Effects of Process Parameters on Cold Spray Additive Manufacturing of Quasicrystalline Al93Fe3Cr2Ti2 Alloy

Abstract

1. Introduction

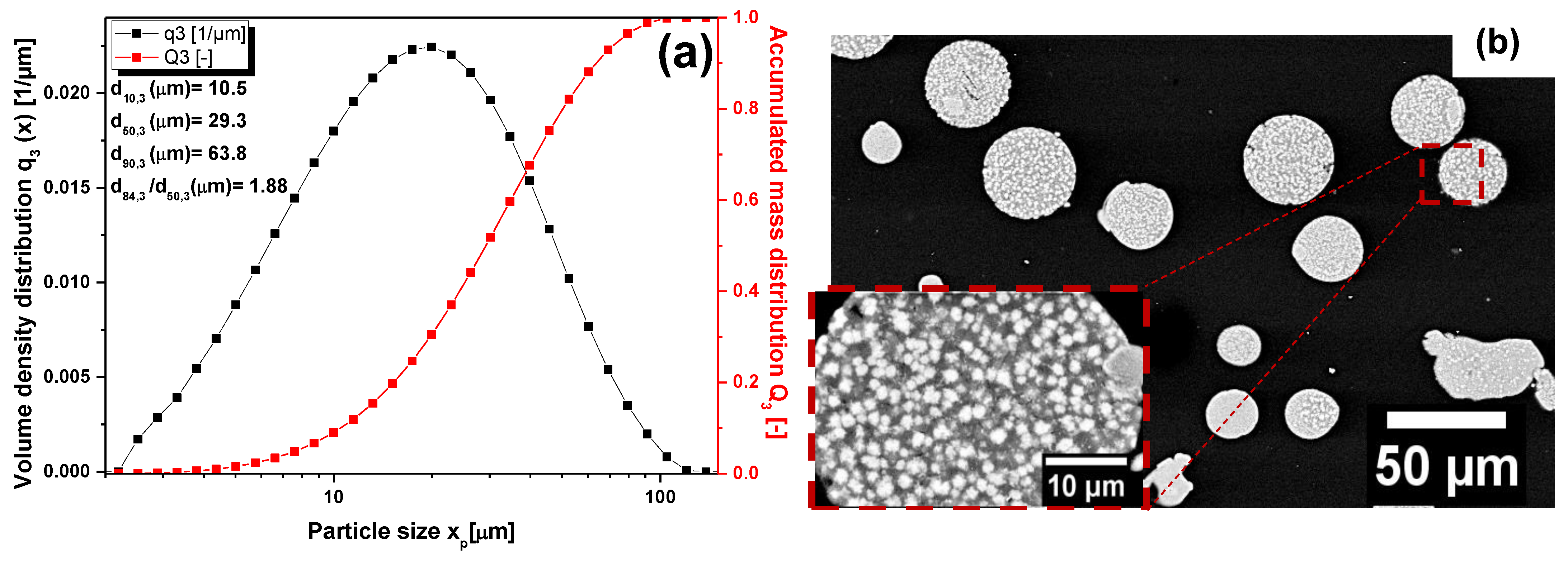

2. Materials and Methods

2.1. Coatings Preparation

2.2. Characterization Methods

3. Results and Discussion

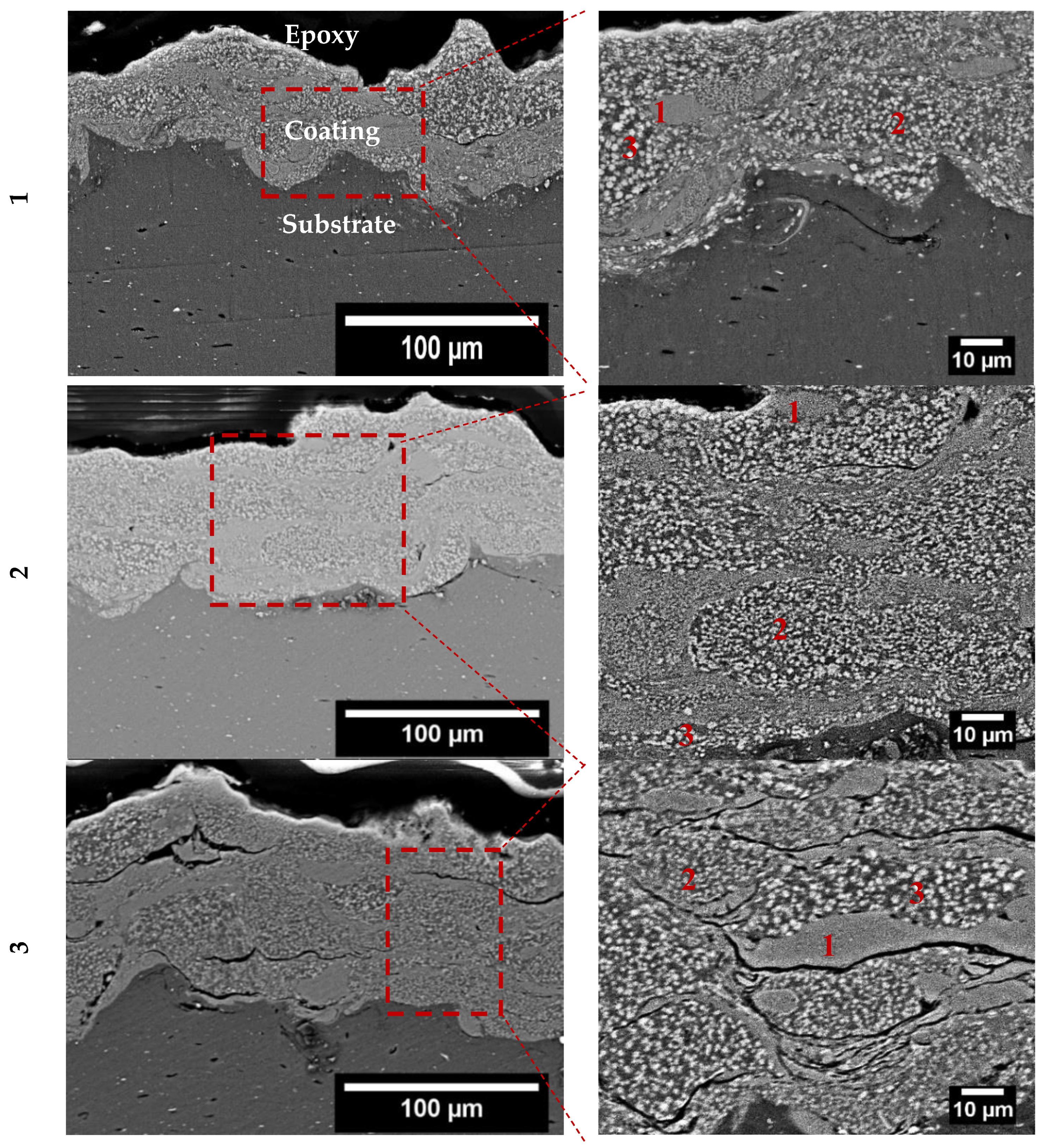

