properties of Fe-based glass and its composites. Mater. Manuf. Process. 2010, 25, 592–597. [Google Scholar] [CrossRef]

- Ramesh, C.S.; Keshavamurthy, R.; Channabasappa, B.H.; Ahmed, A. Microstructure and mechanical properties of Ni-Pcoated Si3N4 reinforced Al6061 composites. Mater. Sci. Eng. A 2009, 502, 99–106. [Google Scholar] [CrossRef]

- Singla, Y.K.; Chhibber, R.; Bansal, H.; Kalra, A. Wear Behavior of Aluminum Alloy 6061-Based Composites Reinforced with SiC, Al2O3, and Red Mud: A Comparative Study. JOM 2015, 67, 2160–2169. [Google Scholar] [CrossRef]

- Omrani, E.; Moghadam, A.D.; Menezes, P.L.; Rohatgi, P.K. Influences of graphite reinforcement on the tribological properties of self-lubricating aluminum matrix composites for green tribology, sustainability, and energy efficiency—A review. Int. J. Adv. Manuf. Technol. 2016, 83, 325–346. [Google Scholar] [CrossRef]

- Selvam, R.; Karunamoorthy, L.; Arunkumar, N. Investigation on performance of abrasive water jet in machining hybrid composites. Mater. Manuf. Process. 2017, 32, 700–706. [Google Scholar] [CrossRef]

- Padmavathi, K.R. Wear Studies on the Heat Treated Al6061-µSIC and Al6061-NSIC Metal Matrix Composites. Int. J. Mech. Eng. Technol. 2019, 10, 241–247. [Google Scholar]

- Srivastava, N.; Chaudhari, G.P. Microstructural evolution and mechanical behavior of ultrasonically synthesized Al6061-nanoalumina composites. Mater. Sci. Eng. A 2018, 724, 199–207. [Google Scholar] [CrossRef]

- Baghel, M.; Krishna, C.M.; Suresh, S. Development of Al-SiC composite material from rice husk and its parametric assessment. Mater. Res. Express 2022, 9, 016518. [Google Scholar] [CrossRef]

- Baghel, M.; Krishna, C.M. Synthesis and characterization of MWCNTs/Al6082 nanocomposites through ultrasonic assisted stir casting technique. Part. Sci. Technol. 2023, 41, 183–195. [Google Scholar] [CrossRef]

- Reddy, A.P.; Krishna, P.V.; Rao, R.N. Tribological Behaviour of Al6061–2SiC-xGr Hybrid Metal Matrix Nanocomposites Fabricated through Ultrasonically Assisted Stir Casting Technique. Silicon 2019, 11, 2853–2871. [Google Scholar] [CrossRef]

- Reddy, A.P.; Krishna, P.V.; Rao, R.N. Two-body abrasive wear behaviour of AA6061-2SiC-2Gr hybrid nano composite fabricated through ultrasonically assisted stir casting. J. Compos. Mater. 2019, 53, 2165–2180. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Kuriachen, B. Microstructural, tribological and mechanical properties evolution of ZrSiO4/A4047 surface composite fabricated through friction stir processing. Trans. Indian Inst. Met. 2019, 72, 1765–1774. [Google Scholar] [CrossRef]

