Research on the Microstructure Evolution of TC4 Titanium Alloy Joint Fabricated by Continuous Drive Friction Welding

Abstract

1. Introduction

2. Materials and Methods

3. Results

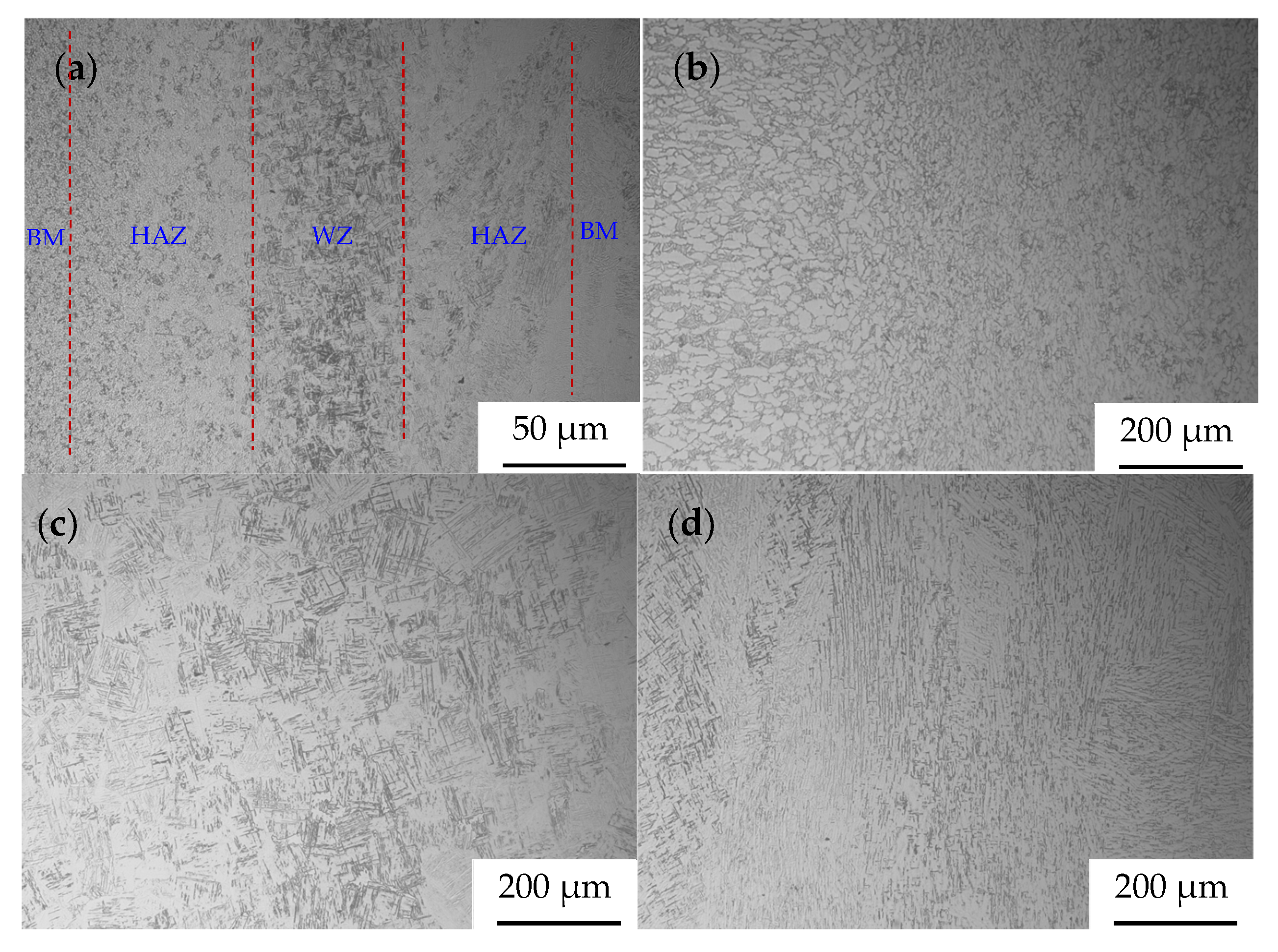

3.1. The Macroscopic Morphology of the Joint

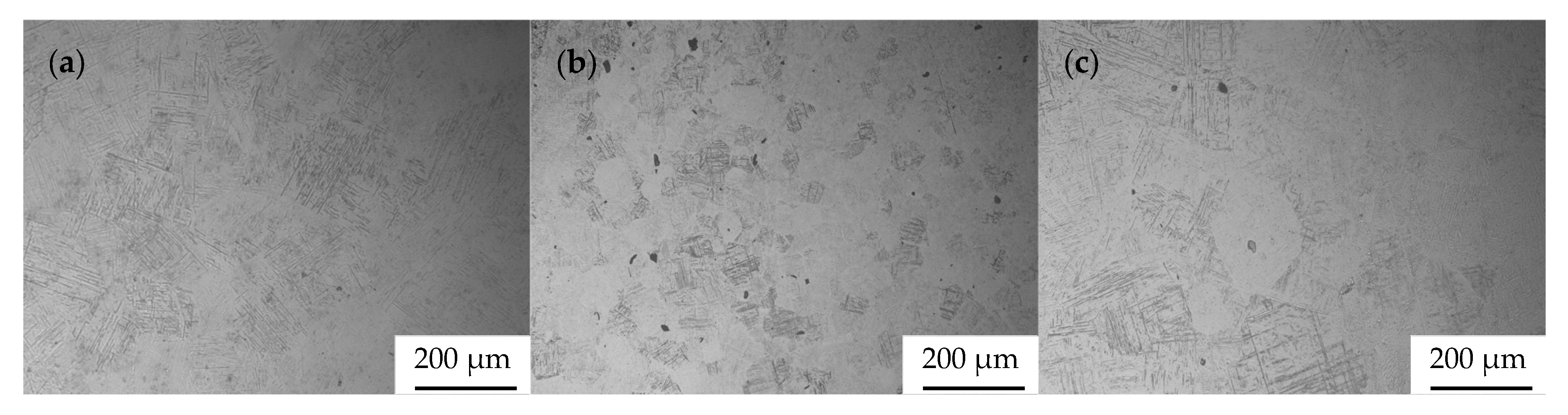

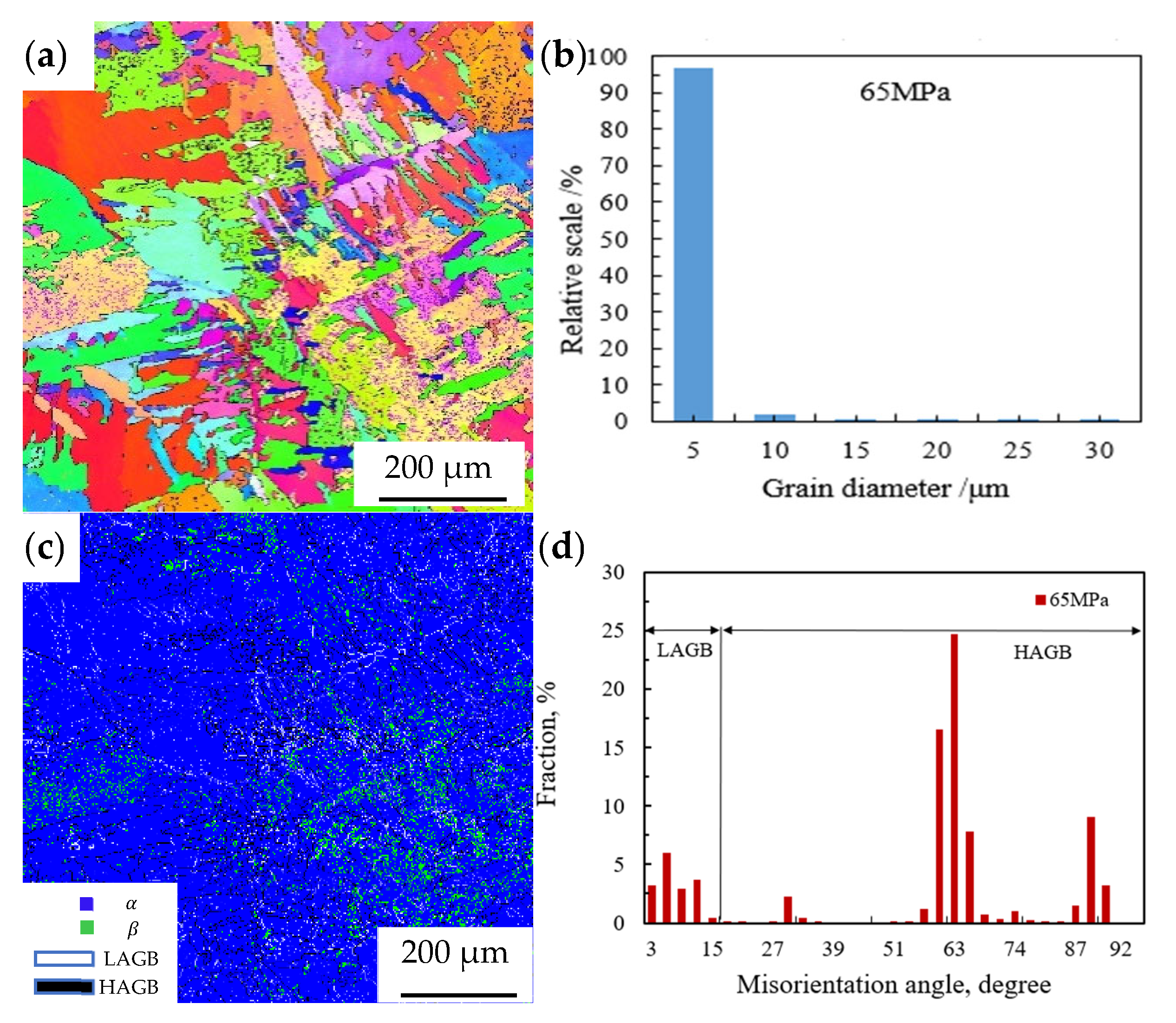

3.2. The Microstructure of Base Metal

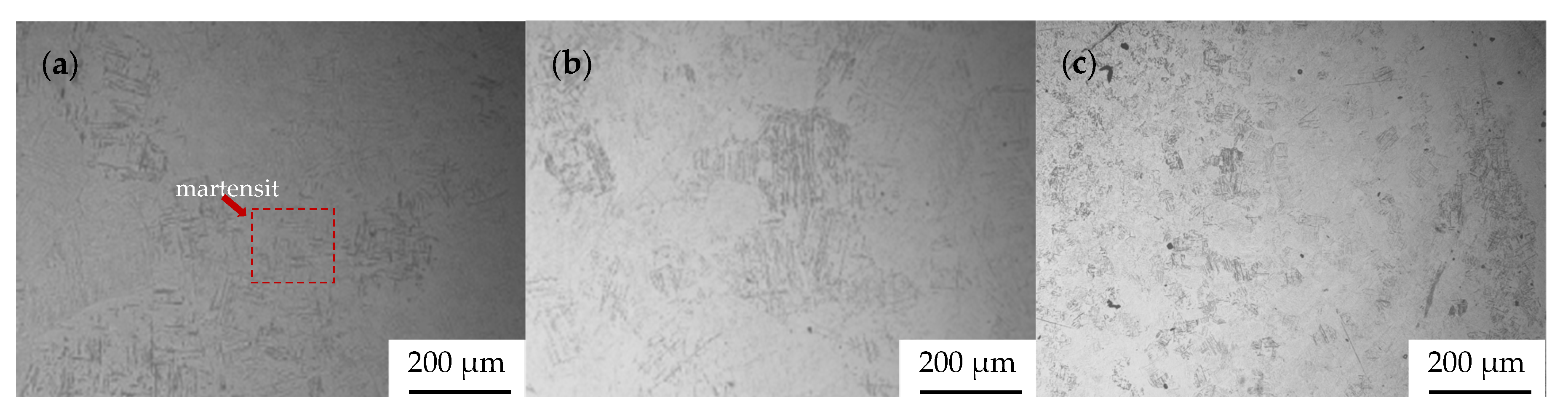

3.3. The Microstructure of Flash

