Evaluating Flow Characteristics of Ground and Cut Biomass for Industrial Applications

Abstract

1. Introduction

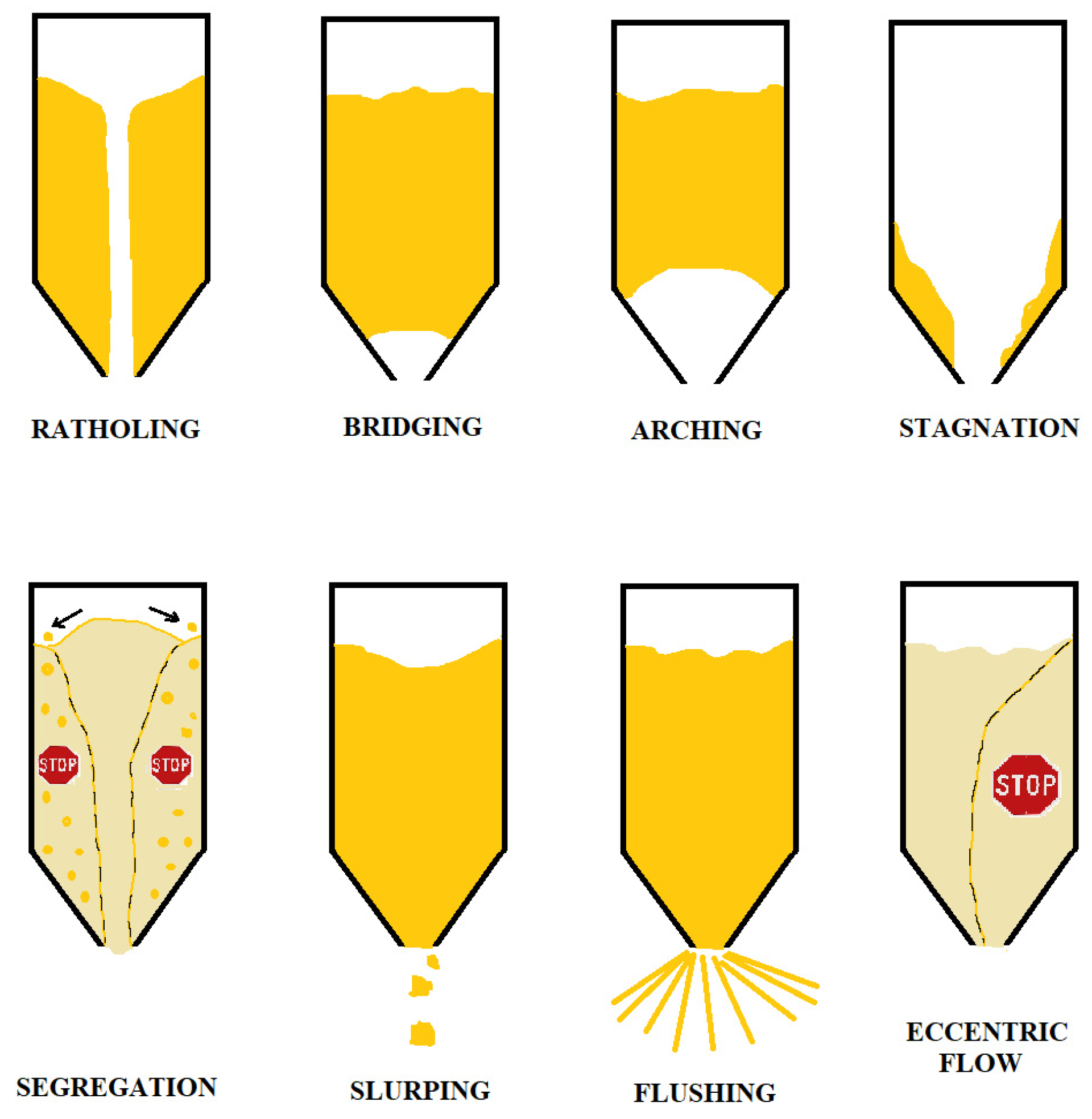

1.1. Applications of Biomass Properties

1.2. Analysis of Existing Research

2. Materials and Methods

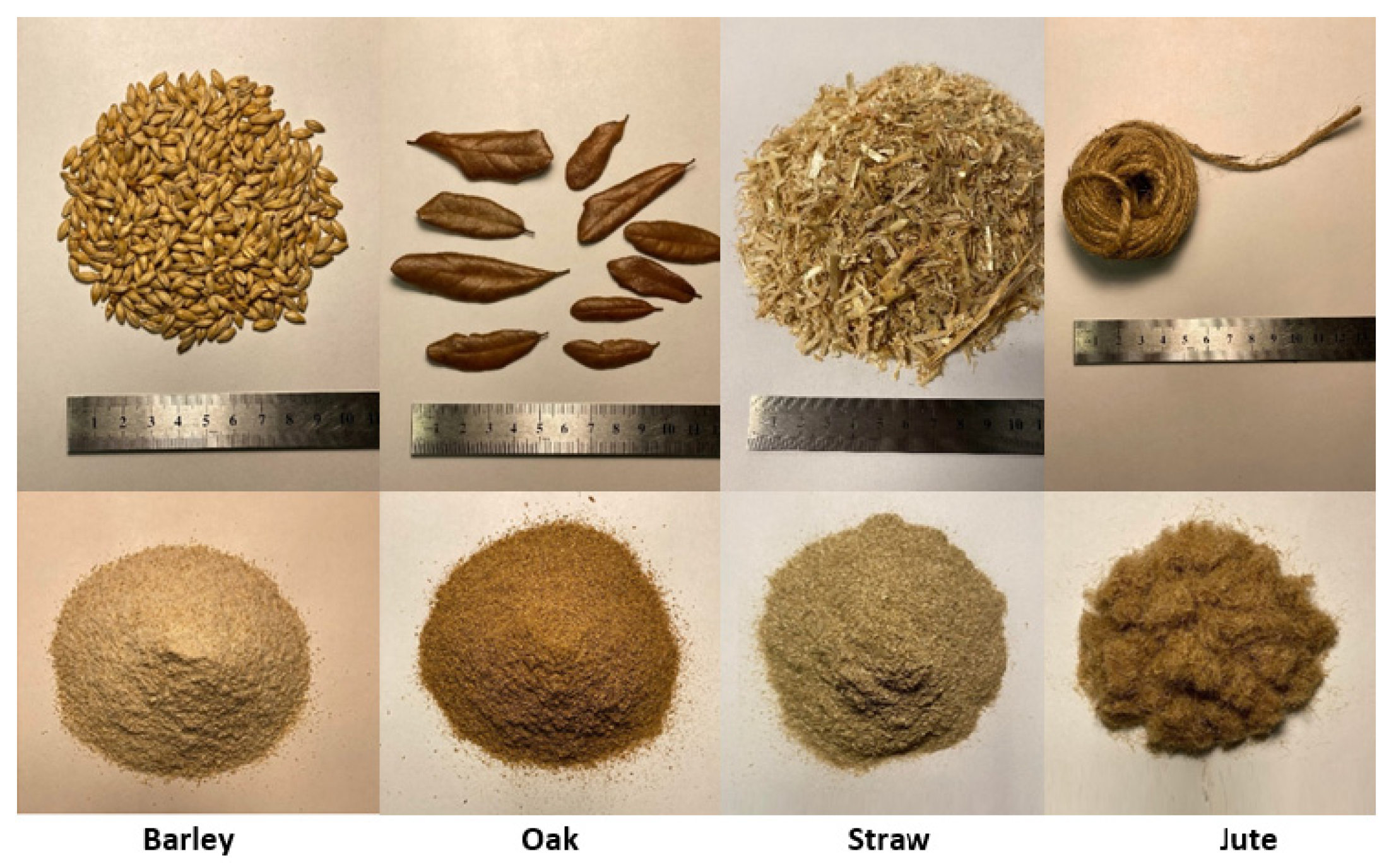

2.1. Biomass Materials

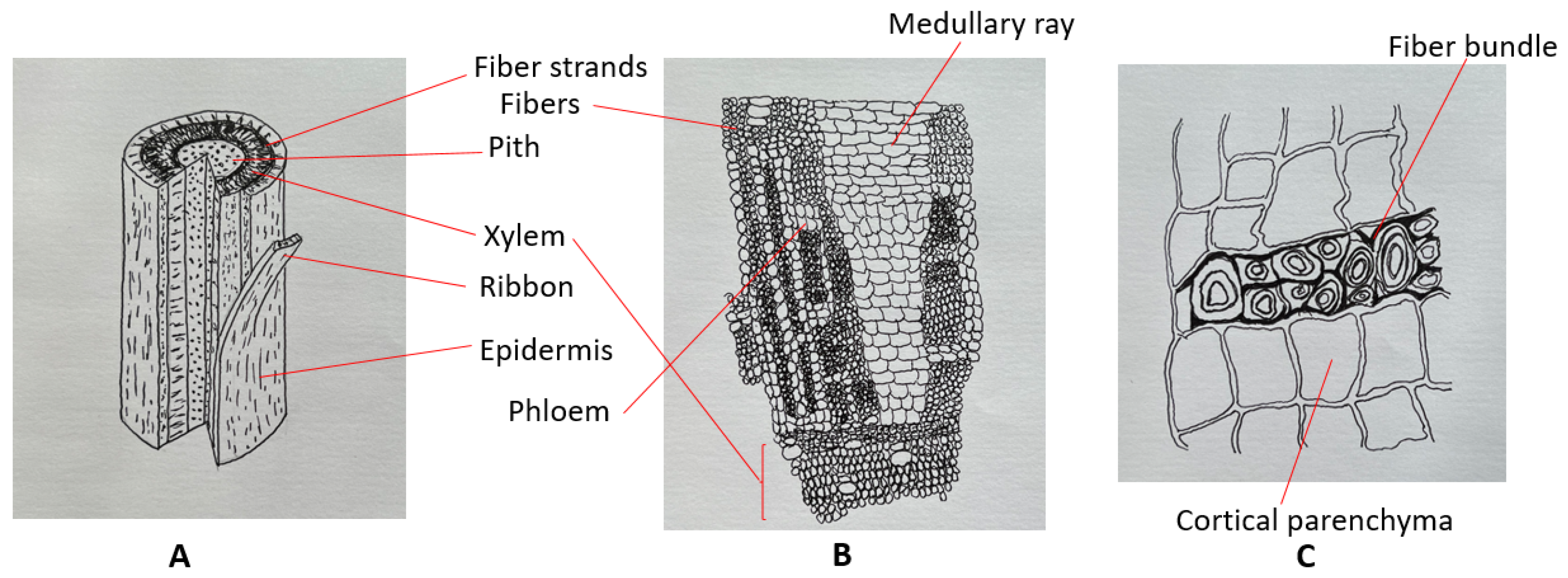

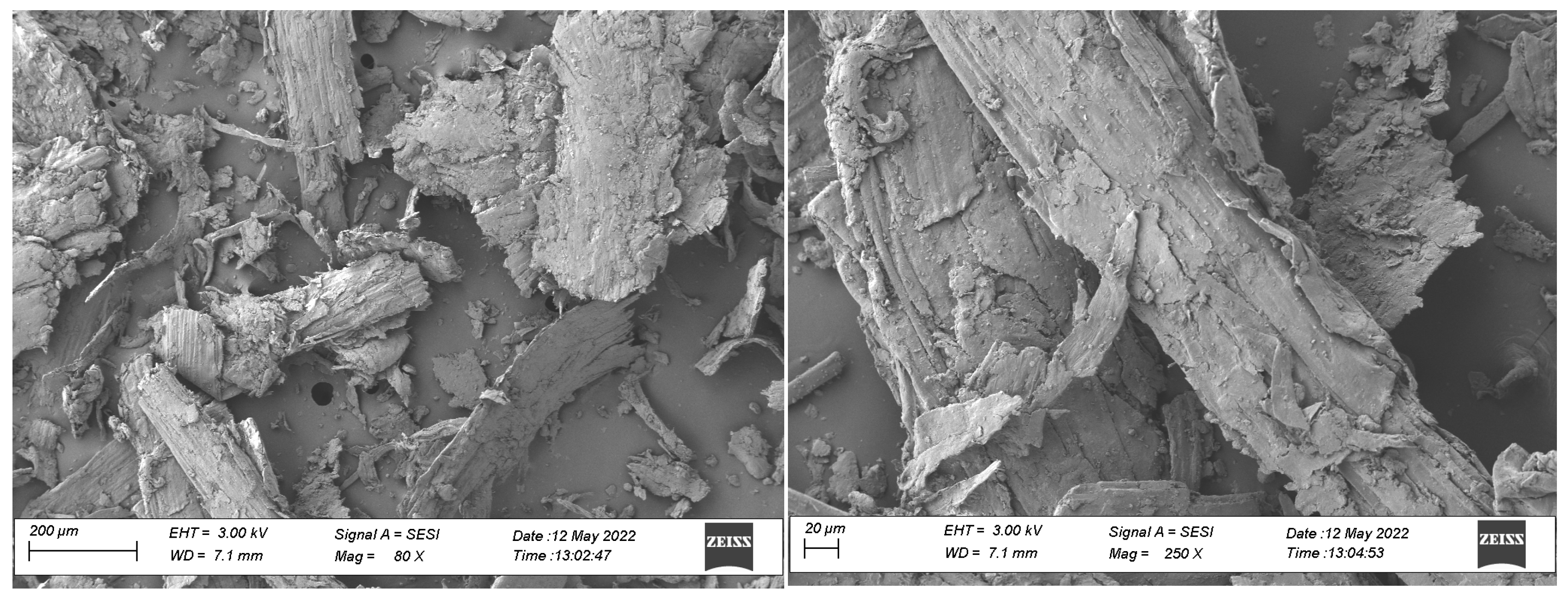

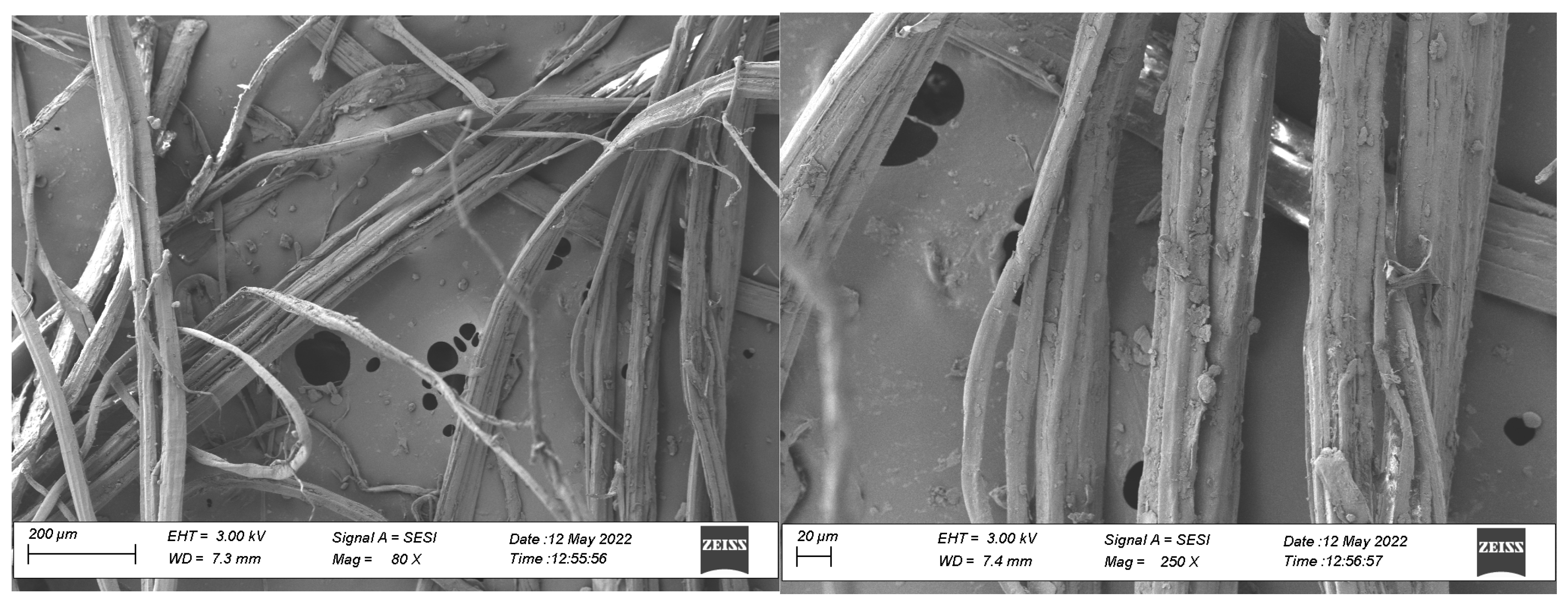

2.2. Scanning Electron Microscopy (SEM)

2.3. Particle Size and Particle Size Distribution (PSD)

2.4. Bulk Density

2.5. Hausner Ratio (HR) and Carr’s Index

2.6. Moisture Content (MC)

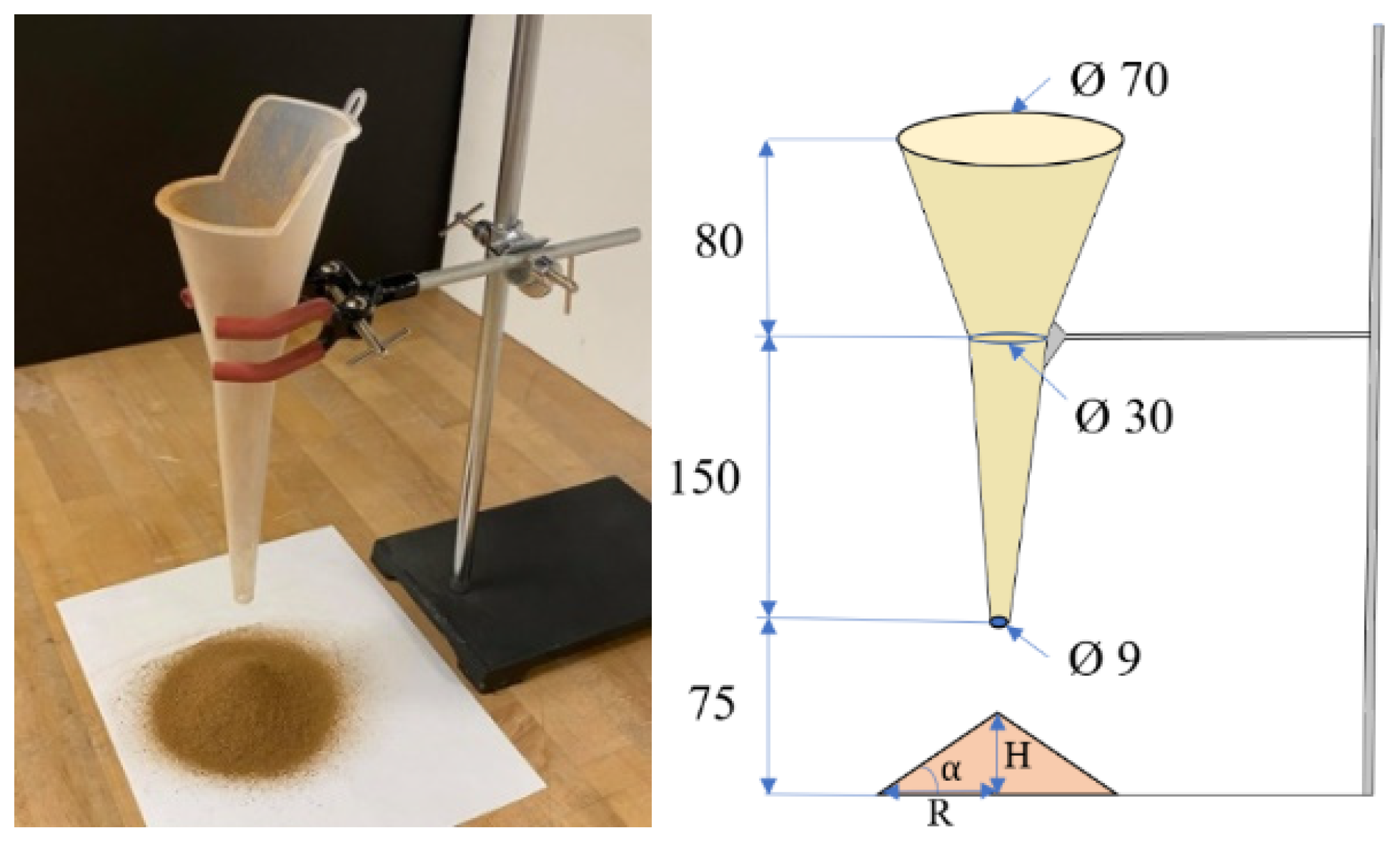

2.7. Static Angle of Repose (AoR)

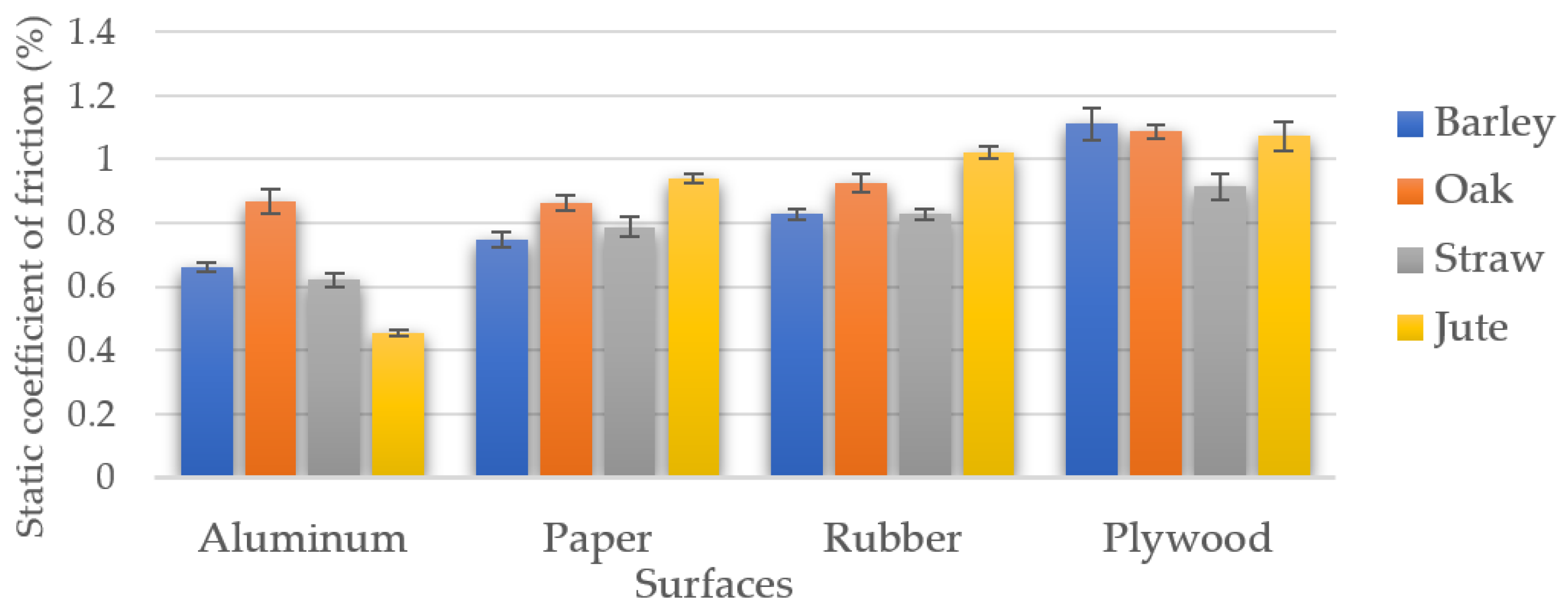

2.8. Angle of Friction (Static Coefficient of Friction)

3. Results and Discussion

3.1. Color, SEM Images, and Particle Size Distribution (PSD)

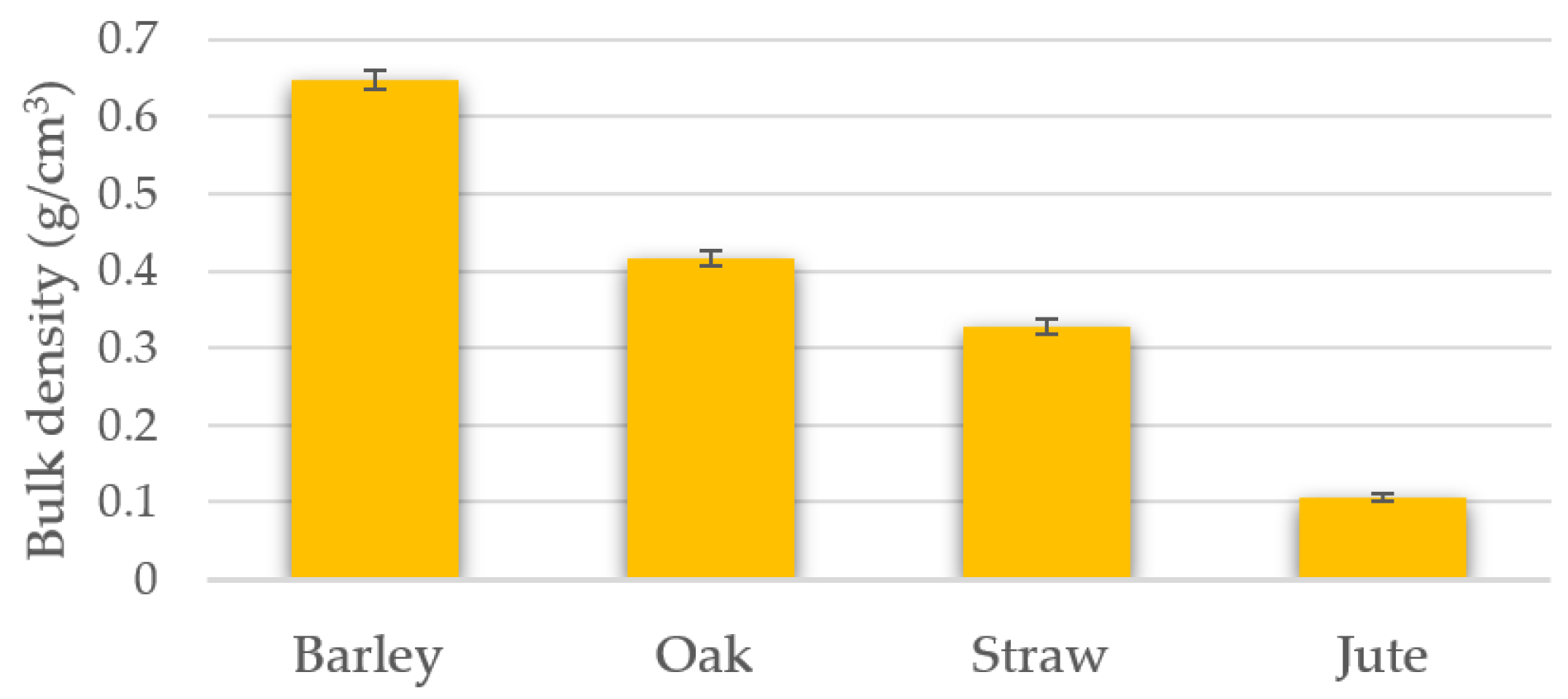

3.2. Bulk Density