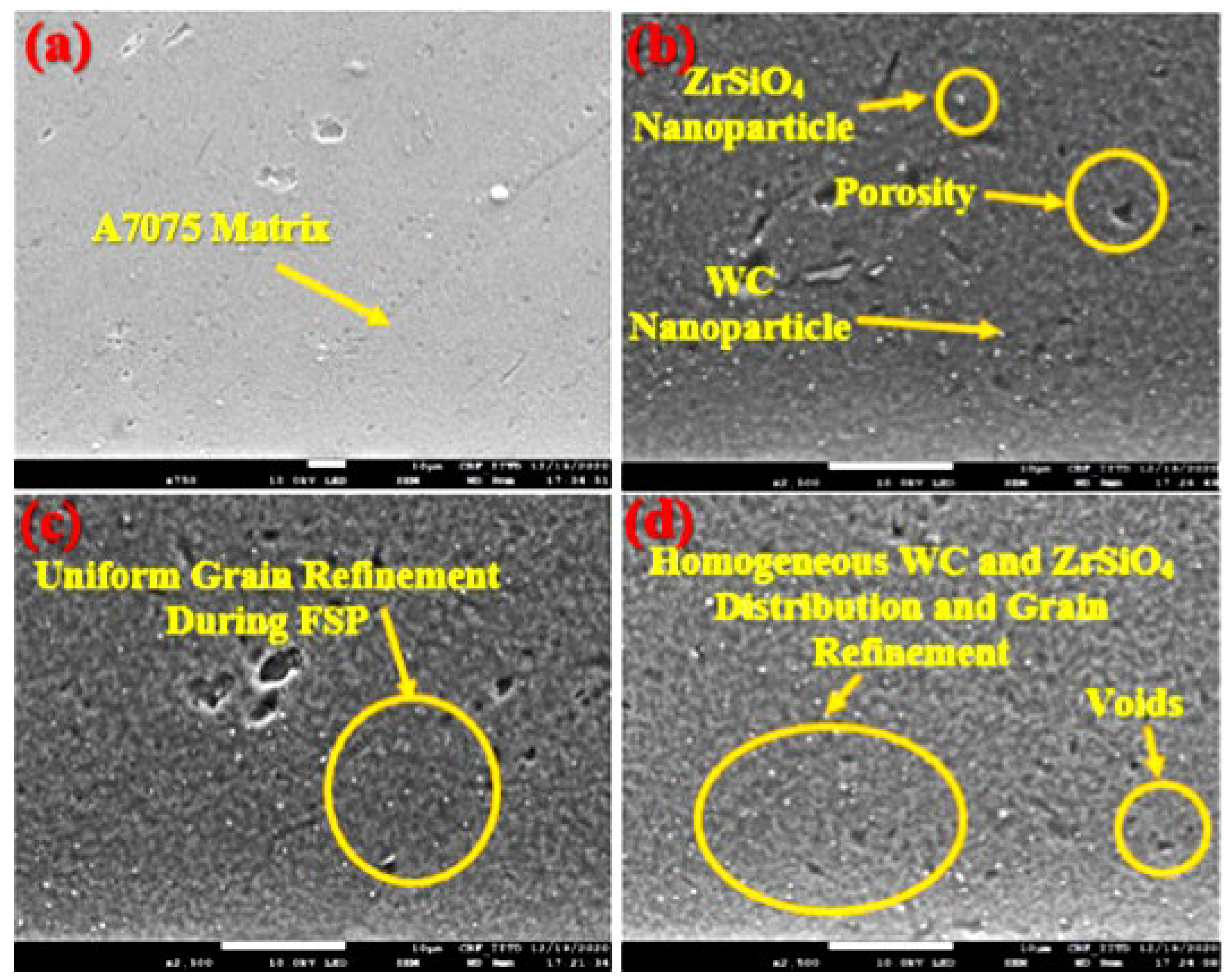

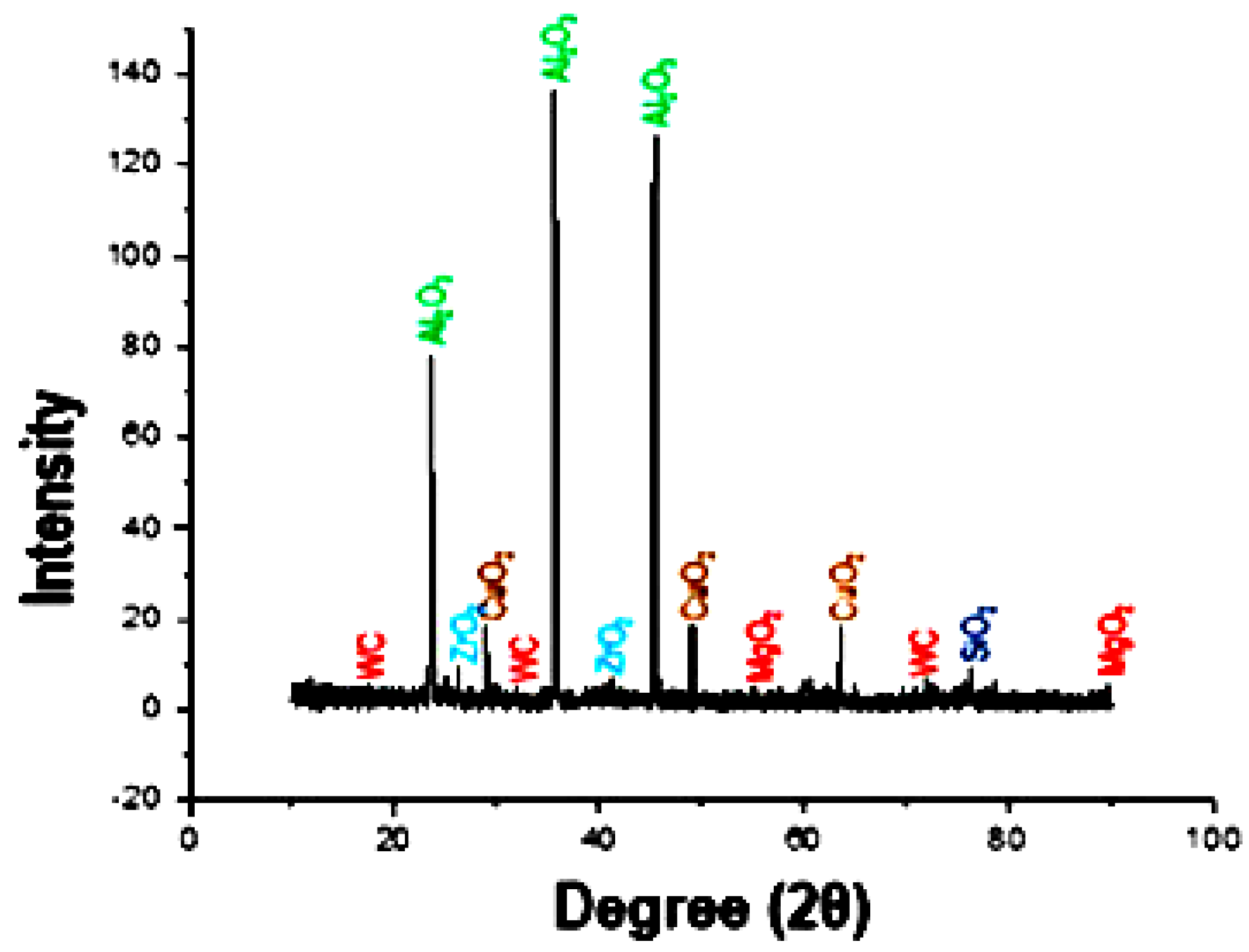

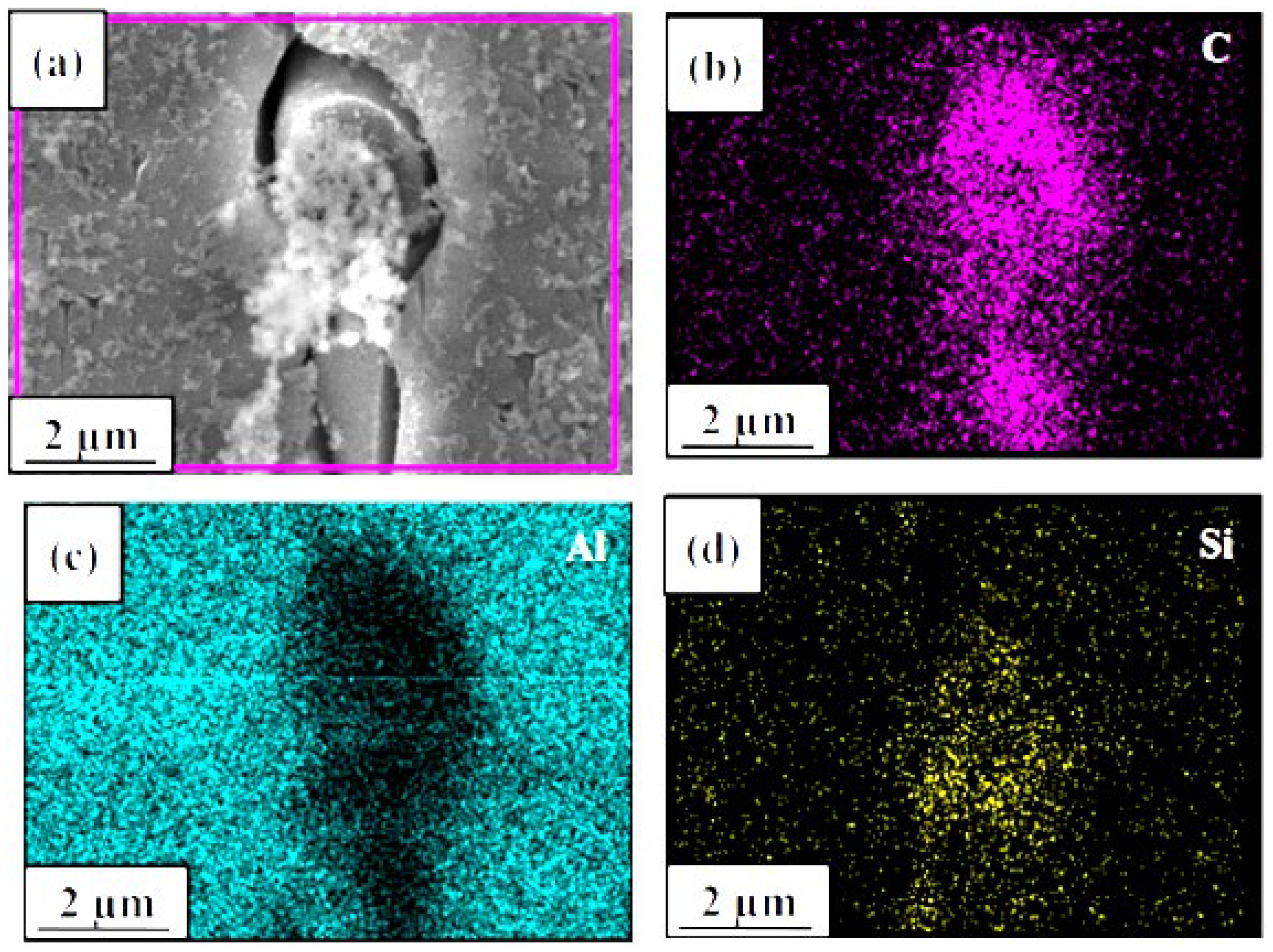

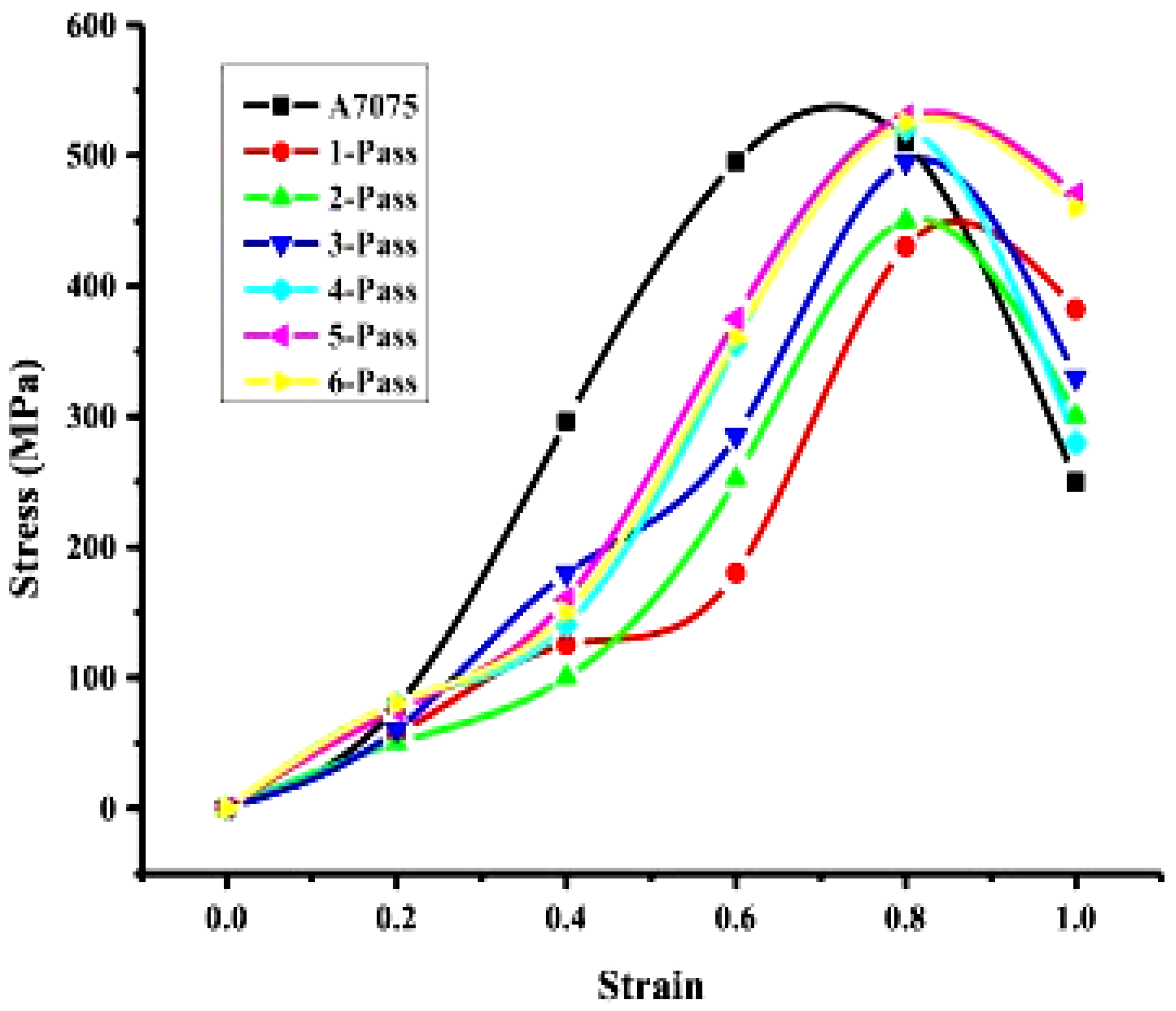

- Patel, S.K.; Singh, V.P.; Roy, B.S.; Kuriachen, B. Microstructural, mechanical and wear behavior of A7075 surface composite reinforced with WC and ZrSiO4 nanoparticle through friction stir processing. J. Manuf. Process. 2021, 71, 85–105. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Yadav, S.K.; Kuriachen, B.; Nateriya, R. Microstructural and Compressive Deformation Behavior of Aluminum-Foam-Filled Sections. Soft Mater. 2018, 17, 14–23. [Google Scholar] [CrossRef]

- Mabuchi, M.; Higashi, K.; Tanimura, S.; Amai, T.; Kubo, K. Superplasticity behavior at high strain rates in a particulate Si3N4/6061 aluminum composites. Scr. Metall. Mater. 2006, 25, 2003–2006. [Google Scholar] [CrossRef]

- Lim, N.S.; Das, S.; Park, S.Y.; Kim, M.C.; Park, C.G. Fabrication and microstructural characterization of nano-structured WC/Co coatings. Surf. Coat. Technol. 2010, 205, 430–435. [Google Scholar] [CrossRef]

- Shi, J.L.; Yan, H.G.; Su, B.; Chen, J.H.; Zhu, S.Q.; Chen, G. Preparation of a functionally gradient aluminum alloy metal matrix composite using the technique of spray deposition. Mater. Manuf. Process. 2011, 26, 1236–1241. [Google Scholar] [CrossRef]

- Prabu, S.B.; Sozhamannan, G.G. Effect of Process Parameter of Stir Casting on Metal Matrix Composites: Stir Casting Process. J. Surf. Eng. Mater. Adv. Technol. 2012, 2, 11–15. [Google Scholar] [CrossRef]