3.1. Porosity, Thickness, and Roughness of the Coatings

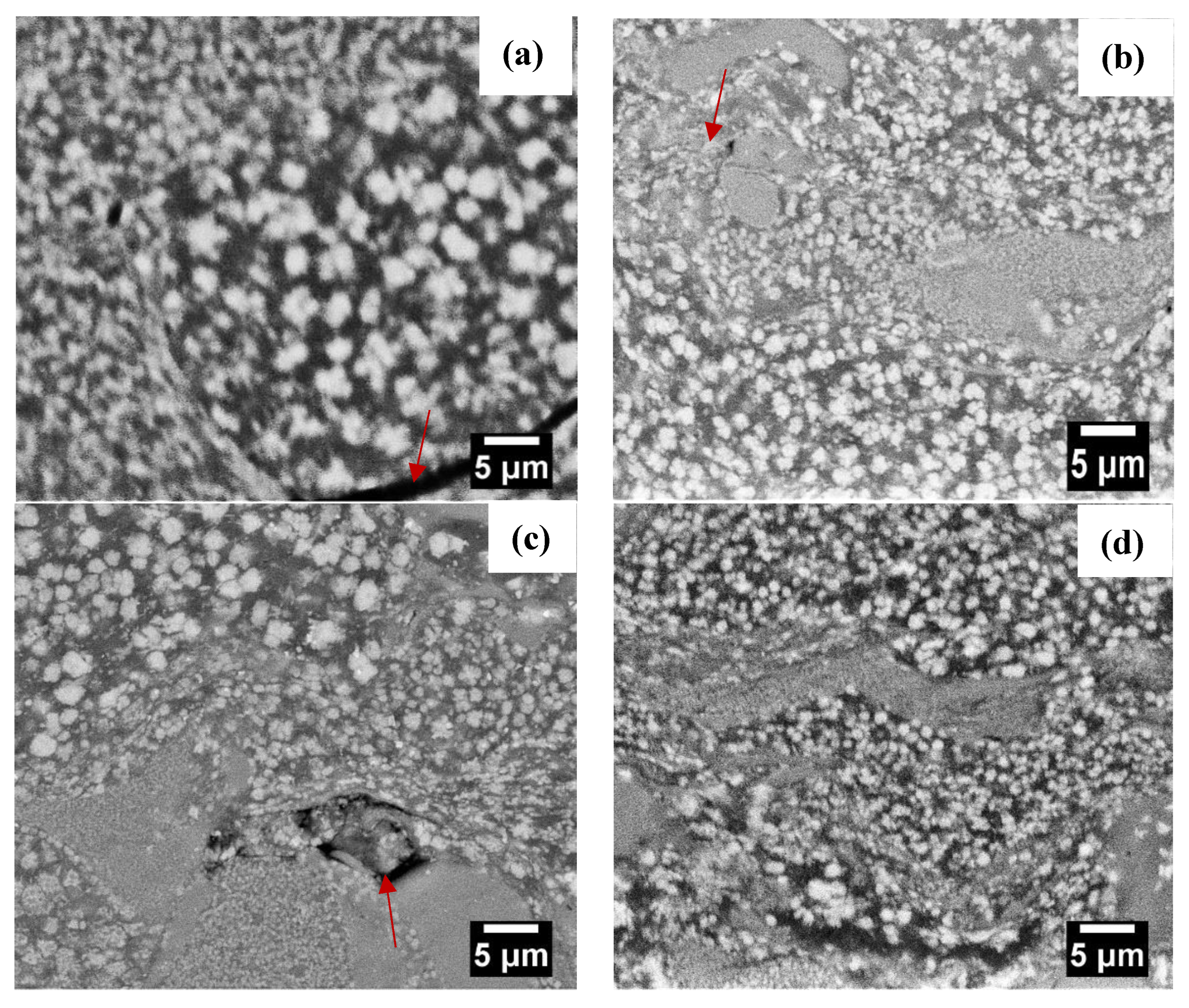

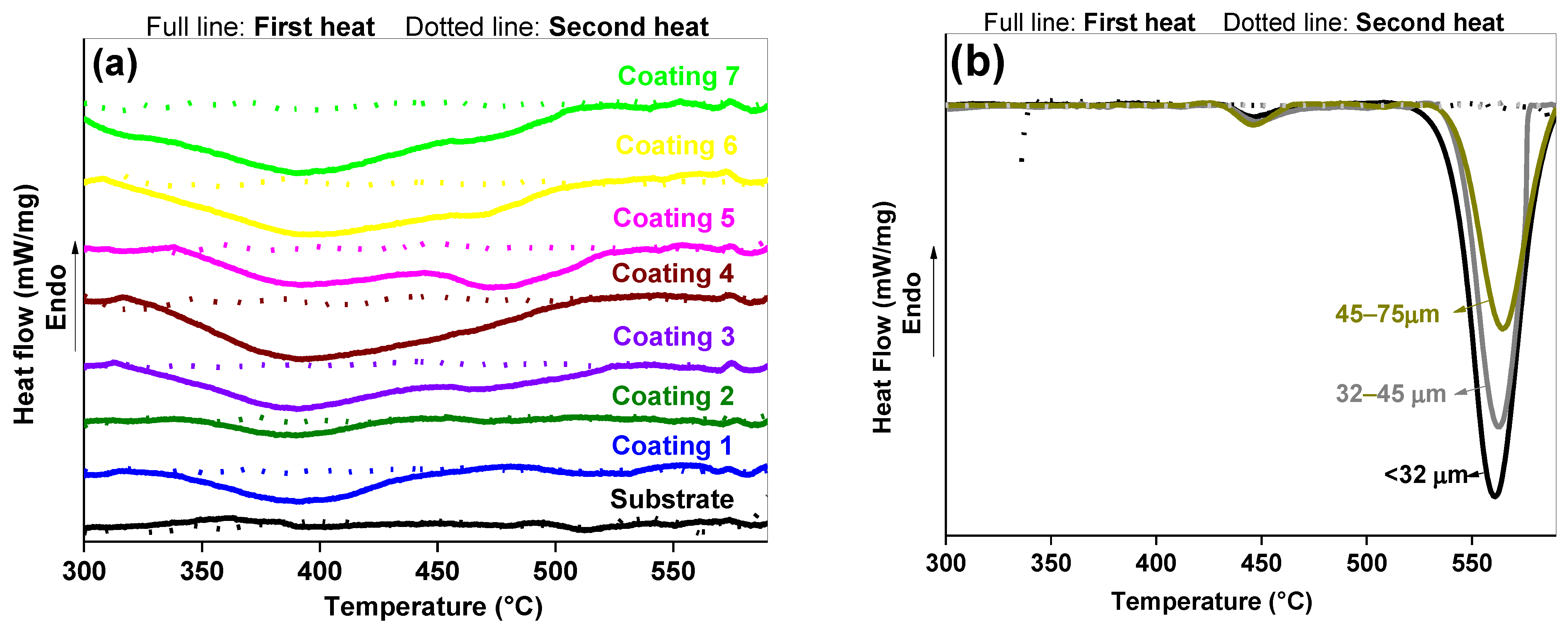

3.2. Microstructural Analyses

3.3. Vickers Microhardness Analyses

4. Conclusions

- (1)

- The cold-sprayed coatings produced onto unblasted Al-6061 substrates presented lower porosity (≤0.50%), better adherence, and greater thickness. Among these, coating 4 was produced with the highest pressure (4.8 MPa), highest temperature (475 °C), and lower nozzle aperture (A), presenting the greatest thickness (185 µm). The coatings’ surface roughness was similar for all coatings.