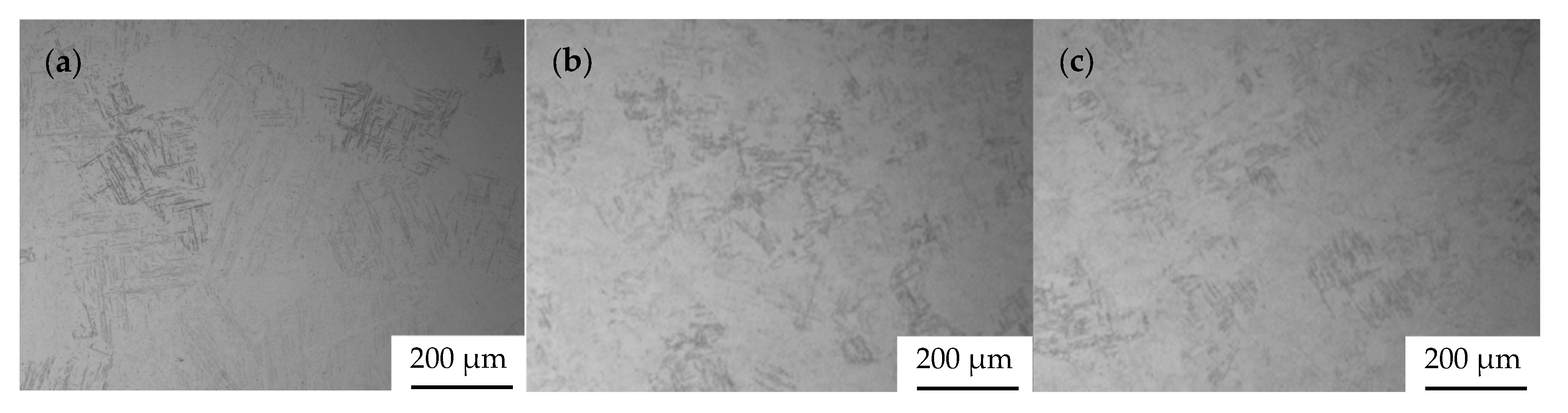

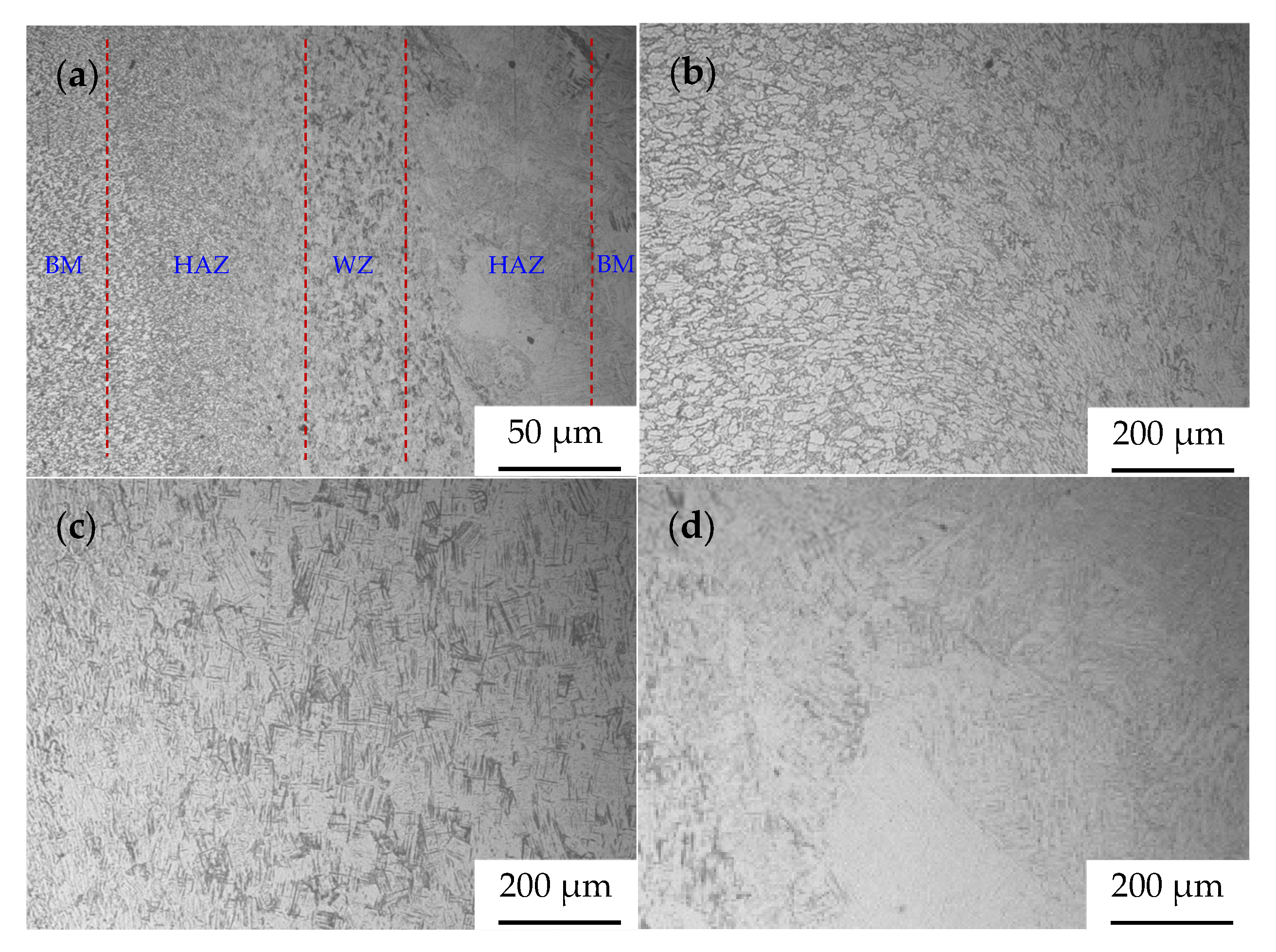

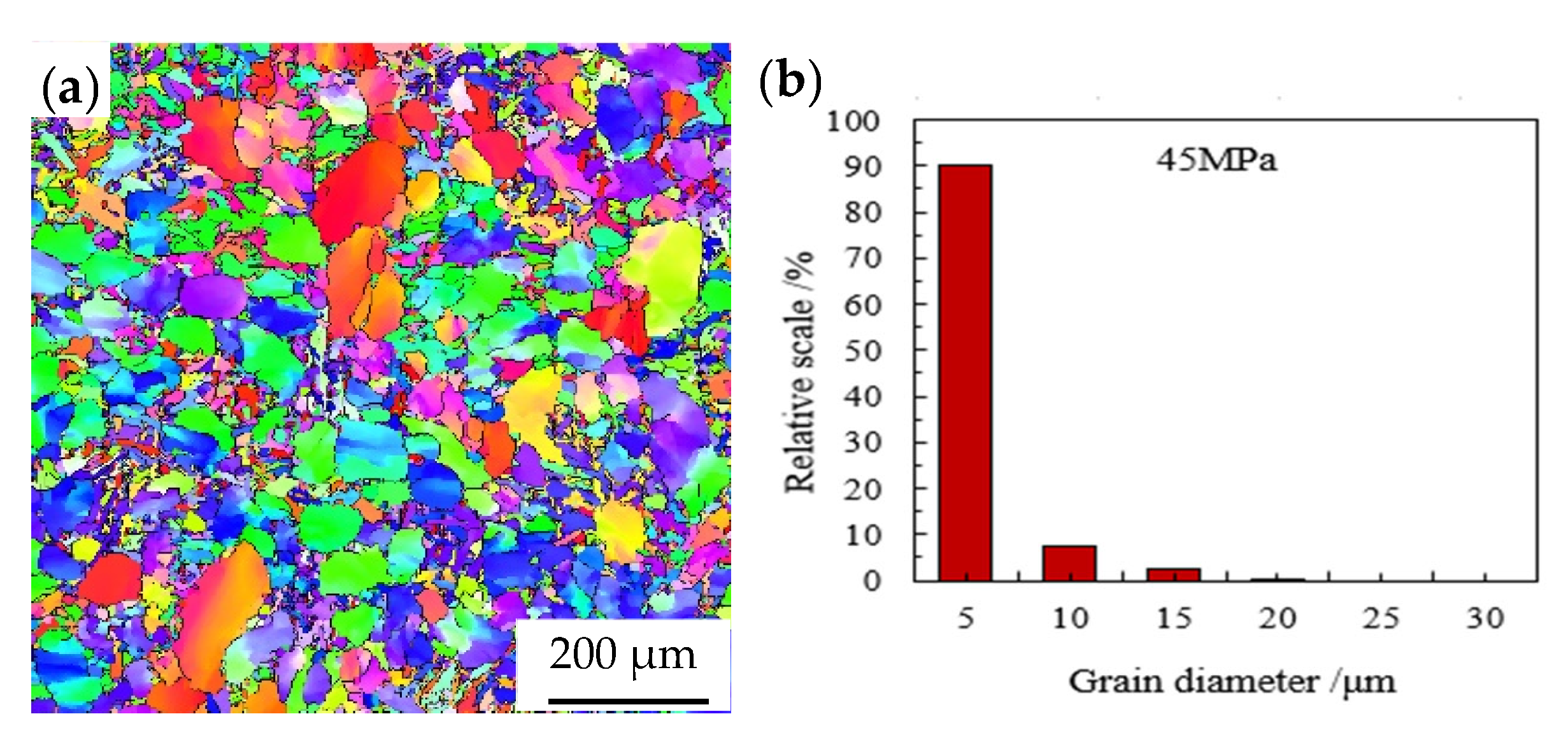

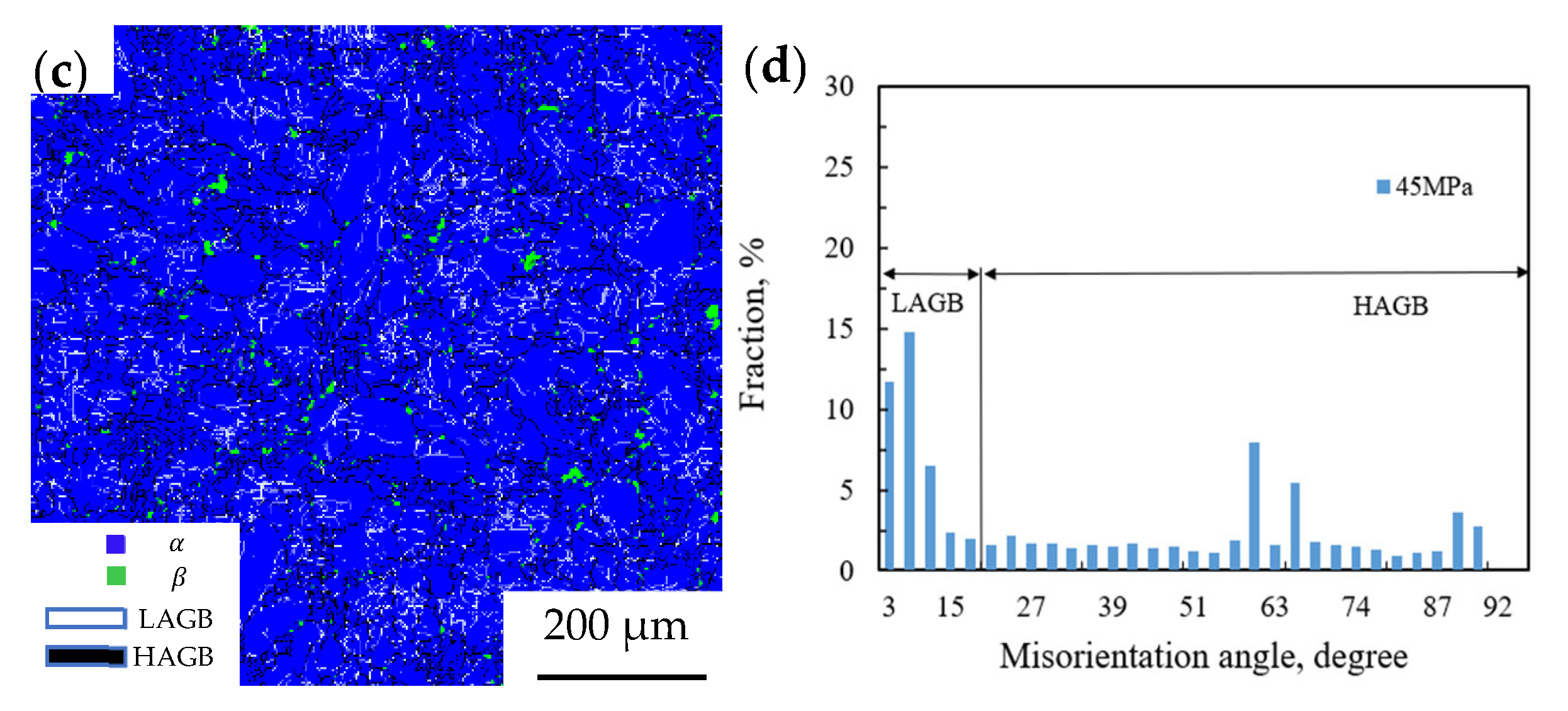

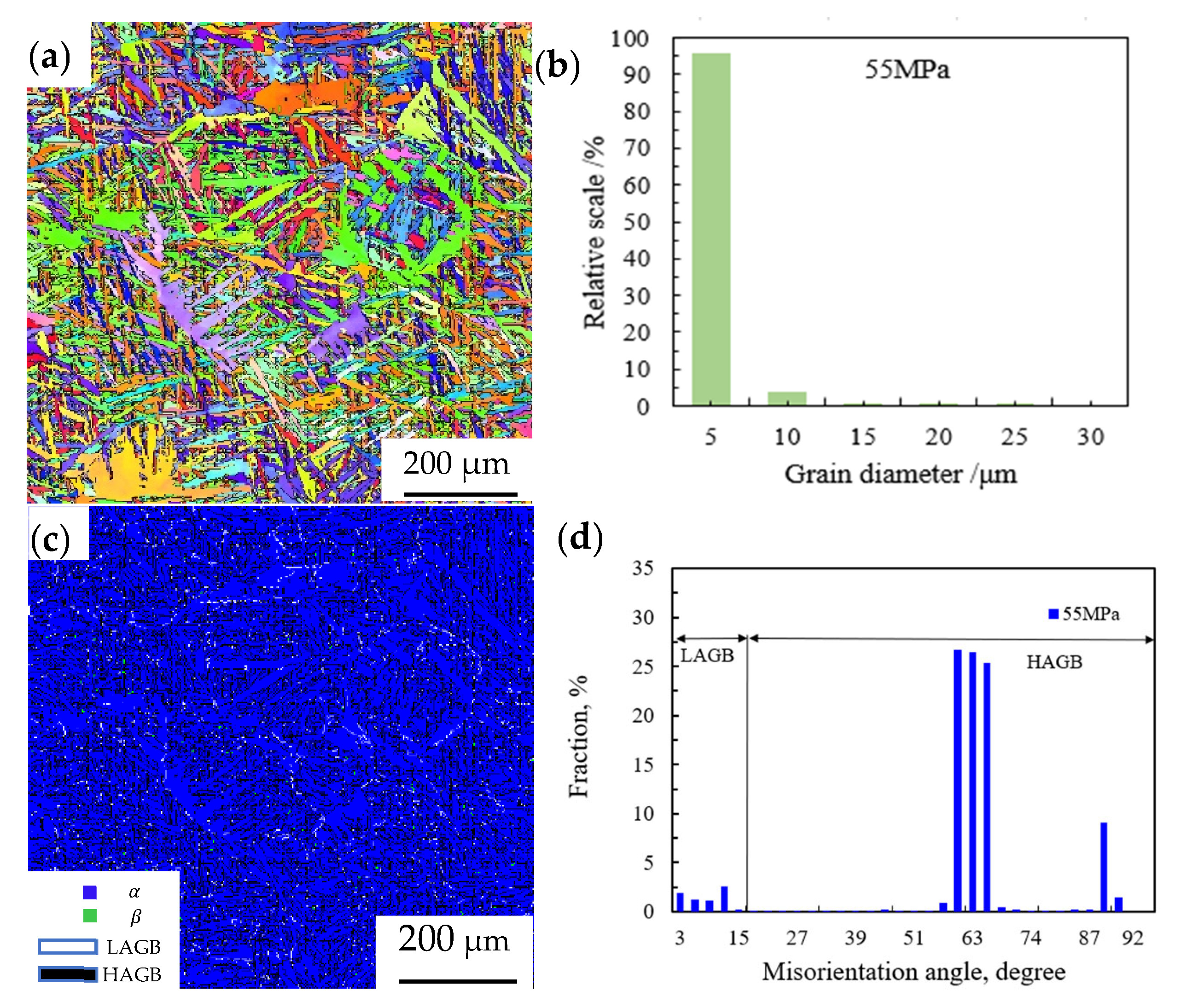

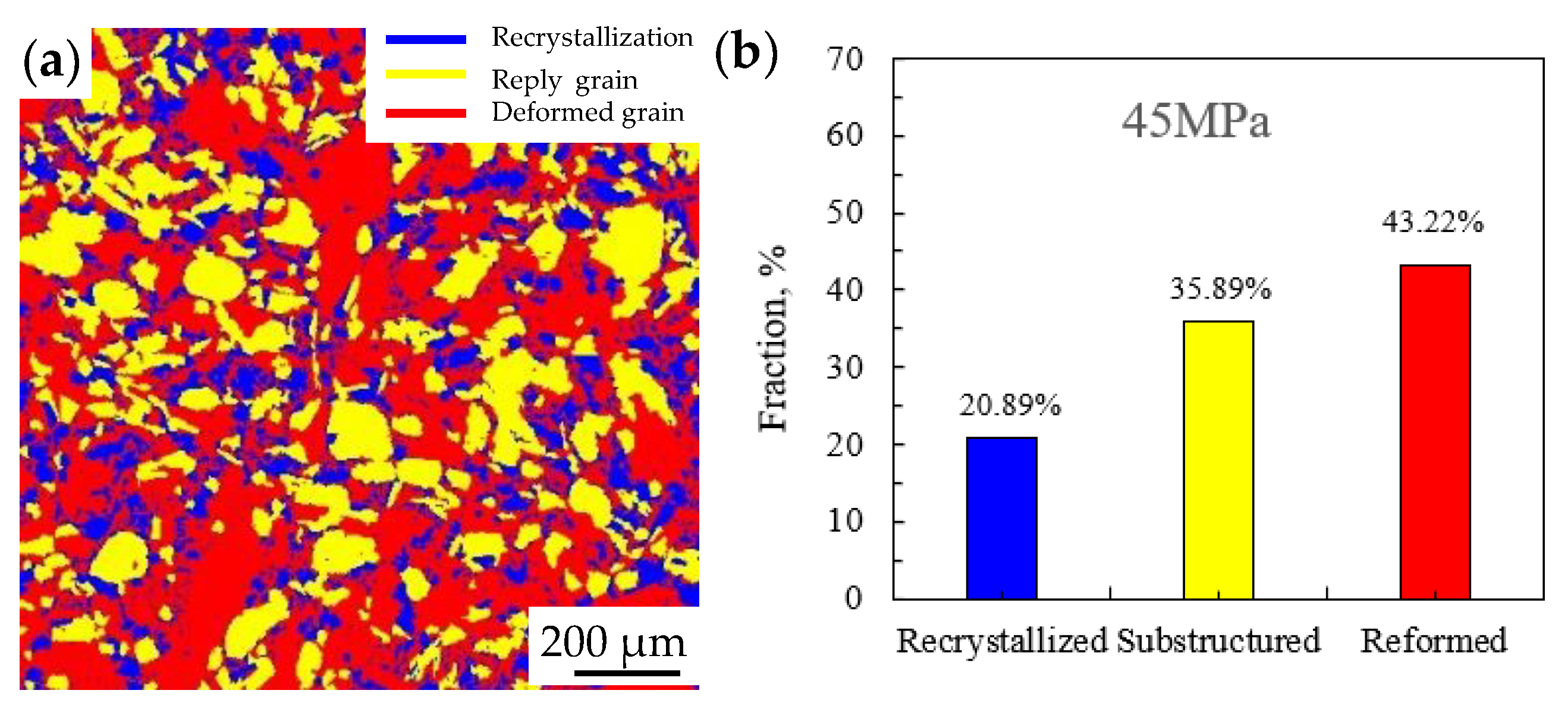

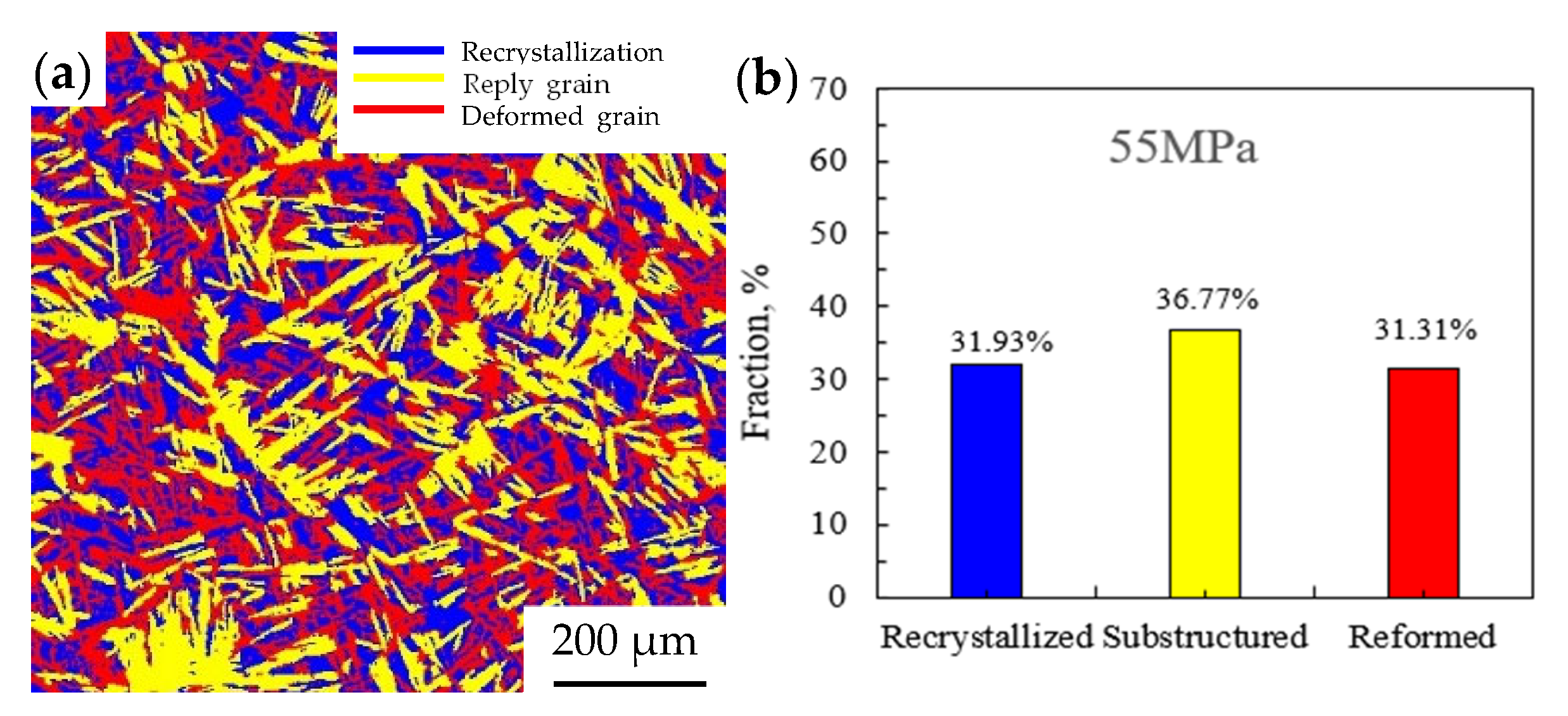

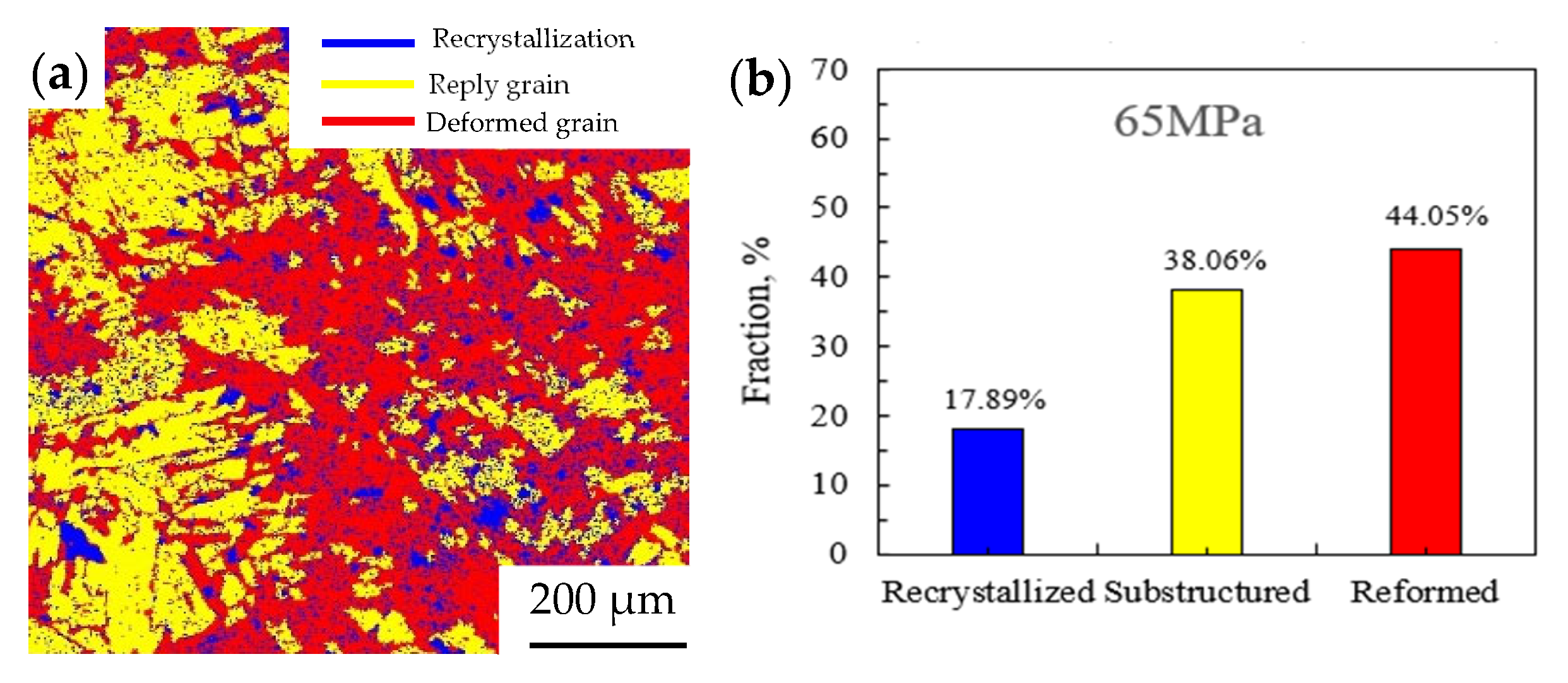

3.4. The Microstructure of Joints

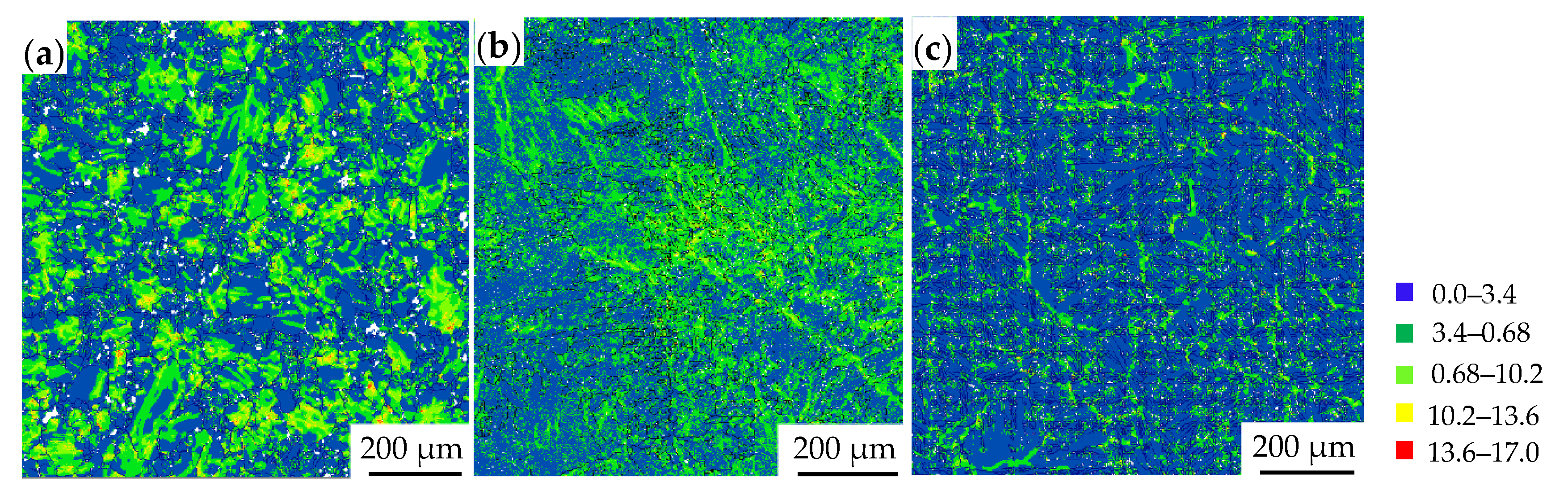

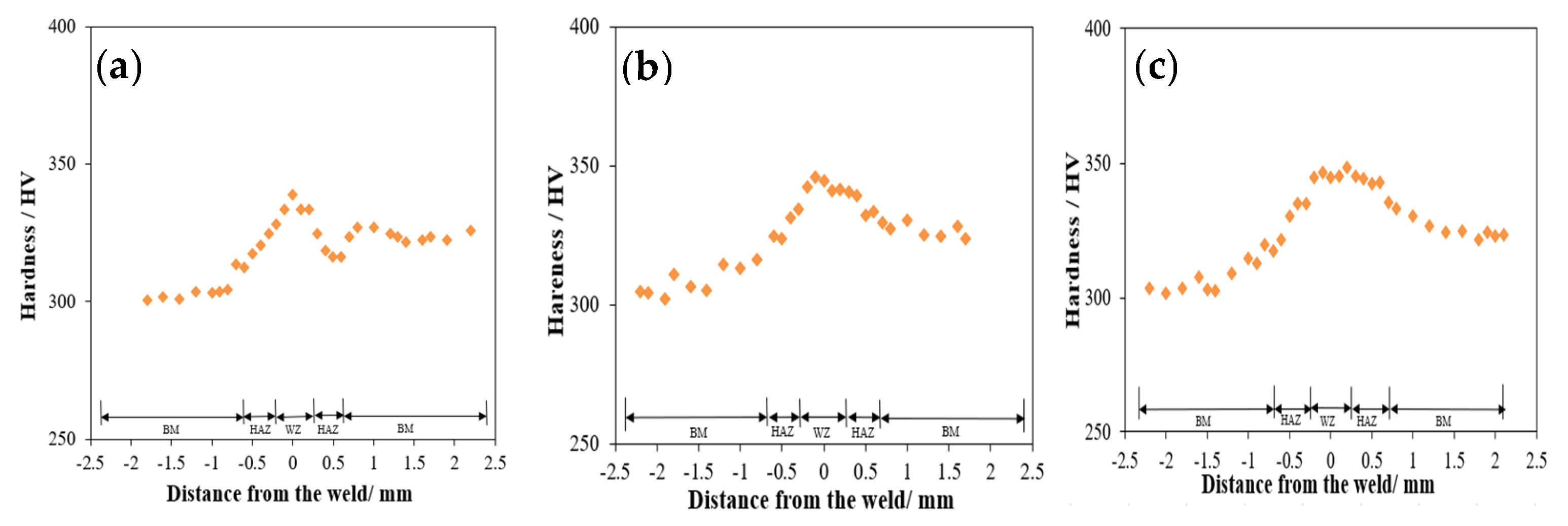