3.3. Moisture

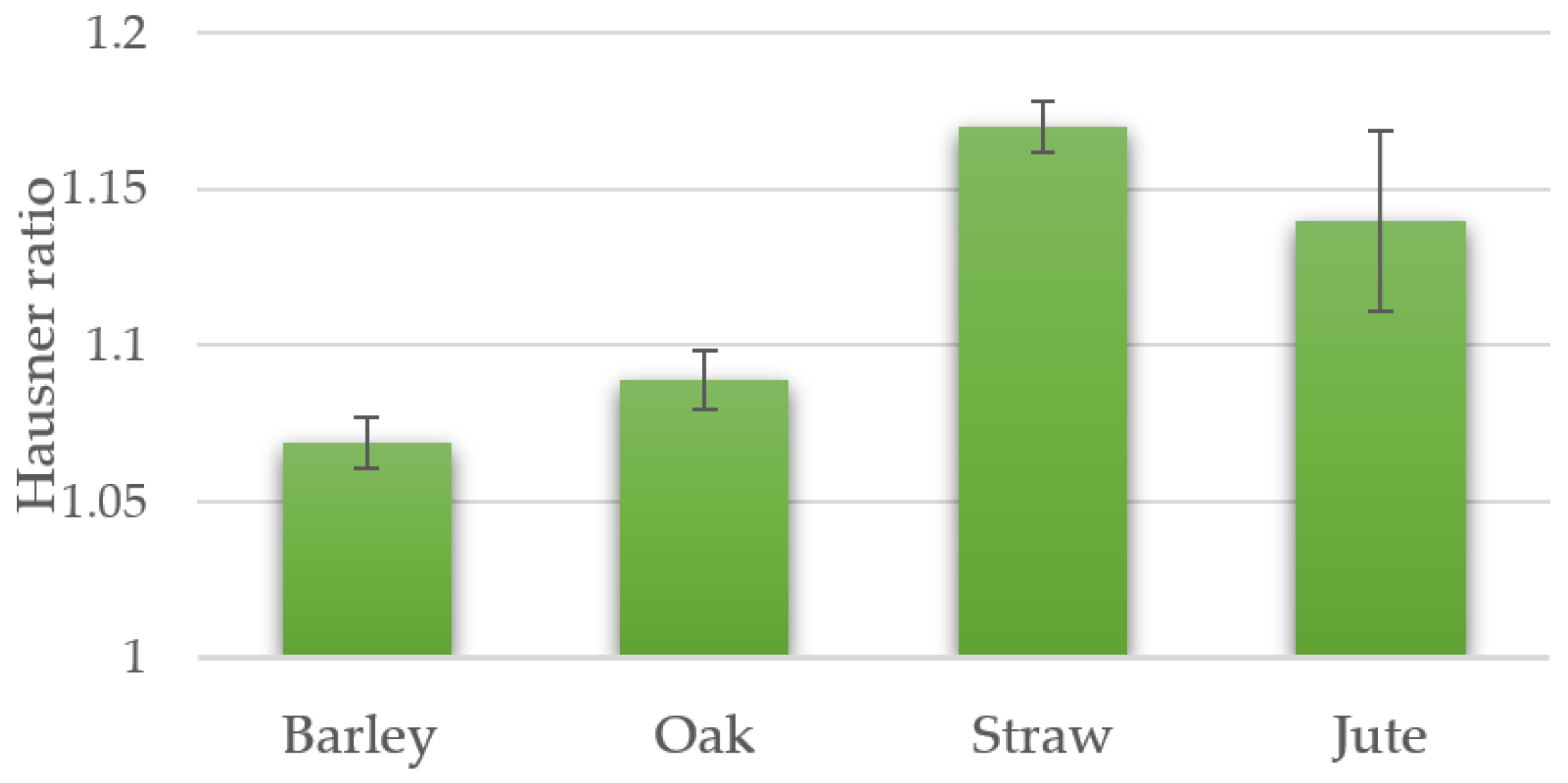

3.4. Hausner Ratio (HR) and Carr’s Index

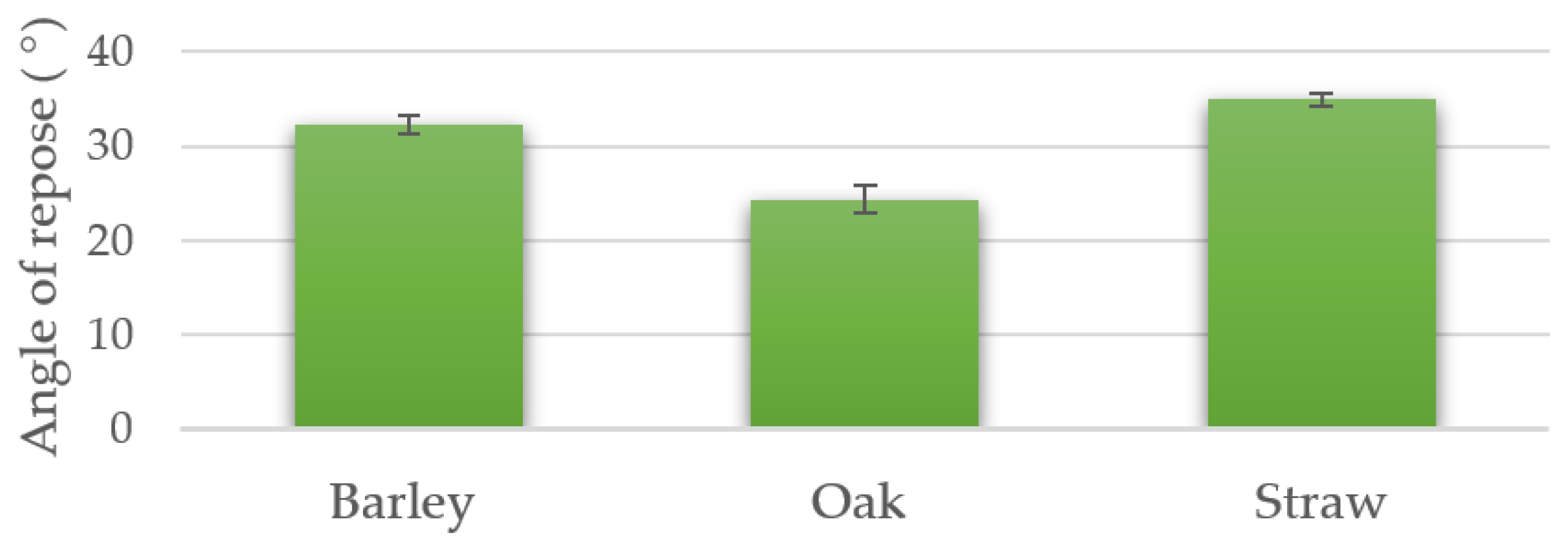

3.5. Static Angle of Repose

3.6. Static Angle of Friction

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghoniem, A. Energy Conversion Engineering towards Low CO2 Power and Fuels; Printed Book; Cambridge University Press: Cambridge, UK, 2022. [Google Scholar]

- Craven, J.M.; Swithenbank, J.; Sharifi, V.N. Investigation into the Flow Properties of Coarse Solid Fuels for Use in Industrial Feed Systems. J. Powder Technol. 2015, 2015, 786063. [Google Scholar] [CrossRef]

- Dikici, B.; Motagi, S.; Kantamani, P.; Ayyagari, S.; Al-Haik, M. Thermal conductivity study of biomass reinforced polymer composites. In Proceedings of the SHTC Summer Heat Transfer Conference, Orlando, FL, USA, 13–15 July 2020. [Google Scholar]