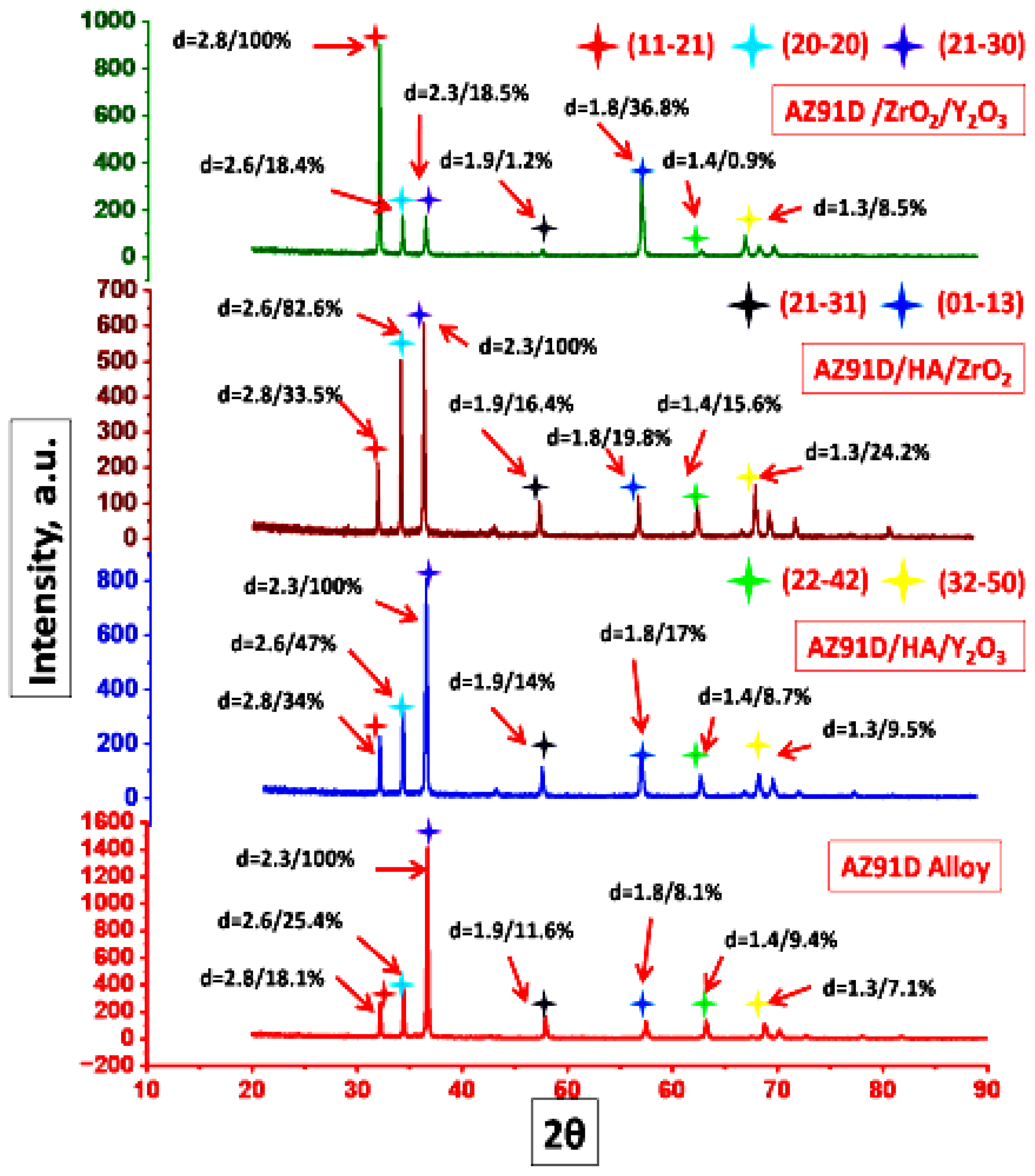

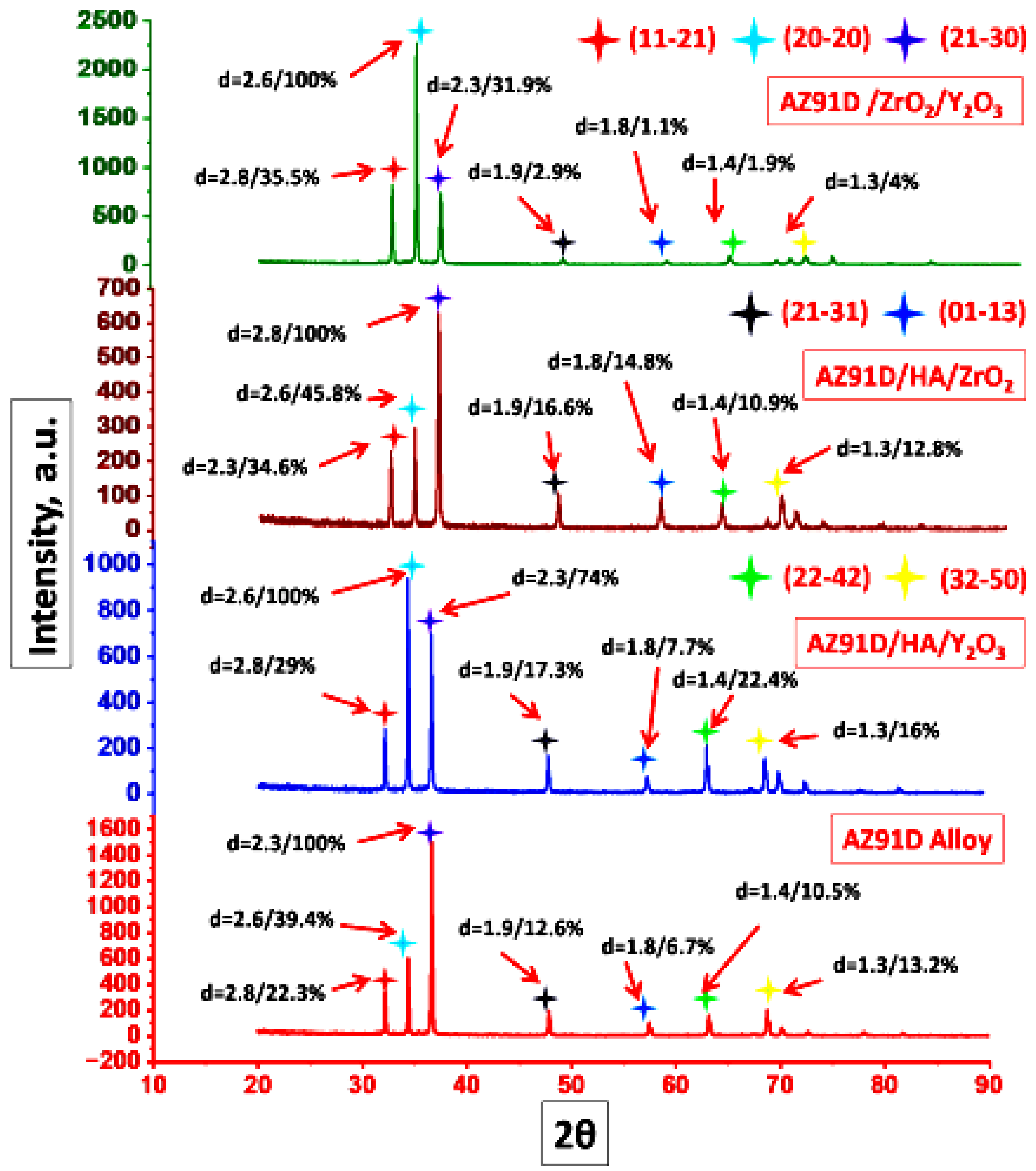

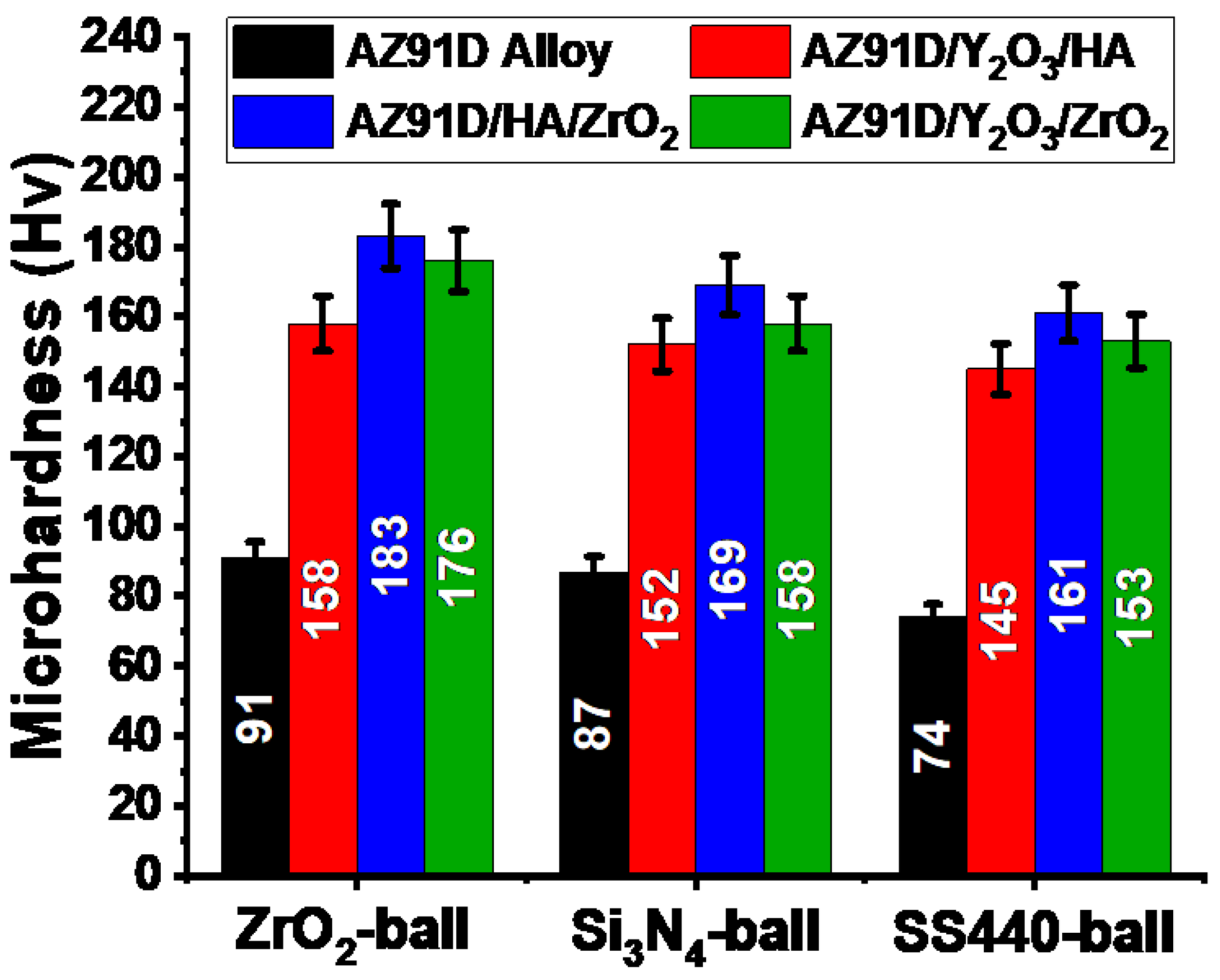

- Patel, S.K.; Singh, S.; Liu, L.; Li, L.; Shi, L.; Kumar, A.; Wu, C.; Wang, Y.; Guan, L. Unveiling the microstructure and advanced bio-tribological behavior of Y2O3/HA, HA/ZrO2, and Y2O3/ZrO2 reinforced AZ91D surface composites via friction stir processing. Tribo. Int. 2026, 213, 111044. [Google Scholar] [CrossRef]

- Seo, Y.W.; Kim, D.; Ramulu, M. Electrical discharge machining of functionally graded 15-35Vol%SiCp/Al composites. Mater. Manuf. Process. 2006, 21, 479–487. [Google Scholar] [CrossRef]

- Shankar, E.; Prabu, S.B.; Kumar, T.S.; John, M.R.S. Investigation of TiAlN coated roller burnishing on Al-(B4C)p MMC workpiece material. Mater. Manuf. Process. 2018, 33, 1242–1249. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, V.M.; Mewar, S.; Pal, S.K.; Paul, J. Friction stir processing of Al6061-SiC-graphite hybrid surface composites. Mater. Manuf. Process. 2018, 33, 795–804. [Google Scholar] [CrossRef]

- Baghel, M.; Krishna, C.M. Multi-objective optimization of mechanical and microstructural characteristics in a stir casting process of MWCNTs/Al6082 composites using neutrosophic TOPSIS and GRA. J. Chin. Inst. Eng. 2023, 46, 345–354. [Google Scholar] [CrossRef]