- (2)

- The coatings produced here exhibited a composite microstructure with the same combination of phases as the feedstock powder, specifically an α-Al with the i-QC phase (icosahedral quasicrystalline phase) and ω phase embedded. A low amount of the approximant θ (Al13(Cr,Fe)2-4) phase was suggested for the coatings, especially those produced with particles at higher velocities (coatings 4, 5, 6, and 7).

- (3)

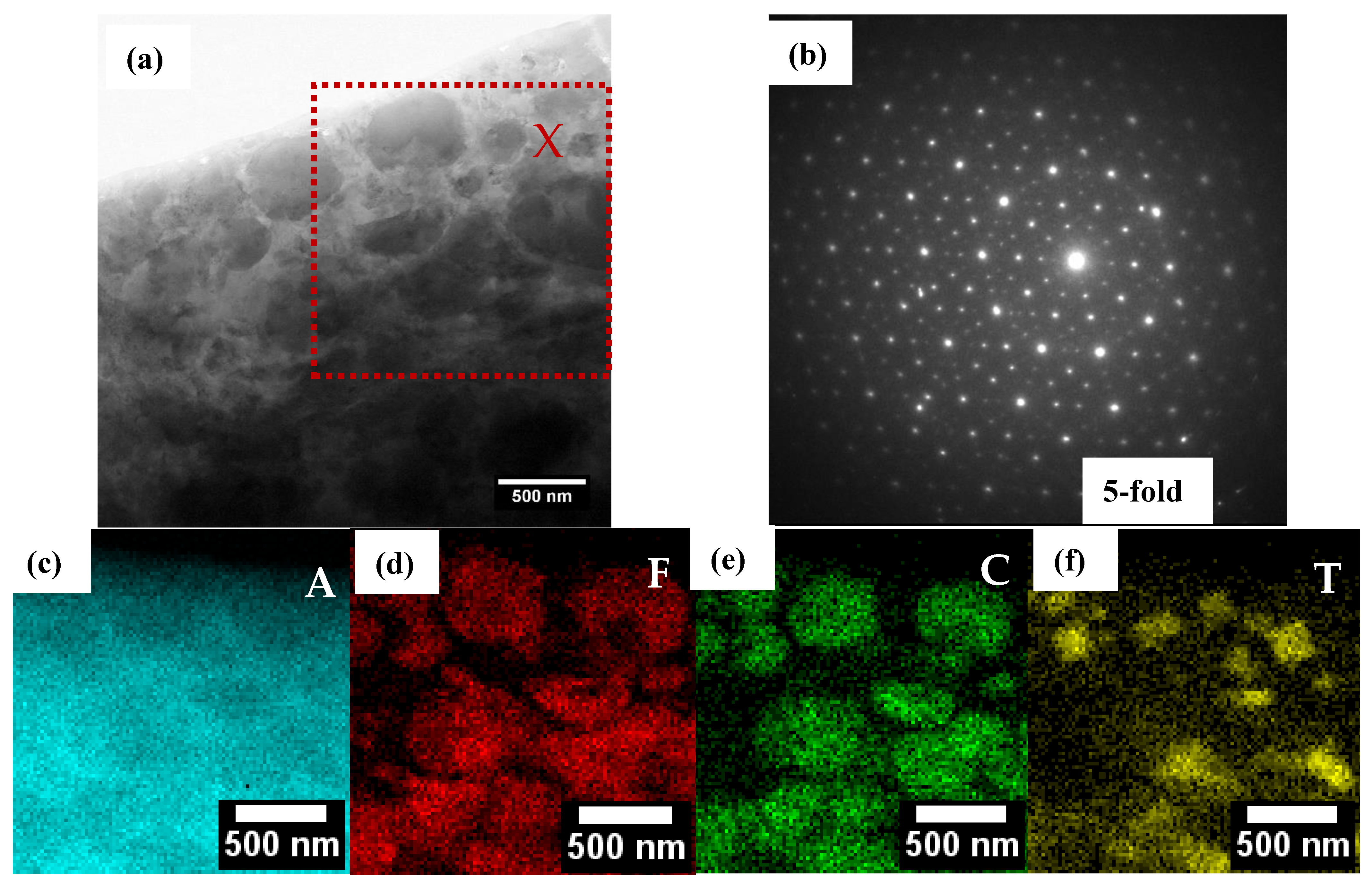

- The presence of the i-phase was confirmed by XRD; its metastability was proved by DSC, and its icosahedral nature was determined by TEM analyses.