3.5. Microhardness of the Joint

4. Conclusions

- (1)

- The joints do not exhibit any defects such as pores or cracks in the current welding parameters. The quality of the joints is good.

- (2)

- As the friction pressure increases, the size of the flash morphology also increases, while the width of the weld zone decreases.

- (3)

- In weld zone and flash, martensite has no obvious change with the increase of friction pressure.

- (4)

- The proportion of LAGB in the joint decreases, which indicates that friction pressure has a certain influence on the microstructure.

- (5)

- With the increase of friction pressure, the recrystallization is sufficient, but when the pressure is high, the deformation dominates in the joint.

- (6)

- The hardness of the weld zone is slightly higher than that of the base metal on both sides. The hardness of the thermal mechanically affected zone on both sides decreases with increasing the distance from the WZ. With the increase of friction pressure, the hardness doesn’t change significantly.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.D.; Huang, Y.; Wu, J.; Shi, T.H.; Zhang, Q.; Zhang, Z.S.; Yu, H.R. Performance Test of Weld Zone of Rotary Friction Welding of Titanium Alloy Drill Pipe. J. Phys. 2023, 3, 2587. [Google Scholar] [CrossRef]

- Zhao, Z.P.; Ma, T.J.; Li, W.Y.; Zhang, Y. The influence of welding pressure on the microstructure and properties of linear friction welded joints of TB2 titanium alloy. Weld. Pipe 2019, 11, 004. [Google Scholar]

- Zhang, X.Y.; Liu, T.; Geng, J.Y. Research on Friction Stir Welding Process and Properties of 7075 Aluminum Alloy. Spec. Cast. Non-Ferr. Alloys 2024, 8, 1114–1118. [Google Scholar]

- Xi, J.H.; Ge, P.; Hou, P. Continuous drive friction welding for the preparation of titanium alloy pipe fittings. Welding 2020, 9, 47–51+64. [Google Scholar]

- Cheng, P.X.; Xi, J.H.; Liu, J.; Shi, L.C.; Zhang, J.J. Microstructure and properties of inertial friction welded joint of TA18 titanium alloy tube. Steel Vanadium Titan. 2024, 6, 74–79. [Google Scholar]

- Chang, C.C.; Li, J.; Cui, Y. Microstructure and properties analysis of TC21 titanium alloy linear friction welded joint. Rare Metal Mater. Eng. 2022, 10, 3843–3849. [Google Scholar]