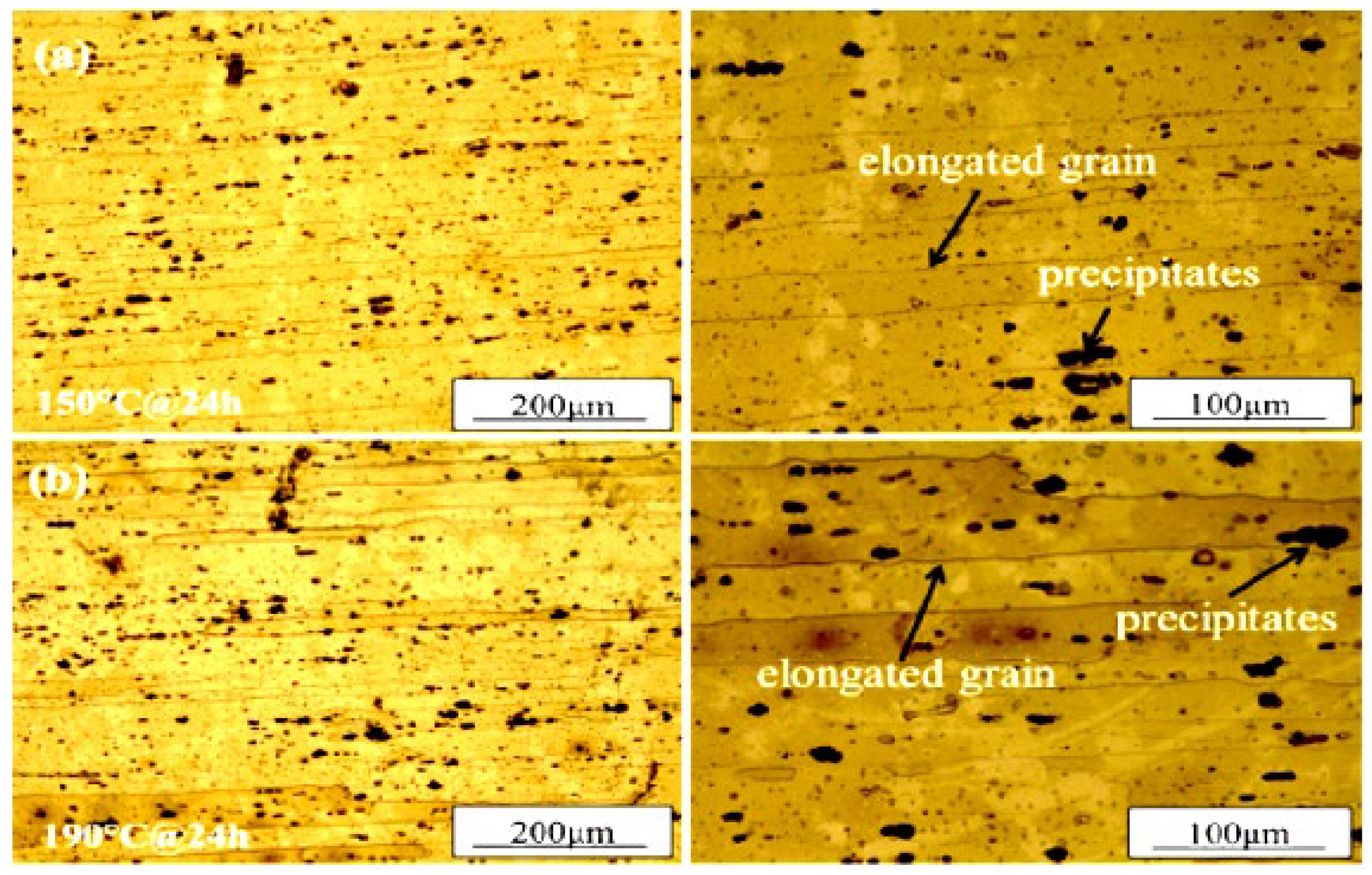

- Baghel, M.; Krishna, C.M. Microstructural evolution and mechanical properties of multiwalled carbon nanotubes/Al6082 nanocomposites through optimized T6 heat treatment process. Proc. Inst. Mech. Eng. E J. Process Mech. Eng. 2022, 237, 1145–1157. [Google Scholar] [CrossRef]

- Thamizhvalavan, P.; Arivazhagan, S.; Yuvaraj, N.; Ramesh, B. Machinability study of abrasive aqua jet parameters on hybrid metal matrix composite. Mater. Manuf. Process. 2019, 34, 321–344. [Google Scholar] [CrossRef]

- Ulutan, D.; Özel, T. Multi objective optimization of experimental and simulated residual stresses in turning of Nickel-Alloy IN100. Mater. Manuf. Process. 2013, 28, 835–841. [Google Scholar] [CrossRef]

- Varghese, V.; Ramesh, M.R.; Chakradhar, D. Experimental investigation and optimization of machining parameters for sustainable machining. Mater. Manuf. Process. 2018, 33, 1782–1792. [Google Scholar] [CrossRef]

- Venkatesh, C.; Venkatesan, R. Optimization of process parameters of hot extrusion of SiC/Al6061 composite using Taguchi’s technique and upper bound technique. Mater. Manuf. Process. 2015, 30, 85–92. [Google Scholar] [CrossRef]

- Venkatesh, V.; Swain, N.; Srinivas, G.; Kumar, P.; Barshilia, H.C. Review on the machining characteristics and research prospects of conventional microscale machining operations. Mater. Manuf. Process. 2017, 32, 235–262. [Google Scholar] [CrossRef]

- Waku, Y.; Nagasawa, T. Future Trends and Recent Developments of Fabrication Technology for Advanced Metal Matrix Composites. Mater. Manuf. Process. 1994, 9, 937–963. [Google Scholar] [CrossRef]

- Wang, S.Y.; Tang, Q.; Li, D.J.; Zou, J.X.; Zeng, X.Q.; Ouyang, Q.B.; Ding, W.J. The hot workability of SiCp/2024Al composite by stir casting. Mater. Manuf. Process. 2015, 30, 624–630. [Google Scholar] [CrossRef]

- Yadav, R.N.; Yadava, V. Machining performance of slotted-electrical discharge diamond face grinding of Al/SiC/Gr composite. Mater. Manuf. Process. 2014, 29, 585–592. [Google Scholar] [CrossRef]

- Zhang, Z.; Lu, X. Preparation process of magnesium alloys by complex salt dehydration-electrochemical code position. Mater. Manuf. Process. 2019, 34, 591–597. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, M.; Dong, G. Experimental Investigation on Rotary Ultrasonic Face Grinding of SiCp/Al Composites. Mater. Manuf. Process. 2016, 31, 673–678. [Google Scholar] [CrossRef]

- How, H.C.; Baker, T.N. Characterisation of sliding friction-induced subsurface deformation of Saffil-reinforced AA6061 composites. Wear 1999, 232, 106–115. [Google Scholar] [CrossRef]

- Baghel, M.; Krishna, C.M. Effect of MWCNTs and heat treatment on coefficient of friction and wear characteristics of MWCNTs reinforced Al6082 composites under dry sliding condition. Proc. Inst. Mech. Eng. Part C J. Mech. 2023, 237, 4295–4306. [Google Scholar] [CrossRef]

- Baghel, M.; Krishna, C.M.; Kumar, A.; Namdev, A. Investigating drilling characteristics of stir-squeeze cast Al6082 composites reinforced with MWCNTs. Proc. Inst. Mech. Eng. Part C J. Mech. 2024, 238, 9514–9526. [Google Scholar] [CrossRef]

- Doddamani, S.; Kaleemulla, M. Comparisons of Experimental Fracture Toughness Testing Methods of Al6061–Graphite Particulate Composites. J. Fail. Anal. Prev. 2019, 19, 730–737. [Google Scholar] [CrossRef]

- Gowrishankar, T.P.; Manjunatha, L.H.; Sangmesh, B. Mechanical and Wear behaviour of Al6061 reinforced with Graphite and TiC Hybrid MMC’s. Mater. Res. Innov. 2020, 24, 179–185. [Google Scholar] [CrossRef]