- (4)

- The composite microstructure of the cold-sprayed coatings consisted of a ductile 𝛼-Al matrix with an i-QC phase and its approximant θ-Al13(Cr,Fe)2,4 phase was embedded. Such a microstructure resulted in coatings with high Vickers microhardness with a mean of about 267 HV and a mean deviation of 8 HV.

- (5)

- The generated results and the knowledge related to the integrity of the parts, microstructure, and achieved mechanical properties allowed the scientific community a better understanding of the quasicrystalline Al93Fe3Cr2Ti2 alloy, and its mechanical behavior when obtained by the CSAM route. Additionally, the generated data were helpful to the industrial sector since the results showed the potential of a non-commercial aluminum alloy being applicable.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, Y.-K.; Lee, K.-A. Effect of carrier gas species on the microstructure and compressive deformation behaviors of ultra-strong pure copper manufactured by cold spray additive manufacturing. J. Mater. Sci. Technol. 2022, 97, 264–271. [Google Scholar] [CrossRef]

- Prasad, K.; Khalik, M.; Hutasoit, N.; Rashid, R.A.R.; Duguid, A.; Palanisamy, S. Printability of low-cost pre-heat-treated ball milled Al7075 powders using compressed air assisted cold spray additive manufacturing. Addit. Manuf. Lett. 2022, 3, 100046. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H. A comprehensive review on sustainable cold spray additive manufacturing: State of the art, challenges and future challenges. J. Clean. Prod. 2021, 310, 127606. [Google Scholar] [CrossRef]

- Ren, Y.; Tariq, N.U.H.; Liu, H.; Zhao, L.; Cui, X.; Shen, Y.; Wang, J.; Xiong, T. Study of microstructural and mechanical anisotropy of 7075 Al deposits fabricated by cold spray additive manufacturing. Mater. Des. 2021, 212, 110271. [Google Scholar] [CrossRef]

- Kim, Y.-K.; Kim, H.-J.; Lee, K.-A. Solid-state cold spray additive manufacturing of pure tantalum with extraordinary high-temperature mechanical properties. J. Mater. Res. Technol. 2023, 23, 5698–5709. [Google Scholar] [CrossRef]

- Vaz, R.F.; Garfias, A.; Albaladejo, V.; Sanchez, J.; Cano, I.G. A Review of Advances in Cold Spray Additive Manufacturing. Coatings 2023, 13, 267. [Google Scholar] [CrossRef]

- Hutasoit, N.; Javed, M.A.; Rashid, R.A.R.; Wade, S.; Palanisamy, S. Effects of build orientation and heat treatment on microstructure, mechanical and corrosion properties of Al6061 aluminium parts built by cold spray additive manufacturing process. Int. J. Mech. Sci. 2021, 204, 106526. [Google Scholar] [CrossRef]

- Tsaknopoulos, K.; Sousa, B.; Massar, C.; Grubbs, J.; Siopis, M.; Cote, D. A Through-Process Experimental Approach to Enable Optimization of Cold Sprayed Al 7075 Consolidation Performance. JOM 2022, 74, 249–259. [Google Scholar] [CrossRef]

- Sabard, A.; McNutt, P.; Begg, H.; Hussain, T. Cold spray deposition of solution heat treated, artificially aged and naturally aged Al 7075 powder. Surf. Coat. Technol. 2020, 385, 125367. [Google Scholar] [CrossRef]

- Audebert, F.; Prima, F.; Galano, M.; Tomut, M.; Warren, P.J.; Stone, I.C.; Cantor, B. Structural Characterisation and Mechanical Properties of Nanocomposite Al-based Alloys. Mater. Trans. 2002, 43, 2017–2025. [Google Scholar] [CrossRef]

- Saida, J.; Inoue, A. Nanoicosahedral Quasicrystal. In Encyclopedia of Nanoscience and Nanotechnology; Nalwa, H.S., Ed.; American Scientific Publishers: Stevenson Ranch, CA, USA, 2004; pp. 795–813. [Google Scholar]

- Galano, M.; Audebert, F.; Cantor, B.; Stone, I. Structural characterisation and stability of new nanoquasicrystalline Al-based alloys. Mater. Sci. Eng. A 2004, 375–377, 1206–1211. [Google Scholar] [CrossRef]