- Dikici, B.; Motagi, S.; Kantamani, P.; Ayyagari, S.; Villarroel, G.; Al-Haik, M. Processing of agricultural biomass for producing reinforced polymer composites. In Proceedings of the ASME Power Conference and Nuclear Forum, Salt Lake City, UT, USA, 15–18 July 2019. [Google Scholar]

- Dikici, B.; Narasimha PR, B.; Kamdar, S.D. Investigation of thermal conductivity variation of biomass products with moisture. In Proceedings of the ASME International Conference on Power Engineering (ICOPE), Charlotte, NC, USA, 26–30 June 2017. [Google Scholar]

- Crawford, N.C.; Nagle, N.; Sievers, D.A.; Stickel, J.J. The effects of physical and chemical preprocessing on the flowability of corn stover. Biomass Bioenergy 2016, 85, 126–134. [Google Scholar] [CrossRef]

- Twidell, J.; Weir, T. Renewable Energy Resources, Printed Book, 3rd ed.; Routledge: New York, NY, USA, 2015; pp. 365–366. [Google Scholar]

- Clean Energy Business Council. (n.d.). Feedstock availability. Clean Energy Business Council. Available online: https://cleanenergybusinesscouncil.com/biomass-energy-glossary/feedstock-availability/ (accessed on 8 August 2024).