- Zulfia, A.; Raga, K.; Narottama, W.; Yunus, S. Al6061 reinforced Al2O3 metal matrix composite produced by double blade stir casting. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 1544–1549. [Google Scholar] [CrossRef]

- Manivannan, I.; Ranganathan, S.; Gopalakannan, S.; Suresh, S. Mechanical Properties and Tribological Behavior of Al6061–SiC–Gr Self-Lubricating Hybrid Nanocomposites. Trans. Indian Inst. Met. 2018, 71, 1897–1911. [Google Scholar] [CrossRef]

- Gireesh, C.H.; Prasad, K.G.D.; Ramji, K. Experimental Investigation on Mechanical Properties of an Al6061 Hybrid Metal Matrix Composite. J. Compos. Sci. 2018, 2, 49. [Google Scholar] [CrossRef]

- Raj, R.; Thakur, D.G. Qualitative and quantitative assessment of microstructure in Al-B4C metal matrix composite processed by modified stir casting technique. Arch. Civ. Mech. Eng. 2016, 16, 949–960. [Google Scholar] [CrossRef]

- Ravi, B.; Naik, B.B.; Prakash, J.U. Characterization of Aluminium Matrix Composites (AA6061/B4C) Fabricated by Stir Casting Technique. Mater. Today Proc. 2015, 2, 2984–2990. [Google Scholar] [CrossRef]

- Hosseini, N.; Karimzadeh, F.; Abbasi, M.H.; Enayati, M.H. A comparative study on the wear properties of course grained Al6061 alloy and nanostructured Al6061-Al2O3 composites. Tribol. Int. 2012, 54, 58–67. [Google Scholar] [CrossRef]

- Xu, G.; Yang, Y.; Feng, G.; Huang, B.; Luo, X.; Chen, Y. Effect of heat treatment on mechanical properties of SiC/Ti-6Al-4V composites. Xiyou Jinshu Cailiao Yu Gongcheng/Rare Met. Mater. Eng. 2011, 40, 1367–1371. [Google Scholar]

- Rajasekaran, S.; Udayashankar, N.K.; Nayak, J. T4 and T6 Treatment of 6061Al-15Vol.%SiCP Composite. ISRN Mater. Sci. 2012, 2012, 374719. [Google Scholar] [CrossRef]

- Gupta, M.; Surappa, M.K. Effect of weight percentage of SiC particulates on the ageing behaviour of 6061/SiC metal matrix composites. J. Mater. Sci. Lett. 1995, 14, 1283–1285. [Google Scholar] [CrossRef]

- Chitturi, S.; Bhaumik, M.; Dandu, K.; Mudidana, R.K. Experimental investigation on mechanical properties of FeCoCrNiMo High Entropy Alloy & B4C reinforced Al6061 hybrid MMCs. Mater. Today Proc. 2021, 46, 752–755. [Google Scholar]

- Appendino, P.; Badini, C.; Marino, F.; Tomasi, A. 6061 aluminium alloy-SiC particulate composite: A comparison between aging behavior in T4 and T6 treatments. Mater. Sci. Eng. A 1991, 135, 275–279. [Google Scholar] [CrossRef]

- Reihani, S.M.S. Processing of squeeze cast Al6061-30vol%SiC composites and their characterization. Mater. Des. 2006, 27, 216–222. [Google Scholar] [CrossRef]

- Kumar, G.B.V.; Rao, C.S.P.; Selvaraj, N. Studies on mechanical and dry sliding wear of Al6061-Si Ccomposites. Compos. Part B Eng. 2012, 43, 1185–1191. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K. Optimization of machining parameters for surface roughness and burr height in drilling hybrid composites. Mater. Manuf. Process. 2012, 27, 320–328. [Google Scholar] [CrossRef]

- Rana, H.; Badheka, V.; Kumar, A.; Satyaprasad, A. Strategical parametric investigation on manufacturing of Al–Mg–Zn–Cu alloy surface composites using FSP. Mater. Manuf. Process. 2018, 33, 534–545. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A.N. Issues and strategies in composite fabrication via friction stir processing: A review. Mater. Manuf. Process. 2018, 33, 239–261. [Google Scholar] [CrossRef]

- Sai, N.V.; Komaraiah, M.; Raju, A.V.S.R. Preparation and properties of sintered copper-tin composites containing copper coated or uncoated fly ash. Mater. Manuf. Process. 2008, 23, 651–657. [Google Scholar] [CrossRef]

- Satish, D.R.; Feyissa, F.; Kumar, D.R. Cryorolling and warm forming of AA6061 aluminum alloy sheets. Mater. Manuf. Process. 2017, 32, 1345–1352. [Google Scholar] [CrossRef]

- Patel, S.K.; Kuriachen, B.; Kumar, N.; Nateriya, R. The slurry abrasive wear behaviour and microstructural analysis of A2024-SiC-ZrSiO4 metal matrix composite. Ceram. Int. 2018, 44, 6426–6432. [Google Scholar] [CrossRef]

- Patel, S.K.; Dai, G.; Shi, L.; Wu, C.; Mironov, S.; Guan, L. Microstructural, mechanical, and corrosion behavior of ZrO2, HA, and Y2O3 hybrid reinforced AZ91D alloy surface composites fabricated through FSP route. Arch. Civ. Mech. Eng. 2025, 25, 56. [Google Scholar] [CrossRef]

- Johnyjames, S.; Annamalai, A. Fabrication of Aluminium Metal Matrix Composite and Testing of Its Property. Mech. Mater. Sci. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Patel, S.K.; Raja, A.R.; Singh, S.; Shi, L. Enhancement of wear resistance by β-precipitates formation on A7075/WC/ZrSiO4 surface composites fabricated through FSP. Int. J. Integr. Eng. 2024, 16, 13–20. [Google Scholar]

- Huang, S.T.; Zhou, L.; Chen, J.; Xu, L.F. Drilling of SiCp/Al metal matrix composites with poly crystalline diamond (PCD) tools. Mater. Manuf. Process. 2012, 27, 1090–1094. [Google Scholar] [CrossRef]

- Huang, S.J.; Lin, P.C.; Aoh, J.N. Mechanical behavior enhancement of AM60/Al2O3p magnesium metal-matrix nano composites by ECAE. Mater. Manuf. Process. 2015, 30, 1272–1277. [Google Scholar] [CrossRef]

- Patel, S.K.; Kuriachen, B.; Lei, S. Microstructural, mechanical and wear behaviour of AA7075/ZrSiO4 surface composite developed via multi pass friction stir processing. Adv. Mater. Process. Technol. 2024, 1–31. [Google Scholar] [CrossRef]

- Patel, S.K.; Dai, G.; Liu, L.; Sun, Z.; Shi, L. Influences of multi-pass friction stir alloying on characterization of AZ91D alloy-based dual reinforcement bio-ceramic nano-composites. J. Appl. Biomater. Funct. Mater. 2025, 23, 22808000251314086. [Google Scholar] [CrossRef] [PubMed]

- Patel, S.K.; Dai, G.; Shi, L.; Wu, C.; Mironov, S.; Guan, L. A comparative investigation on microstructural, mechanical, and corrosion behavior of friction stir processed surface composite of magnesium alloy reinforced with nanoparticles. Int. J. Adv. Manuf. Technol. 2025, 139, 631–656. [Google Scholar] [CrossRef]

- Josyula, S.K.; Narala, S.K.R. Machinability enhancement of stir cast Al-TiCp composites under cryogenic condition. Mater. Manuf. Process. 2017, 32, 1764–1774. [Google Scholar] [CrossRef]

- Kannan, C.; Ramanujam, R.; Balan, A.S.S. Machinability studies on Al7075/BN/Al2O3 squeeze cast hybrid nano composite under different machining environments. Mater. Manuf. Process. 2018, 33, 587–595. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Kumar, D.; Roy, B.S.; Kuriachen, B. Microstructural, mechanical and wear behavior of A7075 surface composite reinforced with WC nanoparticle through friction stir processing. Mater. Sci. Eng. B 2022, 276, 115476. [Google Scholar] [CrossRef]

- Khuntia, S.K.; Pani, B.B.; Nayak, S. Fabrication of composites from different carbon content ferrous powders adopting thermo mechanical processes. Mater. Manuf. Process. 2019, 34, 882–888. [Google Scholar] [CrossRef]