- Kang, N.; Fu, Y.; Coddet, P.; Guelorget, B.; Liao, H.; Coddet, C. On the microstructure, hardness and wear behavior of Al-Fe-Cr quasicrystal reinforced Al matrix composite prepared by selective laser melting. Mater. Des. 2017, 132, 105–111. [Google Scholar] [CrossRef]

- Inoue, A. Amorphous, nanoquasicrystalline and nanocrystalline alloys in Al-based systems. Prog. Mater. Sci. 1998, 43, 365–520. [Google Scholar] [CrossRef]

- Inoue, A.; Kimura, H. High elevated-temperature strength of Al-based nanoquasicrystalline alloys. Nanostruct. Mater. 1999, 11, 221–231. [Google Scholar] [CrossRef]

- Wolf, W.; Coury, F.; Kaufman, M.; Bolfarini, C.; Kiminami, C.; Botta, W. The formation of quasicrystals in Al-Cu-Fe-(M=Cr,Ni) melt-spun ribbons. J. Alloys Compd. 2018, 731, 1288–1294. [Google Scholar] [CrossRef]

- Chlupova, A.; Chlup, Z.; Kruml, T. Fatigue properties and microstructure of quasicrystalline AlFeCrTi alloy. Int. J. Fatigue 2016, 91, 251–256. [Google Scholar] [CrossRef]

- Pedrazzini, S.; Galano, M.; Audebert, F.; Collins, D.; Hofmann, F.; Abbey, B.; Korsunsky, A.; Lieblich, M.; Escorial, A.G.; Smith, G. Strengthening mechanisms in an Al-Fe-Cr-Ti nano-quasicrystalline alloy and composites. Mater. Sci. Eng. A 2016, 672, 175–183. [Google Scholar] [CrossRef]

- Kim, K.; Xu, W.; Tomut, M.; Stoica, M.; Calin, M.; Yi, S.; Lee, W.; Eckert, J. Formation of icosahedral phase in an Al93Fe3Cr2Ti2 bulk alloy. J. Alloys Compd. 2007, 436, L1–L4. [Google Scholar] [CrossRef]

- Gargarella, P.; Almeida, A.; Vilar, R.; Afonso, C.; Rios, C.; Bolfarini, C.; Botta, W.; Kiminami, C.; Gargarella, P.; Almeida, A.; et al. Microstructural characterization of a laser remelted coating of Al91Fe4Cr3Ti2 quasicrystalline alloy. Scr. Mater. 2009, 61, 709–712. [Google Scholar] [CrossRef]

- Stan-Głowińska, K.; Lityńska-Dobrzyńska, L. Influence of Fe addition on the formation of a quasicrystalline phase in bulk Al-rich Al Mn base alloys. Mater. Charact. 2017, 128, 203–208. [Google Scholar] [CrossRef]

- Gargarella, P.; Vilar, R.; Almeida, A.; Kiminami, C.; Rios, C.; Bolfarini, C.; Botta, W. Laser remelting of Al91Fe4Cr3Ti2 quasicrystalline phase former alloy. J. Alloys Compd. 2010, 495, 646–649. [Google Scholar] [CrossRef]

- De Araujo, A.P.M.; Micheloti, L.; Kiminami, C.S.; Gargarella, P. Microstructure, phase formation and properties of rapid solidified Al–Fe–Cr–Ti alloys. Mater. Sci. Technol. 2020, 36, 1205–1214. [Google Scholar] [CrossRef]

- García-Escorial, A.; Lieblich, M. Atomization of Al-rich alloys: Three paradigmatic case studies. J. Alloys Compd. 2018, 762, 203–208. [Google Scholar] [CrossRef]

- Dám, K.; Vojtěch, D.; Průša, F. Powder metallurgy Al–6Cr–2Fe–1Ti alloy prepared by melt atomisation and hot ultra-high pressure compaction. Mater. Sci. Eng. A 2013, 560, 705–710. [Google Scholar] [CrossRef]

- Vojtěch, D.; Michalcová, A.; Průša, F.; Dám, K.; Šedá, P. Properties of the thermally stable Al95Cr3.1Fe1.1Ti0.8 alloy prepared by cold-compression at ultra-high pressure and by hot-extrusion. Mater. Charact. 2012, 66, 83–92. [Google Scholar] [CrossRef]

- Watson, T.; Nardi, A.; Ernst, A.; Cernatescu, I.; Bedard, B.; Aindow, M. Cold spray deposition of an icosahedral-phase-strengthened aluminum alloy coating. Surf. Coat. Technol. 2017, 324, 57–63. [Google Scholar] [CrossRef]

- Galano, M.; Audebert, F.; Escorial, A.G.; Stone, I.; Cantor, B. Nanoquasicrystalline Al–Fe–Cr-based alloys. Part II. Mechanical properties. Acta Mater. 2009, 57, 5120–5130. [Google Scholar] [CrossRef]