- Islam, S.; Kovalcik, A.; Hasan, M.; Thakur, V. Natural Fiber Reinforced Polymer Composites. Int. J. Polym. Sci. 2015, 2015, 813568. [Google Scholar] [CrossRef]

- Salehi, H.; Poletto, M.; Barletta, D.; Larsson, S.H. Predicting the silo discharge behavior of wood chips—A choice of method. Biomass Bioenergy 2019, 120, 211–218. [Google Scholar] [CrossRef]

- Marinelli, J. Industry Insights: ‘Why Is Proper Storage Silo Design Important? Available online: https://www.powderbulksolids.com/storage/why-proper-storage-silo-design-important (accessed on 27 September 2022).

- 911 Metallurgist. (n.d.). Bulk Storage Hopper Flow & Feeder. 911 Metallurgist. Available online: https://www.911metallurgist.com/blog/bulk-storage-hopper-flow-feeder (accessed on 4 July 2024).

- United States Systems, Inc. (n.d.). Hoppers, Bins, Tanks, Vessels & Silos. United States Systems, Inc. Available online: https://unitedstatessystems.com/hoppers-bins-tanks-vessels-silos/ (accessed on 6 May 2024).

- Schulze, D. Storage and Discharge of Bulk Solids. In Production, Handling and Characterization of Particulate Materials; Merkus, H., Meesters, G., Eds.; Particle Technology Series; Springer: Cham, Switzerland, 2016; Volume 25. [Google Scholar] [CrossRef]

- Lam, P.S.; Sokhansanj, S. Engineering Properties of Biomass. In Engineering and Science of Biomass Feedstock Production and Provision; Shastri, Y., Hansen, A., Rodríguez, L., Ting, K., Eds.; Springer: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Wu, M.R.; Schott, D.L.; Lodewijks, G. Physical properties of solid biomass. Biomass Bioenergy 2011, 35, 2093–2105. [Google Scholar] [CrossRef]

- Capareda, S. Introduction to Biomass Energy Conversions; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Powder Process Technology. “Carr Index & Hausner Ratio.” Powder Process Technology. Web. Available online: https://powderprocess.net/Powder_Flow/Carr_Index_Hausner_Ratio.html (accessed on 29 April 2024).

- Hadjittofis, E.; Das, S.C.; Zhang, G.G.Z.; Heng, J.Y.Y. ‘Chapter 8- Interfacial Phenomena’, Developing Solid Oral Dosage Forms. In Pharmaceutical Theory and Practice, 2nd ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 225–252. [Google Scholar] [CrossRef]

- Schlick-Hasper, E.; Bethke, E.; Vogler, N.; Goedecke, T. Flow properties of powdery or granular filling substances of dangerous goods packagings—Comparison of the measurement of the angle of repose and the determination of the Hausner ratio. Packag. Technol. Sci. 2022, 35, 765–782. [Google Scholar] [CrossRef]

- United States Pharmacopeia. “Bulk Density and Tapped Density of Powders <616>.” United States Pharmacopeia. Available online: www.pharmacopeia.cn/v29240/usp29nf24s0_c616.html#google_vignette (accessed on 24 June 2024).