- Kumar, S.S.; Uthayakumar, M.; Kumaran, S.T.; Parameswaran, P. Electrical discharge machining of Al(6351)-SiC-B4C hybrid composite. Mater. Manuf. Process. 2014, 29, 1395–1400. [Google Scholar] [CrossRef]

- Kumar, K.A.; Natarajan, S.; Duraiselvam, M.; Ramachandra, S. Synthesis, characterization and mechanical behavior of Al3003—TiO2 surface composites through friction stir processing. Mater. Manuf. Process. 2019, 34, 183–191. [Google Scholar] [CrossRef]

- Kumar, S.P.L.; Jerald, J.; Kumanan, S.; Prabakaran, R. A review on current research aspects in tool-based micromachining processes. Mater. Manuf. Process. 2014, 29, 1291–1337. [Google Scholar] [CrossRef]

- Wang, F.; Xu, J.; Li, J.; Li, X.; Wang, H. Fatigue crack initiation and propagation in A356 alloy reinforced with in situ TiB2 particles. Mater. Des. 2012, 33, 236–241. [Google Scholar] [CrossRef]

- Liu, J.; Qi, L.; Zhang, H.; Hou, H. Effect of Liquid-Solid Extrusion on the High- Temperature Compressive Properties of Csf/Mg Composites. Mater. Manuf. Process. 2015, 30, 1391–1396. [Google Scholar] [CrossRef]

- Maniraj, S.; Thanigaivelan, R. Effect of electrode heating on performance of electrochemical micromachining. Mater. Manuf. Process. 2019, 34, 1494–1501. [Google Scholar] [CrossRef]

- Manivannan, A.; Sasikumar, R. Exemplary encapsulate feeding in stir casting for quality composites. Mater. Manuf. Process. 2019, 34, 689–694. [Google Scholar] [CrossRef]

- Singh, V.P.; Patel, S.K.; Ranjan, A.; Kuriachen, B. Recent research progress in solid state friction-stir welding of aluminium–magnesium alloys: A critical review. J. Mater. Res. Technol. 2020, 9, 6217–6256. [Google Scholar] [CrossRef]

- Patel, S.K.; Nateriya, R.; Kuriachen, B. Slurry erosive wear and microhardness characteristics with coarse silica sand of dual reinforced particles ADC12 alloy composites. J. Mar. Eng. Technol. 2020, 19, 240–248. [Google Scholar] [CrossRef]

- Shivam, A.; Singla, A.; Chauhan, A. Wear analysis by Taguchi technique of Al6061 based hybrid composite reinforced with SiC and Al2O3. Int. J. Mech. Prod. Eng. Res. Dev. 2017, 7, 371–380. [Google Scholar] [CrossRef]

- Patel, S.K.; Singh, V.P.; Kumar, N.; Kuriachen, B.; Nateriya, R. Wear behaviour of Al-Silicon (LM13) alloy composite reinforcement with TiC and ZrSiO4 particles. Silicon 2020, 12, 211–221. [Google Scholar] [CrossRef]

- Patel, S.K.; Nateriya, R.; Roy, B.S.; Kuriachen, B. Microstructural and mechanical behaviour of WC reinforced particles A3003 surface composite fabricated through friction stir processing. Prot. Met. Phys. Chem. Surf. 2020, 56, 998–1007. [Google Scholar] [CrossRef]

- Requena, G.; Telfser, D.; Hörist, C.; Degischer, H.P. Creep behaviour of AA6061 metal matrix composite alloy and AA 6061. Mater. Sci. Technol. 2002, 18, 515–521. [Google Scholar] [CrossRef]

- Monfared, V. Role of High Order Functions in Analysis of the Creep Behavior of a Short Fiber Composite “Silicon Carbide/Aluminum 6061”. Silicon 2017, 9, 339–345. [Google Scholar] [CrossRef]

- Dai, S.; Bian, Z.; Wang, M.; Wu, Y.; Chen, D.; Li, H.; Wang, H. The high-temperature creep behavior of in-situ TiB2 particulate reinforced Al12Si4Cu2NiMg composite. Metals 2018, 8, 917. [Google Scholar] [CrossRef]

- Spigarelli, S.; Cabibbo, M.; Evangelista, E.; Langdon, T.G. Creep properties of an Al-2024 composite reinforced with SiC particulates. Mater. Sci. Eng. A 2002, 328, 39–47. [Google Scholar] [CrossRef]

- Khorshidi, R.; Mahmudi, R.; Honarbakhsh-Raouf, A. Compressive creep behavior of a cast Al-15Mg2Si in situ composite. Mater. Sci. Eng. A 2016, 668, 112–119. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, W.; Liu, Y.; Guo, B. Cyclic compressive creep-elastoplastic behaviors of in situ TiB2/Al-reinforced composite. Mater. Sci. Eng. A 2016, 666, 1–9. [Google Scholar] [CrossRef]

- Monfared, V. A micromechanical creep model for stress analysis of non-reinforced regions of short fiber composites using imaginary fiber technique. Mech. Mater. 2015, 86, 44–54. [Google Scholar] [CrossRef]

- Chen, C.L.; Lin, C.H. Effect of Y2O3 and TiC Reinforcement Particles on Intermetallic Formation and Hardness of Al6061 Composites via Mechanical Alloying and Sintering. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 46, 3687–3695. [Google Scholar] [CrossRef]

- Li, Y.; Langdon, T.G. Unified interpretation of threshold stresses in the creep and high strain rate super plasticity of metal matrix composites. Acta Mater. 1999, 47, 3395–3403. [Google Scholar] [CrossRef]

- Li, Y.; Langdon, T.G. An examination of a substructure-invariant model for the creep of metal matrix composites. Mater. Sci. Eng. A 1999, 265, 276–284. [Google Scholar] [CrossRef]

- Gupta, R.; Daniel, B.S.S. Impression creep behaviour of ultrasonically processed in-situ Al3Ti reinforced aluminium composite. Mater. Sci. Eng. A 2018, 733, 257–266. [Google Scholar] [CrossRef]

- Davis, L.C.; Allison, J.E. Micromechanics effects in creep of metal-matrix composites. Metall. Mater. Trans. A 1995, 26, 3081–3089. [Google Scholar] [CrossRef]

- Atkins, S.L.; Gibeling, J.C. A finite element model of the effects of primary creep in an Al-SiC metal matrix composite. Metall. Mater. Trans. A 1995, 26, 3067–3079. [Google Scholar] [CrossRef]

- Pan, J.; Yoshida, M.; Sasaki, G.; Fukunaga, H. Metal pipe joining with aluminum alloy by ultrasonic insert casting. Mater. Manuf. Process. 2000, 15, 867–881. [Google Scholar] [CrossRef]

- Nieh, T.G. Creep Rupture of a Silicon Carbide Reinforced Aluminum Composite. Metall. Trans. A 1984, 15, 139–146. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. The high-temperature creep behaviour of aluminium-matrix composites reinforced with SiC, Al2O3 andTiB2 particles. Compos. Sci. Technol. 1997, 57, 697–702. [Google Scholar] [CrossRef]

- Bhagat, R.B.; Amateau, M.F.; House, M.B.; Meinert, K.C.; Nisson, P. Elevated Temperature Strength, Aging Response and Creep of Aluminum Matrix Composites. J. Compos. Mater. 1992, 26, 1578–1593. [Google Scholar] [CrossRef]

- Bhagat, R.B.; House, M.B. Elevated-temperature mechanical properties of silicon-carbide-whisker-reinforced aluminum matrix composites. Mater. Sci. Eng. A 1991, 144, 319–326. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. High-temperature creep behaviour of powder-metallurgy aluminium composites reinforced with SiC particles of various sizes. Compos. Sci. Technol. 1999, 59, 1117–1125. [Google Scholar] [CrossRef]

- Mohamed, F.A.; Park, K.-T.; Lavernia, E.J. Creep behavior of discontinuous SiC-Al composites. Mater. Sci. Eng. A 1992, 150, 21–35. [Google Scholar] [CrossRef]

- Adelakin, T.K.; Suárez, O.M. Study of boride-reinforced aluminum matrix composites produced via centrifugal casting. Mater. Manuf. Process. 2011, 26, 338–345. [Google Scholar] [CrossRef]