- Liotti, E.; Kirk, C.; Todd, I.; Knight, K.; Hogg, S. Synchrotron X-ray and neutron investigation of the structure and thermal expansion of the monoclinic Al13Cr2 phase. J. Alloys Compd. 2019, 781, 1198–1208. [Google Scholar] [CrossRef]

- de Araujo, A.P.; Kiminami, C.S.; Uhlenwinkel, V.; Gargarella, P. Processability of recycled quasicrystalline Al-Fe-Cr-Ti composites by selective laser melting—A statistical approach. Materialia 2022, 22, 101377. [Google Scholar] [CrossRef]

- Klinkov, S.V.; Kosarev, V.F.; Rein, M. Cold spray deposition: Significance of particle impact phenomena. Aerosp. Sci. Technol. 2005, 9, 582–591. [Google Scholar] [CrossRef]

- Audebert, F.; Galano, M.; Rios, C.T.; Kasama, H.; Peres, M.; Kiminami, C.; Botta, W.; Bolfarini, C. Nanoquasicrystalline Al–Fe–Cr–Nb alloys produced by powder metallurgy. J. Alloys Compd. 2013, 577, 650–657. [Google Scholar] [CrossRef]

- Khoruzha, V.G.; Kornienko, K.E.; Pavlyuchkov, D.V.; Grushko, B.; Velikanova, T.Y. The Al–Cr–Fe phase diagram. I. Phase equilibria at subsolidus temperatures over composition range 58–100 at.% Al. Powder Metall. Met. Ceram. 2011, 50, 83–97. [Google Scholar] [CrossRef]

- Galano, M.; Audebert, F.; Stone, I.; Cantor, B. Nanoquasicrystalline Al–Fe–Cr-based alloys. Part I: Phase transformations. Acta Mater. 2009, 57, 5107–5119. [Google Scholar] [CrossRef]

- Audebert, F.; Colaço, R.; Vilar, R.; Sirkin, H. Laser cladding of aluminium-base quasicrystalline alloys. Scr. Mater. 1999, 40, 551–557. [Google Scholar] [CrossRef]

- Bártová, B.; Vojtěch, D.; Verner, J.; Gemperle, A.; Studnička, V. Structure and properties of rapidly solidified Al–Cr–Fe–Ti–Si powder alloys. J. Alloys Compd. 2005, 387, 193–200. [Google Scholar] [CrossRef]

- Levine, D.; Steinhardt, P.J. Quasicrystals: A New Class of Ordered Structures. Phys. Rev. Lett. 1984, 53, 2477–2480. [Google Scholar] [CrossRef]

- Yamasaki, M.; Nagaishi, Y.; Kawamura, Y. Inhibition of Al grain coarsening by quasicrystalline icosahedral phase in the rapidly solidified powder metallurgy Al–Fe–Ti–Cr alloy. Scr. Mater. 2007, 56, 785–788. [Google Scholar] [CrossRef]

- Li, R.; Dong, Z.; Murugan, V.K.; Zhang, Z.; Khor, K. Microstructure characterization of Al–Cr–Fe quasicrystals sintered using spark plasma sintering. Mater. Charact. 2015, 110, 264–271. [Google Scholar] [CrossRef]

- De Graef, M.; McHenry, M.E. Structure of Materials: An Introduction to Crystallography, Diffraction and Symmetry, 2nd ed.; Cam-bridge University Press: Cambridge, UK, 2012. [Google Scholar] [CrossRef]

- Elser, V. Indexing problems in quasicrystal diffraction. Phys. Rev. B 1985, 32, 4892–4898. [Google Scholar] [CrossRef]

- Phillips, M.; Thompson, S. The Mechanical Property Data Base from an Air Force/Industry Cooperative Test Program on High Temperature Aluminum Alloys, Wright Lab., Wright-Patterson AFB, OH. Materials Directorate., Ohio 45433-7734, 1994. Available online: https://ntrl.ntis.gov/NTRL/dashboard/searchResults/titleDetail/ADA282911.xhtml (accessed on 9 June 2023).

- Inoue, A.; Kimura, H.; Yamaura, S.-I. Production and mechanical properties of aluminum alloys with dispersed nanoscale quasicrystalline and amorphous particles. Met. Mater. Int. 2003, 9, 527–536. [Google Scholar] [CrossRef]