- Xu, G.; Li, M.; Lu, P. Experimental investigation on flow properties of different biomass and torrefied biomass powders. Biomass Bioenergy 2019, 122, 63–75. [Google Scholar] [CrossRef]

- Cheng, Z.; Leal, J.H.; Hartford, C.E.; Carson, J.W.; Donohoe, B.S.; Craig, D.A.; Xia, Y.; Daniel, R.C.; Ajayi, O.O.; Semelsberger, T.A. Flow behavior characterization of biomass Feedstocks. Powder Technol. 2021, 387, 156–180. [Google Scholar] [CrossRef]

- Barletta, D.; Poletto, M. An Assessment on Silo Design Procedures for Granular Woody Biomass. Chem. Eng. Trans. 2013, 32, 2209–2214. [Google Scholar] [CrossRef]

- Polo, C.C.; Pereira, L.; Mazzafera, P.; Flores-Borges, D.N.A.; Mayer, J.L.S.; Guizar-Sicairos, M.; Holler, M.; Barsi-Andreeta, M.; Westfahl, H.; Meneau, F. Correlations between lignin content and structural robustness in plants revealed by X-ray ptychography. Sci. Rep. 2020, 10, 6023. [Google Scholar] [CrossRef]

- Khodayari, A.; Thielemans, W.; Hirn, U.; Van Vuure, A.W.; Seveno, D. Cellulose-hemicellulose interactions: A nanoscale view. Carbohydr. Polym. 2021, 270, 118364. [Google Scholar] [CrossRef] [PubMed]

- Botanical-Online. (n.d.). Barley Characteristics. Botanical-Online. Available online: https://www.botanical-online.com/en/botany/barley-characteristics (accessed on 24 June 2024).

- “Hordeum Vulgare (Barley)” Go Botany. Native Plant Trust. Web. Available online: https://gobotany.nativeplanttrust.org/species/hordeum/vulgare/ (accessed on 12 March 2024).

- Li, M.; Lopato, S.; Kovalchuk, N.; Langridge, P. Functional Genomics of Seed Development in Cereals. In Cereal Genomics II, 2nd ed.; Langridge, P., Ed.; Springer: Dordrecht, Netherlands, 2013; pp. 215–245. [Google Scholar] [CrossRef]

- Gous, P.W. Measurement of Barley (Hordeum Vulgare) Feed Quality Parameters in Sacco and Mapping of Associated Quantitative Trait Loci (QTL) in Cattle. Ph.D. Thesis, University of Southern Queensland, Darling Heights, QLD, Australia, 2009. [Google Scholar]

- Plant4Harvest. (n.d.). When do Live oak Trees Lose Their Leaves? Plant4Harvest. Available online: https://plant4harvest.com/when-do-live-oak-trees-lose-their-leaves/ (accessed on 24 June 2024).

- Oak Constituents. World Cooperage. Web. Available online: https://www.worldcooperage.com/oak-constituents/#:~:text=The%20four%20main%20constituents%20(aka,%2C%20hemicellulose%2C%20lignin%20and%20tannin (accessed on 12 March 2024).

- TreeHugger. (n.d.). Anatomy and Biology of Tree Leaves. Available online: https://www.treehugger.com/anatomy-and-biology-of-tree-leaves-1343507 (accessed on 30 April 2024).

- Jankiewicz, L.S.; Dyki, B.; Machlanska, A.; Dubert, F. Oak leaf galls: Neuroterus numismalis and Cynips quercusfolii, their structure and ultrastructure. Acta Soc. Bot. Pol. 2017, 86, 3537. [Google Scholar] [CrossRef]

- Fu, Y.; Zhang, J.; Guan, T. High-Value Utilization of Corn Straw: From Waste to Wealth. Sustainability 2023, 15, 14618. [Google Scholar] [CrossRef]

- Sun, J.X.; Xu, F.; Sun, X.F.; Xiao, B.; Sun, R.C. Physico-chemical and thermal characterization of cellulose from barley straw. Polym. Degrad. Stab. 2005, 88, 521–531. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0141391005000066?via%3Dihub (accessed on 7 April 2024). [CrossRef]

- Mayer, S.; Munz, E.; Hammer, S.; Wagner, S.; Guendel, A.; Rolletschek, H.; Jakob, P.M.; Borisjuk, L.; Neuberger, T. Quantitative monitoring of paramagnetic contrast agents and their allocation in plant tissues via DCE-MRI. Plant Methods 2022, 18, 47. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Khan, T.S.; Mubeen, U. Wheat Straw: A Pragmatic Overview. Curr. Res. J. Biol. Sci. 2012, 4, 673–675. [Google Scholar]

- Zhang, L.; Larsson, A.; Moldin, A.; Edlund, U. Comparison of lignin distribution, structure, and morphology in wheat straw and wood. Ind. Crops Prod. 2022, 187 Pt B, 115432. [Google Scholar] [CrossRef]

- The Knots Manual. (n.d.). Jute Rope. The Knots Manual. Available online: https://www.theknotsmanual.com/rope/types-of-rope/jute/ (accessed on 24 June 2024).

- Wang, W.; Cai, Z.; Yu, J. Study on the Chemical Modification Process of Jute Fiber. J. Eng. Fibers Fabr. 2018, 3, 155892500800300203. [Google Scholar] [CrossRef]

- Mukul, M.M.; Ahmed, S.S.U.; Akter, N.; Mostofa, M.G.; Rahman, M.S.; Talukder, F.U. Responses of seed germination, seedling growth under salinity stresses, and variability for phenotypic traits in Tossa Jute (Corchorus olitorius L.). Plant Sci. Today 2021, 8, 166–180. [Google Scholar] [CrossRef]

- Chong, L.; Zhiyuan, S.; Hongzhen, F.; Chen, C.; Junjie, L.; Qiao, L.; Jianhui, D.; Huazheng, C.; Hongmei, W.; Hongbo, L.; et al. Effect of a promising CSESE pretreatment on the morphological structure and properties of jute fibers. E3S Web Conf. 2021, 252, 02049. [Google Scholar] [CrossRef]

- Song, F.; Wang, Q.; Wang, T. The effects of crystallinity on the mechanical properties and the limiting PV (pressure×velocity) value of PTFE. Tribol. Int. 2016, 93 Pt A, 1–10. [Google Scholar] [CrossRef]

- Izdebska, J. Aging and degradation of printed materials. In Printing on Polymers; Izdebska, J., Thomas, S., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 353–370. [Google Scholar] [CrossRef]

- Krishnan, K.B.; Doraiswamy, I.; Chellamani, K.P. Jute. In Bast and Other Plant Fibres; Franck, R.E., Ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2005; pp. 24–93. ISBN 9781855736849. [Google Scholar] [CrossRef]

- Chand, N.; Fahim, M. Jute-reinforced polymer composites. In Tribology of Natural Fiber Polymer Composites, 2nd ed.; Chand, N., Fahim, M., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2021; pp. 111–130. ISBN 9780128189832. [Google Scholar] [CrossRef]

- Thomas, S.; Hosur, M.; Pasquini, D.; Chirayil, C.J. (Eds.) Handbook of Biomass; Springer Nature: Singapore, 2024; Chapter 13. [Google Scholar] [CrossRef]

- Saad, H.A.K. Biomass Characterization and Insulation Optimization Studies. Ph.D. Dissertation, Embry-Riddle Aeronautical University, Daytona Beach, FL, USA, November 2022. Available online: https://commons.erau.edu/edt/695/ (accessed on 3 April 2023).