- Hu, Z. Injection Parameters Optimization and Artificial Aging of Automotive Die Cast Aluminum Alloy. Mater. Manuf. Process. 2016, 31, 787–793. [Google Scholar] [CrossRef]

- Goo, B.C. Al/SiCp Brake Discs Produced by Dissimilar Cast-Bonding. Mater. Manuf. Process. 2016, 31, 1318–1323. [Google Scholar] [CrossRef]

- Mohal, S.; Kumar, H. Parametric optimization of multiwalled carbon nanotube-assisted electric discharge machining of Al-10%SiCp metal matrix composite by response surface methodology. Mater. Manuf. Process. 2017, 32, 263–273. [Google Scholar] [CrossRef]

- Pavithra, C.L.P.; Sarada, B.V.; Rajulapati, K.V.; Rao, T.N.; Sundararajan, G. Process optimization for pulse reverse electro deposition of graphene-reinforced copper nanocomposites. Mater. Manuf. Process. 2016, 31, 1439–1446. [Google Scholar] [CrossRef]

- Zhang, L.; Duan, Z.; Zhu, H.; Yin, K. Advances in synthesizing copper/graphene composite material. Mater. Manuf. Process. 2017, 32, 475–479. [Google Scholar] [CrossRef]

- Mukhopadhyay, M.; Kundu, P.K.; Das, S. Experimental investigation on enhancing grind ability using alkaline-based fluid for grinding Ti-6Al-4V. Mater. Manuf. Process. 2018, 33, 1775–1781. [Google Scholar] [CrossRef]

- Naseer, A.; Ahmad, F.; Aslam, M.; Guan, B.H.; Harun, W.S.W.; Muhamad, N.; Raza, M.R.; German, R.M. A review of processing techniques for graphene-reinforced metal matrix composites. Mater. Manuf. Process. 2019, 34, 957–985. [Google Scholar] [CrossRef]

- Padhi, P.; Kumar, K.N.; Ghosh, S.; Vishwanatha, H.M.; Panigrahi, S.C.; Ghosh, S. Modeling and experimental validation of deagglomeration of ultra fine nanoparticles in liquid Al during noncontact ultrasonic casting of Al–Al2O3 Nanocomposite. Mater. Manuf. Process. 2016, 31, 1589–1596. [Google Scholar] [CrossRef]

| Method | Equipment Cost | Energy Use | Reinforcement Efficiency | Ideal Volume |

|---|---|---|---|---|

| Stir Casting | Low | Low | Moderate (agglomeration) | >10,000 units |

| Powder Metallurgy | High | Medium | High (uniform dispersion) | <1000 units |

| Additive Mfg. | Very High | Very High | Excellent (hybrid scales) | Prototypes |

| Green Composites | Medium | Low | Moderate (waste compatibility) | Medium scale |

| Composite Material | Particle Size | Processing Method | Change in Properties | Year and Reference |

|---|---|---|---|---|

| Al6061/FA | 1–2 µm | Compo-casting | Improved micro hardness and UTS | 2013 [29] |

| Al2024/Cr2O3 | Friction stir processing (FSP) | FSP reduced wear resistance without reinforcement and increased with rein | 2013 [30] | |

| Al6062/NiTi(FSP, Aging treated, T-6 treated) | 150–178 and 2–74 µm | Friction stir processing (FSP) | Altered the tensile strength (increase, increases, decreases) | 2014 [31] |

| Al6061/Al2O3 | 320 nm | FSP | Increased micro hardness/increased tensile strength | 2014 [32] |

| Al7075/Al2O3/Gr | 45 µm/60 µm | Stir casting | Hardness increased/density increased/good wear behaviour | 2014 [33] |

| Al5052/Al2O3/TiB2 | 500 nm | FSP | Increased hardness/improved wear resistance | 2015 [34] |

| Al6061/RHA | FSP | Increased micro-hardness | 2018 [35] | |

| Al6063/nano-RHA | Ultrasonic and stirring | Increased micro-hardness | 2018 [19] | |

| Al6061/SiC/Coconut shell ash | 40–80 µm | Double stir casting | Increased tensile strength, increased hardness, increased compressive strength, decreased density | 2019 [37] |

| Al6061/RHA/Cu/Mg | Two-step stir casting | Increased hardness, increased Tensile strength, decreased %elongation and impact strength | 2019 [38] | |

| LM-13/B4C/K2TiF6 | 10 µm | Stir casting modified method | Macro and micro hardness enhanced, tensile strength enhanced | 2011 [Al22-14] [83] |

| Al6061/SiC/Gr | 125 µm | Stir casting | Gr addition reduced hardness and increases wear rate; SiC addition increased hardness and tensile strength and reduced wear rate; increased tensile strength | 2012 [Al22-19] [86] |

| ADC12/SiC | 30–40 µm | Stir casting | Micro hardness enhanced and ultimate tensile strength enhanced | 2014 [89] |

| Al7075/SiC/Al2O3 | Stir casting | Porosity improved, surface roughness increased | 2014 [93] | |

| Al6061/Al2O3 | 125 µm | Stir casting | Hardness, tensile and yield strength increased, ductility decreases and at constant load of 19.62 N and 300 rpm, maximum wear rate was observed | 2014 [94] |

| Al6061/SiC Al6061/SiC/Gr | 37 µm–1 µm | Al22 [41] | ||

| Al6061/SiC/FA/SiC-FA | -- | Stir casting | Tensile strength increased, hardness increased | Al22 [70] |

| LM6/SiC/Al2O3 | 80–100/70–230 | Stir casting | Hardness increased, tribological properties improved | Al22 [72] |

| Al6061/SiC/TiB2 | 25 µm/10 µm | Stir casting | Hardness tensile strength, wear resistance and surface roughness improved | Al22 [80] |

| Method | Cost | Application | Comments |

|---|---|---|---|

| Stir casting | Least cost | Applicable for mass production | Appropriate for particulate reinforcement in AMMCs dependency on matrix metal and reinforcement properties and casting speed and duration |

| Powder metallurgy | Medium cost | Used in the production of parts that are heat resistant example piston, valves | Matrix metal and reinforcements are required in powder form. Due to no development of reactive zone, the manufactured AMMCs have high strength. |

| Diffusion Bonding | High cost | For sheets, vane shafts and blades, this process is used. | Suitable for matrix metal in the form of foils or sheets; reinforcements in the form filaments. |

| Liquid infiltration | Low cost | Structural component manufacturing such as rods, beam, tubes | Reinforcement in form of filament is used |

| Squeeze casting | Medium cost | Engine parts production, i.e., piston, connecting rods, cylinder head | Generally preferred for type of reinforcement. Used for mass scale production. |

| Compo-casting | Low cost | Applicable to automobile industry | Conducive for discontinuous fibre in particle form |

| In situ | Medium cost | Applicable to automobile sector | It results in distribution of reinforcing particle homogeneously. |

| Ultrasonic assisted casting | High cost | Suitable for mesh shaped components. Preferred for large scale manufacturing. | Almost uniform dispersion of particulate reinforcements. |

| Reinforcement Type | Key Benefit | Performance Gain | Primary Application |

|---|---|---|---|

| HEAp | Strength–ductility synergy | +29% YS, +40% wear resistance | Corrosive environments |

| Agro-waste hybrids | Cost/environmental advantage | 55% hardness ↑, 20% material cost ↓ | Automotive non-structural |

| Nano planar defects | Ultrahigh strength in 3D prints | σ = 656 MPa post-aged | Aerospace lightweight parts |

| Ticore–shell | Density-compensated strength | σ = 1147 MPa at ρ = 3.7 g/cm3 | Defence, space structures |

| Graphene | Multi functionality | 2× thermal conductivity, 60% COF ↓ | Electronics, tribo systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, S.K.; Shi, L. Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review. Alloys 2025, 4, 18. https://doi.org/10.3390/alloys4030018

Patel SK, Shi L. Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review. Alloys. 2025; 4(3):18. https://doi.org/10.3390/alloys4030018

Chicago/Turabian StylePatel, Surendra Kumar, and Lei Shi. 2025. "Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review" Alloys 4, no. 3: 18. https://doi.org/10.3390/alloys4030018

APA StylePatel, S. K., & Shi, L. (2025). Recent Advances in Ceramic-Reinforced Aluminum Metal Matrix Composites: A Review. Alloys, 4(3), 18. https://doi.org/10.3390/alloys4030018