- Galano, M.; Audebert, F.; Escorial, A.G.; Stone, I.C.; Cantor, B. Nanoquasicrystalline Al–Fe–Cr-based alloys with high strength at elevated temperature. J. Alloys Compd. 2010, 495, 372–376. [Google Scholar] [CrossRef]

| Coating ID | P (MPa) | T (°C) | NA (mm) | PV (m/s) | AB |

|---|---|---|---|---|---|

| 1 | 4.0 | 450 | A | 600 | Yes |

| 2 | 4.3 | 450 | A | 604 | Yes |

| 3 | 4.0 | 450 | A | 588 | Yes |

| 4 | 4.8 | 475 | A | 610 | No |

| 5 | 4.0 | 450 | B | 662 | No |

| 6 | 4.0 | 475 | B | 680 | No |

| 7 | 3.4 | 425 | B | 630 | No |

| Coating ID | Porosity (%) | Thickness (µm) | Coating Roughness (µm) | Substrate Roughness (µm) |

|---|---|---|---|---|

| 1 | 1.50 ± 0.80 | 50.0 ± 8.62 | 9.0 ± 1.43 | 6.7 ± 1.66 |

| 2 | 1.84 ± 1.32 | 85.0 ± 7.49 | 9.8 ± 1.54 | 5.4 ± 0.30 |

| 3 | 4.17 ± 2.56 | 48.0 ± 6.72 | 11 ± 1.60 | 6.5 ± 1.66 |

| 4 | 0.49 ± 0.25 | 185.0 ± 22.3 | 12.2 ± 3.02 | 0.6 ± 0.08 |

| 5 | 0.26 ± 0.19 | 95.2 ± 13.96 | 11.1 ± 2.19 | 0.5 ± 0.06 |

| 6 | 0.35 ± 0.21 | 88.0 ± 12.32 | 12.1 ± 0.69 | 1.2 ± 0.22 |

| 7 | 0.50 ± 0.21 | 116.1 ± 18.00 | 10.5 ± 1.55 | 0.8 ± 0.41 |

| Coating ID | Al | Fe | Cr | Ti |

|---|---|---|---|---|

| 1 | 91.9 ± 0.1 | 4.0 ± 0.1 | 2.2 ± 0.1 | 2.0 ± 0.1 |

| 2 | 91.4 ± 0.1 | 4.3 ± 0.1 | 2.4 ± 0.1 | 1.9 ± 0.1 |

| 3 | 91.8 ± 0.1 | 4.0 ± 0.1 | 2.2 ± 0.1 | 1.9 ± 0.1 |

| 4 | 91.8 ± 0.1 | 4.0 ± 0.1 | 2.3 ± 0.1 | 1.9 ± 0.1 |

| 5 | 91.8 ± 0.2 | 4.1 ± 0.1 | 2.2 ± 0.1 | 1.9 ± 0.1 |

| 6 | 91.5 ± 0.1 | 4.2 ± 0.1 | 2.3 ± 0.1 | 2.0 ± 0.1 |

| 7 | 91.5 ± 0.1 | 4.2 ± 0.1 | 2.3 ± 0.1 | 2.0 ± 0.1 |

| Powder | 92.0 ± 1.3 | 3.2 ± 0.5 | 2.0 ± 0.4 | 2.0 ± 0.2 |

| Coating ID | Microhardness (HV) |

|---|---|

| 1 | 277.9 ± 39.3 |

| 2 | 266.4 ± 49.2 |

| 3 | 254.6 ± 24.2 |

| 4 | 271.9 ± 36.0 |

| 5 | 278.9 ± 43.4 |

| 6 | 270.4 ± 40.7 |

| 7 | 251.9 ± 46.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Araujo, A.P.M.; Carmelo, F.B.D.M.; Rocha, E.M.; Kiminami, C.S.; Gargarella, P. Effects of Process Parameters on Cold Spray Additive Manufacturing of Quasicrystalline Al93Fe3Cr2Ti2 Alloy. Powders 2023, 2, 525-539. https://doi.org/10.3390/powders2030033

de Araujo APM, Carmelo FBDM, Rocha EM, Kiminami CS, Gargarella P. Effects of Process Parameters on Cold Spray Additive Manufacturing of Quasicrystalline Al93Fe3Cr2Ti2 Alloy. Powders. 2023; 2(3):525-539. https://doi.org/10.3390/powders2030033

Chicago/Turabian Stylede Araujo, Aylanna Priscila Marques, Felipe B. Do M. Carmelo, Erlifas M. Rocha, Claudio S. Kiminami, and Piter Gargarella. 2023. "Effects of Process Parameters on Cold Spray Additive Manufacturing of Quasicrystalline Al93Fe3Cr2Ti2 Alloy" Powders 2, no. 3: 525-539. https://doi.org/10.3390/powders2030033

APA Stylede Araujo, A. P. M., Carmelo, F. B. D. M., Rocha, E. M., Kiminami, C. S., & Gargarella, P. (2023). Effects of Process Parameters on Cold Spray Additive Manufacturing of Quasicrystalline Al93Fe3Cr2Ti2 Alloy. Powders, 2(3), 525-539. https://doi.org/10.3390/powders2030033