- Evers, A.D.; O’Brien, L.; Blakeney, A.B. Cereal structure and composition. Crop Pasture Sci. 1999, 50, 629–650. [Google Scholar] [CrossRef]

- Matile, P. Biochemistry of Indian summer: Physiology of autumnal leaf coloration. Exp. Gerontol. 2000, 35, 145–158. [Google Scholar] [CrossRef] [PubMed]

- Aviara, N.A.; Shittu, S.K.; Haque, M.A. Physical properties of guna fruits relevant in bulk handling and mechanical processing. Int. Agrophysics 2007, 21, 7–16. [Google Scholar]

- Gil, M.; Schott, D.; Arauzo, I.; Teruel, E. Handling behavior of two milled biomass: SRF poplar and corn stover. Fuel Process. Technol. 2013, 112, 76–85. [Google Scholar] [CrossRef]

- Kymalaien, H.R.; Sjoberg, A.M. Flax and hemp fibres as raw materials for thermal insulations. Build. Environ. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

- AHDB. (n.d.). Feeding Cereal Grains to Livestock: Moist vs. Dry Grain. Agriculture and Horticulture Development Board. Available online: https://ahdb.org.uk/knowledge-library/feeding-cereal-grains-to-livestock-moist-vs-dry-grain (accessed on 25 June 2024).

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the Drying Temperature and Grinding Technique on Biomass Grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Heikkila, D.J. Biomass Grinding Process Optimization Using Response Surface Methodology and a Hybrid Genetic Algorithm. Bioengineering 2019, 6, 12. [Google Scholar] [CrossRef]

- Tavakoli, H.; Mohtasebi, S.S.; Rajabipour, A.; Tavakoli, M. Effects of moisture content, loading rate, and grain orientation on fracture resistance of barley grain. Res. Agric. Eng. 2009, 55, 85–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Tabil, L.G.; Wang, D. Effect of moisture content, postharvest treatment, and storage time on some properties and quality attributes of red lentil. In Proceedings of the 2008 ASABE Annual International Meeting, Rhode Island Convention Center, Providence, RI, USA, June 29–2 July 2008. [Google Scholar]

- Stasiak, M.; Molenda, M.; Banda, M.; Gondek, E. Mechanical Properties of sawdust and woodchips. Fuel 2015, 159, 900–908. [Google Scholar] [CrossRef]

- Mattsson, J.E. Basic handling characteristics of wood fuels: Angle of repose, friction against surfaces and tendency to bridge for different assortments. Scand. J. For. Res. 1990, 5, 583–597. [Google Scholar] [CrossRef]

- Saad, H.A.K.; Dikici, B.; Villarroel, G.; Divo, E. Characterization methods for biomass materials and optimizing heat transfer by using genetic algorithms. In Proceedings of the 7th Thermal and Fluids Engineering Conference (TFEC), Las Vegas, NV, USA, 15–18 May 2022. [Google Scholar]

- Madrid, M.A.; Fuentes, J.M.; Ayuga, F.; Gallego, E. Determination of the Angle of Repose and Coefficient of Rolling Friction for Wood Pellets. Agronomy 2022, 12, 424. [Google Scholar] [CrossRef]

| Flowability | Hausner Ratio (HR) | Carr’s Index | Angle of Repose |

|---|---|---|---|

| Excellent | 1.00–1.11 | <10 | 25–30 |

| Good | 1.12–1.18 | 11–15 | 31–35 |

| Fair | 1.19–1.25 | 16–20 | 36–40 |

| Passable | 1.26–1.34 | 21–25 | 41–45 |

| Poor flow | 1.35–1.45 | 26–31 | 46–55 |

| Very poor flow | 1.46–1.59 | 32–37 | 56–65 |

| Approximately no flow, very very poor | >1.60 | >38 | >66 |

| Ground Barley Grain | Ground Oak Leaves | Ground Straw | |||

|---|---|---|---|---|---|

| <381 µm | 25.76 ± 5.08 | <660.4 µm | 43.36 ± 3.58 | <1016 µm | 20.96 ± 2.93 |

| 381 µm–508 µm | 34.48 ± 4.23 | 660.4 µm–762 µm | 18.56 ± 0.78 | 1016 µm–1168.4 µm | 21.6 ± 5.00 |

| 508 µm–584.2 µm | 31.94 ± 2.78 | 762 µm–1016 µm | 31.04 ± 3.13 | 1168.4 µm–1295.4 µm | 24.08 ± 1.04 |

| 584.2 µm–660.4 µm | 6.1 ± 1.10 | 1016 µm–1168.4 µm | 6.32 ± 0.66 | 1295.4 µm–1524 µm | 31.28 ± 6.14 |

| >660.4 µm | 1.72 ± 0.39 | >1168.4 µm | 0.72 ± 0.33 | >1524 µm | 2.08 ± 1.00 |

| Sample | Hausner Ratio (HR) | Carr’s Index | Angle of Repose (°) | Evaluation Based on HR or Carr’s Index | Evaluation Based on Angle of Repose |

|---|---|---|---|---|---|

| Barley | 1.07 ± 0.02 | 6.41 ± 1.44 | 32.30 ± 0.94 | Excellent | Good |

| Oak | 1.09 ± 0.02 | 8.15 ± 1.77 | 24.35 ± 1.45 | Excellent | Excellent |

| Straw | 1.17 ± 0.02 | 14.50 ± 1.2 | 34.95 ± 0.72 | Good | Good |

| Jute | 1.14 ± 0.06 | 12.21 ± 4.3 | N/A | Good | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dikici, B.; Saad, H.A.K.; Zhao, B. Evaluating Flow Characteristics of Ground and Cut Biomass for Industrial Applications. Powders 2024, 3, 437-459. https://doi.org/10.3390/powders3030024

Dikici B, Saad HAK, Zhao B. Evaluating Flow Characteristics of Ground and Cut Biomass for Industrial Applications. Powders. 2024; 3(3):437-459. https://doi.org/10.3390/powders3030024

Chicago/Turabian StyleDikici, Birce, Hussein Awad Kurdi Saad, and Bo Zhao. 2024. "Evaluating Flow Characteristics of Ground and Cut Biomass for Industrial Applications" Powders 3, no. 3: 437-459. https://doi.org/10.3390/powders3030024

APA StyleDikici, B., Saad, H. A. K., & Zhao, B. (2024). Evaluating Flow Characteristics of Ground and Cut Biomass for Industrial Applications. Powders, 3(3), 437-459. https://doi.org/10.3390/powders3030024