- Du, S.G.; Liu, G.X.; Chen, H. Microstructure and texture evolution of TC17(α+β)/TC17(β) linear friction welding process. J. Mech. Eng. 2024, 2, 99–106. [Google Scholar]

- Wu, Y.Q.; Zhou, J.; Zhang, C.B. Microstructure, fracture toughness and crack propagation characteristics of TC4 titanium alloy inertia friction joint. Rare Met. Mater. Eng. 2023, 9, 3032–3138. [Google Scholar]

- Gao, S.; Yuan, M.Q. Study on microstructure and properties of Ti60/TC17 dissimilar titanium alloy inertial friction welding joint. Electr. Weld. Mach. 2023, 8, 115–121+143. [Google Scholar]

- Amirov, A.I.; Chumaevskii, A.V.; Utyaganova, V.R.; Gusarova, A.V.; Gurianov, D.A.; Rubtsov, V.E.; Kolubaev, E.A. Structure and Properties of Dissimilar Joint of Ti and Al Alloys Obtained by Friction Stir Welding. Russ. Phys. J. 2023, 66, 970–977. [Google Scholar] [CrossRef]

- Morgane, G.; Fènoël, A.N.M.; Vidal, V.; Farhad, R.A.; Christine, B. Multi-scale effects of the tool shape and length on the interfacial microstructure and the mechanical behaviour of Al2024/Ti-6Al-4V lap friction stir welds. J. Manuf. Process. 2024, 113, 360–372. [Google Scholar]

- Yang, X.W.; Yao, M.X.; Su, Y.; Meng, T.X.; Ma, S.T.; Guo, Z.G.; Li, W.Y. Forming control and the relationship between microstructure and mechanical property in TIG-assisted friction stir welded joint of Ti-6Al-3Nb-2Zr-1Mo titanium alloy. J. Mater. Res. Technol. 2024, 33, 6196–6206. [Google Scholar] [CrossRef]

- Guo, Z.G.; Ma, T.J.; Chen, T.; Wang, J.T.; Chen, X.; Yang, X.W.; Vairis, A. Linear friction welding of equiaxed Ti17 titanium alloy: Effects of microstructure evolution on tensile and impact properties. J. Mater. Sci. 2024, 24, 10189–10200. [Google Scholar] [CrossRef]

- Gong, H.; Liu, M.Q.; Zhang, T.; He, Y.B.; Wu, Y.X.; Yu, Z.X. Study on Residual Stress and Optimization of Welding Parameters in Linear Friction Welding of TC17 Titanium Alloy. Materials 2022, 24, 8963. [Google Scholar] [CrossRef]

- Wang, X.Y.; Quan, Y.Z.; Li, J.; Tao, J.; Li, J.; Li, W.Y. Structure and texture evolution mechanism of TC11 titanium alloy linear friction welding joint. Rare Met. 2023, 5, 692–700. [Google Scholar]

- Lu, Y.; Yuan, K.; Yang, X.; Ding, Y.; Sun, F.X.; Wang, R.H. Effect of friction pressure on the performance of Super304H/T92 friction welded joints. Mater. Rep. 2016, 30, 494–498. [Google Scholar]

- Wen, G.D. Study on the macroscopic deformation and micromorphology of Ti and Fe continuously driven friction weld welding interfaces. Hot Work. Process 2019, 11, 24–27+31.14. [Google Scholar]

- Guo, Z.G.; Ma, T.J.; Li, J.; Li, W.Y.; Liu, Y.S. Effect of friction pressure on the microstructure of Ti17 titanium alloy linear friction welding joint. Hot Work. Process 2023, 21, 77–81. [Google Scholar]

- Wang, S.Q.; Jing, K.; Wen, G.D.; Li, X.; Li, Y.B. Study on the effect of friction time on the structure and properties of drill pipe joints. Hot Work. Process 2017, 3, 192–194. [Google Scholar]

- Meng, T.X.; Yang, X.W.; Su, Y.; Ma, S.T.; Ma, H.Y.; Guo, Z.G.; Guo, W.Y. Formation mechanism and failure behavior in synergistic double-sided probeless friction stir spot welded joints of 6061 aluminum alloy. Mater. Charact. 2024, 219, 114631. [Google Scholar] [CrossRef]

- Guo, Z.G.; Ma, T.J.; Li, W.Y.; Zhang, Y.; Zhao, Z.P.; Tao, J.; Kang, W.J. Intergrowth bonding mechanism and mechanical property of linear friction welded dissimilar near-Alpha to near-Beta titanium alloy joint. Adv. Eng. Mater. 2021, 5, 2001479. [Google Scholar] [CrossRef]

- Ali, Y. The Effect of Different Friction Pressure on the Microstructural and Mechanical Properties of Ti Gr2 Titanium Alloy. J. Mater. Eng. Perform. 2023, 19, 8678–8686. [Google Scholar]

- Xiao, X.; Mao, Y.; Qin, D.Q.; Wang, X.C.; Fu, L. Effects of microstrcture composition and orientation on micro mechanical properties of linear friction welding joint weld zone for heteromorphic TC17 titanium alloy. J. Mater. Sci. 2023, 41, 16208–16224. [Google Scholar] [CrossRef]

- Dai, Z.K. Study on the structure and properties of laser welding joint with spatial structure of TA15 titanium alloy. Master’s Thesis, Nanchang Hangkong University, Nanchang, China, 2023. [Google Scholar]

| Specimen Number | Friction Pressure/MPa | Rotation Speed/rpm | Upsetting Force/MPa | Friction Shortening/mm |

|---|---|---|---|---|

| NO. 1 | 45 | 1311 | 80 | 9 |

| NO. 2 | 55 | 1311 | 80 | 9 |

| NO. 3 | 65 | 1311 | 80 | 9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Wang, S.; Zhang, Y.; Wen, G.; Qiang, W. Research on the Microstructure Evolution of TC4 Titanium Alloy Joint Fabricated by Continuous Drive Friction Welding. Alloys 2025, 4, 4. https://doi.org/10.3390/alloys4010004

Cui S, Wang S, Zhang Y, Wen G, Qiang W. Research on the Microstructure Evolution of TC4 Titanium Alloy Joint Fabricated by Continuous Drive Friction Welding. Alloys. 2025; 4(1):4. https://doi.org/10.3390/alloys4010004

Chicago/Turabian StyleCui, Shanshan, Shiqing Wang, Yiqiang Zhang, Guodong Wen, and Wei Qiang. 2025. "Research on the Microstructure Evolution of TC4 Titanium Alloy Joint Fabricated by Continuous Drive Friction Welding" Alloys 4, no. 1: 4. https://doi.org/10.3390/alloys4010004

APA StyleCui, S., Wang, S., Zhang, Y., Wen, G., & Qiang, W. (2025). Research on the Microstructure Evolution of TC4 Titanium Alloy Joint Fabricated by Continuous Drive Friction Welding. Alloys, 4(1), 4. https://doi.org/10.3390/alloys4010004